Safe tobacco pipe utilizing air bag for supporting combustion

An air bag, safe technology, applied in the field of tobacco, can solve the problems of unfavorable tobacco full combustion, small tobacco gap, poor smoker experience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

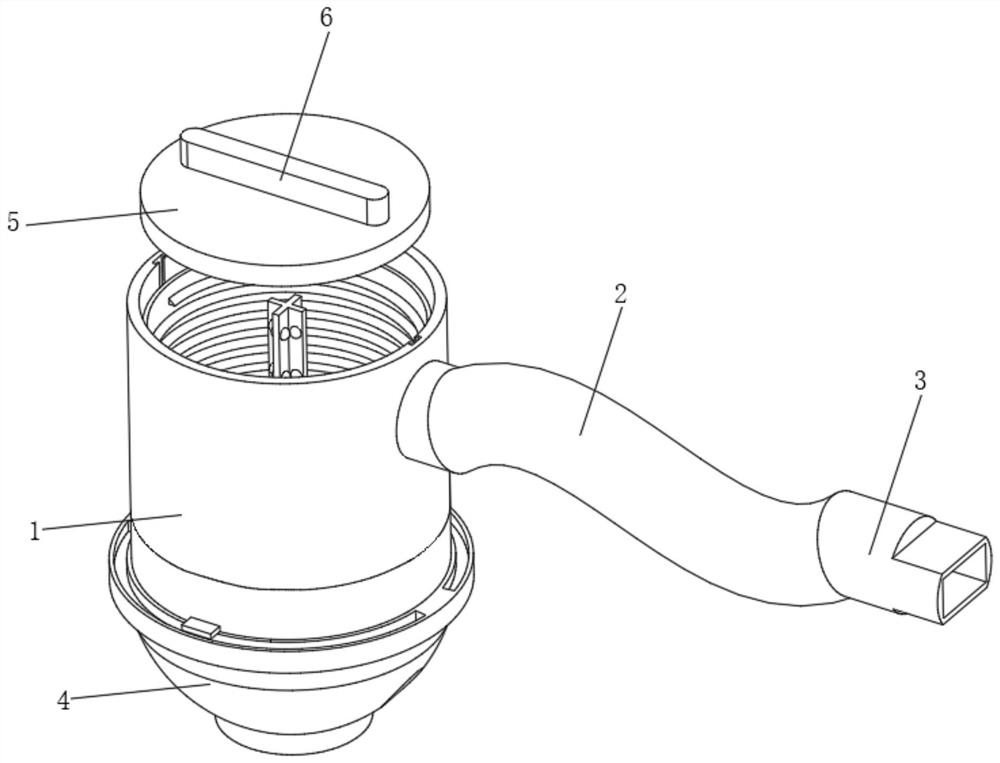

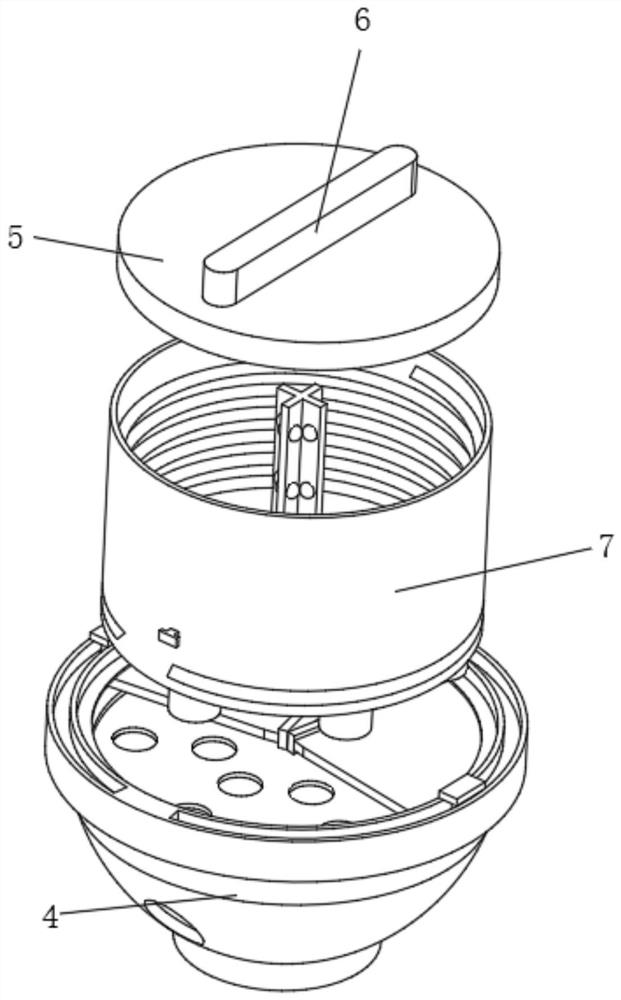

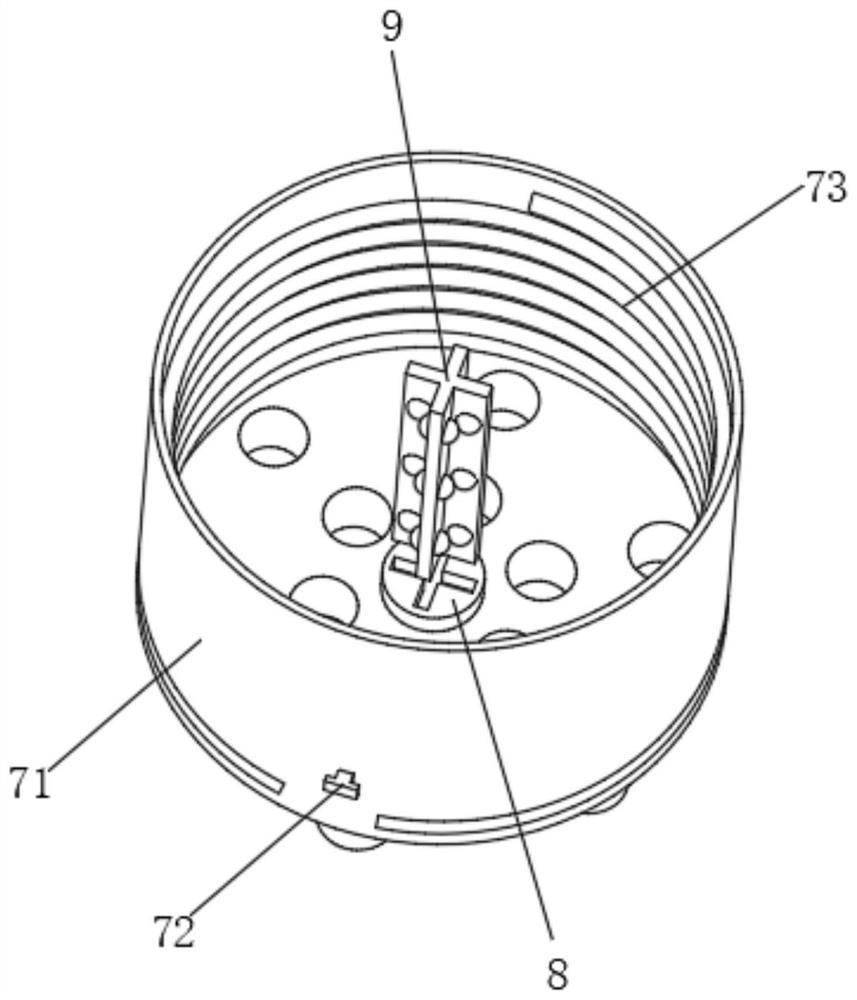

[0039] like Figure 1-5As shown, the present invention provides a technical solution: a safe smoking pipe using an air bag to support combustion, including a cigarette lighting chamber 1, the right side of the cigarette lighting chamber 1 near the top is fixedly connected with a buffer lever 2, and the buffer lever 2 The end away from the cigarette lighting chamber 1 is fixedly connected with a filter tip 3, the bottom of the cigarette lighting chamber 1 is fixedly connected with an external ignition protection mechanism 4, the top of the cigarette lighting chamber 1 is provided with a sealing baffle 5, and the middle position of the top of the sealing baffle 5 A rotating cross bar 6 is fixedly connected, and a storage combustion mechanism 7 is provided in the middle of the interior of the cigarette lighting chamber 1. The position is rotatably connected with a support rotary shaft 8, and the top of the support rotary shaft 8 is clamped with a cross conduction rod 9, and the o...

Embodiment 2

[0041] like Figure 3-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a safety pipe that utilizes an air bag to support combustion. The material storage combustion mechanism 7 includes a tobacco storage tank 71. A limiting block 72 is fixedly connected, and the limiting block 72 is connected with the internal test of the outer ignition protection mechanism 4 correspondingly.

[0042] The inner surface of the tobacco storage tank 71 is fixedly connected with conductive threads 73 , and the tobacco storage tank 71 is provided with movable slots 74 near the bottom and on both sides of the limiting block 72 . The conduction thread 73 can circulate and drive the tobacco downwards to ensure the moderate pressing force of the tobacco and achieve the purpose of uniform distribution of the tobacco.

[0043] The bottom of the tobacco storage tank 71 is evenly fixed and communicated with an ignition extension tank 75 . When using the ignit...

Embodiment 3

[0045] like Figure 6-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a safety pipe that utilizes an air bag to support combustion, and the external ignition protection mechanism 4 includes a heat insulation cover 401, and the The top is fixedly connected with the bottom of the cigarette lighting chamber 1 , the bottom of the heat insulation cover 401 is fixedly connected with a blanking bottom trough 402 , and the middle position of the bottom of the blanking bottom trough 402 is fixedly connected with a slag discharge door 403 .

[0046] One side of the blanking bottom groove 402 near the bottom is provided with an ignition hole 404 .

[0047] A partition plate 405 is fixedly connected to the inside of the heat insulation cover 401 and close to the bottom end. The interior of the partition plate 405 is evenly provided with ignition sockets 406 , and the ignition extension slots 75 are correspondingly provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com