Upward and downward double circulation stirring dispensing system

A dispensing system and circulation stirring technology, which is applied in the direction of mixer accessories, dissolving, mixing machines, etc., can solve the problems of difficult maintenance, high technical level requirements of maintenance workers, complex mechanical stirring structure, etc., and achieve the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The upper and lower double circulation stirring dispensing process includes the following steps:

[0051] A, weigh a certain amount of coagulant as required;

[0052] B. When tap water is added to the dispensing tank 22, the coagulant required for sewage treatment is added, and the water is added to the liquid level sensor 1, and the water addition is stopped;

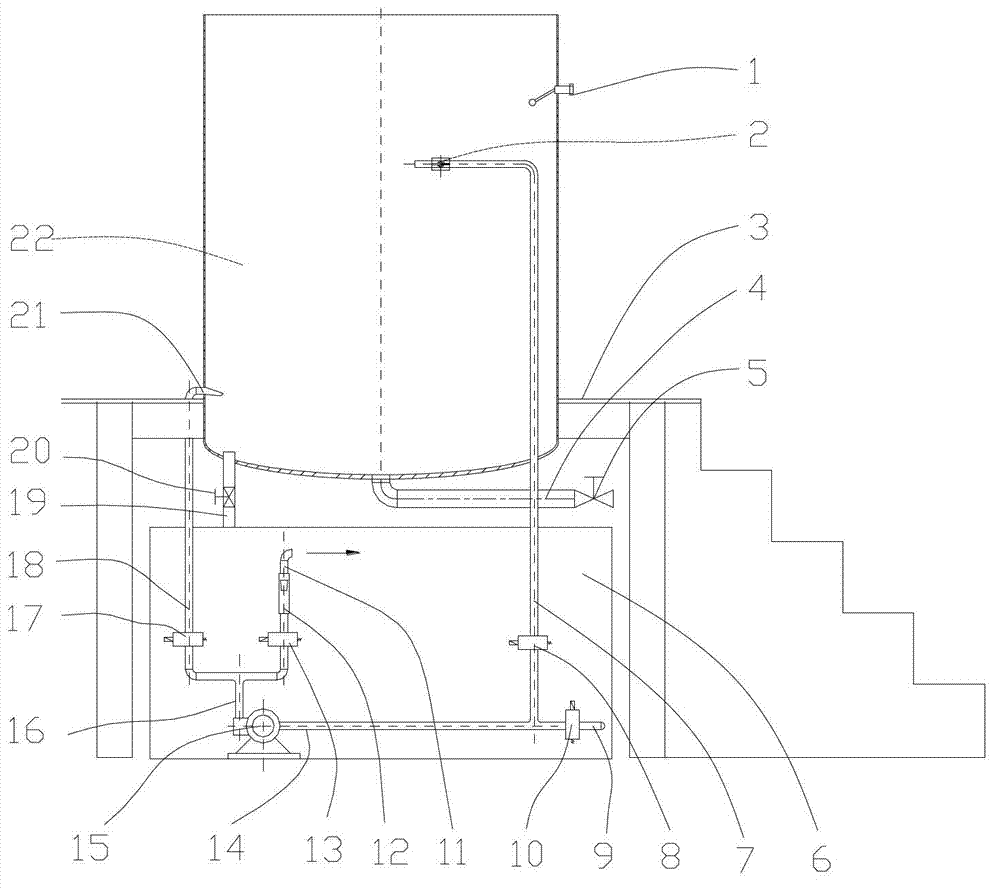

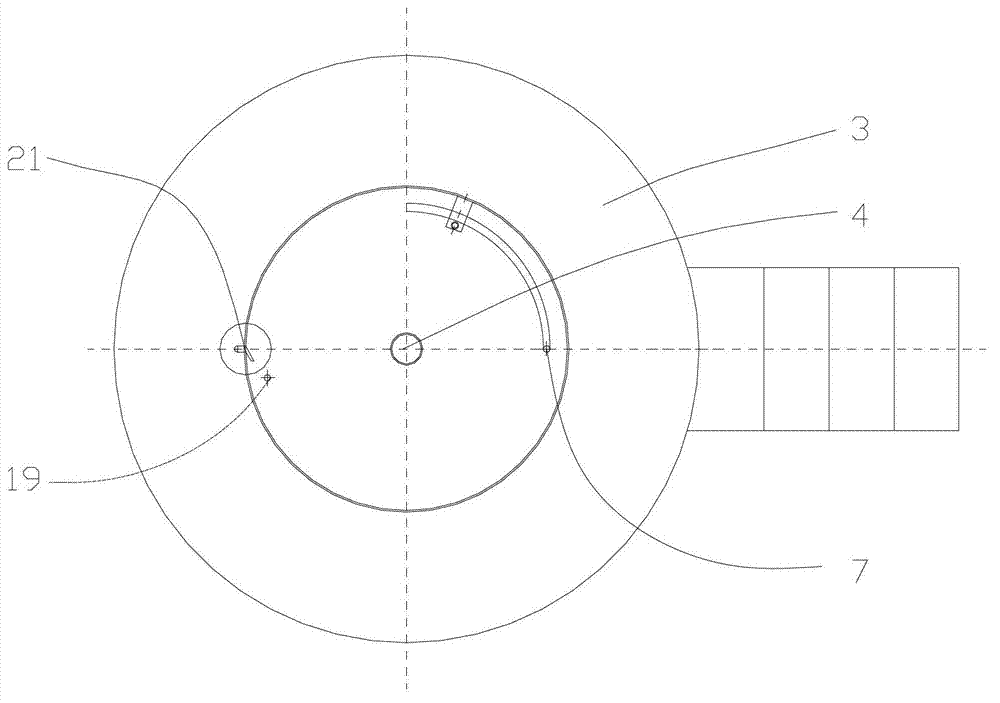

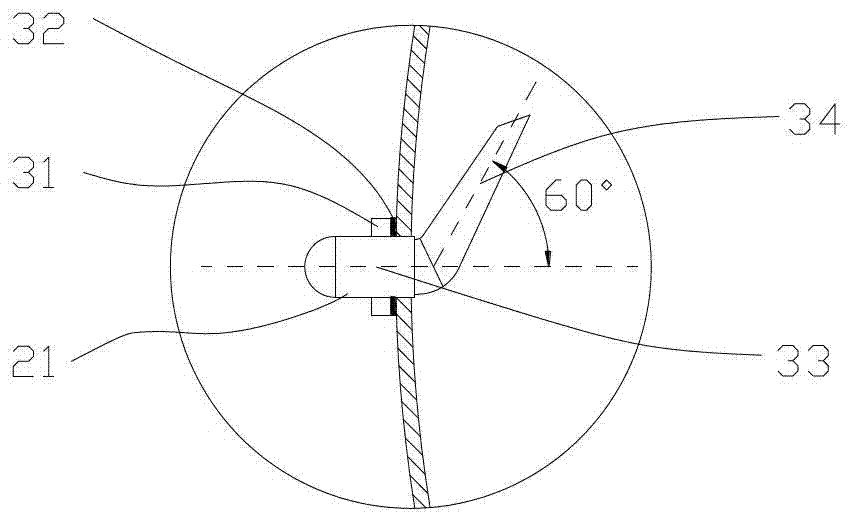

[0053] C. Close the solenoid valve B10, open the solenoid valve A8, close the solenoid valve C13, open the centrifugal pump 15, open the solenoid valve D17, and the supernatant in the dispensing tank 22 is stirred into the pump pipe 7, the pump inlet pipe 14, and the centrifugal pump through circulation 15. The stirring tube 18 and the stirring nozzle 21 enter the dispensing tank 22, because the angle between the inlet pipe 33 of the stirring nozzle and the center line of the outlet pipe of the stirring nozzle 34 is 60°. The coagulant is stirred, and at the same time, it circulates and stirs the liquid in the s...

Embodiment 2

[0059] The upper and lower double circulation stirring dispensing process includes the following steps:

[0060] A, weigh a certain amount of coagulant as required;

[0061] B. When tap water is added to the dispensing tank 22, the coagulant required for sewage treatment is added, and the water is added to the liquid level sensor 1, and the water addition is stopped;

[0062] C. Close the solenoid valve B10, open the solenoid valve A8, close the solenoid valve C13, open the centrifugal pump 15, open the solenoid valve D17, and the supernatant in the dispensing tank 22 is stirred into the pump pipe 7, the pump inlet pipe 14, and the centrifugal pump through circulation 15. The stirring tube 18 and the stirring nozzle 21 enter the dispensing tank 22, because the angle between the inlet pipe 33 of the stirring nozzle and the center line of the outlet pipe of the stirring nozzle 34 is 60°. The coagulant is stirred, and at the same time, it circulates and stirs the liquid in the s...

Embodiment 3

[0068] The upper and lower double circulation stirring dispensing process includes the following steps:

[0069] A, weigh a certain amount of coagulant as required;

[0070] B. When tap water is added to the dispensing tank 22, the coagulant required for sewage treatment is added, and the water is added to the liquid level sensor 1, and the water addition is stopped;

[0071] C. Close the solenoid valve B10, open the solenoid valve A8, close the solenoid valve C13, open the centrifugal pump 15, open the solenoid valve D17, and the supernatant in the dispensing tank 22 is stirred into the pump pipe 7, the pump inlet pipe 14, and the centrifugal pump through circulation 15. Stirring pipe 18 and stirring nozzle 21 enter into the dispensing tank 22, because the angle between the inlet pipe 33 of the stirring nozzle and the center line of the outlet pipe of the stirring nozzle 34 is 60°, the liquid enters the dispensing tank 22 and pushes the liquid in the tank to rotate to treat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com