Nuclear reactor with improved cooling in an accident situation

A technology of nuclear reactors and reactors, which is applied in the field of nuclear reactors and can solve problems such as container wall perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The invention will be described in the context of high power pressurized water reactors (PWR) above 1000 MWe, but the invention is also applicable to low power reactors.

[0051] In the following description, the cooling liquid used is pure water, but any other composition providing suitable thermal properties is suitable (water to remove dirt, water filled with nanoparticles to facilitate heat exchange, etc.).

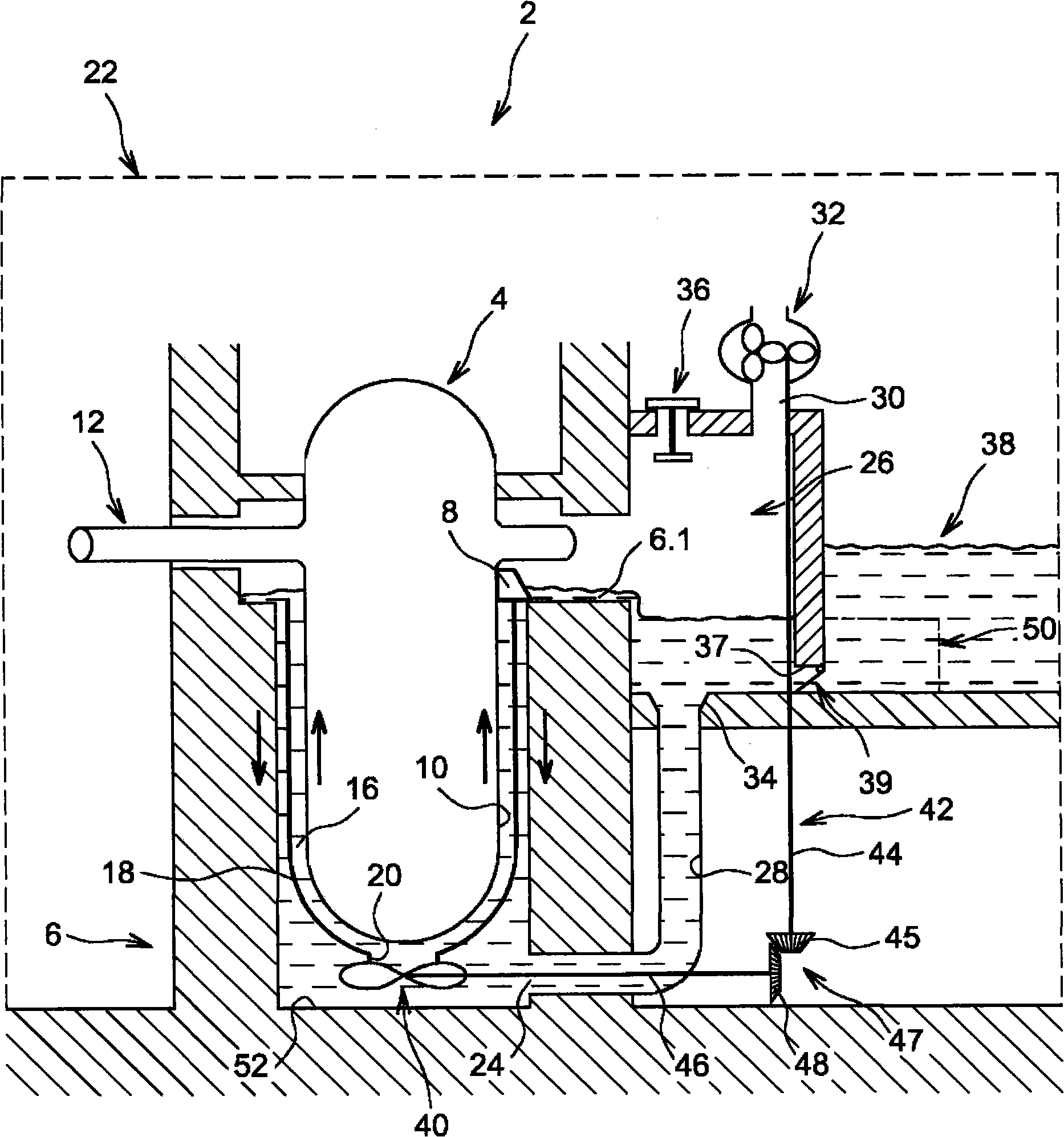

[0052] exist figure 1 In , it can be seen partly representing a reactor 2 according to the invention comprising a vessel 4 placed in its lower part in a concrete reactor pit 6 . The vessel 4 sits on the upper end 6.1 of the reactor pit 6 through the intermediary of an annular flange 8 protruding in a radial pattern towards the outside of the vessel. The vessel 4 is accommodated exactly in the reactor pit 6 , an annular space then being formed between the side wall 10 of the vessel and the wall of the reactor pit 6 .

[0053] The container 4 delimits a defined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com