Preparation method of metal-organic framework material modified metal nanoparticles

A technology of nano metal particles and metal organic frameworks, which is applied to attack equipment, generation of compressed gas, non-explosive/non-thermal agent components, etc., can solve problems such as poor practicability, achieve good practicability, improve energy performance, and the method is simple Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

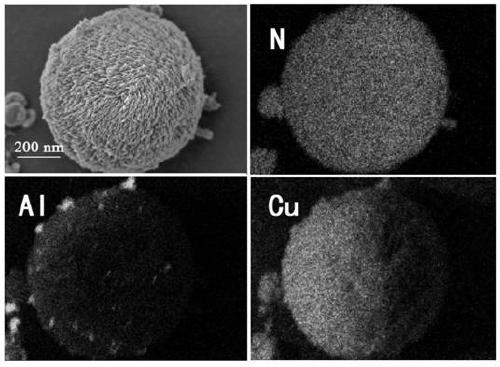

[0029] Step 1. Coating of nano aluminum powder: Measure 400 ml of deionized water and add it to a three-necked flask, weigh 0.54 g of Tri buffer and 0.72 g of dopamine into the deionized water, and stir until the color becomes slightly yellow. Add 7.2g of nano aluminum powder, stir quickly for 10 hours, filter and freeze-dry in vacuum;

[0030] Step 2. Preparation of energetic MOF ligand: Weigh 483mg copper nitrate and 148mg H 2 BT was dissolved in 100ml of deionized water, stirred for 30 minutes, filtered and washed with deionized water 3 times.

[0031] Step 3. Coordination of transition metal ions: 150 mg of copper nitrate and 50 mg of dopamine-coated nano aluminum powder were stirred in 100 ml of deionized water for 2 hours, and filtered.

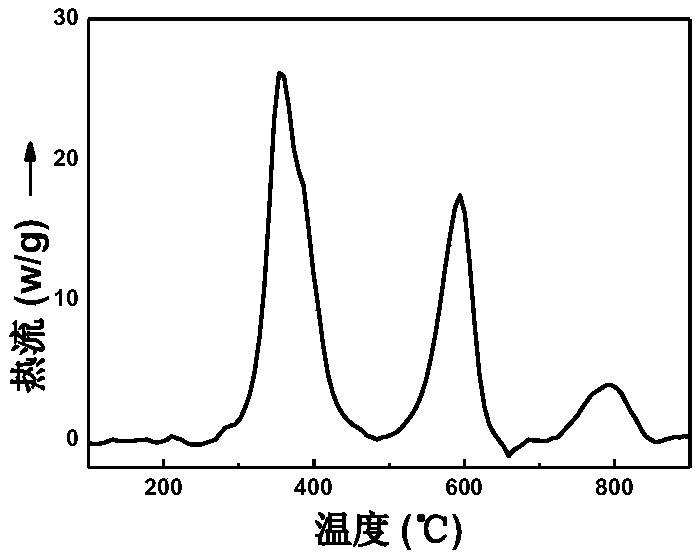

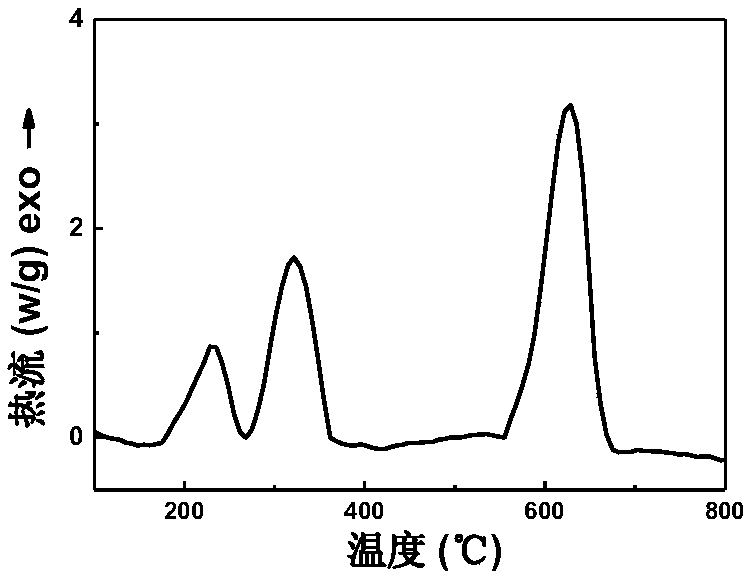

[0032] Step 4. Hydrothermal nano-aluminum powder shows that the energetic MOF crystal is grown in situ: Take the nano-aluminum particles immobilized with transition metal ions and the energetic MOF ligand prepared in the above steps, and add t...

Embodiment 2

[0039] Step 1. Coating of nano aluminum powder: Measure 400 ml of deionized water and add it to a three-necked flask, weigh 0.54 g of Tri buffer and 0.72 g of dopamine into the deionized water, and stir until the color becomes slightly yellow. Add 7.2g of nano aluminum powder, stir quickly for 10 hours, filter and freeze-dry in vacuum;

[0040] Step 2. Preparation of energetic MOF ligand: Weigh 483mg copper nitrate and 178mg DHBT in 100ml deionized water, stir for 30 minutes, filter and wash with deionized water 3 times.

[0041] Step 3. Immobilization of transition metal ions: 150 mg of copper nitrate and 50 mg of dopamine coated nano aluminum powder were stirred in 100 ml of deionized water for 2 hours and filtered.

[0042] Step 4. In-situ growth of energetic MOF by hydrothermal method: Take the transition metal ion-immobilized nano aluminum particles and energetic MOF ligand prepared in the above steps, and add them to 50ml of methanol and N,N-dimethylacetamide In the mixed solv...

Embodiment 3

[0048] Step 1. Coating of nano aluminum powder: Measure 400 ml of deionized water and add it to a three-necked flask, weigh 0.54 g of Tri buffer and 0.72 g of dopamine into the deionized water, and stir until the color becomes slightly yellow. Add 7.2g of nano aluminum powder, stir quickly for 10 hours, filter and freeze-dry in vacuum;

[0049] Step 2. Preparation of energetic MOF ligand: Weigh 483mg copper nitrate and 178mg DHBT in 100ml deionized water, stir for 30 minutes, filter and wash with deionized water 3 times.

[0050] Step 3. Immobilization of transition metal ions: 150 mg of copper nitrate and 150 mg of dopamine coated nano aluminum powder were stirred in 100 ml of deionized water for 2 hours, and filtered.

[0051] Step 4. In-situ growth of energetic MOF by hydrothermal method: Take the transition metal ion-immobilized nano aluminum particles and energetic MOF ligand prepared in the above steps, and add them to 50ml of methanol and N,N-dimethylacetamide In the mixed so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com