A forward and backward swing guide mechanism for the tool holder body of a gear shaping machine

A guide mechanism, gear shaper technology, applied in the direction of gear cutters, gear teeth, mechanical equipment, etc., can solve the problems of cutting rigidity, tool holder body vibration, affecting the tool shaft of the gear shaper, etc., to reduce friction and wear and improve coordination. Accuracy, the effect of eliminating the guide gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the invention will be further described below in conjunction with the accompanying drawings.

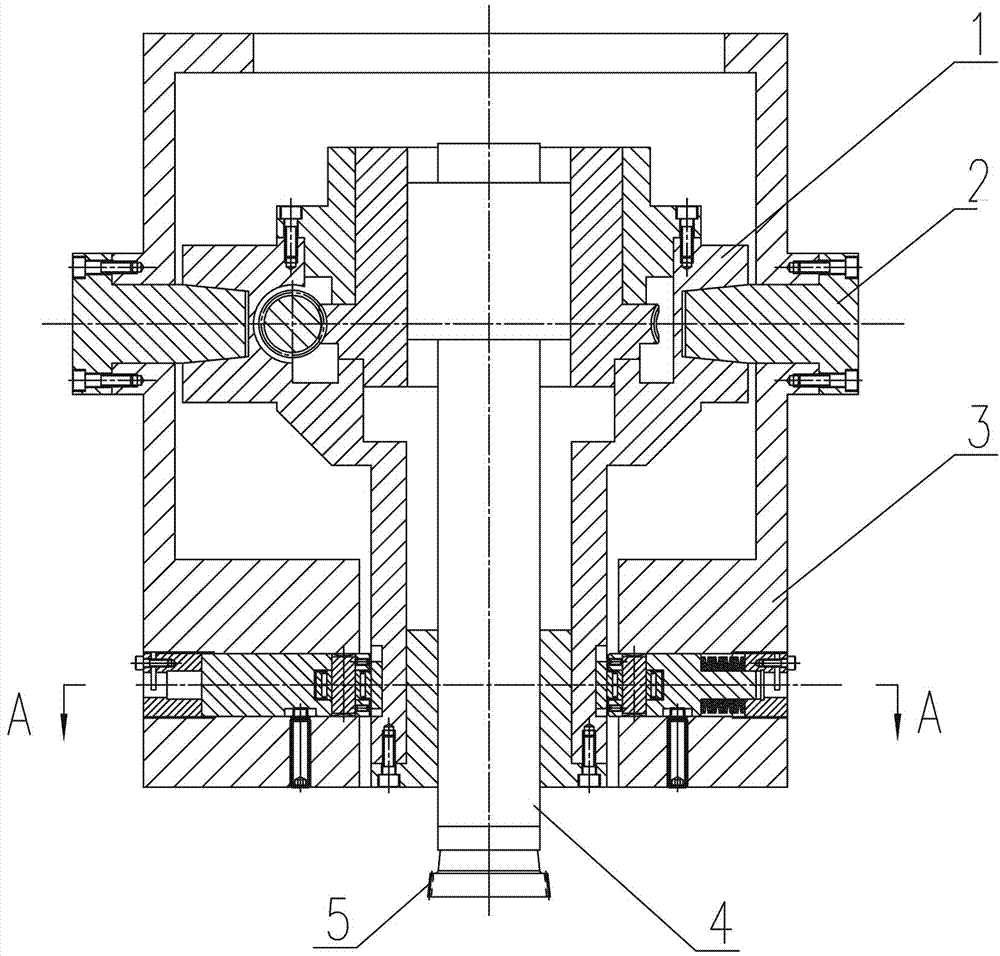

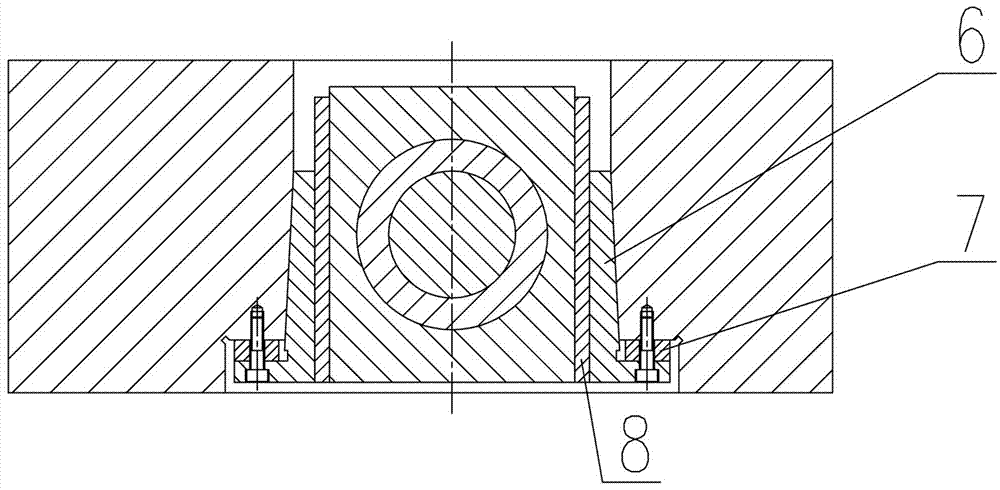

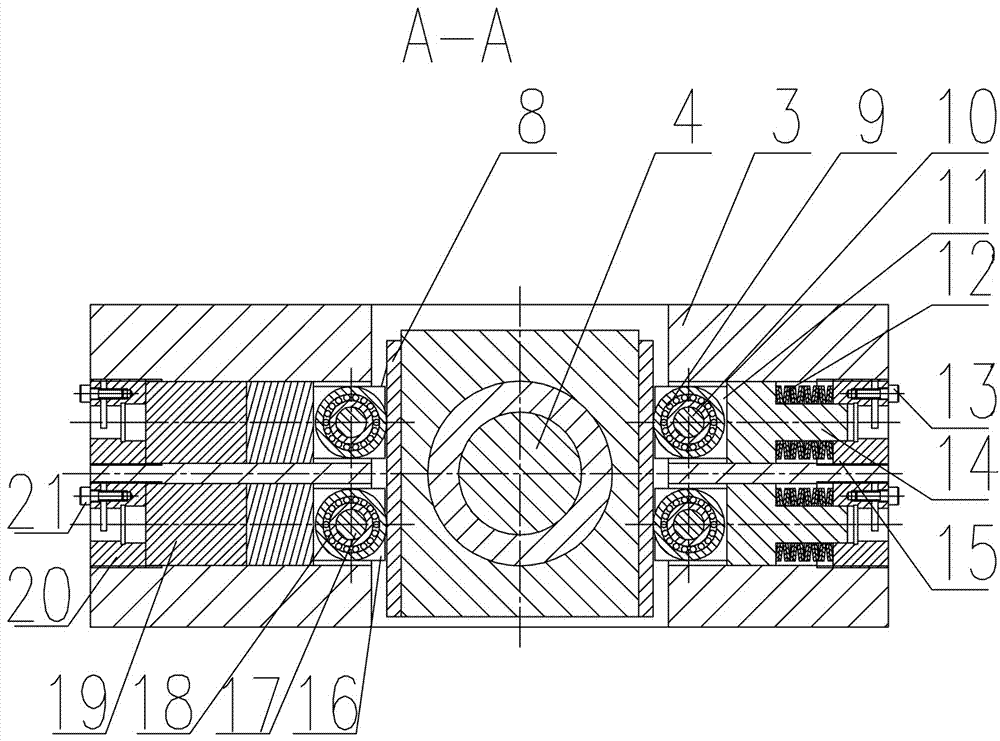

[0032] see figure 1 Or 3, a forward and backward swing guide mechanism of the tool rest body of the gear shaping machine, which includes a tool rest body 1, the tool rest body 1 is hinged on the column 3 through the ear shaft 2, and a main shaft 4 is installed inside the tool post body 1, and the main shaft 4 A gear shaper cutter 5 is installed at the end of the main shaft 4, and it is characterized in that: a crank linkage mechanism is installed on the top of the main shaft 4 to drive it to reciprocate up and down, and a longitudinal swing guide rail mechanism is installed at the position where the lower end of the main shaft 4 matches the column 3; The longitudinal swing guide rail mechanism includes a steel guide rail 8, which is fixedly installed on the tool holder body 1, and the right side of the steel guide rail 8 cooperates with the right side gap compe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com