Vacuum brazing tool for water-cooling plate

A water-cooled plate and vacuum technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve problems such as uneven pressure, long brazing time, and low fixture life, so as to prolong the fixture life and improve brazing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

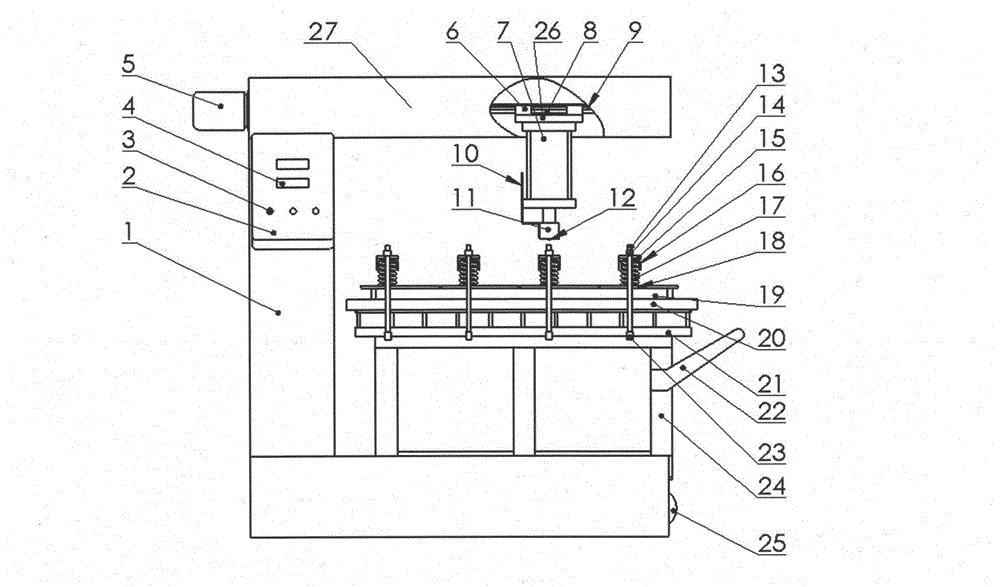

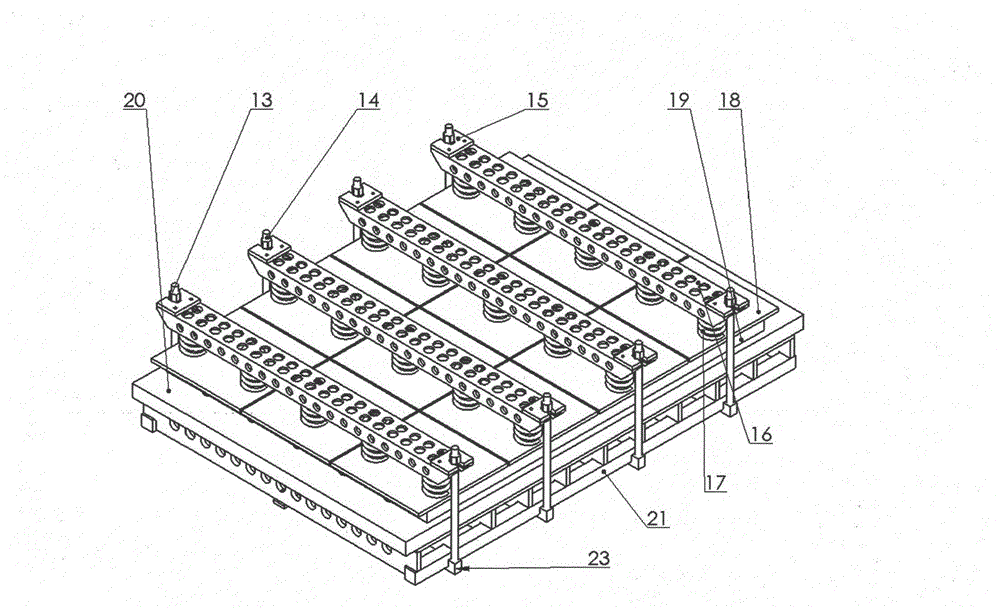

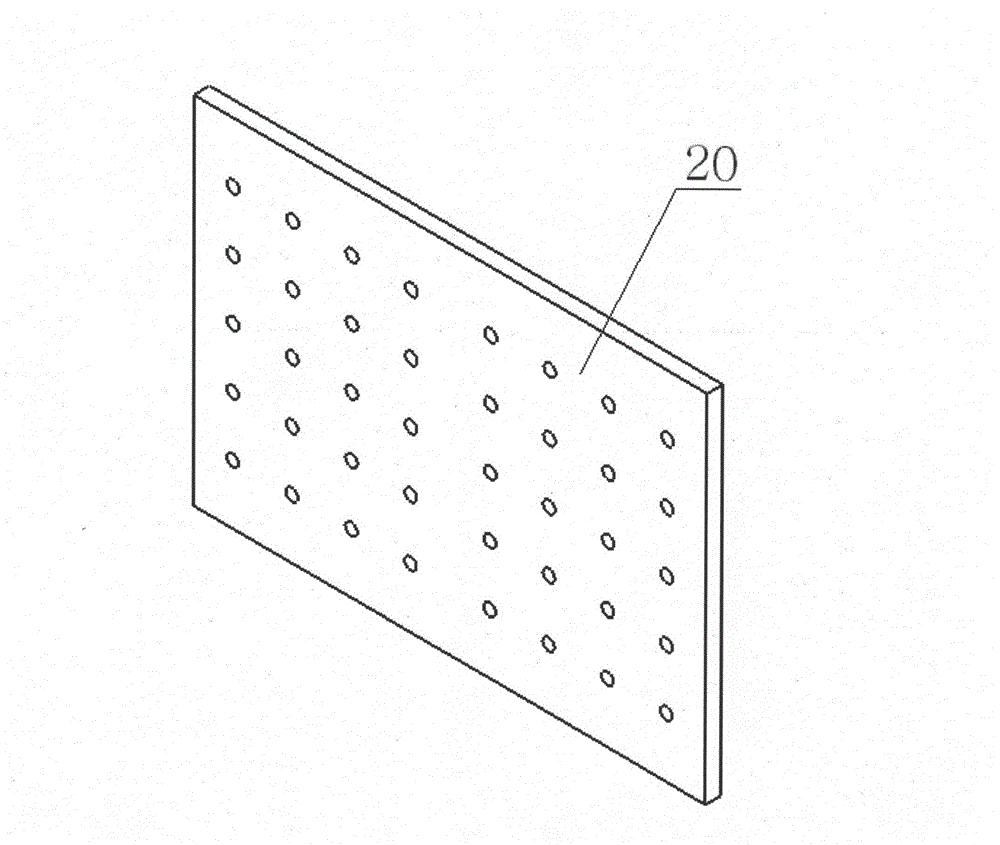

[0031] Such as Figure 1-4 As shown, it is a structural schematic diagram of the water-cooled plate vacuum brazing tooling provided by the present invention, the C-shaped main frame 1 and the mobile trolley 24 that can be pushed into the opening of the C-shaped main frame 1, and the bottom of the mobile trolley 24 is provided with 4 uniformly distributed Caster 25, a cart handle 24 is installed on mobile dolly 24 sides. The mobile trolley 24 is provided with a water-cooled plate vacuum brazing fixture, such as figure 2 As shown, the fixture includes 4 sets of clamping devices and a cover plate 18 , a bottom plate 20 , and a support frame 21 arranged overlappingly from top to bottom. Both the cover plate 18 and the bottom plate 20 are made of graphite, the thickness of the cover plate 18 is 10-15mm, the cover plate 18 is composed of 12 cover plate units arranged in 3*4, and there is 2-3mm between each two cover plate units gap; the thickness of the bottom plate is 40mm, and ...

Embodiment 2

[0033] Welding 800*600*40mm water cooling plate, the surface area of the welding cavity is 48dm 2 :

[0034] The difference from Embodiment 1 is that the cover plate 18 is composed of 6 cover plate units arranged in 2*3. A total of 20 compression springs are placed on the cover plate 18, divided into 5 rows and 4 columns, and a C-shaped pressure plate 16 is placed on each column. .

[0035] Place the cleaned base plate, composite board, fins, and cover plate of the water-cooled plate 19 according to the design requirements, and place the cover plate 18 on the cover plate of the water-cooled plate 19. The size of the cover plate 18 is 300*300*10mm. According to the 4-5 kg load per square decimeter, the output force of the pressing plate needs to be 48-60 kg. The upper limit of the weighing instrument 4 is set to 30 kg. Press the control button 3 on the control electric box 2 to press Block 11 moves left and right to the top of the C-shaped pressure plate 16 that needs to ...

Embodiment 3

[0037] Welding 600*400*25mm water-cooled plate, the surface area of a single welded water-cooled plate cavity is 24dm 2 :

[0038]Two water-cooled plates 19 can be placed on the bottom plate 20, and the base plate, composite plate, fin and cover plate of the cleaned water-cooled plate 19 are placed according to the design requirements. The difference from Embodiment 2 is that the size of the cover plate 18 placed on the cover plate of the water-cooled plate 19 is 400*300*10mm, and a total of 4 cover plate units arranged in 2*52 are laid, and a total of compressed air is placed on the cover plate 18. 16 springs, divided into 4 rows and 4 columns, place a C-shaped pressing plate 16 on each column, calculate the output force of the pressing plate according to the load of 4-5 kg per square decimeter to be 48-60 kg, and set the weighing instrument 4 The upper limit is 30 kilograms, press the control button 3 on the control electric box 2 to move the pressure block 11 left and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com