Patents

Literature

132results about How to "Reduce suction resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

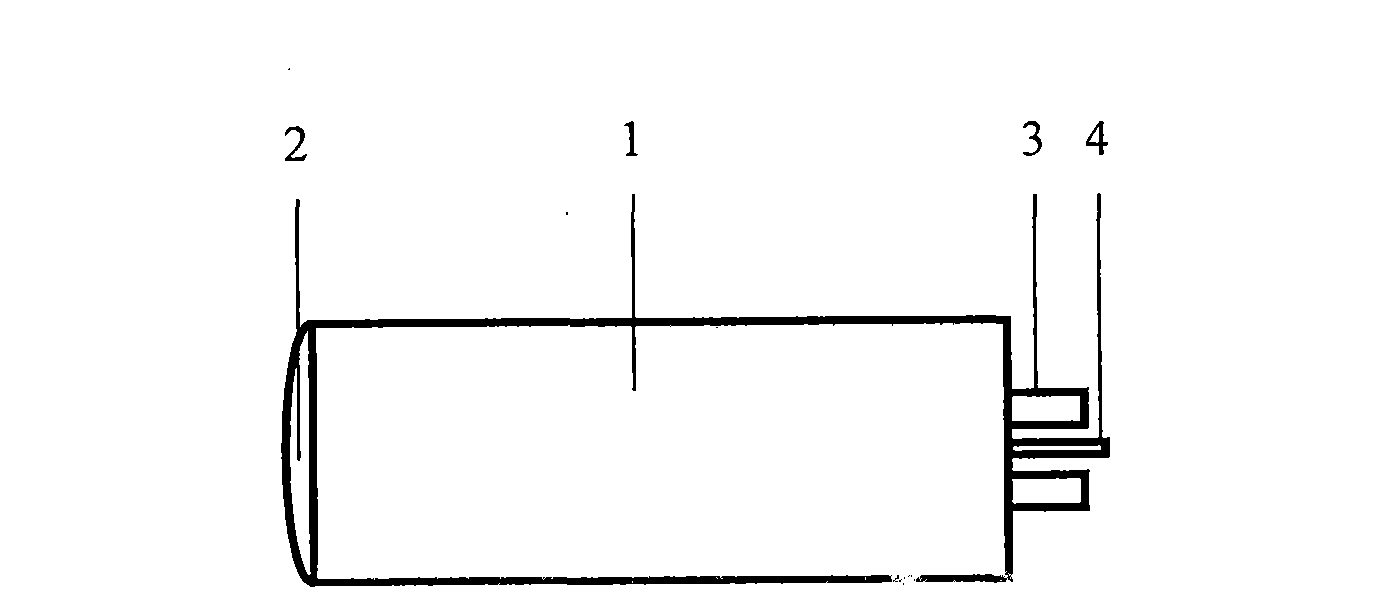

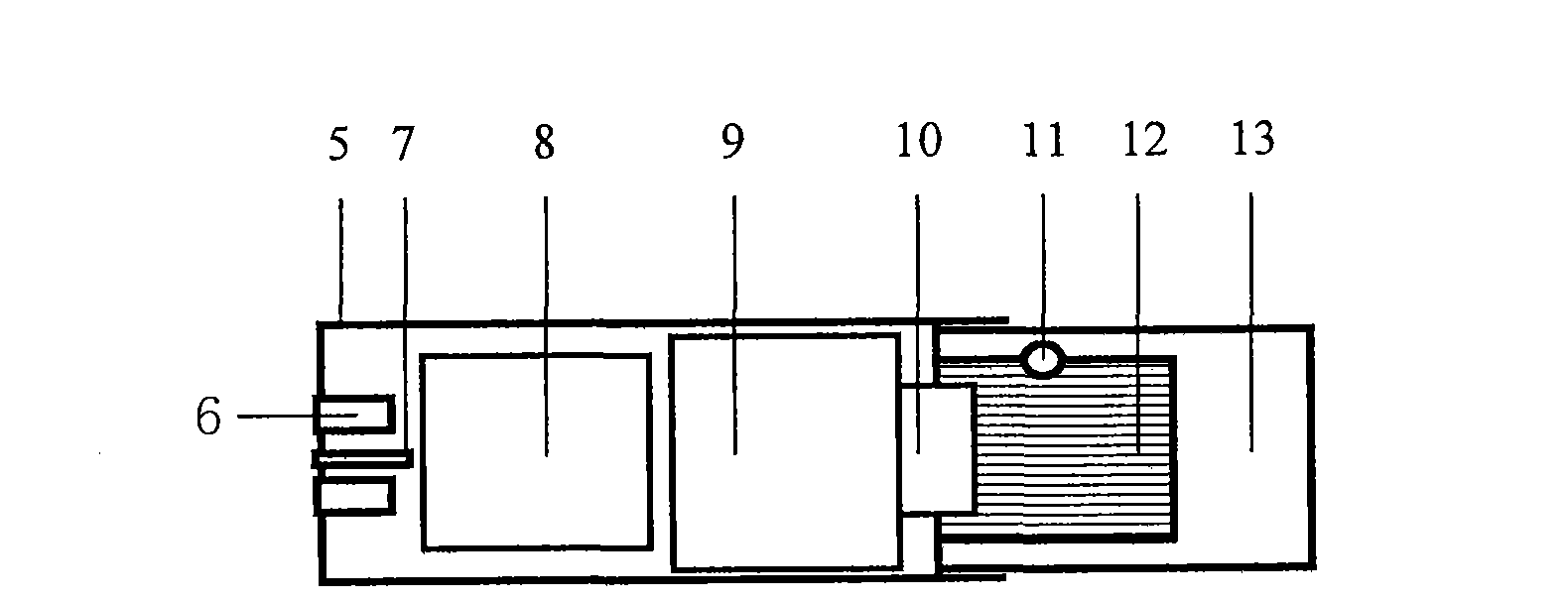

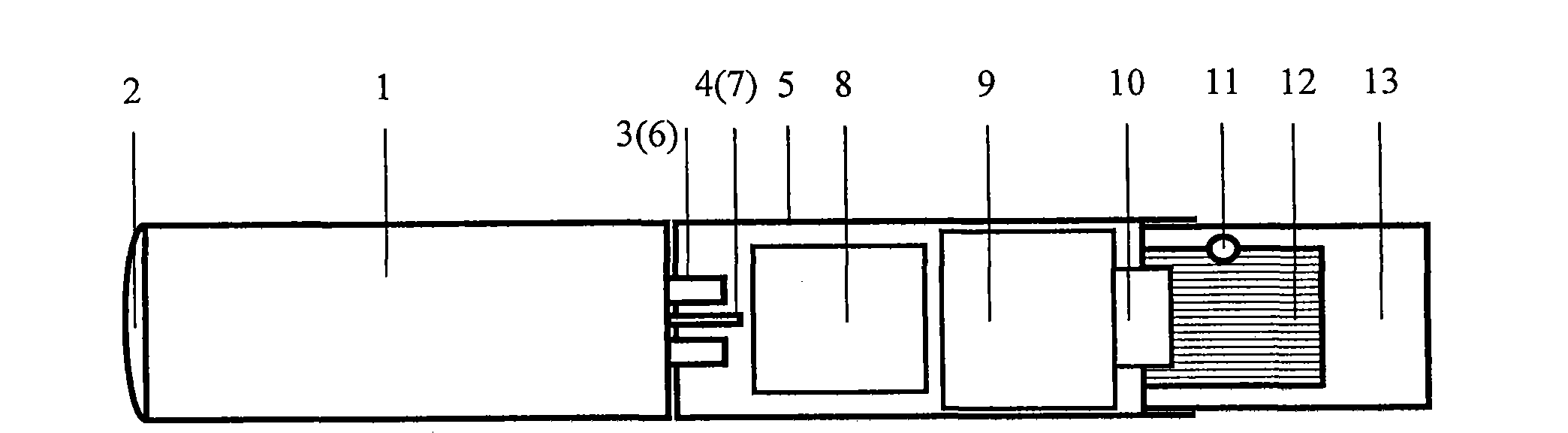

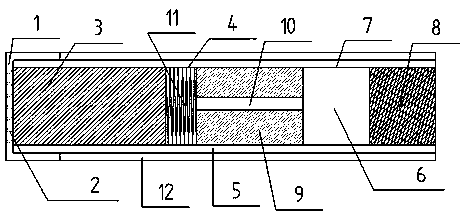

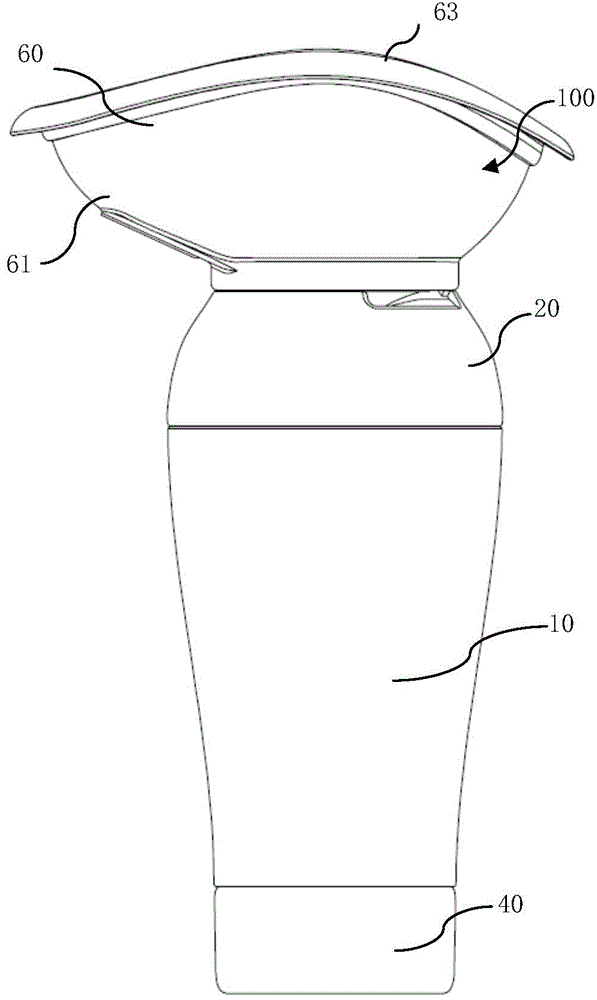

Heating atomization electronic cigarette using capacitances to supply power

The invention provides a heating atomization electronic cigarette using capacitances to supply power, which comprises a power supply part, a cigarette body part and a hollow cigarette holder part, wherein the power supply part comprises an indicator light, a pair of electrode connection-pegs and a lead connection-peg, the indicator light is arranged at the back end of a power supply, and the electrode connection-pegs and the lead connection-peg are arranged at the front end of the power supply; the cigarette body part comprises a pair of electrode plug interfaces, a lead plug interface, a control circuit module, a heating atomization device, a liquid suction head and a nicotine reservoir, the electrode plug interfaces and the lead plug interface are arranged at the back end of a hollow cigarette stem, and the control circuit module, the heating atomization device, the liquid suction head and the nicotine reservoir are sequentially arranged in the hollow cavity of the hollow cigarette stem; a sponge body is arranged in the nicotine reservoir, and a liquid inlet is arranged on the wall of the nicotine reservoir; the two ends of the liquid suction head are respectively contacted and connected with the heating atomization device and the sponge body, and the power supply part and the cigarette body part can be separated or connected by the electrode connection-pegs, the lead connection-peg, the electrode plug interfaces and the lead plug interface in a plug-in way; and the front end of the cigarette body is in plug-in or threaded connection with the back end of the hollow cigarette holder, and the power supply, the indicator light, the control circuit module and the heating atomization device are sequentially and electrically connected.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

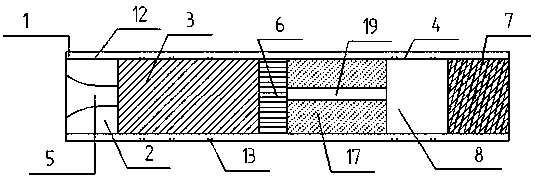

Heating non-combustible cigarette

The inVention belongs to the technical field of noVel cigarettes, and particularly relates to a cigarette structure of a heating non-combustible cigarette. The heating non-combustible cigarette is composed of a cylinder hollow coiling block, a cleaning spacer sleeVe arranged at the front end of the coiling block, and a smoking product section and a cooling filtering section which are sequentiallyarranged inside the coiling block. By arranging the cleaning spacer sleeVe, a user can insert a heating body into a cigarette, no cut tobacco can drop out, meanwhile, small parts in smoking products cannot fall into a heater in the heating process, and cleanness in the heater is ensured.

Owner:赵雪

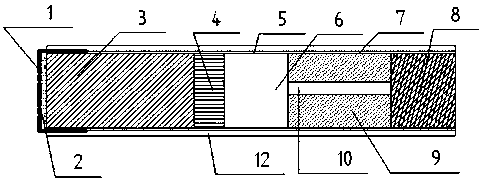

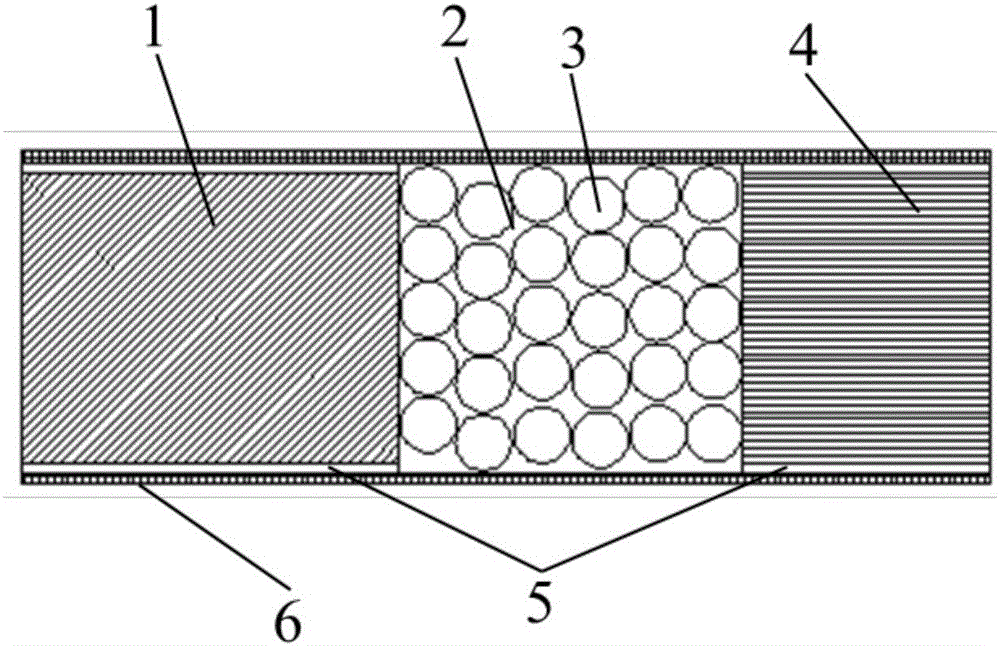

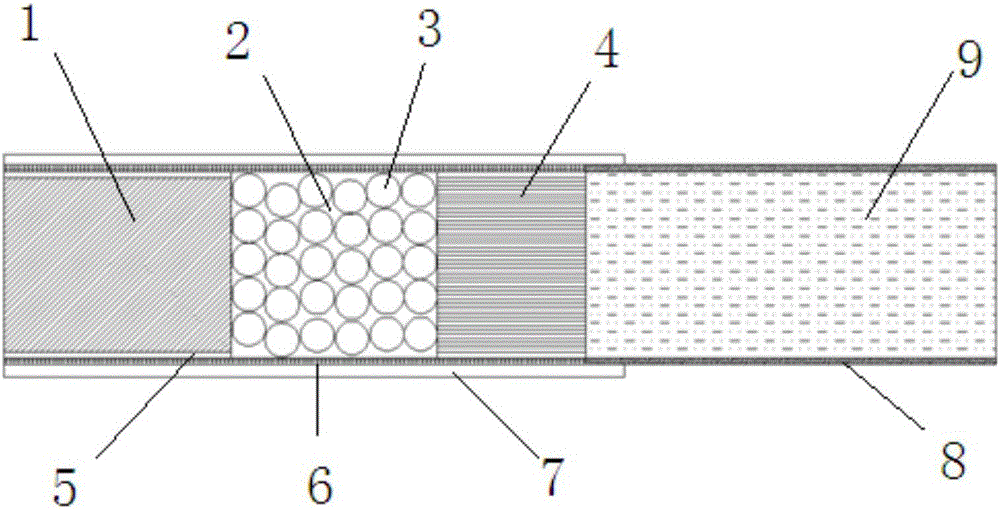

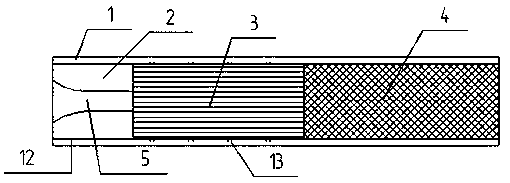

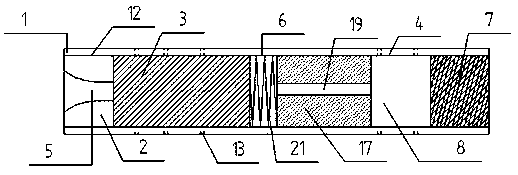

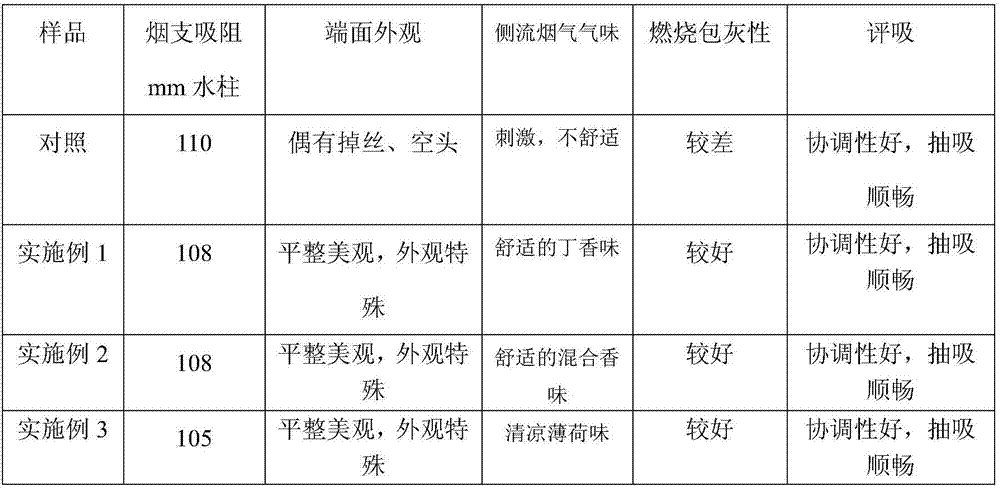

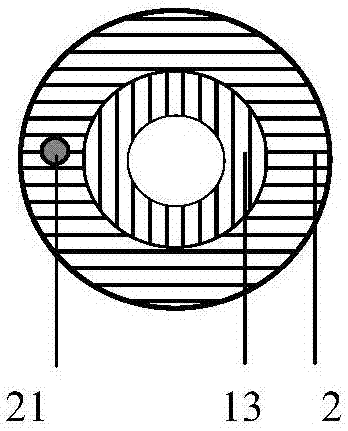

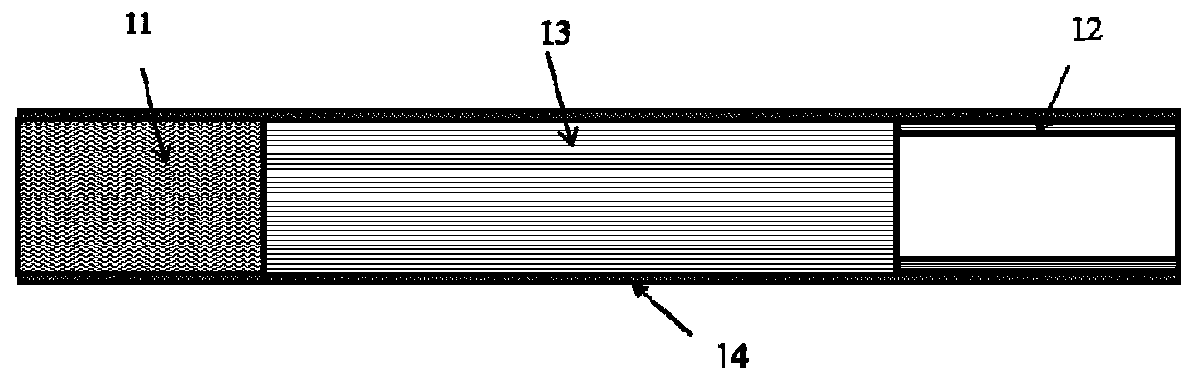

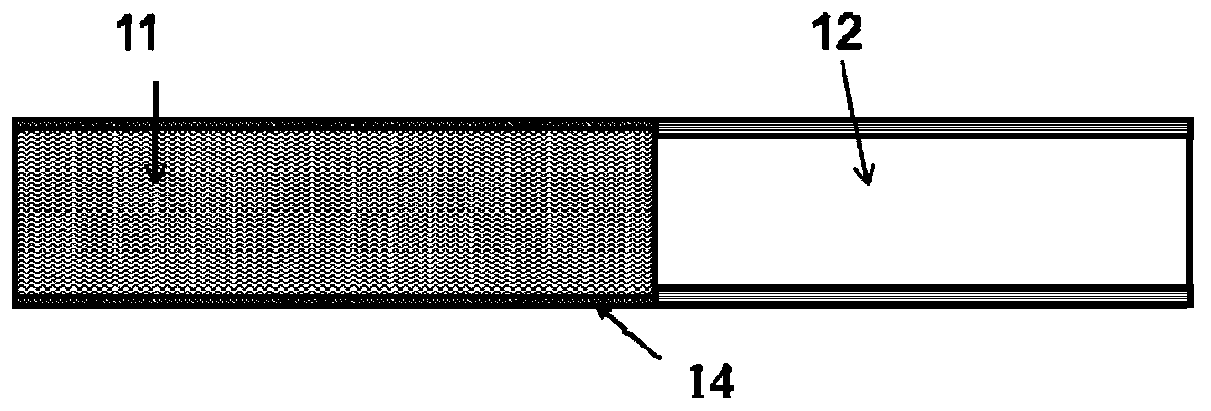

Three-component-unit compounding filter tip rod

InactiveCN105077576AReduce flue gas temperatureReduce suction resistanceTobacco smoke filtersFilling materialsSmoke

The invention provides a three-component-unit compounding filter tip rod. The three-component-unit compounding filter tip rod comprises three component units including a solid filter (1), a cavity (2) and a filter (4) which are sequentially arranged from the near lip end to the far lip end, wherein a piece of first forming paper (5) covers the outer side of the solid filter (1); a piece of first forming paper (5) covers the outer side of the filter (4); then, the three component units are compounded and formed through a piece of second forming paper (6); and the cavity (2) is filled with filling materials (3). The three-component-unit compounding filter tip rod has the effects of lowering the smoke gas temperature, increasing the smoke quantity, reducing the sucking resistance, reducing the CO content in the smoke gas and the like.

Owner:CHINA TOBACCO YUNNAN IND

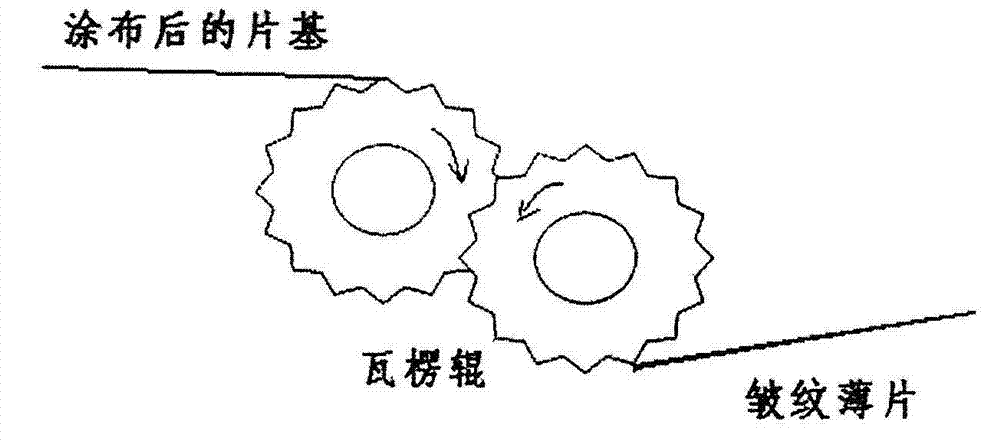

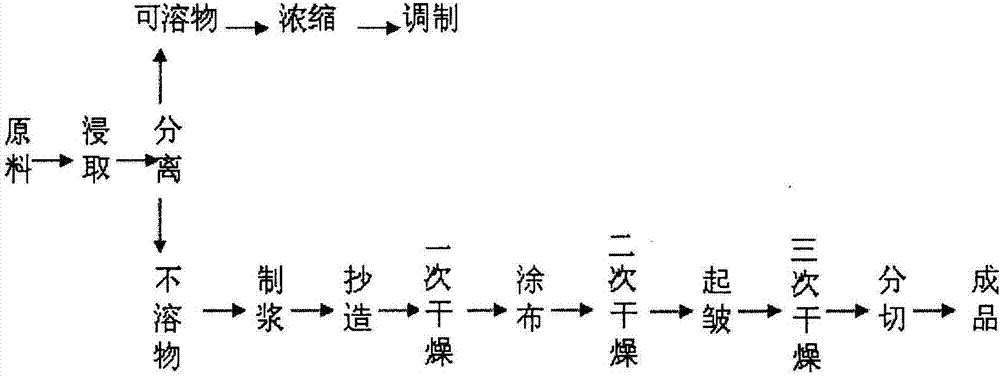

Manufacturing technique of tobacco remaking with fold paper-making method

InactiveCN103082396AEasy to fillGood size controllabilityTobacco preparationCombustionInsoluble fiber

The invention provides a manufacturing technique of tobacco remaking with a fold paper-making method. The manufacturing technique of tobacco remaking with the fold paper-making method comprises the following steps: raw materials of tobacco are soaked and extracted through extraction agent, insolubility fiber materials are separated from soluble substances, film base is made of insoluble substances through pulping, coating liquid is made of the soluble substances by concentration in a modulation mode, and the coating liquid is dip-coated or spray-coated on a slice film base, and enters a drying machine to dry. The manufacturing technique of tobacco remaking with the fold paper-making method is characterized in that slice film base after being dried is made to be diamond-shaped through a pair of corrugated rollers reversely rotating, and is made into a fold tobacco slice after being dried and cut. The manufacturing technique of tobacco remaking with the fold paper-making method is not limited by drying modes, is simple in manufacturing technique, and capable of being widely applied to the production of tobacco remaking with the fold paper-making method, and facilitates improving padding performance of remade tobacco, and reducing consumption of raw materials and production cost. According to measurement and calculation, compared with the prior ordinary tobacco remaking, the manufacturing technique of tobacco remaking with the fold paper-making method can save the consumption of the raw materials by 1.0% or so, improve combustion performance of cigarettes, reduce suction resistance and improve suction quality of the cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

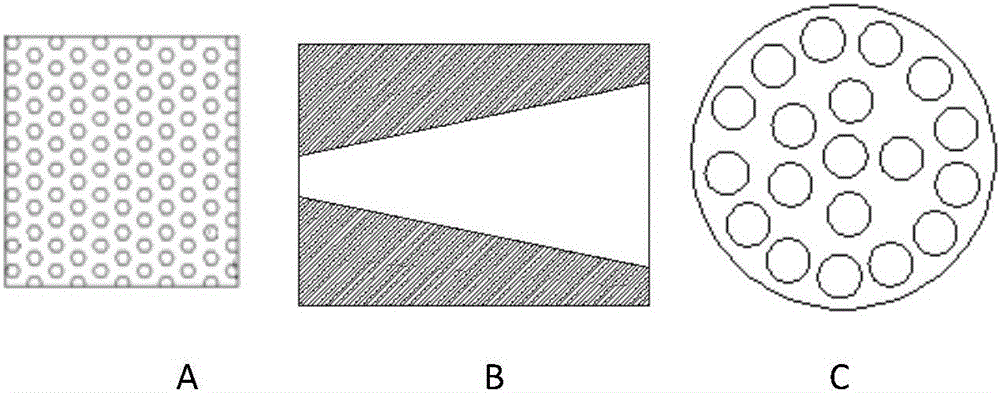

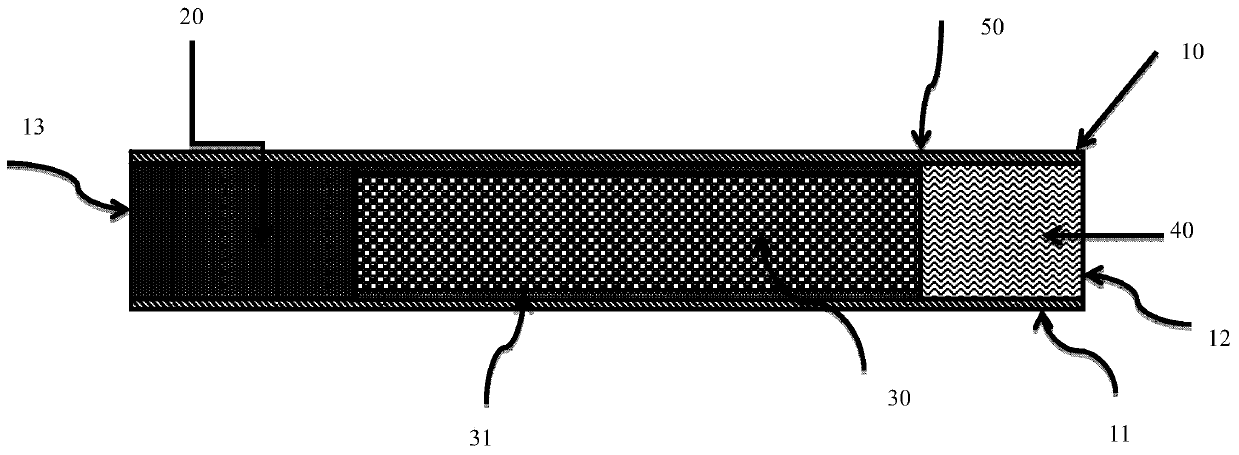

Aerosol product, preparation method and application

ActiveCN109691697AImprove cooling effectReduce the temperatureCigar manufactureTobacco smoke filtersParticulatesEngineering

An aerosol product comprises an aerosol atomizing unit and a smoke cooling unit located downstream of the smoke flow direction produced by the aerosol atomizing unit; the aerosol product further comprises a filtering unit located downstream of the flow direction of smoke passing the smoke cooling unit or comprises a hollow unit located upstream of the flow direction of smoke passing the smoke cooling unit. The structure is formed by particle aggregation and contains gaps allowing cigarette smoke to pass, and the gaps allowing the cigarette smoke to pass are three-dimensional and non-linear. The structure is bar-type. When cigarette aerosol passes the cooling unit, the smoke is endowed with smooth channels. A porous substance has through holes, so that low suction resistance can be kept while large smoke cooling area is provided, smoke flux is guaranteed, and experience of a cigarette consumer is improved.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

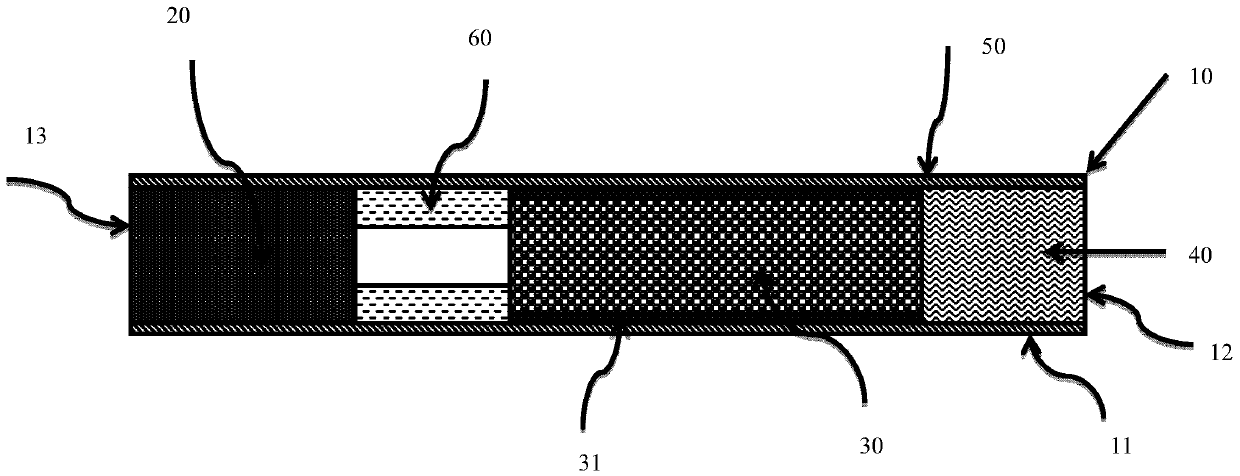

Heating non-combustible cigarette

PendingCN108669662APrevent fallingGuaranteed cleanlinessTobacco devicesEngineeringBiomedical engineering

The inVention belongs to the technical field of noVel cigarettes, and particularly relates to a cigarette structure of a heating non-combustible cigarette. The heating non-combustible cigarette is composed of a cylinder hollow coiling block and a cigarette front section, a cigarette middle section and a cigarette back section which are sequentially arranged inside the coiling block, and the diameters of the cigarette front section, the cigarette middle section and the cigarette back section are all equal to the inner diameter of the coiling block. By forming multiple sheet heating body insertion grooVes, a consumer can conVeniently insert sheet heating bodies into cigarettes. When the structure of the multiple sheet heating body insertion grooVes is adopted for heating, the surplus sheet type heating body insertion grooVes and suction resistance regulating air holes can jointly achieVe the air guiding effect, and the insertion grooVes can also replace the suction resistance regulatingair holes to directly achieVe the air guiding effect.

Owner:赵雪

High-efficiency cigarette filter tip containing nano-carbon material

The invention provides a high-efficiency cigarette filter core containing a nano-carbon material and a cigarette filter tip prepared from the same. The cigarette filter core is characterized in that nano-carbon particles which are absorbed on fiber bundles, are subjected to surface modification and have rich active groups and high specific surface area can remove a plurality of free radicals as well as poisonous and harmful substances such as benzopyrene (a, b) and partial cigarette tar in cigarette smoke through physical and chemical absorption when the cigarette smoke passes through the fiber bundles of the filter core of the filter tip. To improve the action effect, one or more auxiliary substances can be synchronously absorbed on the fiber bundles. The filter core does not affect the unique taste and filtration aeration of cigarettes during the smoking, and can effectively remove a plurality of the poisonous and harmful substances in the smoke and improve the mouthfeel at the sametime. The filter core can be used for producing disposable cigarette filter tips, filter tips on the cigarettes, and filter tips in matroospipes to reduce the hazard caused by smoking.

Owner:许以华

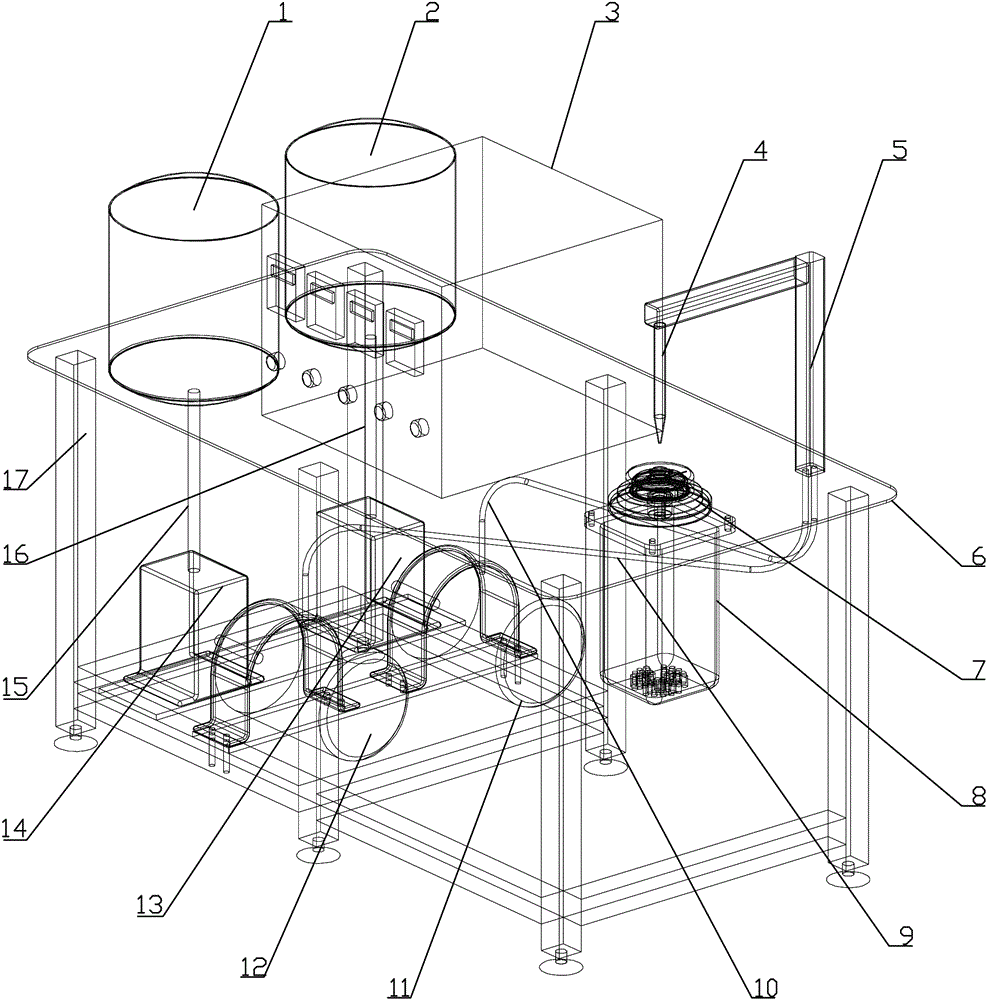

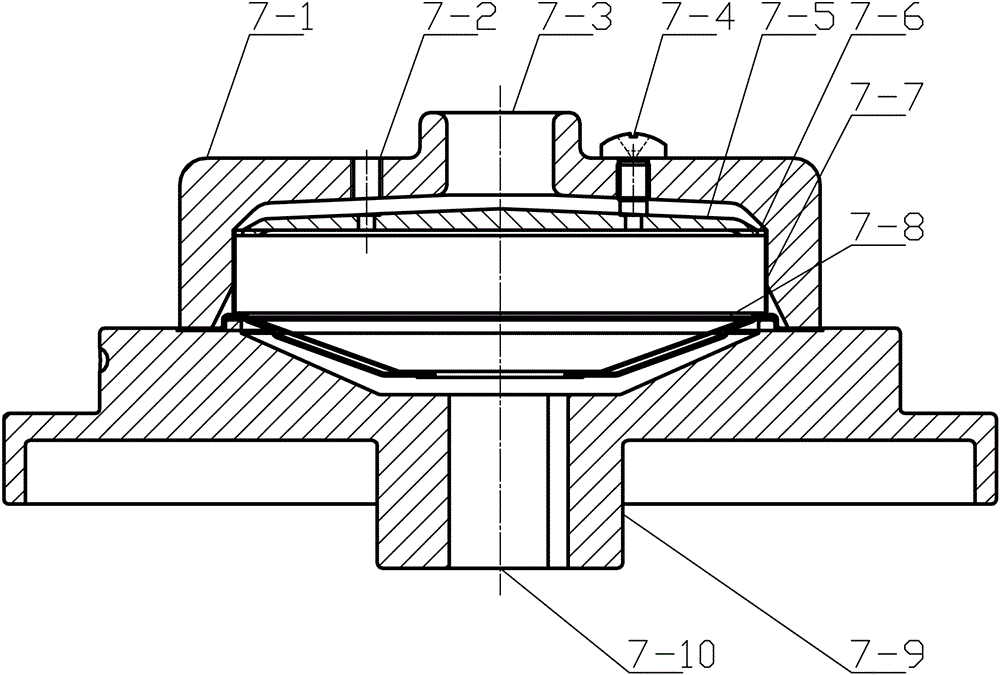

Automatic glue throwing and filling device and method for filtering piece

ActiveCN105880110AAdjustable spinning speedAvoid cloggingLiquid surface applicatorsCoatingsVacuum pumpNarrow gap

The invention discloses an automatic glue throwing and filling device and method for a filtering piece, and belongs to automatic glue throwing and filling devices in the technical field of chemical defense. The automatic glue throwing and filling device mainly comprises accessories including a first glue tank, a second glue tank, a control box, a mixer, a mixer support, a working table, a glue filling clamp, a variable frequency motor, a first glue outlet tube, a second glue outlet tube, a second vacuum pump, a first vacuum pump, a second buffering tank, a first buffering tank, a first glue inlet tube, a second glue inlet tube, a connecting cable and the like. Multi-component glue can be mixed uniformly, and is automatically thrown into a narrow gap between the outer shell of the filtering piece and a filtering element for precision glue filling by the glue filling clamp which is designed specially, so that a surface, which is in contact with the filtering element, of the outer shell of the filtering piece is sealed completely, and quite high consistent sealing level and glue filling appearance quality are obtained.

Owner:HUBEI HUAQIANG HIGH TECH CO LTD

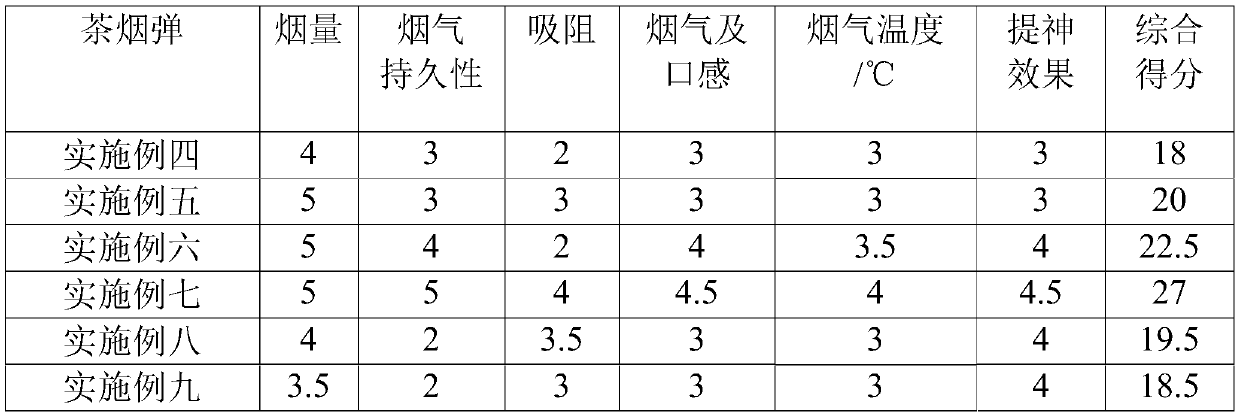

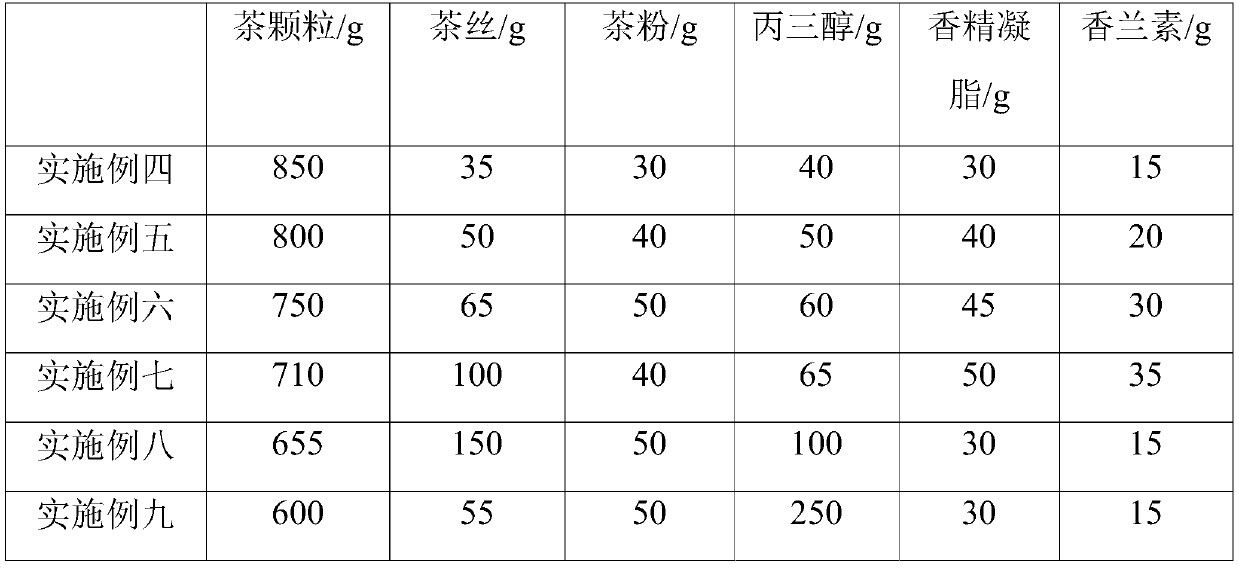

Smoke formation matrix for electronic cigarette cartridge and preparation method

Embodiments of the invention disclose a smoke formation matrix for an electronic cigarette cartridge and a preparation method. The smoke formation matrix comprises the following components in parts byweight: 60-85 parts of tea particles, 3.5-15 parts of tea shreds, 3-5 parts of tea powder and 4-25 parts of a smoking agent. A mixture of the tea particles, the tea shreds and the tea powder is usedas the smoke formation matrix; compared with tobacco shreds, harmful substances such as tar, nicotine and the like are not contained in smoke generated after smoking of a tea product, so that environment-friendliness and healthiness are achieved; in addition, the particle sizes of mixtures are different, so that the overall density of the smoke formation matrix and the smoking resistance during smoking can be adjusted; and due to the setting of different particle sizes, the smoke can be released in a gradient manner to improve the durability of the smoke.

Owner:SHENZHEN SHUNBAO TECH CO LTD

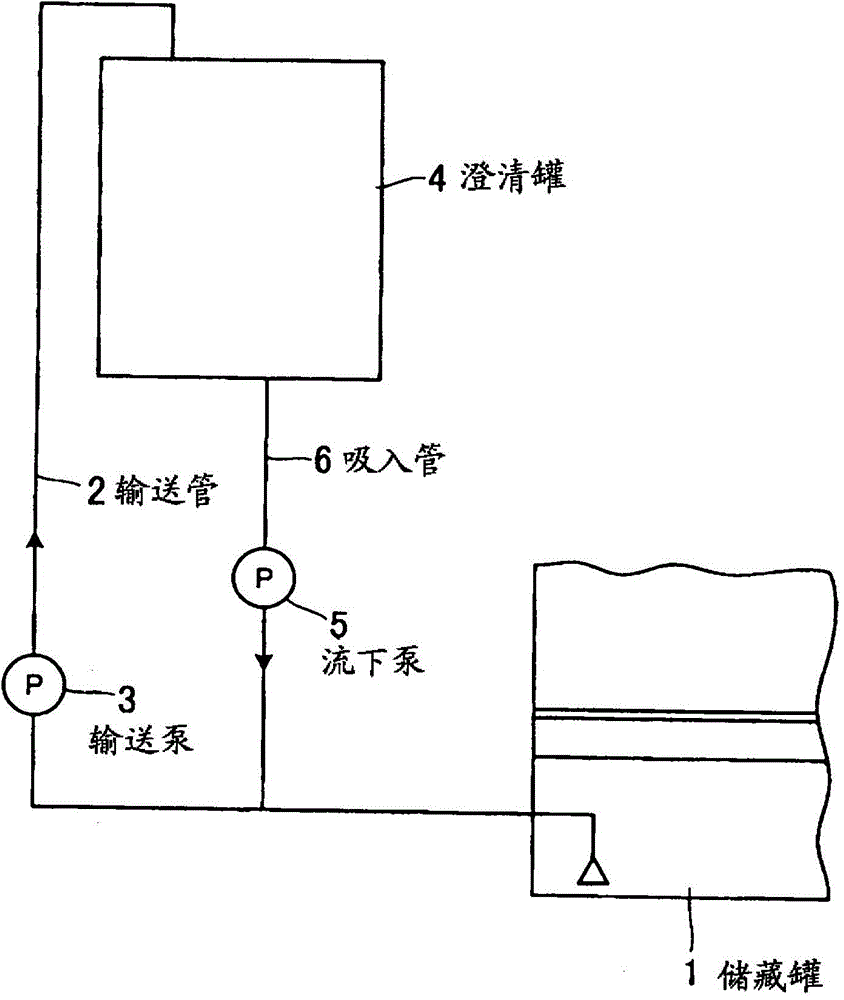

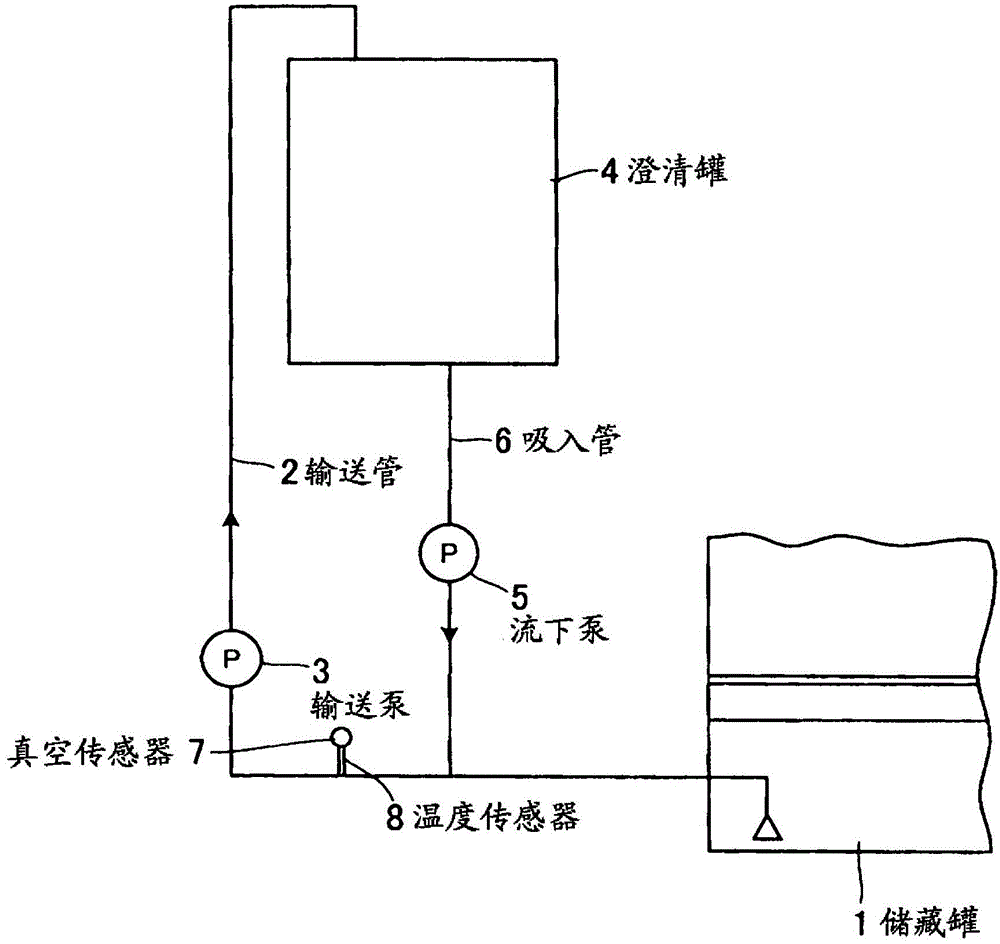

Heating method of fuel oil

ActiveCN104443339AImprove power loadReduce conveying speedPropulsion power plantsMachines/enginesEngineeringFuel oil

The present invention aims for improving power load of a delivery pump and reducing absorbing resistance of a delivery pipe. When the delivery pump (3) of the fuel oil is used for delivering, a downflow pump (5) is kept to operate continuously, so that the high temperature oil form the downflow pump (5) is mixed and delivered to the fuel oil form a storage tank (1) and absorbed by the delivery pump (3) so that the viscosity of the fuel oil is reduced, and therefore the power load of the delivery pump (3) is improved, the delivery amount of the fuel oil form the storage tank (1) is reduced as much as the amount of the downflow oil, the delivery speed of the storage tank is reduced and the absorbing resistance is reduced.

Owner:HOKUSHIN ENG

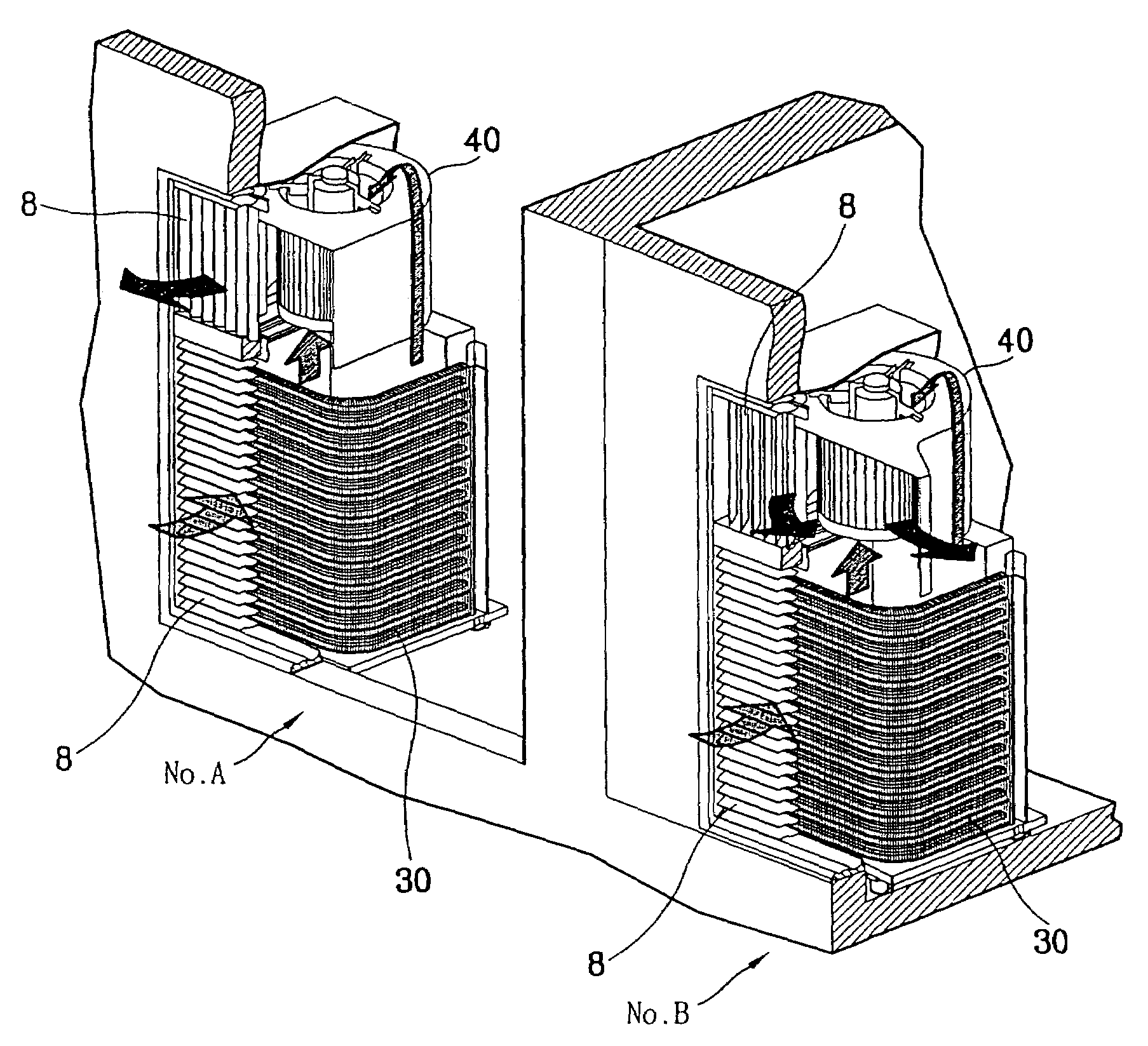

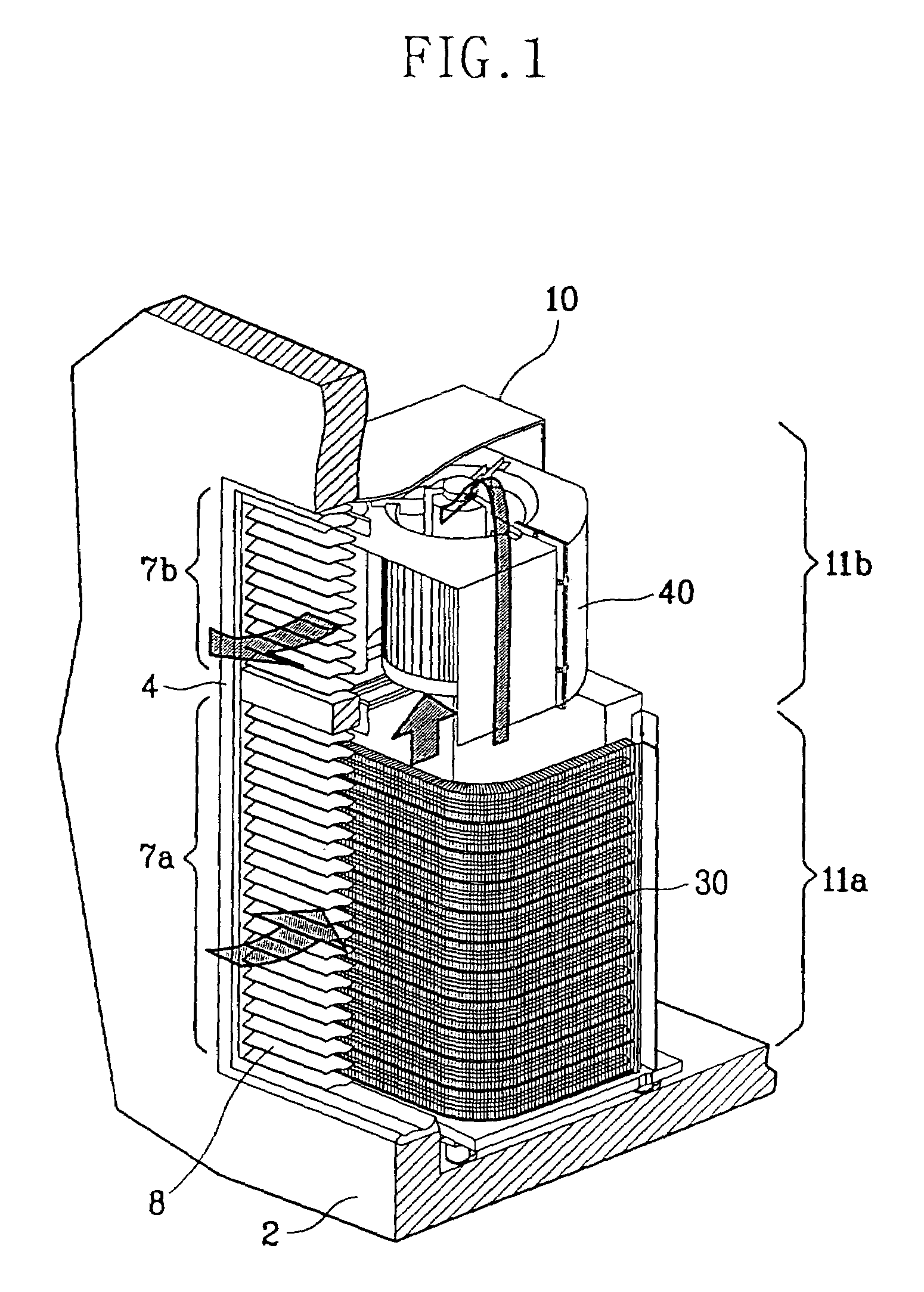

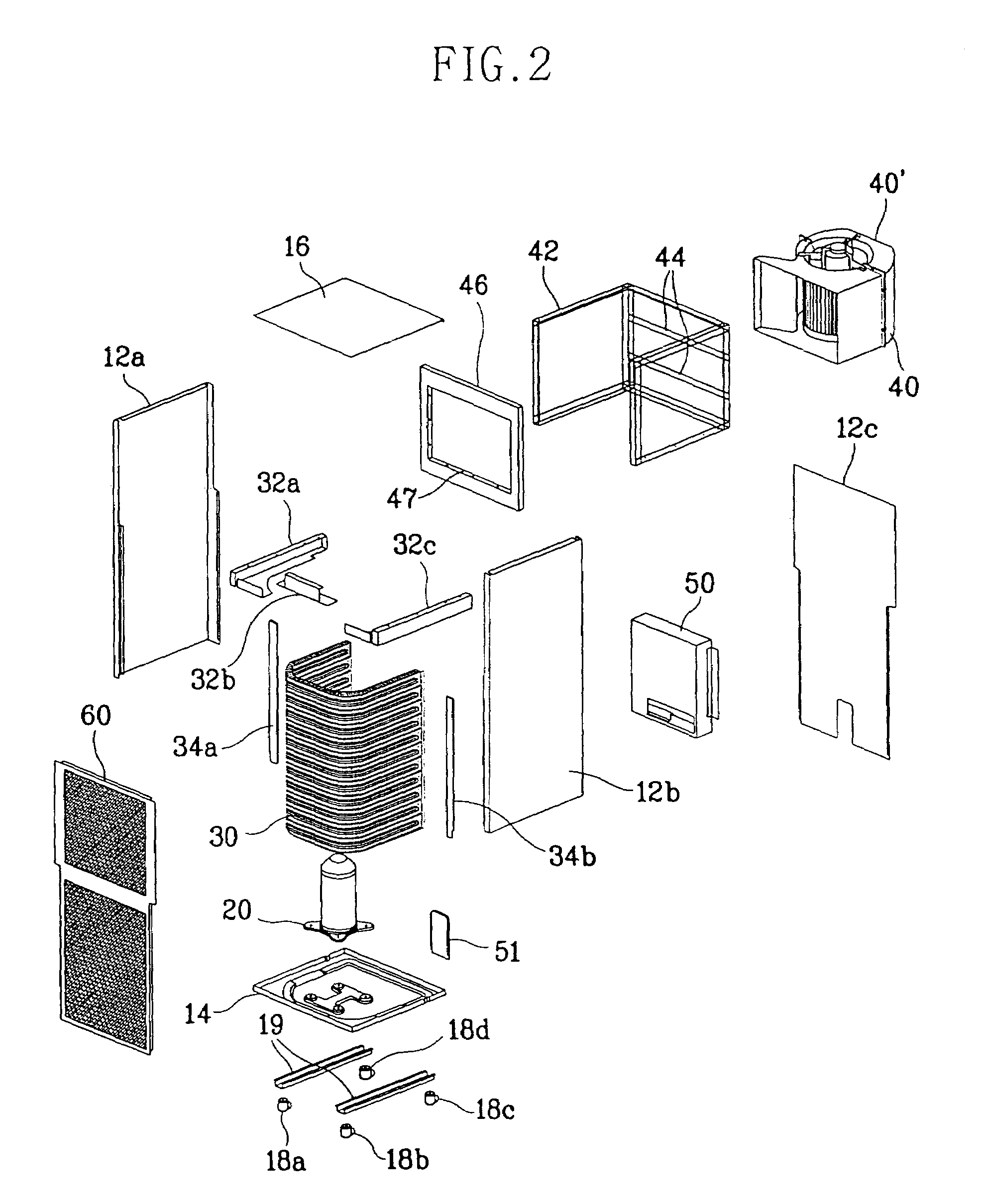

Front suction/discharge type outdoor unit for air-conditioner and outdoor unit installation system using it

InactiveUS7191616B2Minimize of heat exchange efficiencyReduce heat exchangeHeating and ventilation casings/coversEvaporators/condensersEngineeringRefrigerant

The present invention discloses a front suction / discharge type outdoor unit for an air conditioner including: an outdoor unit casing being formed in a rectangular parallelepiped shape, having its one surface externally opened and its other surfaces closed, and being divided into a suction unit and a discharge unit; a compressor installed in the outdoor unit casing, for compressing a refrigerant gas supplied from an indoor unit through pipe lines; an air-cooled condenser positioned in the outdoor unit casing, for condensing the refrigerant gas from the compressor; and a sirocco cooling fan installed in the outdoor unit casing, for forming a diffuser opposite side part of a curvature unit of a housing as a plane unit, forming the fan housing to separate a diffuser opposite side member from a diffuser side member, supplying external air to the air-cooled condenser, and discharging heat exchanged air. A discharge direction of air from the sirocco cooling fan becomes more distant from the most adjacent outdoor unit.

Owner:LG ELECTRONICS INC

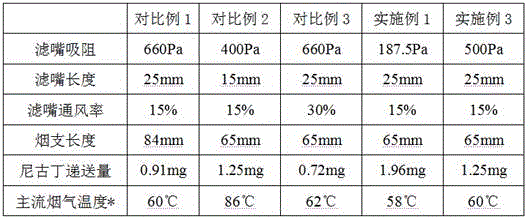

Filter stick for short cigarettes

The invention discloses a filter stick for short cigarettes. A thin-film material is taken as a filter material, and the filter stick with a porous cross section is formed by bundling the thin-film material. By reducing the suction resistance of the filter stick for the short quickly-smoked cigarettes, the interception of nicotine is reduced, the smoking mouth feel of the short quickly-smoked cigarettes is relatively guaranteed, the satisfaction of the cigarettes is improved, and the demand of solving the smoking addiction of a smoker is met; after the filter stick which is prepared from the thin-film material and has low suction resistance is used, the temperature of smoke flow is effectively reduced, and the temperature of the smoke flow reaching the oral cavity is reduced to an appropriate degree, so that a thermal prickle caused by the too hot smoke flow is avoided, and the appropriate mouth feel is guaranteed; the filter stick is simple in technology and convenient to mold; compared with an acetate fiber filter stick, the filter stick provided by the invention is lower in cost under the same conditions; the filter stick can be separately used as a filter tip of the short quickly-smoked cigarette, and also can be prepared into a binary or polynary composite filter stick by being compounded together with the acetate fiber filter stick or functional filter sticks (such as a particle filter stick, a wire-buried filter stick, a capsule filter stick and a hollowed-out filter stick) derived from the acetate fiber stick, or is prepared into a coaxial core filter stick, thus being used for the short quickly-smoked cigarettes.

Owner:YUNNAN YANGRUI TECH GRP

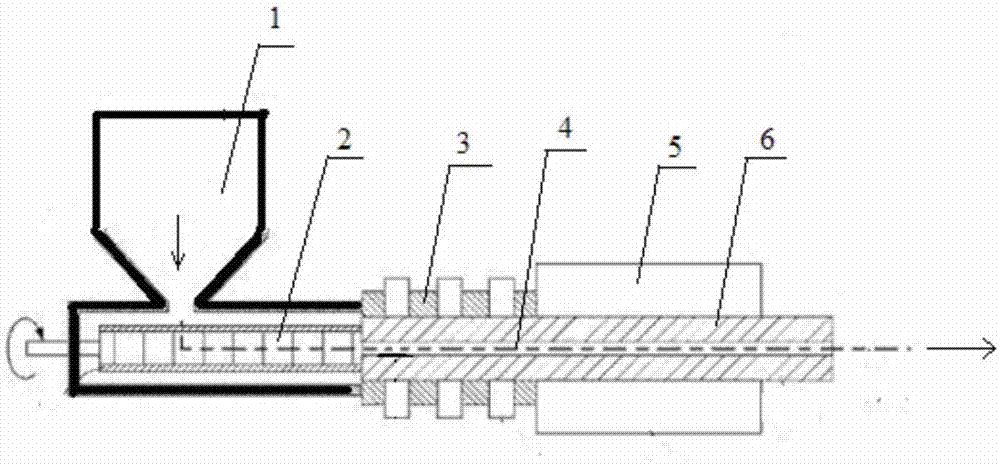

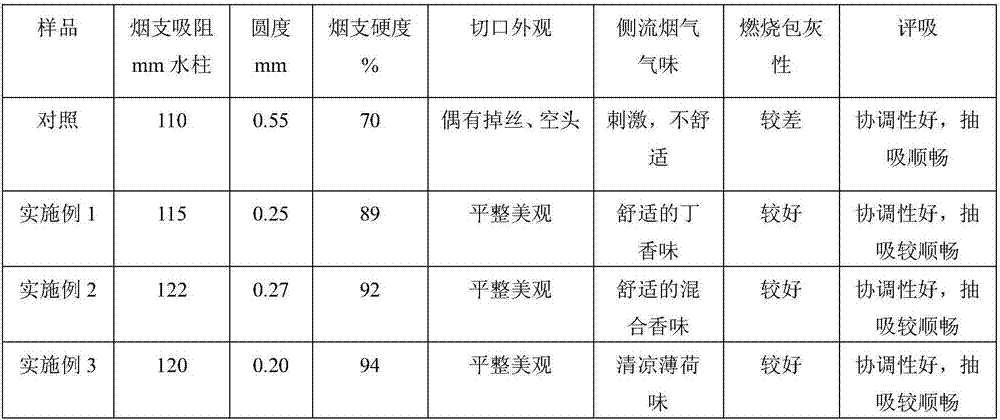

Preparation method of specially-shaped cigarettes with naturally endowed aroma

The invention discloses a preparation method of specially-shaped cigarettes with naturally endowed aroma. The preparation method comprises the following steps: respectively grinding a tobacco raw material and natural plant perfumes into powder, and uniformly mixing the powder, thus obtaining mixed powder; uniformly stirring a combustion promoter, an adhesive and a humectant, thus obtaining a mixedsolution; carrying out mixed granulation on the mixed powder and the mixed solution, and carrying out drying, thus obtaining tobacco particles; preparing the tobacco particles into tobacco particle round rods by adopting a tobacco particle round rod forming device; wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carrying out compounding withfilter sticks, thus obtaining the specially-shaped cigarettes with high homogenization, good stability and naturally endowed aroma. The cigarettes are smooth in smoking, the aroma is fresh and elegant, and good sensual experience can be endowed to a smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

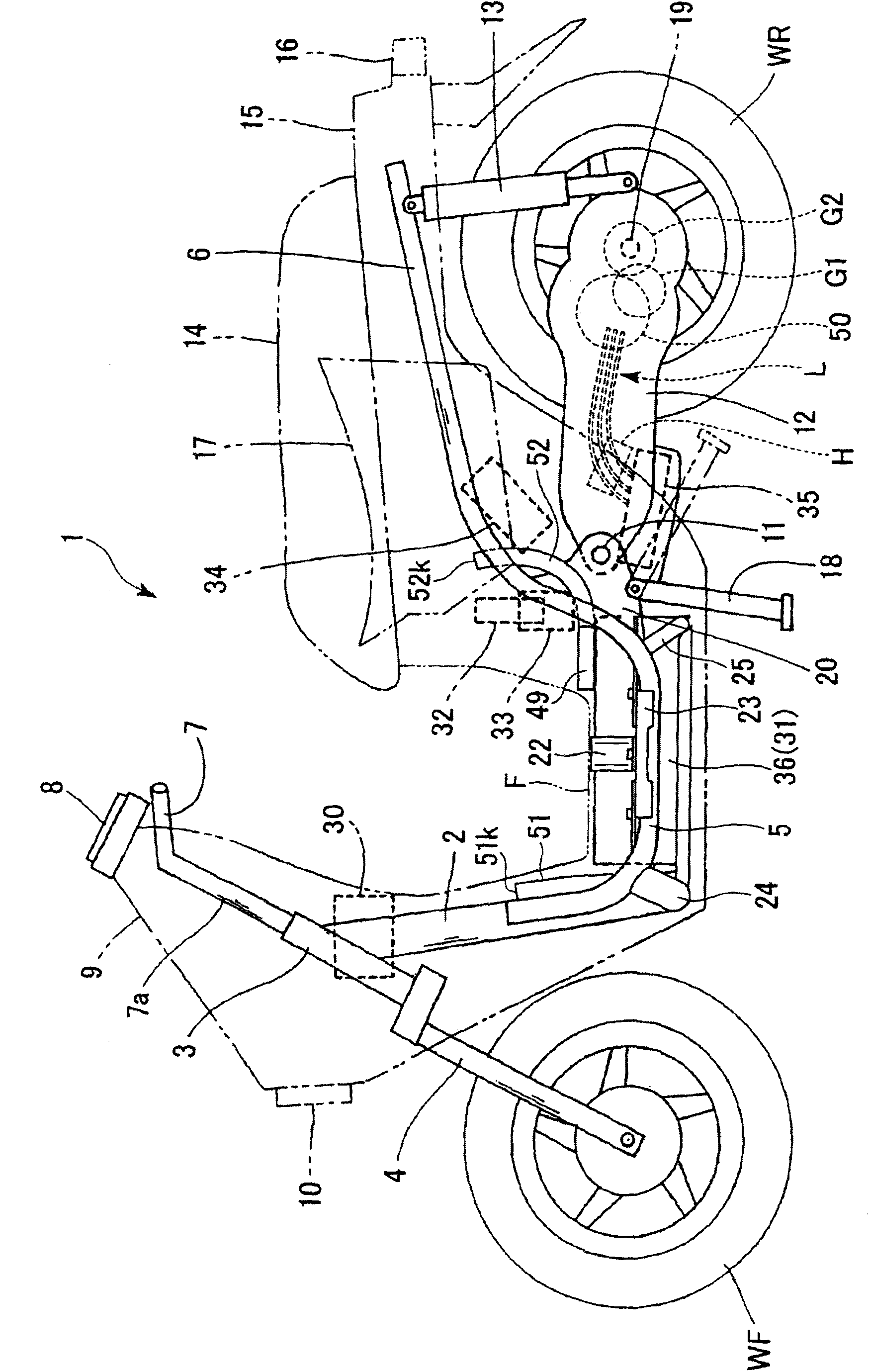

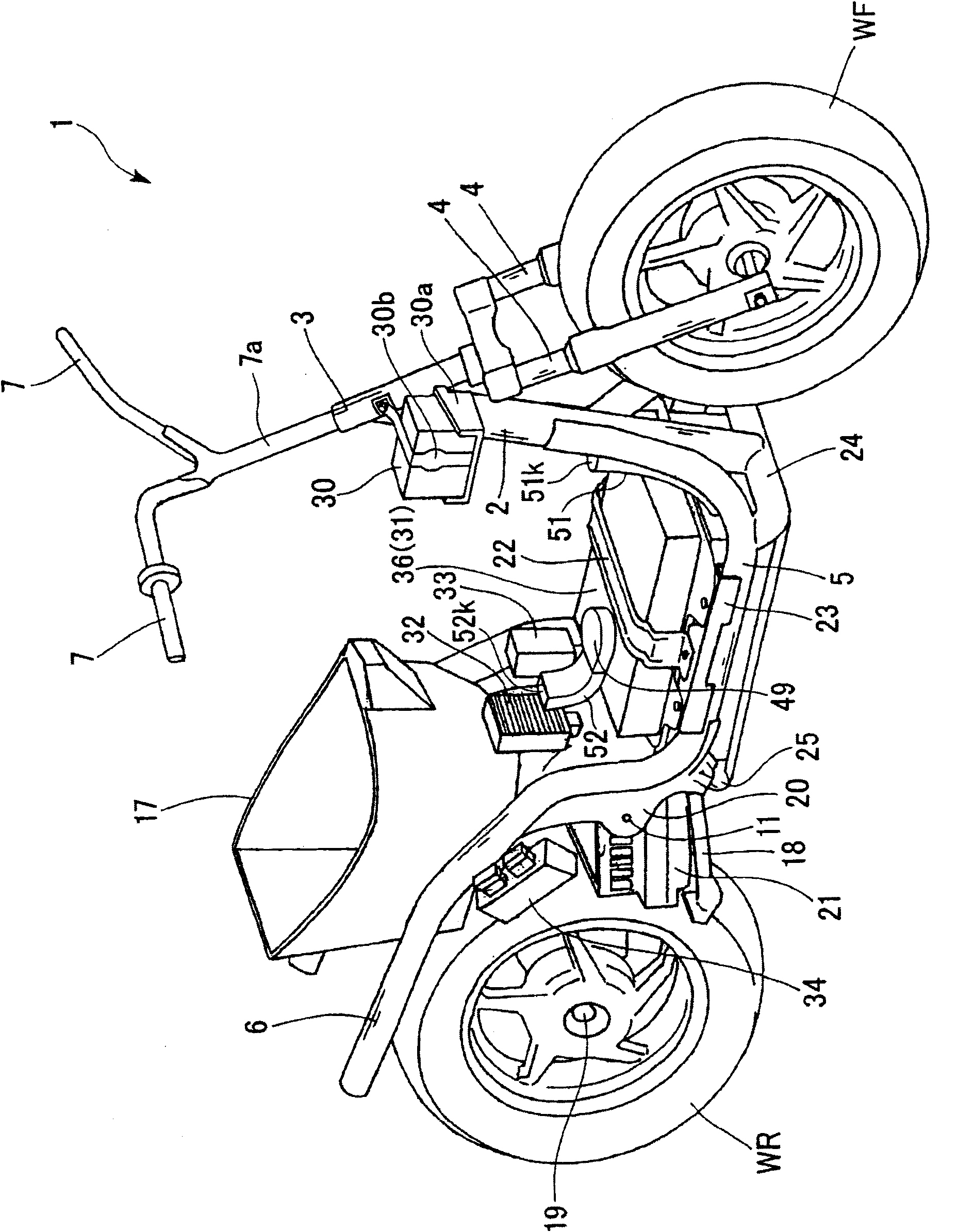

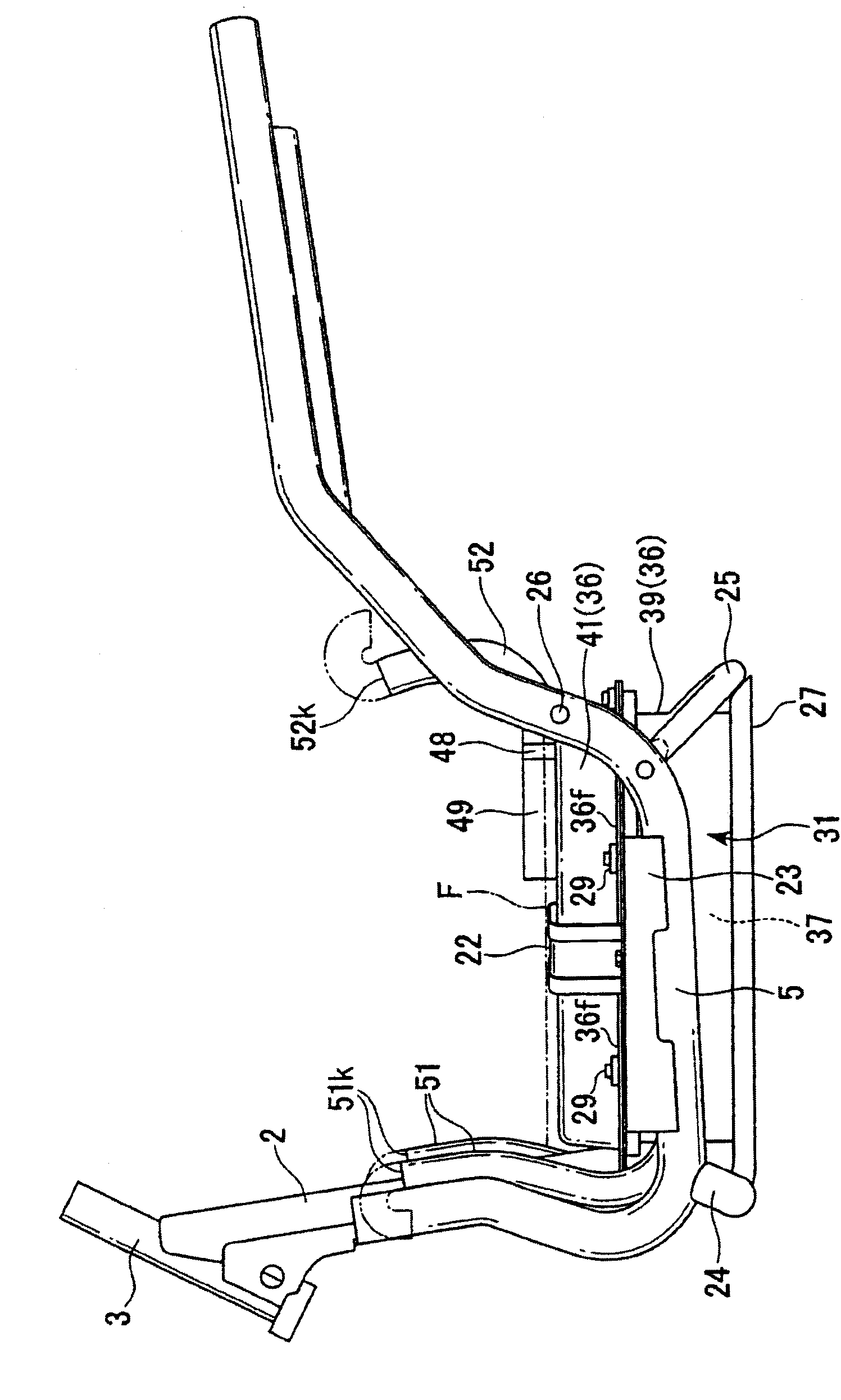

Accumulator device for motorcycle

ActiveCN101847737APrevent floodingImprove cooling effectMotorised scootersCell temperature controlEngineeringElectric motor

The invention provides an accumulator device for a motorcycle, which seeks for a low centre of gravity and includes an accumulator box (36) arranged under a foot pedal section (F), an electric motor for driving, a control device (34) for controlling the electric motor (50) to drive, a sucking pipe (51) which introduces air to the accumulator box (36) and a discharge pipe (52) which discharges the interior air, wherein the opening sections (51k, 52k) of the sucking pipe (51) and the discharge pipe (52) are arranged on top of the foot pedal section (F).

Owner:HONDA MOTOR CO LTD

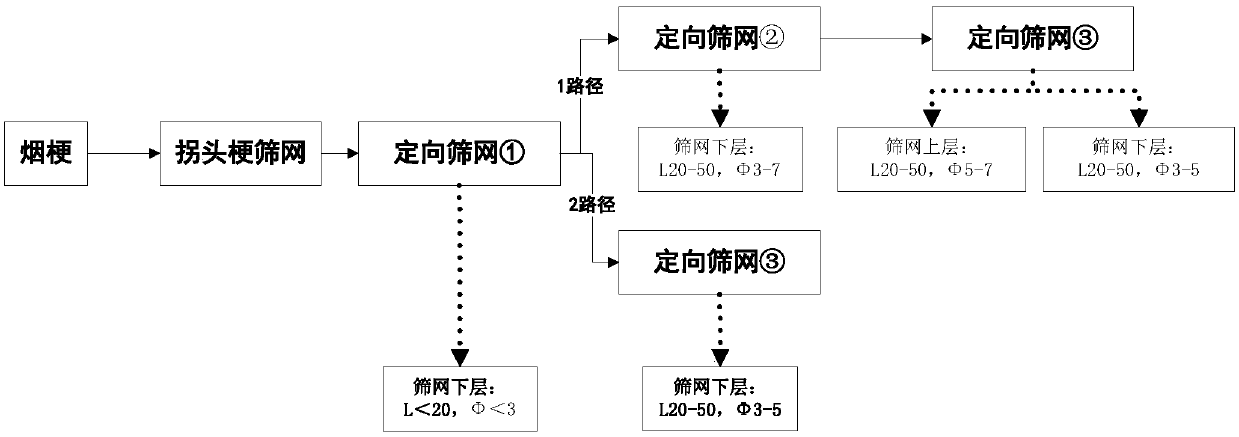

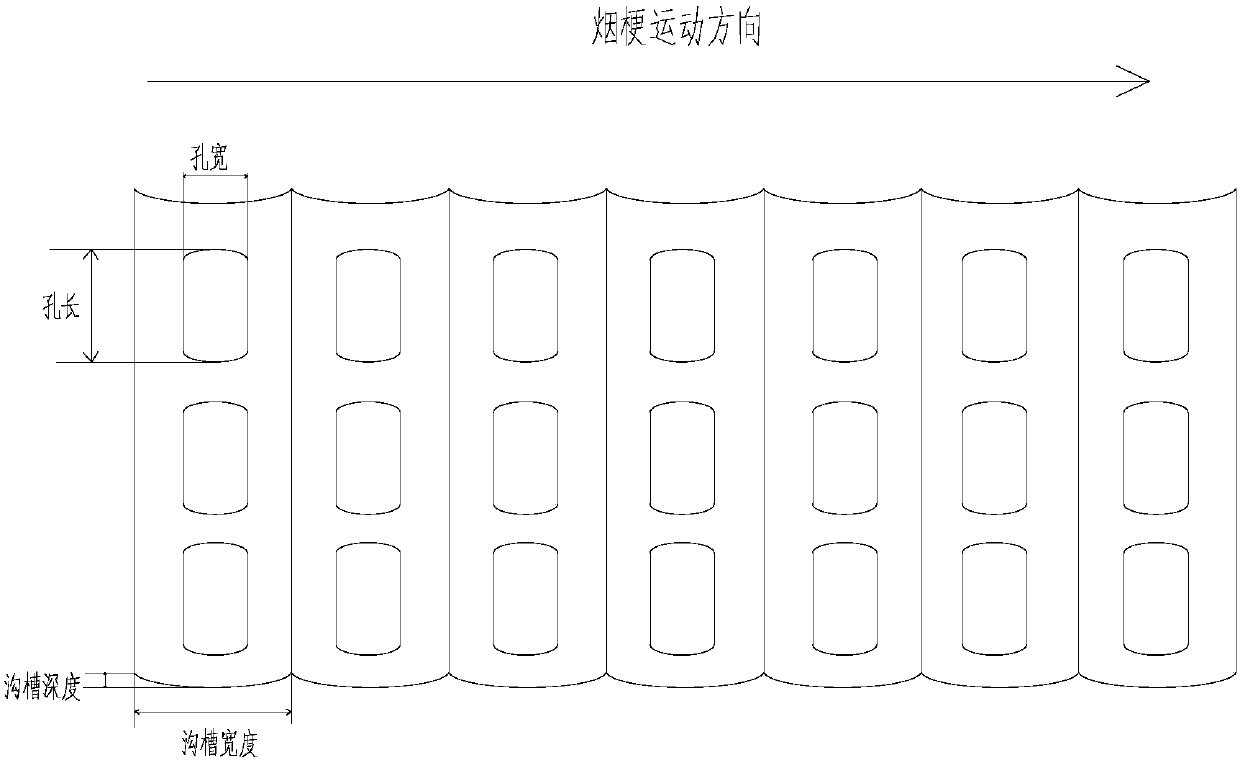

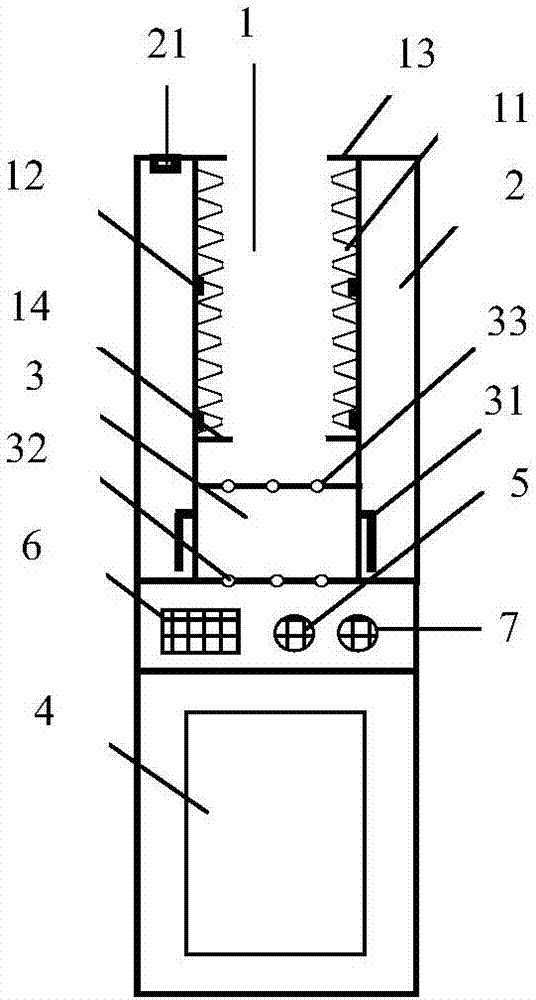

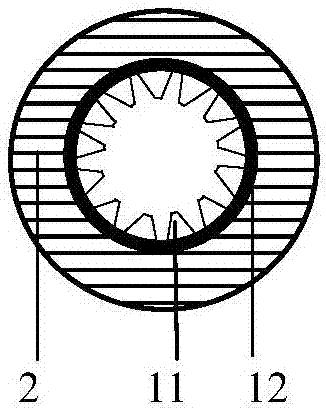

Tobacco stem sorting method suitable for different cigarettes

The invention provides a tobacco stem sorting method suitable for different cigarettes. The method comprises the following steps: (1) preliminary screening of tobacco stems; (2) first screening: screening the tobacco stems obtained by the preliminary screening in the step (1) by adopting a vibrating screen screening device with a directional screen (1); (3) second screening: dividing the tobacco stems obtained in the step (2) into two strands, wherein the first strand is screened by a vibrating screen screening device with a directional screen (2) and the second strand is screened by a vibrating screen screening device with a directional screen (3); (4) third screening: screening the tobacco stems screened by the vibrating screen screening device with the directional screen (2) in the step(3) by using a vibrating screen screening device with a directional screen (3); and (5) respective collecting, packaging and marking and storing of the screened tobacco stems. According to the methodprovided by the invention, process route selection can be carried out according to actually required tobacco stem types. According to the method provided by the invention, the incoming quality of thetobacco stems is improved, so that the cut tobacco stem forming quality is improved, the cigarette quality is improved, and the blending of fine cut cigarette stems can be realized.

Owner:HUBEI CHINA TOBACCO IND

Double heating type low-temperature cigarette smoking set

The invention discloses a double heating type low-temperature cigarette smoking set. The double heating type low-temperature cigarette smoking set is characterized by comprising a hollow cylindrical heating cavity, a tobacco tar bin, an atomizing device, a support frame and a gas inlet hole, wherein a heating wire is placed in the hollow cylindrical heating cavity; a truncated cone shaped projection is arranged on the inner wall of the hollow cylindrical heating cavity; a rotary cover is arranged at an end of the tobacco tar bin; the tobacco tar bin is connected with the atomizing device through a liquid guiding bar; the atomizing device communicates with the gas inlet hole and is provided with a ventilating hole which communicates with the bottom end of the heating cavity; and the heating cavity and the atomizing device are placed in the hollow cylindrical tobacco tar bin in parallel. On one hand, the inner wall of the heating cavity is heated by the heating wire, and a cigarette is heated directly; and on the other hand, atomized smoke is heated when flowing through a trapezoidal cross section channel in the heating cavity so as to indirectly heat the cigarette. Because the double heating mode is adopted, the prefect heating effect can be achieved under the condition that the temperature of the heating wire only needs to be 150-200 DEG C when the smoking set works normally, cigarette gelatinization and scalding of a user by smoke are avoided effectively, and smoking taste is improved.

Owner:CHINA TOBACCO JIANGSU INDAL

Preparation method of naturally aromatized cigarettes

The invention discloses a preparation method of naturally aromatized cigarettes. The preparation method comprises the following steps: grinding a tobacco raw material and natural plant perfumes into powder respectively, and uniformly mixing the powder with a pore-foaming agent, hot melt adhesive powder and a combustion improver, thus obtaining mixed powder; uniformly stirring an adhesive and a humectant, thus obtaining a mixed solution; carrying out mixed granulation on the mixed powder and the mixed solution, and preparing the obtained reconstituted tobacco / perfume composite particles into tobacco particle round rods by adopting a tobacco particle round rod forming device; and wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carryingout compounding with filter sticks, thus obtaining the cigarettes which are high in hardness, are mellow and full, and have regular and attractive cutting faces. The cigarettes are high in homogenization degree and good in stability, the problem that the homogenization is difficult to satisfy existing in the existing cigarettes is fundamentally solved, and the phenomena of tobacco shred falling atthe cut opening and empty head existing in the conventional cigarettes are avoided. The cigarettes are smooth in smoking and strong in satisfaction, the aroma is fresh and elegant, and good sensual experience can be endowed to a smoker.

Owner:CHINA TOBACCO HUNAN INDAL CORP

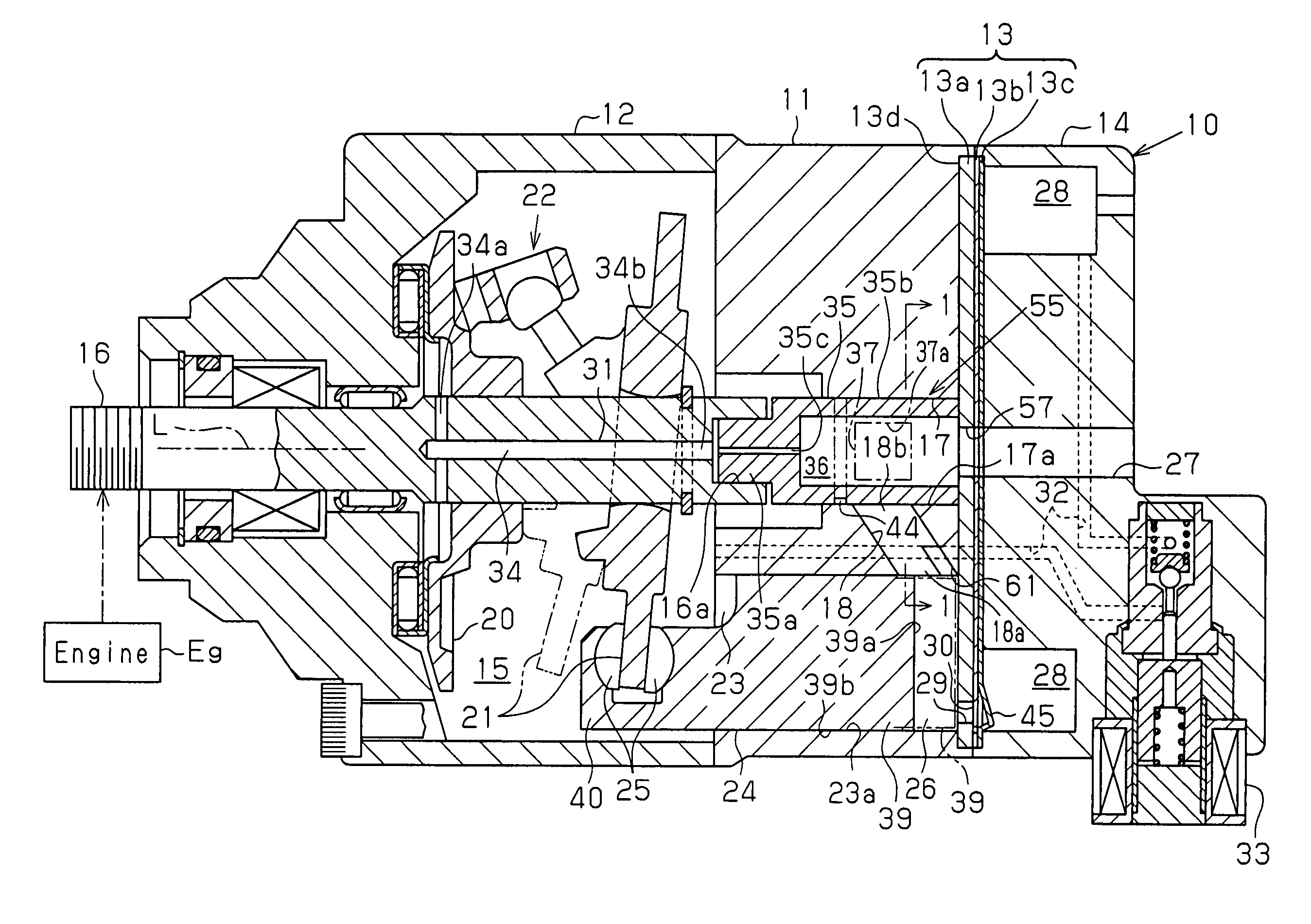

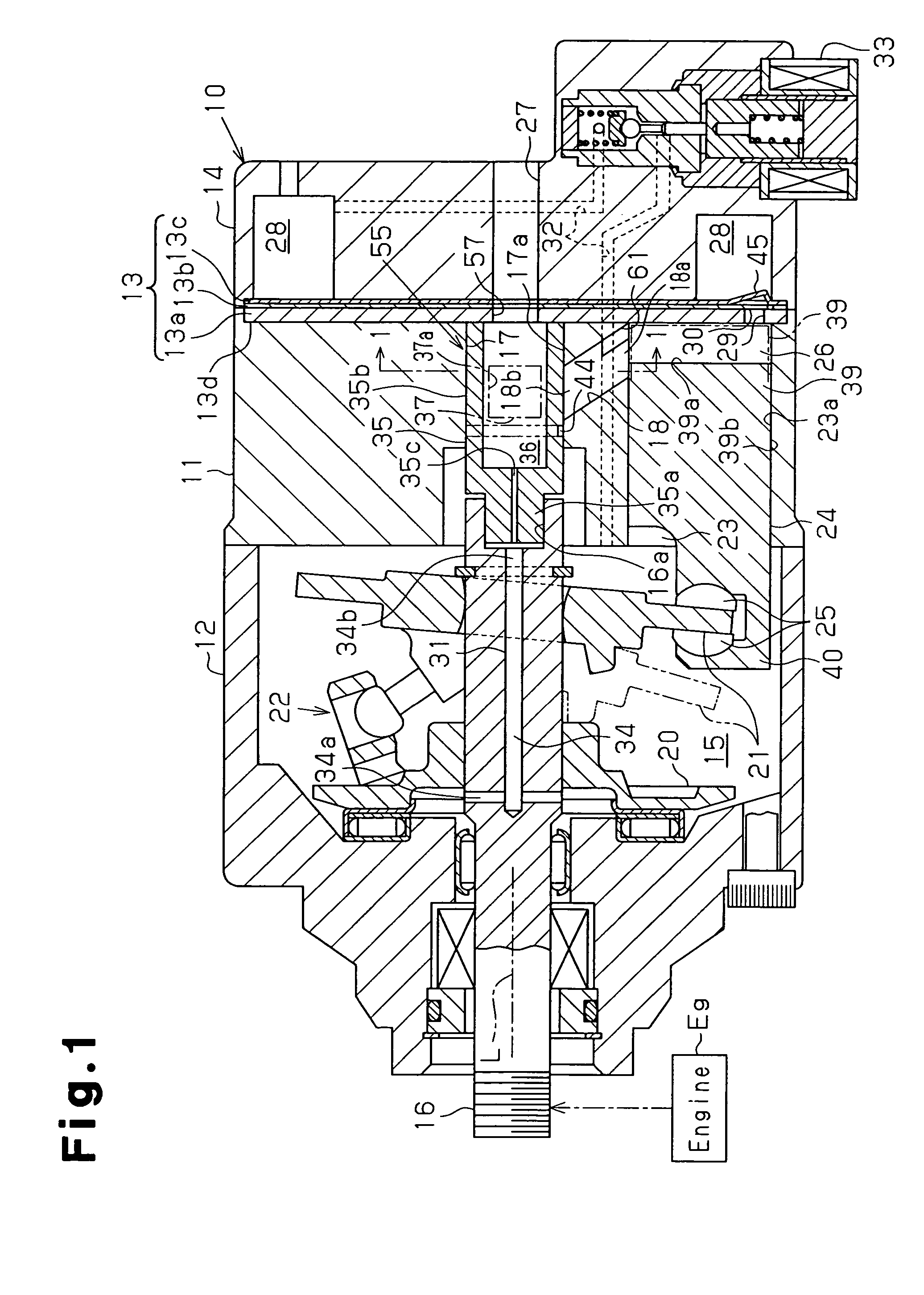

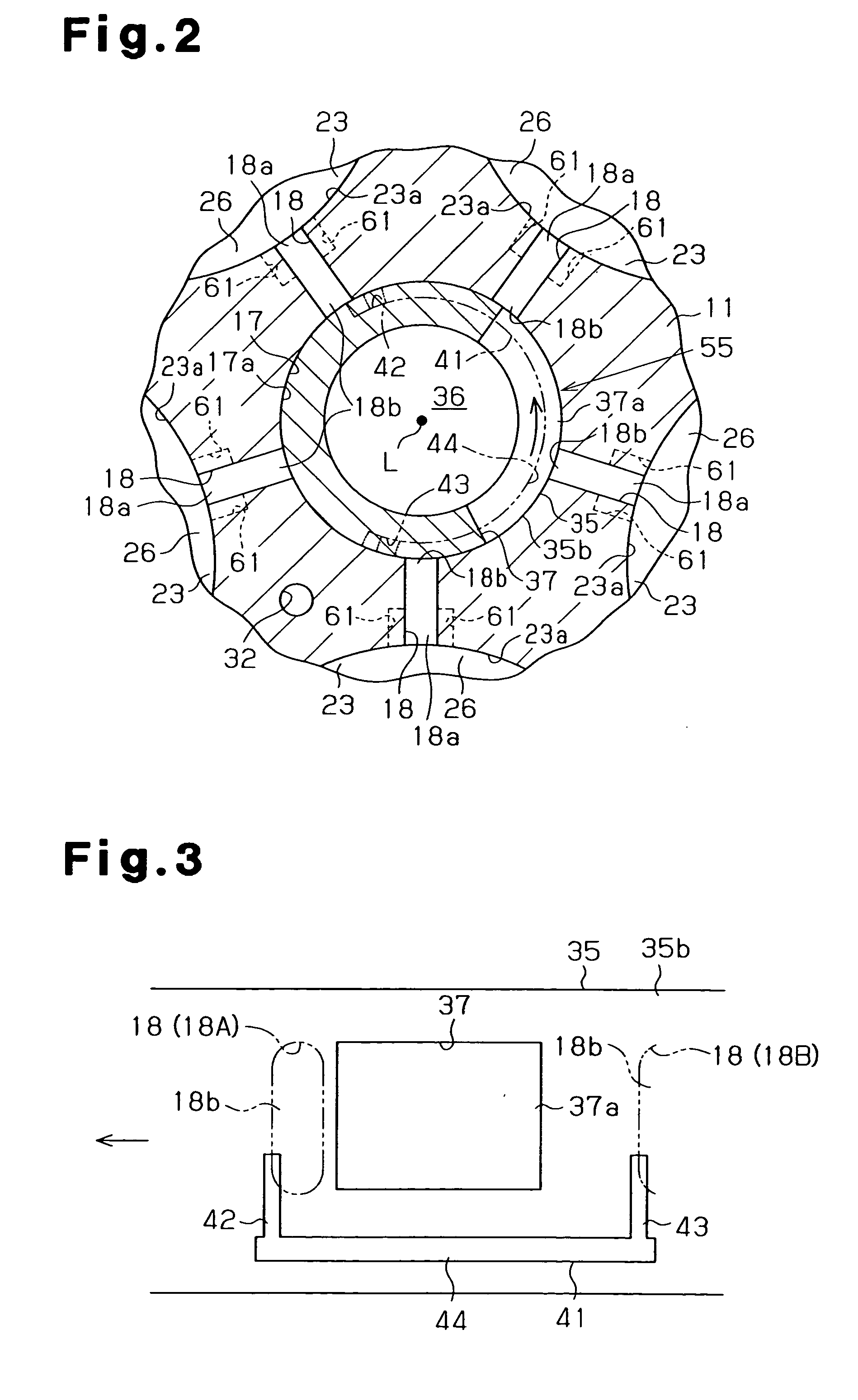

Piston compressor

InactiveUS20050196291A1Reduce suction resistancePositive displacement pump componentsPiston pumpsRotary valveEngineering

A piston compressor includes a rotary valve having a suction guide hole. A plurality of introducing passages are formed in a cylinder block to connect compression chambers to the rotary valve. The inner circumferential surface of each cylinder bore has a suction auxiliary recess, which is connected to the outlet of the corresponding introducing passage in the circumferential direction of the cylinder bore at the end of the cylinder bore facing a valve assembly. Therefore, the compressor reduces suction resistance of gas at the beginning of the suction stroke without enlarging introducing passages formed in the cylinder block.

Owner:TOYOTA IND CORP

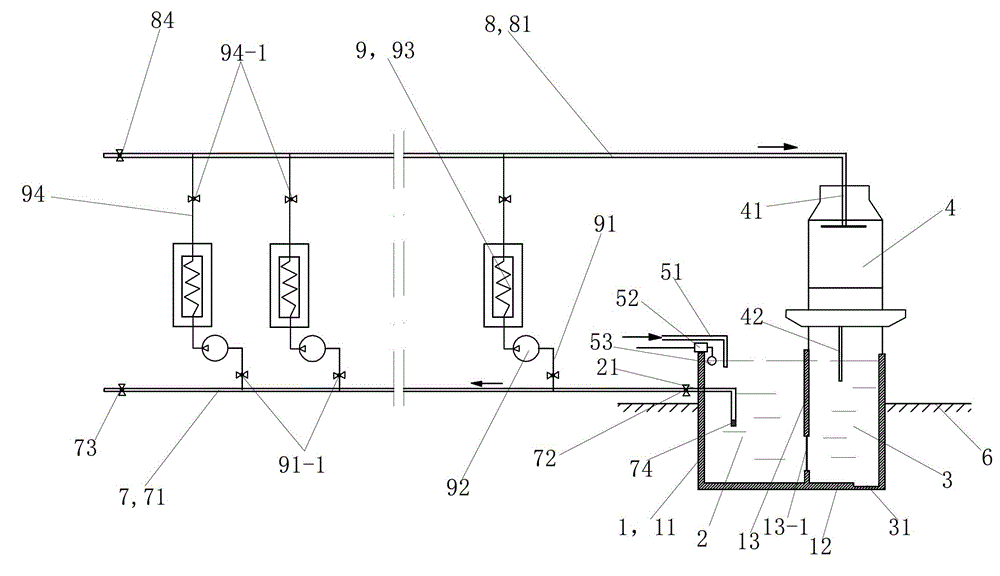

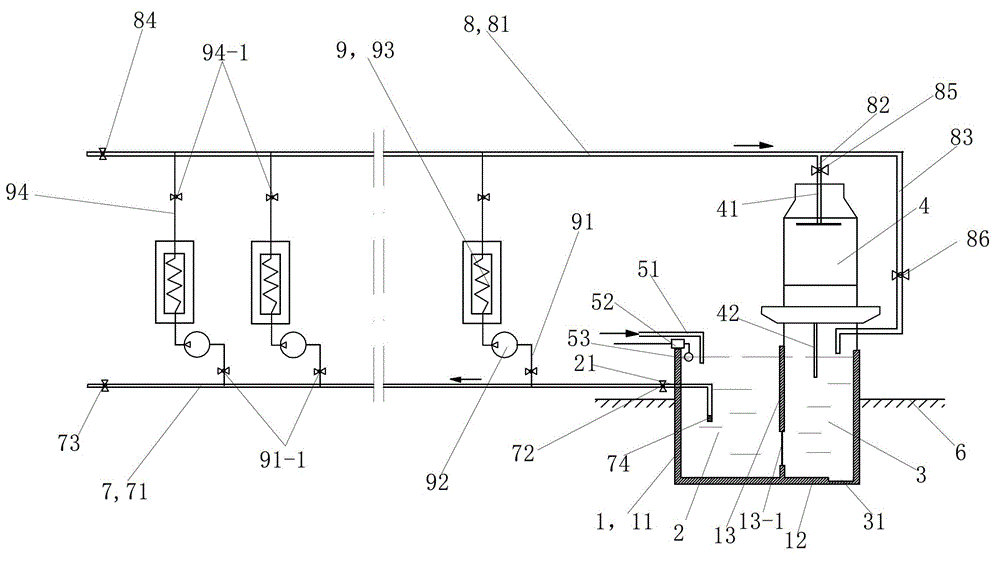

Cooling water circulation system of injection molding workshop

The invention discloses a cooling water circulation system of an injection molding workshop. The cooling water circulation system comprises a reservoir and a cooling water circulation pipeline. A reservoir body of the reservoir is divided into a water supply tank and a return water sedimentation tank by a partition, the tank wall of the water supply tank is provided with a water outlet, and the upper portion of the return water sedimentation tank is provided with a cooling tower. The cooling water circulation pipeline comprises a water inlet pipeline, a return water pipeline and cooling branches connected between the water inlet pipeline and the return water pipeline, each cooling branch comprises a subsidiary water inlet pipeline, a water pump, a heat exchanger and a subsidiary return water pipeline sequentially, a subsidiary water inlet of the water inlet pipeline of each cooling branch is connected onto a main water inlet pipeline, a water outlet of the subsidiary return water pipeline is connected onto a main return water pipeline, and the water pump is arranged between a water outlet of the subsidiary water inlet pipeline and a water inlet of the exchanger. Each injection molding machine is equipped with a water supply pump, so that one or more injection molding machines can be started according to requirements of enterprises by starting the water supply pumps for the corresponding injection molding machines.

Owner:CHANGZHOU WANJIALE PLASTIC

Method for increasing production quality stability of thin cigarettes

ActiveCN108323788ASimple structureImprove stabilityTobacco preparationTobacco treatmentCombustionHazardous substance

The invention relates to a method for increasing the production quality stability of thin cigarettes and belongs to the technical field of cigarette production. The method includes: selecting tobaccocutting width, selecting drying intensity and moisture, purifying cut tobacco, optimizing tobacco structures, reasonably screening and selecting, selecting the type of a cigarette making machine, improving the cigarette making machine, and optimizing the parameters of the cigarette making machine. Compared with the prior art, the method has the advantages that the weight standard deviation of thethin cigarettes produced by the method is lowered from 13mg to 11mg, and the smoking resistance standard deviation of the thin cigarettes is lowered from original 90pa to 40pa; the produced cigarettesare low in main stream smoke tar content and CO content, sufficient combustion is achieved due to the fact that the looseness and filling value of the cut tobacco are increased, few harmful substances are generated during smoking, and low tar and CO generation quantity is achieved; the sensory quality of the produced cigarettes is improved the cigarettes are low in smoking resistance due to the fact that the looseness and filling value of the cut tobacco are increased, and the cigarettes are full and penetrating in aroma and high in smoke concentration.

Owner:CHINA TOBACCO HENAN IND +1

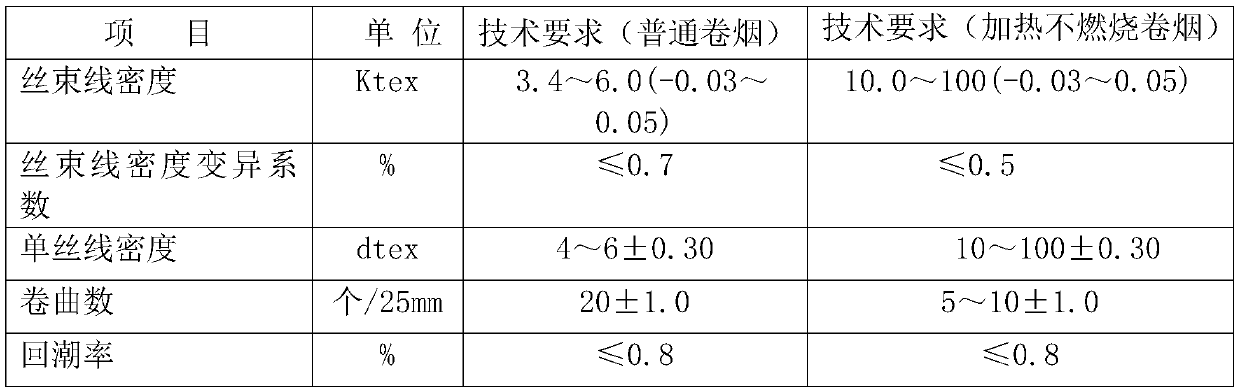

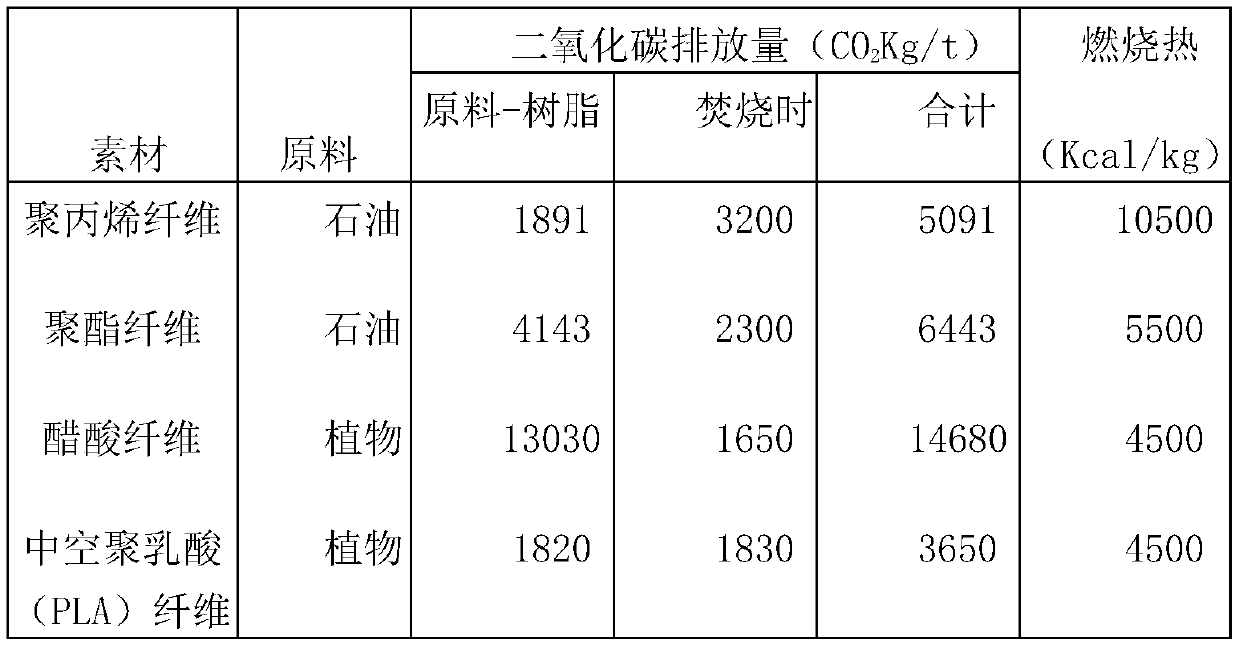

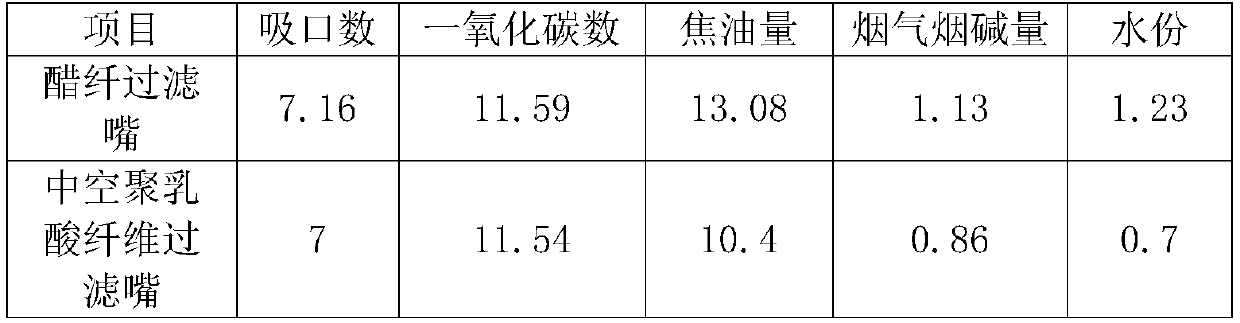

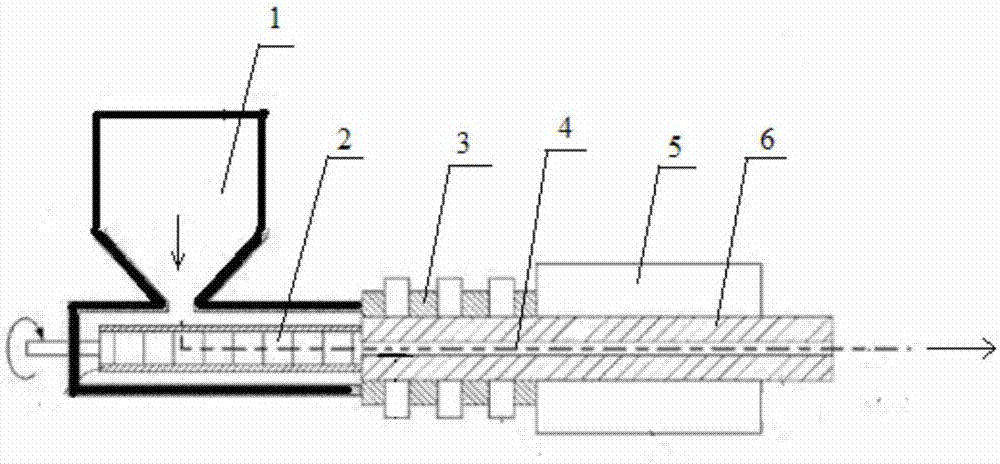

Hollow polylactic acid fiber for cigarette cooling filter section and preparation method of hollow polylactic acid fiber

InactiveCN109763185AIncrease distanceIncrease the areaHollow filament manufactureTobacco smoke filtersFiberPolymer science

The invention discloses a hollow polylactic acid fiber for a cigarette cooling filter section and a preparation method of the hollow polylactic acid fiber. The method comprises the follow steps: withfood fiber-grade polylactic acid as a raw material, drying, melting, spinning, cooling, oiling, drafting, crimping, drying and shaping are performed, and the fiber is prepared. In the smoking processof a cigarette with a filter tip prepared from the hollow polylactic acid fiber, the hollow polylactic acid fiber has high adsorption and absorption capability to polar and non-polar smoke component gases; smoke is heated after passing through the filter tip, the polylactic acid material absorbs heat during phase transition, and the prepared hollow fiber has large diameter and large smoke passage,the contact exchange specific surface of the cigarette filter tip and the smoke is increased, the smoke temperature is reduced, and the harm reduction effect is achieved.

Owner:云南中成道和新材料科技有限公司

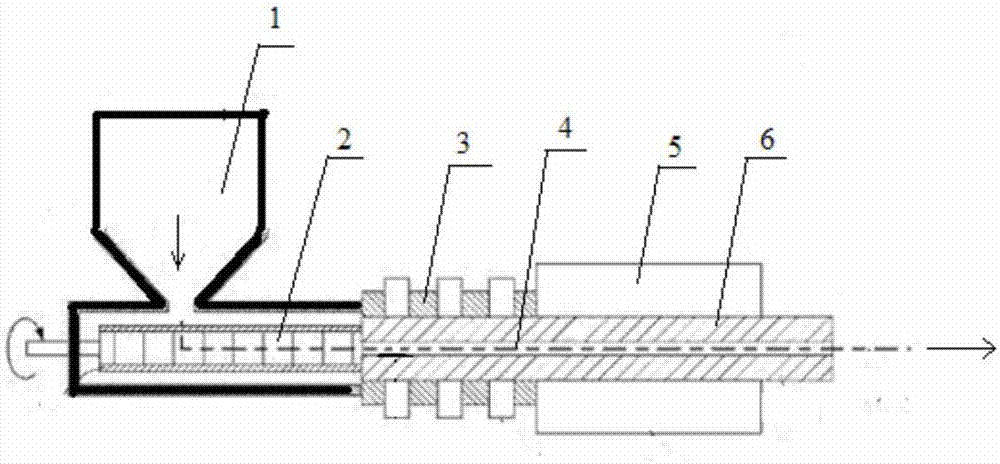

Preparation method of homogenized specially-shaped cigarettes

The invention discloses a preparation method of homogenized specially-shaped cigarettes. The preparation method comprises the following steps: grinding a tobacco raw material, carrying out mixed granulation on the grinded tobacco raw material and a solution containing a combustion promoter, an adhesive, a humectant and tobacco essence, and carrying out drying, thus obtaining reconstituted tobaccoparticles; adding an adhesive on the surfaces of the reconstituted tobacco particles, and preparing tobacco particle round rods by adopting a tobacco particle round rod forming device; and wrapping the tobacco particle round rods by adopting cigarette paper, carrying out cutting forming, and carrying out compounding with filter sticks, thus obtaining the highly homogenized specially-shaped cigarettes. The specially-shaped cigarettes are good in quality controllability, the homogeneity and stability of the quality of the cigarettes can be guaranteed to the maxim, the phenomena of tobacco shredfalling at the cut openings and empty heads existing in the conventional cigarettes are avoided, the smoking is smooth, and the satisfaction is strong. The cross sections of the cigarettes have special patterns, the appearance is novel, and good sensual experience can be endowed to a consumer.

Owner:CHINA TOBACCO HUNAN INDAL CORP

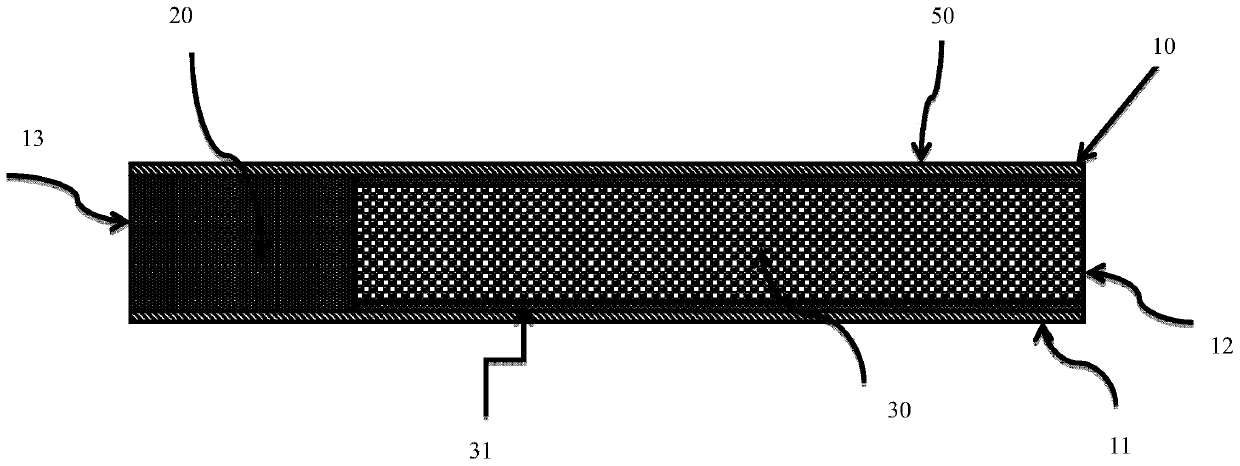

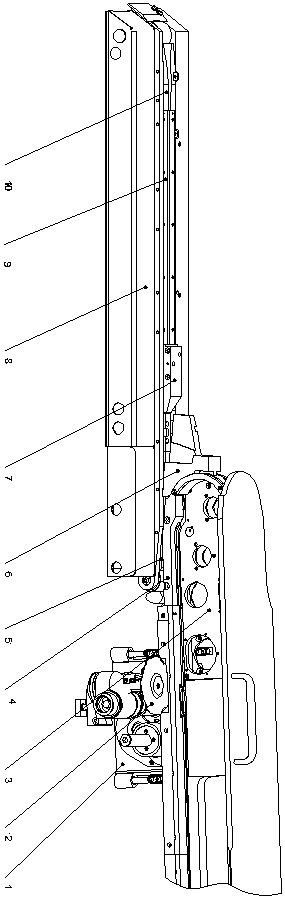

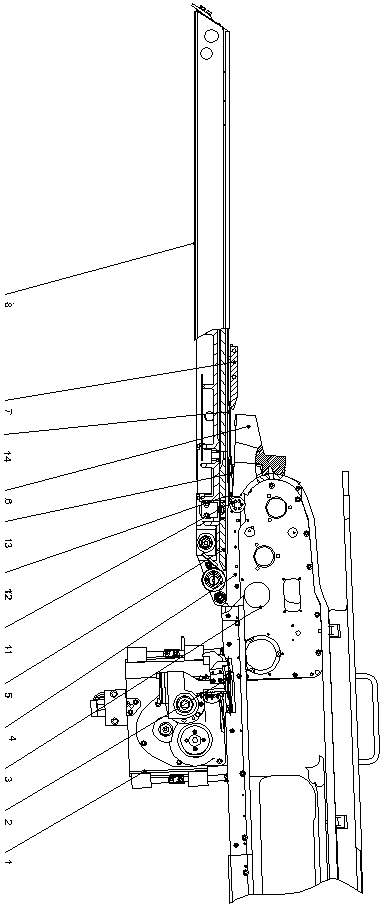

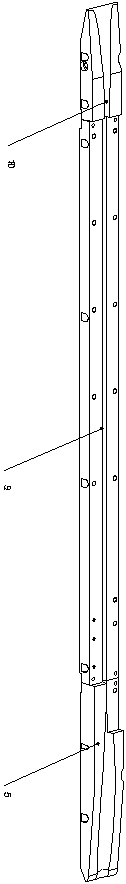

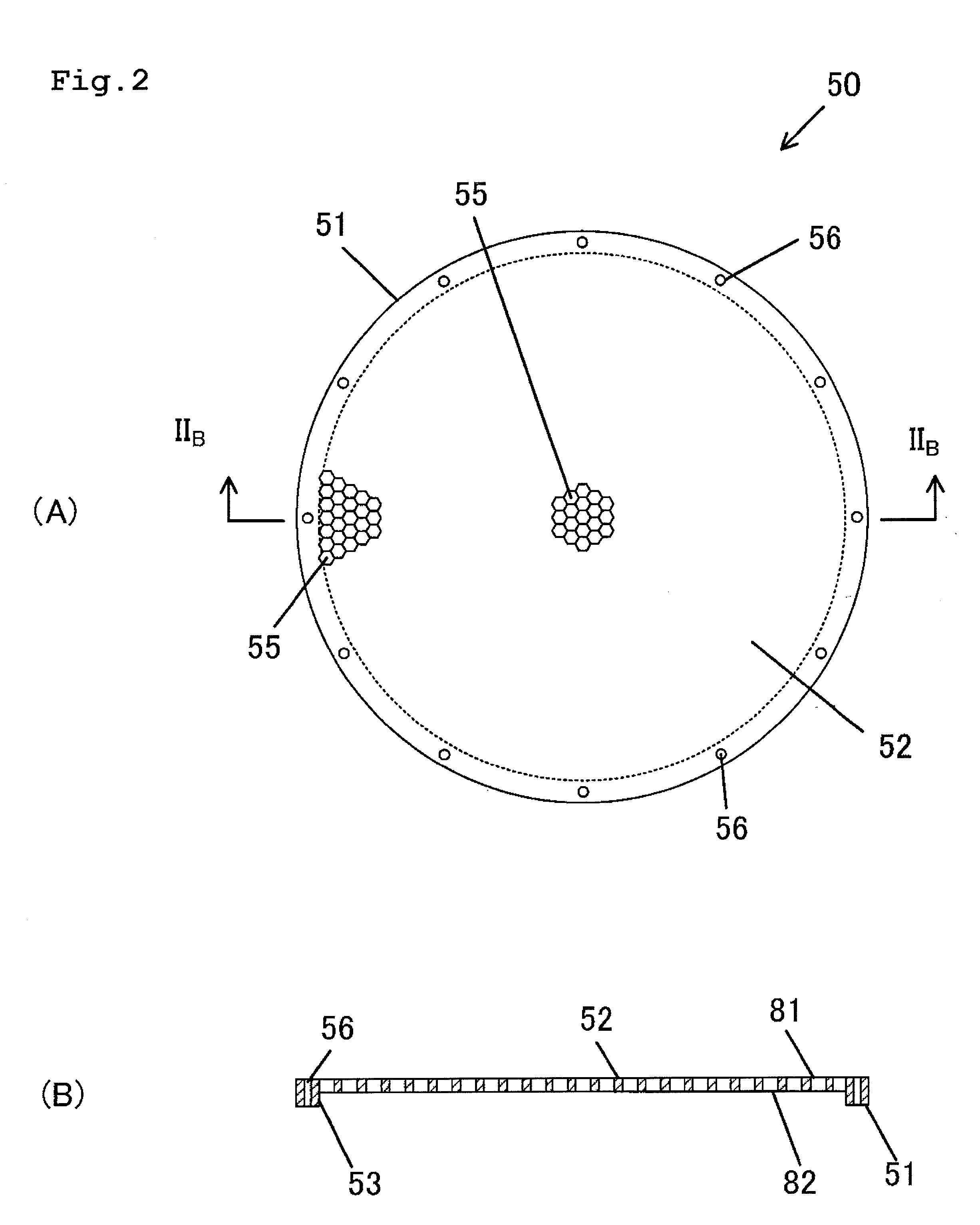

Vacuum pump protection net, method for manufacturing the same, and vacuum pump

ActiveUS20150204353A1Ensure attachment strengthReduce suction resistancePositive displacement pump componentsEngine componentsEngineeringVacuum pump

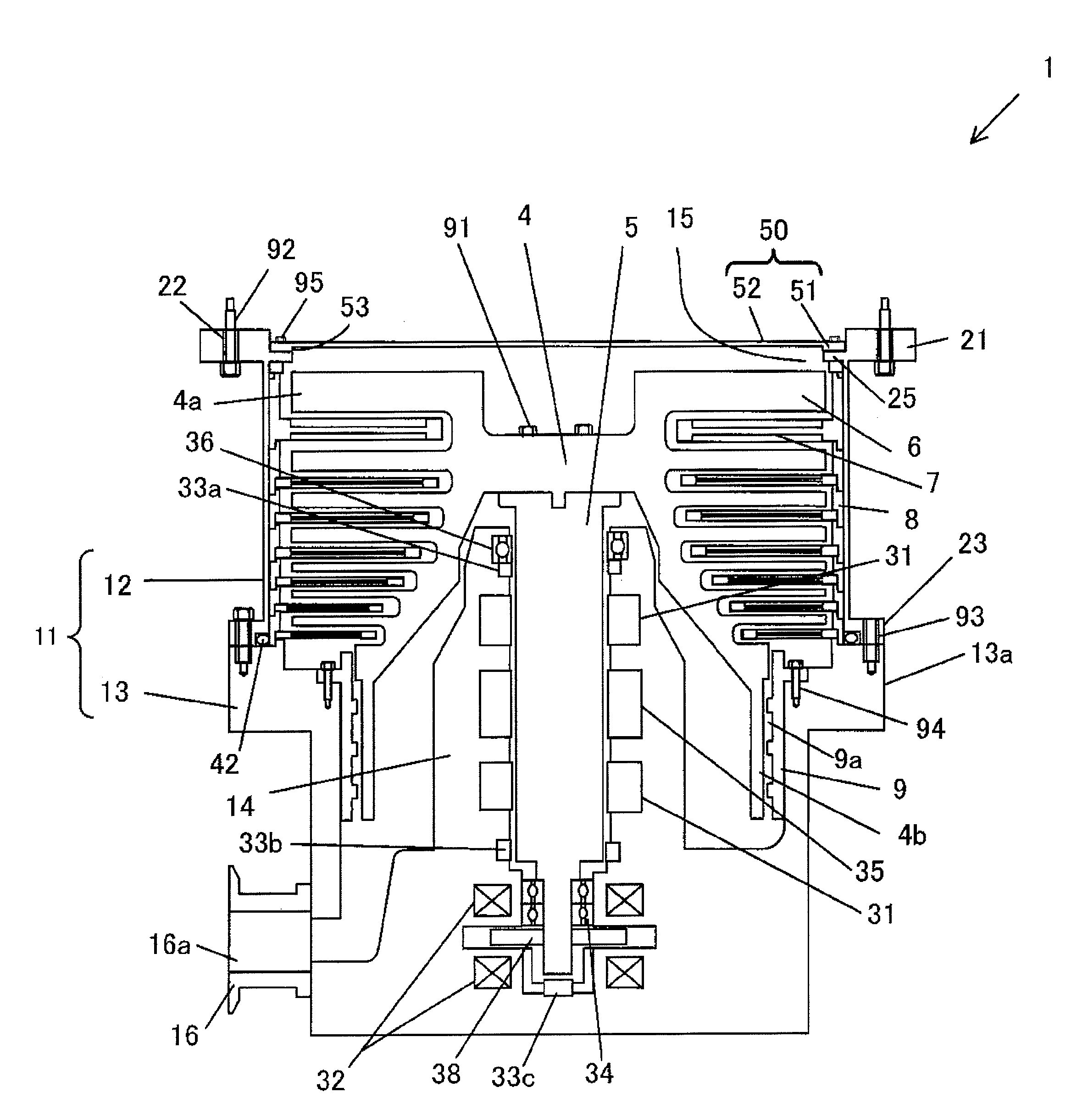

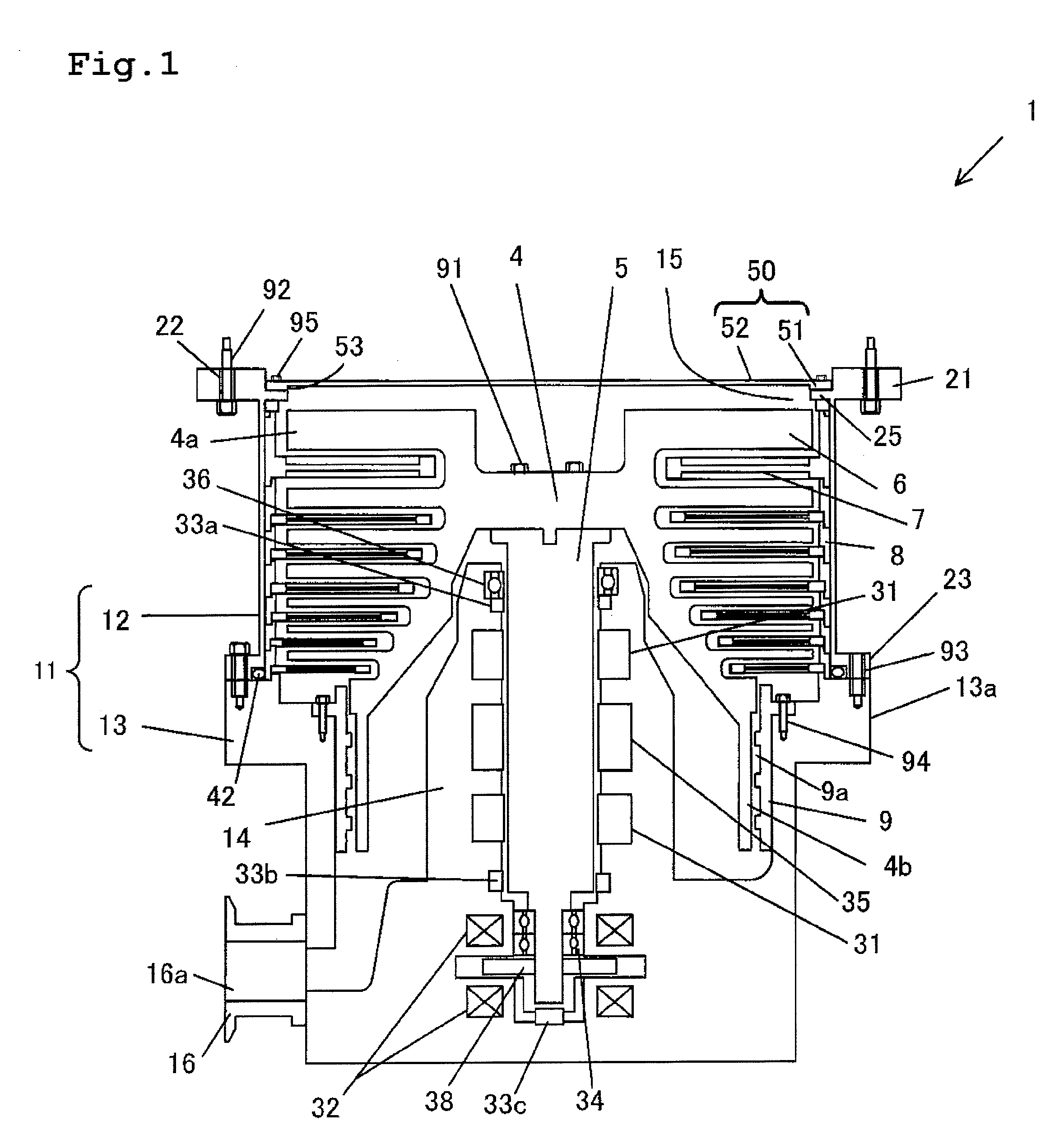

A vacuum pump protection net 50 is provided with a peripheral edge section 51 and a flat mesh section 52 which is formed on the inner side of the peripheral edge section 51 and has a plurality of through holes 55. The thickness of the mesh section 52 is equal to or less than half the thickness of the peripheral edge section 51. A first surface of the mesh section 52 is located on the same plane as a first surface of the peripheral edge section 52. A second surface of the mesh section 52 is recessed from a second surface of the peripheral edge section 51.

Owner:SHIMADZU CORP

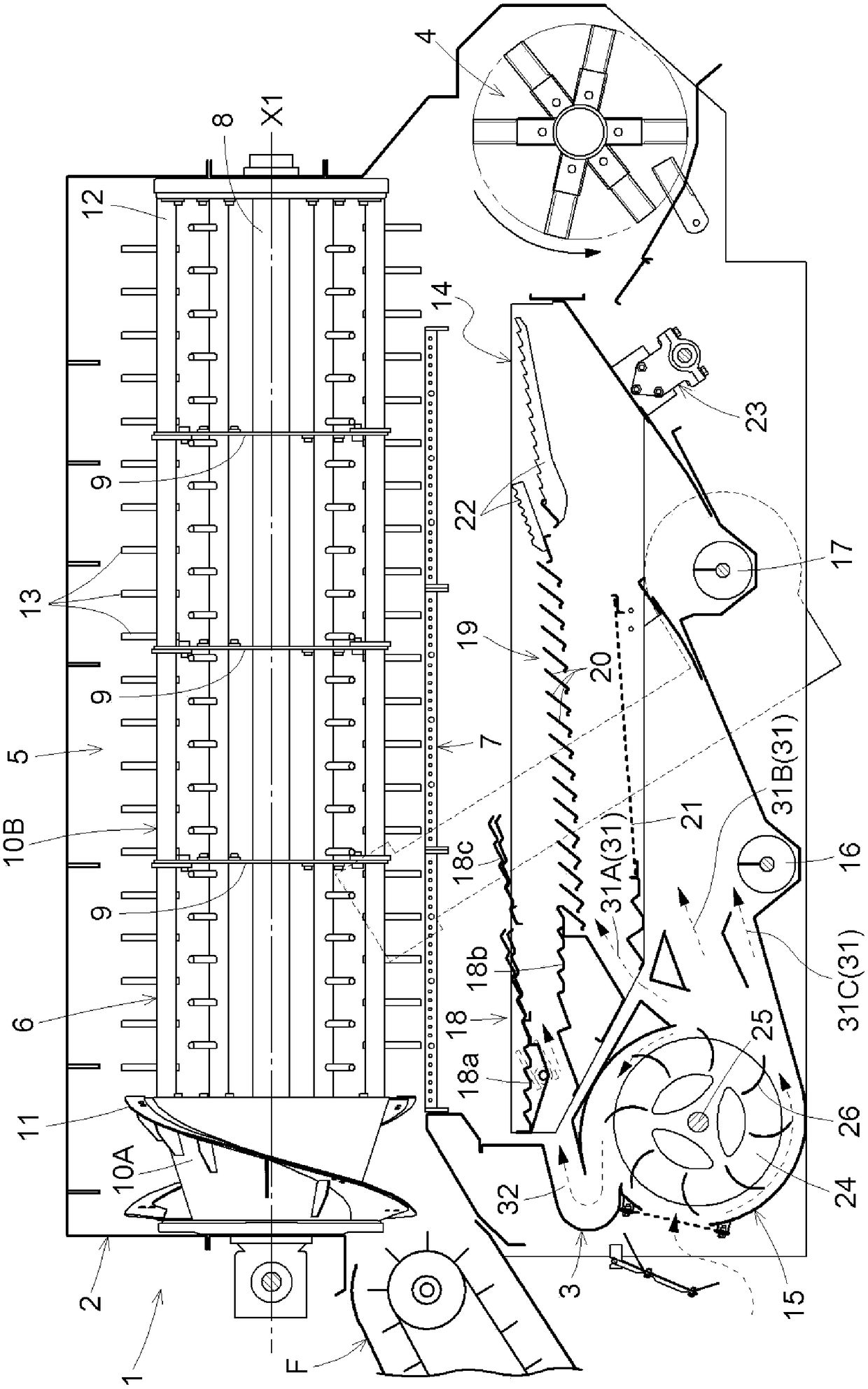

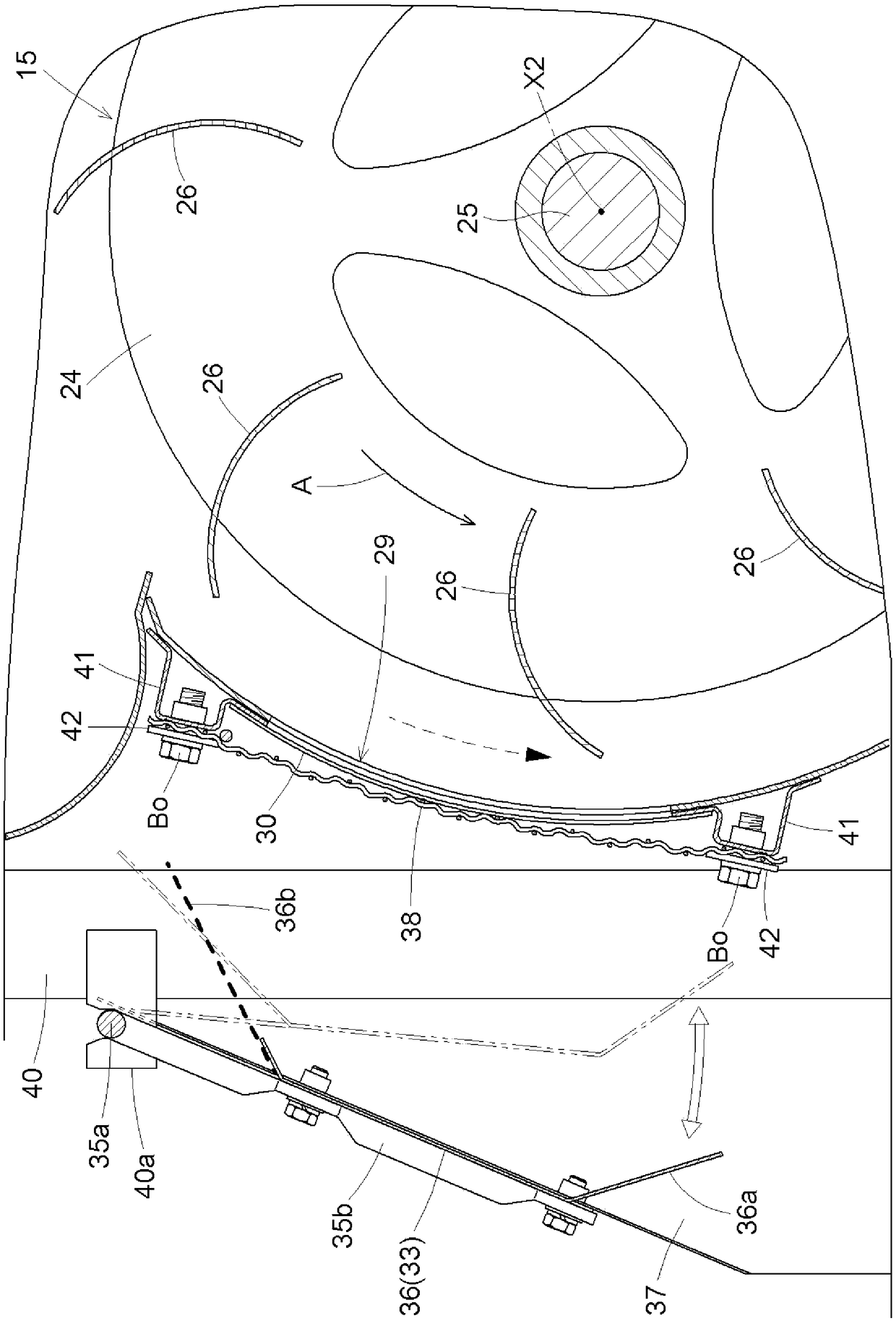

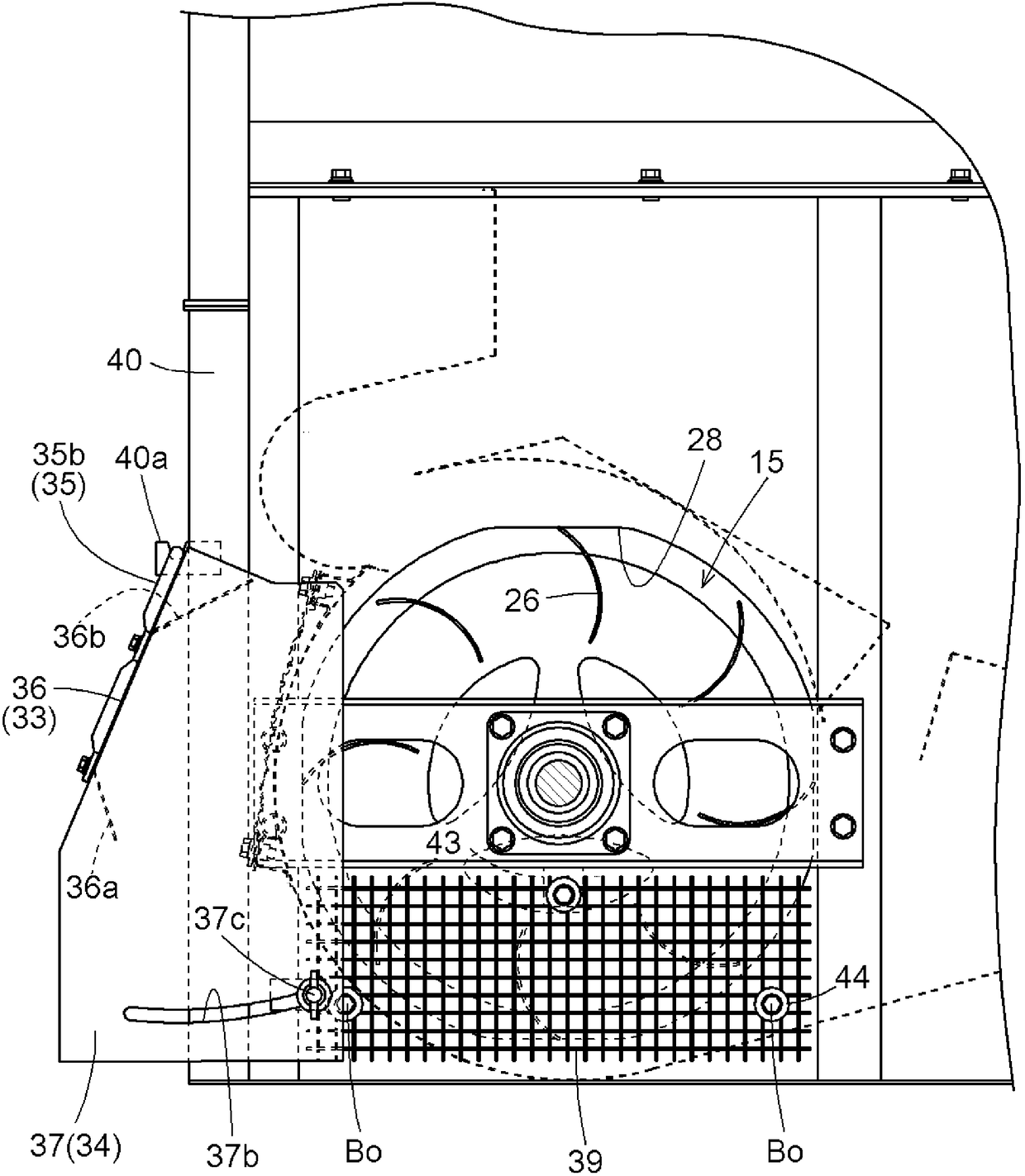

Threshing device

The invention provides a threshing device, which can efficiently increase the amount of cleaning wind from a cleaning blower fan. The threshing device comprises a threshing part, which is provided with a threshing cylinder and a screening net; and a sorting part, which is provided with a swing screening device and a cleaning blower fan. The swing screening device screens processed objects, which have been threshed by the threshing part and go through the screening net, through swinging. The cleaning blower fan is arranged in the front-lower direction of the swing screening device and deliverscleaning wind to the swing screening device. The cleaning blower fan comprises a fan for blowing cleaning wind and a cleaning blower fan shell that covers the front part and horizontal lateral part ofthe fan. The lateral part of the blower fan shell is provided with a horizontal suction opening for sucking external air, and the front part of the blower fan shell is provided with a front suction opening for sucking external air.

Owner:KUBOTA LTD

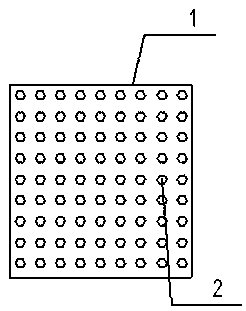

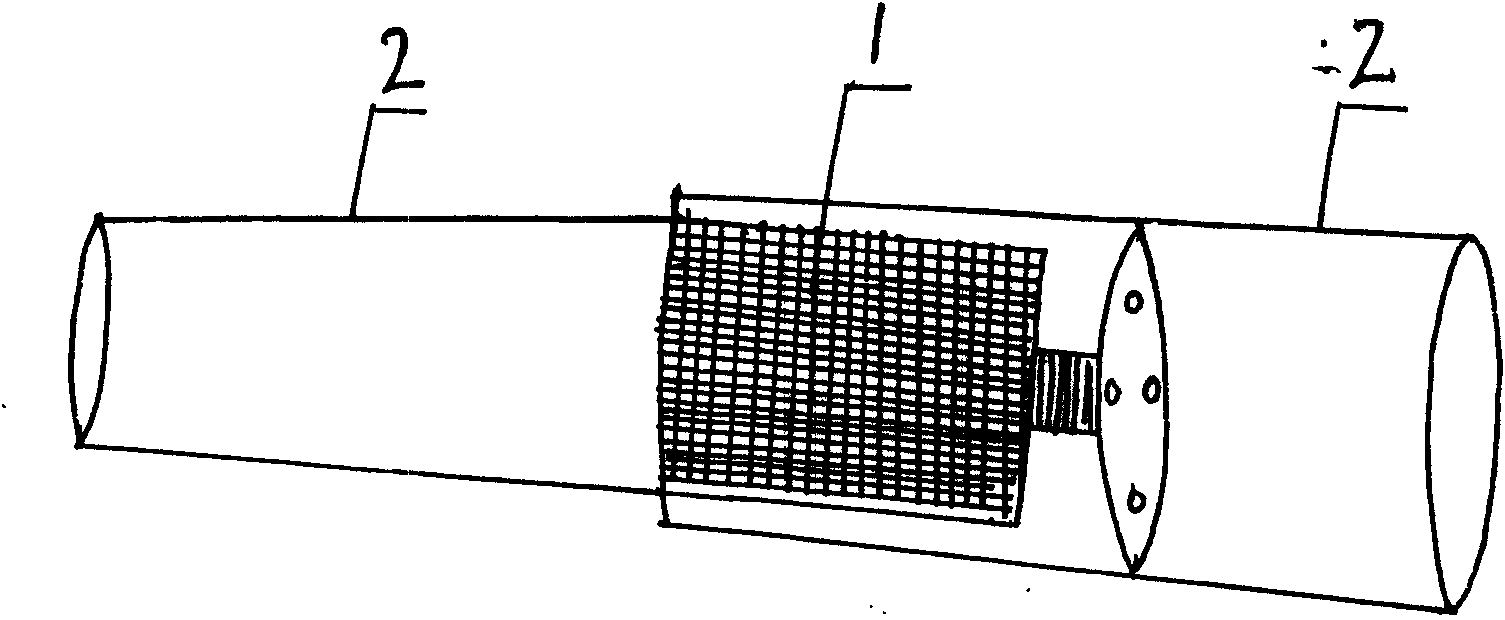

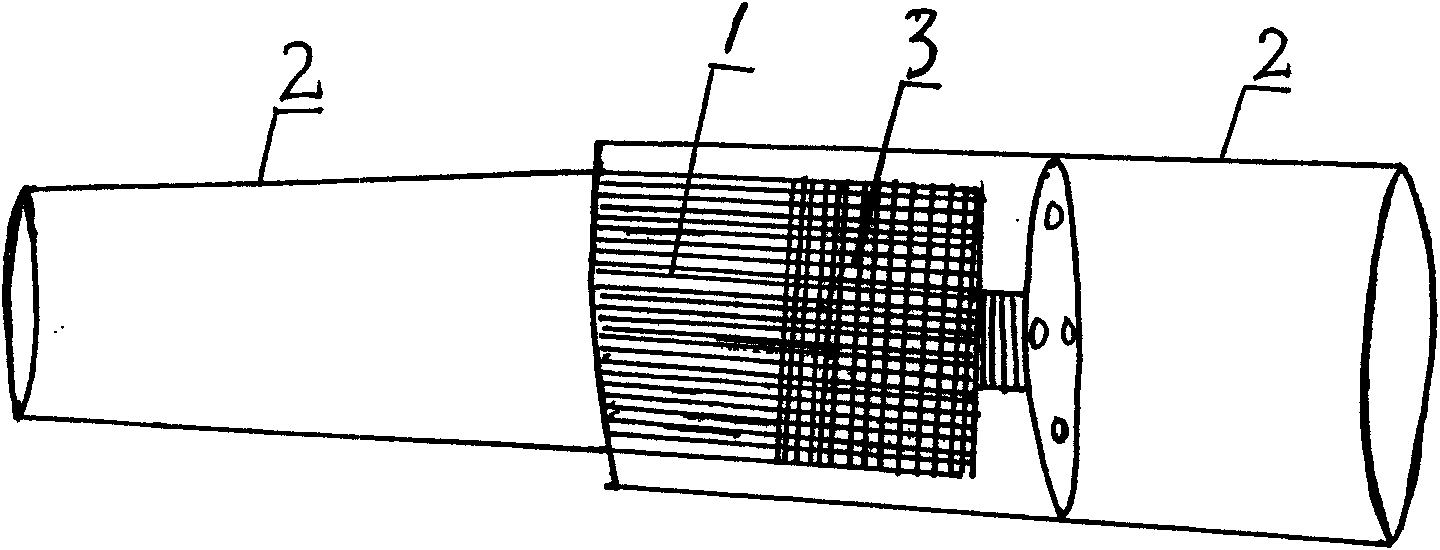

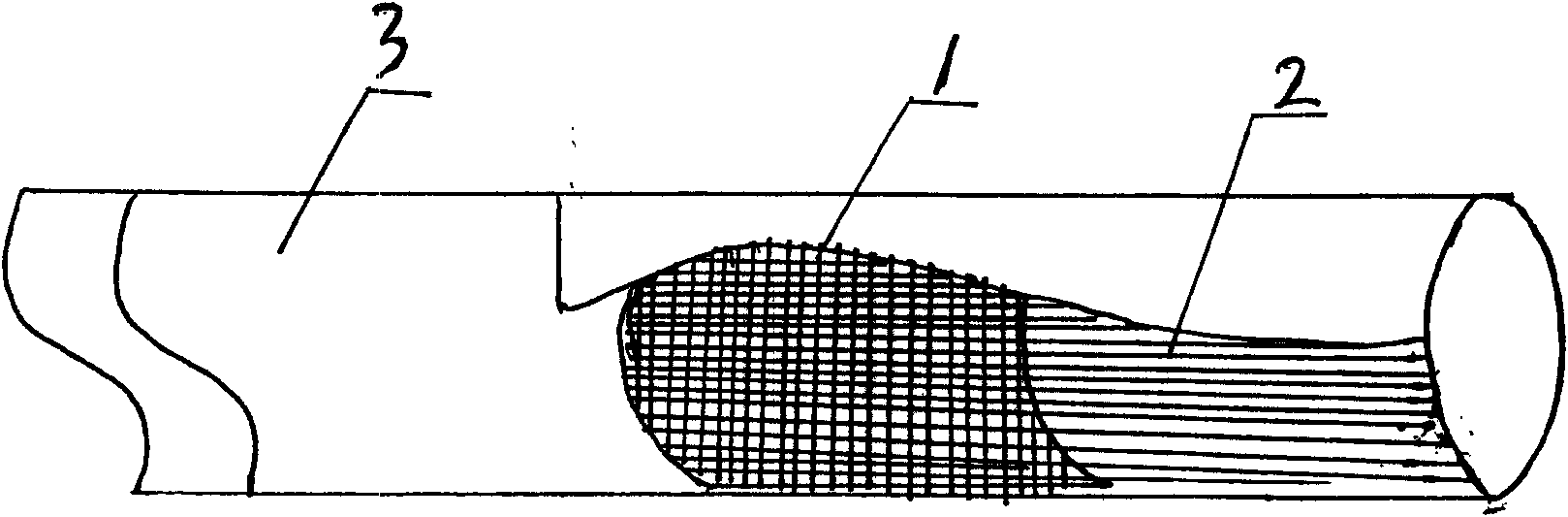

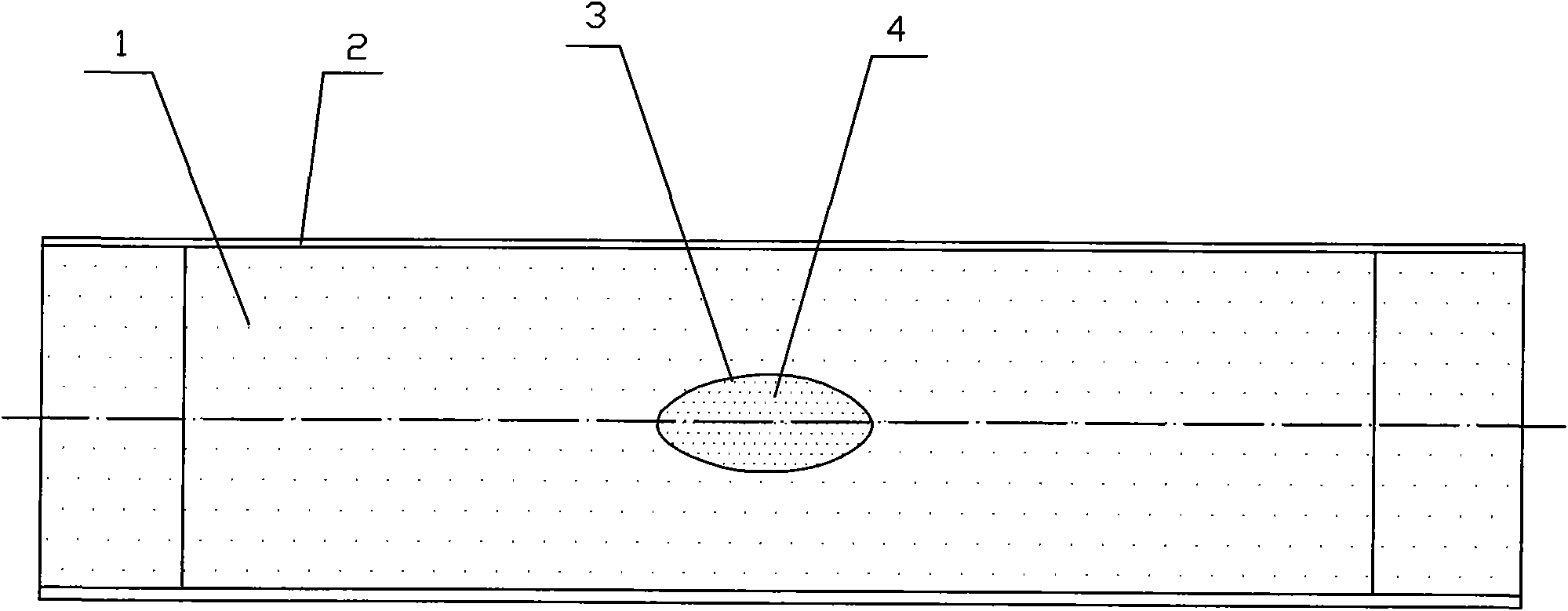

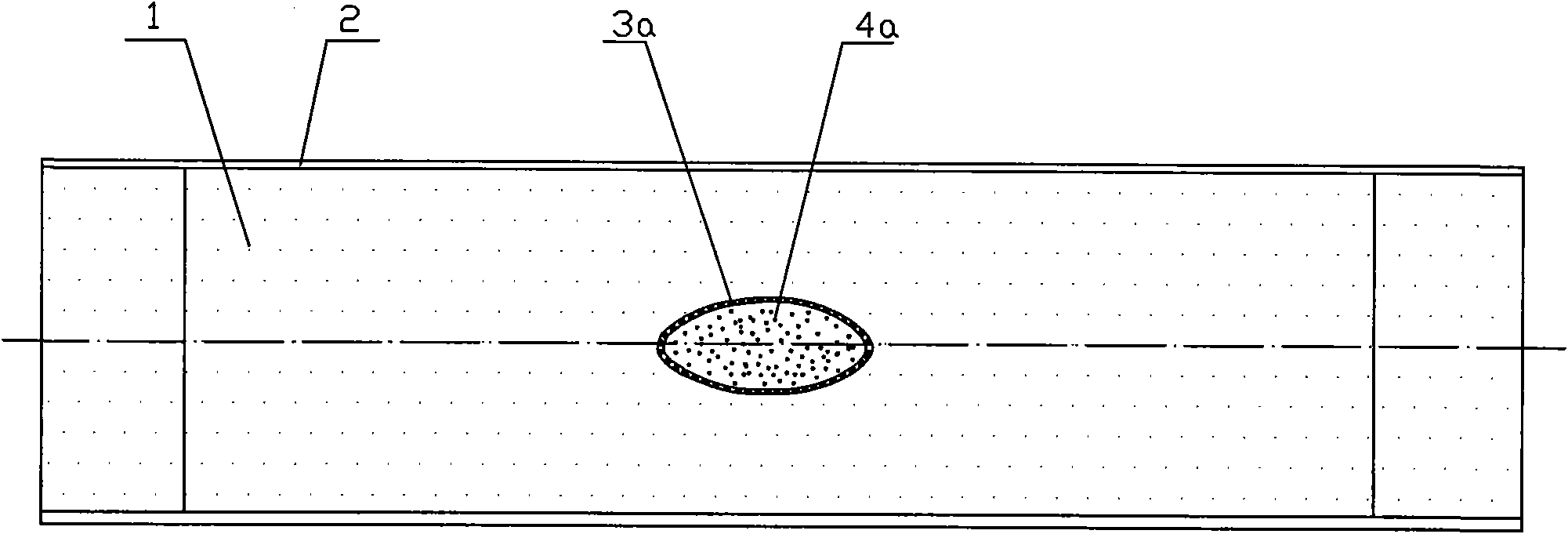

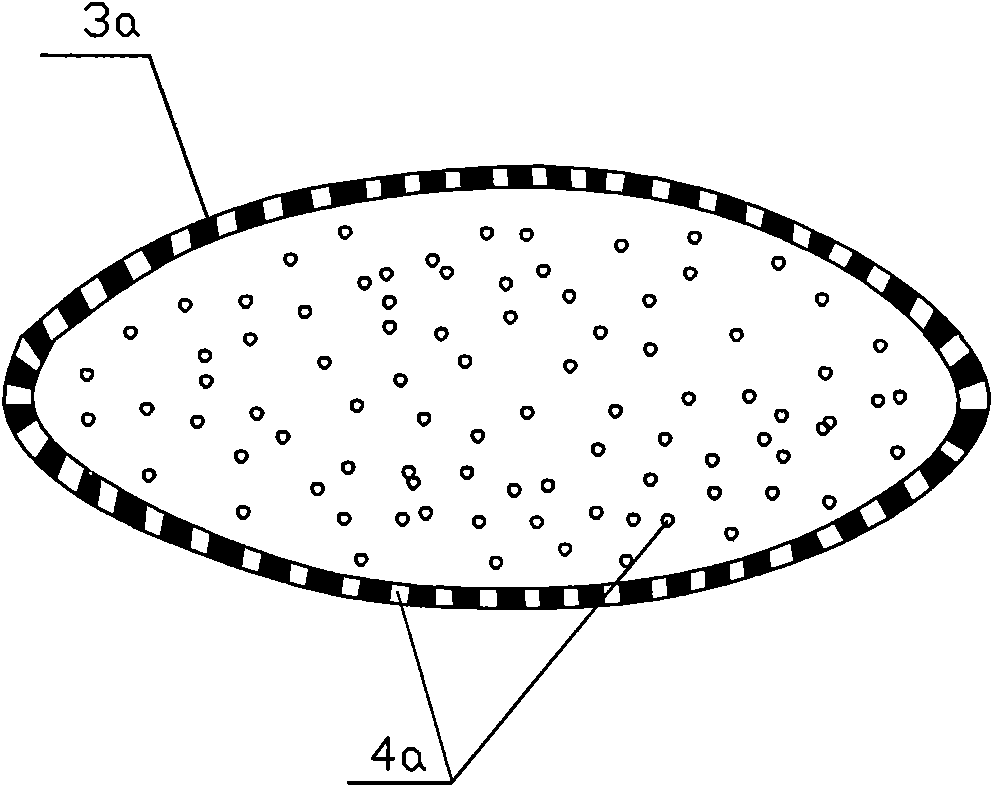

Central buried olive-shaped interception nozzle rod

InactiveCN101933663ALow densityLarge particlesCigarette manufactureTobacco smoke filtersHigh absorptionEngineering

The invention provides a central buried olive-shaped interception nozzle rod comprising a tow mandrel (1) and forming paper (2), wherein the forming paper (2) is coated on an outer layer of the tow mandrel (1), high-absorption materials (such as active carbon and nano-adsorption materials) are buried in the center of the tow mandrel along an axial direction to prepare a solid or hollow olive-shaped adsorption core (3), and the surface of the adsorption core is provided with adsorption micro pores (4). Because the adsorption core has high adsorption performance for smoke gas, a large amount of smoke gas is adsorbed, and aerosol grains are enlarged to increase deposition efficiency, therefore, grains in the smock gas are greatly intercepted by repeatedly passing through a plurality of adsorption cores.

Owner:BENGBU CIGARETTE MATERIAL FACTORY

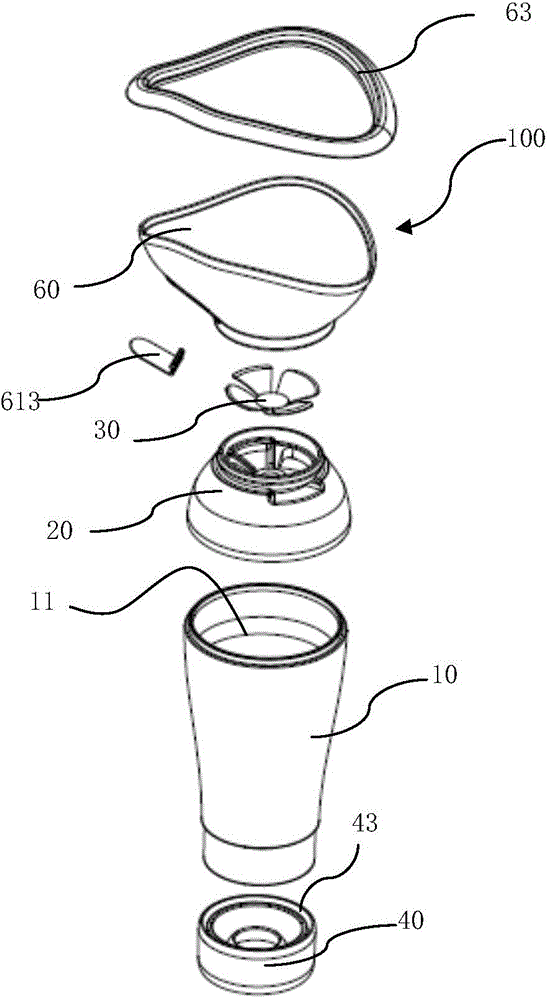

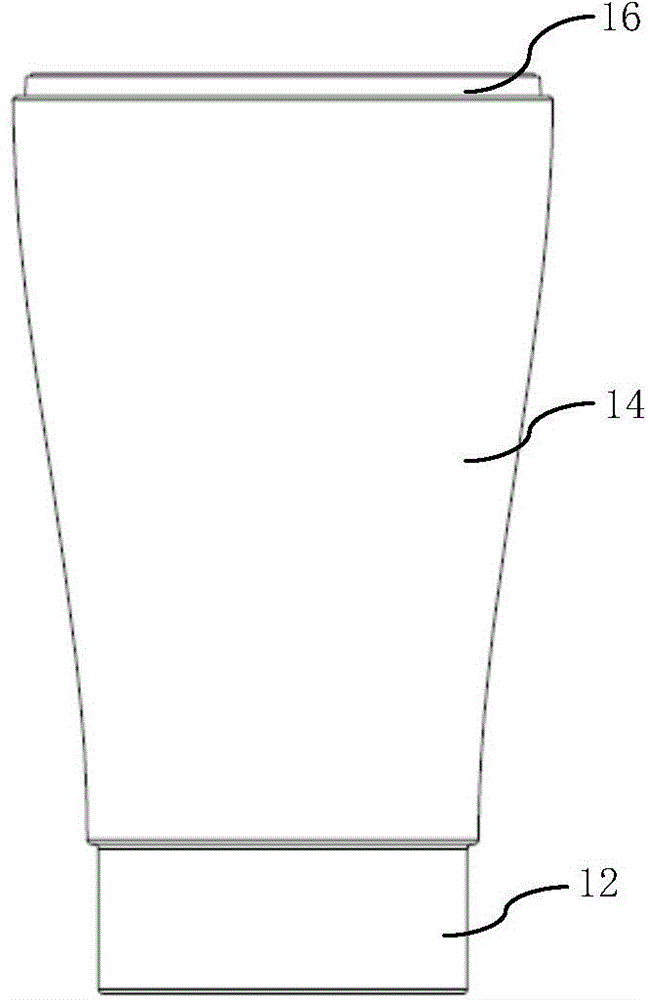

Spacer for metered dose inhaler

The invention discloses a spacer for a metered dose inhaler. The spacer comprises a shell, a one-way valve and an inhalation component, wherein a cavity is formed in the shell and a one-way valve supporting structure is formed at one end; the one-way valve supporting structure comprises a sealing part, a mounting seat and an exhaust passage; the sealing part is provided with a suction hole; the one-way valve comprises a joint part, a first valve flap and a second valve flap; the first valve flap and the second valve flap can bend elastically relative to the joint part along the same direction, so that the first valve flap seals the suction hole and meanwhile the second valve flap opens the exhaust passage, or the first valve flap opens the suction hole and meanwhile the second valve flap seals the exhaust passage; the inhalation component is detachably buckled on the shell and is provided with the one-way valve in a covering manner. The spacer has smaller inhalation resistance and a simpler structure, and the one-way valve is detachable.

Owner:RESGOOD MEDICAL CO LTD

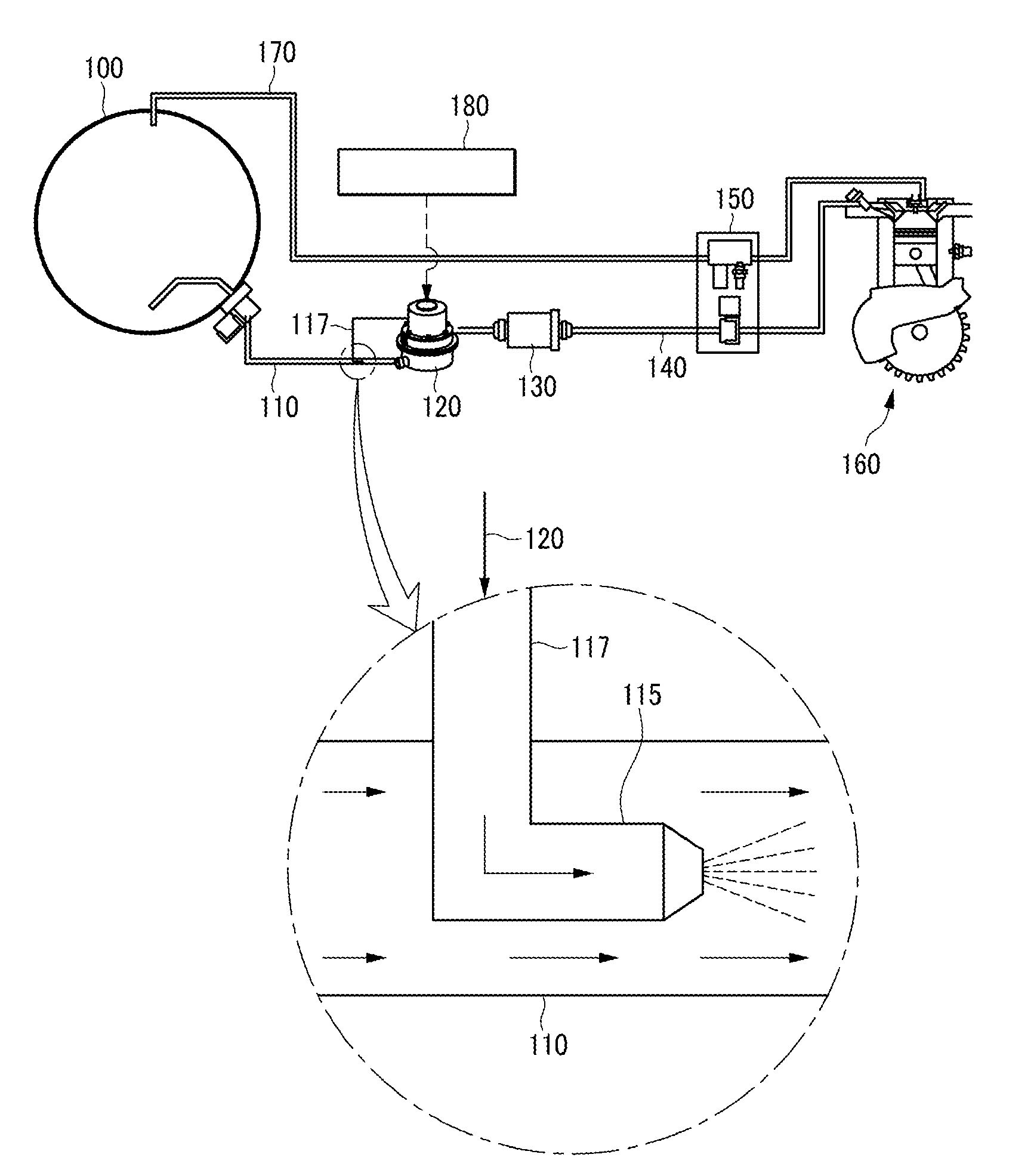

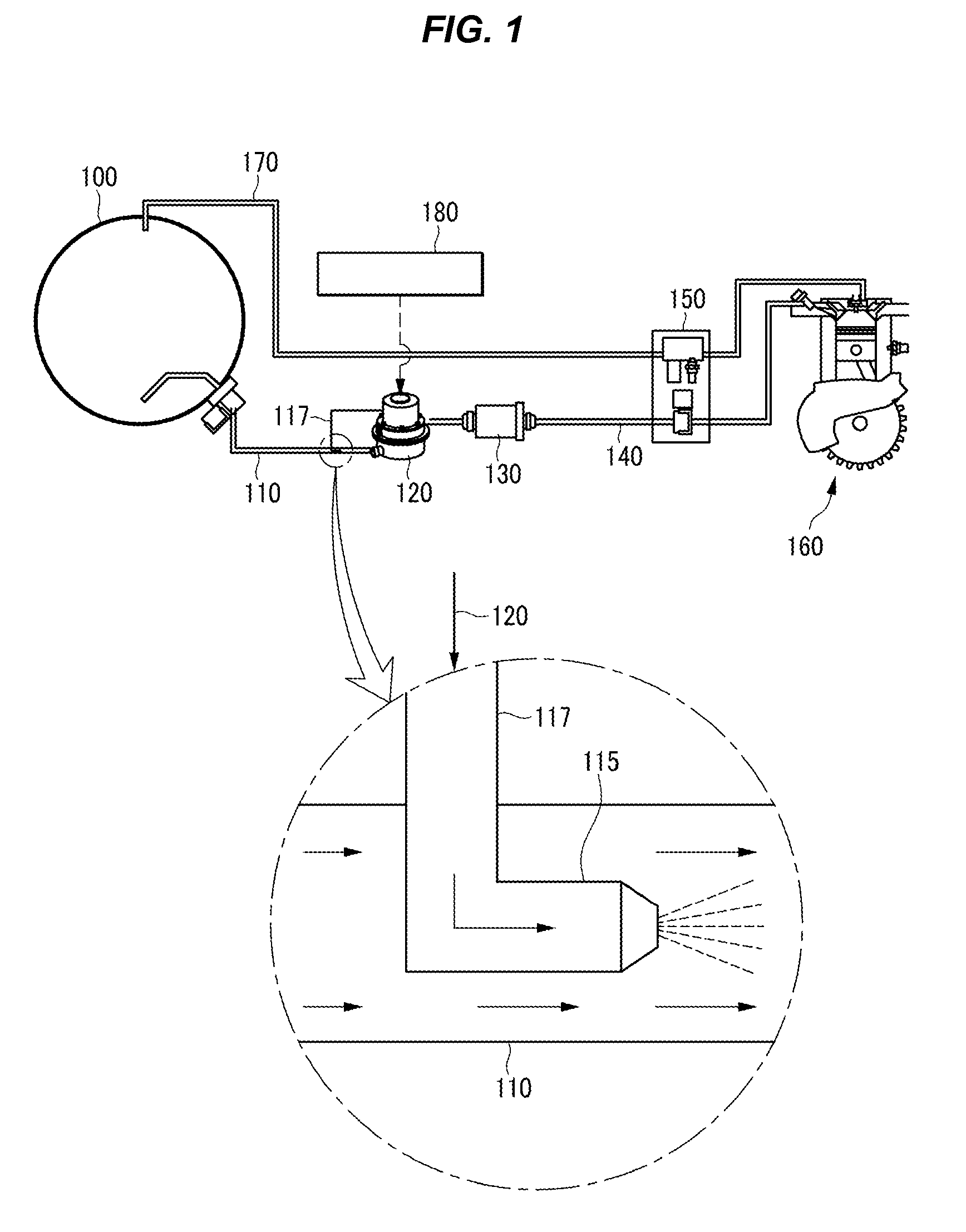

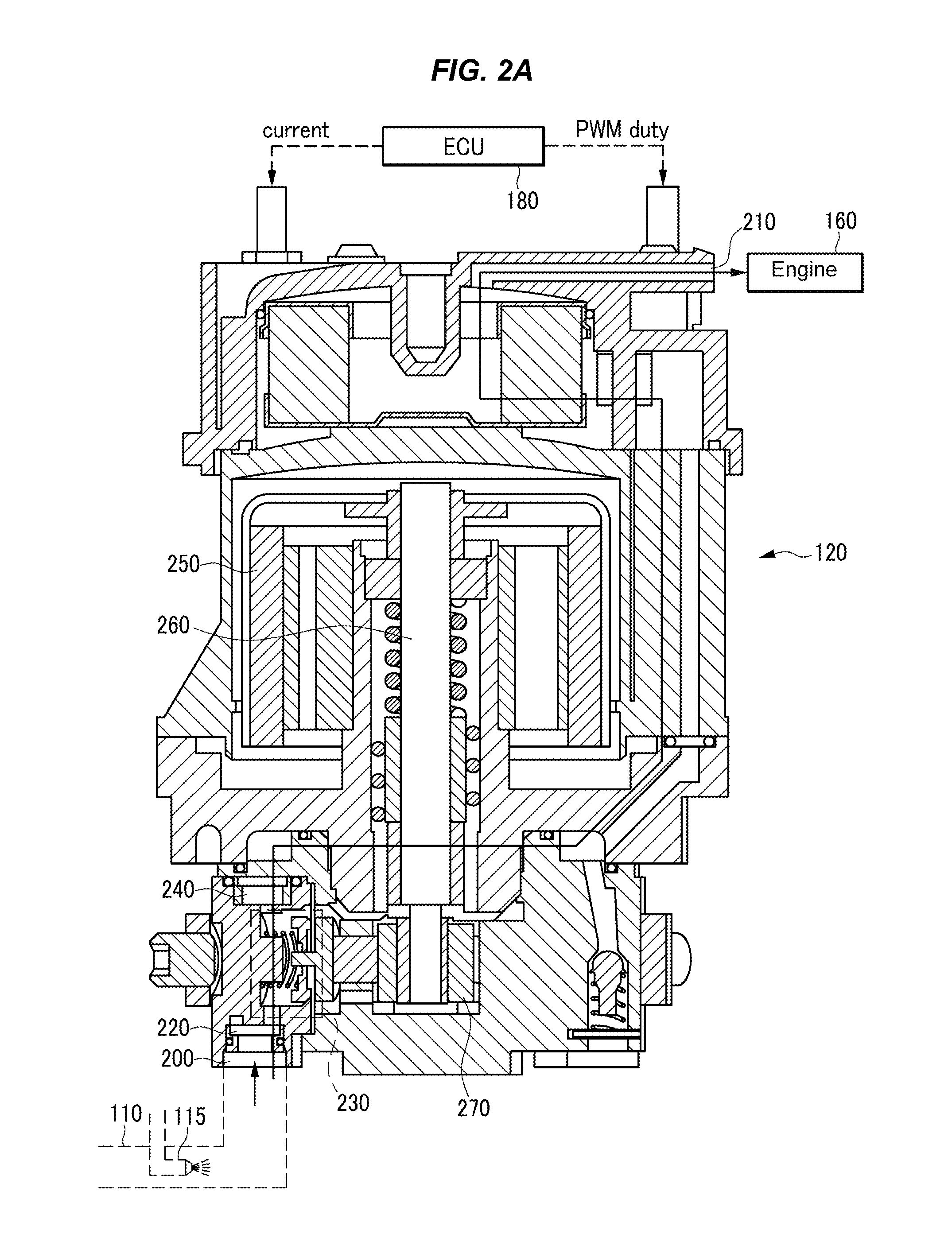

Lpi fuel supply system

ActiveUS20110048376A1Reduce suction resistanceGreat suctionElectrical controlInternal combustion piston enginesFuel tankFuel supply

A fuel supply system may include a fuel tank that is filled with fuel, a fuel pump supplying an engine with the fuel in the fuel tank, a suction line connecting the fuel tank to the fuel pump, a supply line connecting the fuel pump to the engine, and a jet nozzle disposed in the suction line to inject a portion of fuel that is supplied from the fuel pump in a flowing direction of the fuel supplied from the fuel tank.

Owner:HYUNDAI MOTOR CO LTD

Low-temperature cigarette with loose integral tobacco section with high thermal conductivity and preparation method thereof

InactiveCN108741206AQuality improvementHigh thermal conductivityTobacco preparationCigar manufactureAdhesiveMetal powder

The invention provides a low-temperature cigarette with a loose integral tobacco segment with high thermal conductivity and a preparation method thereof, wherein the method comprises the following steps of: crushing tobacco leaves into fine powder; uniformly mixing, by mass, 50-80% of tobacco powder, 10-25% of atomizing agent, 0.5-10% of adhesive, 0.01-0.2% of leavening agent; 5-35% of metal powder, 1-8% of perfume essence perfume for smoke, and 0-30% of water, feeding the mixture into a mold, pressing into a tobacco rod, drying, wrapping with aluminum foil paper, connecting a filter tip especially for the low-temperature cigarette, and making the low-temperature cigarette according to the traditional cigarette rolling method. According to the invention, under the condition that the lengthand the diameter of a prior low-temperature cigarette are not changed, the quality of the low-temperature cigarette tobacco segment is obviously increased; metal powder is added into the raw materialformula, and the thermal conductivity can be effectively improved.

Owner:HUBEI CHINA TOBACCO IND

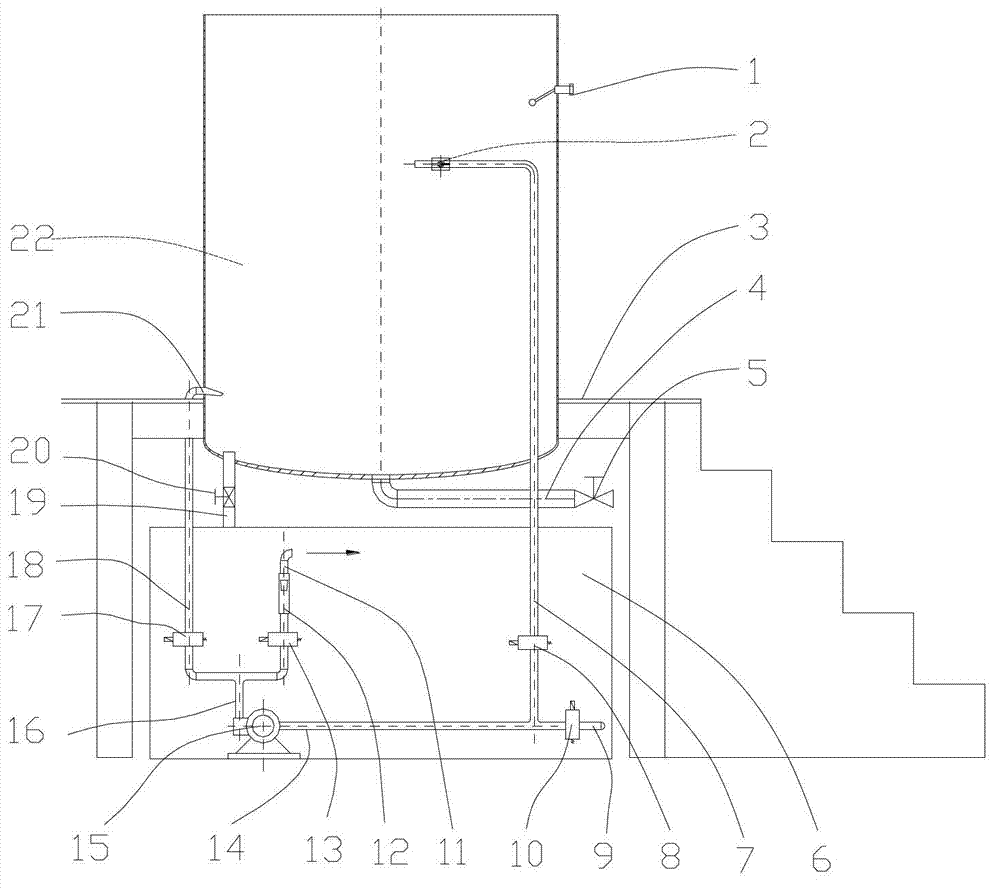

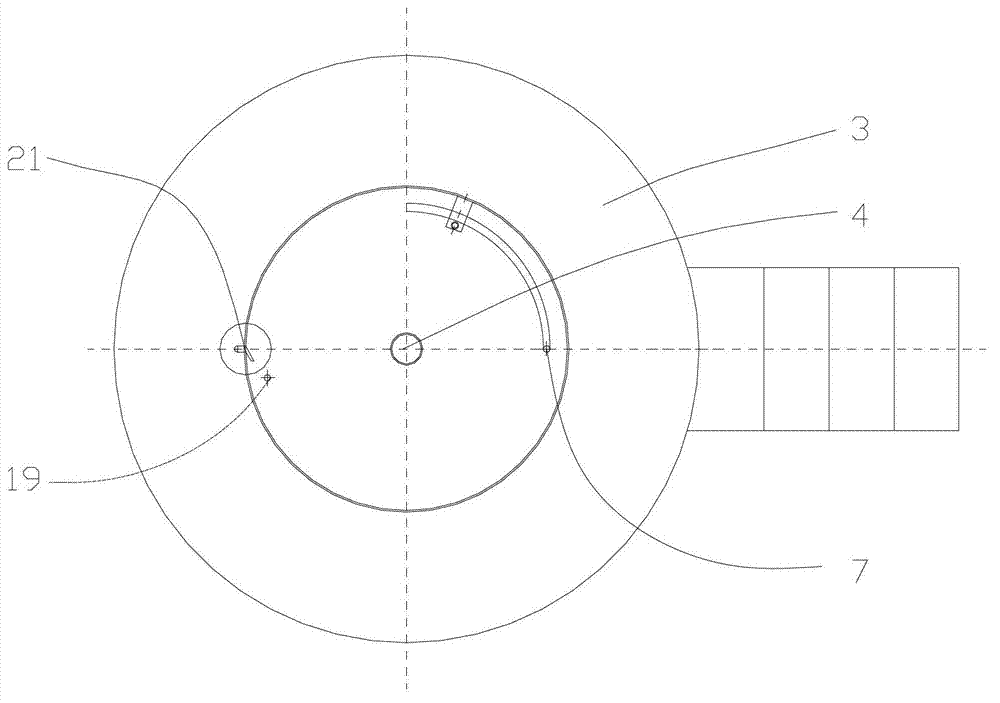

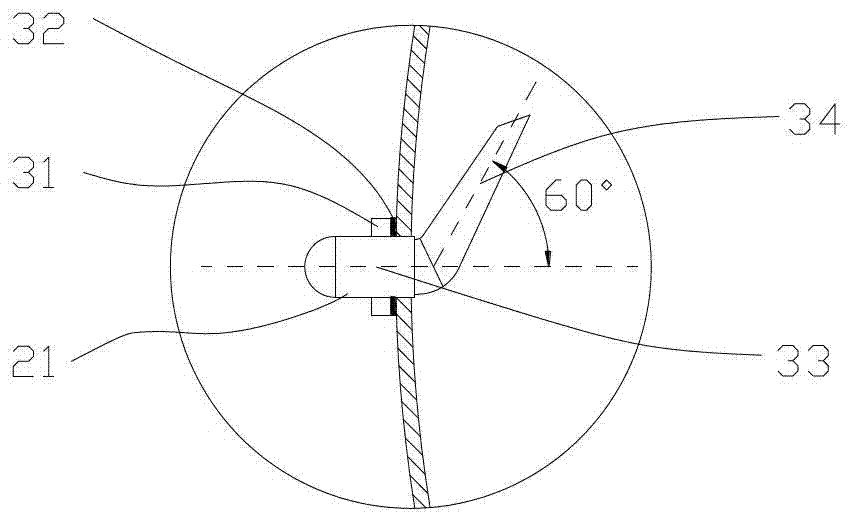

Upward and downward double circulation stirring dispensing system

InactiveCN102806030ALess investmentReduce suction resistanceFlow mixersMixer accessoriesSpray nozzleEngineering

The invention relates to the technical field of stirring dispensing in sewage treatment equipment. An upward and downward double circulation stirring dispensing system mainly comprises a dispensing tank, a liquid medicament storing box, a circular stirring pump feed pipe, electromagnetic valves A, B and C, a liquid medicament storing box discharge pipe, a liquid medicament conveying pipe, a rotor flow meter, a centrifugal pump and a stirring nozzle, and is characterized in that: the circular stirring pump feed pipe is connected to one side of the bottom of the dispensing tank; the liquid medicament storing box discharge pipe and the centrifugal pump are connected to one end of the circular stirring pump inlet pipe; the upper end of the circular stirring pump inlet pipe has a horizontal circular-arc structure; the pipe orifice of the circular stirring pump inlet pipe is positioned at a position which is two thirds of the total height of the dispensing tank; the discharge pipe is connected to one side of the bottom of the dispensing tank, and is connected with the liquid medicament storing box; a pump outlet pipe is connected with the liquid medicament conveying pipe and a stirring pipe respectively; the stirring pipe is connected with the stirring nozzle; the electromagnetic valve D is arranged on the stirring pipe; a liquid level sensor is arranged on the upper side part of the dispensing tank; an emptying pipe is connected to the center of the bottom of the dispensing tank; and the liquid medicament storing box is connected with the liquid medicament storing box discharge pipe. The upward and downward double circulation stirring dispensing system has the characteristics of dual functions of a single pump, saving in investment of the pump and mechanical stirring equipment, convenience in maintaining and easiness in operating.

Owner:UNIV OF JINAN

High-density hollow filter tip and composite filter tip thereof

PendingCN111134357AReduce suction resistanceLarge mixing cavityTobacco smoke filtersPolymer scienceCellulose diacetate

The invention discloses a high-density hollow filter tip which is of a hollow revolving body structure formed by rolling a high-density material; wherein the density range is 0.9 g / cm < 3 > to 1.6 g / cm < 3 >, the wall thickness is 0.05-0.7 mm, and the outer diameter is 5.0-8.0 mm. Materials for preparing the high-density hollow filter tip comprise cellulose acetate and derivatives thereof, polyhydroxyalkanoate and polyolefin organic high-molecular polymers; cellulose acetate and the derivatives thereof comprise cellulose diacetate, cellulose acetate propionate, cellulose acetate butyrate, methyl cellulose, ethyl cellulose and hydroxypropyl cellulose; the hydroxyl substitution degree of cellulose acetate and the derivative thereof is 1.5-2.8. The invention further discloses a composite filter tip comprising the high-density hollow filter tip and application of the composite filter tip in cigarette heating. When the composite filter tip is applied to heating cigarettes, the cigarette pressure drop can be reduced, a smoke mixing space can be increased, smoke adsorption can be reduced, the smoke temperature can be reduced, the smoke amount can be increased, and the cigarette smoking comfort can be kept.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com