Heat exchanger with covering layer

A technology of heat exchangers and coatings, applied in the field of heat exchangers, to achieve the effects of reducing air flow, improving heat absorption and heat release capabilities, and fast heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

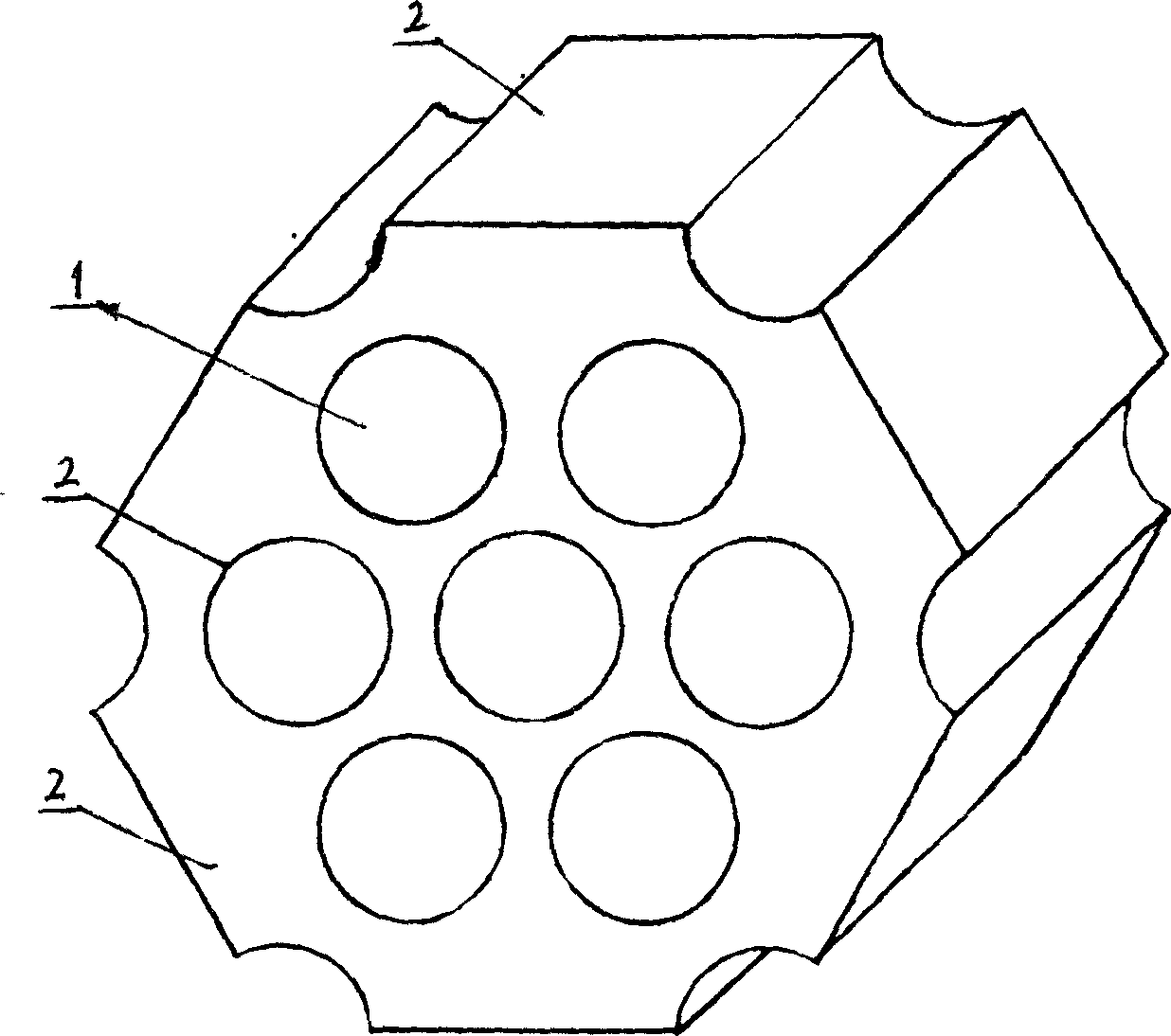

[0025] Such as figure 1 As shown, the regenerator used in the ironmaking blast furnace hot blast stove-checker brick, the checker brick (regenerator) has a circular inner hole 1, and all surfaces of the checker brick (regenerator) including the surface of the inner hole are brushed Coated with a layer of high radiation material cladding 2, thickness 0.2mm. The base of the heat storage body is a refractory material, and the high-radiation material coating 2 is a high-radiation far-infrared material with a higher emissivity than the base material of the heat storage body. The composition is: Cr 2 o 3 , 110 parts, 80 parts of clay, 90 parts of bentonite, 300 parts of brown corundum, 100 parts of silicon carbide, 400 parts of PA80 glue, and 100 parts of water, all are parts by weight. The solid components are ultra-fine processed to make the particle size between 25-700nm. Compared with existing heat exchangers of the same kind, the heat exchanger can save energy by more than 2...

Embodiment 2

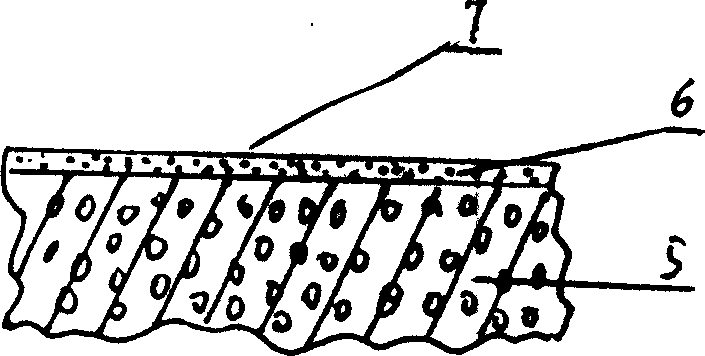

[0027] As described in Example 1, the difference is that the cross-sectional shape of the honeycomb heat storage body is a rectangle, with a circular inner hole 8 and a high-radiation material coating 9, such as Figure 4 shown.

Embodiment 3

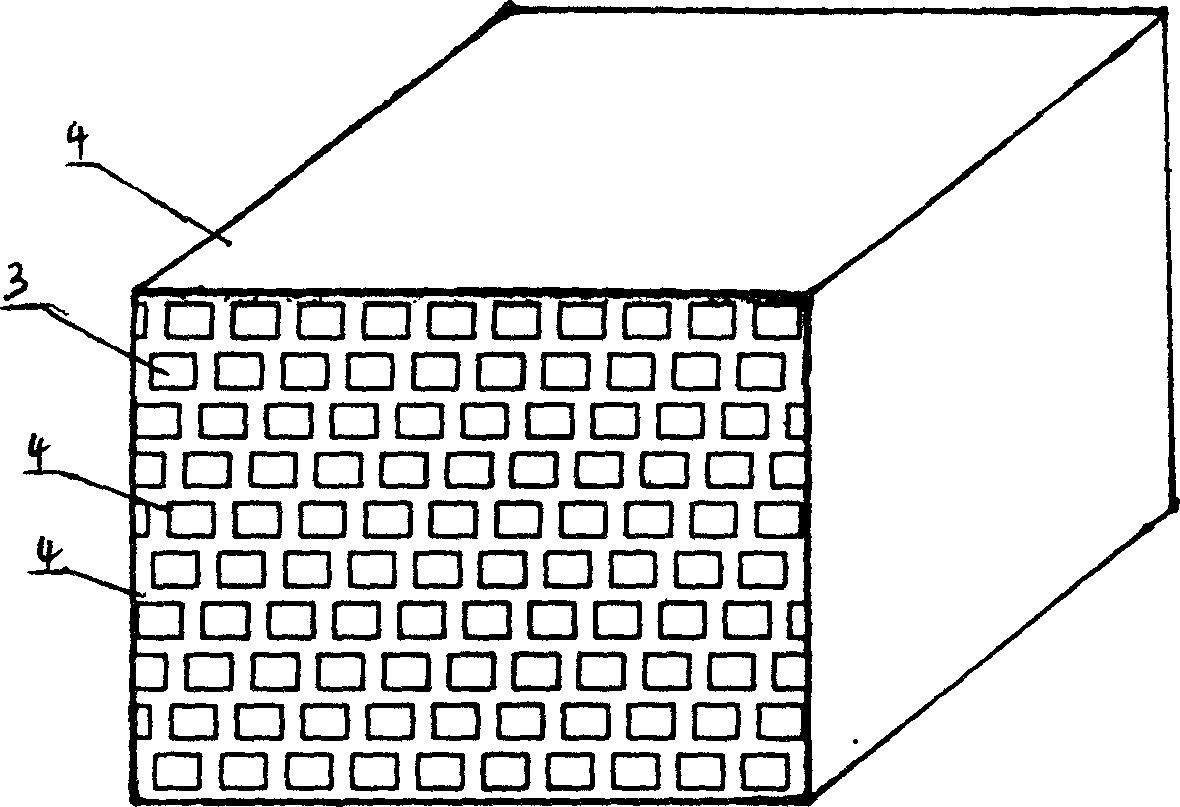

[0029] Such as figure 2 As shown, the heat storage body of the heat exchanger is fin-shaped, and the heat storage body has a rectangular inner hole 3, and a layer of high-radiation material coating 4 is brushed on all surfaces (including the surface of the inner hole) of the heat exchanger heat storage body, and the thickness is 0.03mm. The base body of the regenerator is ceramic material, and the high-radiation material coating 4 is a high-radiation far-infrared material whose emissivity is higher than that of the base material of the regenerator. The components are: 15 parts of ZrO, Cr 2 o 3 8 parts, TiO 2 10 parts, bentonite 2 parts, Al 2 o 3 , 15 parts, 10 parts of silicon carbide, 30 parts of PA80 glue, 10 parts of water, all are parts by weight. Compared with existing heat exchangers of the same kind, the thermal efficiency of the heat exchanger is increased by more than 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com