Fly ash-based soil water-retaining conditioner and preparation method thereof

A water-retaining conditioner, fly ash technology, applied in soil conditioning materials, chemical instruments and methods, other chemical processes, etc., can solve the problems of high equipment cost, high pressure, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

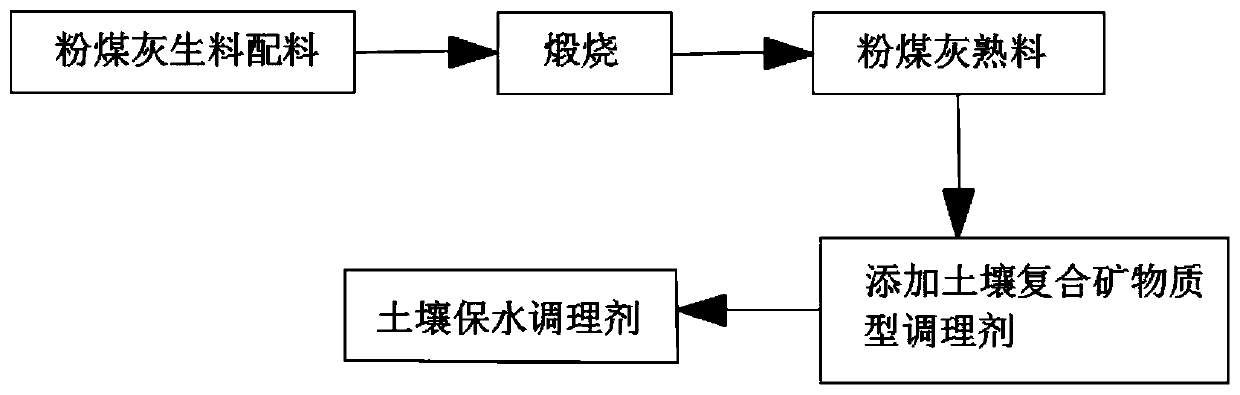

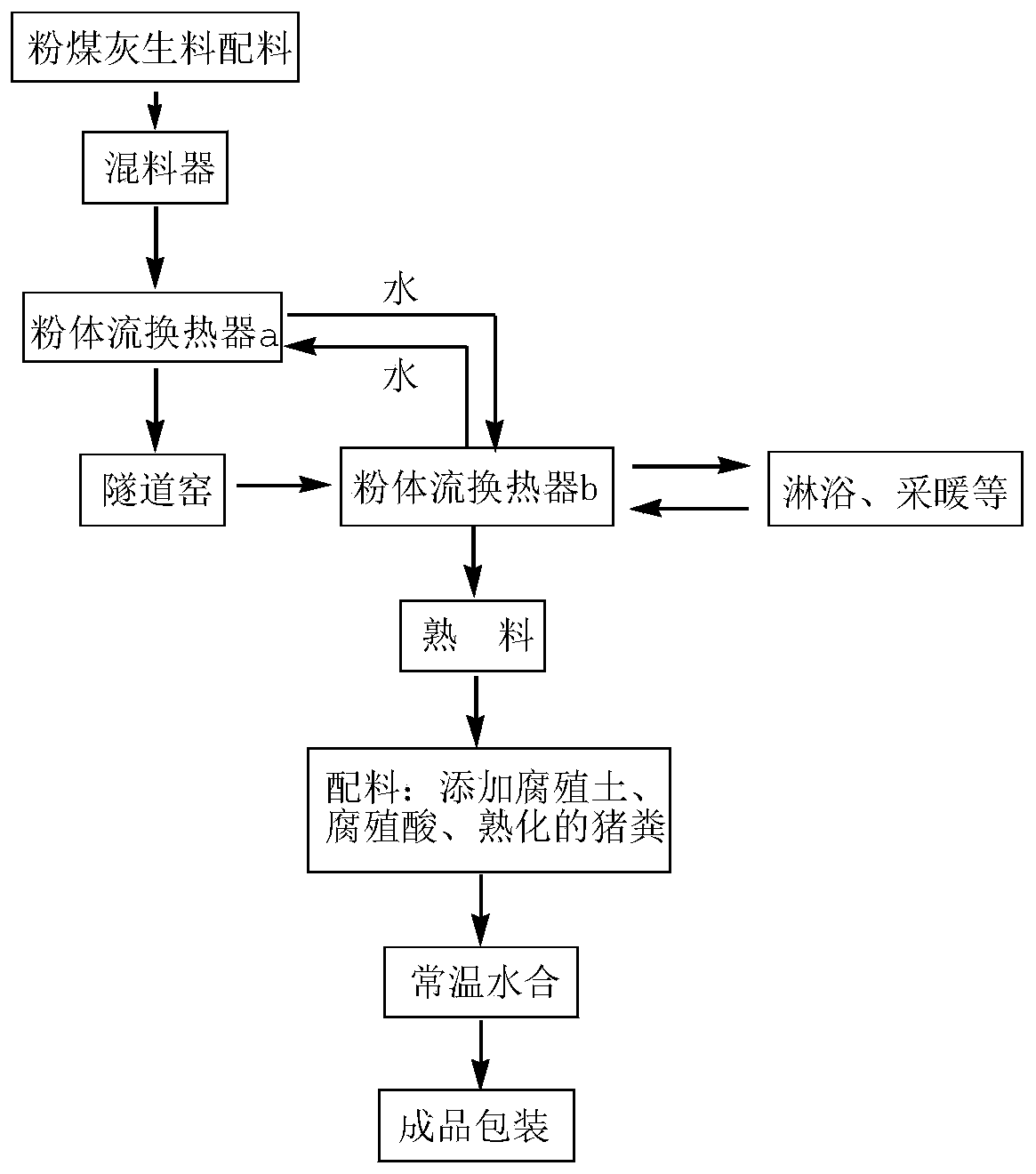

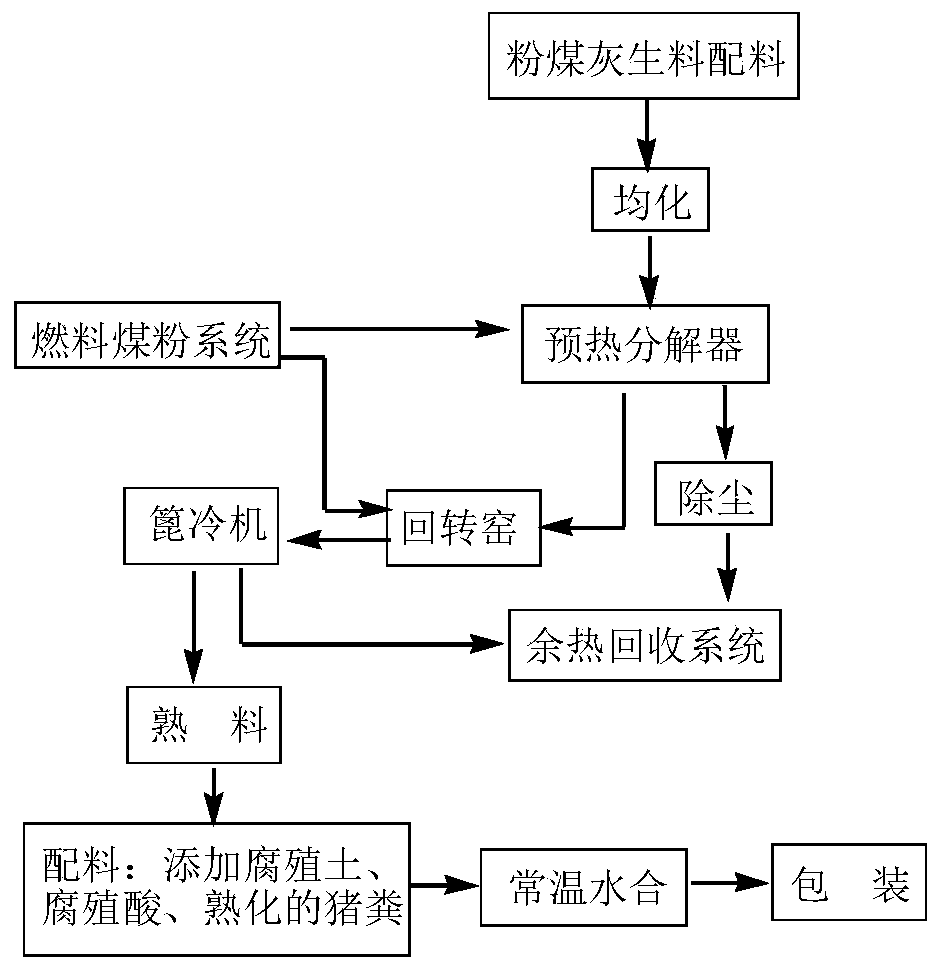

[0069] Such as figure 2 Shown, a kind of preparation method of fly ash-based soil water retention conditioner comprises the following steps:

[0070] S1: Weigh 100kg of fly ash;

[0071] S2: Preheat the fly ash to above 90°C through the powder flow heat exchanger a, wherein the preheating medium is hot water, and the preheated fly ash is transported to the tunnel kiln for static calcination, and the calcination in the tunnel kiln The temperature is 800-1250°C, and the calcination time is controlled within 30-150 minutes. After the calcination is completed, the temperature is lowered to 480-500°C through a grate cooler, and then the powder flow heat exchanger b is used to exchange heat with water, so that the temperature drops to 60°C. In the following, the hot water from the powder flow heat exchanger b can be used in places where hot water is needed, such as rain or heating, and the low temperature water in the heating process can be returned to the powder flow heat exchang...

Embodiment 2

[0076] Such as figure 2 Shown, a kind of preparation method of fly ash-based soil water retention conditioner comprises the following steps:

[0077] S1: Weigh 100kg of fly ash, 60kg of calcium oxide, 20kg of sodium carbonate, and 25kg of potassium carbonate, prepare sodium carbonate and potassium carbonate into an aqueous solution or a standard solution, mix the fly ash and calcium oxide evenly, and then add the prepared aqueous solution or standard solution to obtain fly ash raw meal;

[0078] S2: The fly ash raw meal is preheated to above 90°C through the powder flow heat exchanger a, wherein the preheating medium is hot water, and the preheated fly ash raw meal is transported to the tunnel kiln for static calcination. The calcination temperature in the kiln is 800-1250°C, and the calcination time is controlled within 30-150 minutes. After the calcination is completed, it is cooled to 480-500°C by a grate cooler, and then the powder flow heat exchanger b is used to exchan...

Embodiment 3

[0084] Such as figure 2 Shown, a kind of preparation method of fly ash-based soil water retention conditioner comprises the following steps:

[0085] S1: Weigh 100kg of fly ash, 100kg of calcium oxide, 50kg of sodium carbonate, 50kg of potassium carbonate, sodium carbonate and potassium carbonate to prepare an aqueous solution or a standard solution, mix the fly ash and calcium oxide evenly, and then add the prepared aqueous solution or standard solution to obtain fly ash raw meal;

[0086] S2: The fly ash raw meal is preheated to above 90°C through the powder flow heat exchanger a, wherein the preheating medium is hot water, and the preheated fly ash raw meal is transported to the tunnel kiln for static calcination. The calcination temperature in the kiln is 800-1250°C, and the calcination time is controlled within 30-150 minutes. After the calcination is completed, it is cooled to 480-500°C by a grate cooler, and then the powder flow heat exchanger b is used to exchange he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com