Patents

Literature

365results about How to "Increase heat release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

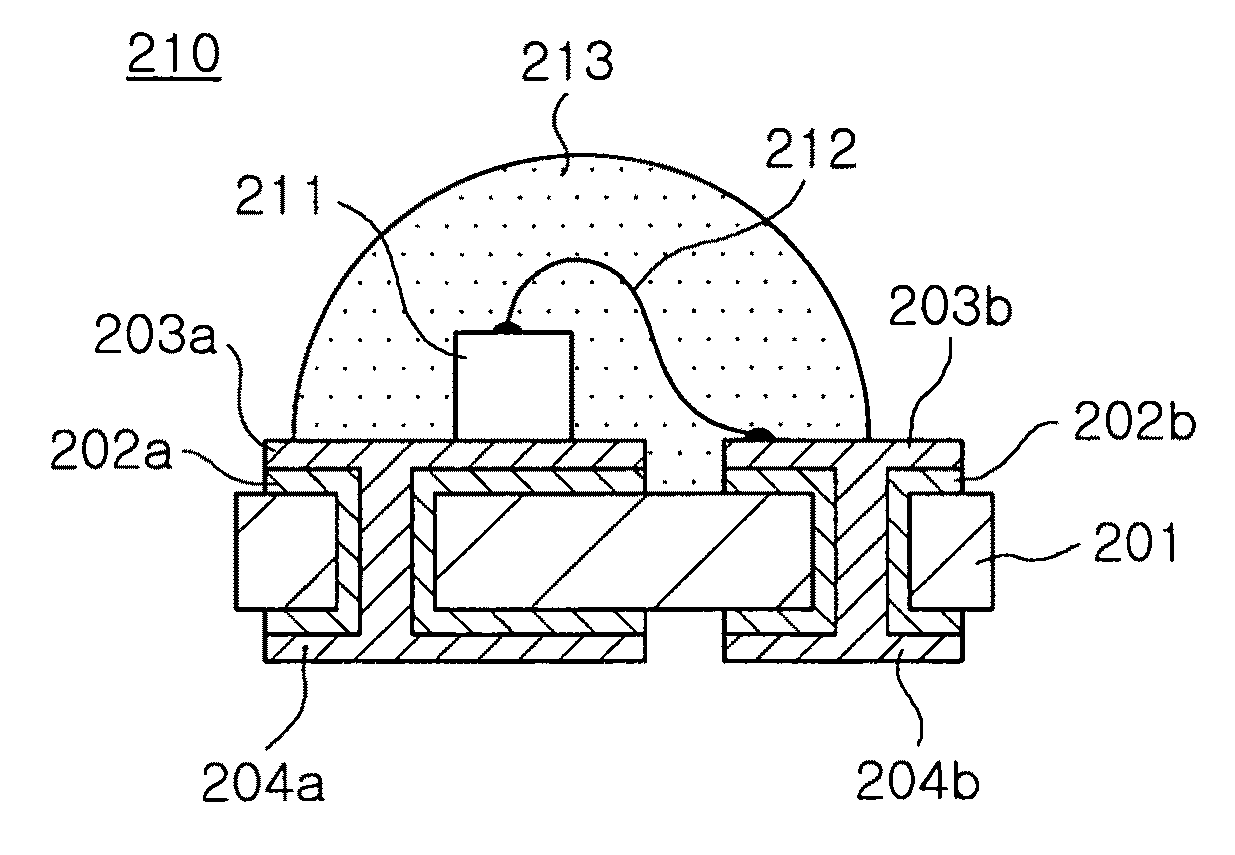

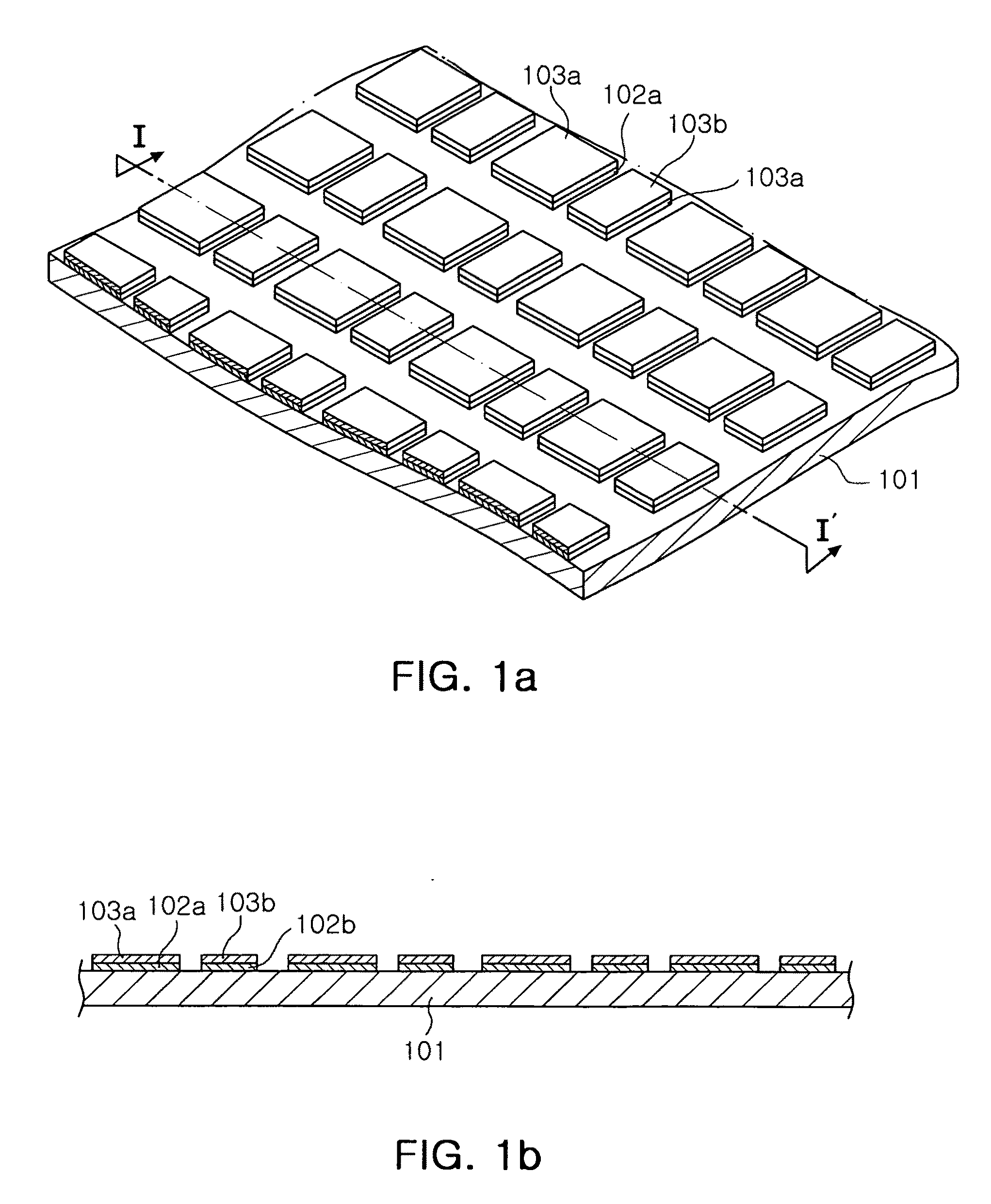

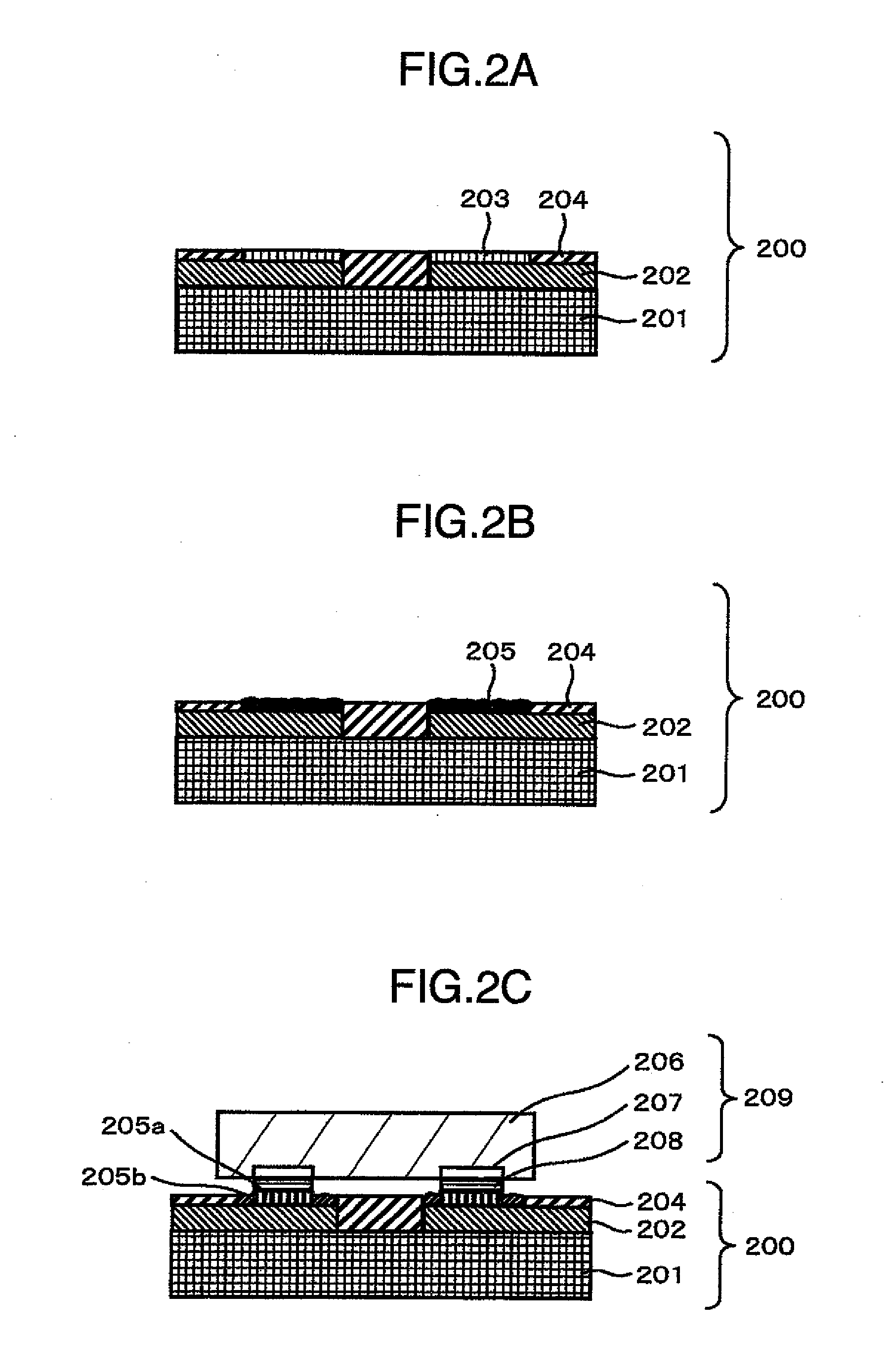

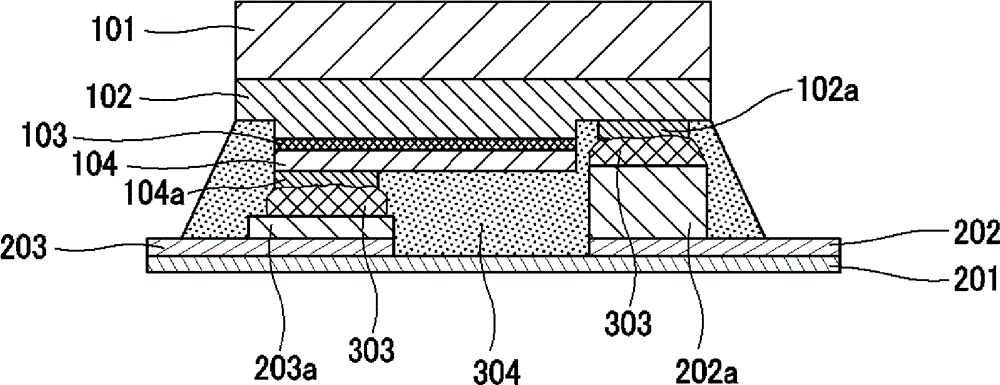

Substrate for light emitting diode package and light emitting diode package having the same

InactiveUS20110042699A1Increase heat releaseIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeMetal

A substrate for a light emitting diode (LED) package, and an LED package having the same are disclosed. The substrate for an LED package includes: a metal plate; an insulation oxide layer formed on a portion of the surface of the metal plate; a first conductive pattern formed at one region of the insulation oxide layer and providing a light emitting diode mounting area; and a second conductive pattern formed at another region of the insulation oxide layer such that it is separated from the first conductive pattern. In the substrate for an LED package, because regions of the insulation oxide layer other than regions for insulating conductive patterns are removed, heat generated from the light emitting diode can be effectively released. In addition, degradation of reflexibility and luminance of the LED due to the insulation oxide layer can be prevented.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

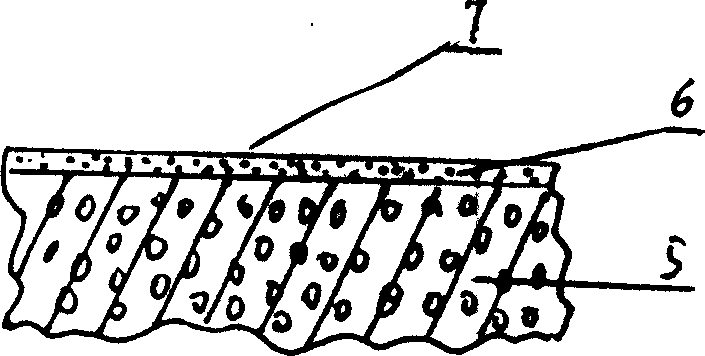

Low volatile reinforcing system

InactiveUS6211259B1Increase heat releaseImprove brittlenessOrganic-compounds/hydrides/coordination-complexes catalystsSynthetic resin layered productsThermoplasticPolyol

The present invention includes new compositions for making polyurethane and polyurethane foam compositions. These compositions comprise the reaction product of an isocyanate A-Side and a B-Side comprising: (i) a polyol having a molecular weight of about 1000 g / mol or more, and having an average functionality of 2.0 or greater; (ii) a polyol having a Tg of about -80° C. or less, and having a molecular weight of about 1000 g / mol or more, and having an average functionality of 2.0 or greater; and(iii) a polyhydric alcohol having a molecular weight of about 90 g / mol or more, and having an average functionality of 3.0 or more. In the case of polyurethane foam compositions, the system also comprises water. The invention also includes processes for making the polyurethane and polyurethane foam compositions, as well as methods of adhering the same to cosmetic layers comprising thermoplastic, acrylic, and gel coat materials. The invention also includes articles made from these reinforced cosmetic layers.

Owner:ARISTECH SURFACES

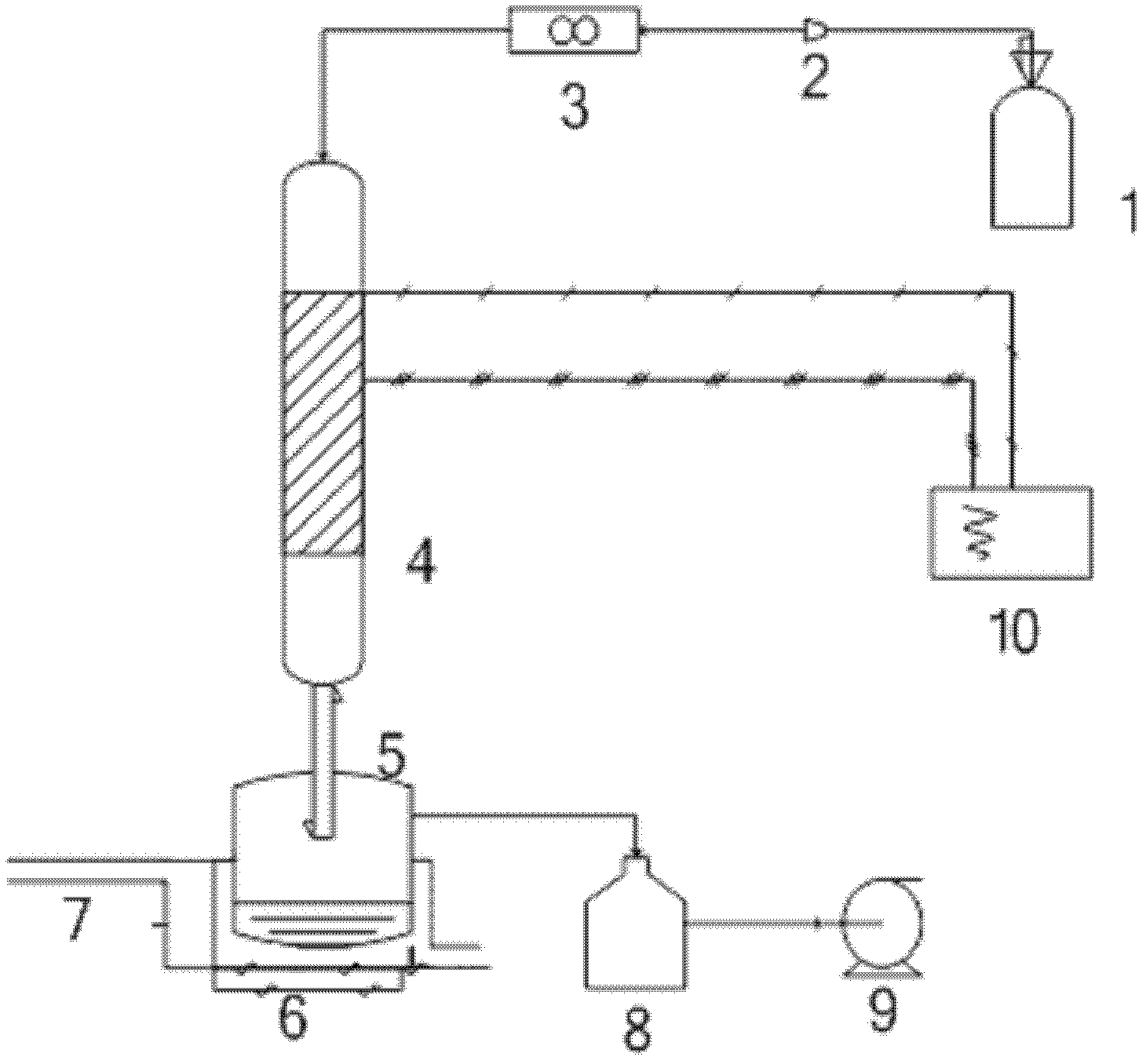

Method for coating micro/nano-metal powder by chemical vapor deposition

ActiveCN102581274ALow ignition temperatureShorter ignition delay timeChemical vapor deposition coatingThermal chemical vapor depositionIgnition delay

The invention discloses a method for coating micro / nano-metal powder by chemical vapor deposition, including: decomposing difluorocarbene precursor gas via a cracking pipe to generate difluorocarbene free radicals; contacting the generated difluorocarbene free radicals with micro / nano-metal powder, and due to polymerization between difluorocarbene free radicals, a compact polytetrafluoroethylene coating film is generated on the surface of micro / nano-metal powder. In allusion to disadvantages and defects of the application of micro / nano-metal powder in energy-containing materials, polytetrafluoroethylene is polymerized on the surface of metal powder by chemical vapor deposition in order to coat micro / nano-metal powder. In the invention, the ignition temperature of metal powder is effectively decreased, the ignition delay time is shortened, and the combustion speed of metal powder is improved; the surface of metal powder coated with polytetrafluoroethylene is highly hydrophobic, so that reactive metal powder can be effectively prevented from absorption of moisture and oxidation.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

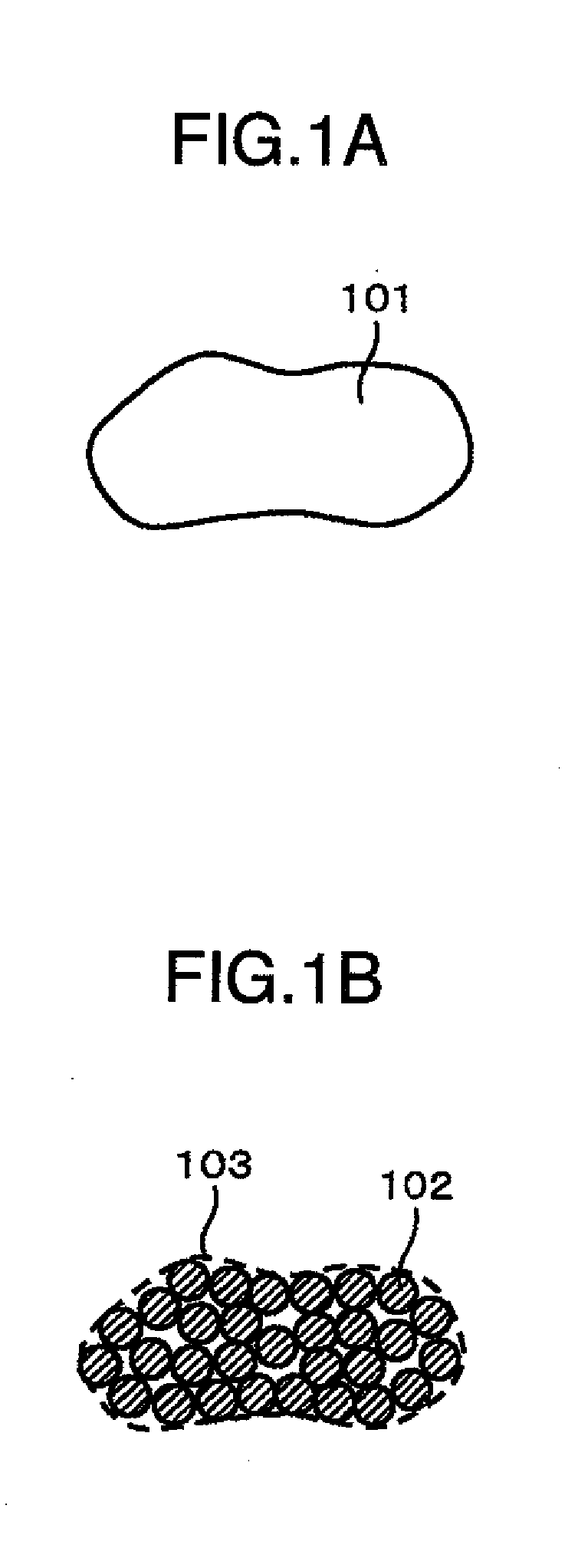

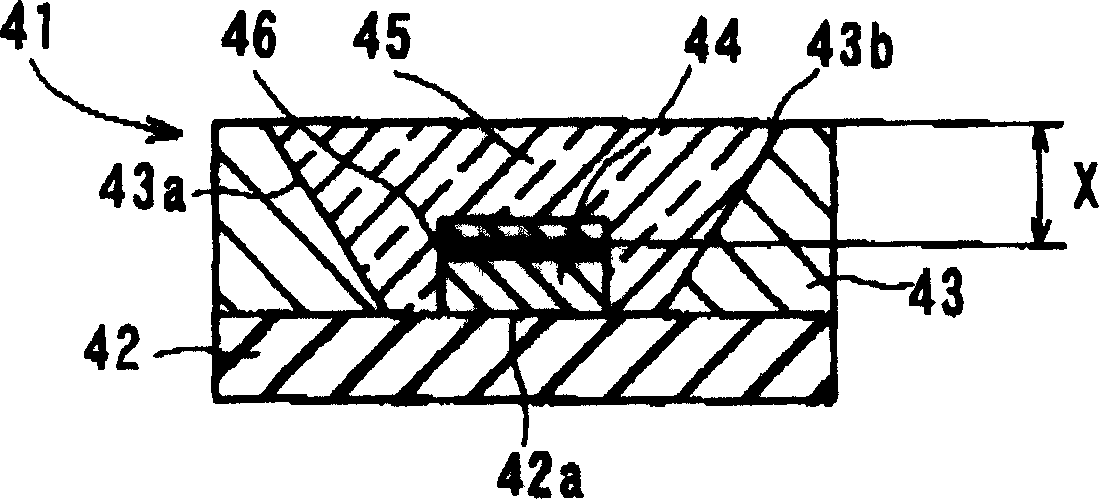

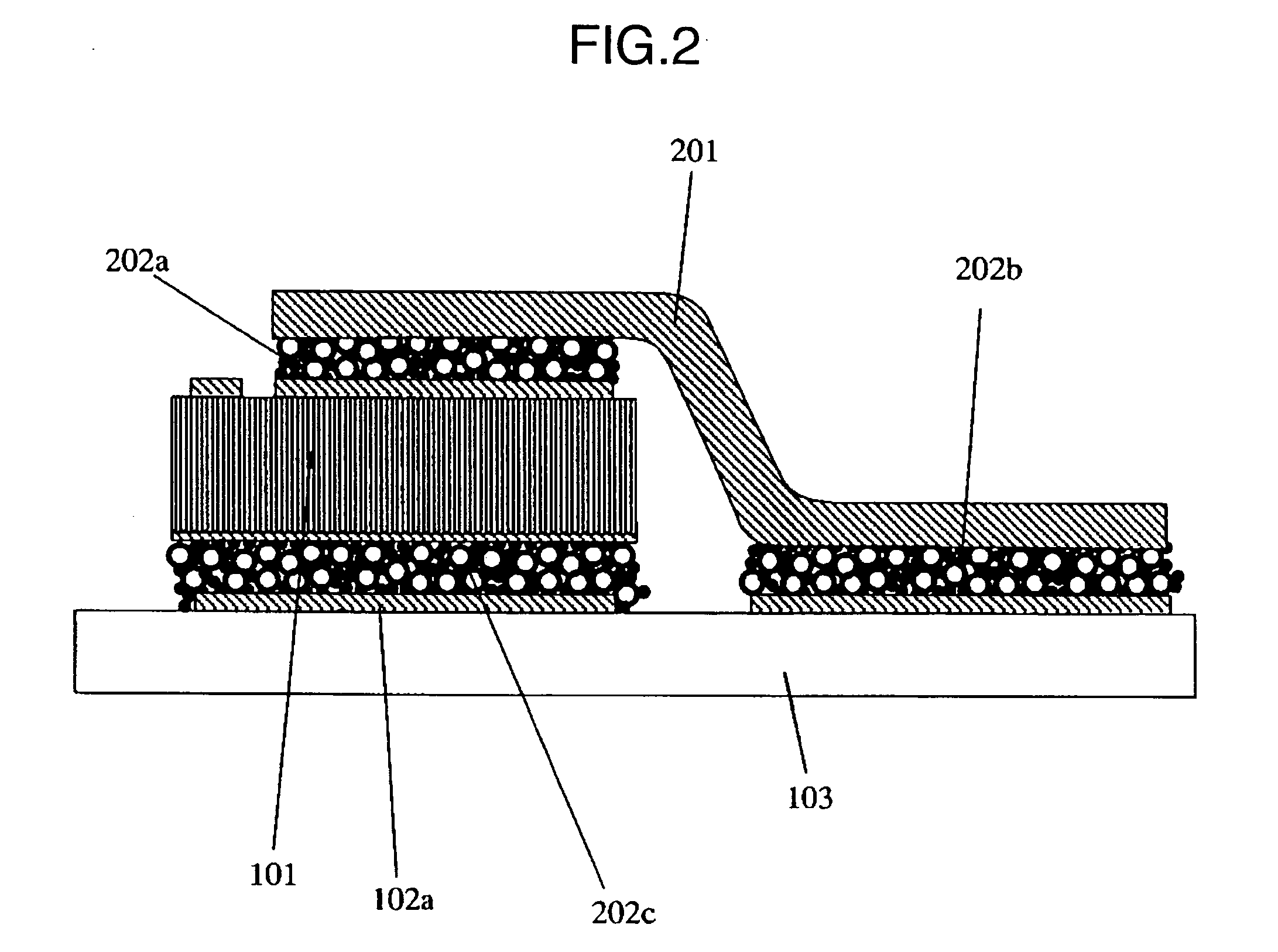

Electronic member, electronic part and manufacturing method therefor

InactiveUS20100195292A1Decrease in pitch spacingIncrease heat releaseAnodisationNon-insulated conductorsElectronic componentElectron

When silver oxide is reduced to silver, a large number of cores of metallic silver are formed inside the silver oxide. Then, the silver oxide is reduced in a manner of being hollowed out while its original outer configuration is being maintained. As a result, the curvature of the silver generated becomes larger. The utilization of this microscopic-particle implementation mechanism allows accomplishment of the bonding even if the silver oxide is supplied not in a particle-like configuration, but in a closely-packed layer-like configuration. In the present invention, there is provided an electronic member including an electrode for inputting / outputting an electrical signal, or a connection terminal for establishing a connection with the electrical signal, wherein the uppermost surface of the electrode or the connection terminal is a silver-oxide layer.

Owner:HITACHI LTD

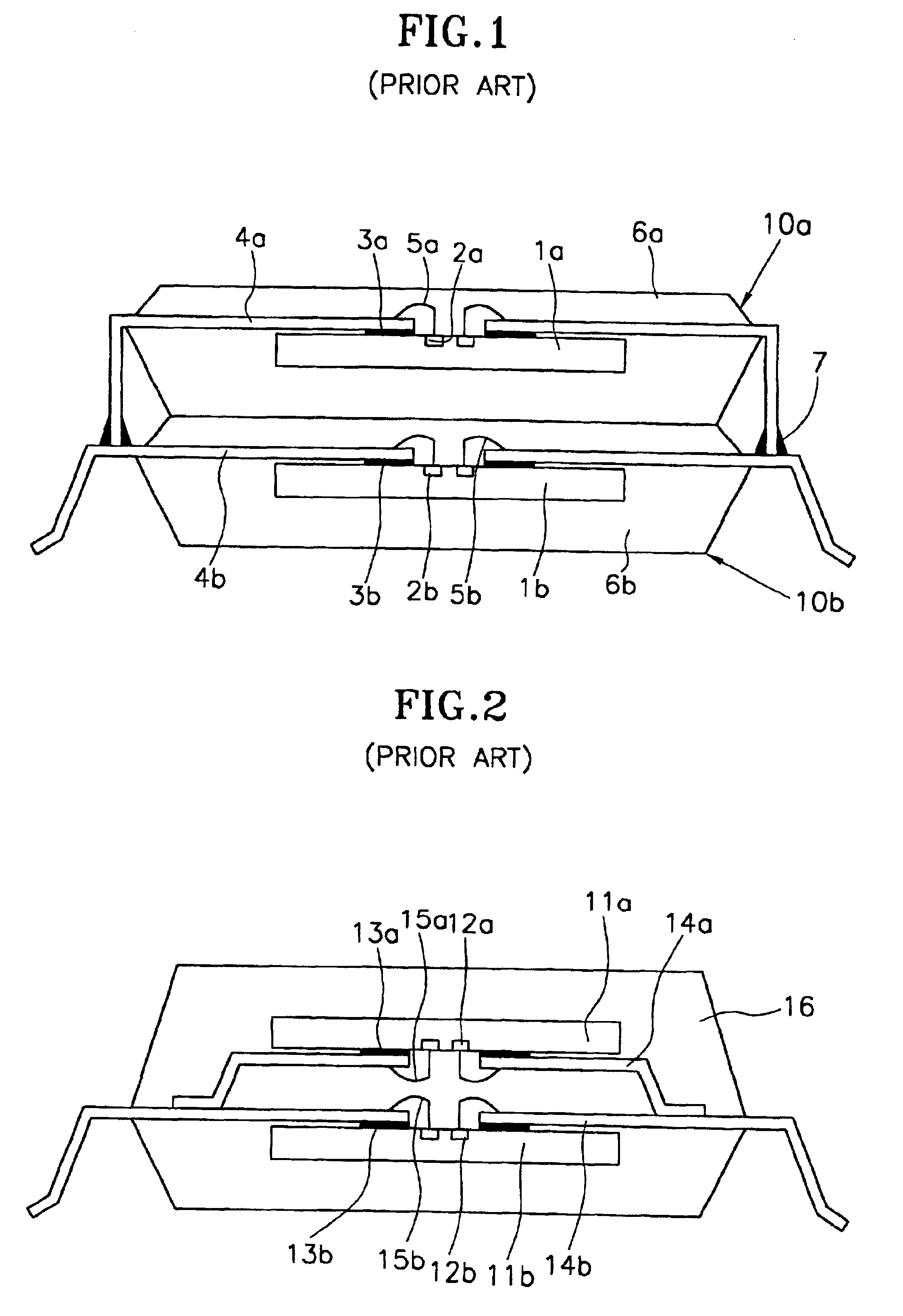

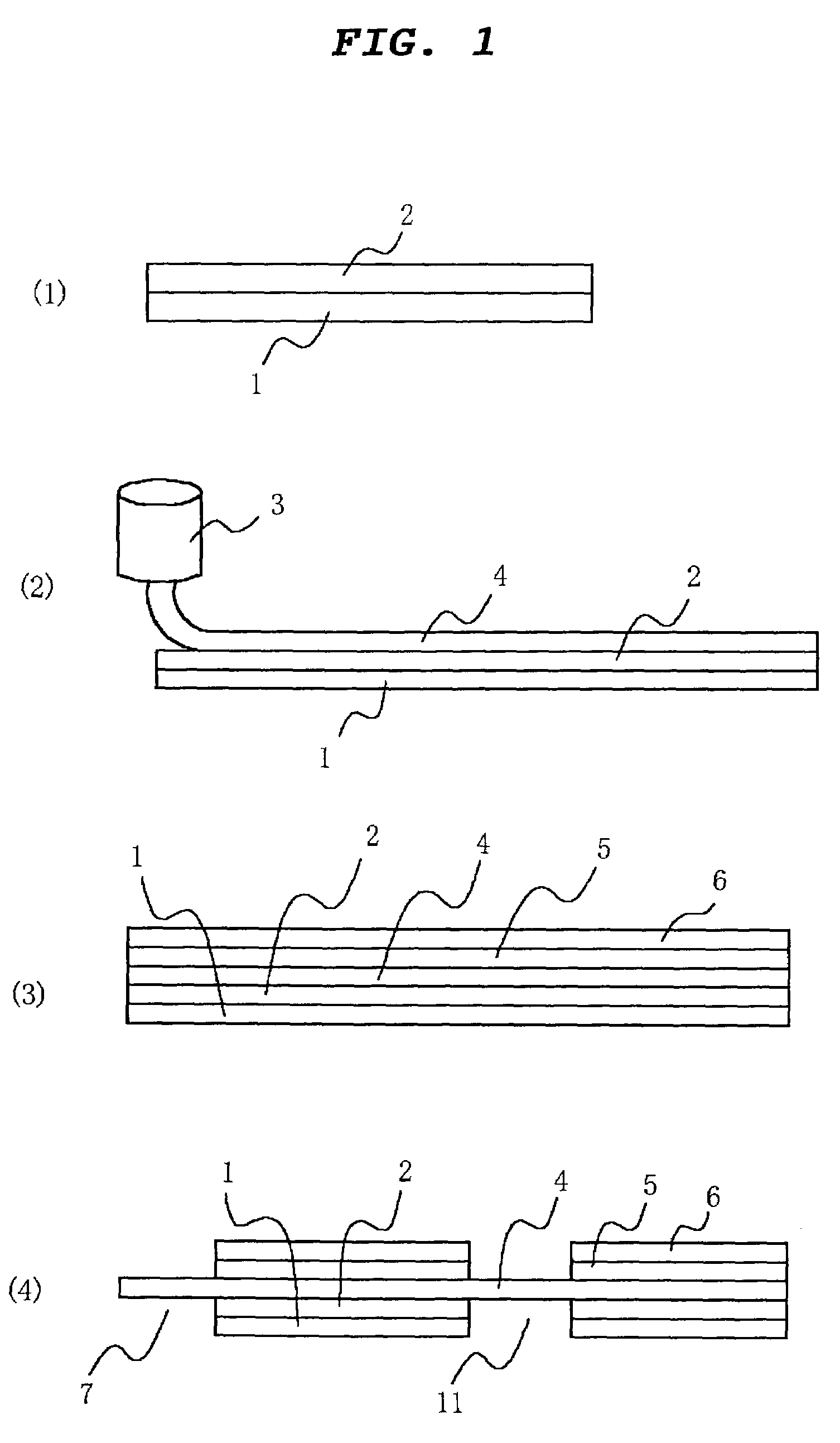

Stack chip module with electrical connection and adhesion of chips through a bump for improved heat release capacity

InactiveUS6867486B2Increase heat releaseImprove electrical performanceSemiconductor/solid-state device detailsSolid-state devicesAdhesiveSemiconductor chip

A stack chip module includes a substrate having a predetermined-size groove on one side and a circuit pattern, one end of the circuit pattern being adjacent to the groove; a first semiconductor chip adhered in the groove of the substrate by adhesive and having a plurality of center pads and a plurality of edge pads, electrically connected to each other, on the upper part thereof; a plurality of gold wires for electrically connecting the circuit pattern of the substrate and the edge pads of the first semiconductor chip, respectively; a second semiconductor chip having a plurality of center pads corresponding to those of the first semiconductor chip, the formative side being opposite to that of the first semiconductor chip; and a plurality of bumps interposed between the center pads of the first semiconductor chip and the center pads of the second semiconductor chip for joining and electrically connecting them.

Owner:SK HYNIX INC

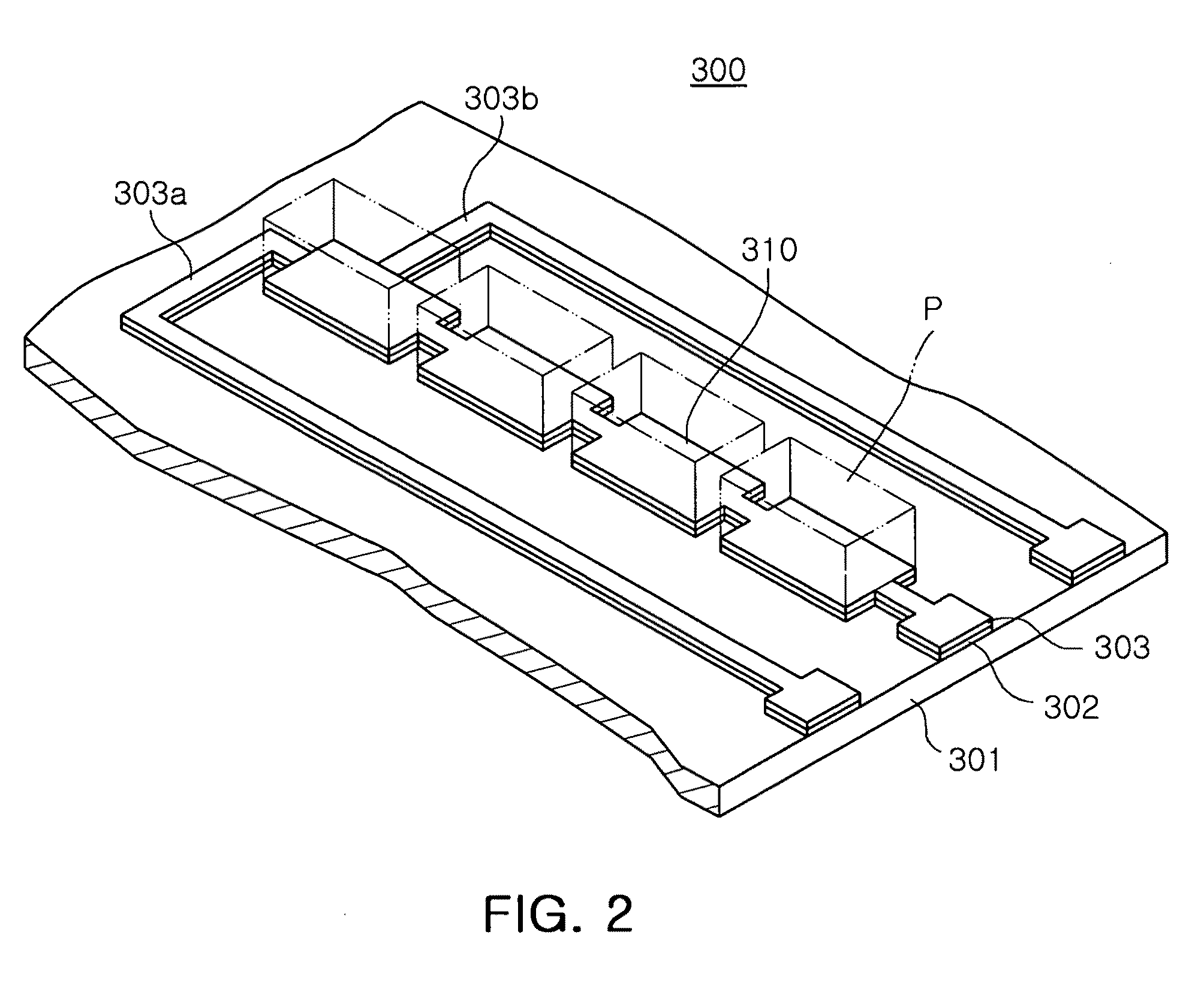

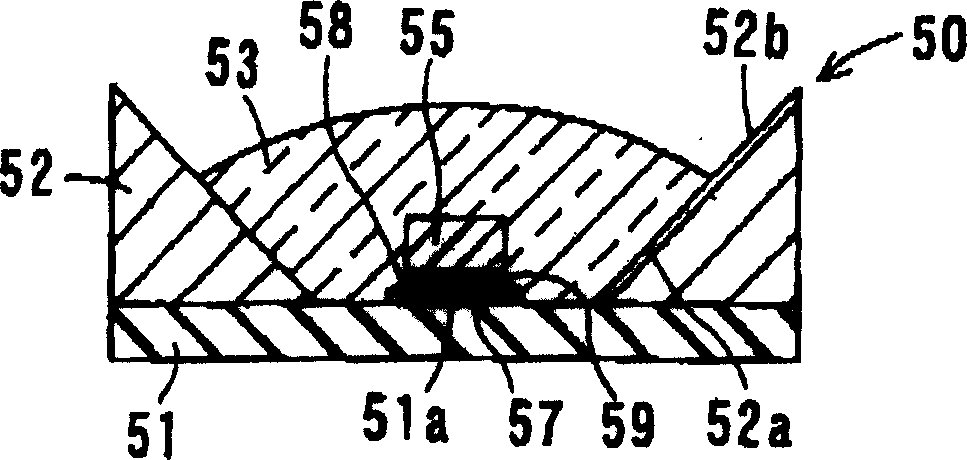

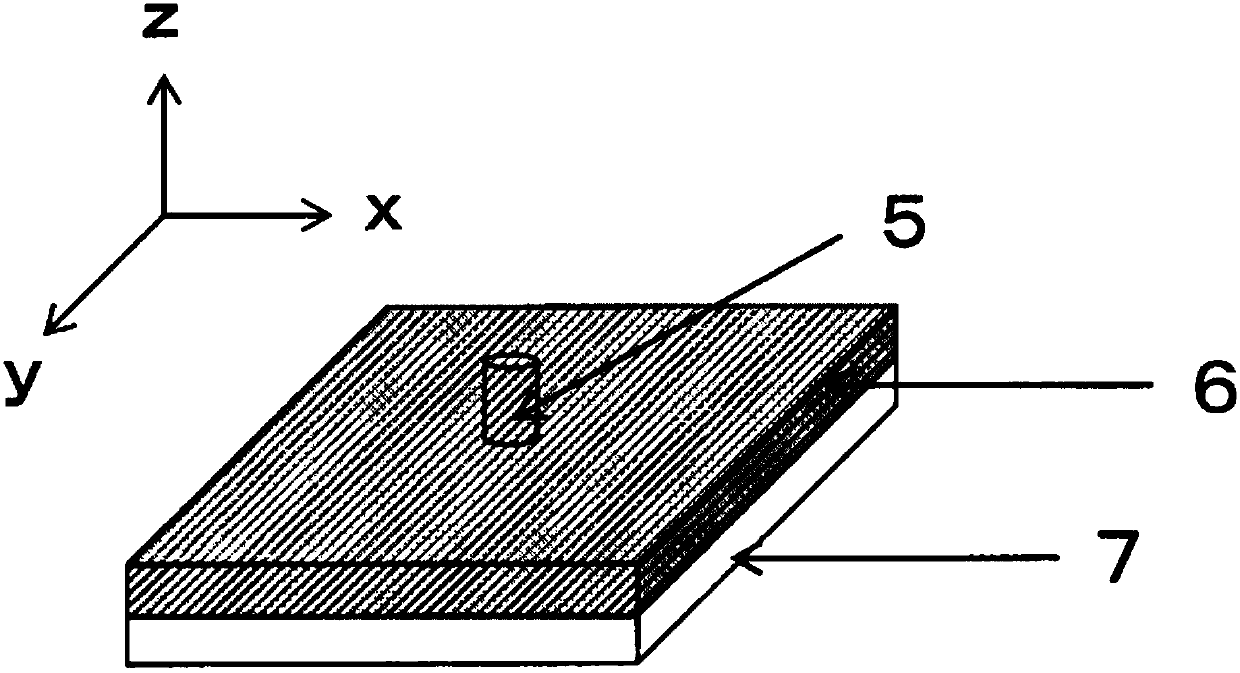

Light-emitting element reception package, light-emitting device and lighting device

InactiveCN1612369ARaise the ratioImprove light outputSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorEffect light

The package has a base body (51) with a mounting portion for mounting a light-emitting unit. A frame body is joined to an outer edge of the body (51) to surround the portion. A wiring conductor has its one end formed on an upper surface of the base body, to electrically connect an electrode of the light emitting unit. The light transmitting unit (53) is inside the frame body to cover the light emitting unit. - Independent claims are also included for the following: - (A) a light-emitting apparatus comprising a package for housing a light emitting unit - (B) an illumination apparatus constructed by setting up a light-emitting apparatus in a predetermined arrangement.

Owner:KYOCERA CORP

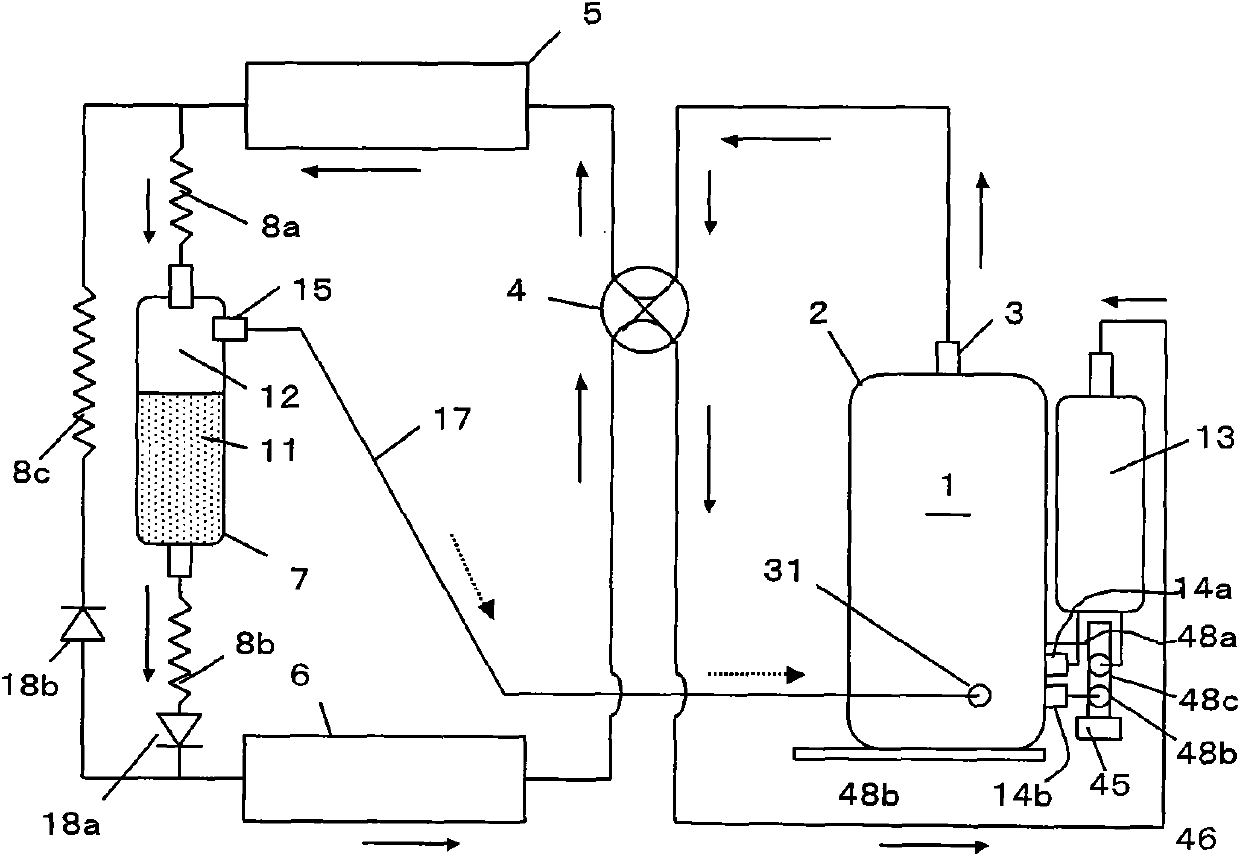

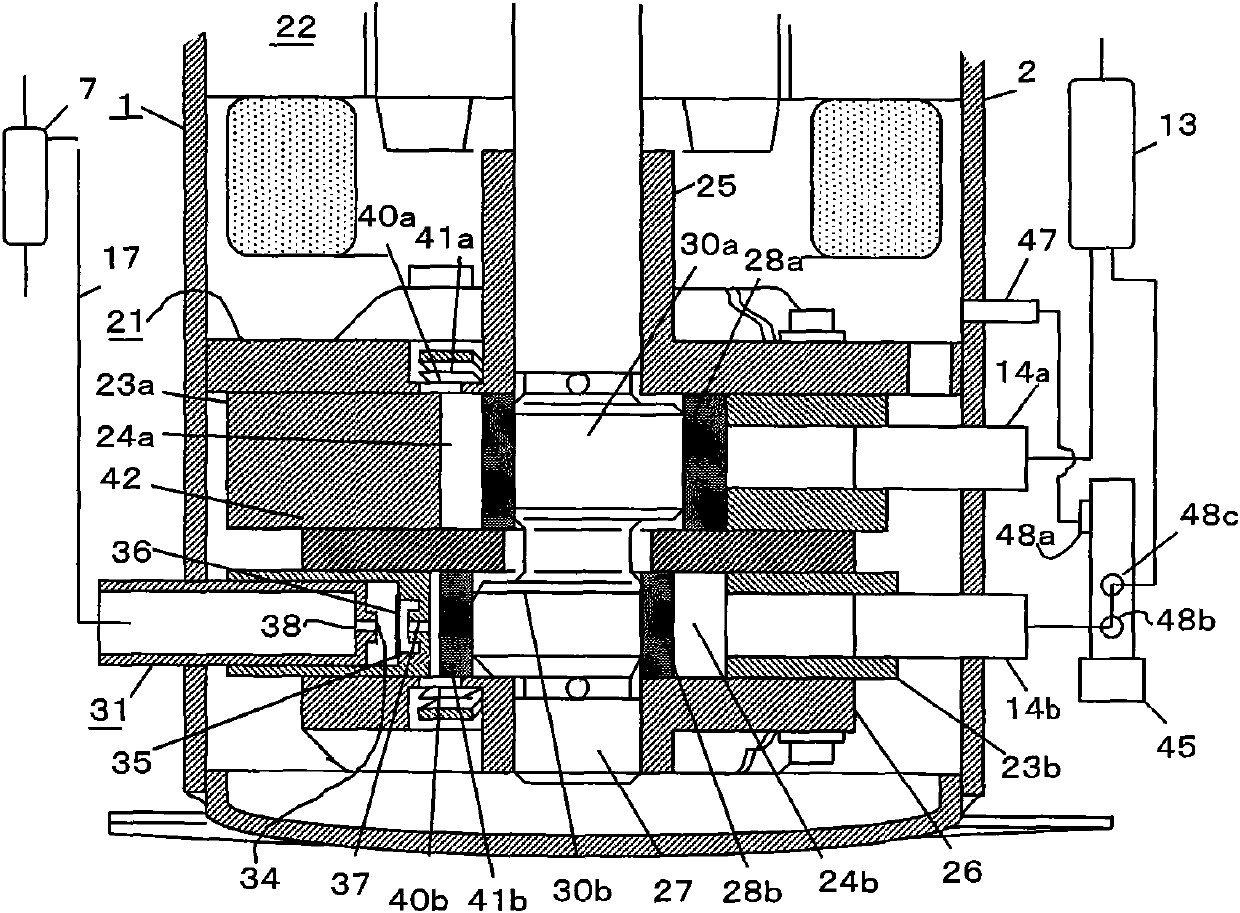

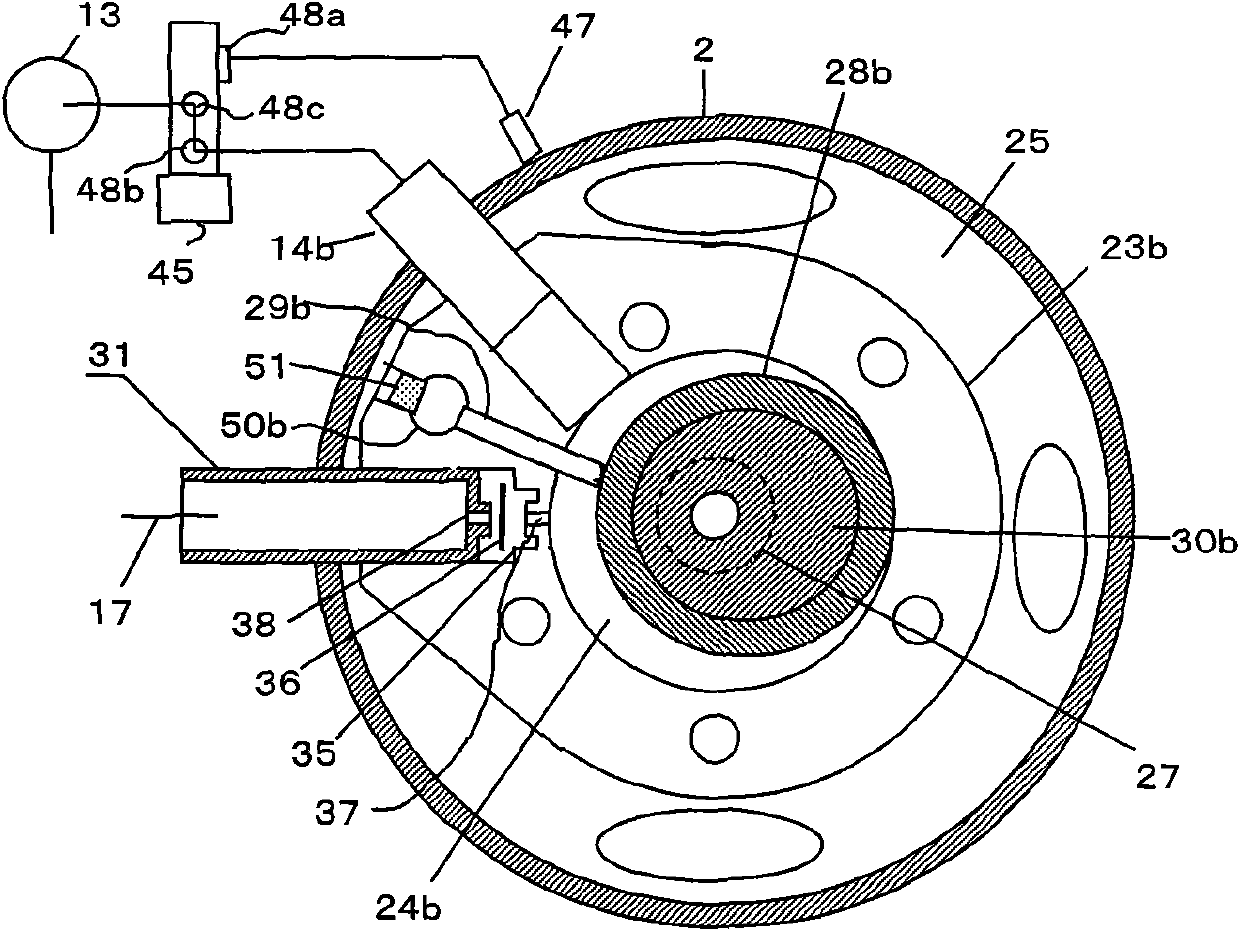

Capacity-control type double-cylinder rotary compressor and control method thereof

ActiveCN102022332AImprove energy efficiencyAvoid inefficiencyRotary/oscillating piston combinations for elastic fluidsMachines/enginesPhysicsPiston

The invention discloses a capacity-control type double-cylinder rotary compressor and a control method thereof. The capacity-control type double-cylinder rotary compressor comprises a seal shell, wherein the internal pressure of the seal shell is a high-pressure side pressure, and a motor assembly and a compression assembly connected with the motor assembly are arranged in the shell; the compression assembly comprises a first cylinder, a second cylinder, an intermediate plate, a crankshaft, a first piston, a second piston, a first slip sheet, a second slip sheet, a first slip sheet cavity, a second slip sheet cavity, a main bearing and an auxiliary bearing, wherein the crankshaft is connected with the motor assembly; the first piston and the second piston are connected with the crankshaft to carry out eccentric rotation, and respectively arranged in a first cylinder compression chamber and a second cylinder compression chamber; the first slip sheet cavity and the second slip sheet cavity are respectively used for accommodating the back side end of the slip sheet; the main bearing and the auxiliary bearing are used for supporting the crankshaft; and the double-cylinder rotary compressor is provided with a gas refrigerant injection device which injects gas refrigerants into the second cylinder compression chamber and is also provided with a volume control device which switches the pressure of the second cylinder compression chamber between the high-pressure side pressure and the low-pressure side pressure. The capacity-control type double-cylinder rotary compressor has the advantages that the efficiency is improved effectively, and the EER (energy efficiency ratio) is high.

Owner:GUANGDONG MEIZHI COMPRESSOR

Semiconductor device, power converter device using it, and hybrid vehicle using the power converter device

InactiveUS20060022326A1Improve long-term reliabilityImprove heat release/radiationSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device which uses a semiconductor element having main current input / output electrodes, one and the other of which are extended up to a one surface and a remaining surface of a semiconductor chip respectively for causing one of the input / output electrodes to be contacted with a conductive layer of a insulating substrate, whereby the semiconductor element is supported on or above the insulating substrate. A conductive strip which is made of a composite material of carbon and aluminum or a composite material of carbon and copper is used for connection between the remaining input / output electrode of the semiconductor chip and the conductive layer of the insulating substrate.

Owner:HITACHI LTD

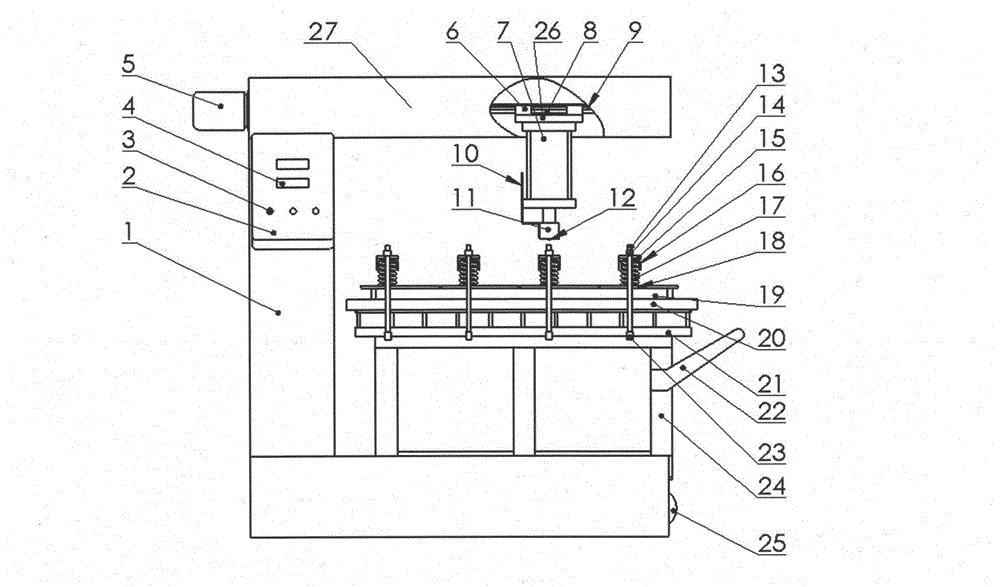

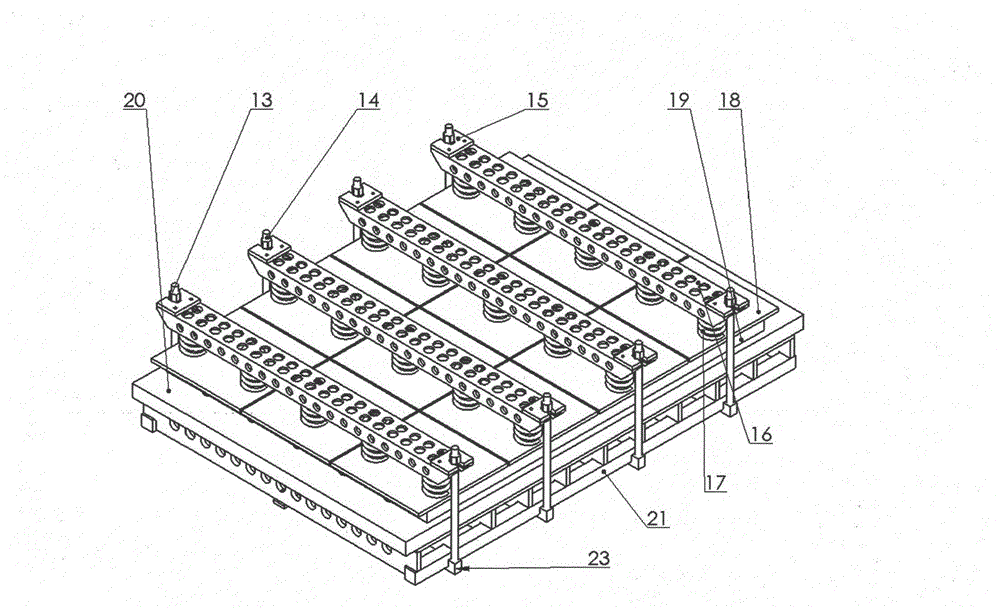

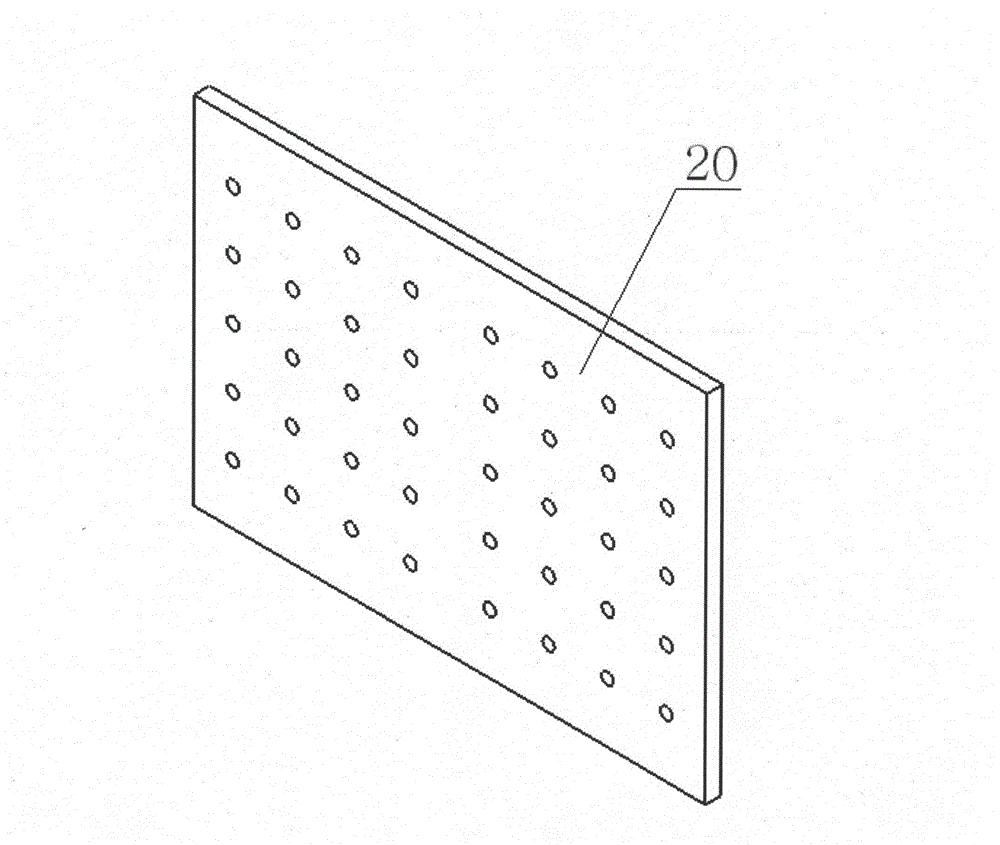

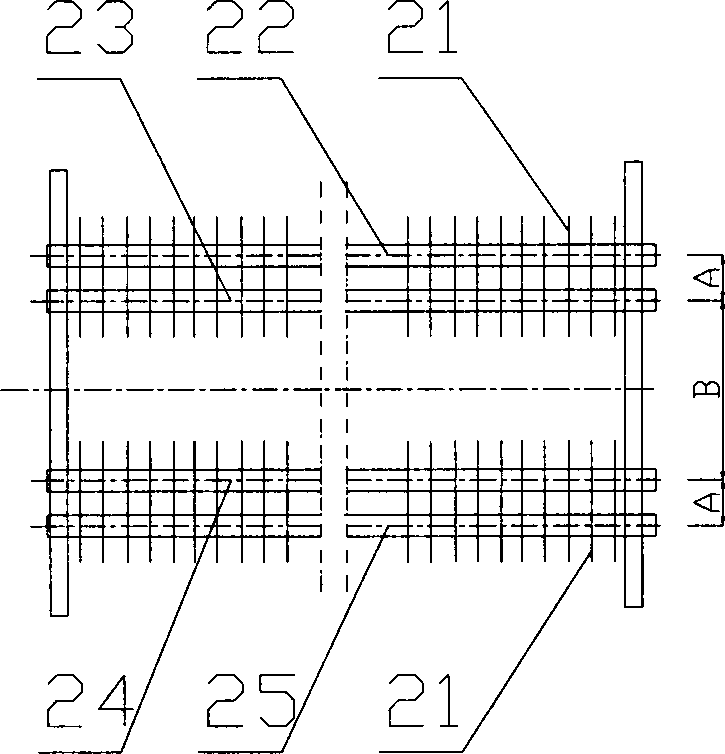

Vacuum brazing tool for water-cooling plate

InactiveCN102873491APrecisely control the total pressing forcePrecisely control the pressing forceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringInternal radiation

The invention discloses a vacuum brazing tool for a water-cooling plate. The vacuum brazing tool comprises a movable trolley, wherein a clamping device is arranged on the movable trolley and comprises a bottom board, a cover plate and at least one group of clamping device, wherein the bottom board and the cover plate are vertically superposed; and the vacuum brazing tool is characterized by further comprising a C-shaped main frame, wherein a suspension beam is arranged on the upper part of the C-shaped main frame, a vertical moving device which can move along the direction of the suspension beam is arranged on the lower side of the suspension beam, a pressing block is arranged on the bottom end of the vertical moving device, and at least one load sensor is arranged on the bottom of the pressing block. According to the tool, total press fitting force on the water-cooling plate can be accurately controlled, the press fitting force on each part of the water-cooling plate is basically consistent, and thus, the deformation of each clamp is slight and consistent, the service life of each clamp is prolonged, round hole structures of parts such as the bottom board and a pressing board are beneficial to the internal radiation heat adsorption and heat dissipation of a product in a vacuum brazing furnace, so that the brazing efficiency is improved, after the tool is adopted to weld the water-cooling plate, the once finished product rate can reach above 90%, and the tool can be widely applied to the assembling of the water-cooling plate before the vacuum brazing.

Owner:SHANGHAI EAGTOP ELECTRONICS TECH

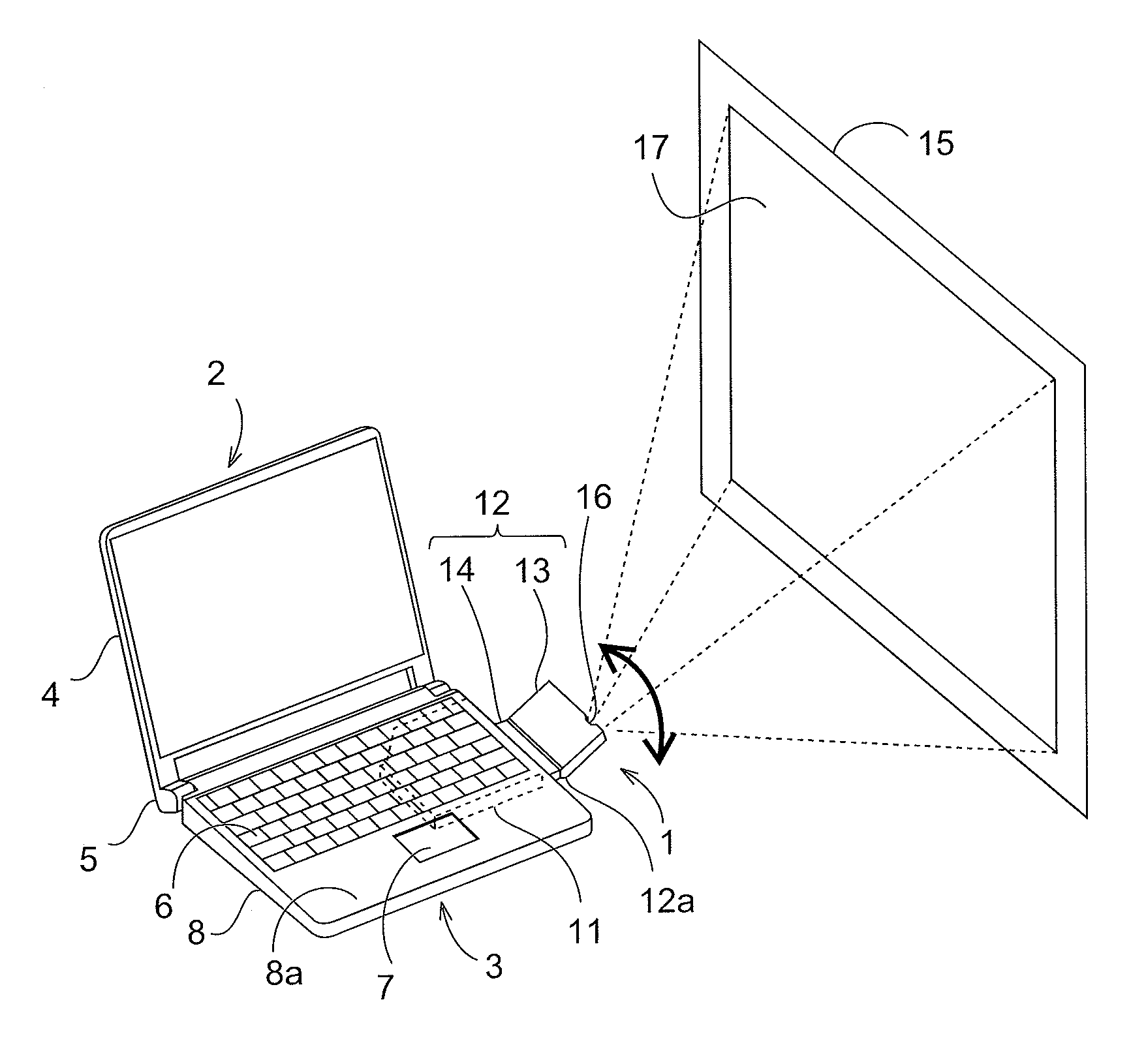

Image display apparatus

InactiveUS20120327379A1Increase heat releaseSimple processProjectorsColor photographyLaser lightWavelength conversion

An image display apparatus including a laser light source apparatus with a semiconductor laser as a light source increases the heat releasing ability of the laser light source apparatus in the image display apparatus. In order to accomplish this, a heat sink is provided to a green color laser light source apparatus, which generates green color light by wavelength conversion from infrared light and, therefore, produces a greater amount of heat than the other laser light source apparatuses. In addition, an air flow blocking cover is mounted on the surface of the holder, covering the temperature sensor, to prevent distribution to the temperature sensor of cooling air from the cooling fan disposed adjacent to the red color laser light source apparatus. It is thus possible to comply with laser safety standards.

Owner:PANASONIC CORP

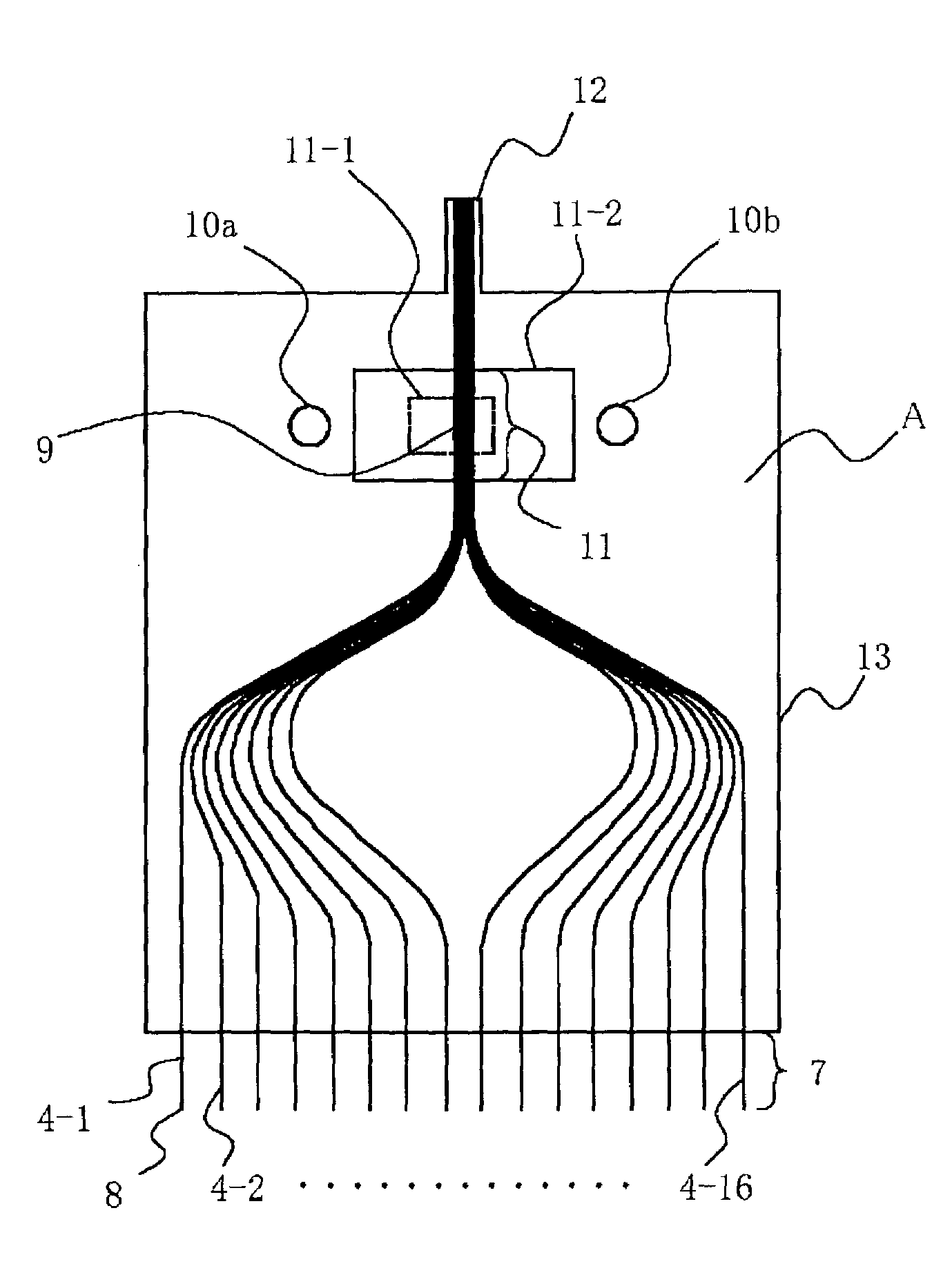

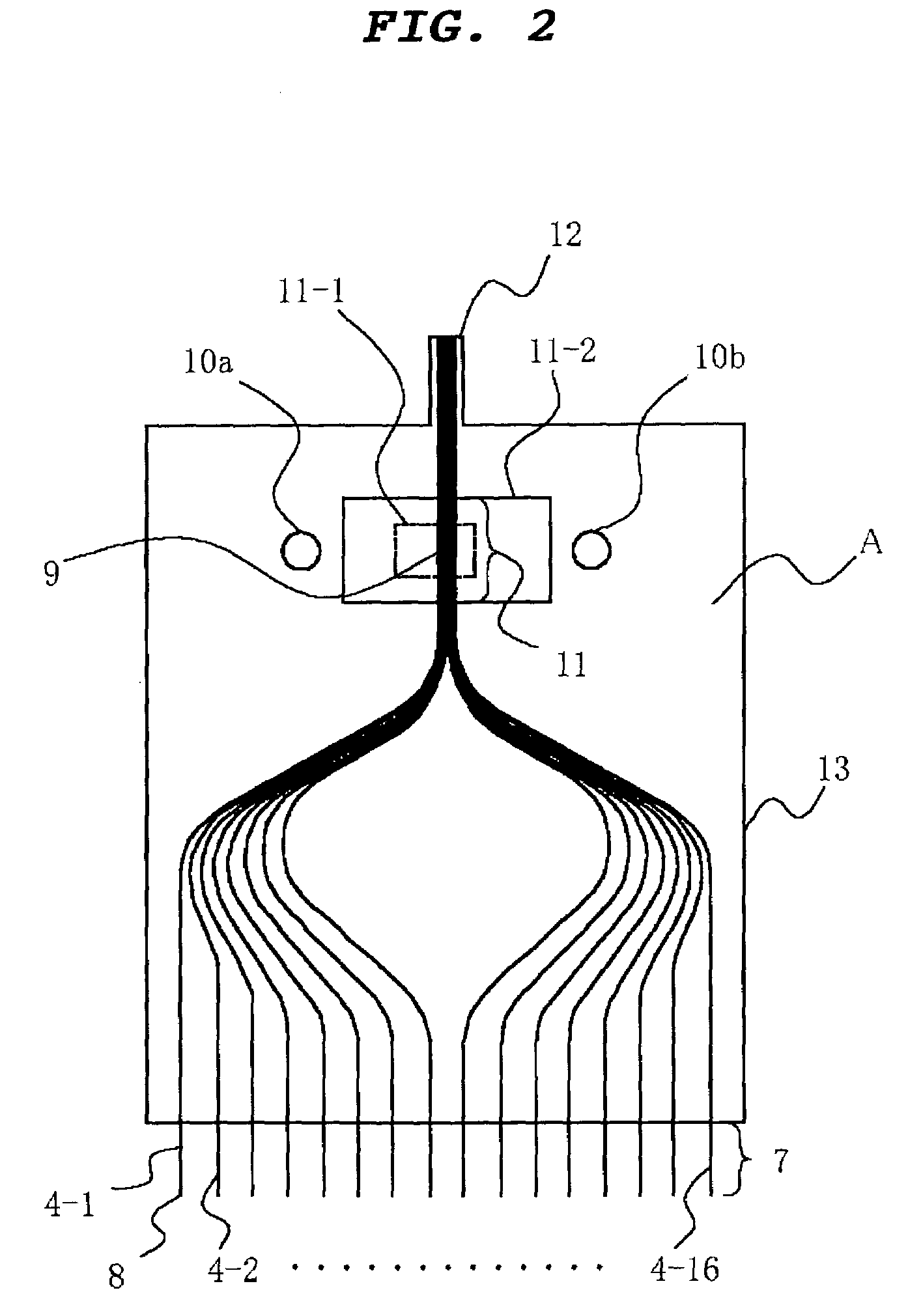

Electrophoresis member, production thereof and capillary electrophoresis apparatus

ActiveUS7195699B2Accurate and compact capillary arrayEasy to handleButtonsSludge treatmentCapillary electrophoresisElectrophoresis

An electrophoresis member is produced by laying a plurality of capillaries on an adhesive layer born on a support layer to form a capillary layer, laminating thereon a second support layer, and partially removing the first support layer, the first adhesive layer and the second support layer to partially expose the capillaries to form a window portion for irradiation and detection and a sample injection portion for injecting a sample.

Owner:HITACHI CHEM CO LTD +1

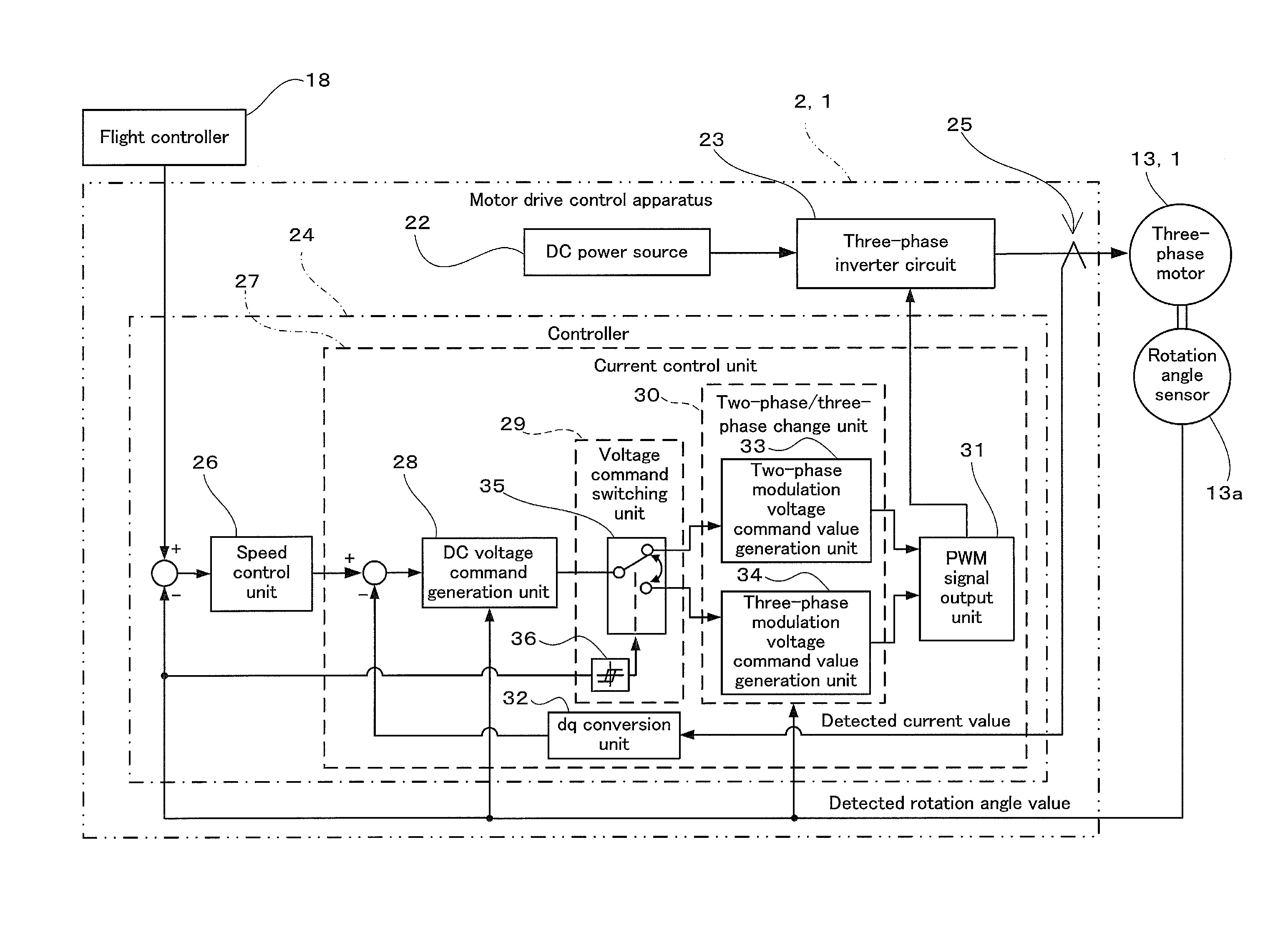

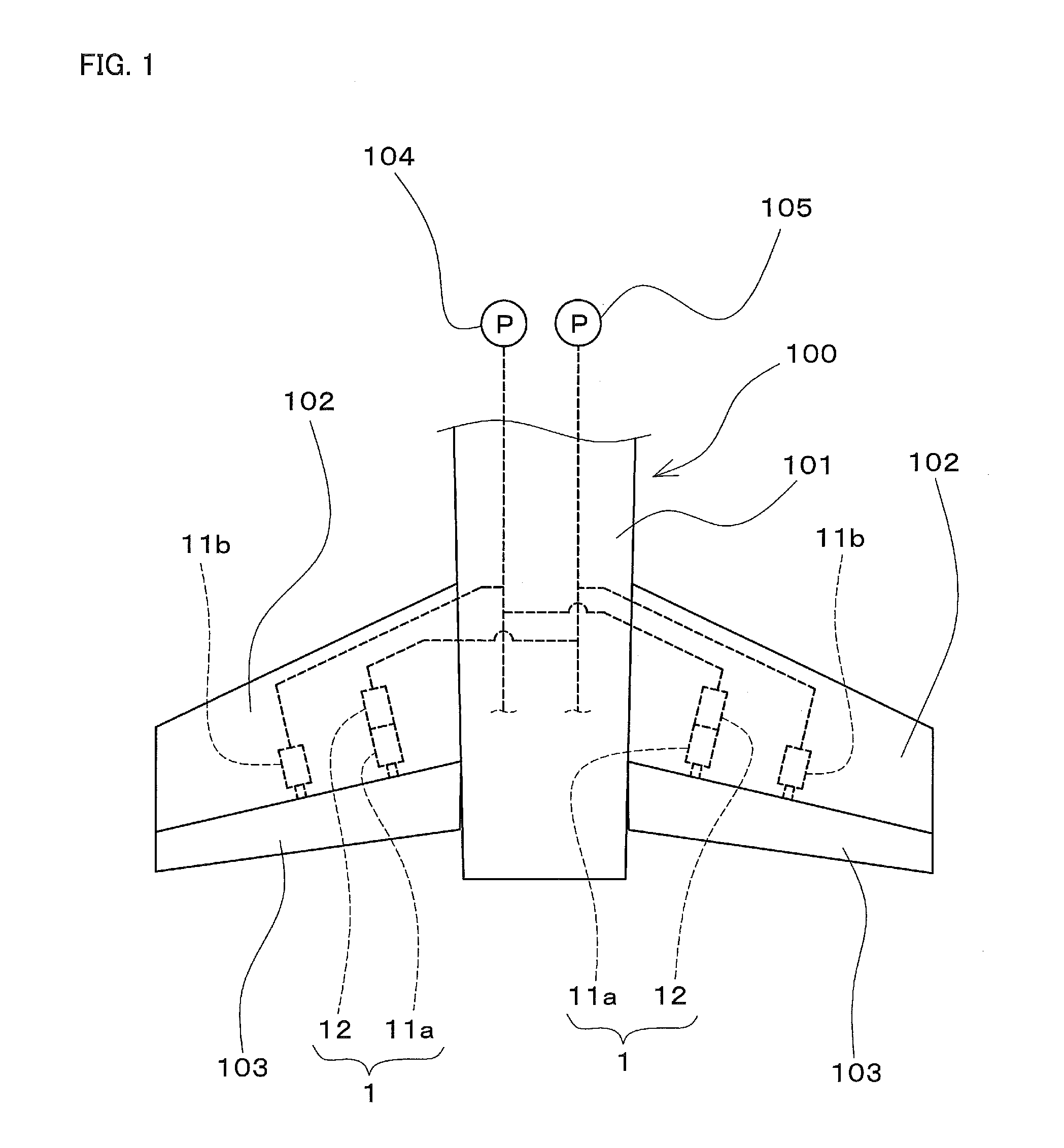

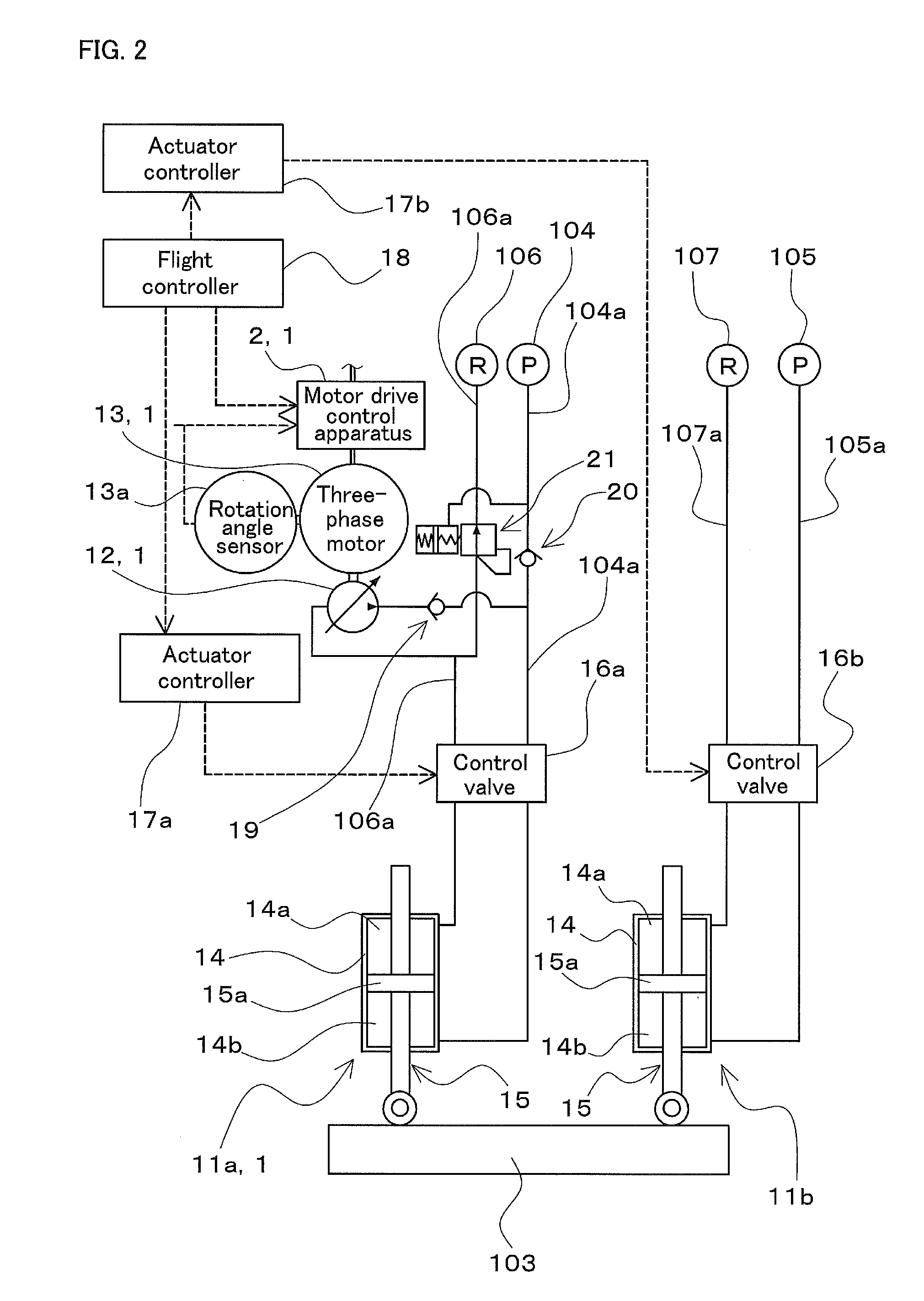

Aircraft motor drive control apparatus and aircraft actuator hydraulic system

ActiveUS20130330207A1Small sizeReduce weightSynchronous motors startersSingle motor speed/torque controlMotor driveEngineering

A controller that performs pulse width modulation control of a three-phase inverter circuit includes a three-phase modulation voltage command value generation unit, a two-phase modulation voltage command value generation unit, a voltage command switching unit, and a PWM signal output unit. The voltage command switching unit switches a voltage command value to a two-phase modulation voltage command value when a determination value becomes larger than or equal to a first threshold value, and switches the voltage command value to a three-phase modulation voltage command value when the determination value becomes smaller than a second threshold value, which is smaller than the first threshold value.

Owner:NABLESCO CORP

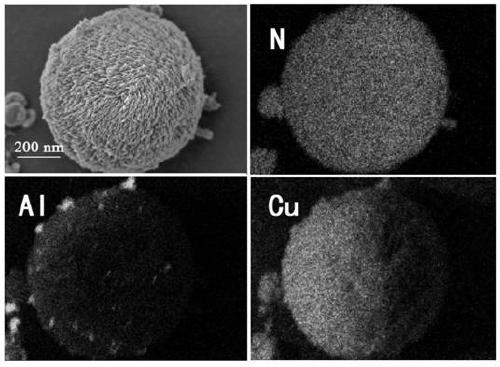

Preparation method of metal-organic framework material modified metal nanoparticles

ActiveCN109467493AIncrease heat releaseSimple methodNon-explosive/non-thermic compositionsPressure gas generationFreeze-dryingMetal-organic framework

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Boosted-ventilation direct air cooling tower

InactiveCN103712473AAdd adjustment functionImprove overall heat transfer coefficientSteam/vapor condensersAssisted ventilationCooling tower

The invention belongs to the field heat exchange, and relates to a boosted-ventilation direct air cooling tower, in particular to an air-cooling power generation air cooling island and an air driving mode. Due to winter-summer difference and day-night difference of air temperature, frequent natural wind and multiple changes of wind speed and wind direction, a pure natural ventilation and simple mechanical-assisted ventilation air cooling tower is difficult to meet current air cooling requirements. Condensation triangles composed of axial flow fans, finned tubes and the like are disposed around the lower portion of a natural ventilator. Cooling capacity of the air cooling tower in summer is greatly enhanced, damage of strong wind is weakened greatly, excess draft in the air cooling tower in winder can be utilized, energy is recovered through the axial flow fans, and hot air in the tower can be pumped out by reverse rotation of the fans to melt the accidentally-frozen fined tubes. The boosted-ventilation direct air cooling tower can be matched with direct air cooling and indirect air cooling units in various sizes.

Owner:李宁

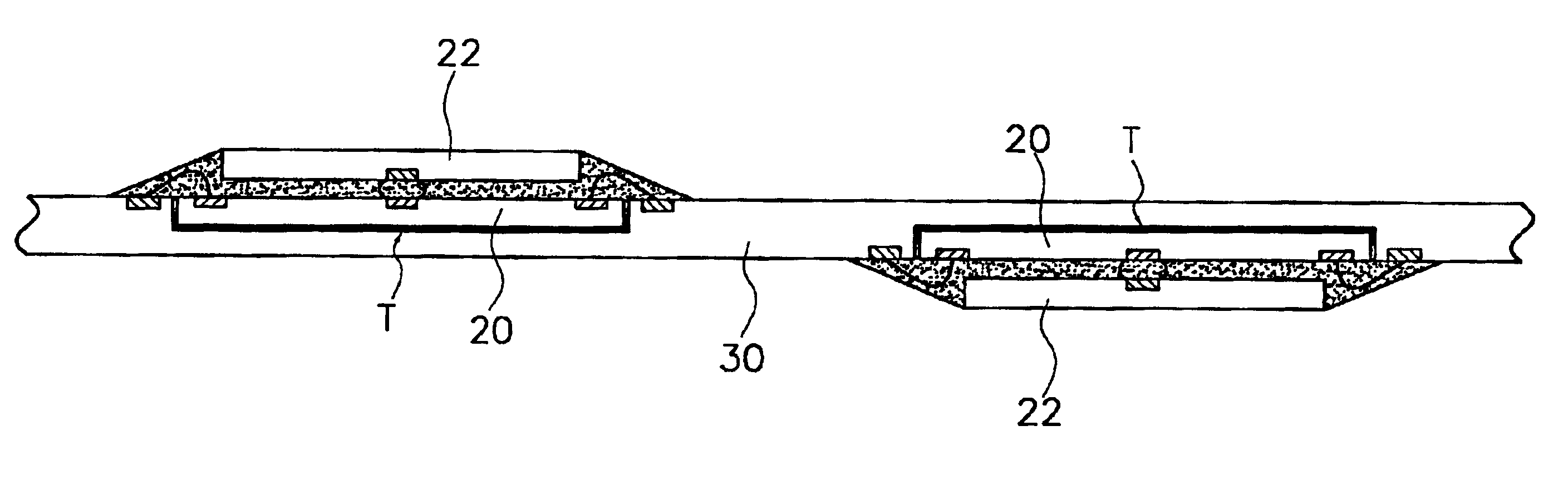

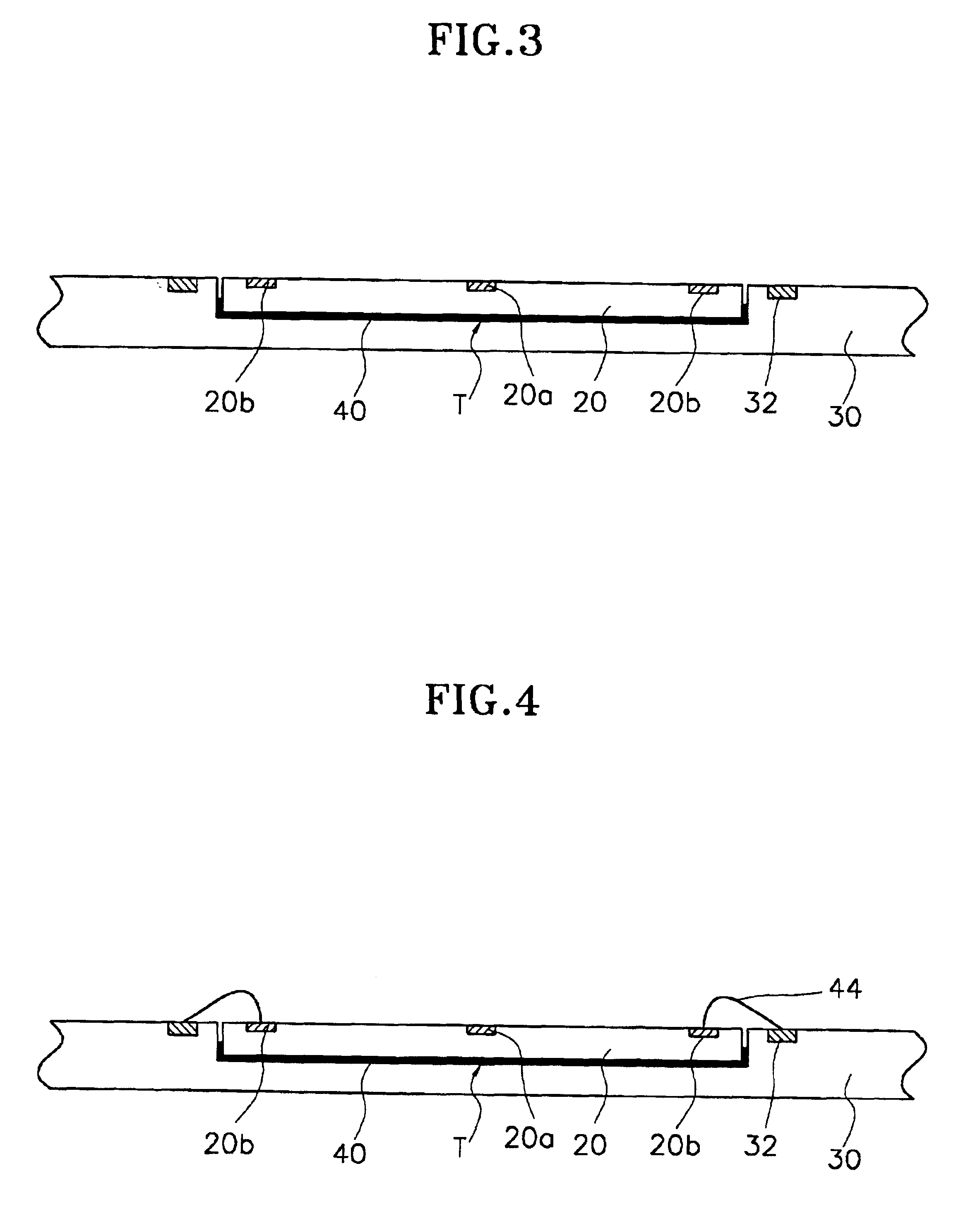

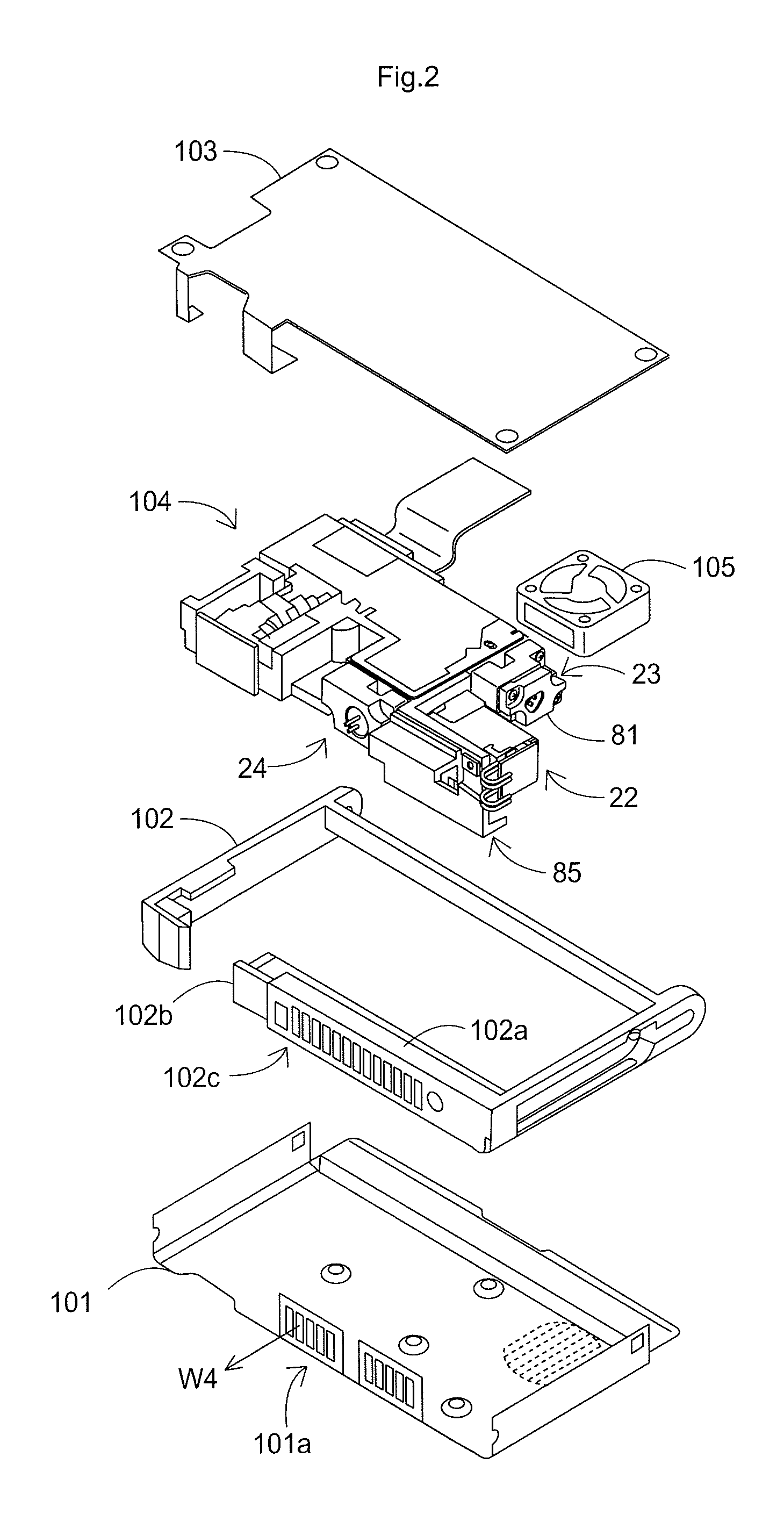

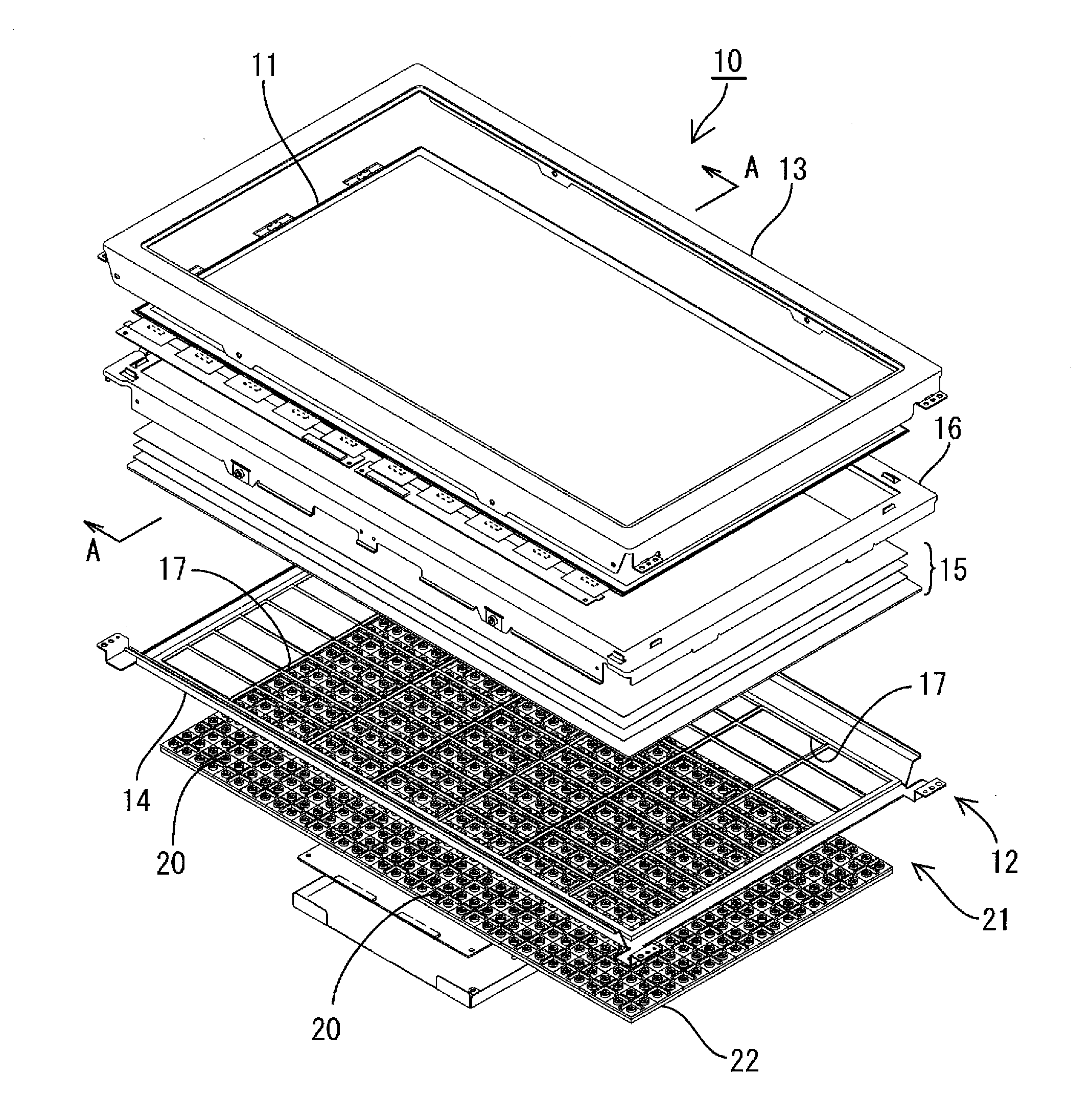

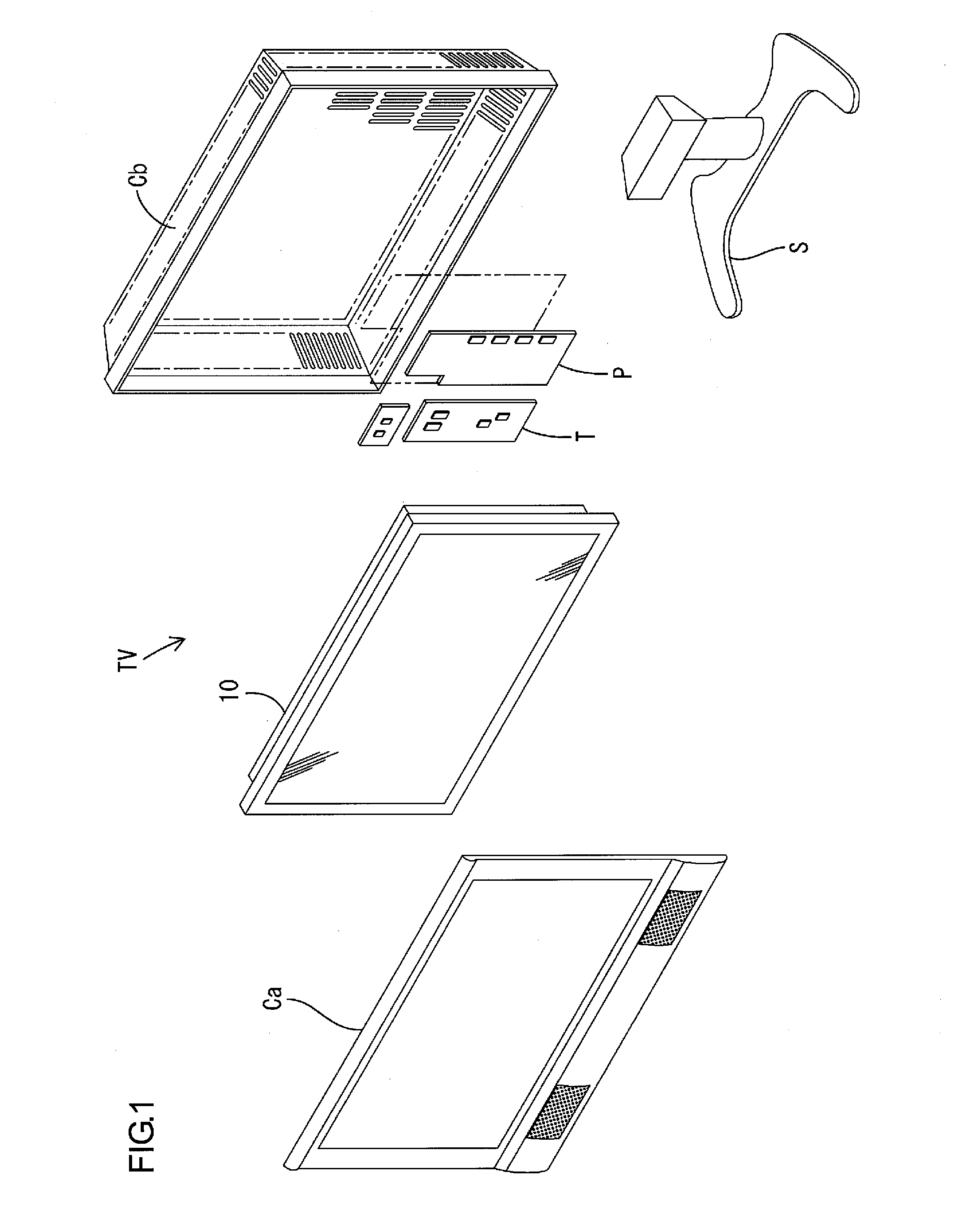

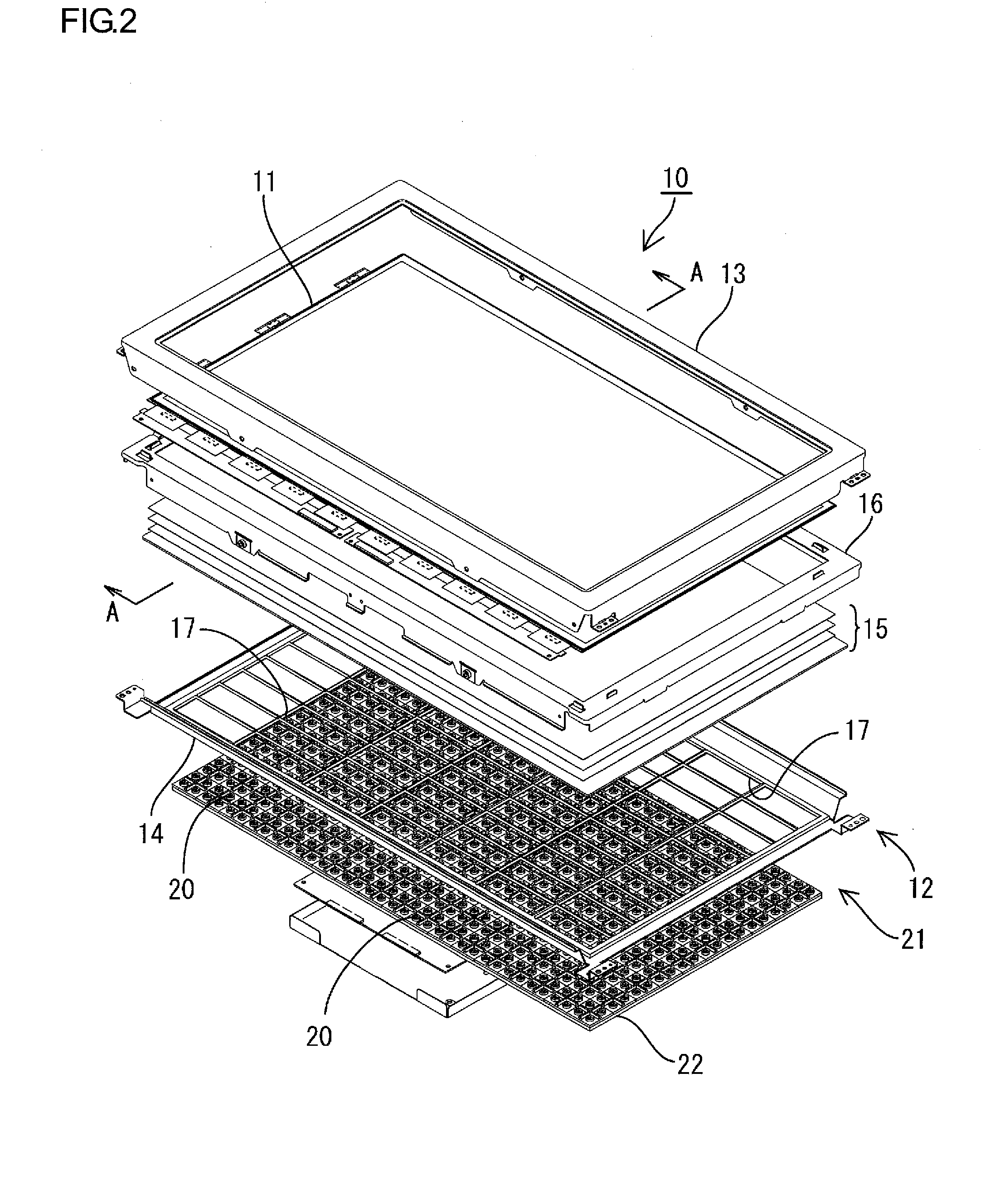

Lighting device for display device, display device, and television receiver

InactiveUS20100231804A1High heat release effectSimplify workTelevision system detailsColor television detailsEngineeringLight source

A lighting device 12 for a display device comprising: a plurality of LED light sources 20, an LED substrate 21 having the plurality of LED light sources 20 mounted thereon, an optical member 15 arranged on a light emission side of the LED sources 20, and a chassis 14 for supporting the plurality of LED light sources 20. The chassis 14 has a cutout 17. The LED substrate 21 is attached to an opposite surface of the chassis 14 from a surface that faces the optical member 15 such that the LED light sources 20 are exposed toward the optical member 15 side through the cutout 17.

Owner:SHARP KK

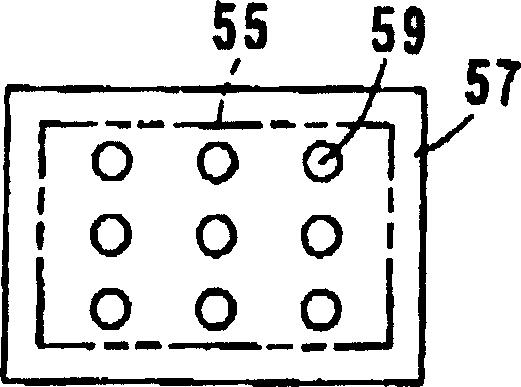

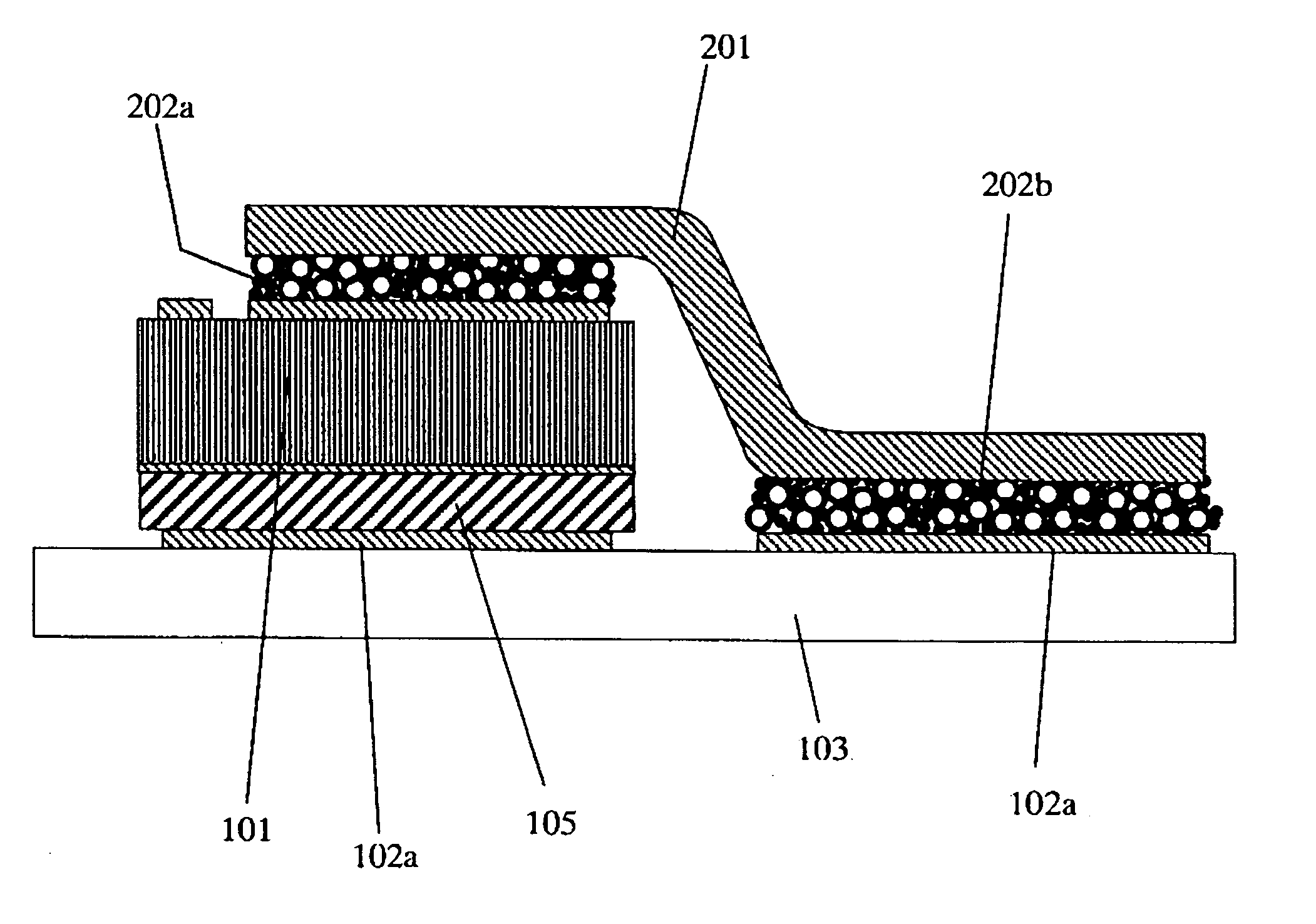

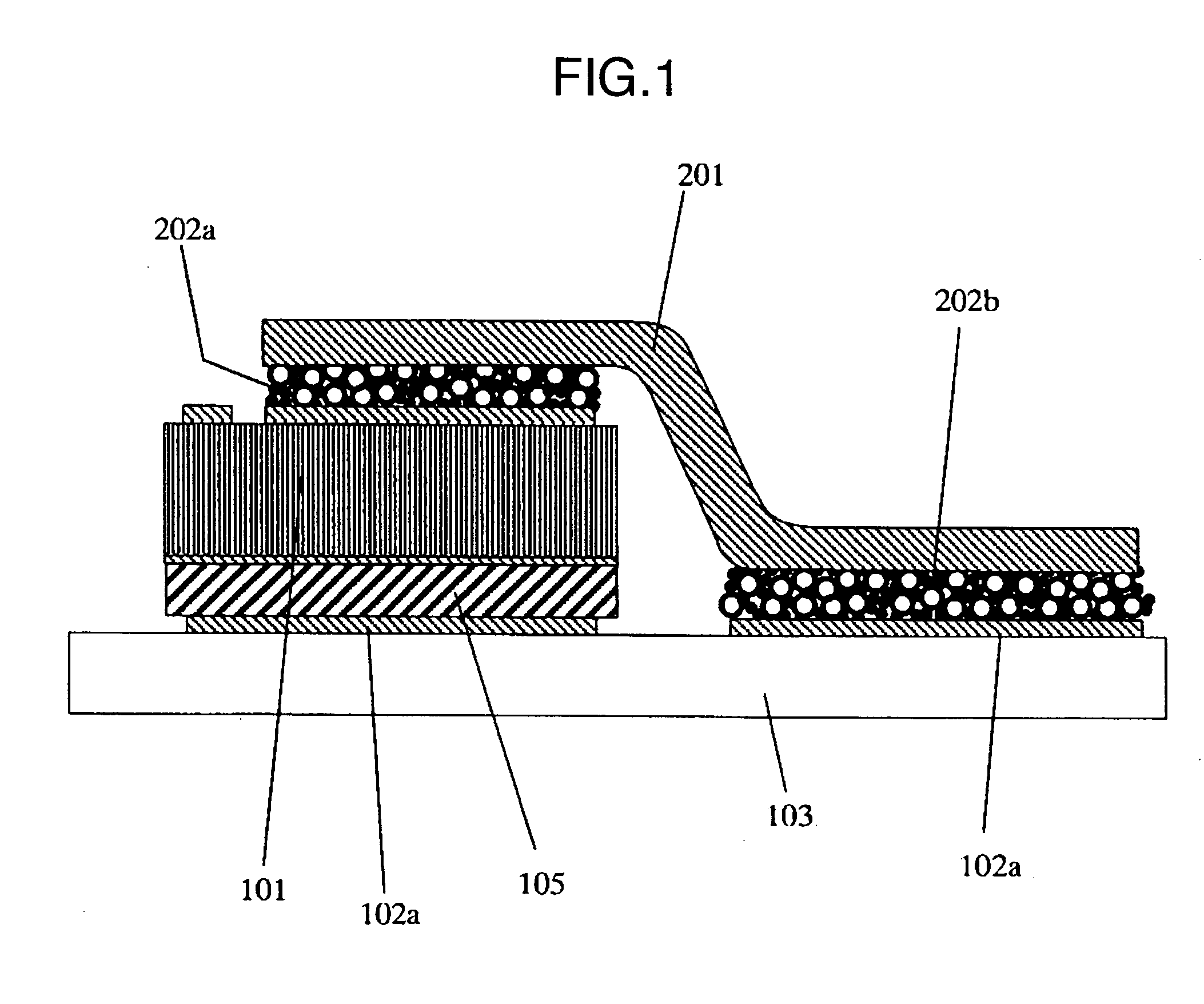

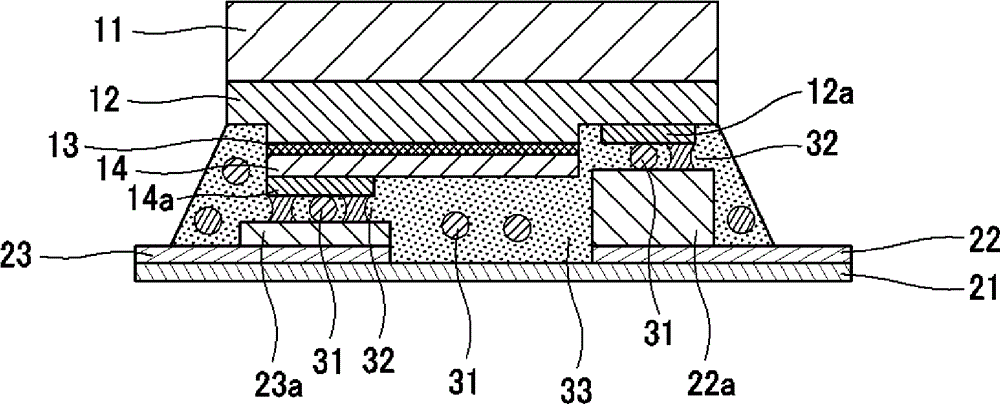

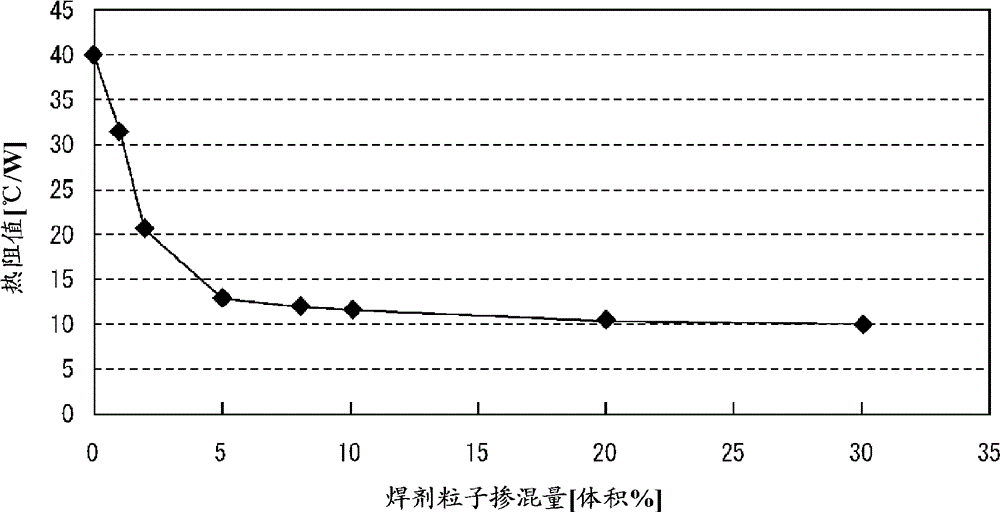

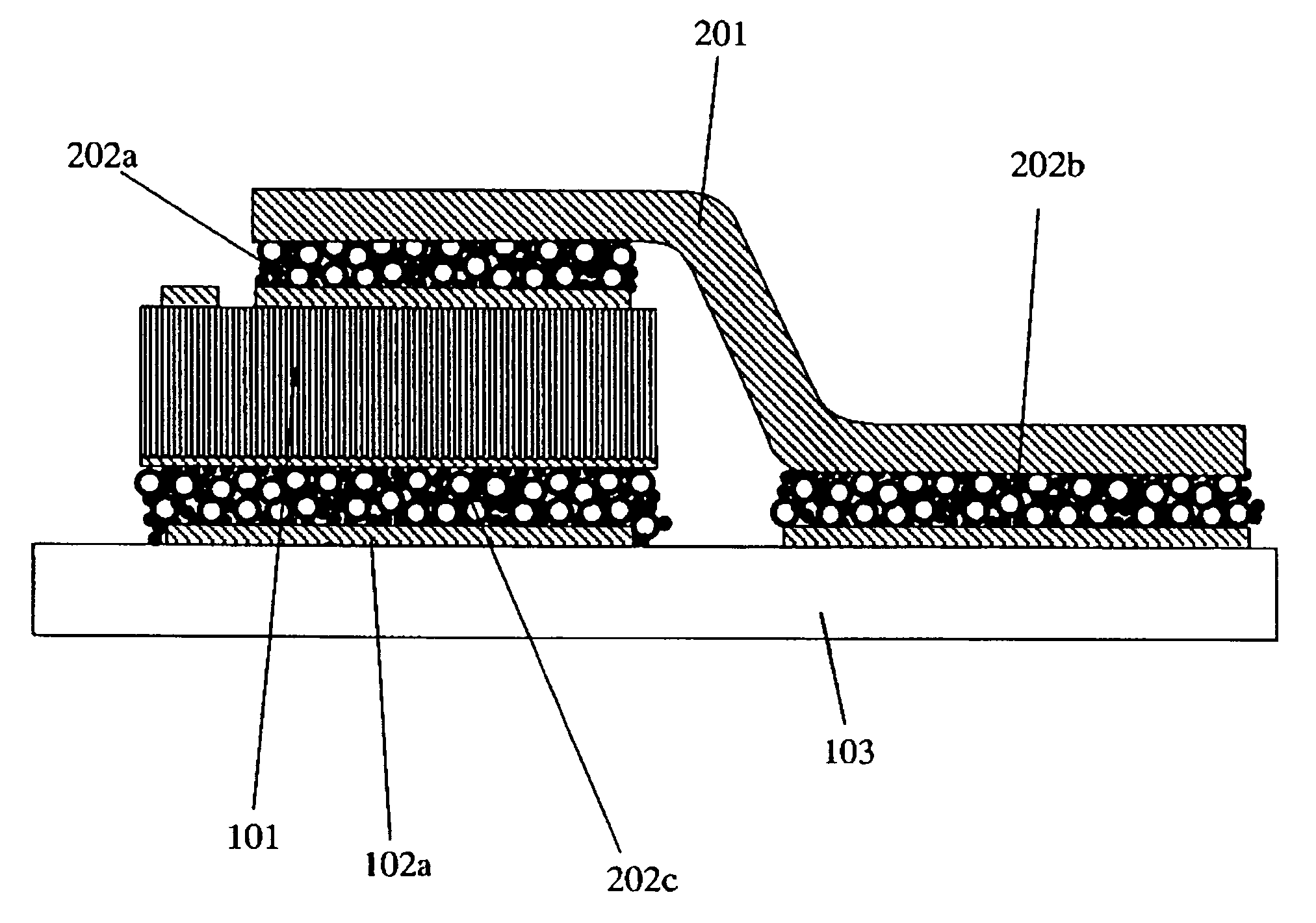

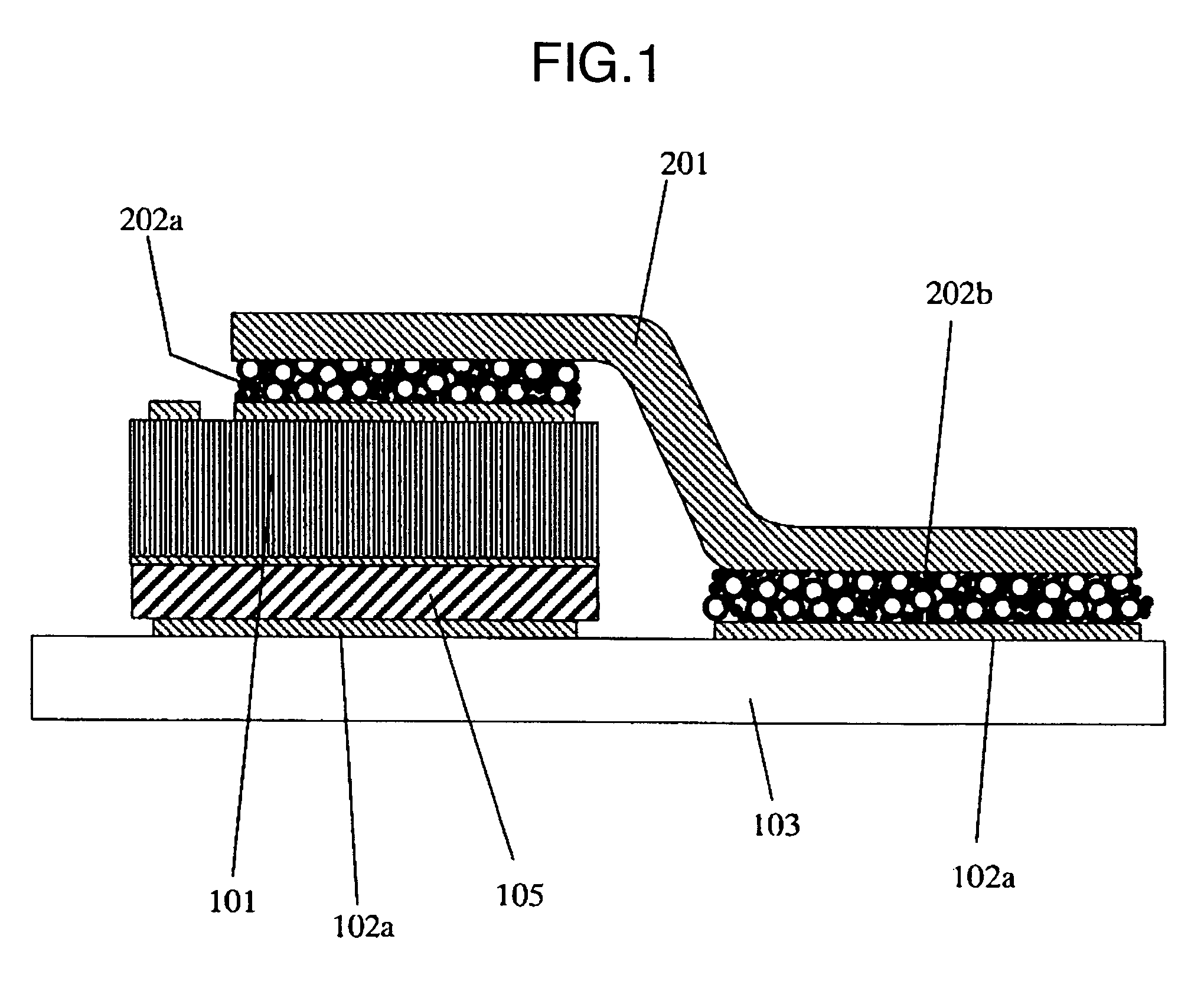

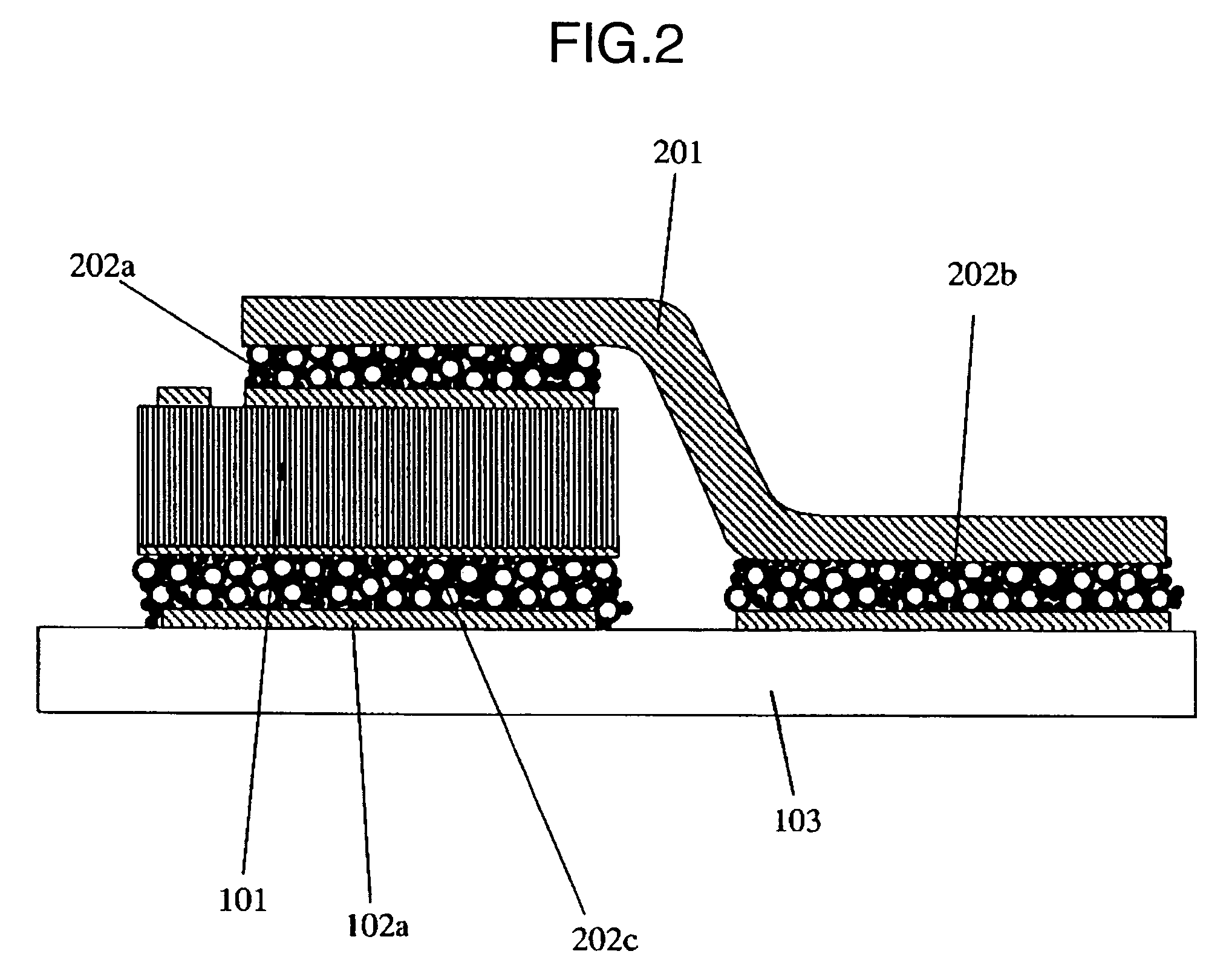

Anisotropic conductive adhesive

ActiveCN104662118AIncrease contact areaIncrease heat releaseNon-insulated conductorsNon-macromolecular adhesive additivesAnisotropic conductive adhesiveThermal compression

Provided is an anisotropic conductive adhesive which is capable of achieving high heat dissipation performance. Conductive particles (31) and solder particles (32) are dispersed in a binder. In an LED package which is obtained by thermal compression bonding using this anisotropic conductive adhesive, terminals (electrodes (12a, 14a)) of an LED element and terminals (electrodes (22a, 23a)) of a substrate are electrically connected with each other through the conductive particles (31), while the terminals of the LED element and the terminals of the substrate are solder-joined with each other.

Owner:DEXERIALS CORP

Low height lead frame for LED device and the manufacturing method thereof

InactiveCN101005109ANo crackNo peelingSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

Provided is a small size LED apparatus which will not easily cause separation between the lead frame and the resin and resin crack, and has a height lower than 1 mm. In addition, a manufacturing method for the small size LED apparatus is also provided. The small size LED apparatus uses the lead frame to drill the long and abnormal metal material which arranged in order with common part, thin wall part and common part in longer direction with a thickness rate of 2.5:1-3.5:1, forms a chip pad part and an inner wire part on the thin wall part, forms an external wire part on the common part, and jets a formed resin cup shape part, and cuts off the external wire part to form the end part for the external wire part and will not bend the external wire part.

Owner:ENOMOTO

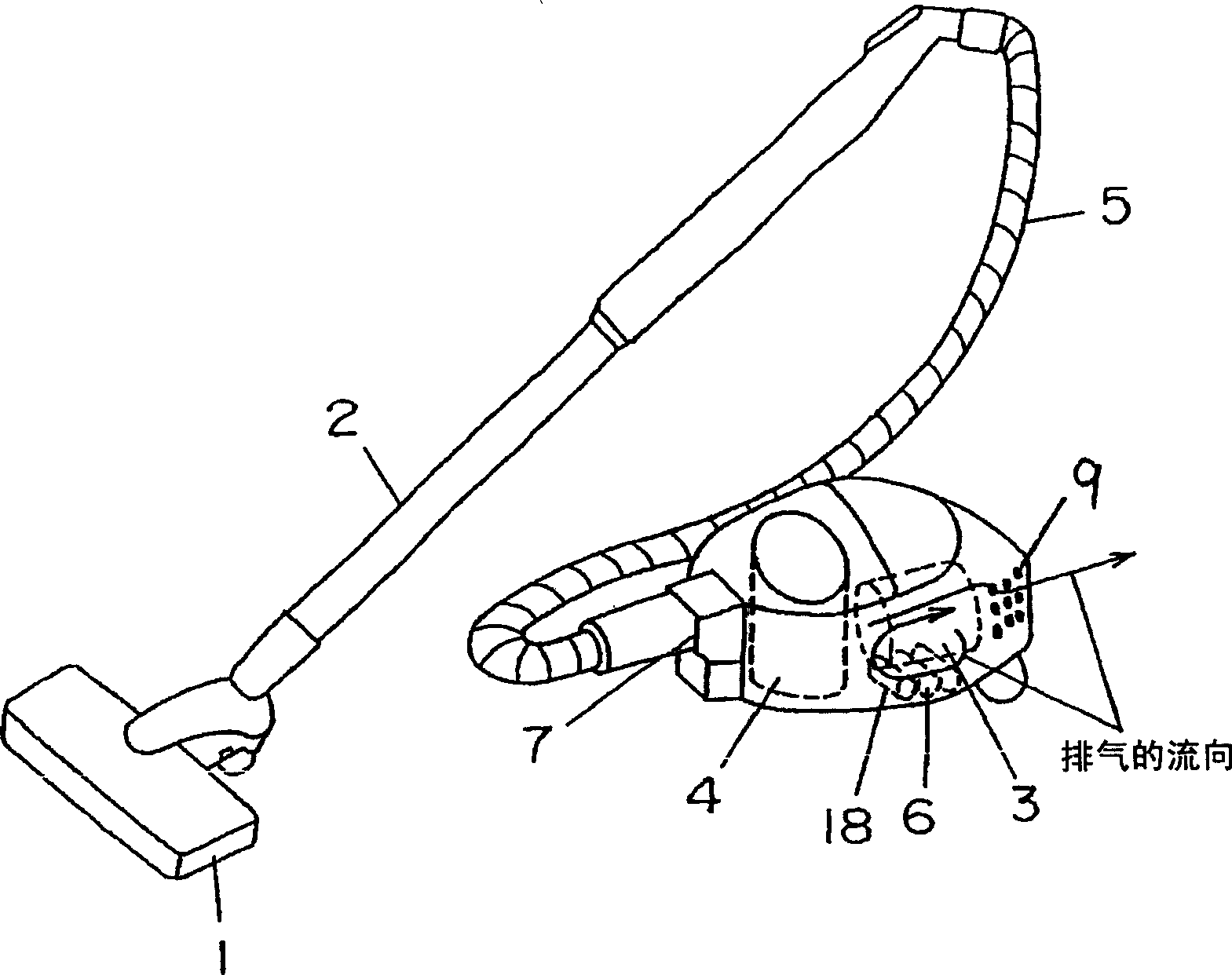

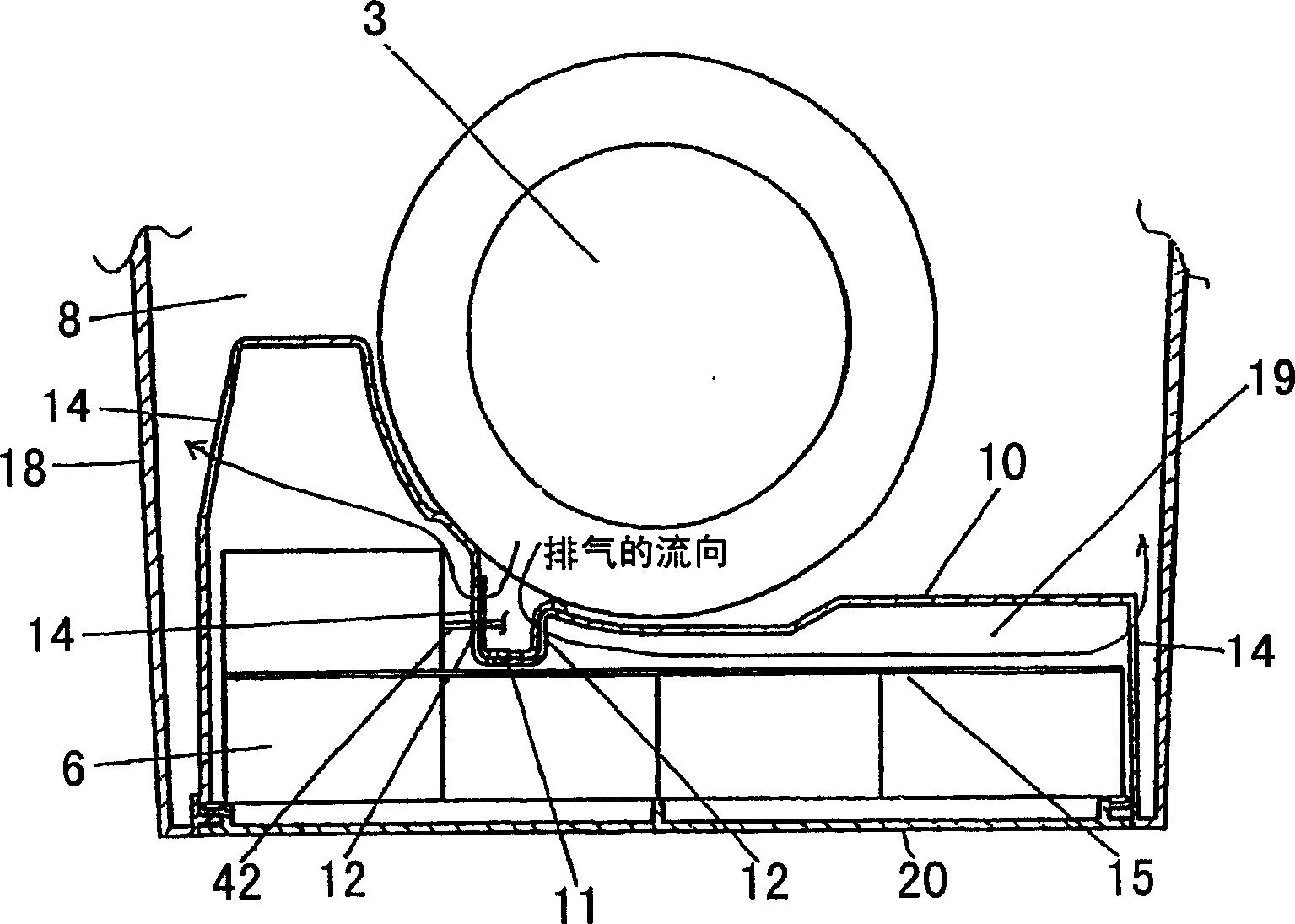

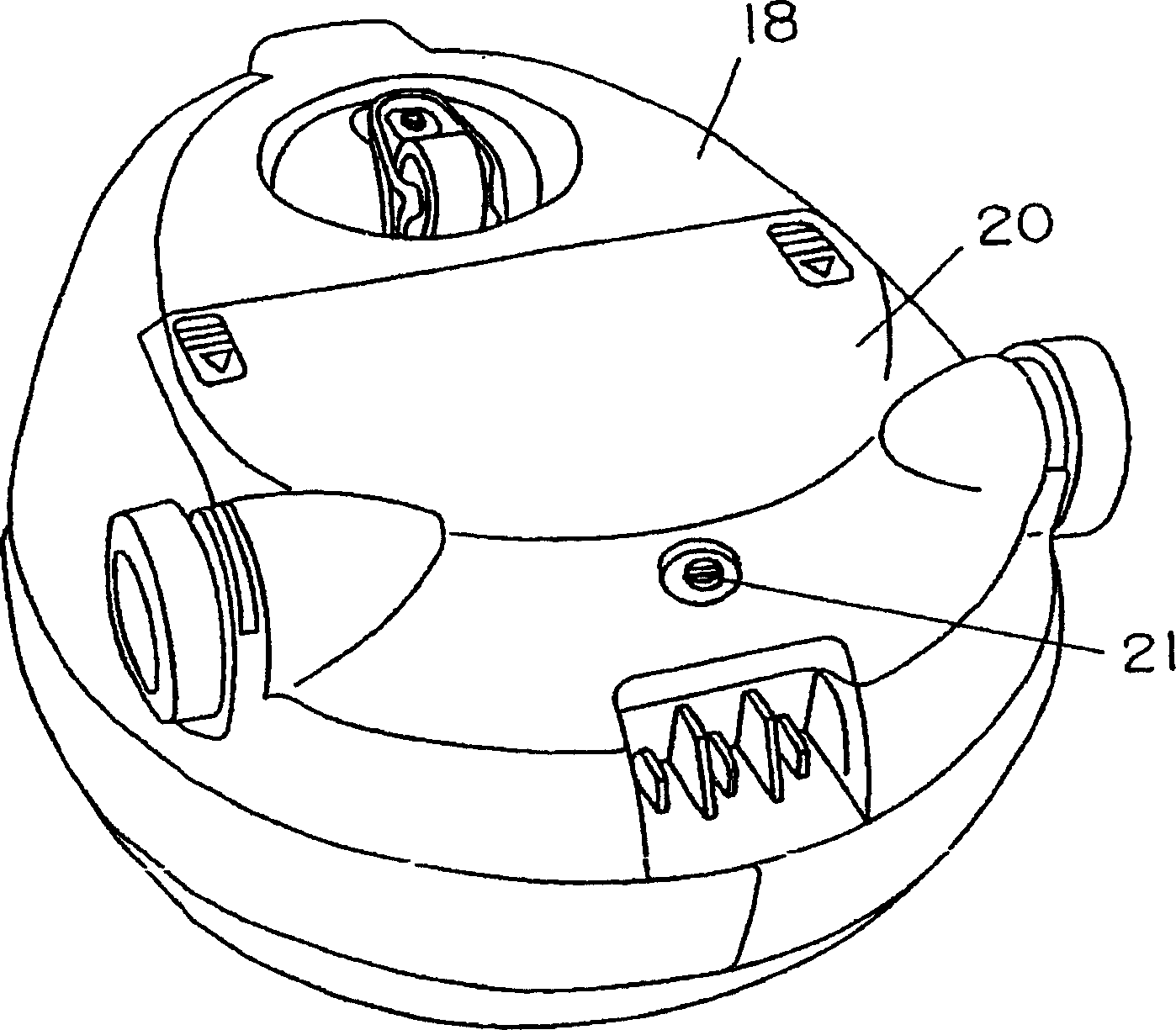

Electric vacuum cleaner

The vacuum cleaner has an electric blower chamber 3 having an electric blower 3 built in it for generating suction wind, and a secondary battery storing part 19 having the secondary battery 6 built in it for supplying power source to the electric blower 3. At least a part of exhaust discharged by the electric blower 3 flows into the secondary battery storing part 19, and thereafter it flows back again to the electric blower chamber 8. After cooling the secondary battery 6 by the exhaust, the exhaust does not discharged directly to the atmosphere from the secondary battery storing part 19 but it is returned to the electric blower chamber 8. Thereby, temperature of the exhaust discharged to the atmosphere is low and usability is high, and cooling of the secondary battery 6 can also be performed, so that the vacuum cleaner capable of improving life of the secondary battery is achieved.

Owner:PANASONIC CORP

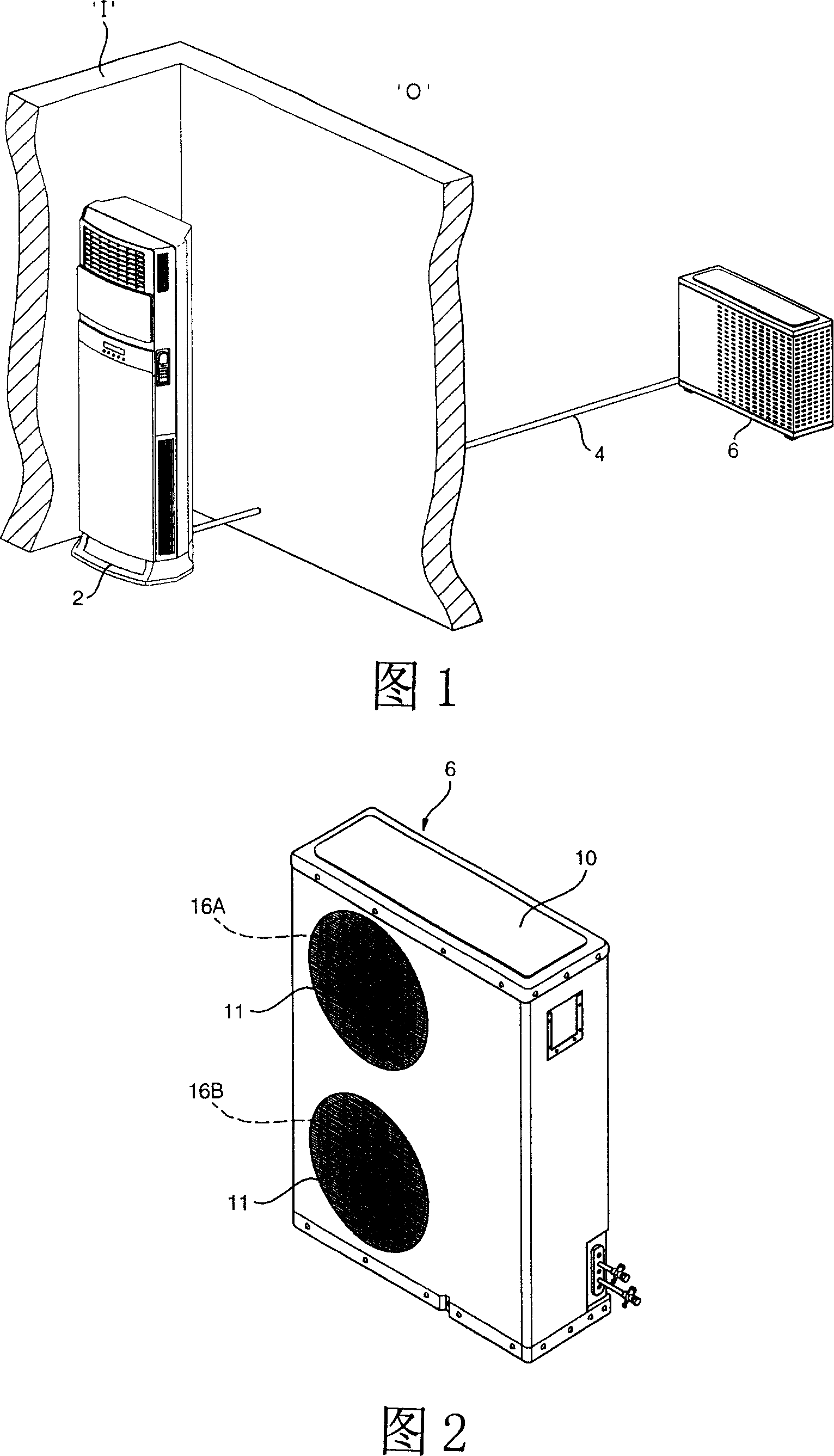

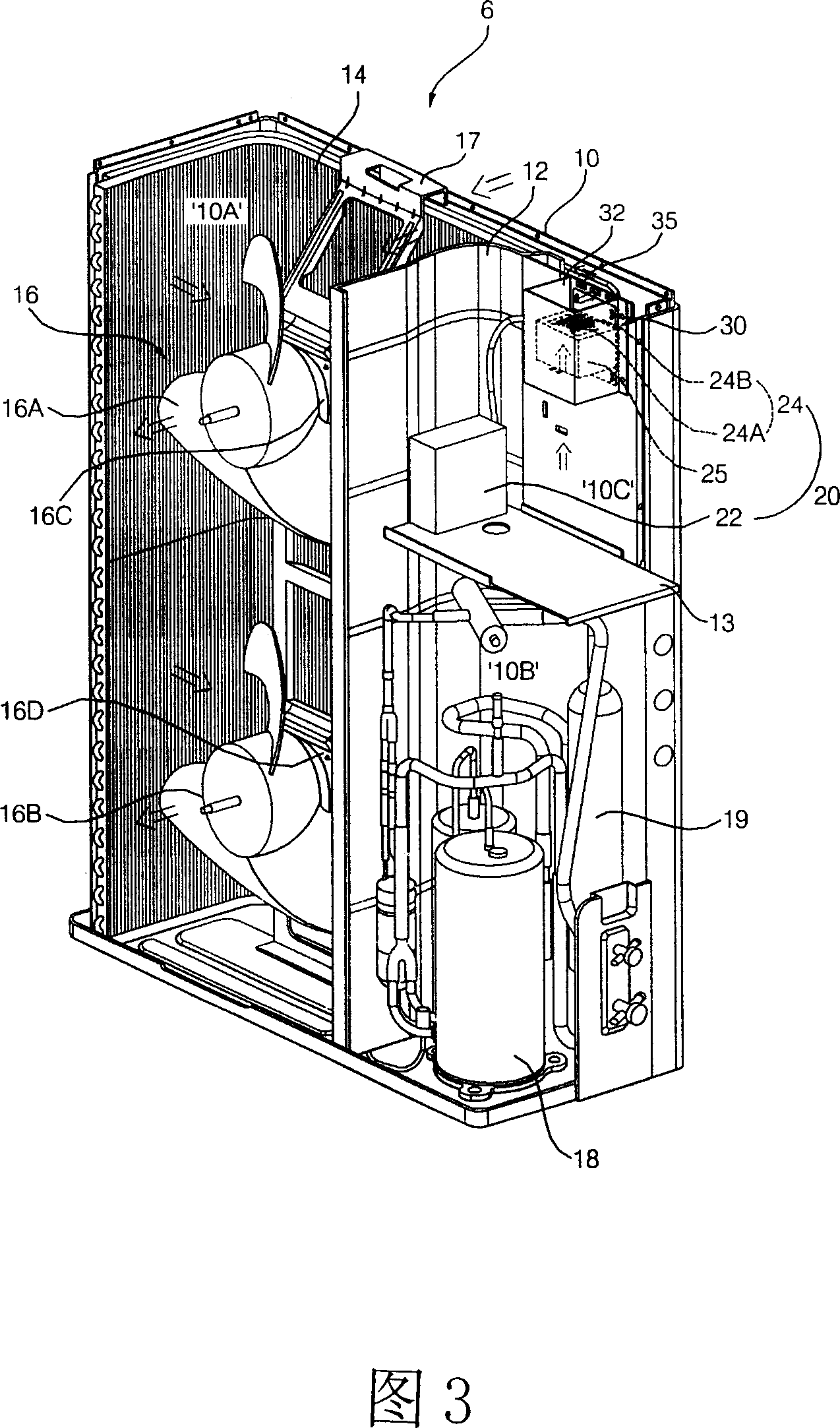

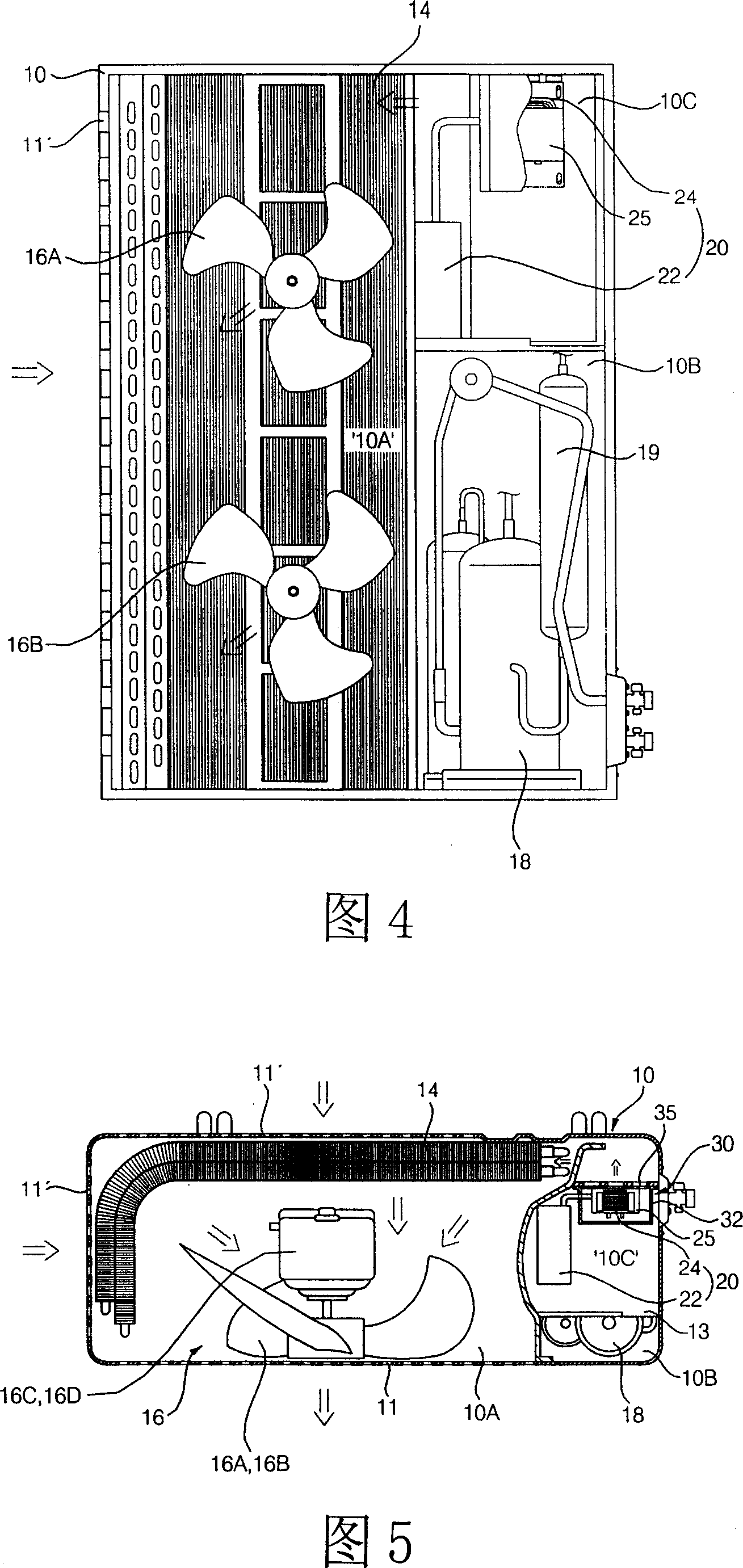

Air conditioner

InactiveCN1987264AIncrease heat releaseAvoid heat damageSpace heating and ventilation safety systemsLighting and heating apparatusForce convectionEvaporator

An air conditioner features that a heat releasing channel for its electric elements is arranged in order to use the fan to generate a forced convection for releasing heat from electric elements, or a heat exchanger for said electric elements is arranged in order to make the flowing cold medium to suck the heat from electric elements.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Metal Resin Complex

InactiveCN107708998AIncrease heat releaseEasy to processLighting heating/cooling arrangementsSignalling/lighting devicesIn planeInorganic particle

Provided is a metal resin complex, in which a heat-conductive resin composition and a surface-treated metal are molded integrally by injection molding to closely adhere the metal to the resin at the interface therebetween, and which has excellent heat-dissipating properties and moldability, is lightweight and can be produced easily. A metal resin complex, in which a member comprising a heat-conductive resin composition and a member comprising a metal having a surface that is treated to form fine recesses thereon are bonded to each other in a contacted state, wherein the bonding of the membersin a contacted state is achieved by flowing the heat-conductive resin composition into the recesses during the ejection molding of the heat-conductive resin composition to fix the members to each other, the heat-conductive resin composition comprises a thermoplastic resin (A) and an inorganic filler (B), the in-plane heat conductivity of the heat-conductive resin composition is 1 W / (mK) or more, and the inorganic filler (B) comprises at least one component selected from the group consisting of the following components (B1) and (B2): (B1) inorganic particles having a heat conductivity of 2 W / (mK) or more and a volume average particle diameter of 1 to 700 mum; and (B2) inorganic fibers having a heat conductivity of 1 W / (mK) or more, a number average fiber diameter of 1 to 50 mum and a numberaverage fiber length of 6 mm or less.

Owner:KANEKA CORP

Semiconductor device, power converter device using it, and hybrid vehicle using the power converter device

InactiveUS7528485B2Long-term reliabilityImprove long-term reliabilitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

A semiconductor device which uses a semiconductor element having main current input / output electrodes, one and the other of which are extended up to a one surface and a remaining surface of a semiconductor chip respectively for causing one of the input / output electrodes to be contacted with a conductive layer of a insulating substrate, whereby the semiconductor element is supported on or above the insulating substrate. A conductive strip which is made of a composite material of carbon and aluminum or a composite material of carbon and copper is used for connection between the remaining input / output electrode of the semiconductor chip and the conductive layer of the insulating substrate.

Owner:HITACHI LTD

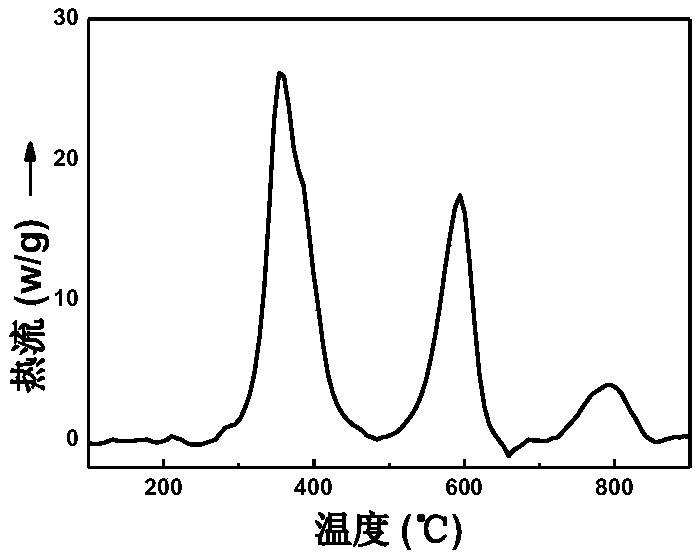

Aluminum powder/polyvinylidene fluoride composite particle as well as preparation method and application thereof

ActiveCN110640136AMaintain active aluminum contentPrevent oxidationTransportation and packagingMetal-working apparatusAluminium powderPolyvinylidene difluoride

The invention discloses an aluminum powder / polyvinylidene fluoride composite particle as well as a preparation method and application thereof. The composite particle is a core-shell structure with nano aluminum powder as a core and PVDF as a shell, and comprises 70%-90% of the nano aluminum powder and 10%-30% of the PVDF according to mass fraction. The method comprises the following steps of preparing a suspension liquid of the PVDF and nano aluminum powder by taking a mixed solution of acetone and dimethylformamide with the volume ratio of 3:2 as a solvent, carrying out electrostatic sprayingon the suspension liquid, and collecting the Al / PVDF composite particle. The composite particle has good corrosion resistance in the natural environment, the content of active aluminum in the nano aluminum powder can be kept for a long time so that the active aluminum can be prevented from being oxidized, and the heat release amount of the composite particle is improved. In addition, the Al / PVDFcomposite particle has good dispersibility and is high in reaction speed when reacting under high temperature, and the combustion speed can reach 60 m / s and above; and therefore, as an energy-containing material, the Al / PVDF composite particle has a wide application prospect.

Owner:NANJING UNIV OF SCI & TECH

Novel sound-proof building material and preparation method thereof

The invention discloses a novel sound-proof building material and a preparation method thereof and relates to the technical field of novel building materials. The novel sound-proof building material is prepared from raw materials in parts by weight as follows: 30-45 parts of polyethylene, 28-36 parts of polybutadiene rubber, 15-24 parts of kaolin, 10-18 parts of asbestos, 8-17 parts of plant fiber, 12-20 parts of volcanic mud, 8-16 parts of hollow glass beads, 7-15 parts of glass fibers, 5-9 parts of montmorillonite, 4-8 parts of nanometer oxide, 8-13 parts of silica particles, 10-16 parts ofpolyurethane resin particles, 4-9 parts of diatom ooze, 8-14 parts of calcium silicate, 4-7 parts of a foaming agent, 3-8 parts of an antioxidant, 4-7 parts of a flame retardant and 2-5 parts of a plasticizer. The novel sound-proof building material is light and easy to mount, has the advantages of stable chemical property, good sound absorbing effect and good flame retardance, can effectively weaken noise outside space, is low in raw material cost and has good market prospect.

Owner:HEFEI OUSHIJIA ELECTRICAL & MECHANICAL EQUIP CO LTD

Preparation method of metal oxide composite magnesium hydride hydrogen storage material

PendingCN110980635AAccelerate the rate of hydrogenationSmall particle sizeHydrogenOxide compositeBall mill

The invention belongs to the technical field of hydrogen storage materials, and particularly relates to a preparation method of a metal oxide composite magnesium hydride hydrogen storage material. Themethod comprises the steps that magnesium hydride serves as a base material, metal oxide particles are mixed, the mass percentage content of metal oxide in the mixture is 1%-8%, and the mixture is subjected to hydrogen filling ball milling in a ball mill to obtain the metal oxide composite magnesium hydride hydrogen storage material. By adding the nanoscale metal oxide particles, the hydrogenation speed of the magnesium-based composite powder in the hydrogen charging ball milling process can be increased, and reduction of the particle size of magnesium hydride is facilitated; the nanocrystalline MgH2 is coated with the metal oxide to form a core-shell structure with an excellent synergistic effect, the core-shell structure has a good catalytic effect and remarkable dynamic performance, the hydrogen storage reaction speed can be improved, microcell heat release can be controlled, agglomeration of a hydrogen storage reactant Mg (OH) 2 can be effectively eliminated through the metal oxide, and the hydrogen storage efficiency is improved. Therefore, the purpose of sufficient hydrolysis reaction is achieved.

Owner:世能氢电科技有限公司 +1

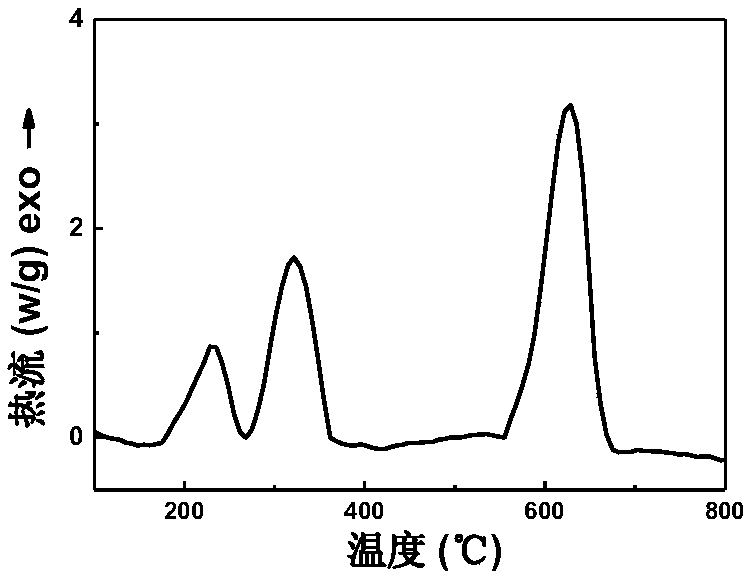

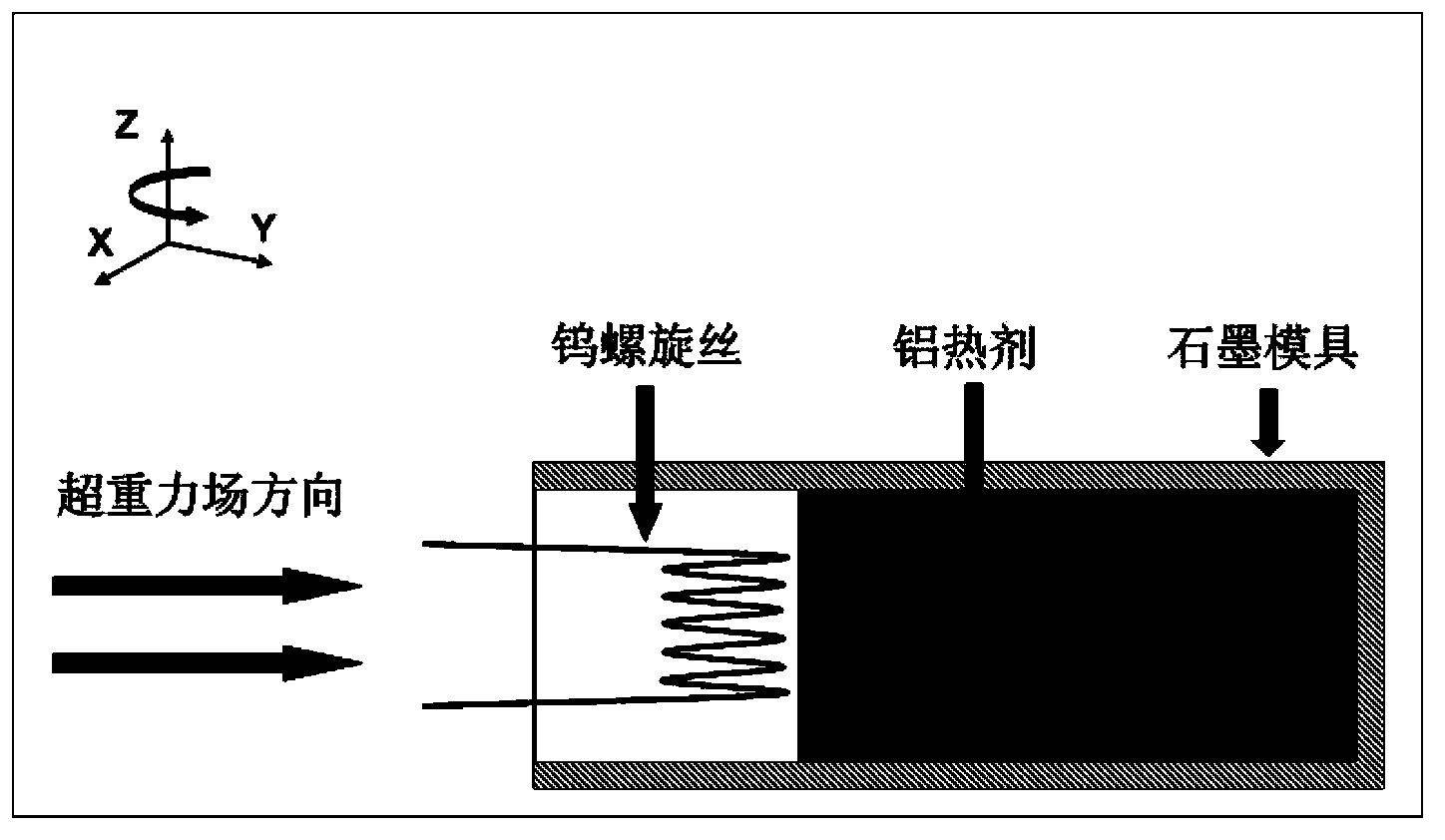

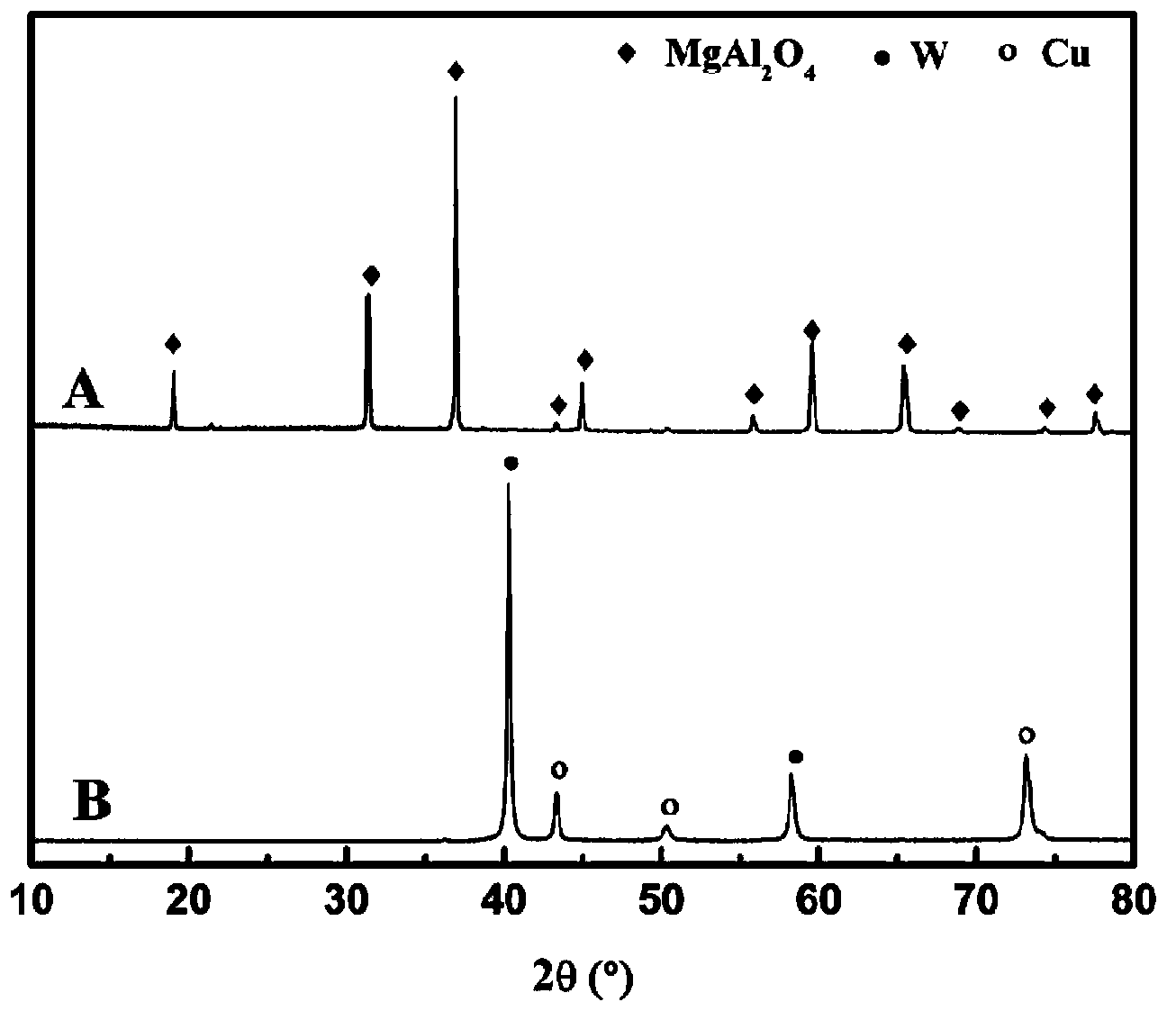

Thermite for hypergravity-assisted combustion synthesis of copper-based composite material

The invention belongs to the technical field of combustion synthesis preparation, and in particular relates to a thermite for hypergravity-assisted combustion synthesis of a copper-based composite material. According to the thermite provided by the invention, the formula employs a CuO powder with particle size in gradient distribution and an Al powder with particle size in gradient distribution, combustion rate and heat release amount in the preparation of the copper-based composite material is controlled by adding a Cu2O powder, a Cu powder, a MgO powder and a CaF2 powder, so as to realize stability and controllability of thermit reaction in the supergravity field. The thermite provided by the invention has the advantages of low sputtering rate, high heat release amount, stability and controllability, and is suitable for hypergravity-assisted combustion synthesis of various copper-based composite materials.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

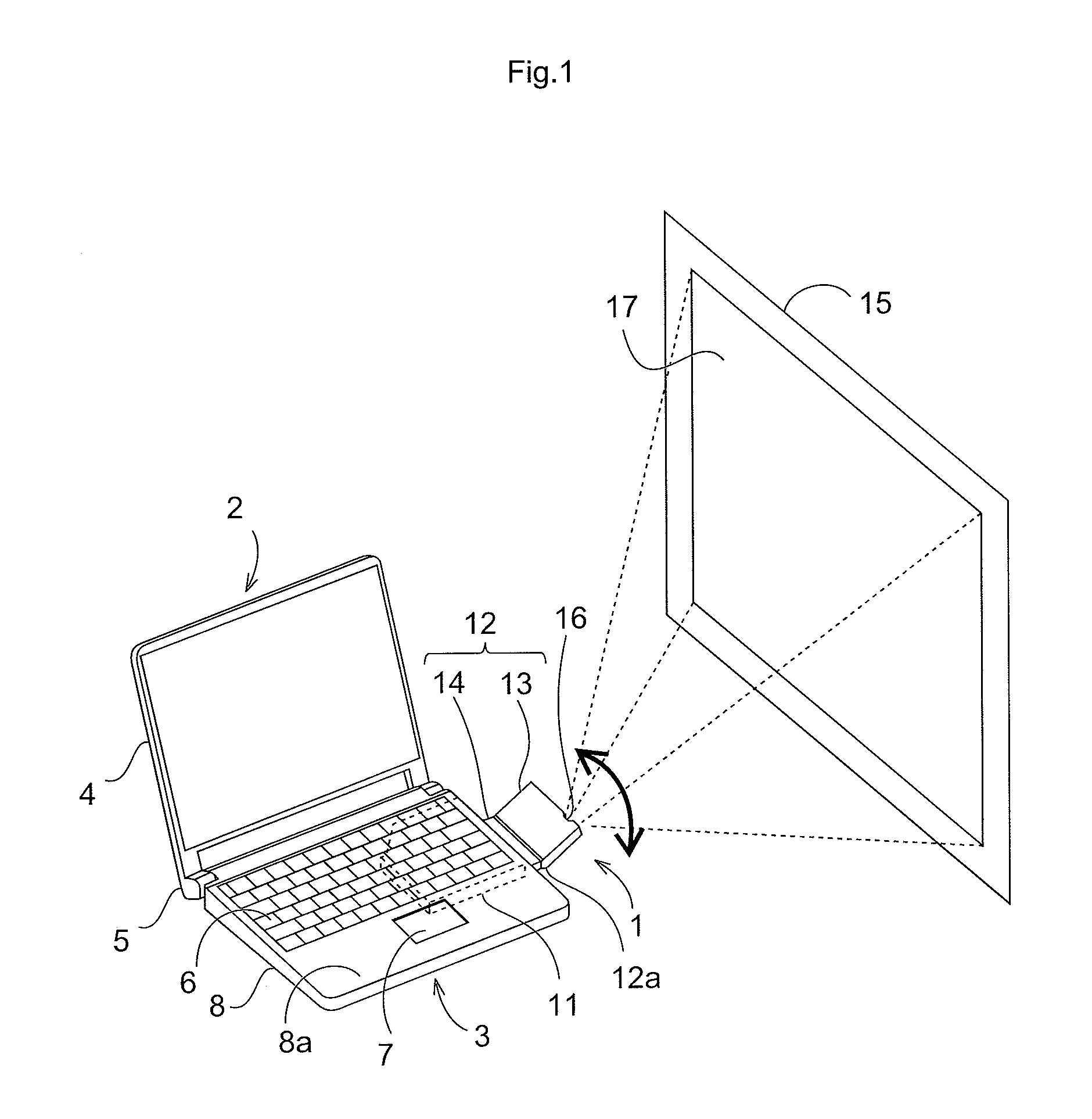

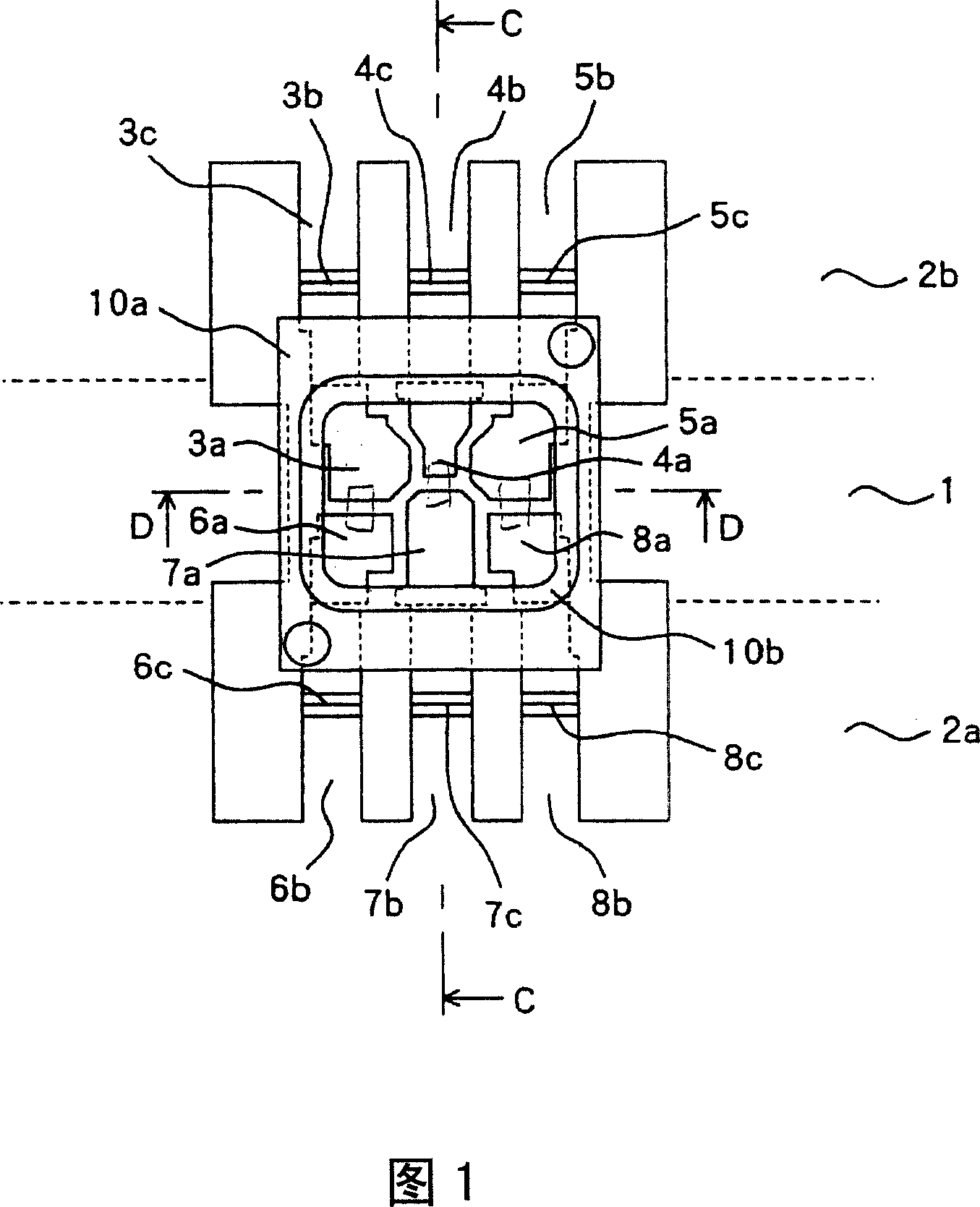

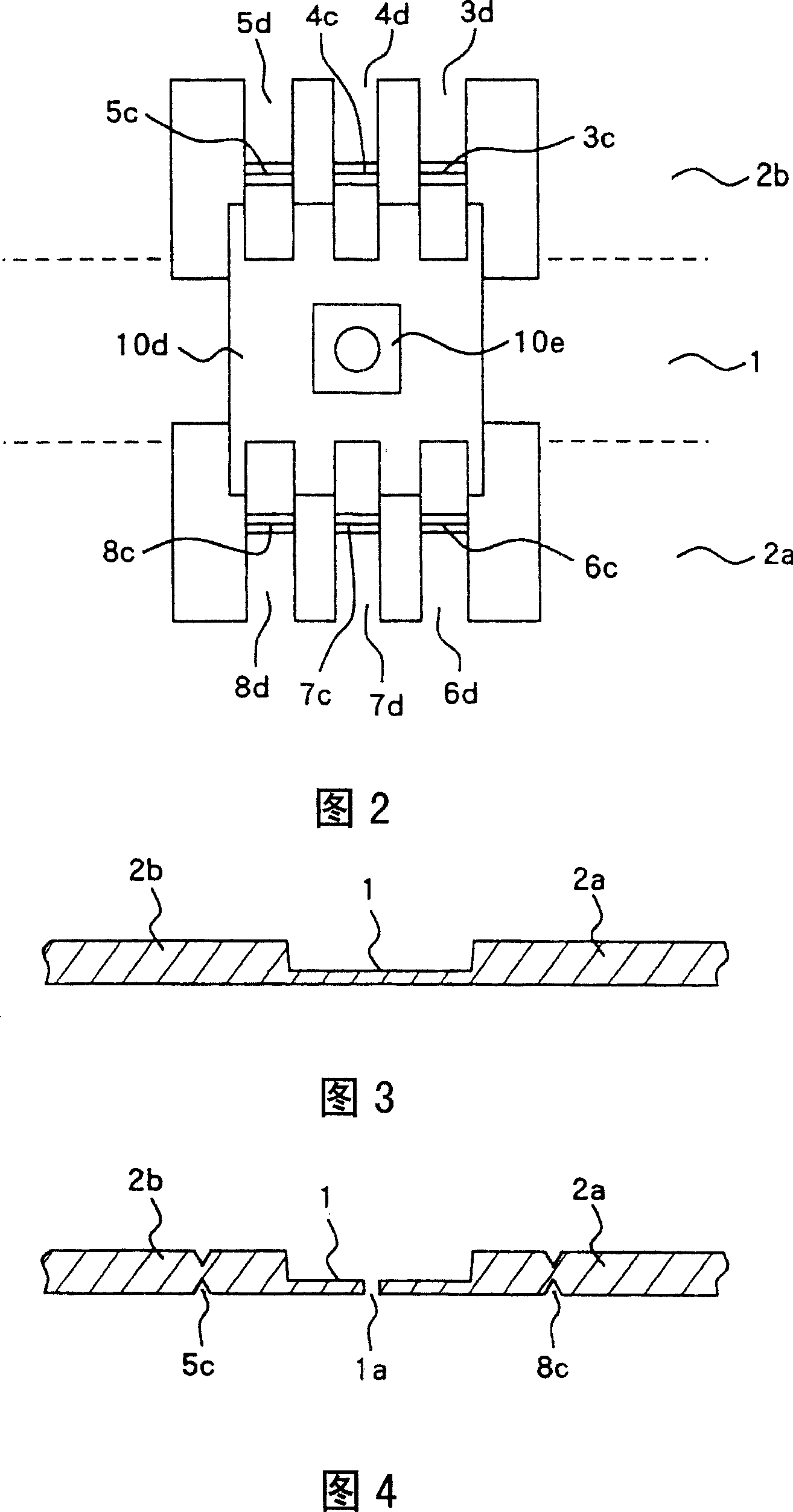

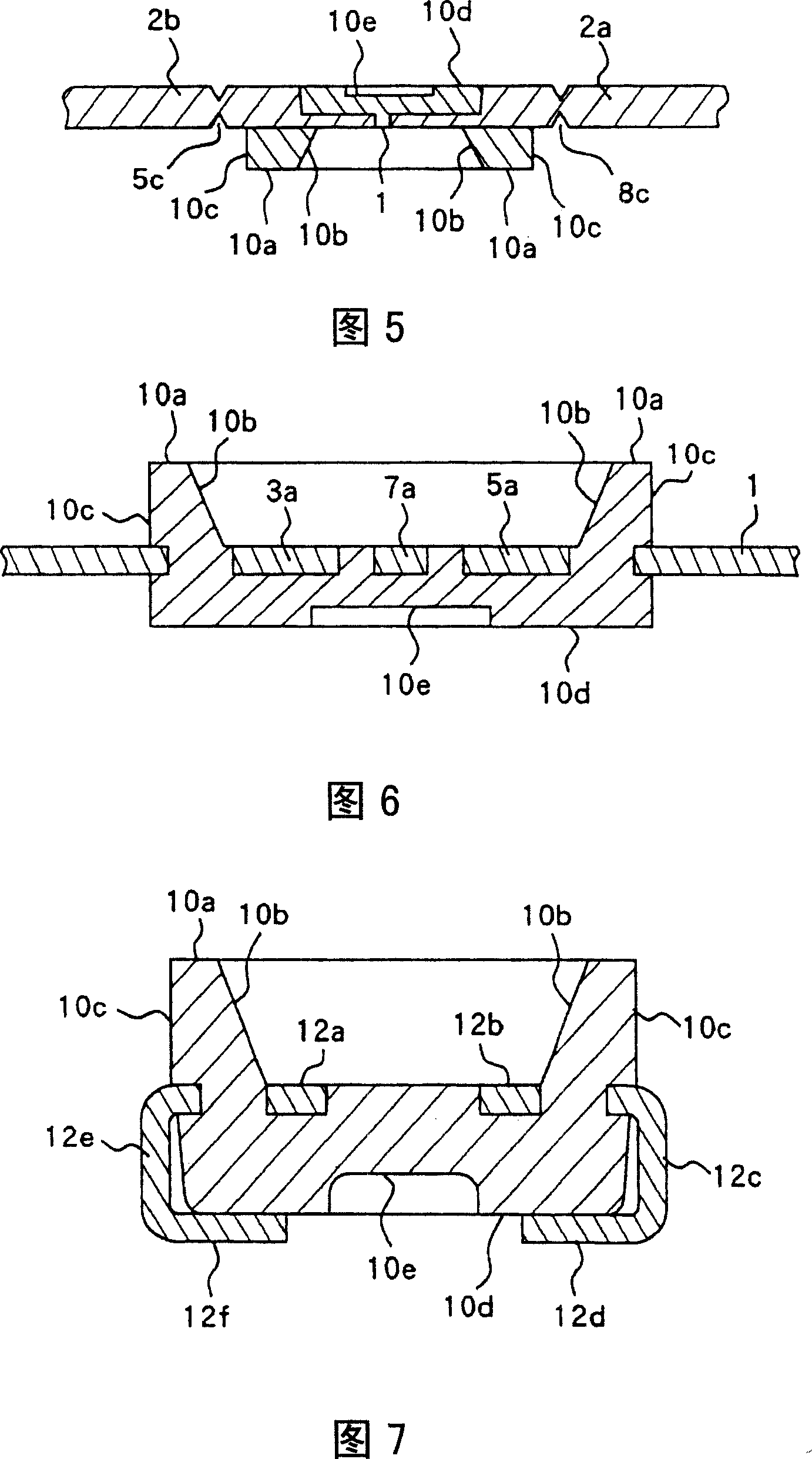

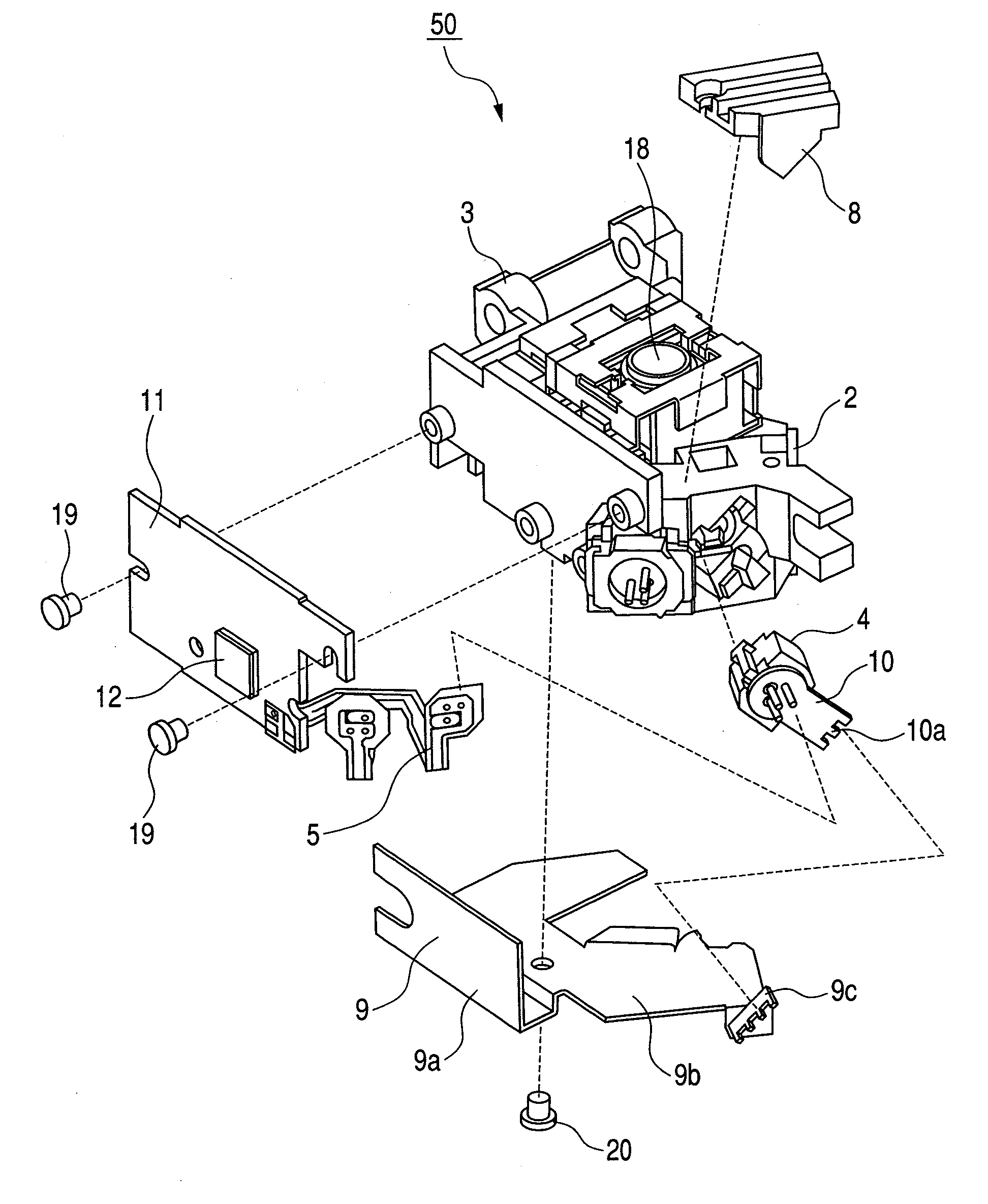

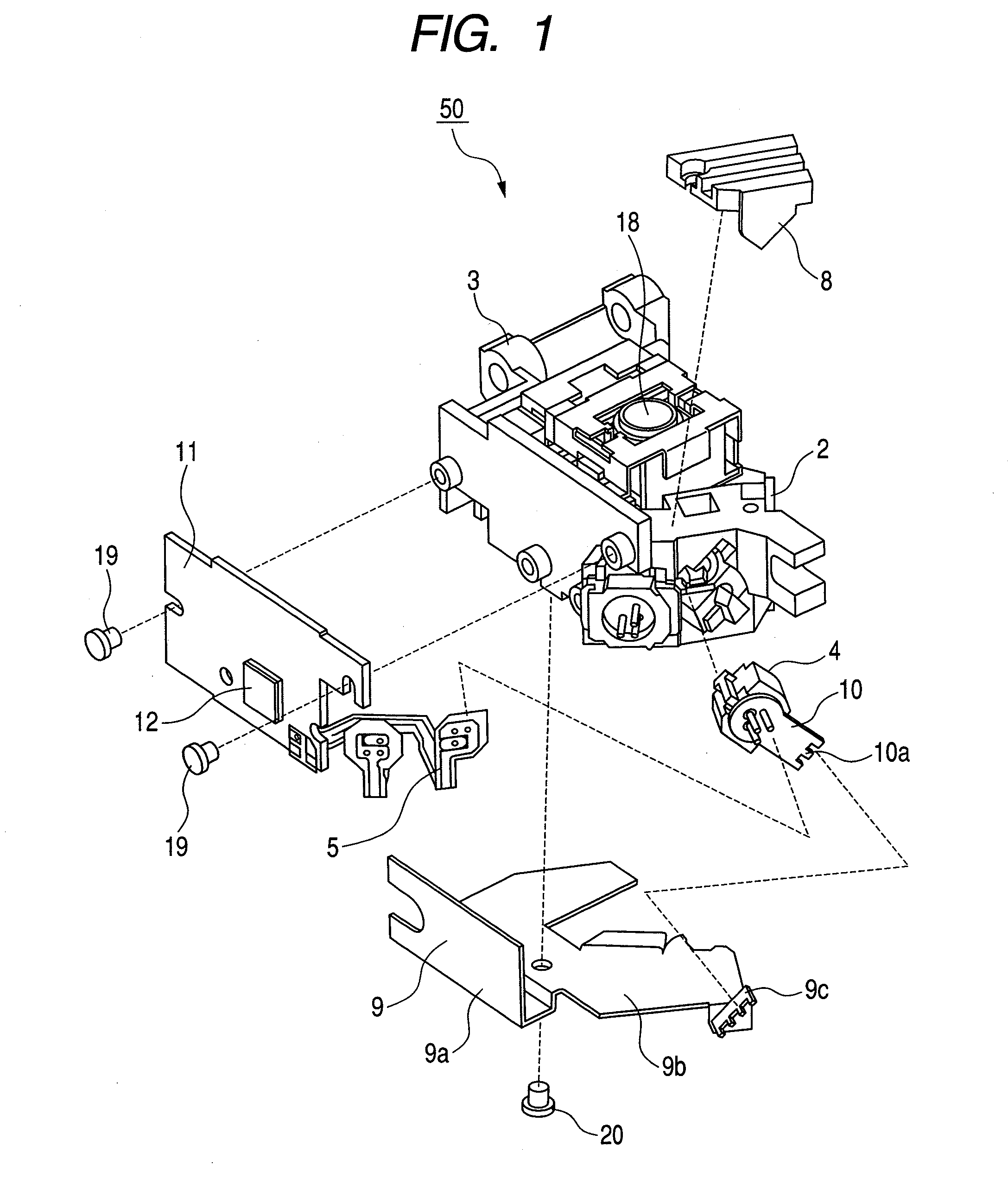

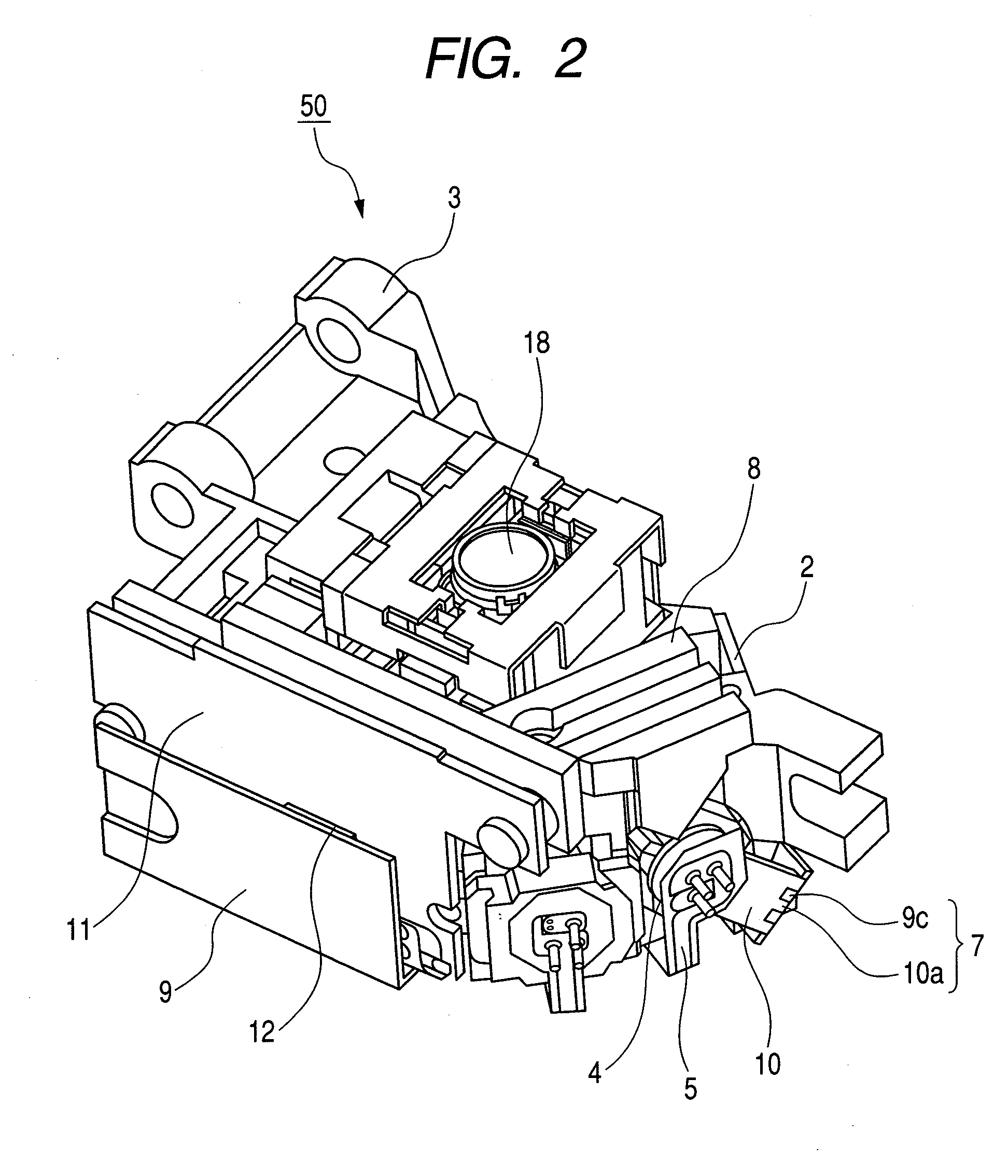

Optical pickup device

InactiveUS20080074962A1Increase heat release abilityHigh productivity and reliabilityOptical beam sourcesRecord information storagePhysicsPhotovoltaic detectors

An optical pickup device 50 comprising a laser diode 1, a photo detector 2, a housing 3 having an optical system for guiding light from the laser diode 1 to an optical disk and guiding light reflected on the optical disk to the photo detector, a wiring 5 to supply current to the laser diode 1, and a metallic cover 9 provided outside of the housing 3, whereinthe laser diode 1 is bonded to the housing 3 by adhesive, a metallic member 10 is mounted on the surface of the laser diode 1 by connecting thermally, and the metallic member 10 is thermally connected to the cover 9 by solder.

Owner:HITACHI MEDIA ELECTORONICS CO LTD

Gel type emulsion explosive and preparation thereof

InactiveCN101328099AImprove intrinsic safetyImprove securityExplosive working-up apparatusLow speedEmulsion explosive

The invention discloses a gel-type emulsion explosive and a method for preparing the same. The explosive is prepared by 75%-86% of ammonium nitrate, 4%-7% of emulsifier-compound grease, 0.5%-4% of crystal modifier and water balance, different models of coal permissible products are prepared by adding 3%-7% of flame reducer into the explosive. When preparation, the ammonium nitrate, crystal modifier, water and flame reducer are mixed, heated and dissolved to form an oxidant water solution as an aqueous phase solution, the emulsifier-compound grease is heated to form a combustible agent solution as an oil phase solution, the aqueous phase solution and oil phase solution are pumped into an open type emulsifier for emulsification after accurate measurement and are sensitized to finished products in a low speed mixing device by means of a belt device. The explosive energy of the product can be released to a maximum extent, the density can reach 1.4g / cm<3>, the explosion strength can reach 360ml and the detonation velocity can reach 6500m / s.

Owner:耿一平

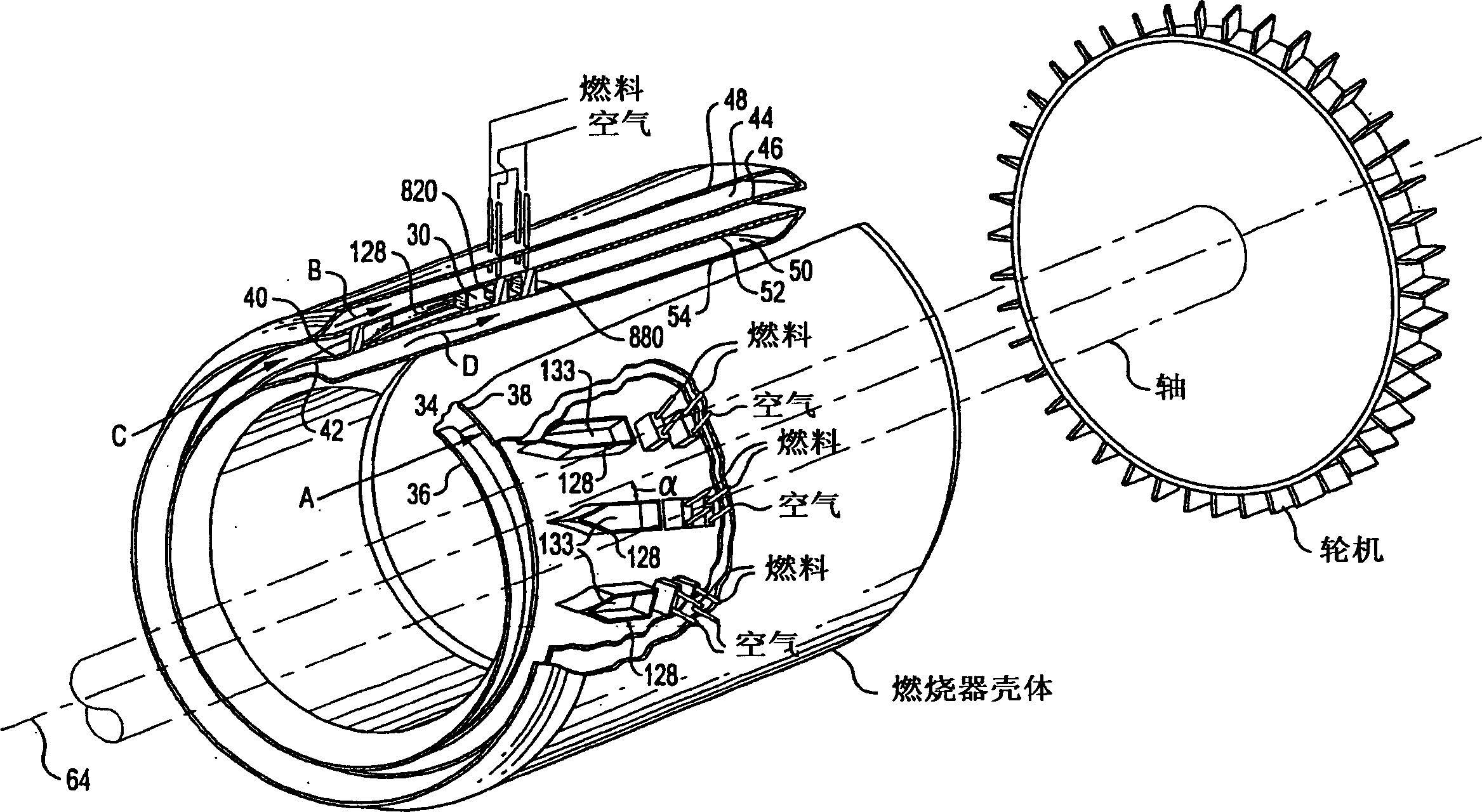

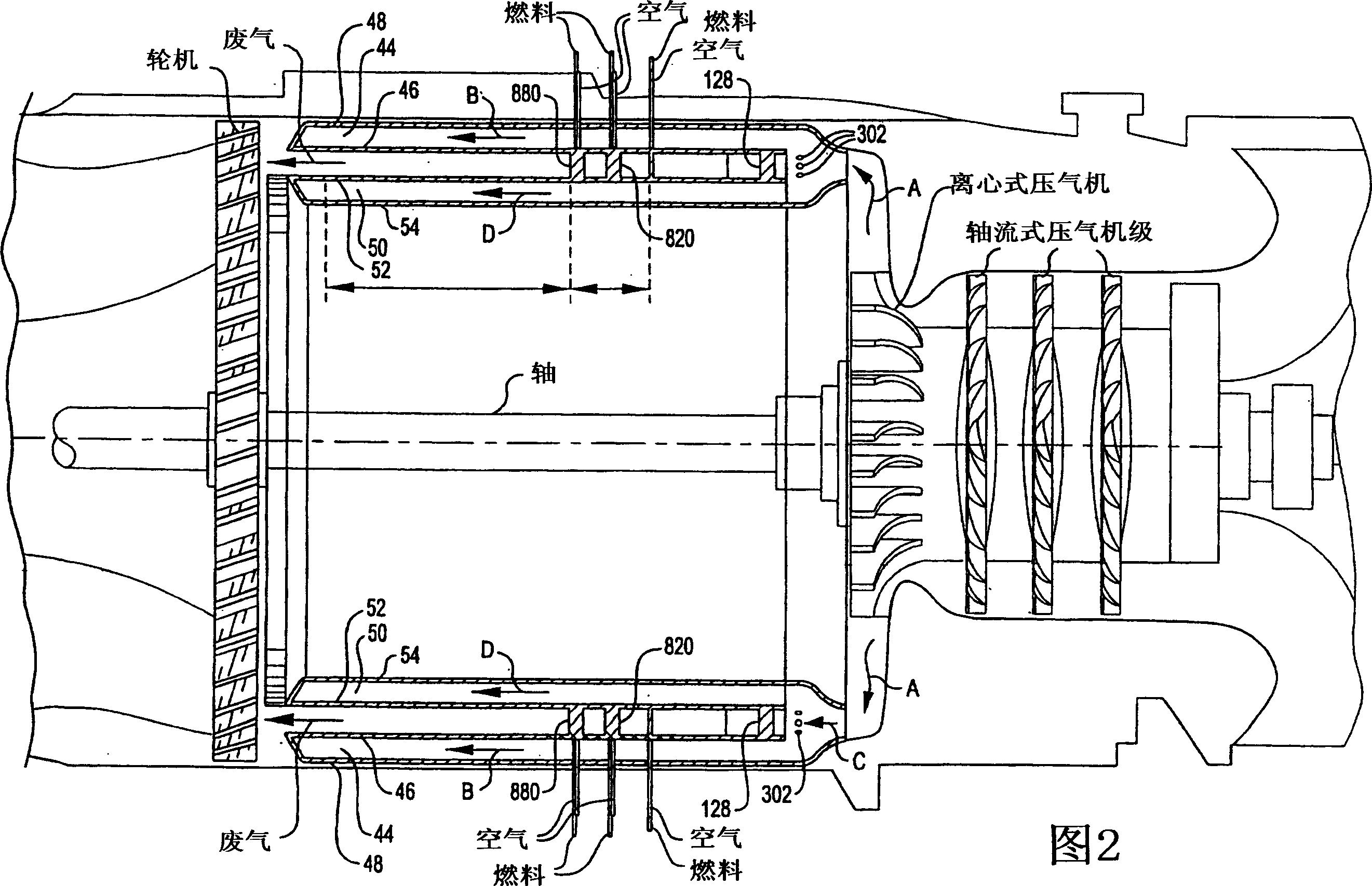

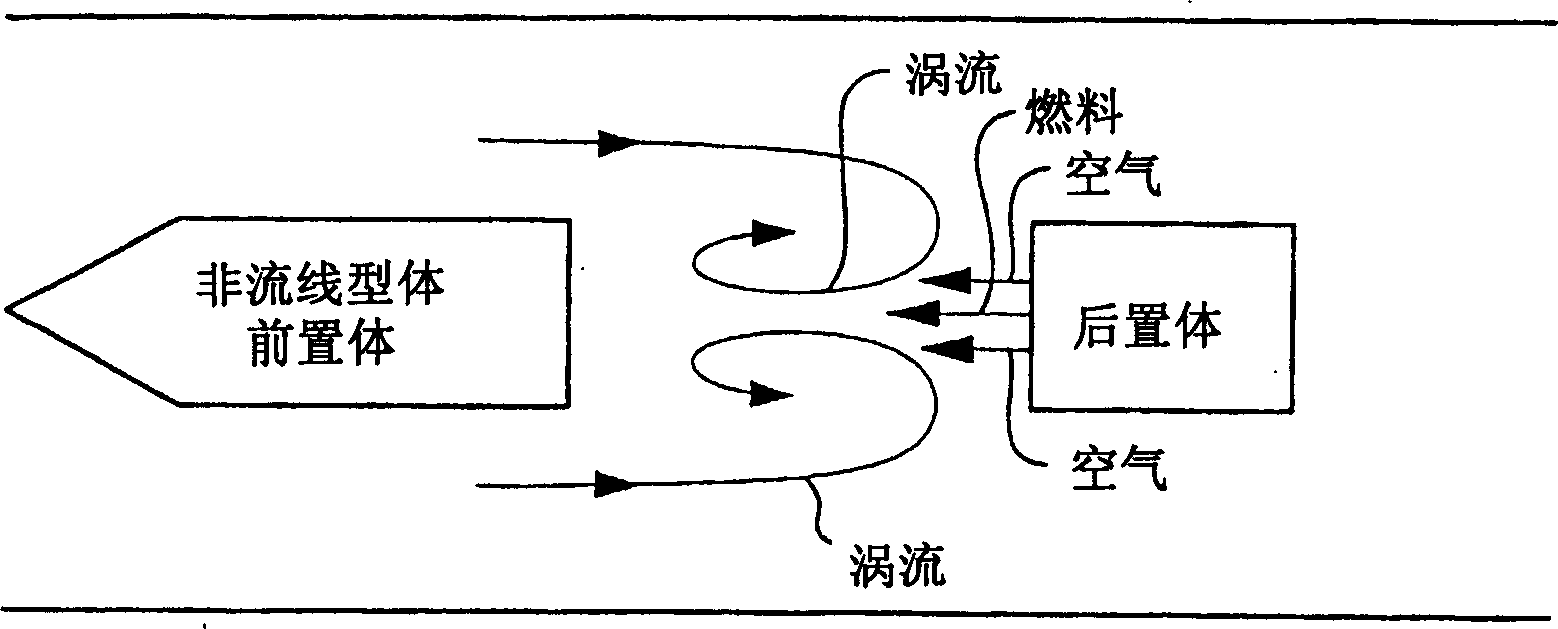

Trapped vortex combustor

InactiveCN1784574AReduce "high temperature sectionOptimize volumeContinuous combustion chamberEngine manufactureLeading edgeCombustor

Cut-off vortex combustors for gas turbines. The annular burner housing has a plurality of inlet centerpieces arranged along the helical axis. The inlet centerbody includes a leading edge structure, opposing side walls, a pressurizable chamber, and a rear wall. The inlet center body cooperates with the adjacent structure and the rear body bluff body to define a shut-off swirl chamber combustor for mixing the inlet fluid and combustible fuel to form hot combustion gases. Mixing is enhanced by utilizing posts adjacent to the rear wall to create swirls in the fluid flow, and by injecting fuel and / or air in the opposite direction to the swirl created by the bulk fluid flow. The hot combustion gases are used in a turbine for kinetic energy extraction or in a heat exchange device for thermal energy recovery. High combustion efficiency can be obtained and the emission of nitrogen oxides and carbon monoxide is less than 10ppm.

Owner:DRESSER RAND CO

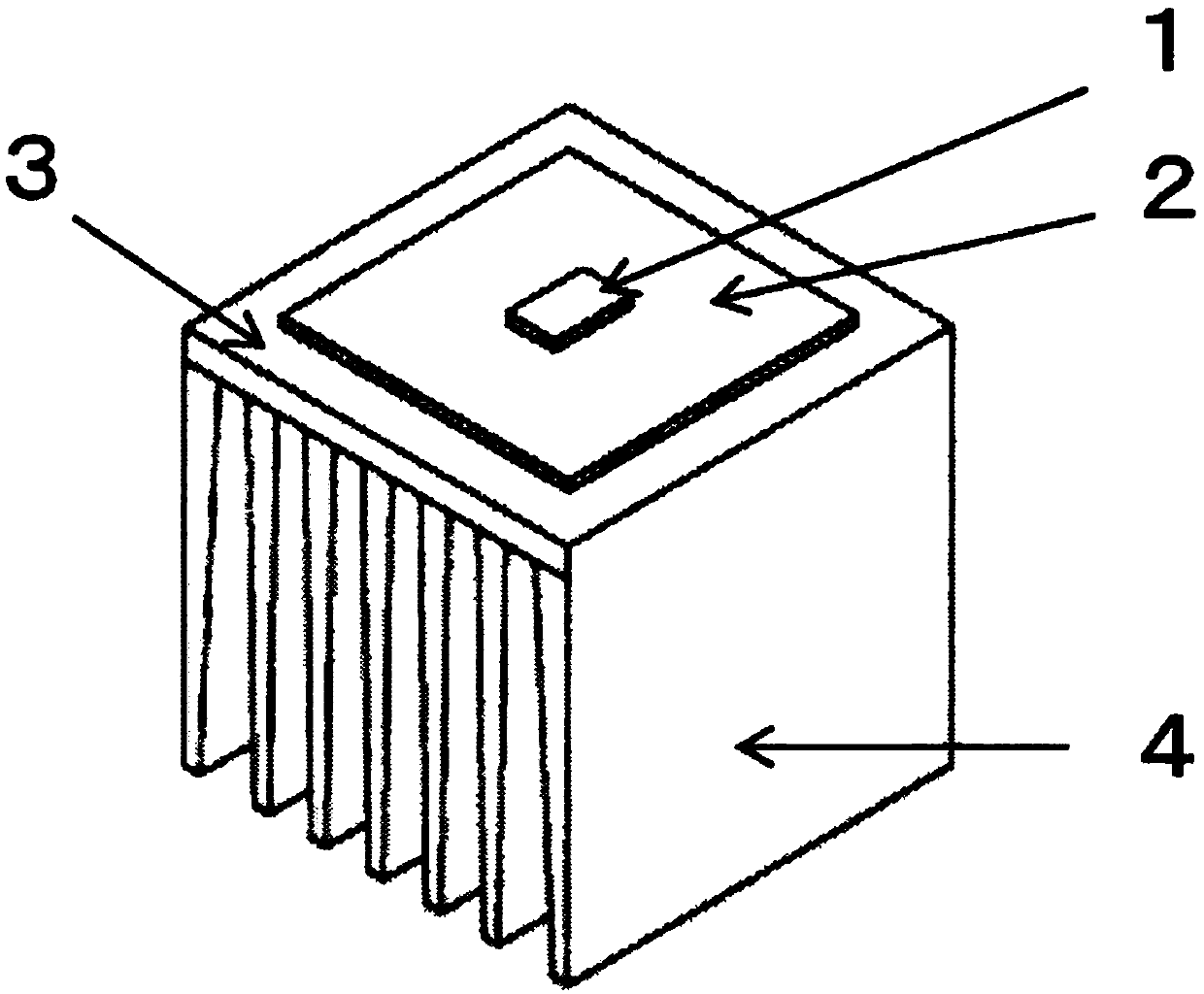

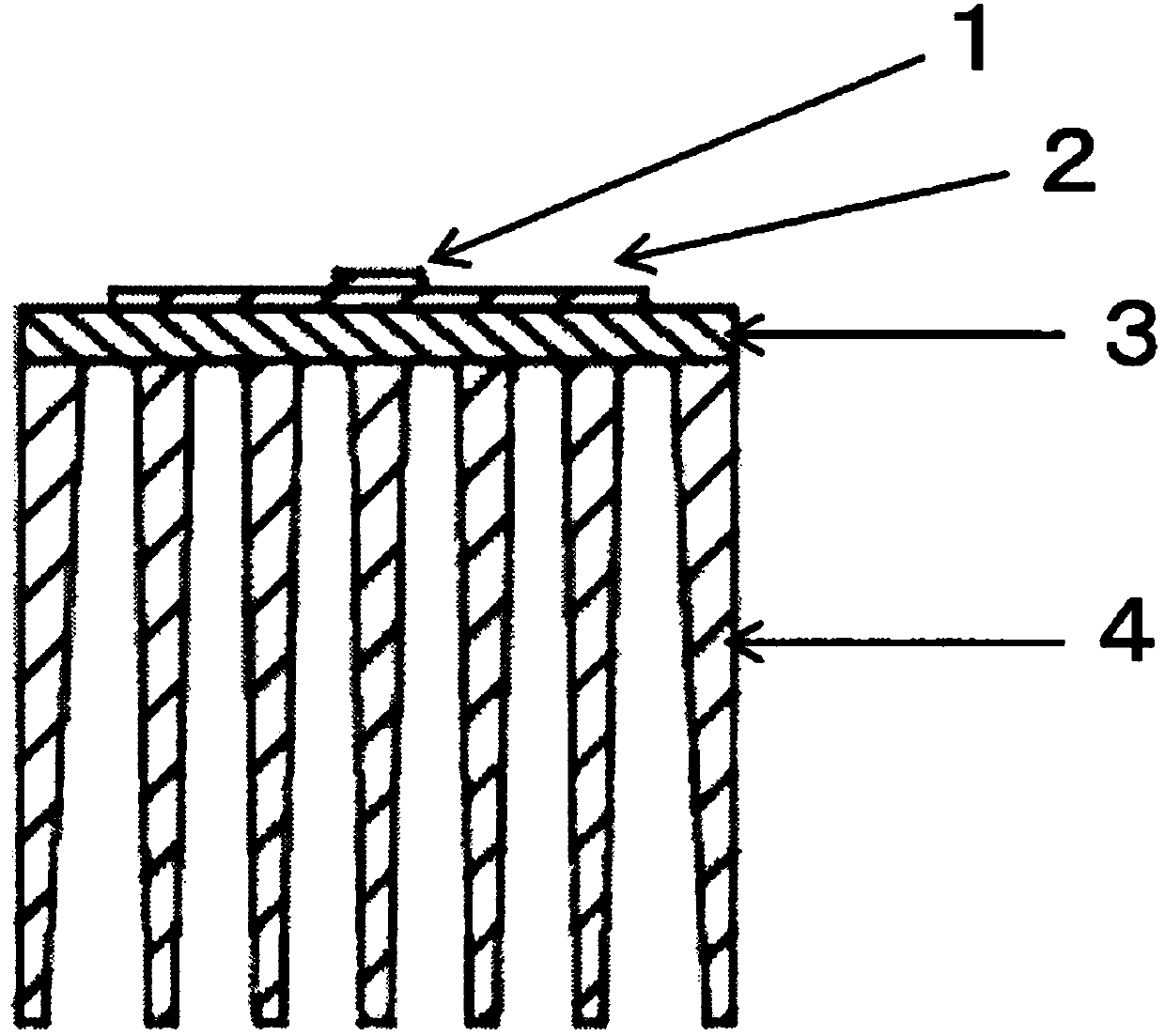

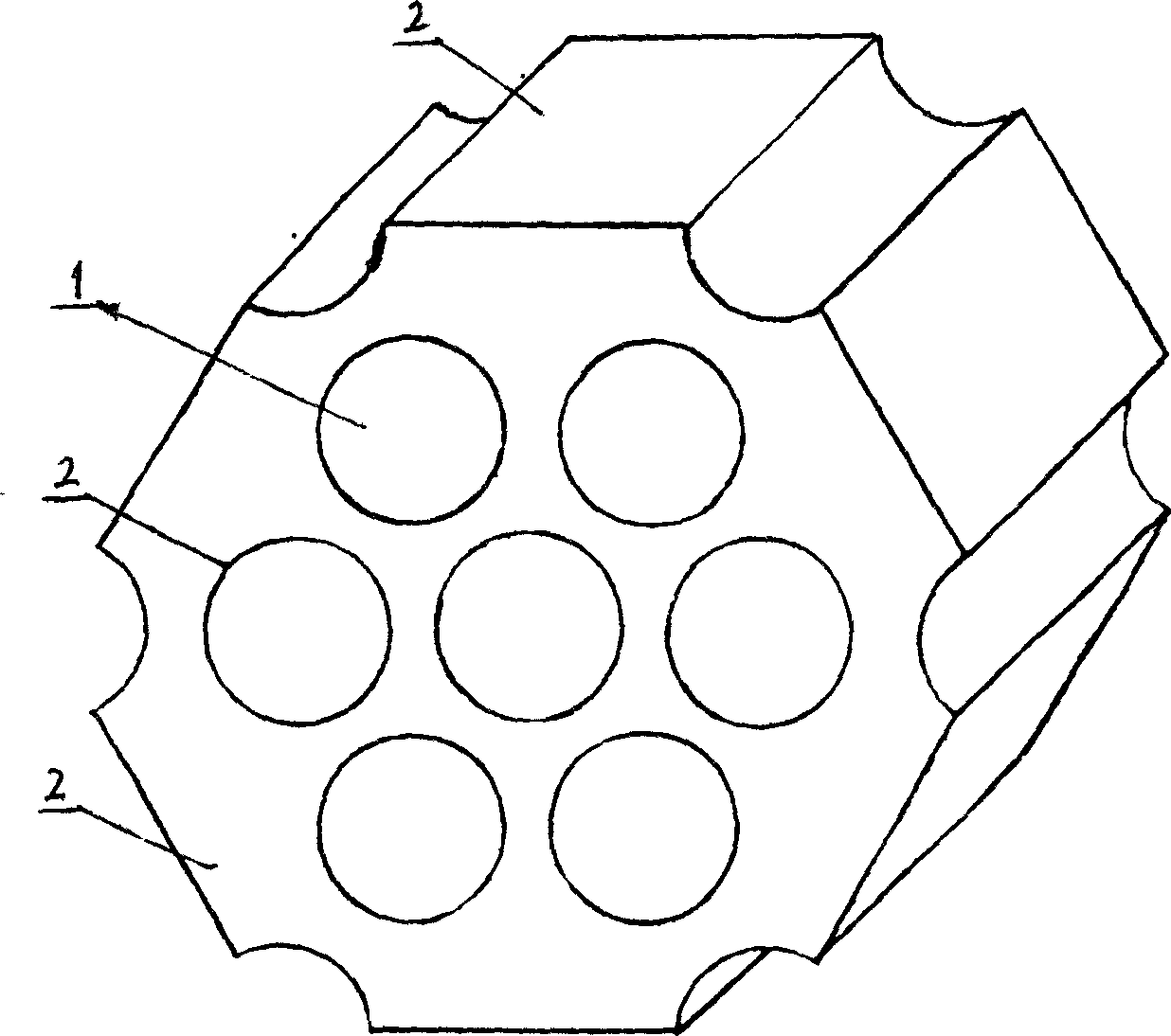

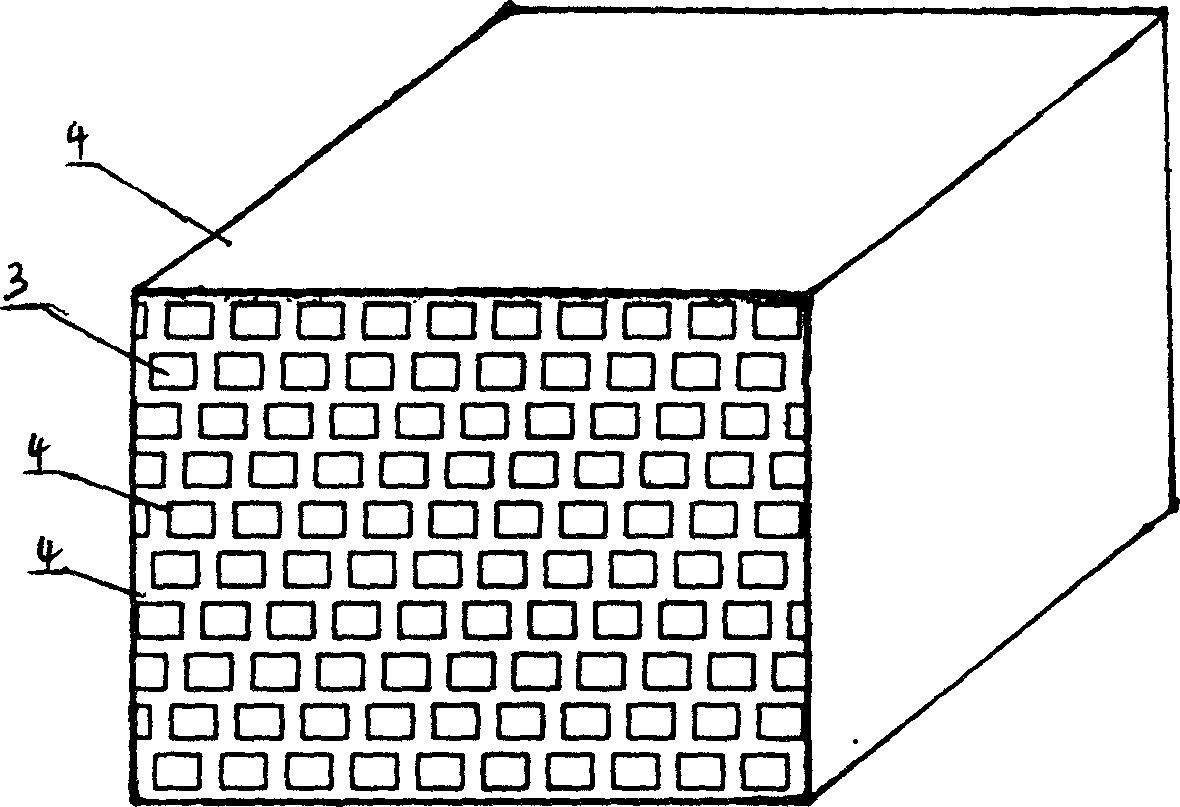

Heat exchanger with covering layer

ActiveCN1696596AIncrease heat absorptionIncrease heat releaseBrick-hot blast stovesFurnace componentsPlate heat exchangerEmissivity

The present invention relates to a heat exchanger with covering layer, belonging to the field of heat exchanger technology. Said heat exchanger is characterized by that one side or several sides of surface of its heat storage body are coated with a layer of high radiation material, whose radiation factor is higher than that of heat storage body base material. The heat storage body form can be honeycomb, fin form, ball form or plate form, and base body of heat storage body is made up by using refractory material, ceramic material or metal material.

Owner:山东慧敏科技开发有限公司

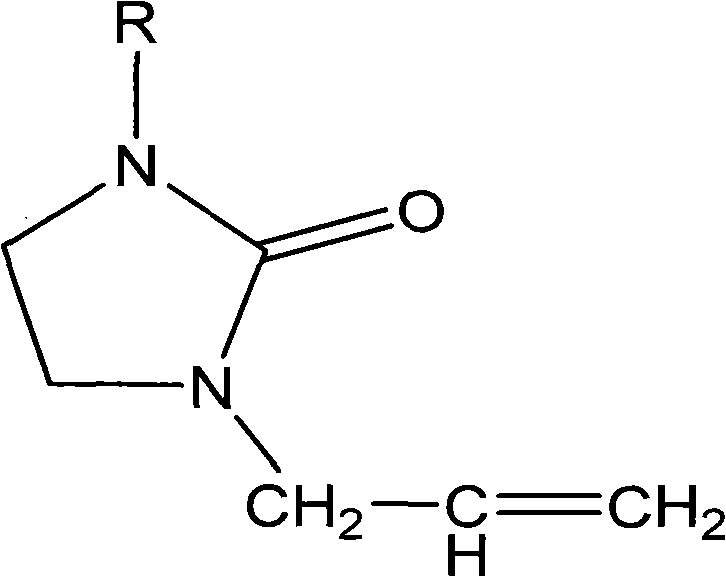

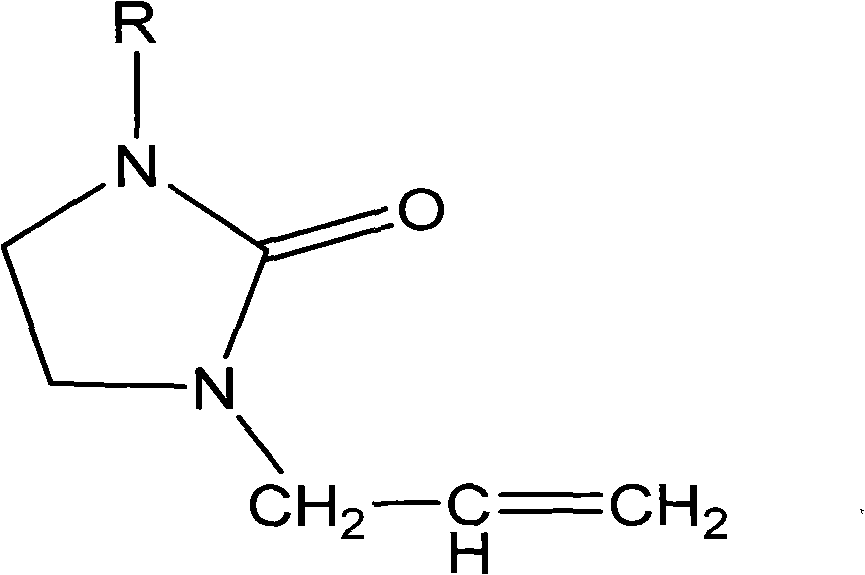

High-hydrophilic and exothermal spinning solution for polyacrylonitrile-based carbon fibers and preparation method thereof

InactiveCN101831729AImprove hydrophilicityReduced spinnabilityFibre chemical featuresCarbon fibersRoom temperature

The invention discloses high-hydrophilic and exothermal spinning solution for polyacrylonitrile-based carbon fibers and a preparation method thereof. The spinning solution consists of N,N-dimethyl formamide solution of monomer and co-monomer random copolymer. The preparation method for the spinning solution comprises the following steps of: adding azodiisobutyronitrile initiator, acrylonitrile main monomer, allylimidazolidone co-monomer and N,N-dimethyl formamide solvent into a reaction kettle with a condensation and mechanical stirring device, stirring and mixing the components at the room temperature, bubbling the mixture for 10 to 40 minutes by using nitrogen, then reacting the mixture for 6 to 36 hours at the constant temperature of between 50 and 70 DEG C under the protection of the nitrogen, and then removing residual monomers and bubbles to obtain the spinning solution with high hydrophilic property and good exothermal property, wherein the main monomer accounts for 94 to 98 percent of the total mass of the monomers, the co-monomer accounts for 2 to 6 percent of the total mass of the monomers, the azodiisobutyronitrile accounts for 0.2 to 1.0 percent of the total mass of the monomers, and the mass total concentration of the monomers is 15 to 35 percent. The weight-average molecular weight of the copolymer can be controlled to be between 0.1 and 0.35 million, the contact angle of the copolymer and the water is about 32.3 degrees, and the spinning solution has good hydrophilic property and low exothermal rate.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com