High-temperature fuel gas adjusting valve used for rocket engine

A rocket engine and gas regulation technology, which is applied to rocket engine devices, engine components, machines/engines, etc., can solve problems such as affecting the accuracy of flow regulation, and achieve the effects of convenient installation and operation, rapid adjustment, and good thermal protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

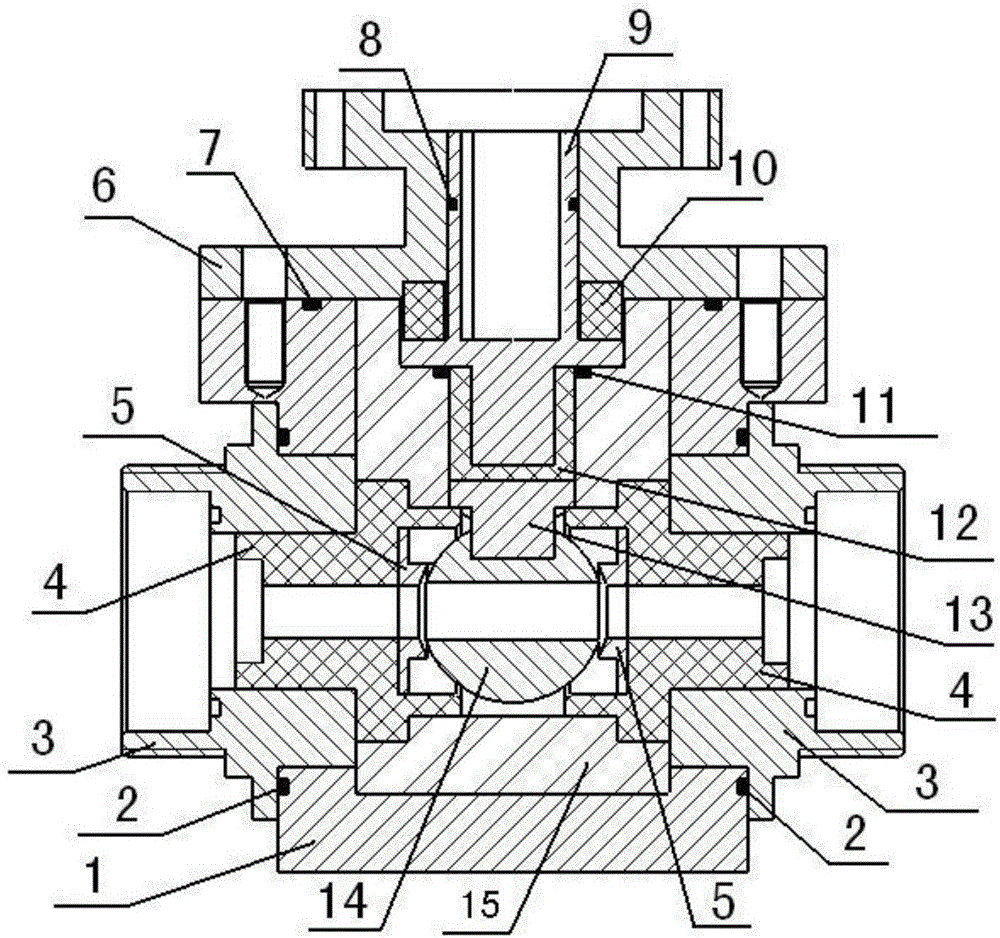

[0023] This embodiment is a high-temperature gas regulating valve used in a rocket engine.

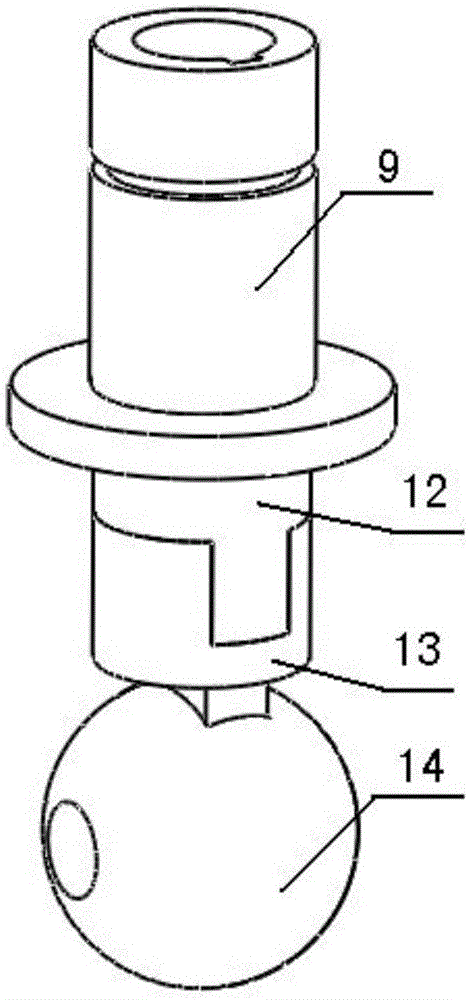

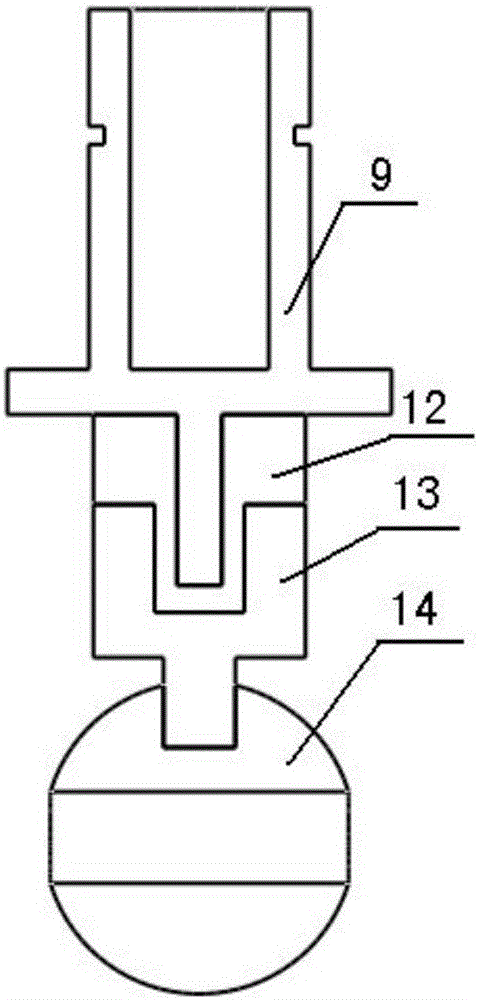

[0024] refer to Figure 1 to Figure 6 , this embodiment is used for the high-temperature gas regulating valve of rocket engine, which is composed of valve body 1, connecting end cover sealing ring 2, connecting end cover 3, gas pipeline heat insulating part 4, valve core bracket 5, upper end cover 6, and upper end cover sealing Ring 7, motor shaft sleeve seal ring 8, motor shaft sleeve 9, bearing 10, heat insulation seal ring 11, heat insulation 12, rotating shaft 13, valve core 14 and valve body heat insulation 15. The valve body 1 carries and serves as the installation base for internal components; the valve body 1 and the connecting end cover 3 are connected by threads, and a sealing groove is provided between the valve body 1 and the connecting end cover 3, and the sealing ring 2 of the connecting end cover is built in the sealing groove. The seal between the valve body 1 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com