Capacity-control type double-cylinder rotary compressor and control method thereof

A rotary compressor, control technology, applied in the direction of compressors, compressors with reversible cycles, refrigerators, etc., can solve problems such as unsatisfactory actual results, and achieve the effect of high possibility, improving energy efficiency, and preventing efficiency reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

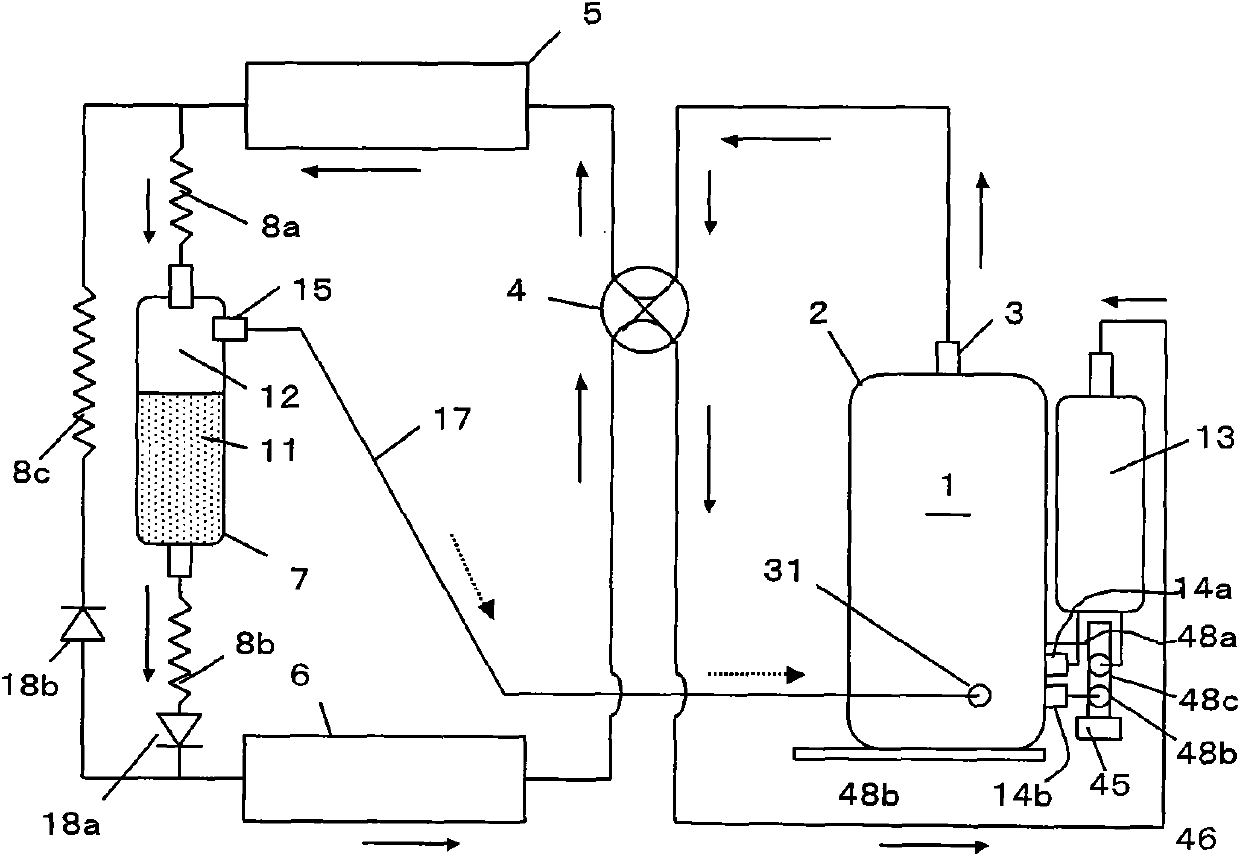

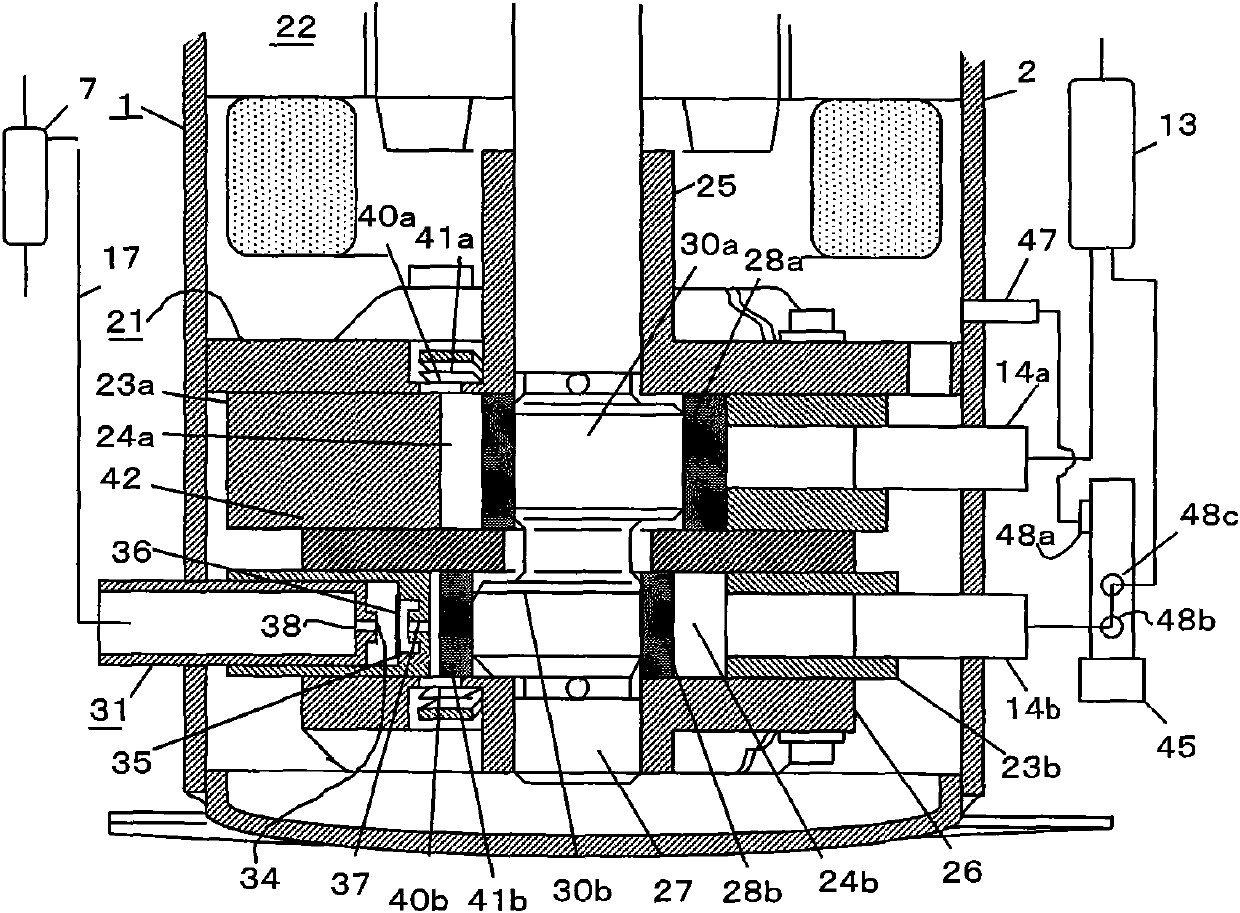

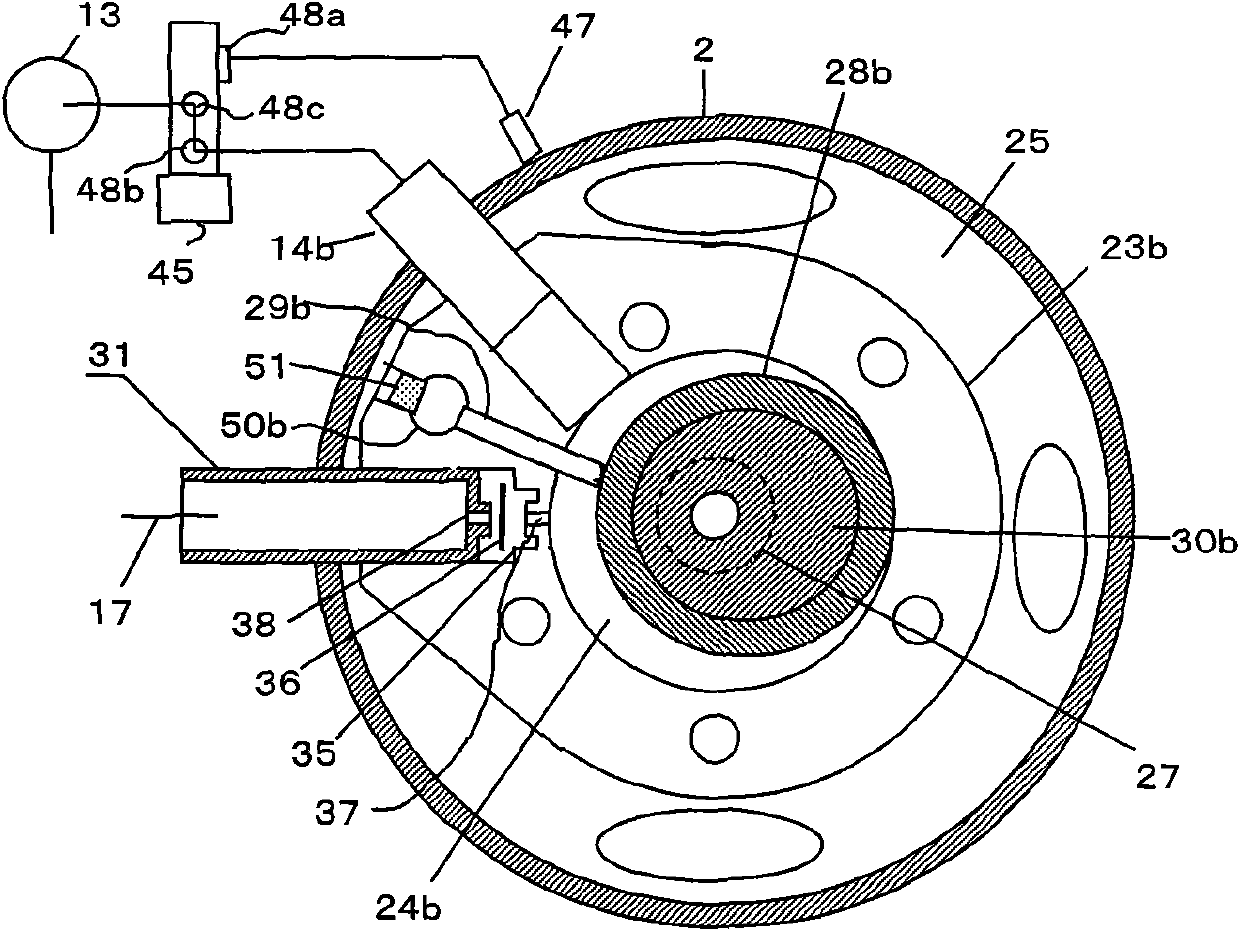

[0025] see figure 1 , shows the air conditioning system equipped with the dual-cylinder rotary compressor 1 of the present invention, that is, the cycle diagram when the air conditioner is in heating operation. The internal pressure of the sealed casing 2 of the compressor 1 and the high pressure side corresponding to the discharge pressure, the discharge pipe 3 welded to the upper end are connected to the inlet of the indoor heat exchanger 5 through the four-way switching valve 4 .

[0026] The other end of the indoor heat exchanger 5, that is, the outlet, and the other end of the outdoor heat exchanger 6, that is, the inlet, are provided with a gas-liquid separator 7, and between the gas-liquid separator 7 and the indoor heat exchanger 5 A first decompression pipe 8a is connected between the other ends of the two, and a second decompression pipe 8b and a first one-way valve 18a are connected between the gas-liquid separator 7 and the other end of the outdoor heat exchanger 6...

Embodiment 2

[0065] see Figure 5 , Omit the three-way valve 45 for control in Embodiment 1, if the second suction pipe 14b is directly connected between the four-way switching valve 4 and the outdoor heat exchanger 6, almost the same effect as in Embodiment 1 can be obtained. That is, under heating conditions, the above-mentioned junction pressure is on the low-pressure side, and therefore, it is the second cylinder compression mode. After switching to cooling condition, it becomes the second cylinder non-compression mode. Therefore, in Example 2, the heating capacity is maximized and the cooling capacity is decreased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com