Heating non-combustible cigarette

A heat-not-burn and cigarette technology, applied in tobacco, smoker’s products, applications, etc., can solve problems such as the release of odorous and harmful components, reduce the service life of heating appliances, reduce user experience and product safety, and achieve sufficient oxygen supply, Guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

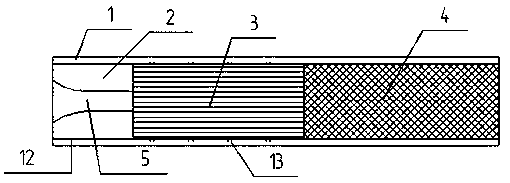

[0044] A heat-not-burn cigarette, made of paper with a thickness of 0.15mm and high stiffness, a hollow roll with a length of 45mm and a diameter of 7.2mm, and the front section of the cigarette that is sequentially arranged in the roll and closely connected (the heating body insertion direction) , the middle part of the cigarette and the back part of the cigarette (the direction of the lips sucking). The front section of the cigarette is a cylindrical isolation member, the isolation member is made of ceramics, and its thickness is 2mm, and the insertion port of the heating body and the air hole for adjusting the draw resistance are opened on the said isolation member; the middle section of the cigarette is made of It is filled with tobacco thin slices and filaments arranged in equal order in the axial direction of cigarettes, and its length is 12mm; the length of the rear section of the cigarette is 31mm, and the rear section of the cigarette is composed of two parts, of which...

Embodiment 2

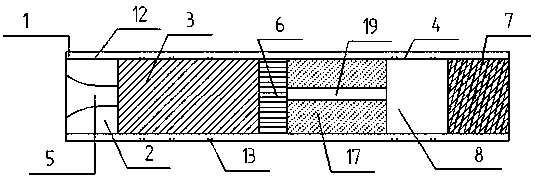

[0050] A heat-not-burn cigarette, made of PP material with a thickness of 0.2mm and high toughness, a hollow roll with a length of 48mm and a diameter of 7.4mm, and the front section of the cigarette that is arranged in sequence in the roll and closely connected (the heating body insertion direction) , the middle part of the cigarette and the back part of the cigarette (the direction of the lips sucking). The front part of the cigarette is a cylindrical isolation member, the isolation member is made of high temperature resistant polylactic acid material, and its thickness is 1mm; the insertion port of the heating body and the air hole for adjusting the draw resistance are opened on the isolation member; The middle section of the cigarette is filled with thin tobacco thin shreds smoking products arranged in the same order in the axial direction of the cigarette, and its length is 14mm; the length of the rear section of the cigarette is 33mm, and the rear section of the cigarette...

Embodiment 3

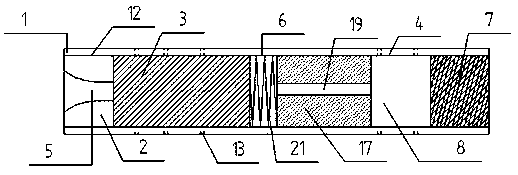

[0056] A heat-not-burn cigarette, made of PAI (polyamide-imide) material with a thickness of 0.2mm and a hollow roll with a length of 45mm and a diameter of 7.2mm, and tightly connected It is composed of the front part of the cigarette (the direction in which the heating body is inserted), the middle part of the cigarette and the rear part of the cigarette (the direction in which the lips are sucked). The front part of the cigarette is a cylindrical isolation member, and the isolation member is made of high temperature resistant PP material, and its thickness is 3mm; the insertion port of the heating body and the air hole for adjusting the draw resistance are opened on the isolation member; The middle part of the cigarette is filled with microwave-expanded tobacco stem particle smoking products, and its length is 12 mm; the length of the rear part of the cigarette is 30 mm, and the rear part of the cigarette is composed of two parts, of which the limit part is near the end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com