Preparation method of homogenized specially-shaped cigarettes

A homogenization and special-shaped technology, applied in the field of cigarette production, can solve the problems of unstable quality, unstable quality of cigarette products, incision shedding, etc., to ensure homogenization and stability, increase exchange rate, and avoid shedding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

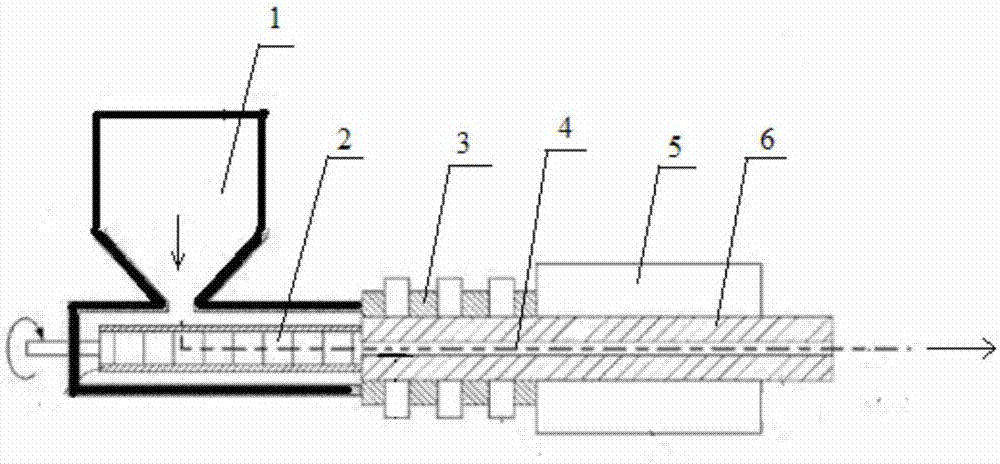

Method used

Image

Examples

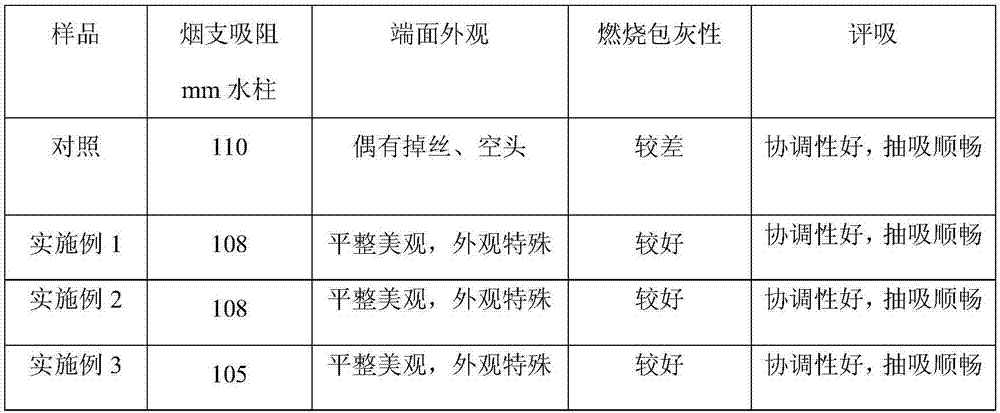

Embodiment 1

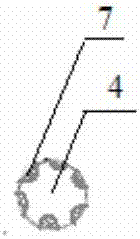

[0042] 1) Pulverize tobacco raw materials such as tobacco leaves and tobacco stems into 100-150 mesh tobacco powder at 40°C; 2) Mix potassium citrate, 10% aqueous solution of hydroxypropyl cellulose, propylene glycol and tobacco essence in 0.2 parts by mass , 8 parts, 0.2 parts and 0.05 parts were stirred evenly to obtain a mixed solution; 3) 100 parts of the above-mentioned tobacco powder and the mixed solution were granulated in one step, dried and air-selected to obtain tobacco particles with a particle size of 20-80 mesh for subsequent use; 4) Take by weighing 10% white latex for tobacco (solid content 10%) of tobacco particle weight, and it is evenly sprayed on above-mentioned tobacco particle surface, use continuous feeding device to press it from one end of the cylindrical mold of diameter 7.5mm (this cylindrical mold There are 10 semicircular ridges with a diameter of 0.8mm on the inner side), which are dried, solidified and shaped, and cooled to extrude from the other ...

Embodiment 2

[0044] 1) Grinding tobacco raw materials such as tobacco leaves and tobacco stems into 100-150 mesh tobacco powder at 40°C; 1, 0.3, and 0.03 parts were stirred evenly to obtain a mixed solution; 3) 100 parts of the above-mentioned tobacco powder and the mixed solution were granulated in one step, dried and air-selected to obtain tobacco particles with a particle size of 20-80 mesh for subsequent use; 4) Weighing Tobacco particle weight 15% ethylene-vinyl acetate copolymer hot-melt glue, after it melts, evenly sprays on the above-mentioned tobacco particle surface, uses continuous feeding device to press it from one end of a cylindrical mold with a diameter of 7.5mm (the inner side of the cylindrical mold has a There are 8 semicircular convex strips with a diameter of 1mm), which are dried and solidified, and then extruded from the other end to obtain a special-shaped tobacco particle round rod (density 1.2g / mL, moisture content is 8%); 5) Tobacco round After the rod is extrude...

Embodiment 3

[0046] 1) Grinding tobacco raw materials such as tobacco leaves and tobacco stems into 100-150 mesh tobacco powder at 40°C; 2) mixing sodium citrate, 10% aqueous solution of gum arabic, glycerin and tobacco essence according to 0.3 parts by mass and 8 parts by mass , 1 part, and 0.1 part are stirred evenly to obtain a mixed solution; 3) 100 parts of the above-mentioned tobacco powder and the mixed solution are granulated in one step, dried and air-selected to get a particle size of 20-80 mesh tobacco particles for subsequent use; 4) Weigh the tobacco Particle weight 15% polyethylene hot melt adhesive, after it is melted, evenly spray on the surface of the above-mentioned tobacco particles, use a continuous feeding device to press it from one end of a cylindrical mold with a diameter of 7.5mm (the inner side of the cylindrical mold has 6 pieces with a diameter of 2mm). semi-circular protruding strips), dried and solidified, and then extruded from the other end to obtain special-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com