Manufacturing technique of tobacco remaking with fold paper-making method

A technology for reconstituting tobacco leaves and production process, which is applied in the directions of tobacco, tobacco preparation, application, etc., and can solve the problems of filling performance and combustion performance limitation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

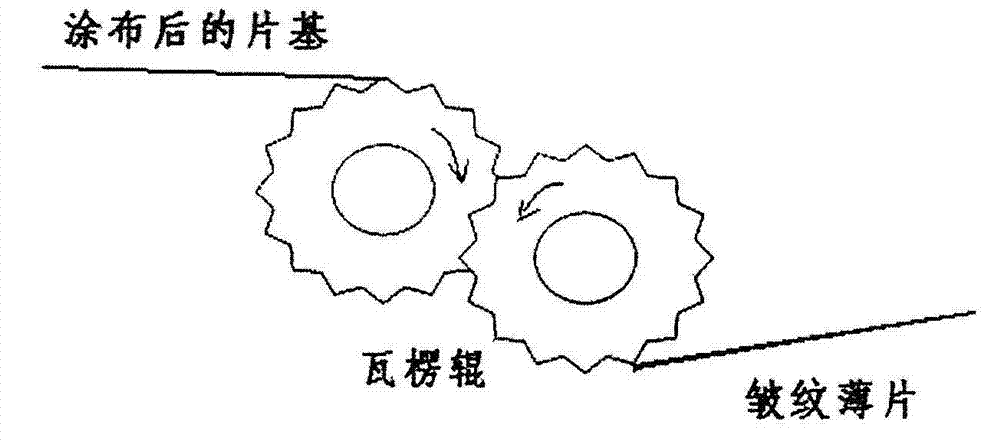

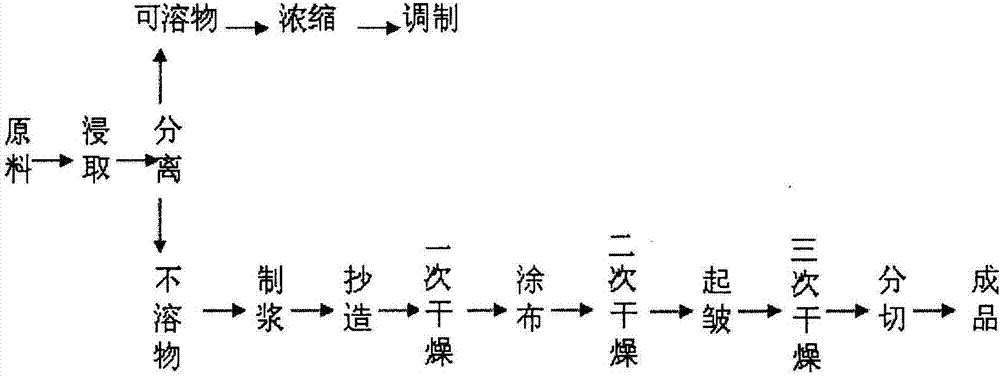

[0017] Take 100kg of tobacco stems, tobacco dust and waste shredded tobacco as mixed raw materials, and soak them in 700kg of water twice for 20 minutes at 20°C. It is stirred by paddle type straight leaf method, squeezed, separated and filtered after leaching. Pour the leaching solution into the concentration tank, and concentrate it at a temperature of 100°C and a vacuum of 0.09MPa until the Baume number reaches 38-45 0 Stop concentration when Be. The insoluble fiber material is dissociated by a fiber dissociation machine, the dissociation concentration is 15%, and the degree of beating is 17 0 Fiber stock from SR, re-refined to 40 0 For the slurry of SR, adjust the slurry to 0.5% concentration with water, and finally send it to the cylinder former to form a film base, dehydrate it by pressing and dry it once. When the moisture content of the film base is 20-30%, it will be concentrated and The prepared dipping solution is sprayed on the sheet, and then dried by the dryer...

Embodiment 2

[0019] Take 50kg of tobacco dust and waste tobacco leaf mixture, and soak it with 300kg of ethanol solution for 3 times at 30°C, each time for 20min. Take 50kg of tobacco stems and soak them in 300kg of water for 3 times at 30°C for 20 minutes each time. It is stirred by paddle type straight leaf method, squeezed, separated and filtered after leaching. Combine the two leaching solutions and pour them into the concentration tank, and concentrate them at a temperature of 100°C and a vacuum of 0.05MPa until the Baume number reaches 38-45. 0 Stop concentration when Be. The insoluble fiber material is dissociated by the fiber dissociation machine, the dissociation concentration is 15%, and the beating degree is 35% after the fine pulp treatment. 0 For SR slurry, adjust the slurry to 0.5% concentration with water, and finally send it to the fourdrinier former to form a film base, dehydrate it by pressing and dry it once. When the moisture content of the film base is 20-30%, it wil...

Embodiment 3

[0021] Take 50kg of waste tobacco leaf mixture and leaching twice with 300kg of ethanol solution at 80°C, each time for 60min. Take 50kg of tobacco stems and soak them in 300kg of water for 2 times at 80°C for 60 minutes each time. It is stirred by paddle type straight leaf method, squeezed, separated and filtered after leaching. The two kinds of leaching solutions are poured into the concentration tank respectively, and concentrated at a temperature of 100°C and a vacuum of 0.05MPa until the Baume number reaches 38-45. 0 Stop concentrating when Be, and combine the concentrates for preparation. The insoluble fiber material is dissociated by the fiber dissociation machine, the dissociation concentration is 20%, and the degree of beating is 40 after the fine pulp treatment. 0 For the slurry of SR, in order to improve the strength of the sheet, add a beating degree of 40 to the slurry before the slurry goes online. 0 SR wood pulp, after mixing evenly, adjust the pulp to a conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com