Automatic compression device of cable performance testing equipment

A technology of testing equipment and pressing devices, which is applied in the direction of measuring devices, measuring device casings, and parts of electrical measuring instruments, etc., can solve the problems of low manual pressing efficiency, uncontrollable pressing force, and low degree of automation. Achieve the effects of reducing labor intensity, increasing automation, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

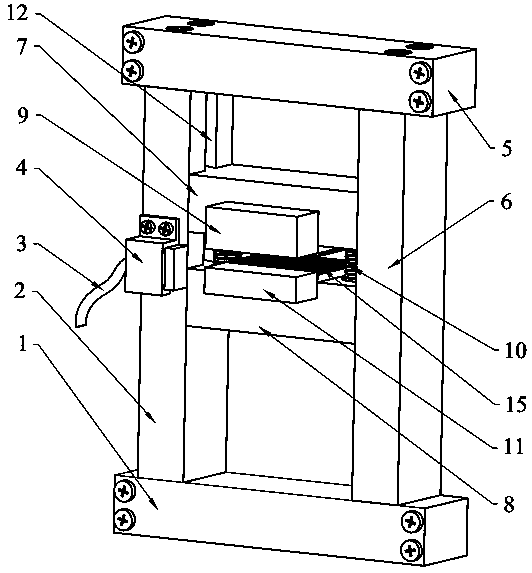

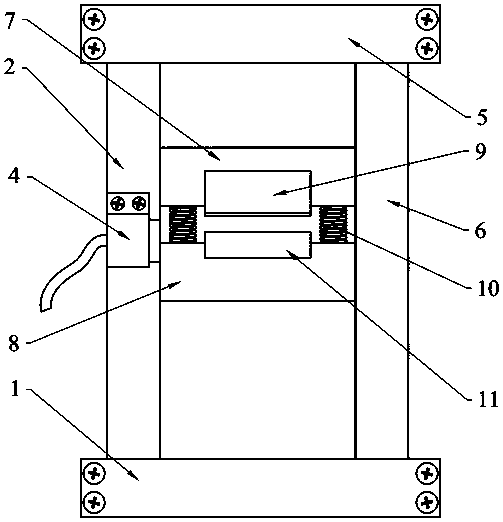

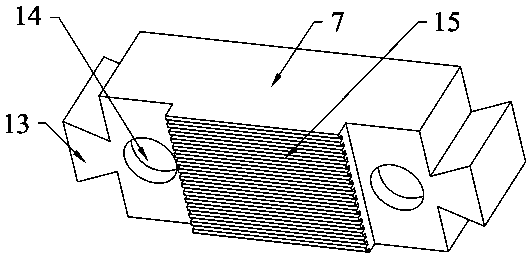

[0026] Please refer to Figure 1 to Figure 4 , the preferred embodiment of the present invention provides an automatic compression device for cable performance testing equipment, including a square frame body, the square frame body is vertically arranged, and the two sides of the square frame body are oppositely provided with chute 12, the square frame body The frame body is provided with an upper compression block 7 and a lower compression block 8 from top to bottom, the upper compression block 7 and the lower compression block 8 have the same structure, and the two ends of the upper compression block 7 and the lower compression block 8 are respectively The sliding block 13 is matched and installed in the chute 12 on both sides of the square frame, and a return spring 10 is arranged between the upper pressing block 7 and the lower pressing block 8 so that the upper pressing block 7 and the lower pressing block 8 Separated from each other when standing still, the opposite side...

Embodiment 2

[0036] Please refer to Figure 5 , is a preferred embodiment of the present application. Unlike Embodiment 1, in this preferred embodiment, the pressing device also includes an adjustable clamping member, and the adjustable clamping member includes a first clamping plate 16. The connecting rod 17 provided on the first clamping plate 16 and the second clamping plate 18 provided on the connecting rod 17, the adjustable clamping parts are used to clamp the upper pressing block 7 and the lower pressing block 8 .

[0037] In a preferred embodiment, the adjustable clamping member can be set movably, detachably, or be fixedly set on the pressing device; the first clamping plate 16 and the second clamping plate 18 can be movably set on On the connecting rod 17 , or one of the first clamping plate 16 and the second clamping plate 18 is fixedly arranged, and the other is movably arranged on the connecting rod 17 . The movable setting mode of the first clamping plate 16 and / or the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com