Device for directionally solidifying by locally and forcibly heating with resistance at high gradient

A technology of resistance heating and directional solidification, which is applied in the field of directional solidification material preparation, can solve the problems of low temperature gradient and insufficient melting of samples, and achieve the effect of high temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

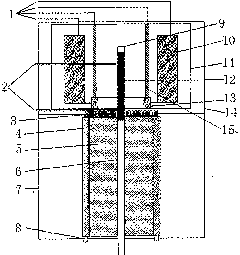

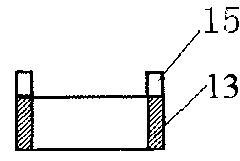

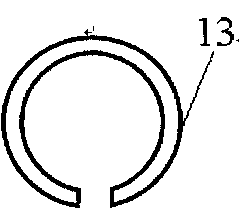

[0021] This embodiment is a local enhanced resistance heating high-gradient directional solidification device, including a power line 1, a thermocouple 2, a heat shield 3, a crystallizer 4, a furnace body, a liquid metal 5, a drawing system 6, a crucible 9, tungsten Barrel 10, shielding layer 11, resistance ring 13 and tantalum electrode 15. The alloy heated in this example is DZ125 directionally solidified nickel-based superalloy, the local strengthening temperature is 2000°C, the overall heating temperature is 1500°C, and a temperature gradient of 600°C / cm is obtained on the basis of ensuring the complete melting of the sample.

[0022] The furnace body includes an upper furnace body 14 and a lower furnace body 7. In the lower furnace body 7, from the center of the lower furnace body to the outside, there are successively a drawing system 6 and a crystallizer 4. Liquid metal 5 is housed in the crystallizer 4; The pulling system 6 passes through the furnace bottom of the lowe...

Embodiment 2

[0030] This embodiment is a local enhanced resistance heating high-gradient directional solidification device, including a power line 1, a thermocouple 2, a heat shield 3, a crystallizer 4, a furnace body, a liquid metal 5, a drawing system 6, a crucible 9, tungsten Barrel 10, shielding layer 11, resistance ring 13 and tantalum electrode 15. The alloy heated in this example is AM3 single crystal superalloy alloy, the local strengthening temperature is 1650°C, the overall heating temperature is 1500°C, and a temperature gradient of 290°C / cm is obtained on the basis of ensuring the complete melting of the sample.

[0031]The furnace body includes an upper furnace body 14 and a lower furnace body 7. In the lower furnace body 7, from the center of the lower furnace body to the outside, there are sequentially a drawing system 6 and a crystallizer 4, and the crystallizer 4 is equipped with liquid metal 5; The pulling system 6 passes through the bottom of the lower furnace body 7 and...

Embodiment 3

[0039] This embodiment is a locally enhanced resistance heating high gradient directional solidification device, including a power cord 1, a thermocouple 2, a heat shield 3, a crystallizer 4, a furnace body, a liquid metal 5, a drawing system 6, a crucible 9, a tungsten The barrel 10 , the shielding layer 11 , the resistance ring 13 and the tantalum electrode 15 . The alloy heated in this example is DZ125 directional solidification nickel-based superalloy, the local strengthening temperature is 2000 °C, and the overall heating temperature is 1500 °C, and a temperature gradient of 600 °C / cm is obtained on the basis of ensuring the complete melting of the sample.

[0040] The furnace body includes an upper furnace body 14 and a lower furnace body 7. In the lower furnace body 7, from the center of the lower furnace body to the outside, there are sequentially a drawing system 6 and a crystallizer 4, and the crystallizer 4 is equipped with liquid metal 5; The pulling system 6 passe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com