Fuel strut injector

A technology of injector and support plate, applied in combustion chamber, combustion method, combustion equipment and other directions, can solve the problems of high cost of support plate, harsh thermal environment of support plate, complicated structure of support plate, etc., and avoid serious ablation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] This embodiment is a fuel branch injector.

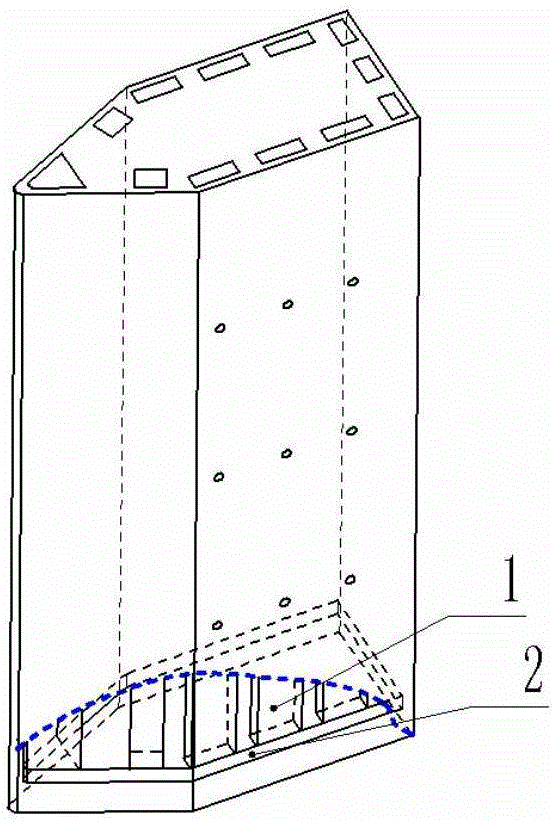

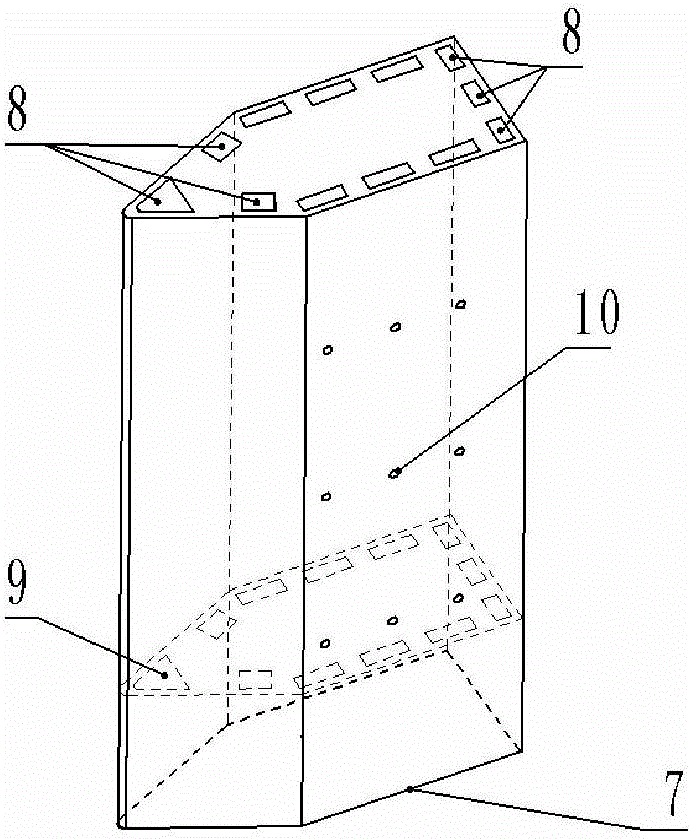

[0024] refer to Figure 1 to Figure 5 , the fuel strut injector in this embodiment uses the fuel of scramjet and combined cycle power engine as coolant, and adopts regenerative cooling mode; the coolant flows in the cooling passage to cool the strut plate, and is sprayed into the combustion chamber and The gas is mixed and burned to realize the normal operation of the support plate for a long time.

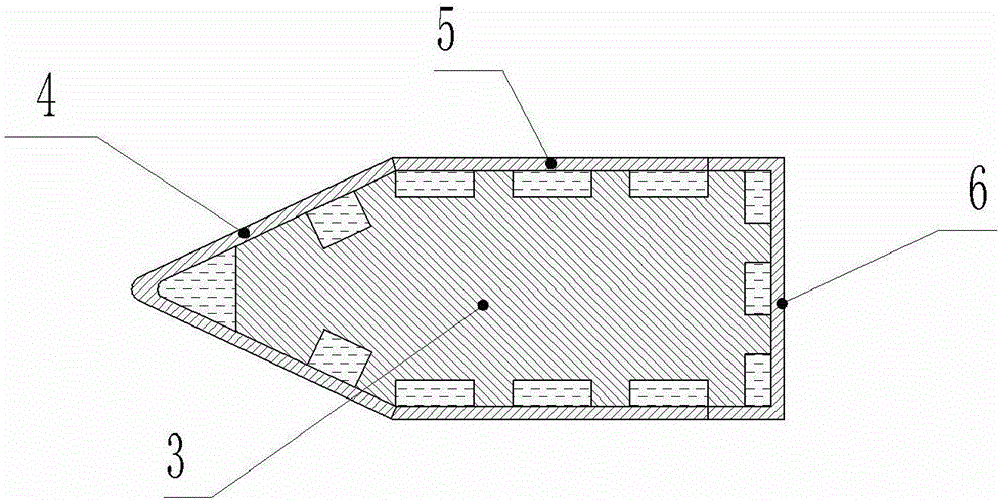

[0025] The fuel branch injector in this embodiment includes a cooling channel 1, a liquid collection chamber 2, a support plate 3, a front edge wall surface 4 of the support plate, a side wall surface 5 of the support plate, a rear wall surface 6 of the support plate, a bottom portion of the support plate 7, and a passage inlet 8 , the flow channel 9, the fuel injection hole 10, and the cooling channel is arranged on the inner side of the wall surface close to the support plate; wherein, the support plate 3 is a rounded wedge-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com