Partition-based 3D printing filling path generation method

A 3D printing and path generation technology, applied in the field of 3D printing technology path generation, can solve the problems of affecting the filling speed, low filling speed, slow path generation speed, etc., and achieve the effect of commercialization, easy embedding and good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

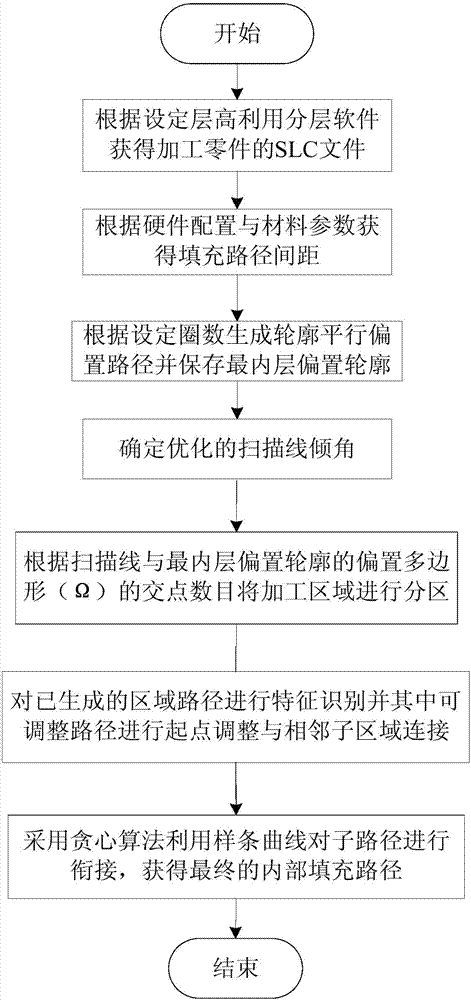

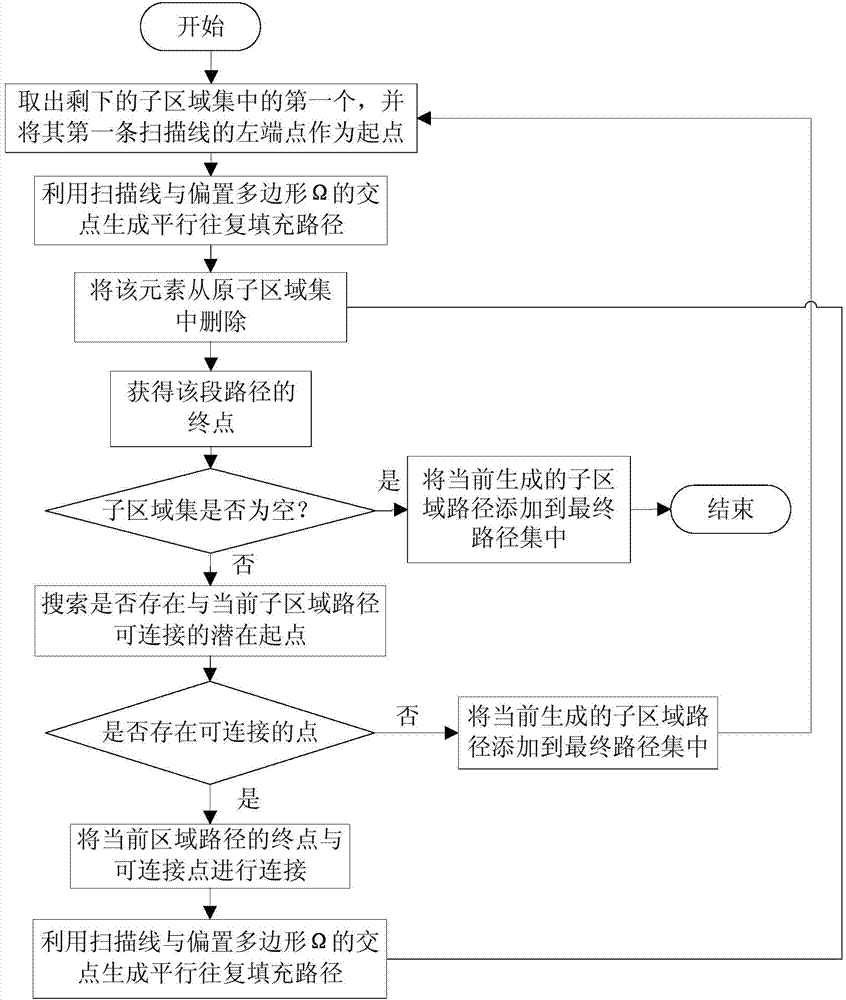

[0036] figure 1 Shown is a flow chart of the general internal filling path generation method of the 3D printing technology of the present invention. to attach Figure 6 The section of the part in (a) is taken as an example to illustrate the internal filling path generation method.

[0037] Step 1. Set the layer height to 0.5mm according to the precision of the part, and use the slicing software to obtain the contour information of each layer of the part. Figure 6 (a) is one of the cross-sectional profiles;

[0038] Step 2. According to the 3D printing equipment and printing materials used, determine the appropriate filling path spacing to be 0.8mm;

[0039] Step 3. Set the number of circles of the contour offset path to 2 (generally 2-4 circles), generate the contour parallel filling path according to the offset distance, and obtain the fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com