Tobacco stem sorting method suitable for different cigarettes

A technology for tobacco stems and cigarettes, which is applied in the field of sorting tobacco stems, which can solve the problems that the shredded stems cannot be used in thin cigarettes, and achieve the effects of improving the quality of cigarettes, improving the quality, and increasing the whole shred rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

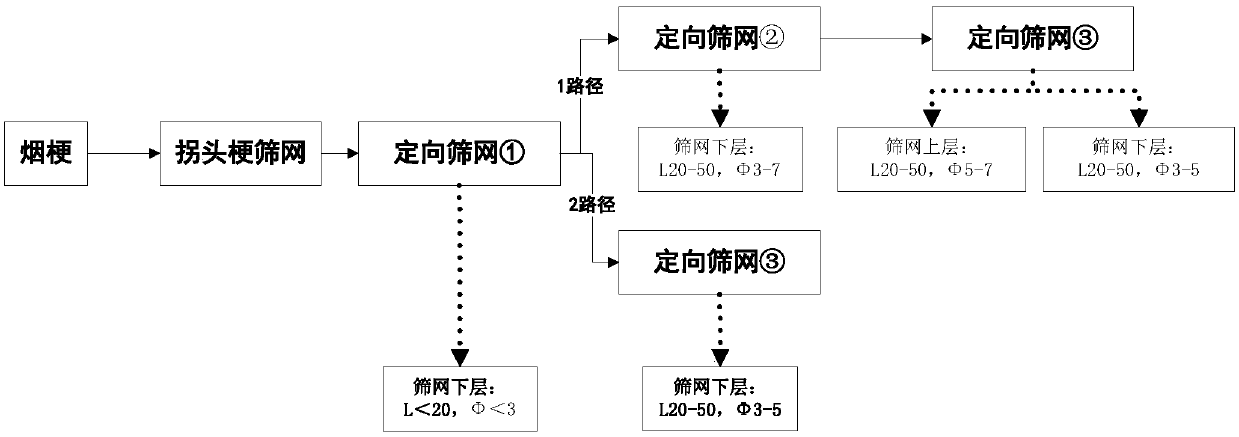

[0018] A method for sorting tobacco stems suitable for different cigarettes, comprising the steps of:

[0019] (1) Primary screening of tobacco stems: threshing and redrying online tobacco leaves feeding and threshing, classification of leaf stems, screening and removal of tobacco stems, and the obtained tobacco stems enter the first screening;

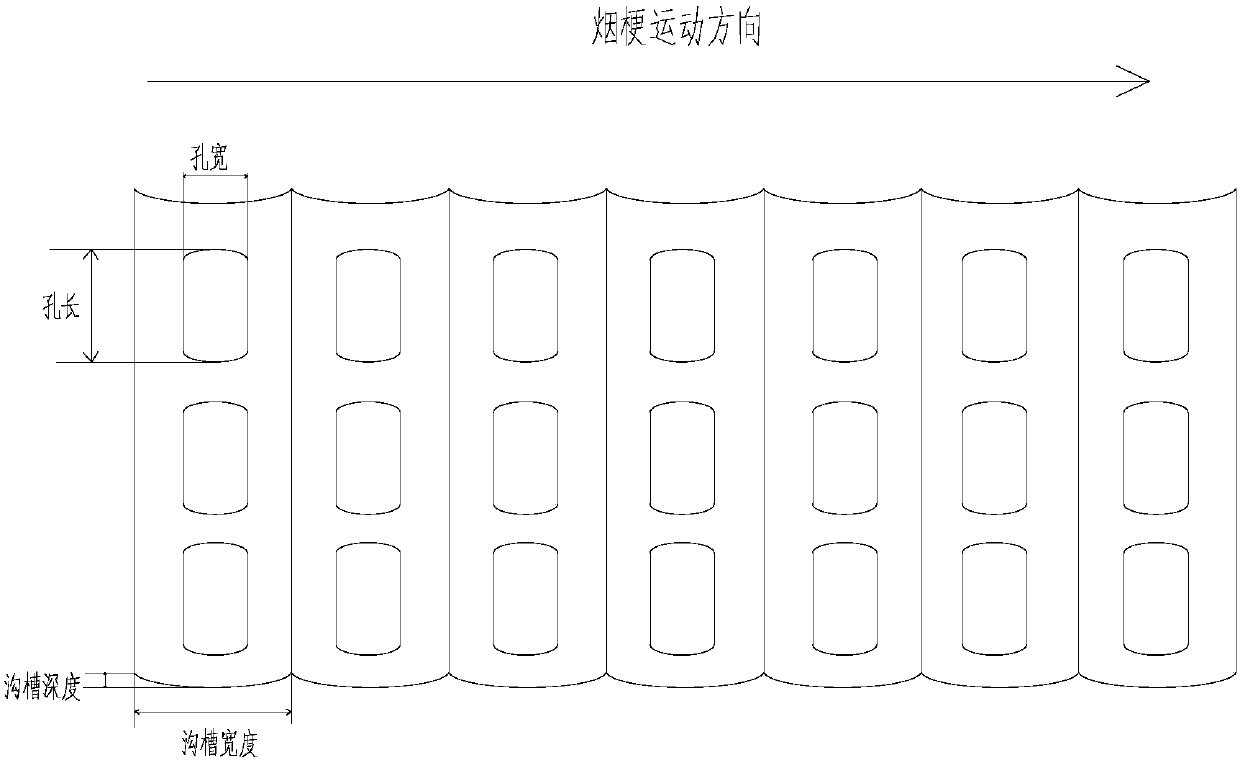

[0020] (2) First sieving: Use a vibrating sieving device with directional screen ① to sieve the tobacco stems obtained in step (1) primary sieving, and sieve out short thin stems with a length L20mm Tobacco stems, the opening size of the directional screen ① is 23mm*5mm in length and width, and the bottom of the directional screen ① is provided with an arc-shaped groove, the groove width is 10mm, and the groove depth is 5mm;

[0021] (3) Second screening: Divide the tobacco stems of L > 20mm obtained in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com