Central buried olive-shaped interception nozzle rod

An olive-shaped, mouth stick technology, applied in tobacco, food science, application, etc., can solve the problem of low interception efficiency and achieve the effect of improving deposition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

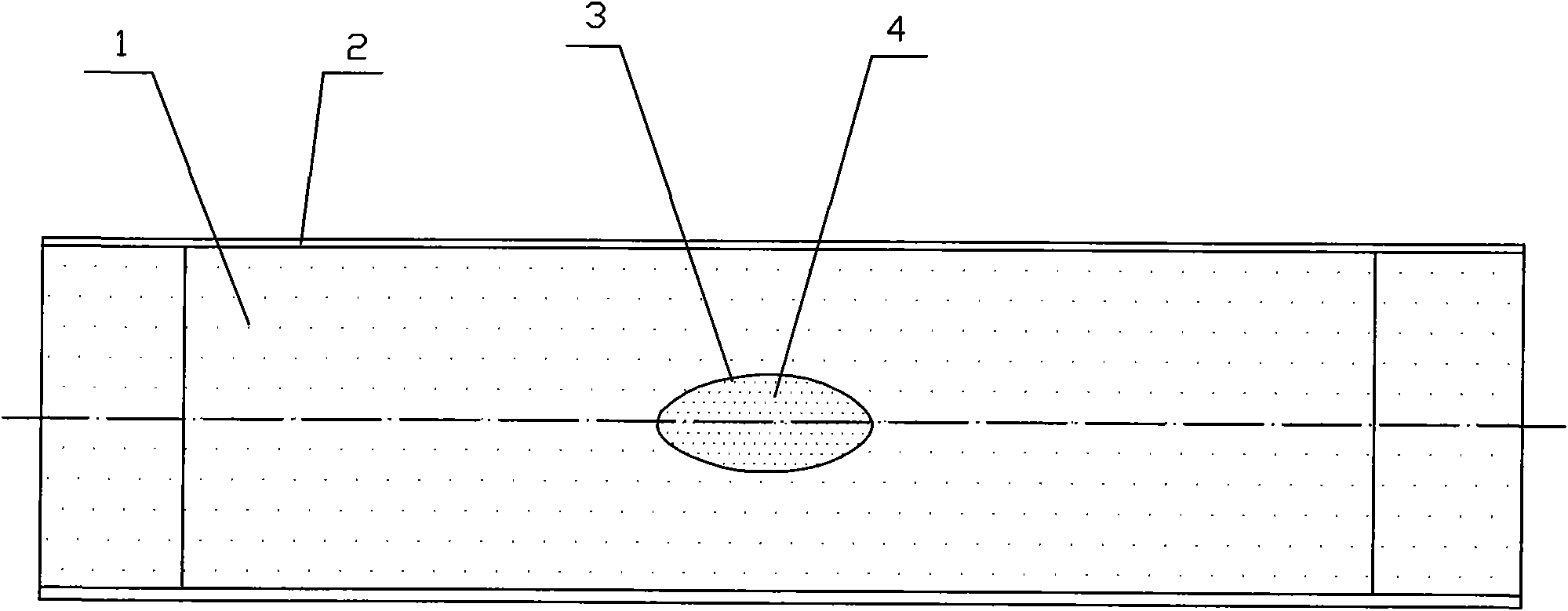

[0022] Such as figure 1 As shown, the present invention provides a center-buried olive-shaped nozzle rod, which is composed of a tow mandrel 1 and an outer wrapping molding paper 2, and a high-adsorptive material is embedded in the center of the tow mandrel along the axial direction. The olive-shaped adsorption core 3 made of (such as activated carbon, nano-adsorption material), the surface and the solid of the adsorption core 3 have adsorption micropores 4 for absorbing smoke.

[0023] Due to the high adsorption of the adsorption core to the flue gas, a large amount of flue gas is adsorbed and the aerosol particles are increased, which improves the deposition efficiency. After passing through multiple adsorption cores in this way, the particles in the flue gas are largely trapped.

Embodiment 2

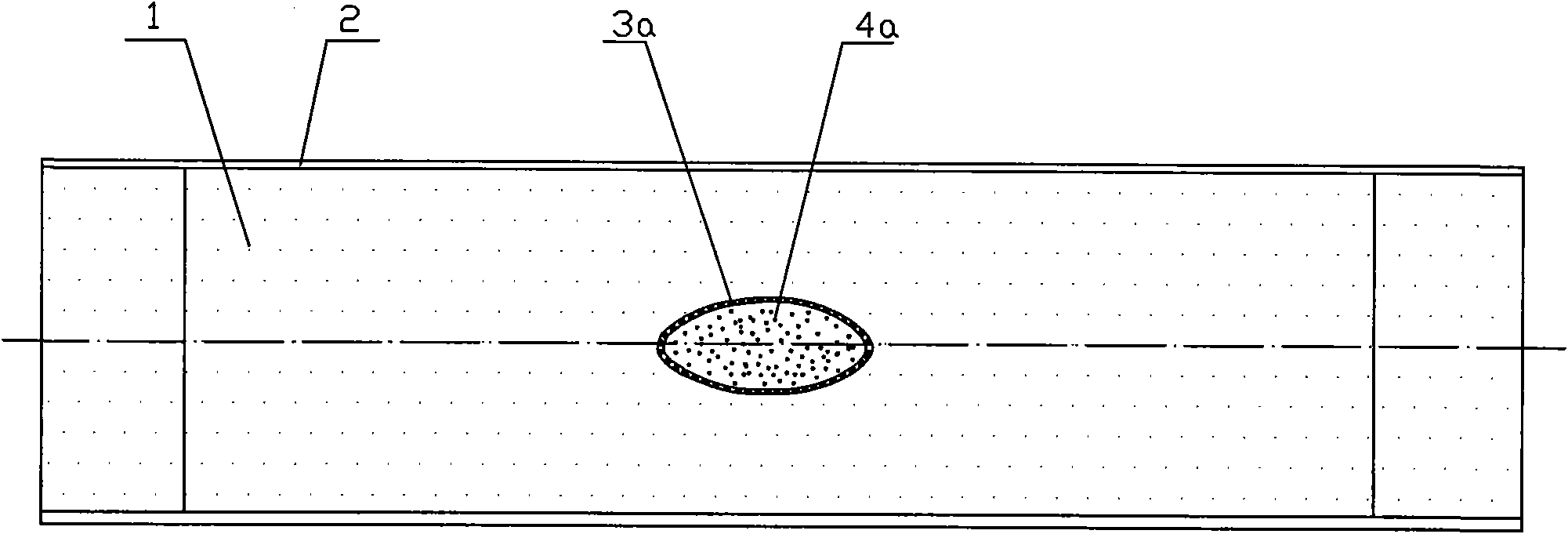

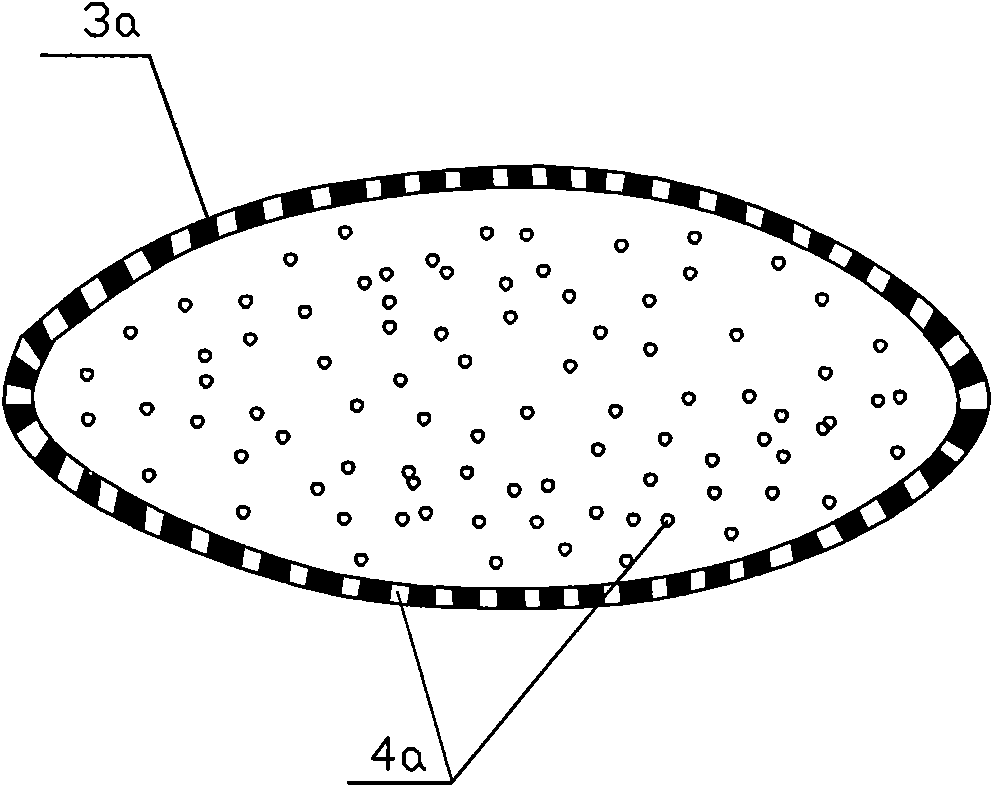

[0025] Such as figure 2 , image 3 As shown, the present invention provides a center-buried olive-shaped nozzle rod, which is composed of a tow mandrel 1 and an outer wrapped molding paper 2, and a high hollow olive-shaped nozzle is buried in the center of the tow mandrel The adsorption core 3a has drainage holes 4a on the surface of the adsorption core 3a. Since the smoke passing through the drainage holes 4a enters the hollow of the olive-shaped adsorption core 3a, the space suddenly enlarges, forming a cold well effect, which makes the smoke aerosol particles condense and increase , is adsorbed and deposited in the hollow olive-shaped adsorption core, and the particles in the flue gas are largely trapped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com