Resistive heater used for engine combustion chamber experiment system

A technology of resistance heaters and experimental systems, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of high operating costs, high operating costs, and limited range, and achieve long-term stable operation and stable operation. The effect of low cost and continuous work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] This embodiment is a resistance heater used in an engine combustion chamber experiment system.

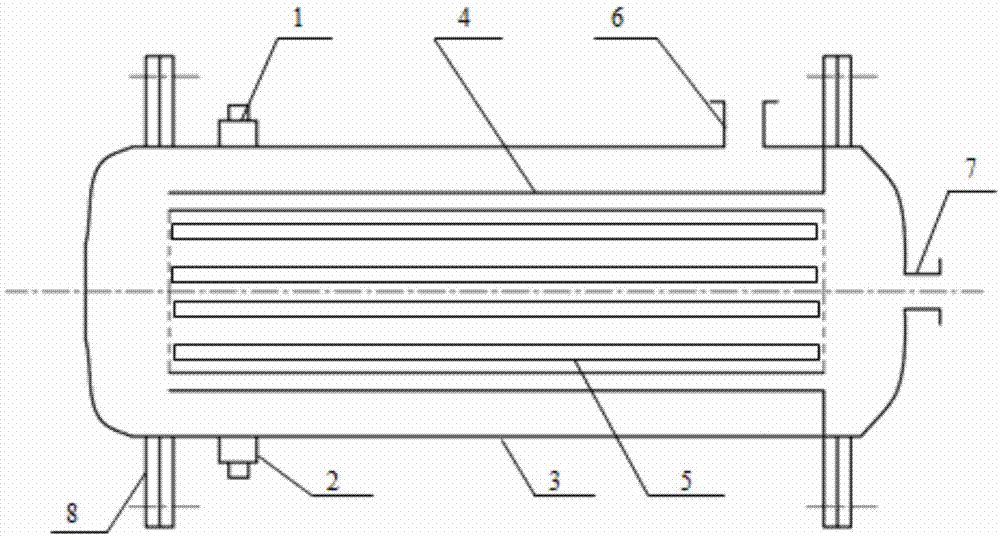

[0022] refer to figure 1 ,The resistance heater used in the engine combustion chamber experiment system consists of a thin-walled tube heating body 5, an inner cylinder 4, a heater shell 3, a live wire electrode 1, a neutral wire electrode 2, a flange 8, and a cold air inlet 6 And high-temperature gas outlet 7 constitutes. The air inlet 6 of the resistance heater is connected with the gas supply source, and the air outlet 7 of the resistance heater is connected with the pipeline of the test section through the flange 8, and there is no air leakage under pressure. The thin-walled tube heating body 5 is connected to a 380v power supply through the live wire electrode 1 . The neutral wire electrode 2 is connected to the ground below the side wall of the heater housing 3 . During the test, the airflow in the air source enters the resistance heater from the cold air inlet 6, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com