Patents

Literature

1309results about How to "Enhanced convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

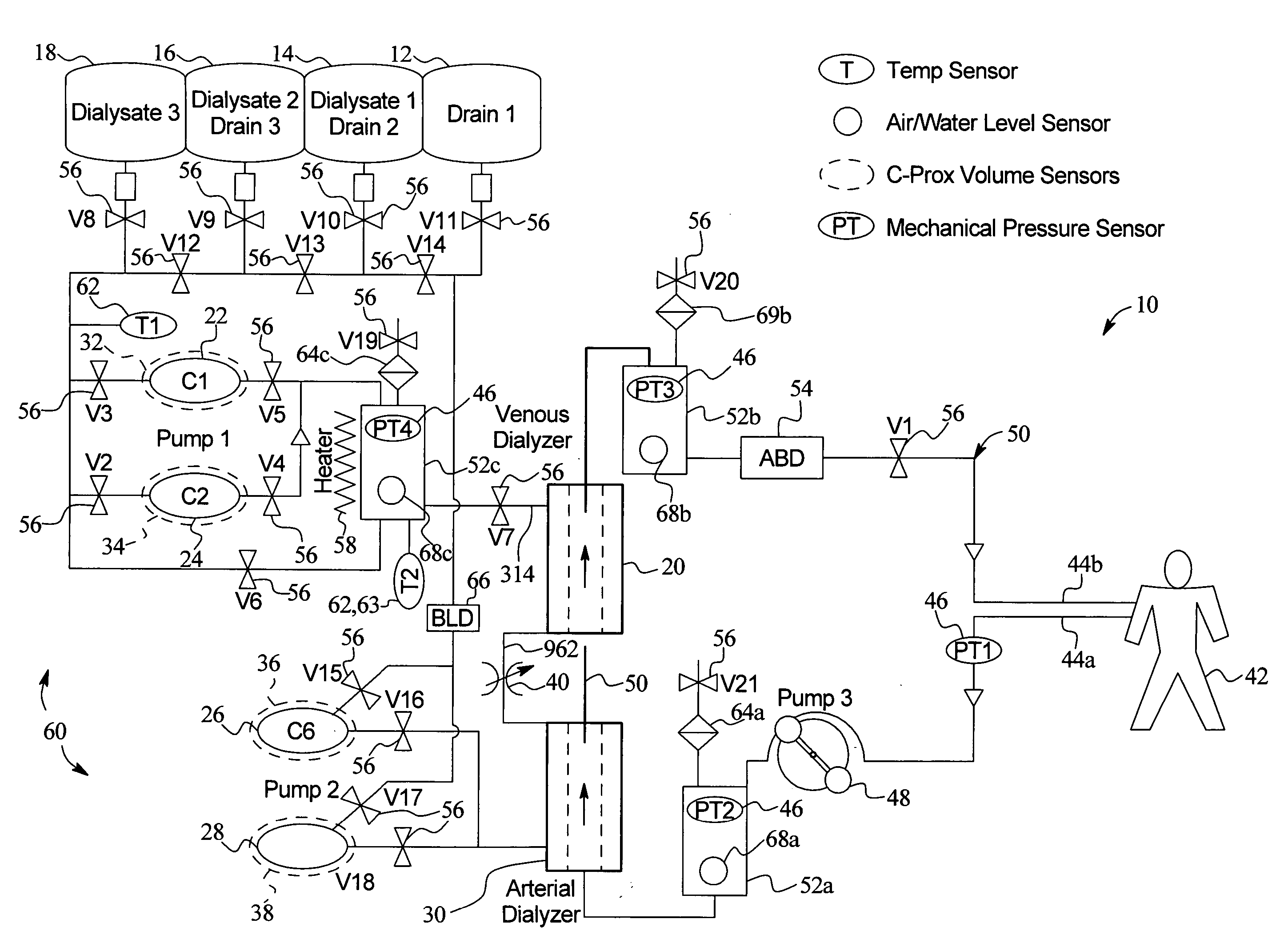

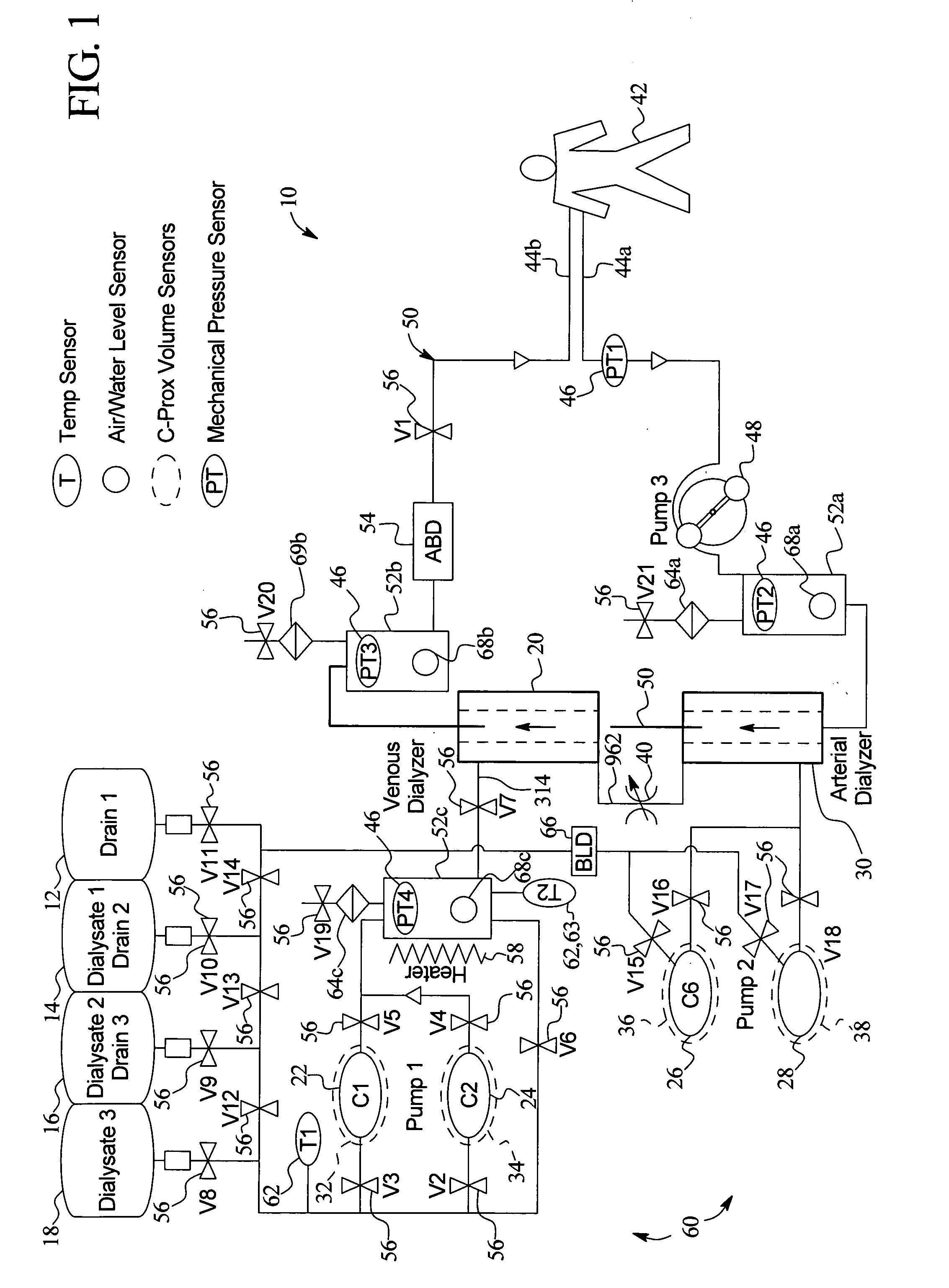

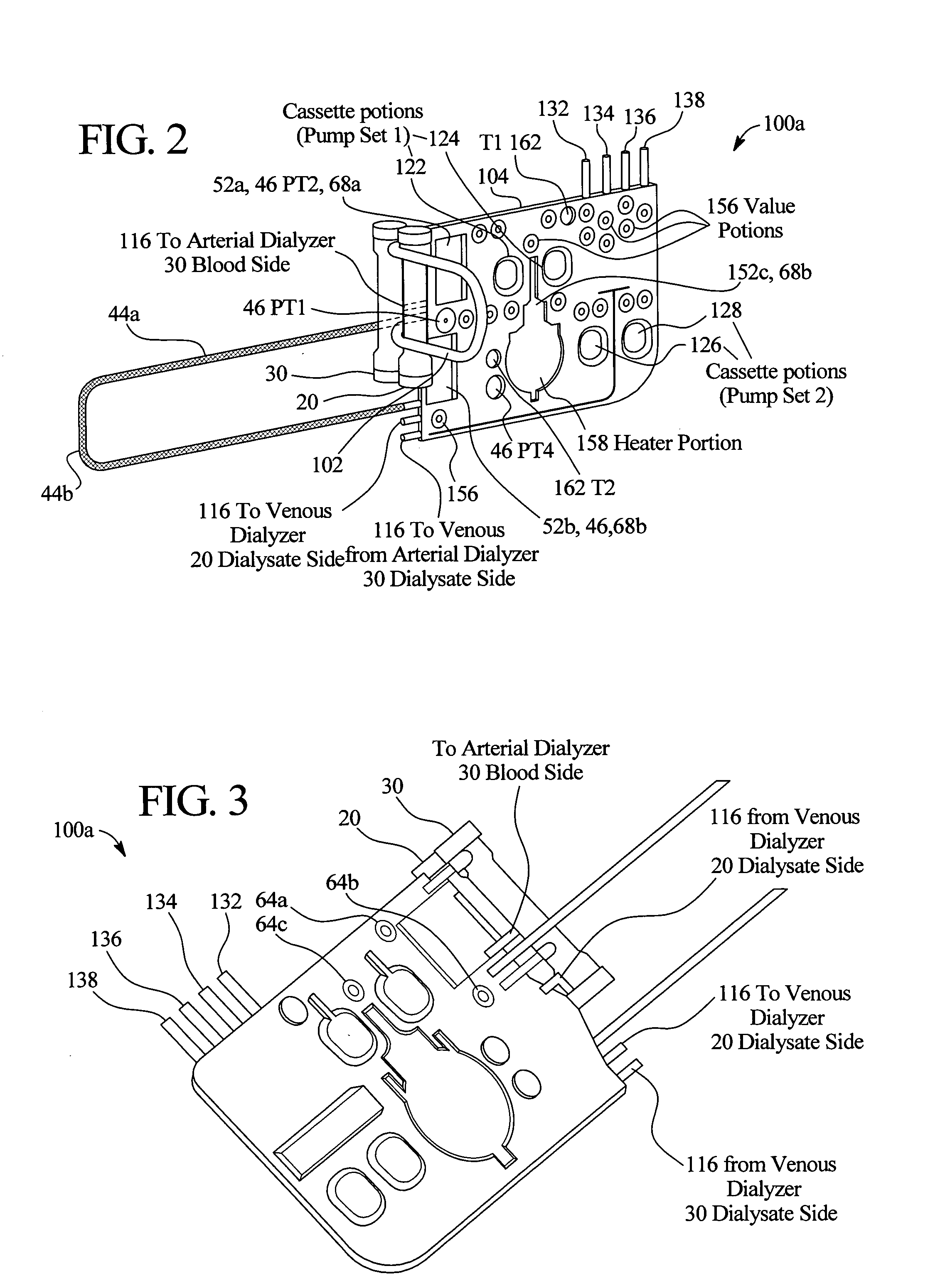

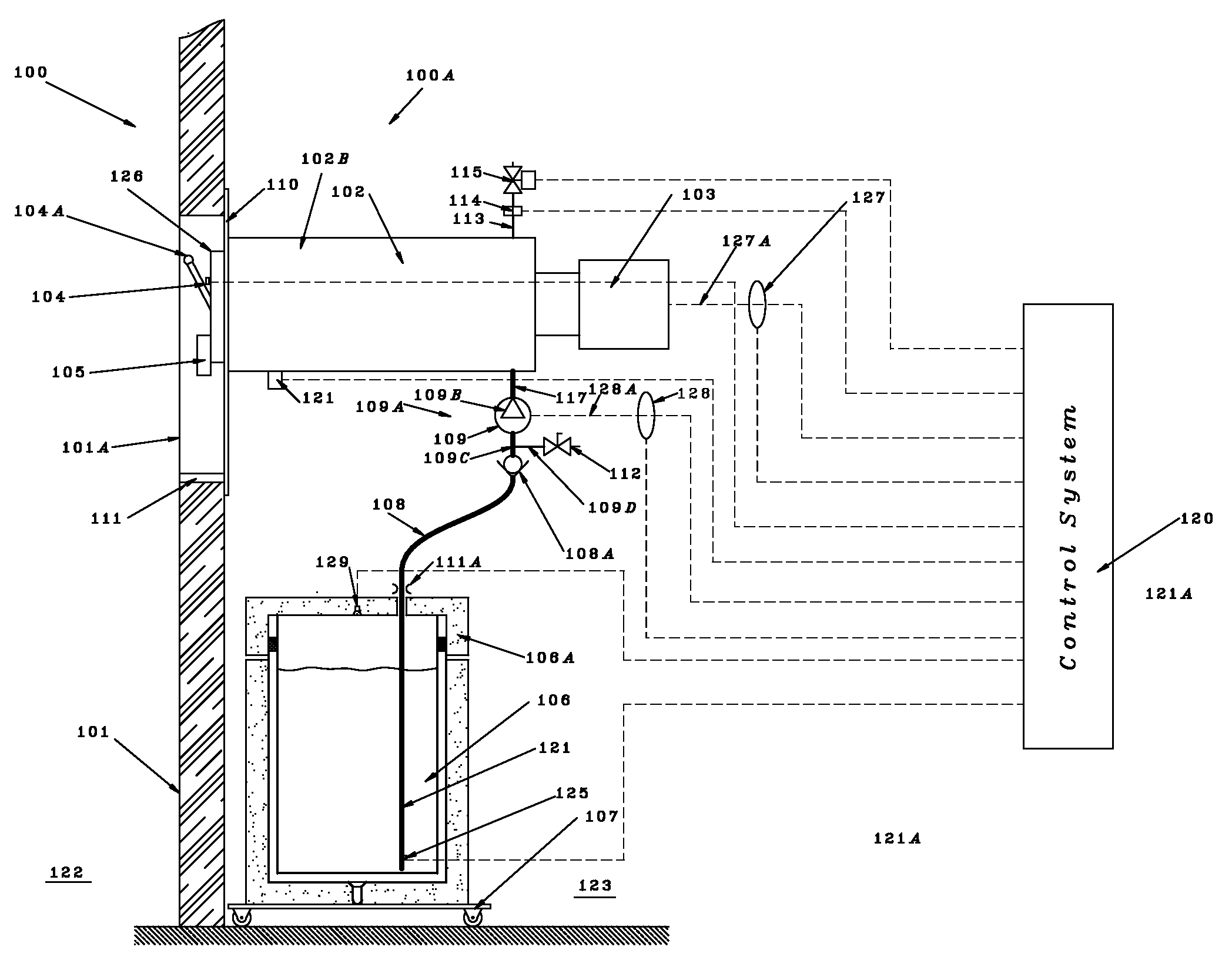

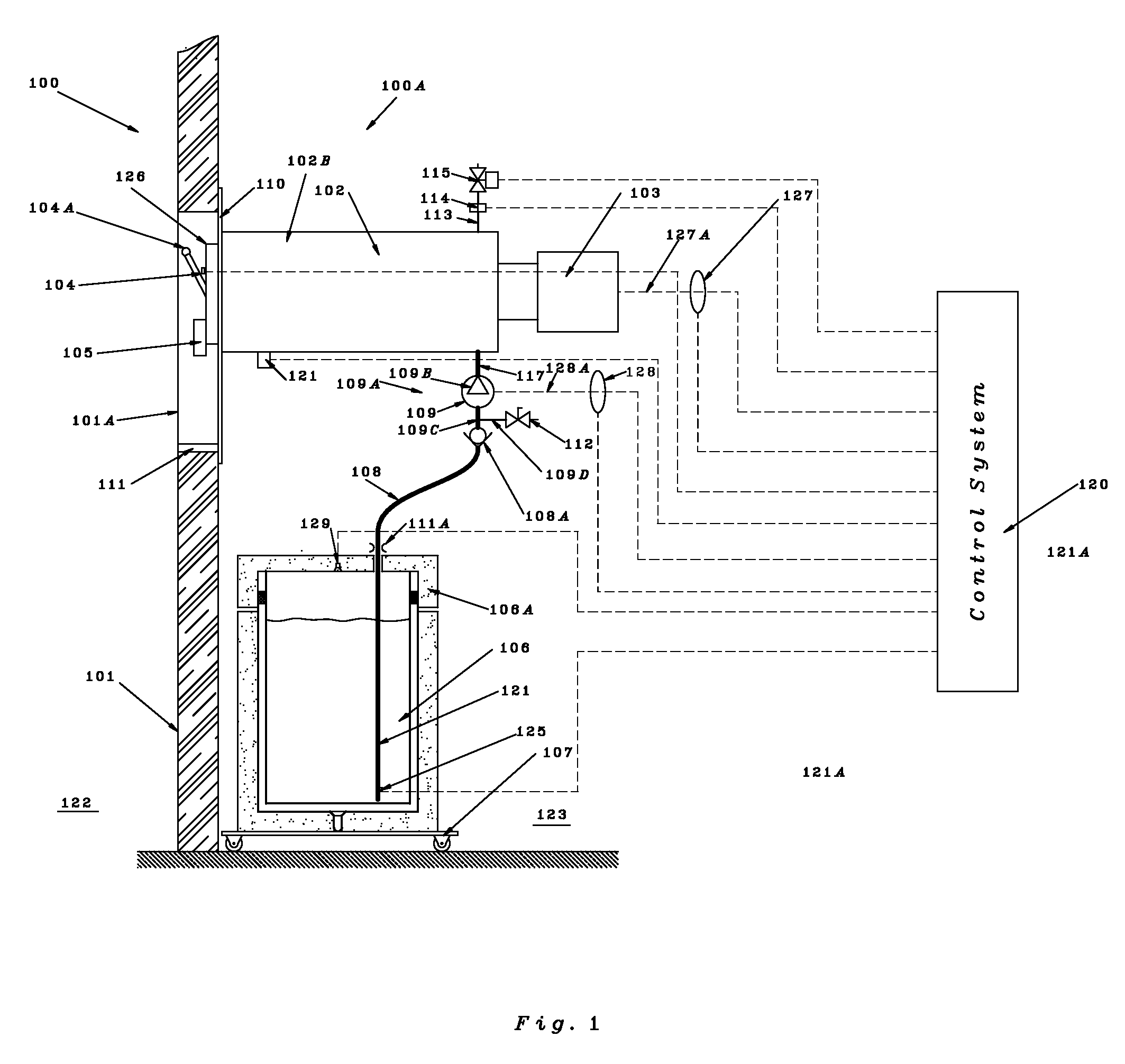

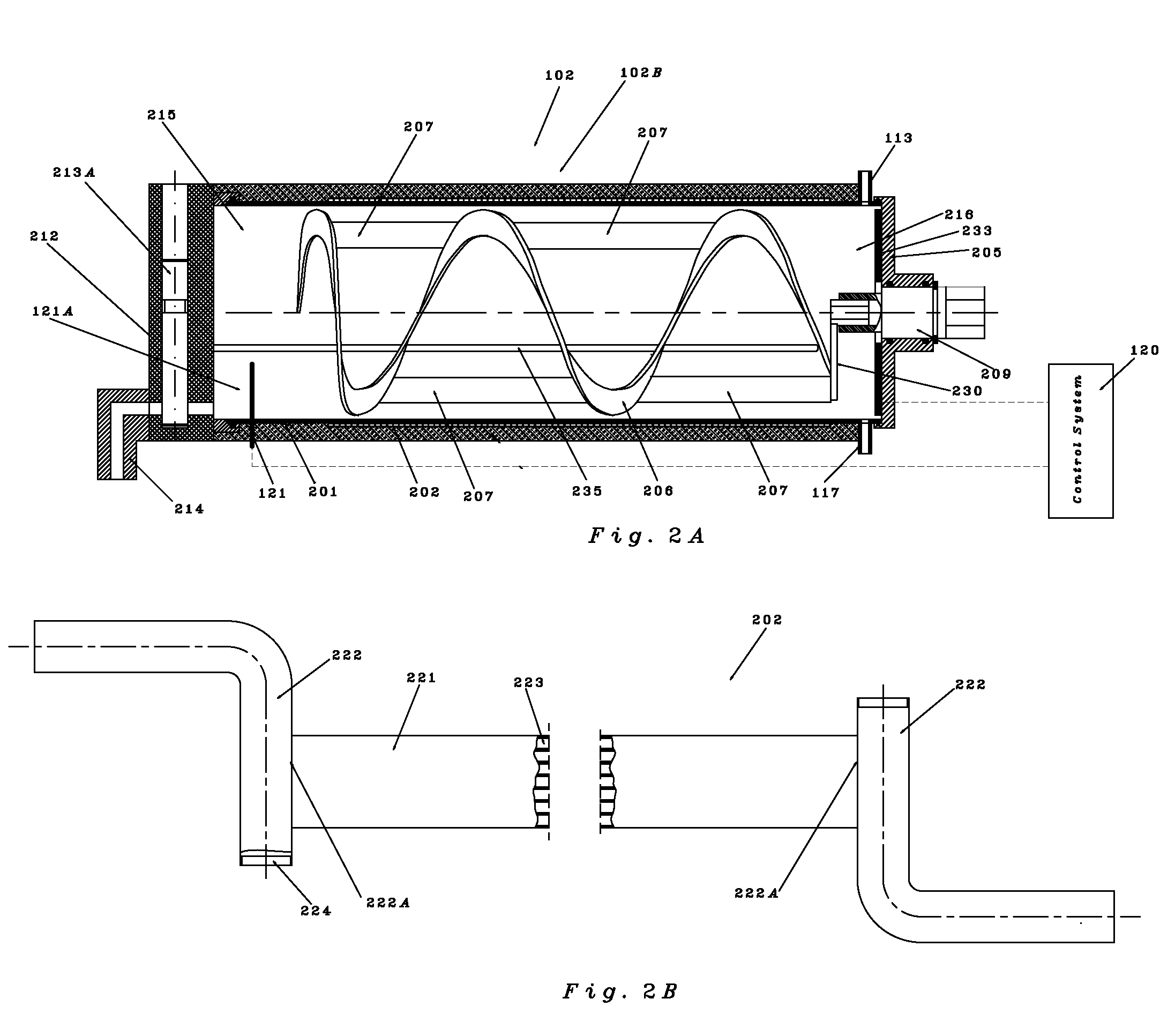

High convection home hemodialysis/hemofiltration and sorbent system

InactiveUS20050131332A1Easily set up sterile blood therapy systemImprove efficiencySemi-permeable membranesHaemofiltrationPositive pressureSorbent

A system, method and apparatus for performing a renal replacement therapy is provided. In one embodiment, two small high flux dialyzers are connected in series. A restriction is placed between the two dialyzers in the dialysate flow path. The restriction is variable and adjustable in one preferred embodiment. The restriction builds a positive pressure in the venous dialyzer, causing a high degree of intentional backfiltration. That backfiltration causes a significant flow of dialysate through the high flux venous membrane directly into the patient's blood. That backfiltered solution is subsequently ultrafiltered from the patient from the arterial dialyzer. The diffusion of dialysate into the venous filter and removal of dialysate from the arterial dialyzer causes a convective transport of toxins from the patient. Additionally, the dialysate that does not diffuse directly into the patient but instead flows across the membranes of both dialyzers provides a diffusive clearance of waste products.

Owner:BAXTER HEALTHCARE SA +1

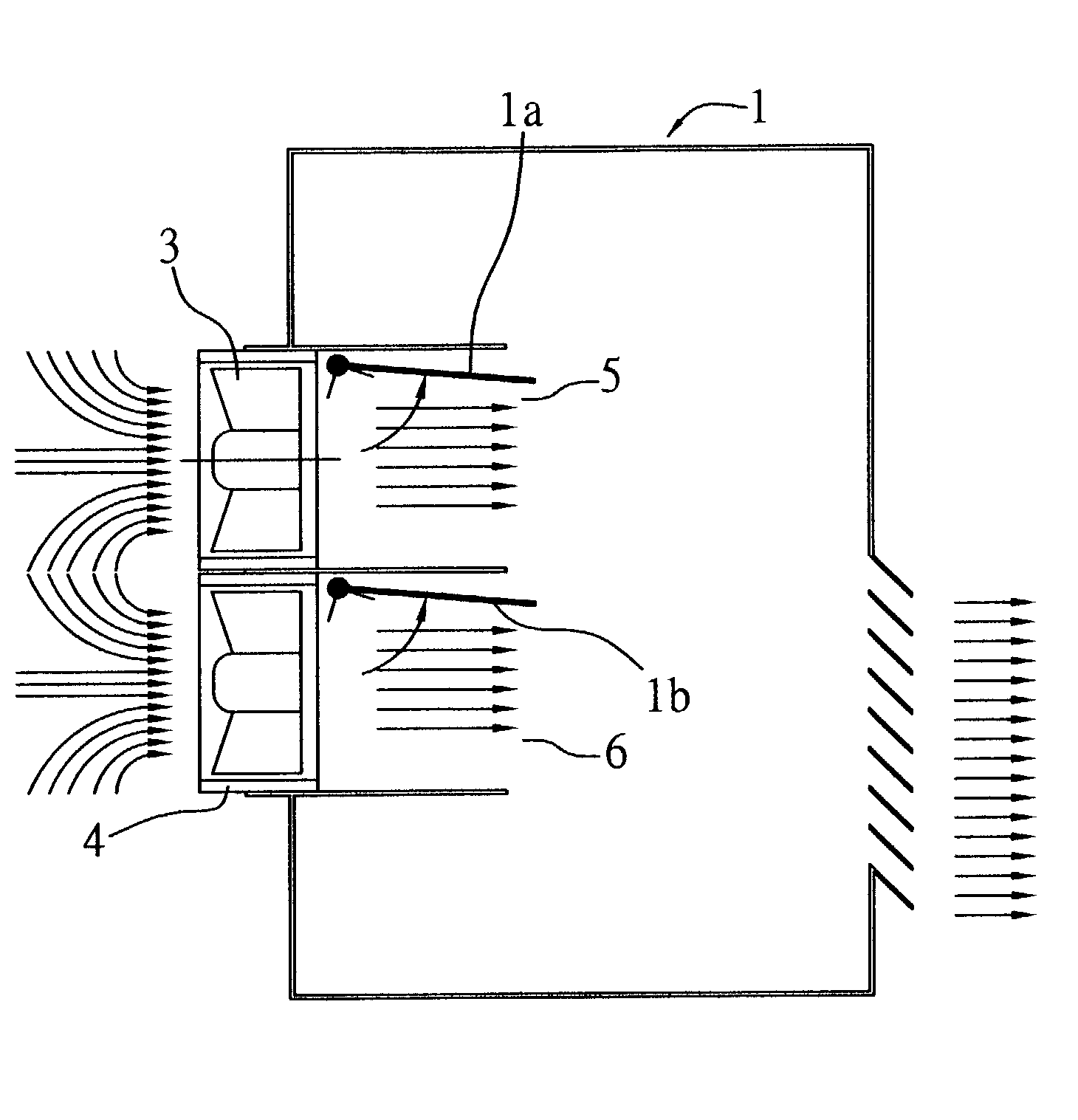

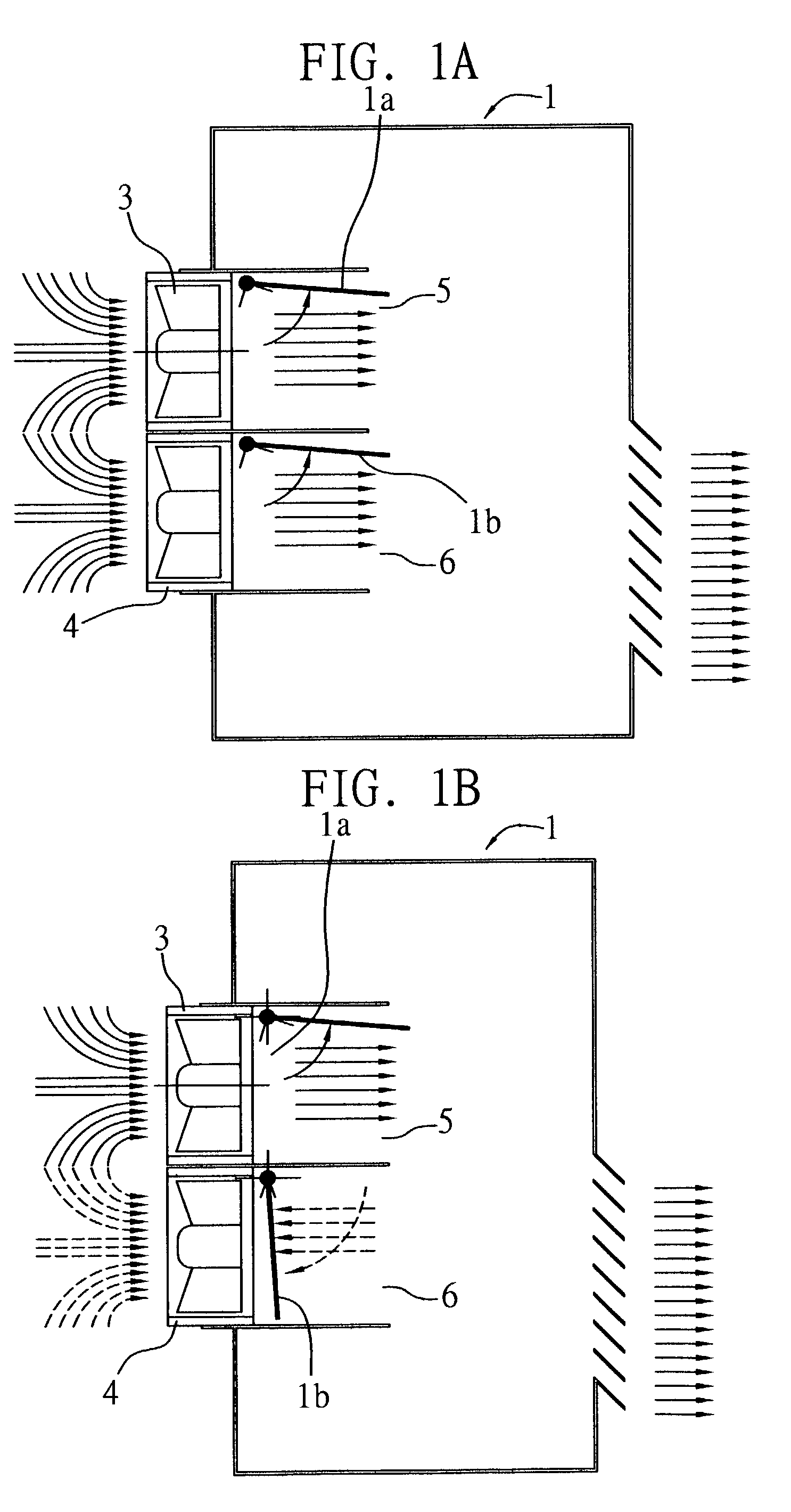

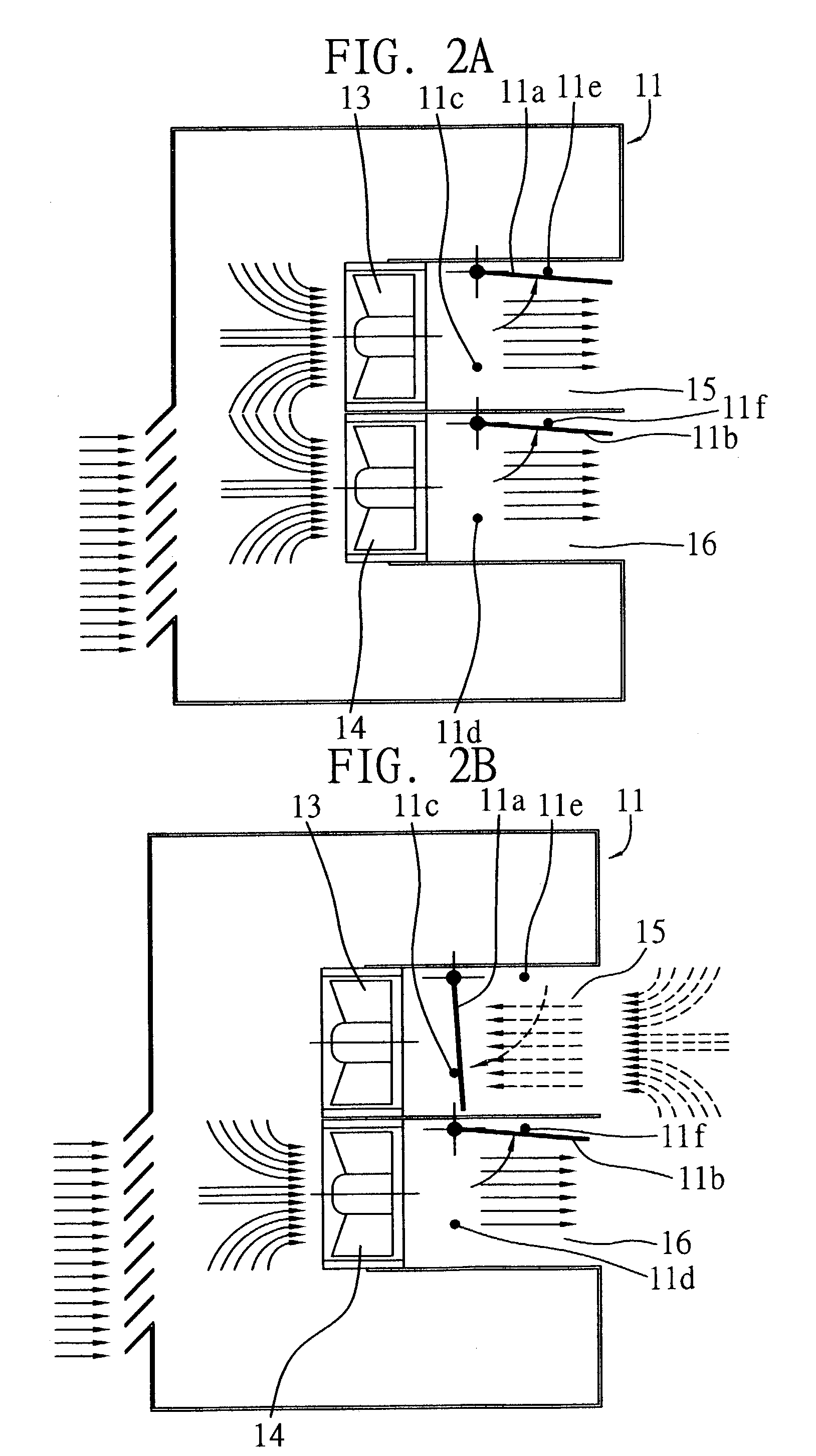

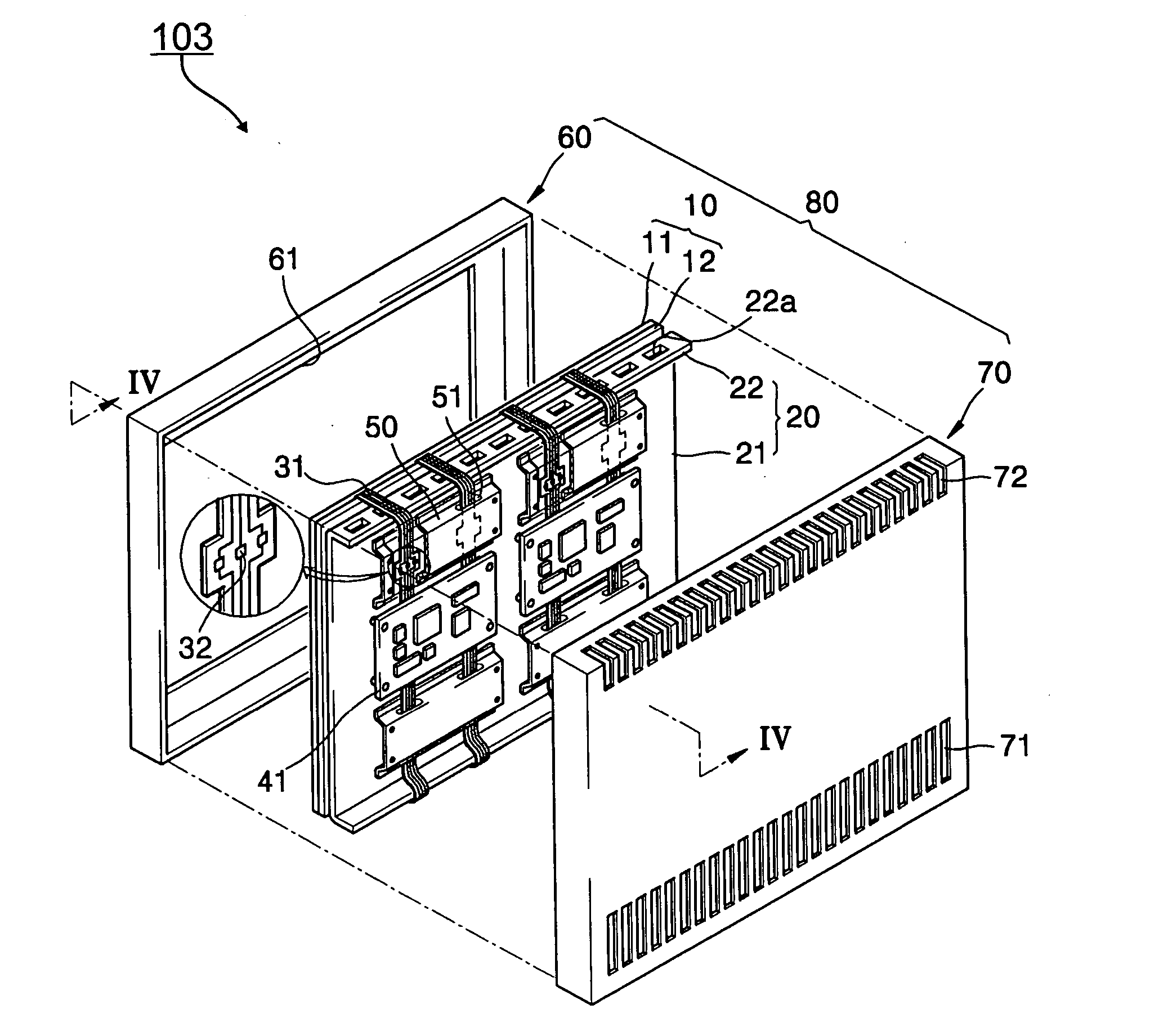

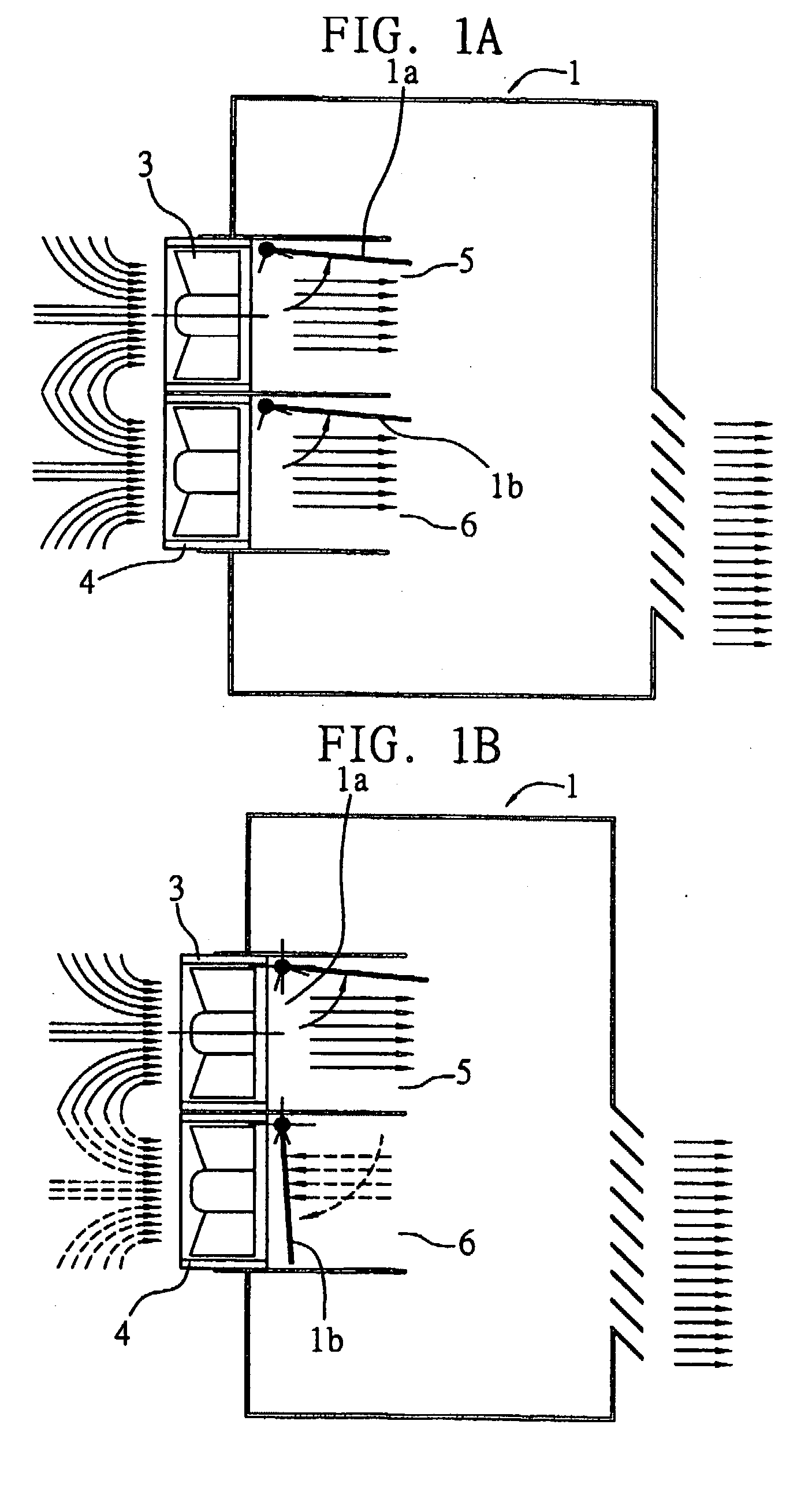

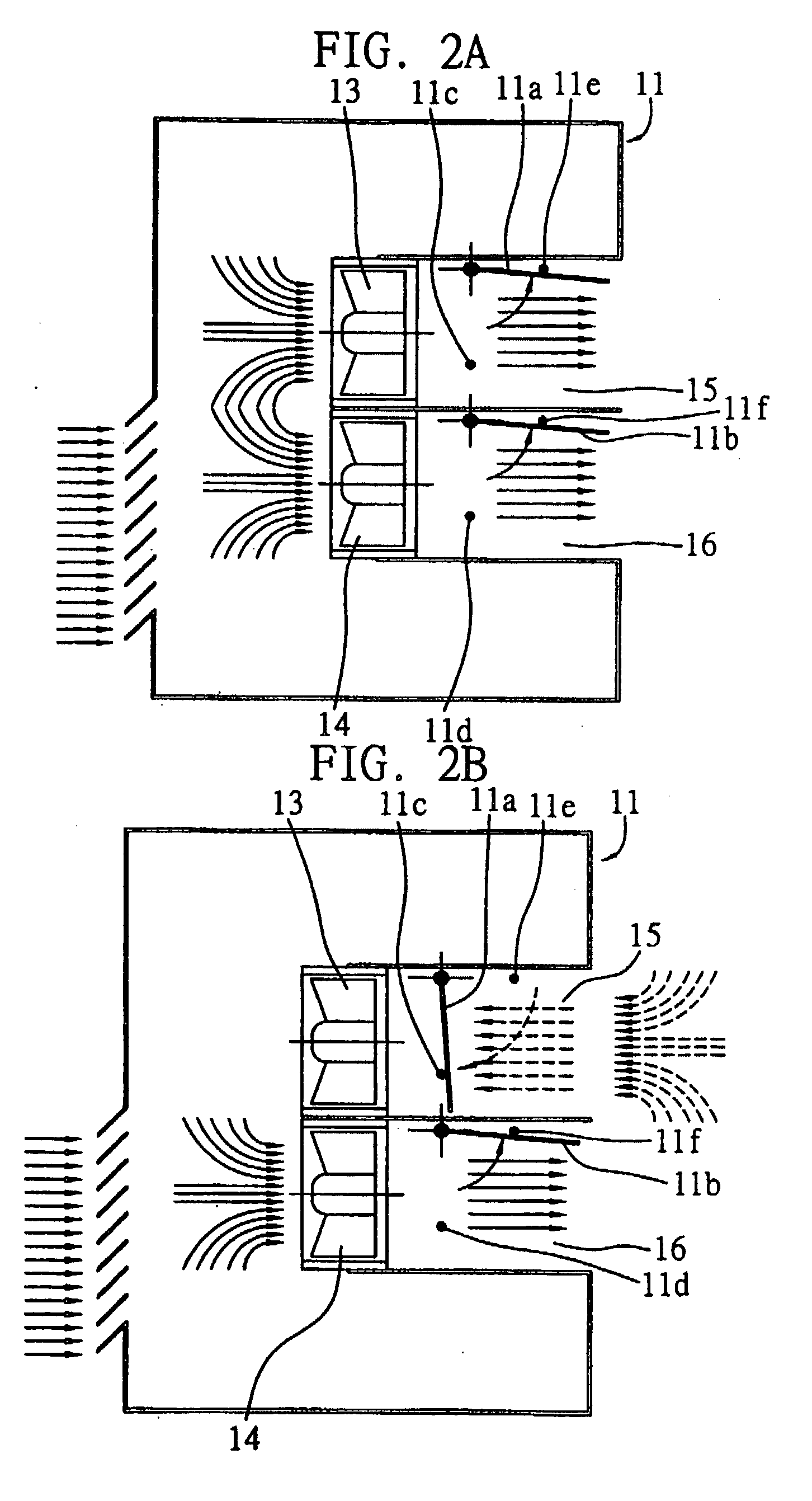

Flow direction control mechanism

InactiveUS6991533B2Increasing fabrication costIncreased control of airflowDomestic cooling apparatusLighting and heating apparatusElectronic systemsMechanical engineering

A flow direction control mechanism is provided, which includes at least a rotatable means provided in a passage of an electronic system or apparatus. The rotatable means moves to an open position by means of a force generated from fluids flowing through the passage and returns to a close position in the absence of the force. Further, a restrictor is disposed adjacent to the rotatable means for restricting movement of the rotatable means between the open position and the close position.

Owner:DELTA ELECTRONICS INC

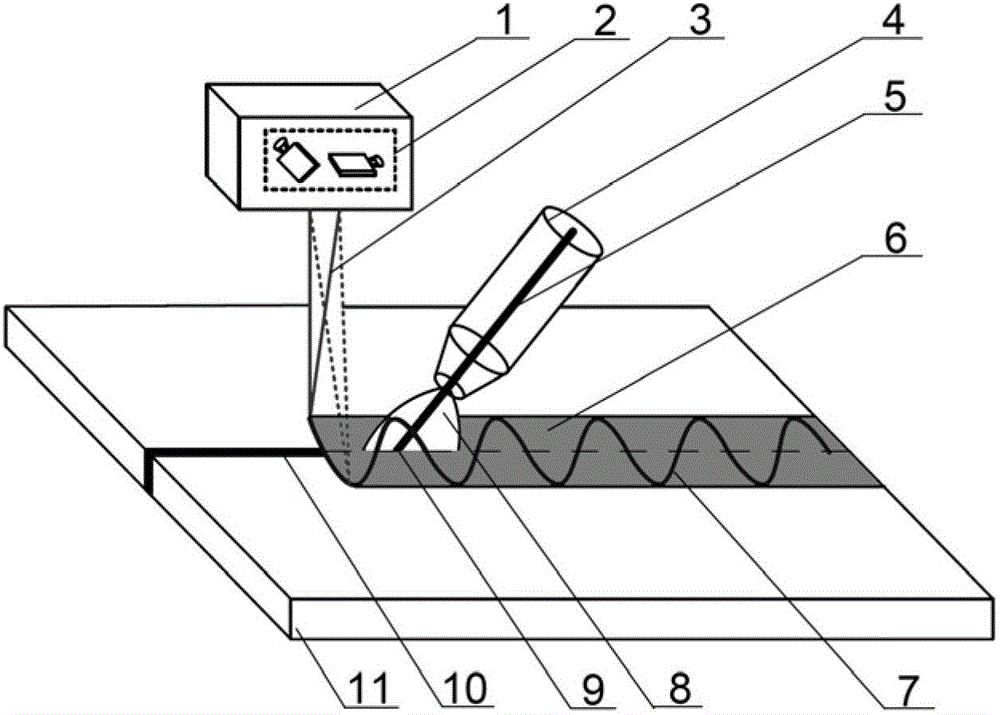

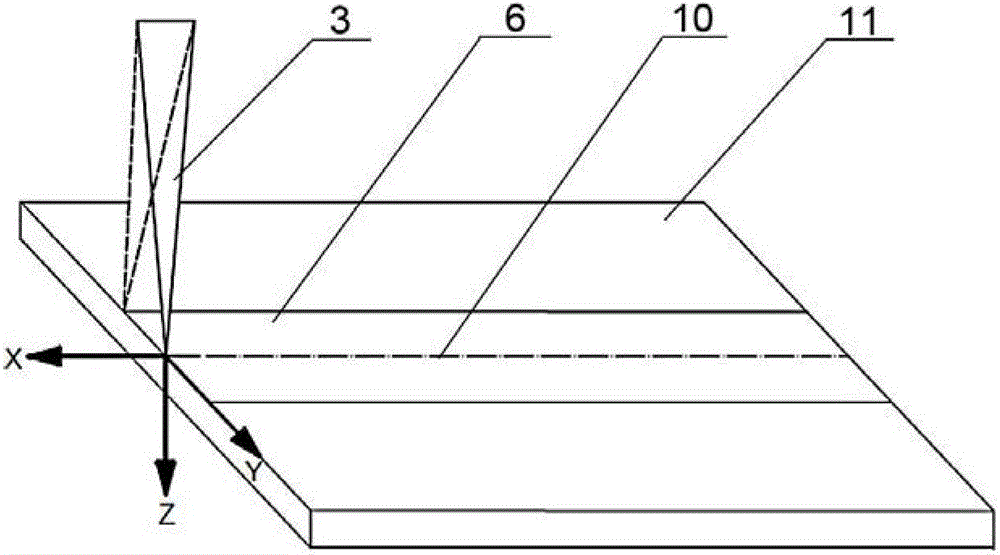

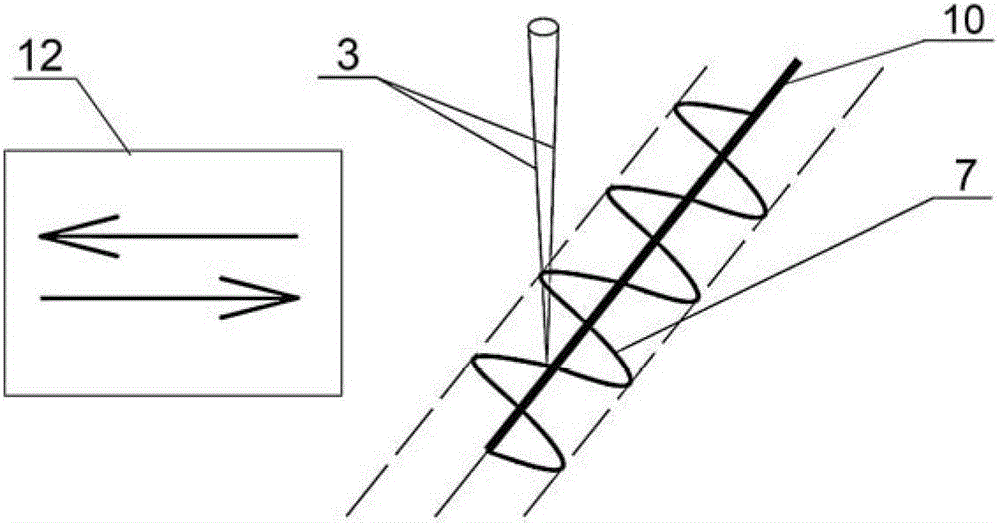

Oscillatory scanning laser beam-electric arc hybrid welding method and system

ActiveCN103056533AImprove featuresImprove welding qualityLaser beam welding apparatusPorosityLaser scanning

The invention discloses an oscillatory scanning laser beam-electric arc hybrid welding method and system. Laser beams and electric arc move together along an abutted seam in large range space, simultaneously the laser beams surround acting points of the electric arc to perform oscillatory scanning movement in a local small area, and an actual welding track is a curve formed by overlying two types of movements. As for an optimal range of laser beam oscillatory scanning displacement, the range in the direction of an X axis is minus 2mm to 3mm, the range in the direction of an Y axis is minus 5mm to 5mm, the range in the direction of a Z axis is minus 2mm to 2mm, and the oscillation frequency is in a range from 20Hz to 500Hz. According to the method and the system, an enhanced technical effect is achieved by the aid of interaction of a laser beam oscillatory scanning effect and a laser-electric arc synergistic effect, and the welding quality is improved. Compared with existing laser-electric arc hybrid welding and laser scanning welding methods and systems, the method and the system have the advantages that higher weld porosity inhibiting capability is achieved, and the weld strength is improved by 10% to 50%.

Owner:武汉飞能达激光技术有限公司

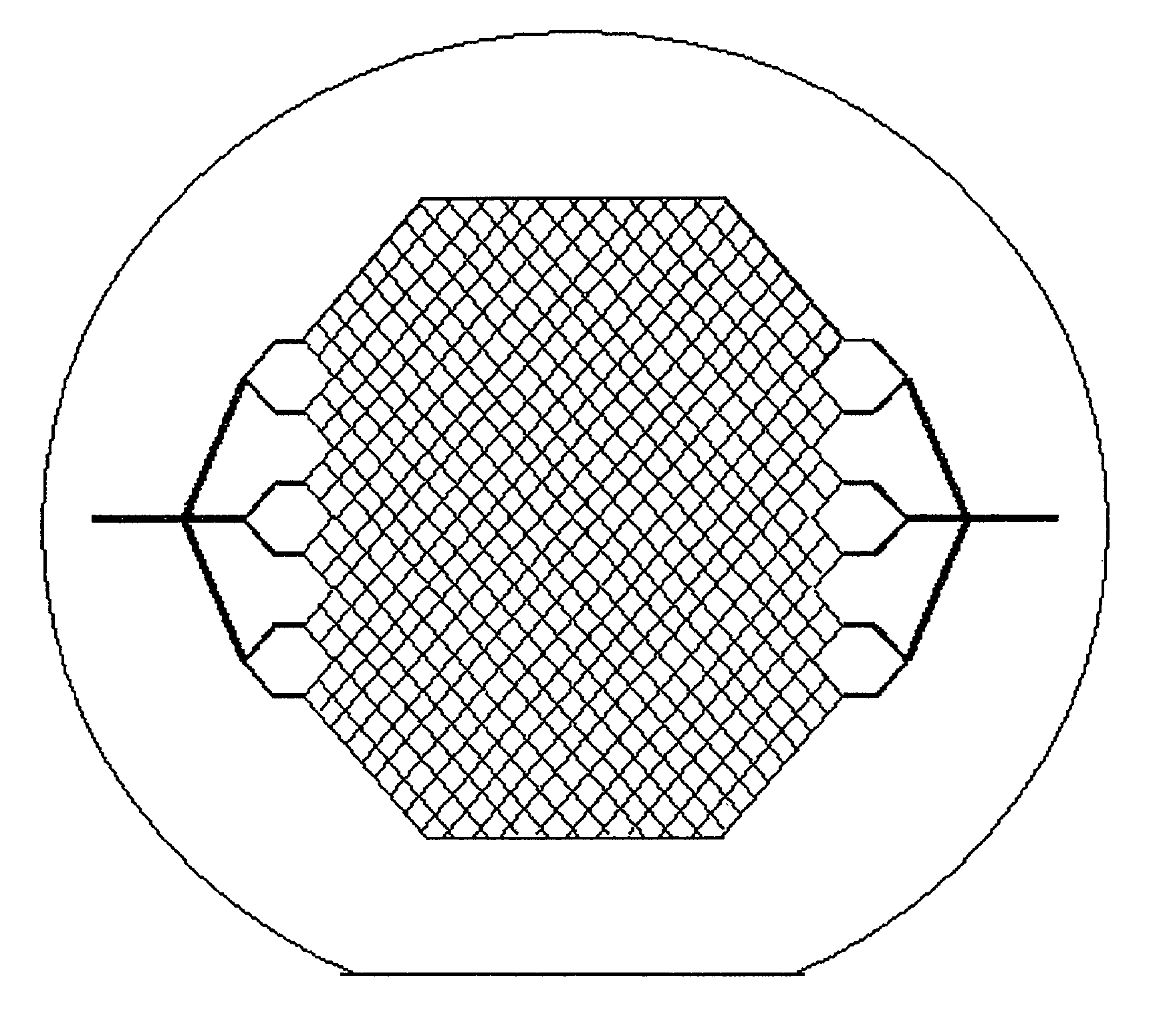

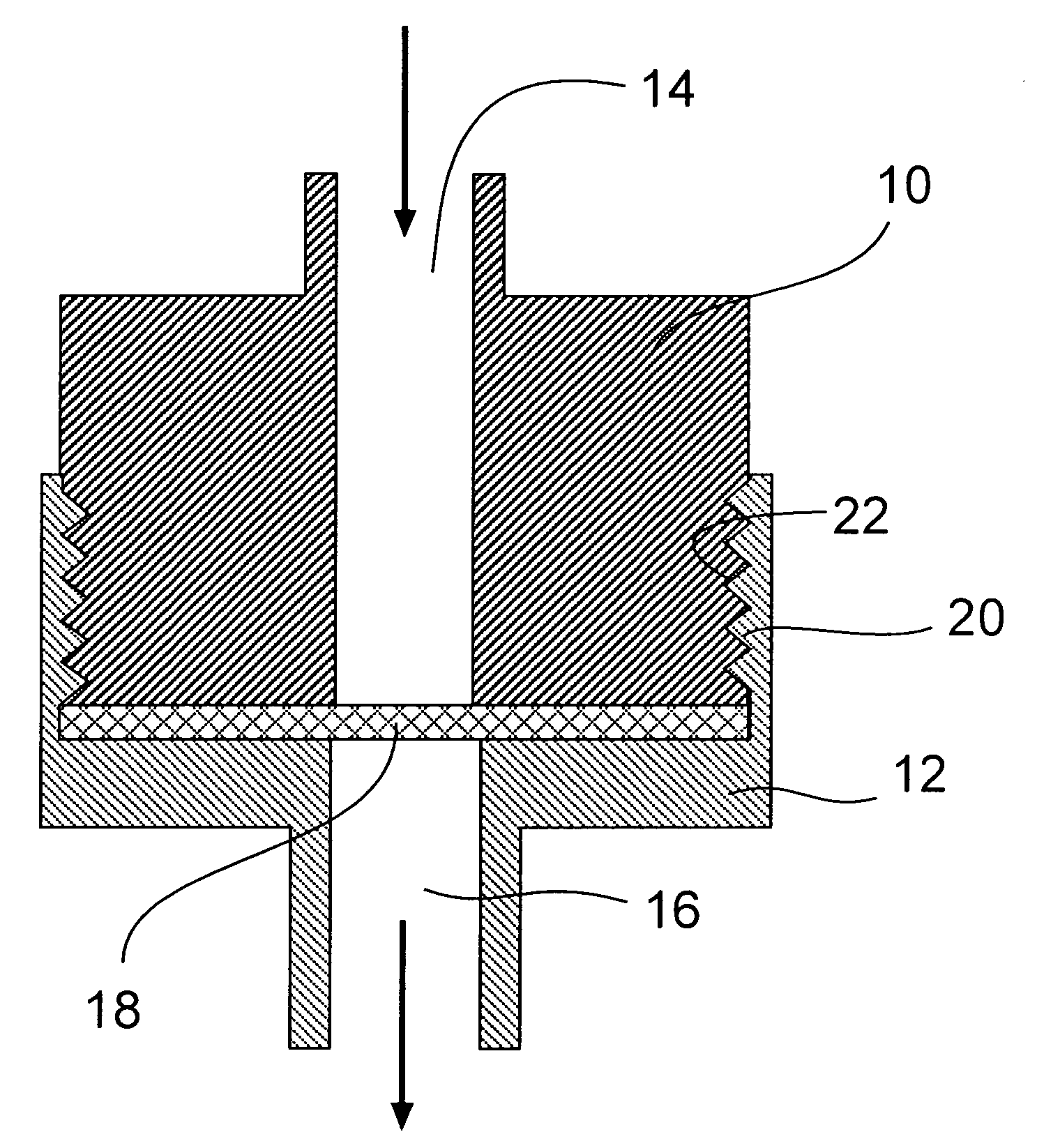

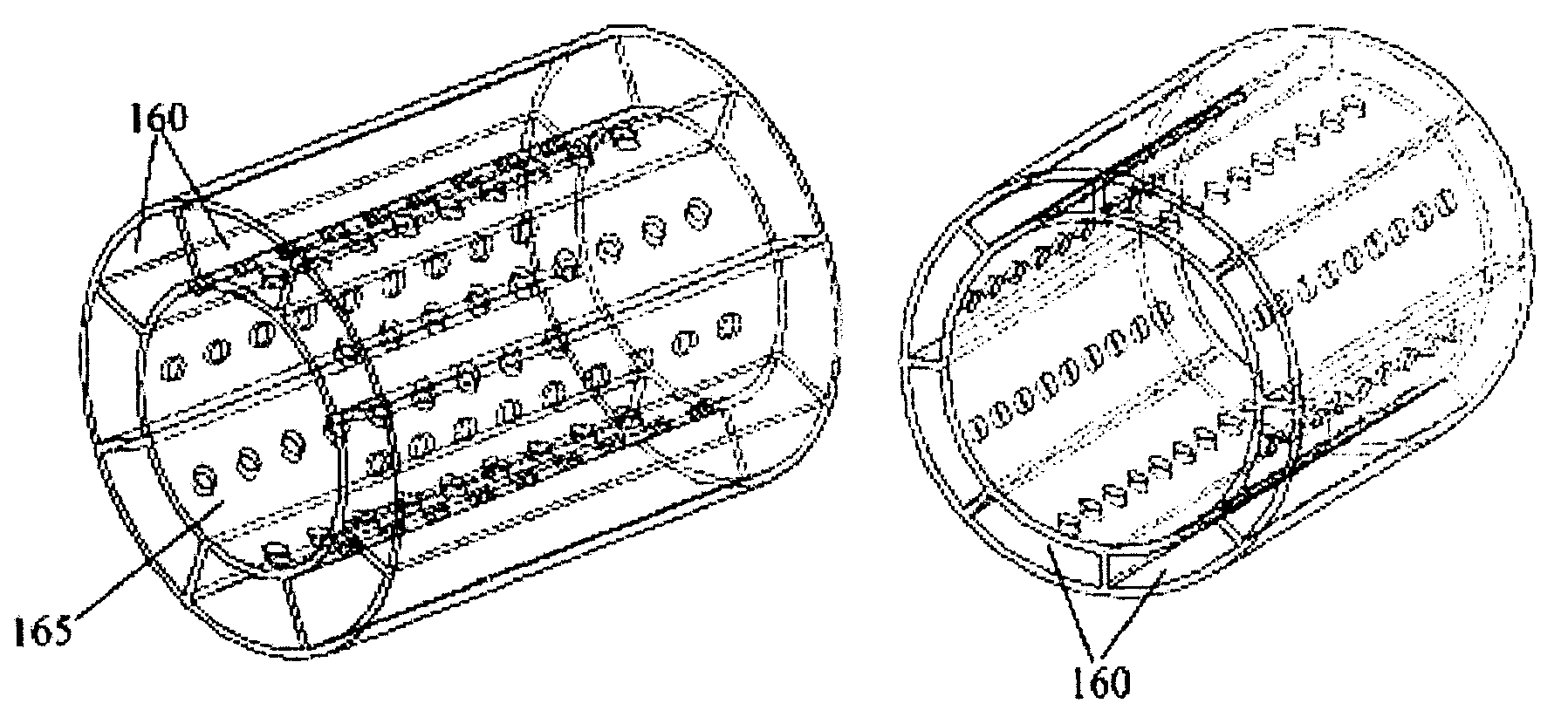

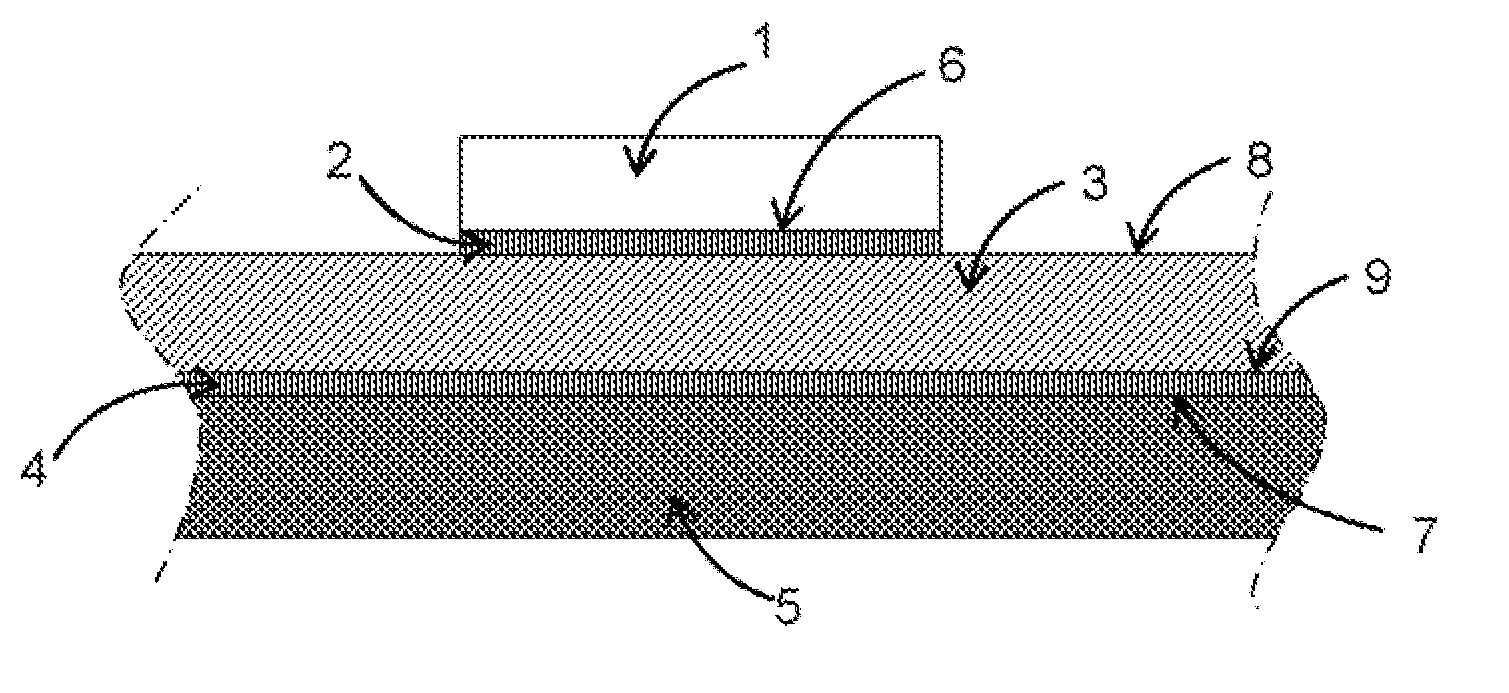

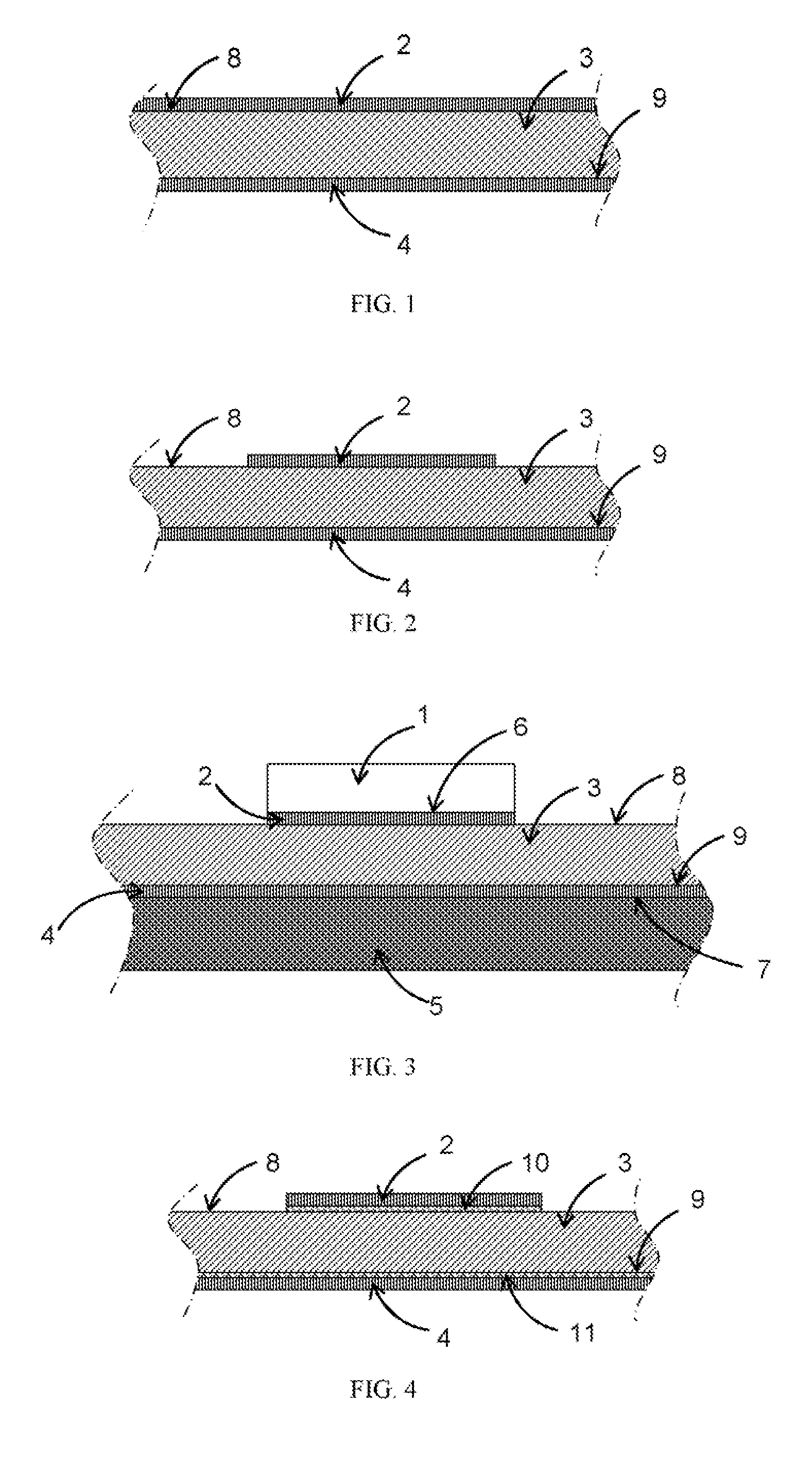

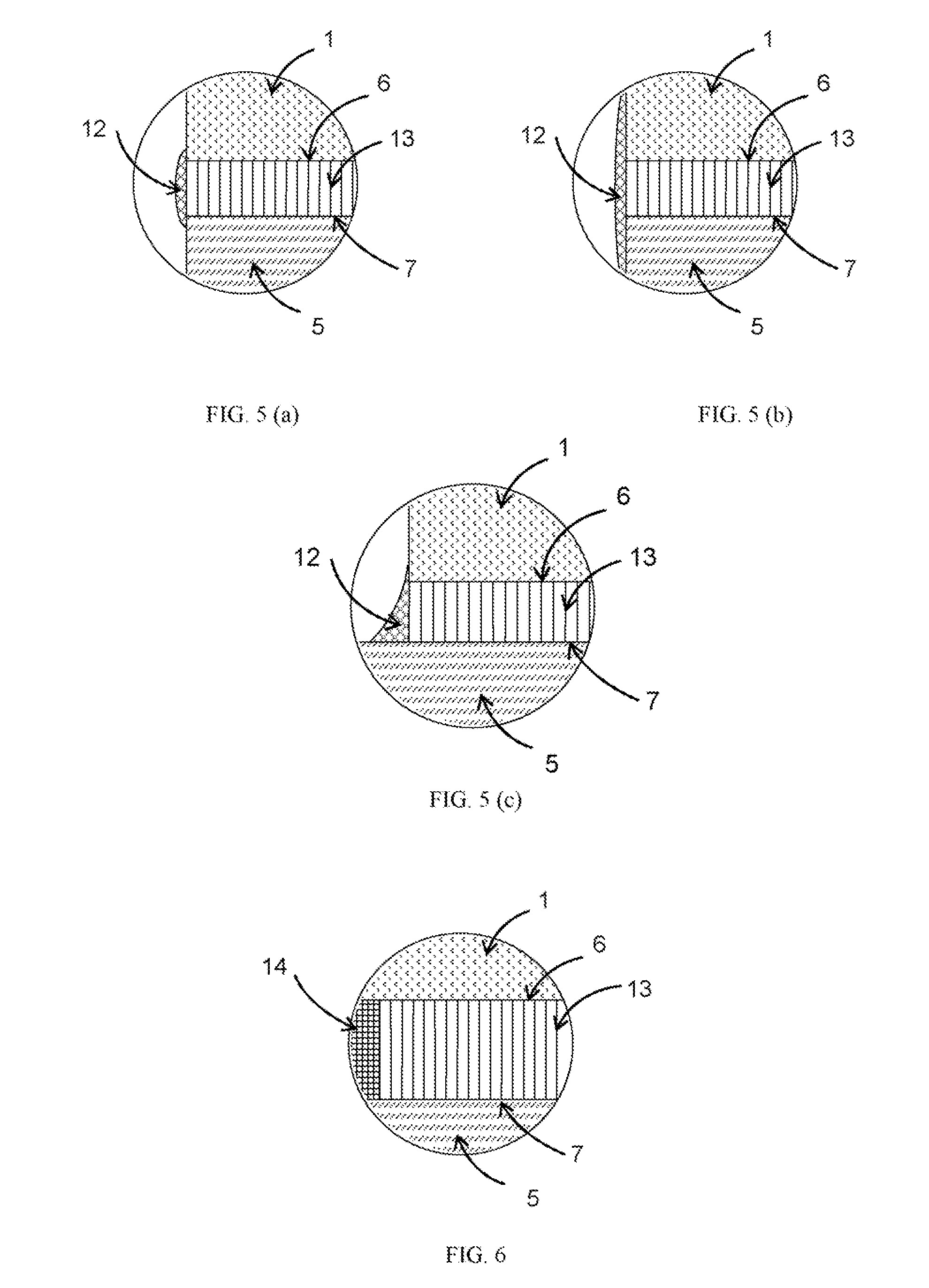

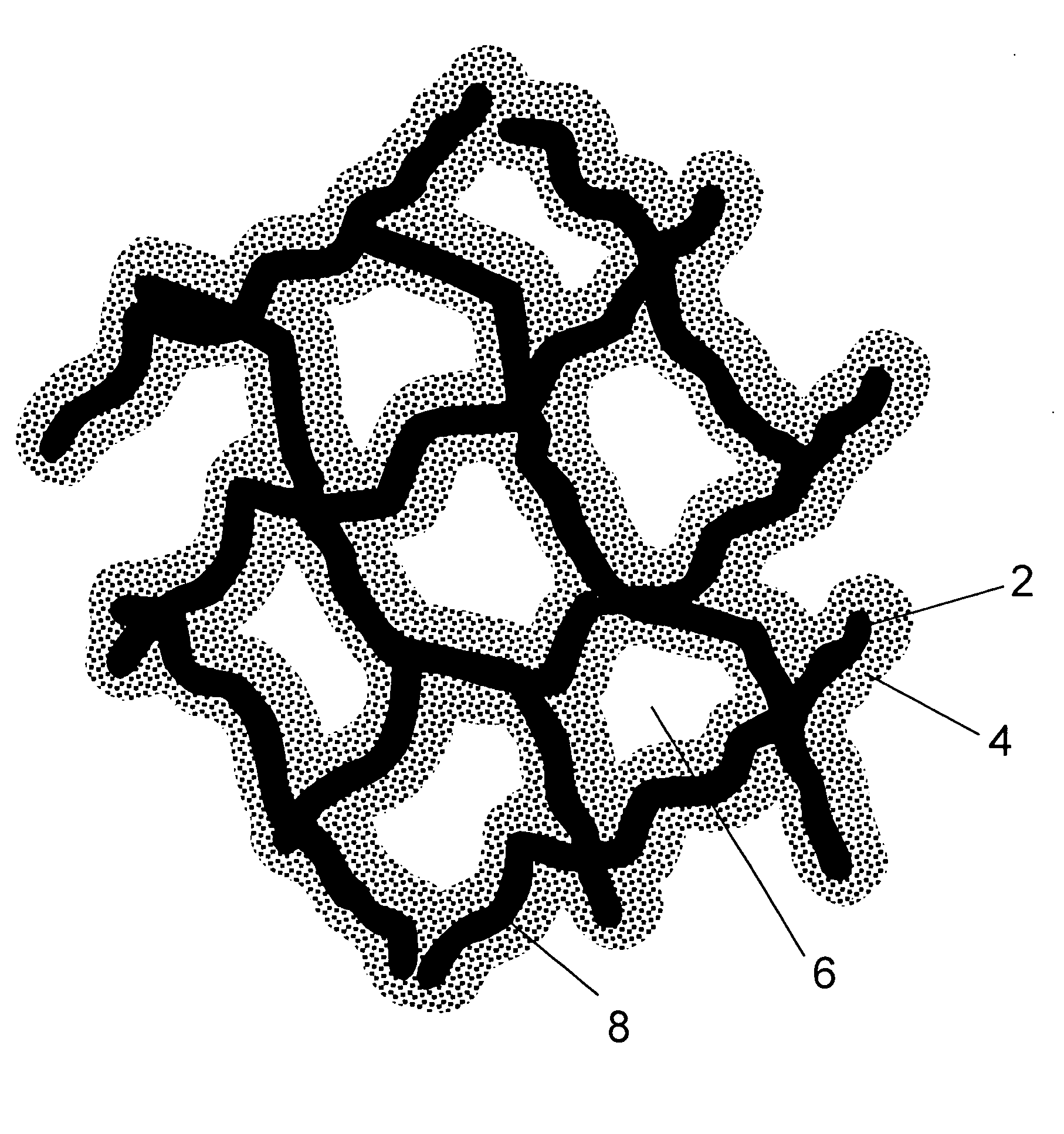

Micromachined bilayer unit for filtration of small molecules

InactiveUS7776021B2Enhanced convectionFacilitated DiffusionBioreactor/fermenter combinationsBiological substance pretreatmentsFiltrationSmall molecule

Methods and materials for making an apparatus which duplicates the functionality of a physiological system id provided.

Owner:THE GENERAL HOSPITAL CORP +2

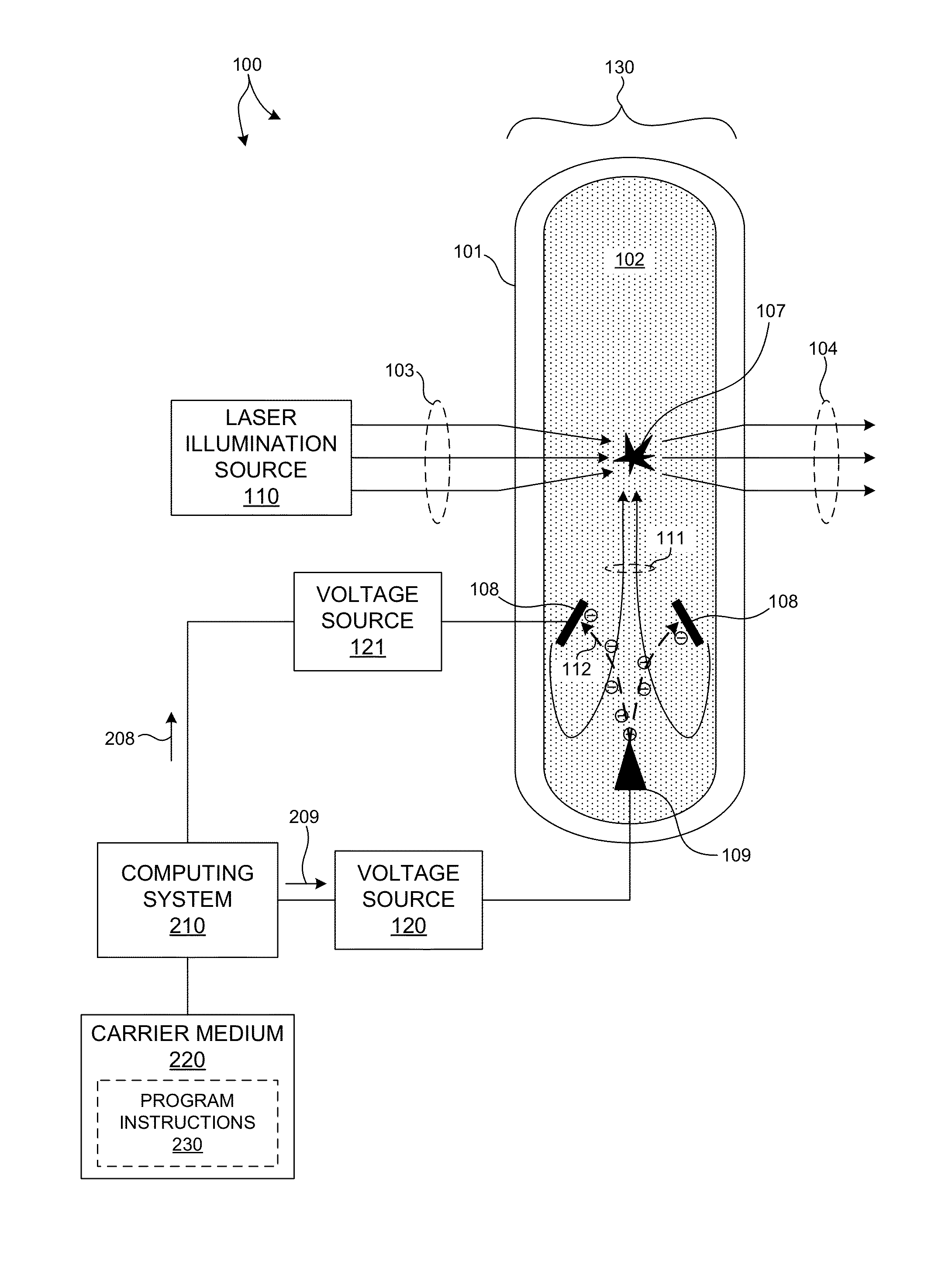

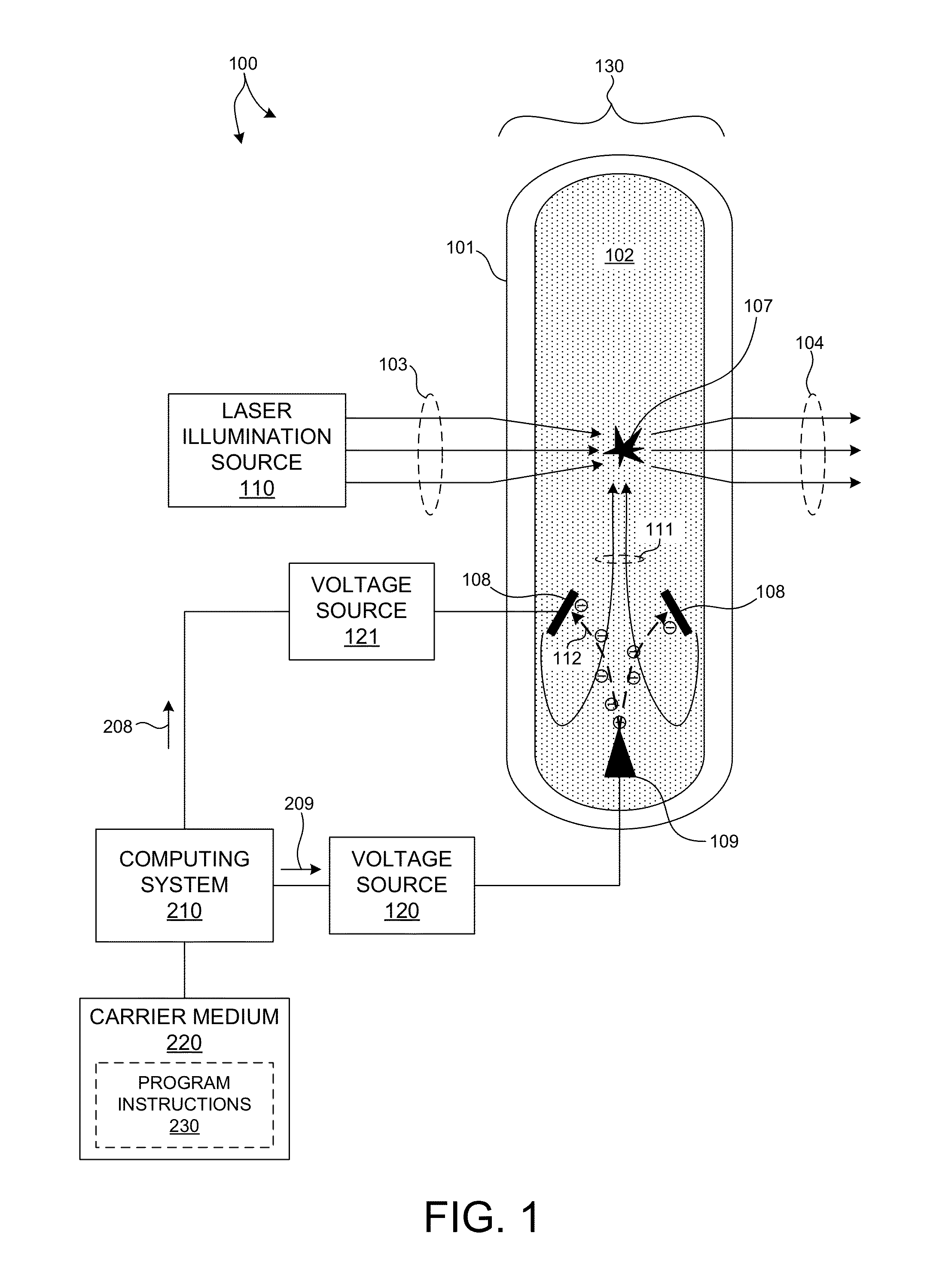

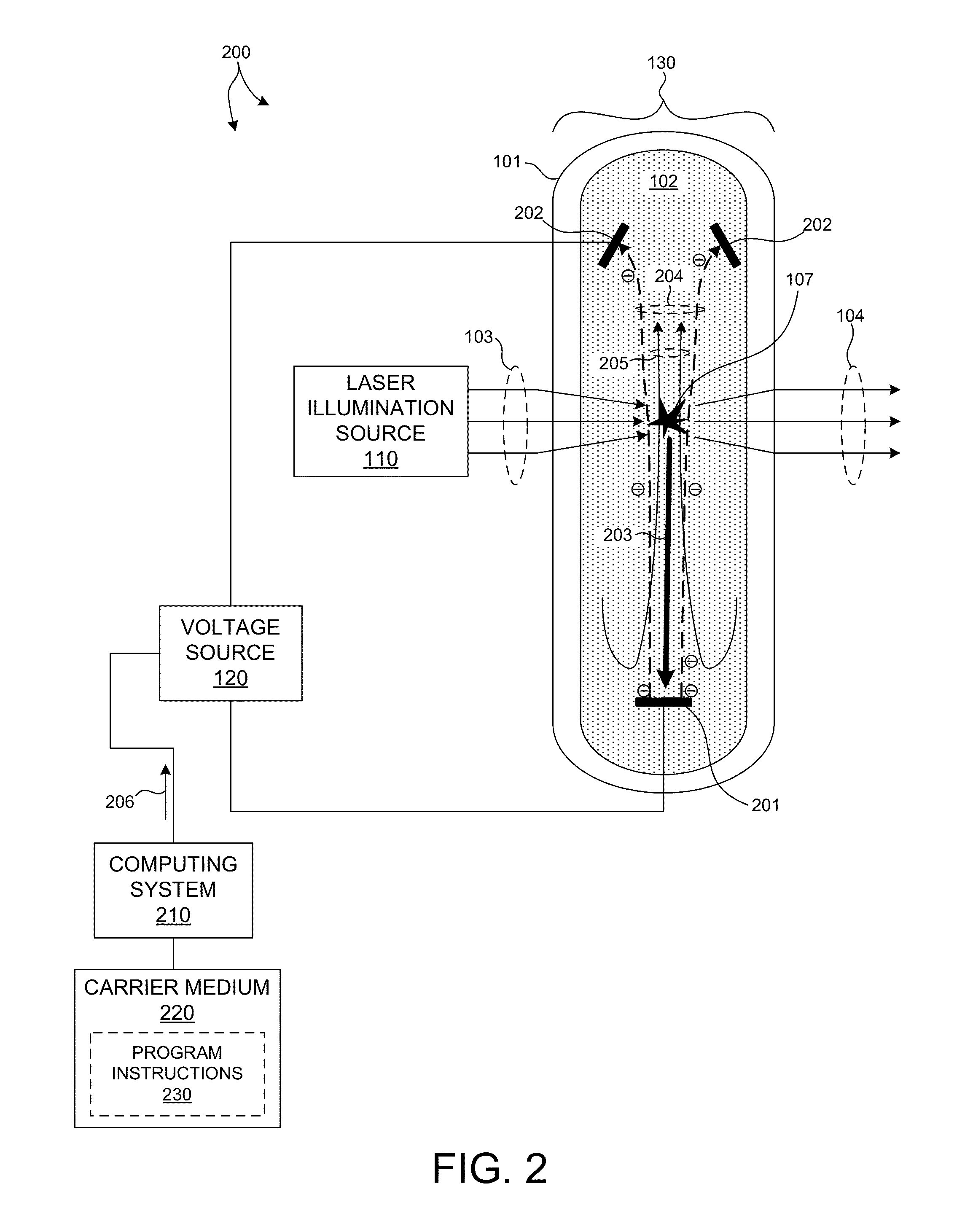

Laser Sustained Plasma Light Source With Electrically Induced Gas Flow

ActiveUS20130342105A1Increase control flexibilityImprove stabilityElectric discharge tubesElectric arc lampsAirflowVoltage

A laser sustained plasma light source includes a plasma bulb containing a working gas flow driven by an electric current sustained within the plasma bulb. Charged particles are introduced into the working gas of the plasma bulb. An arrangement of electrodes maintained at different voltage levels drive the charged particles through the working gas. The movement of the charged particles within the working gas causes the working gas to flow in the direction of movement of the charged particles by entrainment. The resulting working gas flow increases convection around the plasma and increases laser to plasma interaction. The working gas flow within the plasma bulb can be stabilized and controlled by control of the voltages present on the each of the electrodes. A more stable flow of working gas through the plasma contributes to a more stable plasma shape and position within the plasma bulb.

Owner:KLA TENCOR CORP

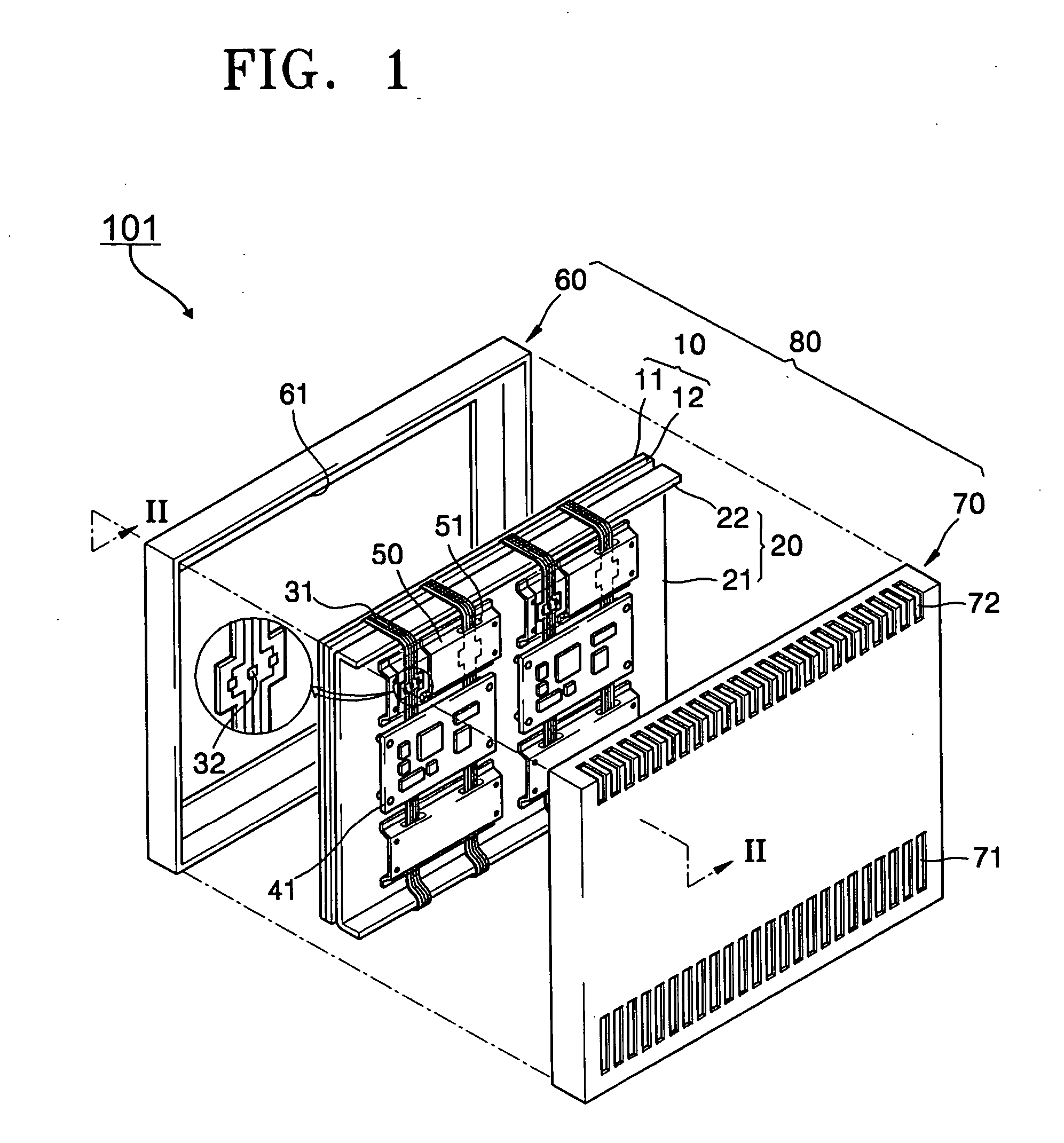

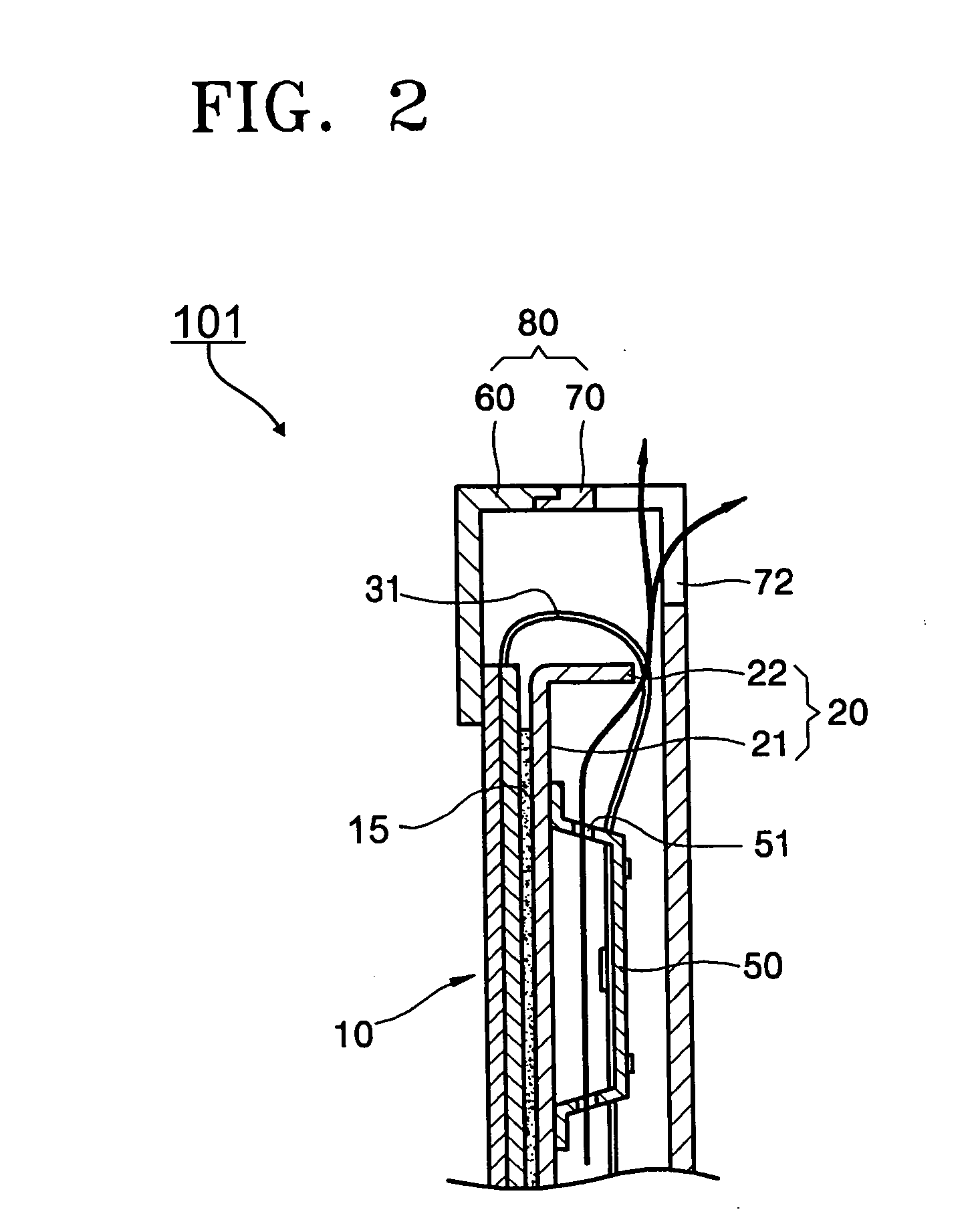

Display apparatus having improved heat dissipation capabilities

InactiveUS20050047067A1Reduce the temperatureIncrease air circulationStatic indicating devicesDigital data processing detailsEngineeringPrinted circuit board

A design for a display apparatus that allows for improved convection for the removal of hot air from heated circuit components. The display apparatus includes a display panel, a chassis having a base, which supports the display panel, and a flange formed along an upper edge of the base to prevent the base from bending, the flange having at least one air passage hole to allow smooth air flow. The display apparatus also has a printed circuit board on which parts for driving the display panel are mounted, the printed circuit board being supported by the chassis, and a case which accommodates the display panel, the chassis, and the printed circuit board. The case also is perforated by two sets of holes to allow hot air to escape and cool air to enter the display apparatus.

Owner:SAMSUNG SDI CO LTD

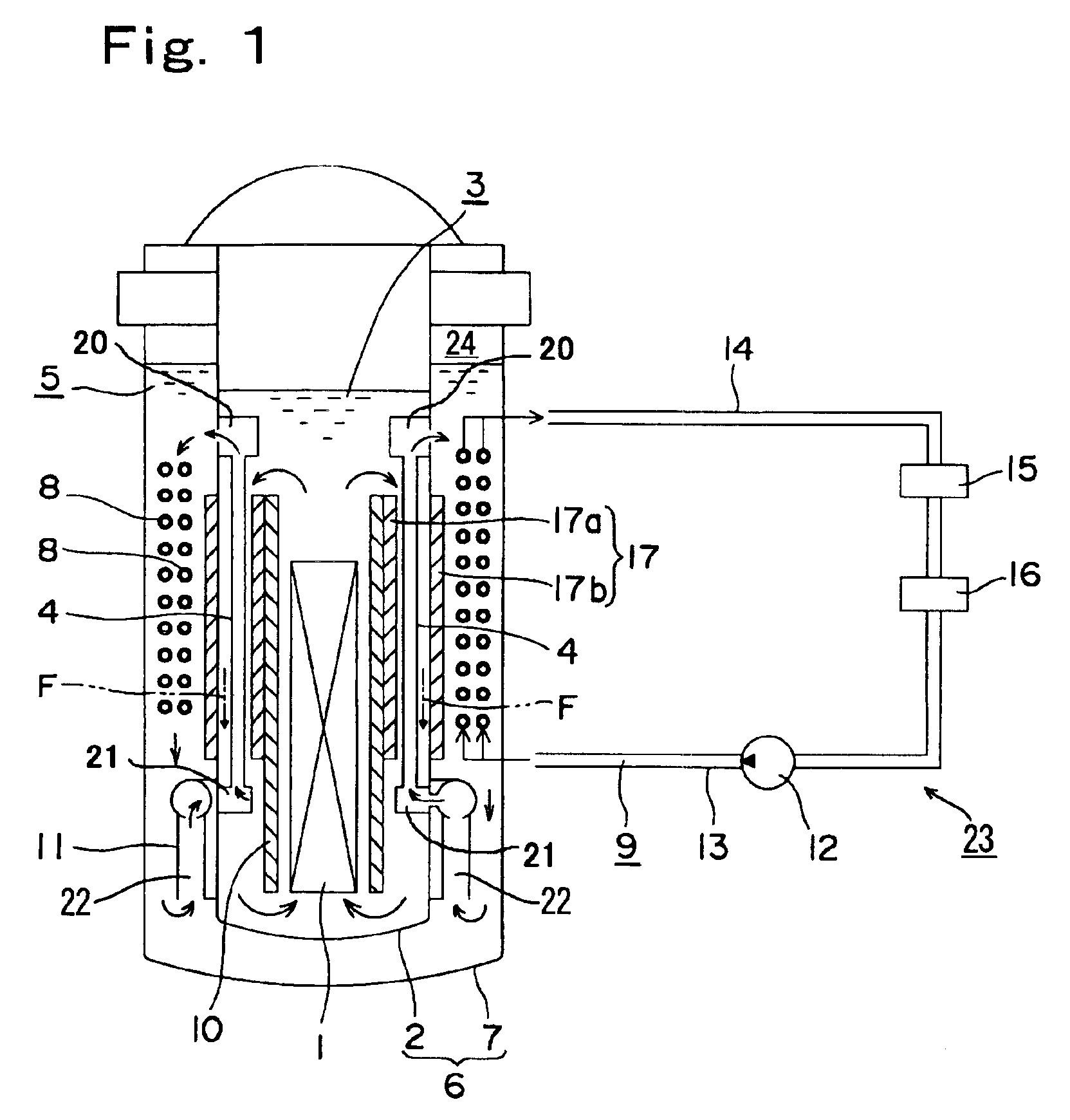

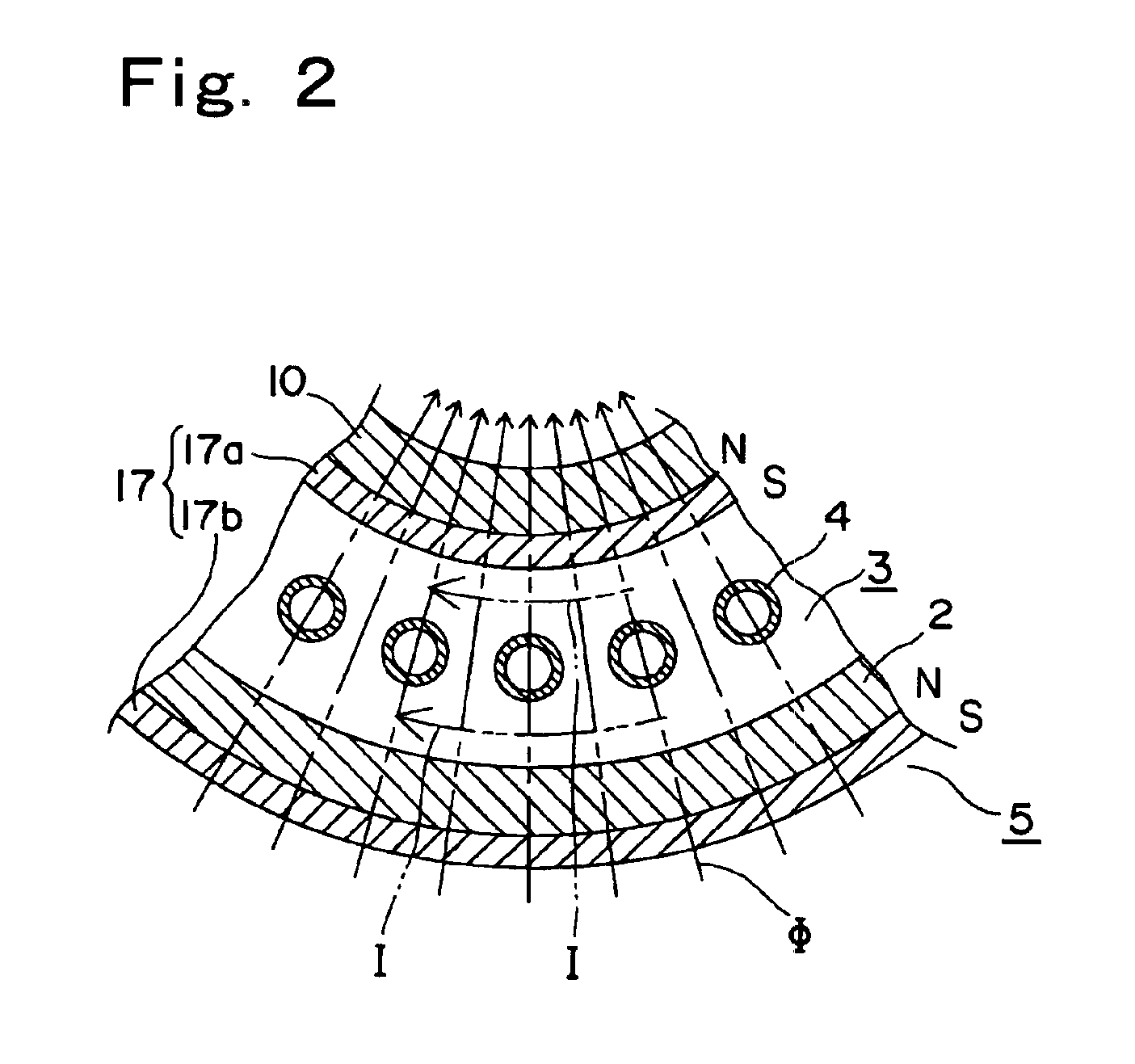

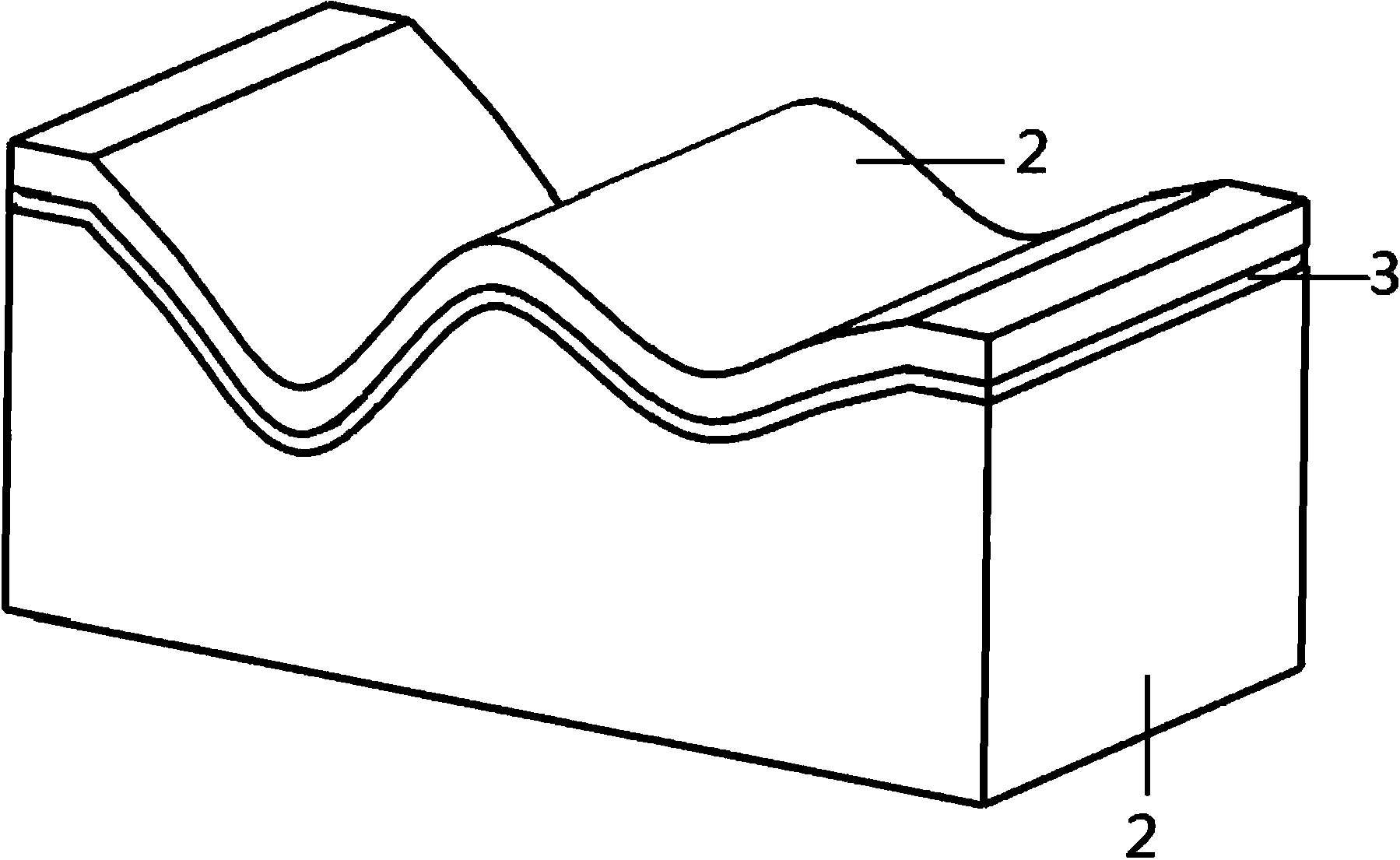

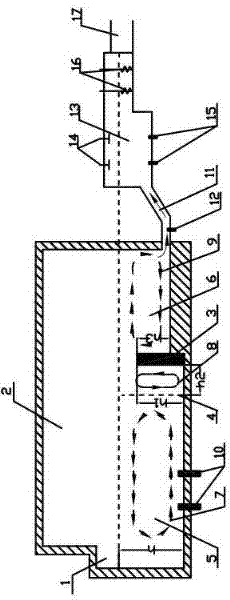

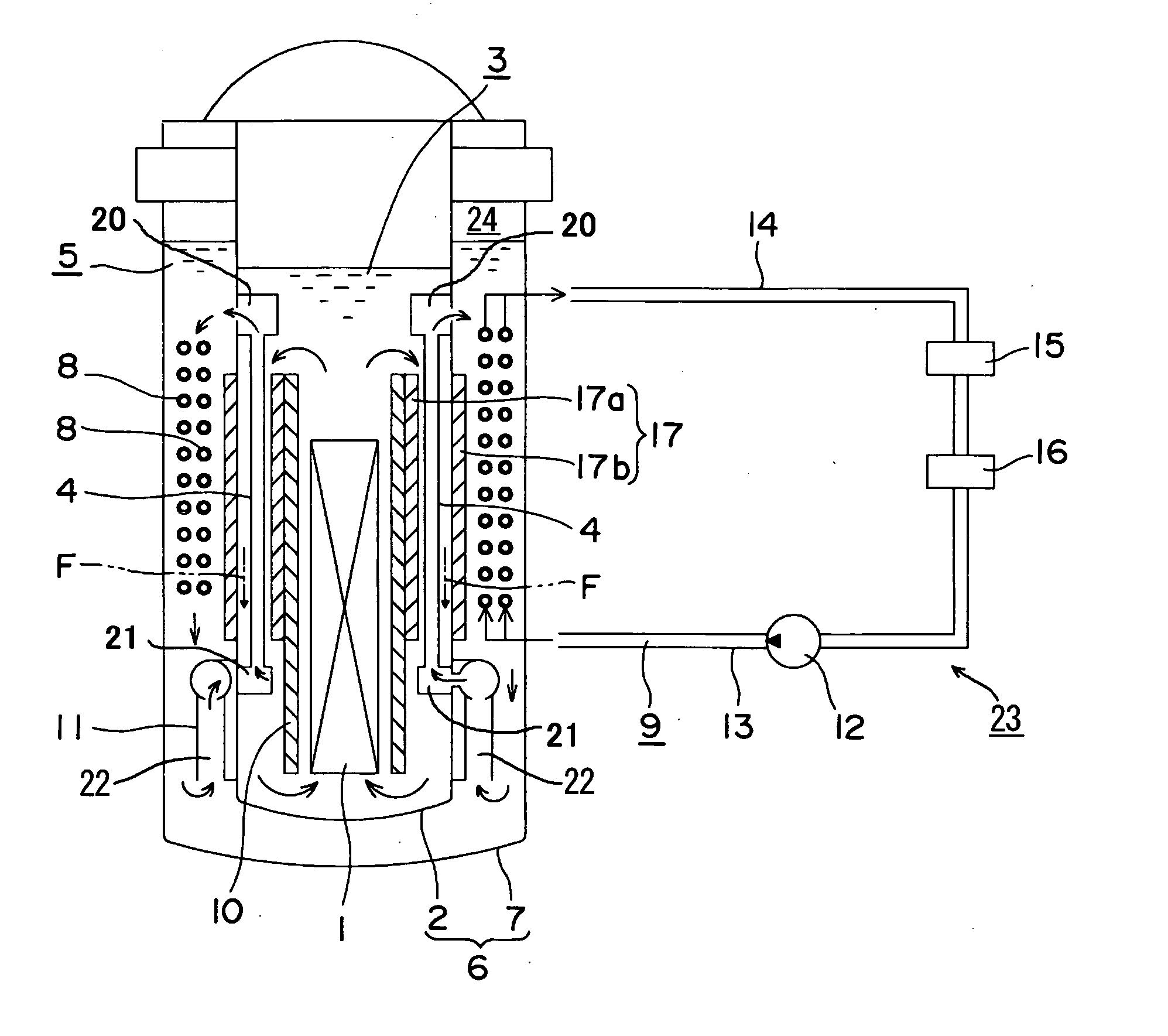

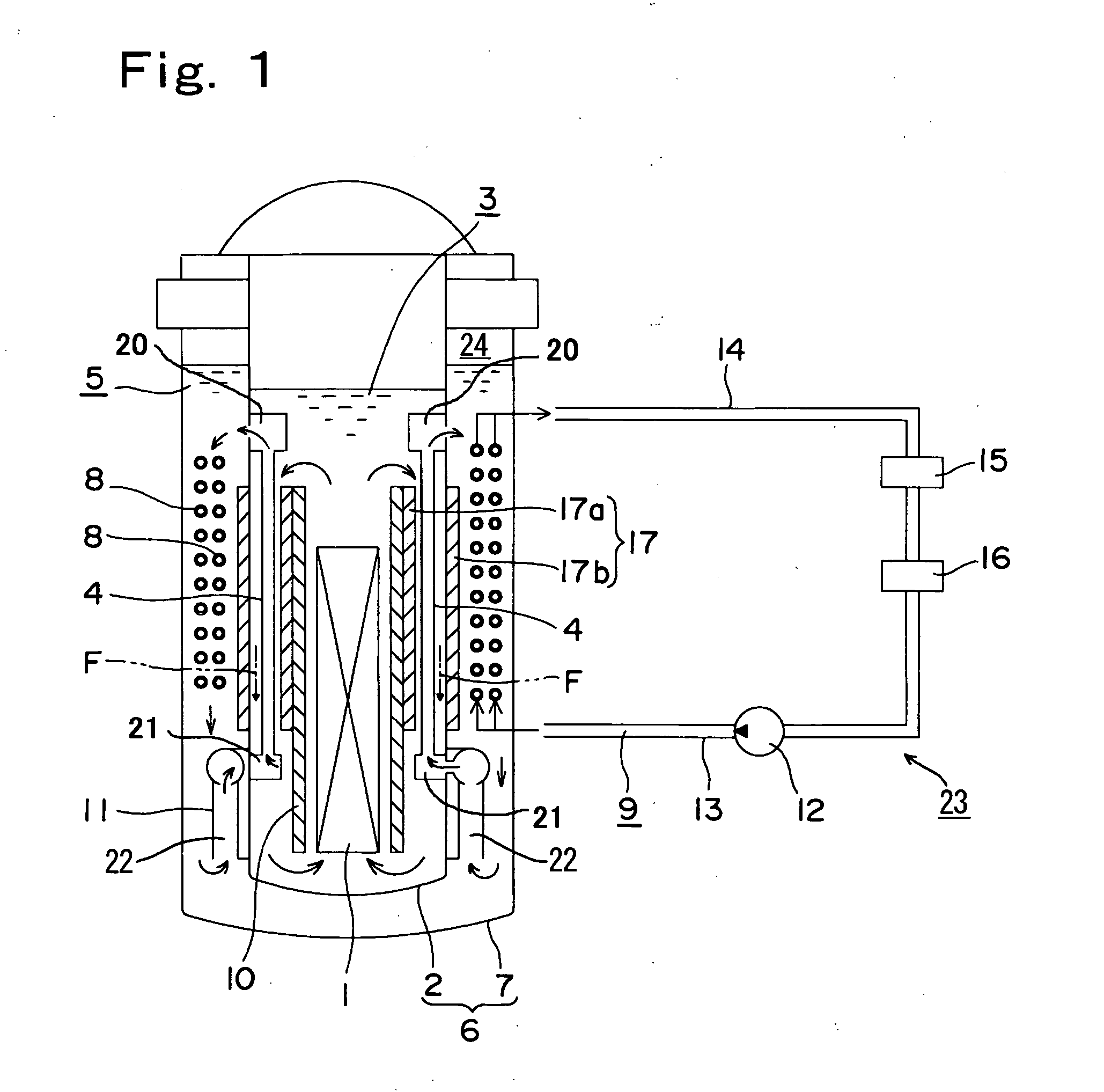

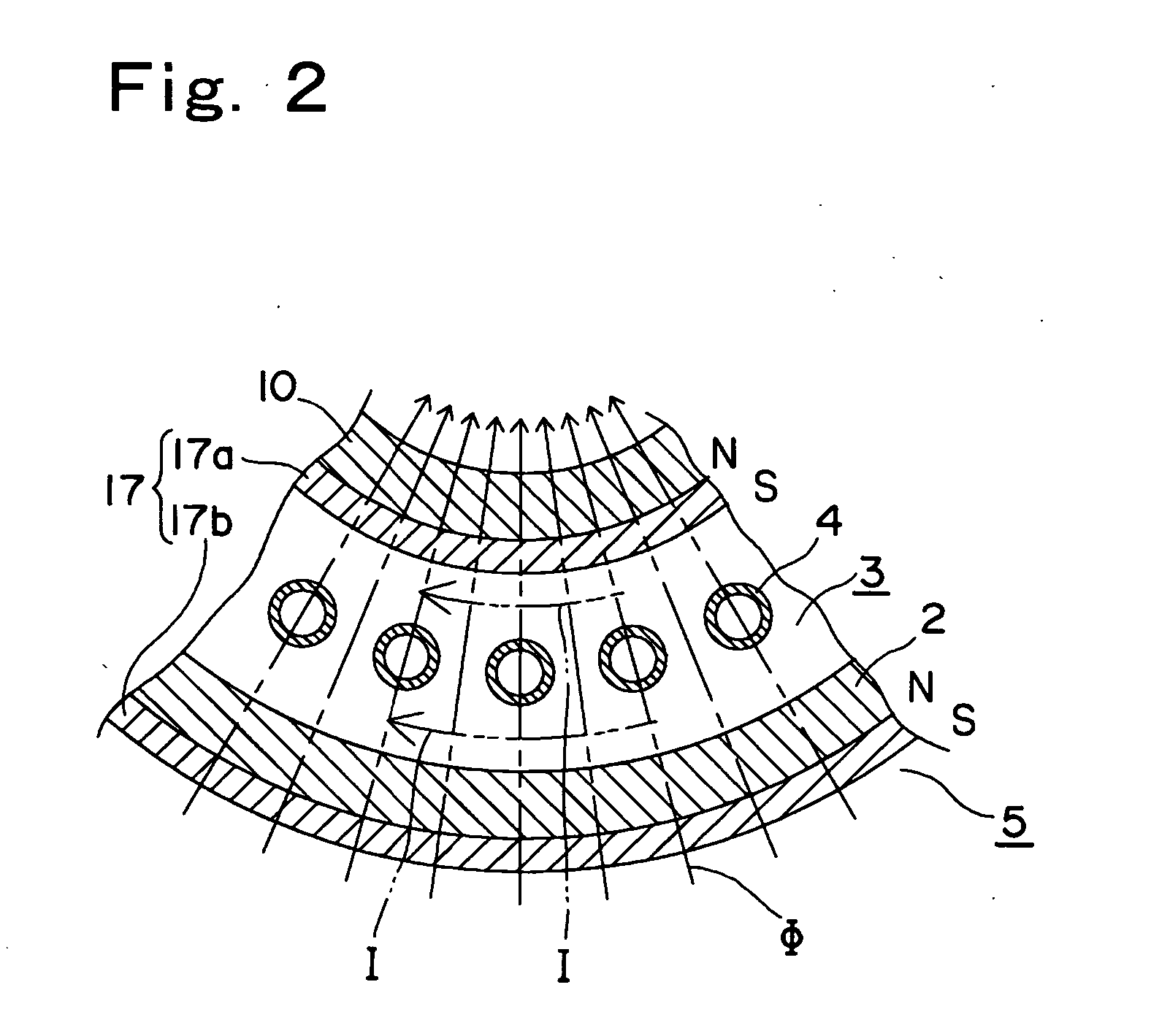

Nuclear reactor

InactiveUS6944255B2Small sizeReduce manufacturing costIntegral reactorsNuclear energy generationNuclear reactorHeat transfer tube

A nuclear reactor in which a secondary or tertiary coolant system of a nuclear steam supply system is simplified, comprising: a reactor vessel (2) which integrates a reactor core (1); a first coolant (3) which is stored in the reactor vessel (2) and heated by the reactor core (1) to convect; a first heat transfer tube (4) which is arranged in the reactor vessel (2) and comes into contact with the first coolant (3); and a second coolant (5) which is supplied from the outside of the reactor vessel (2) to the first heat transfer tube (4), cools the first coolant (3) and led to the outside of the reactor vessel (2).

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

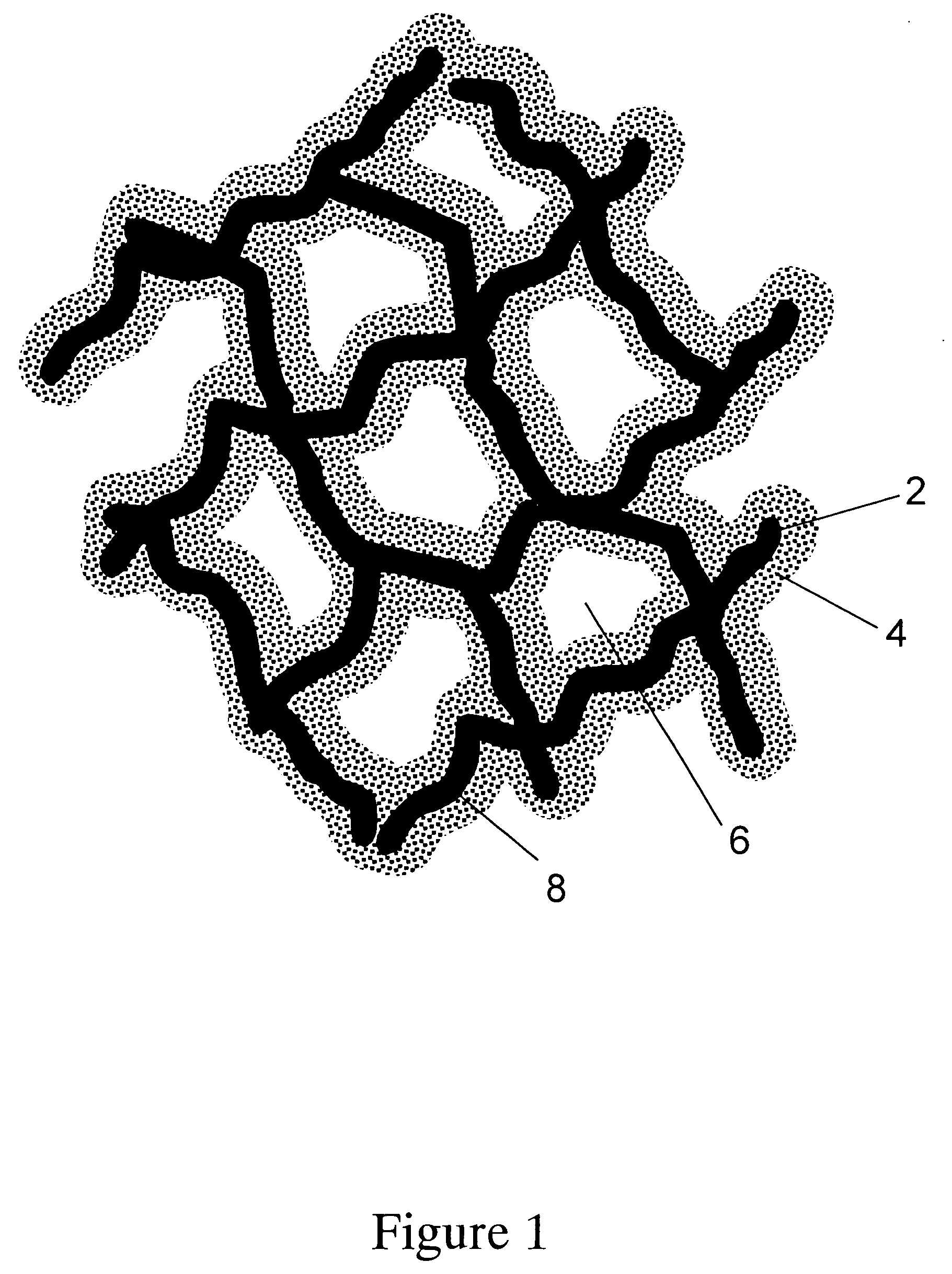

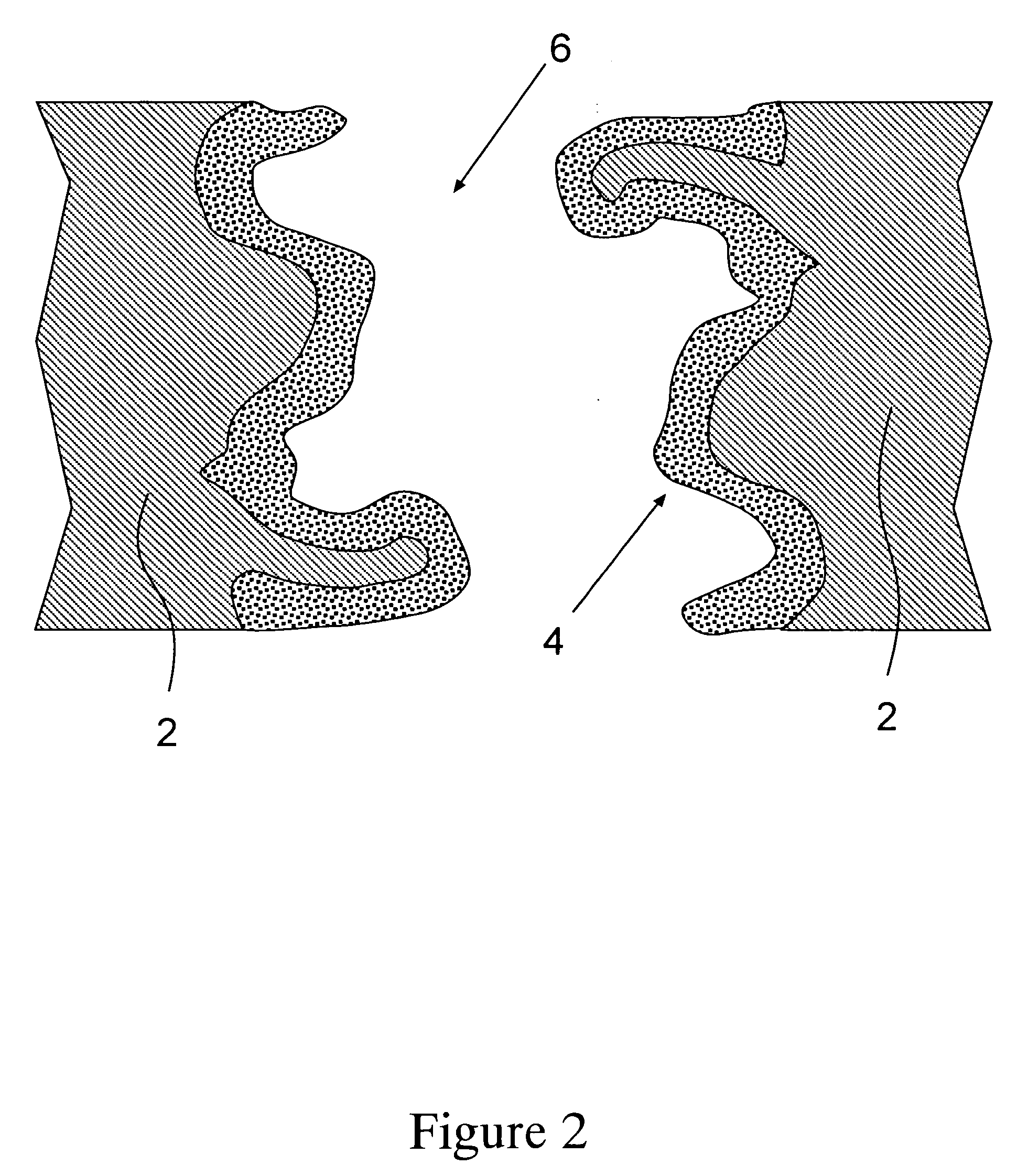

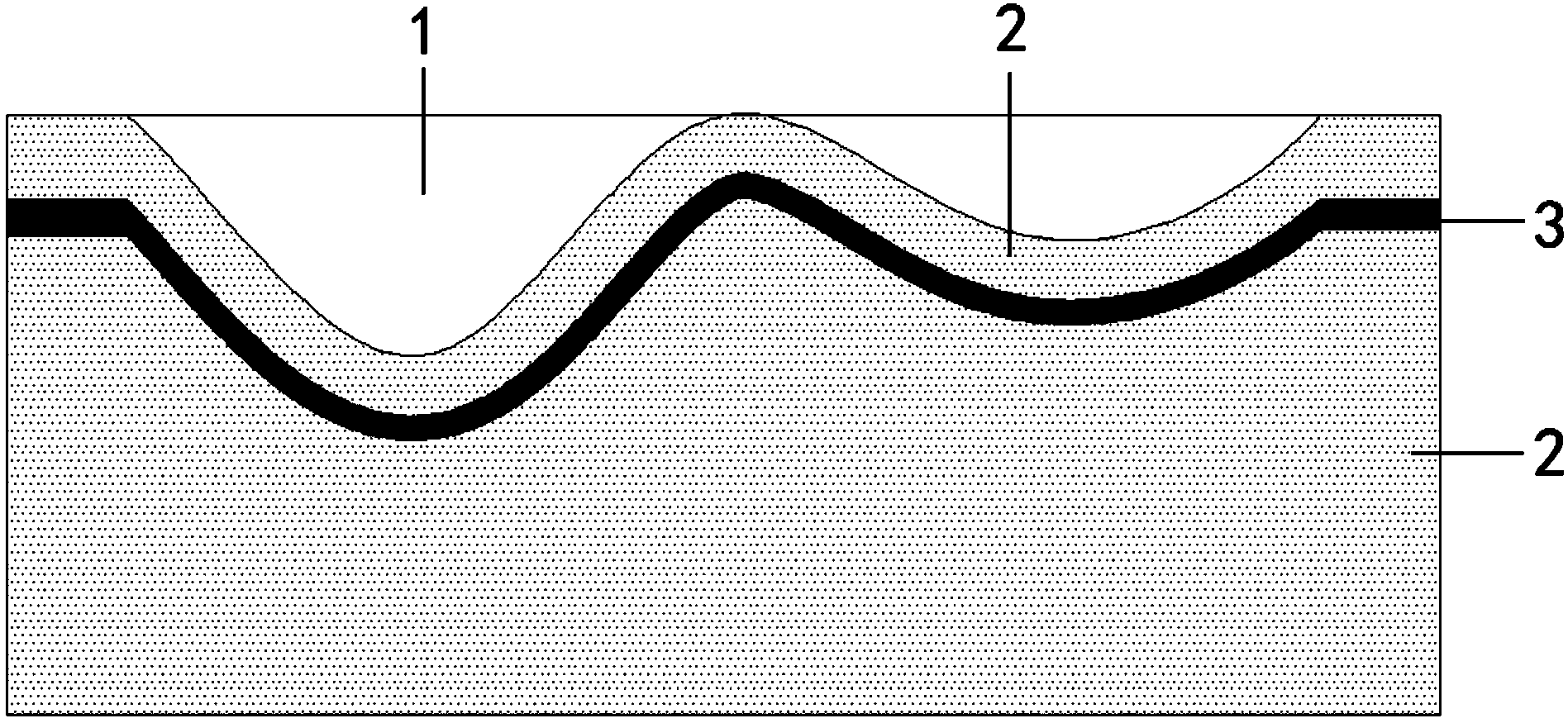

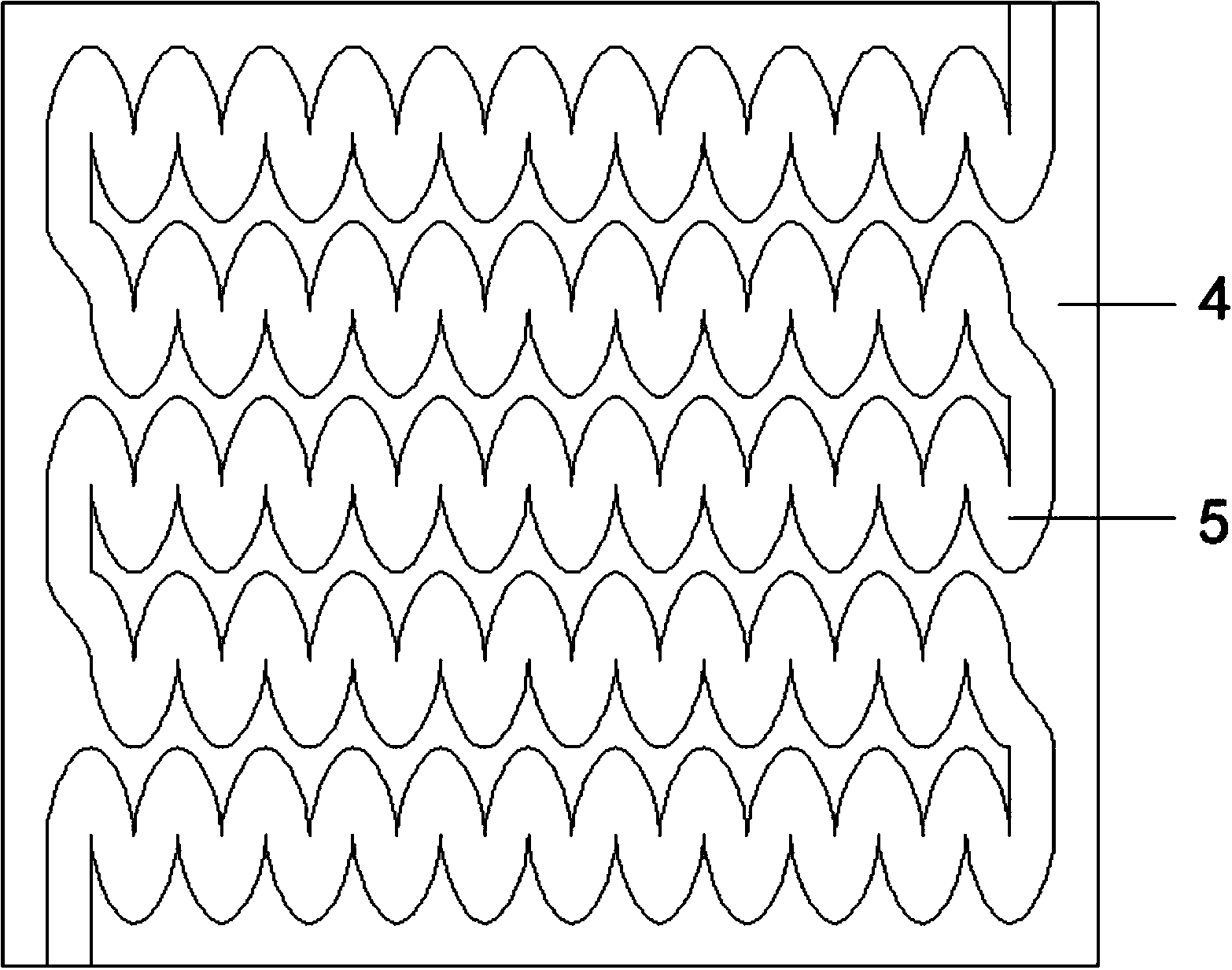

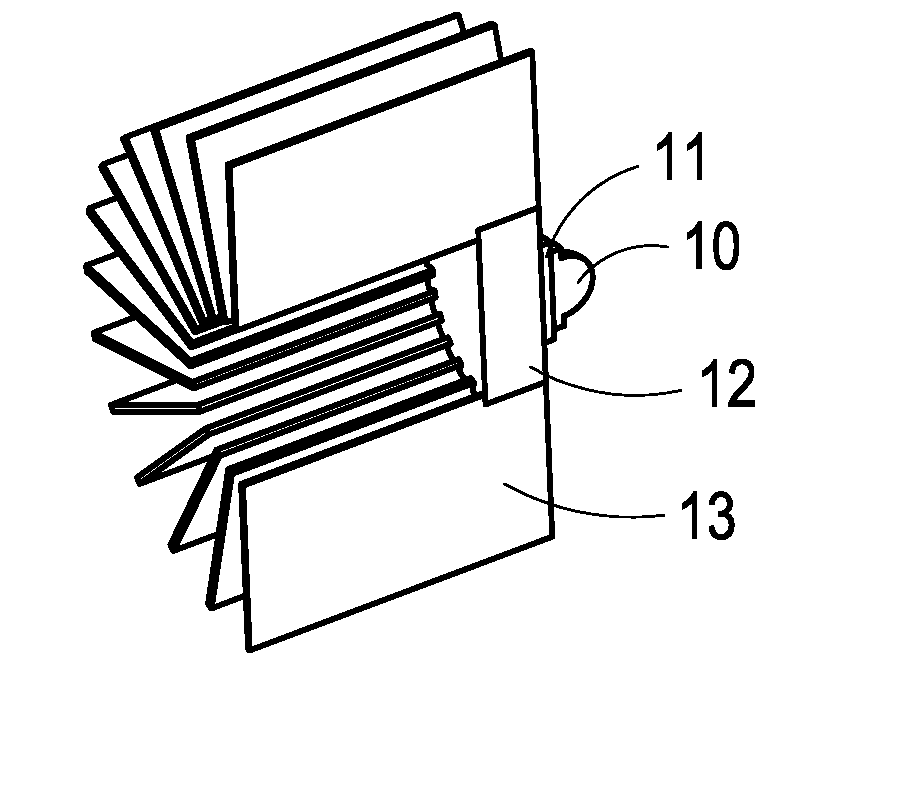

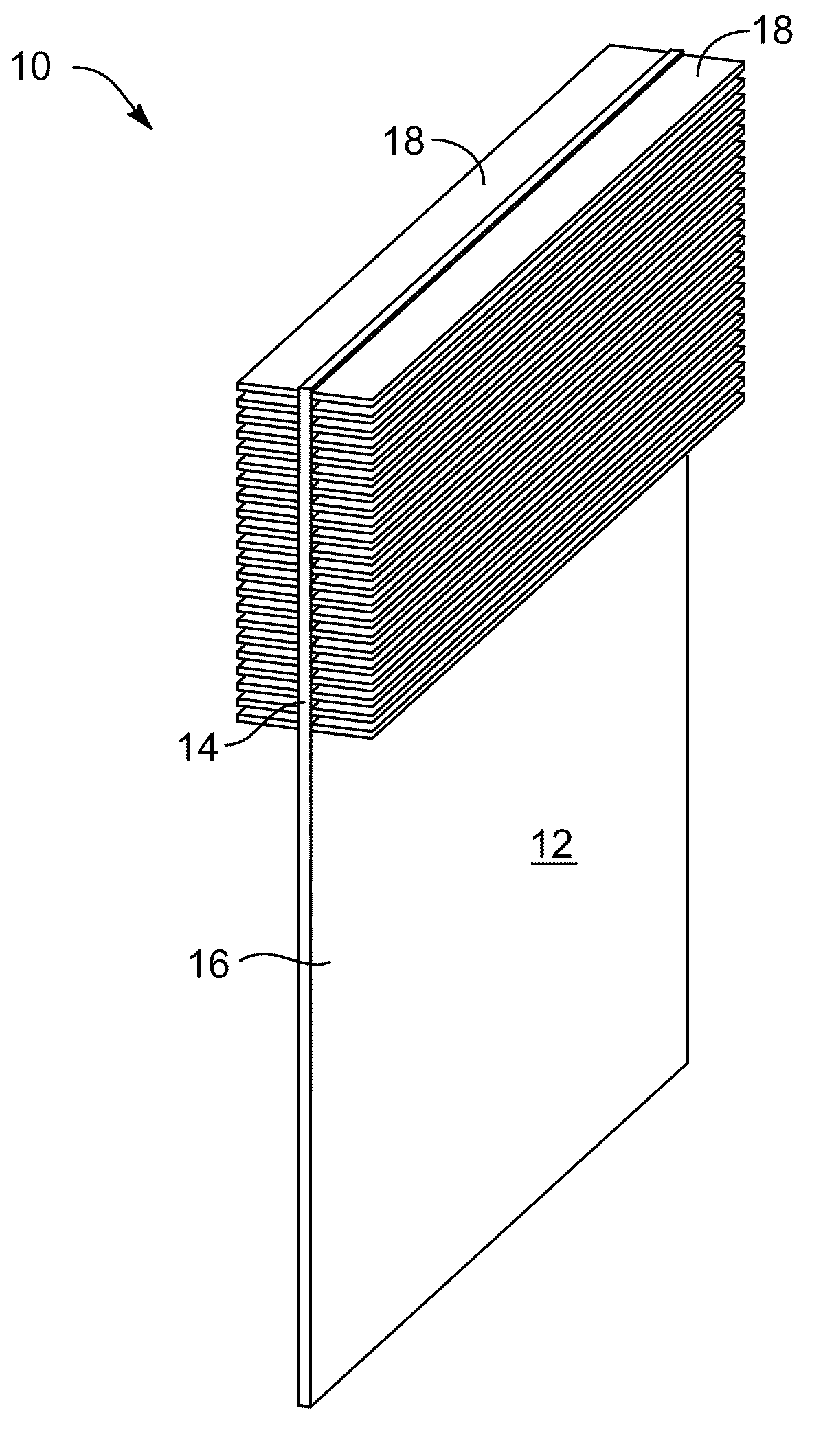

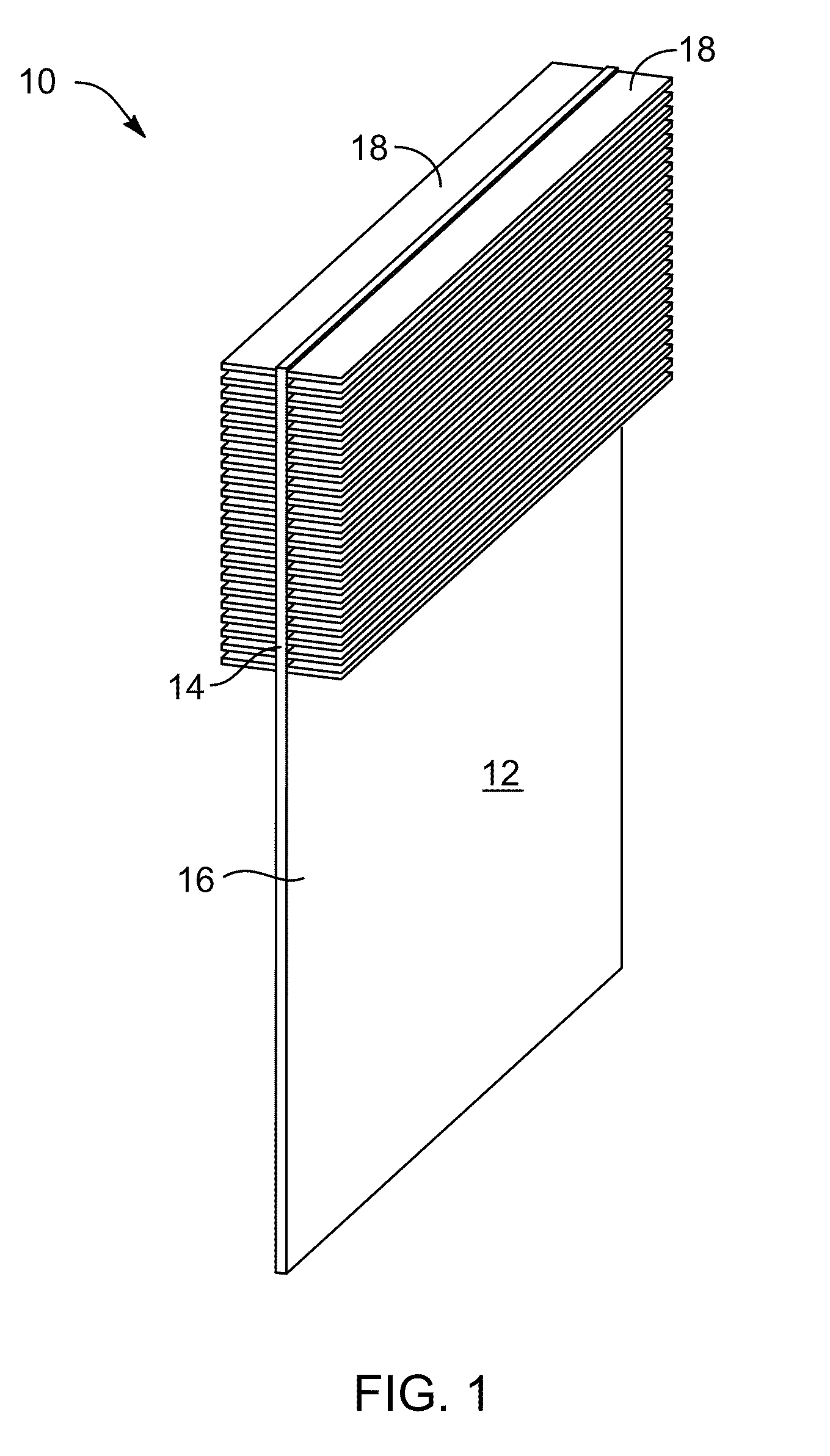

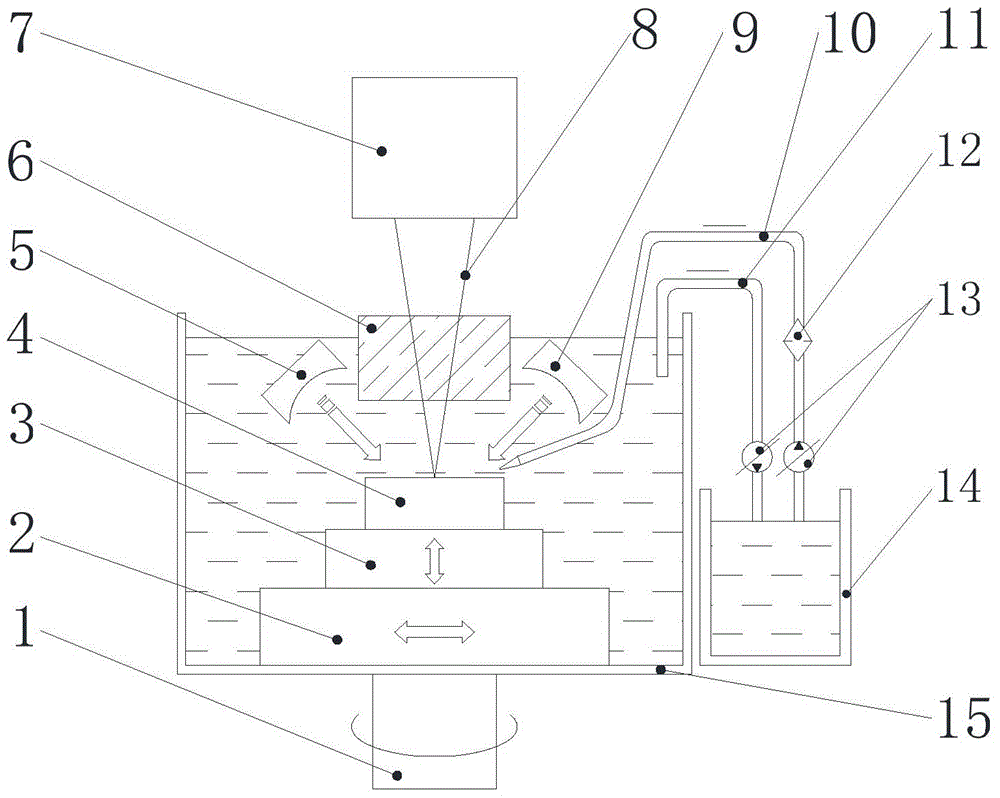

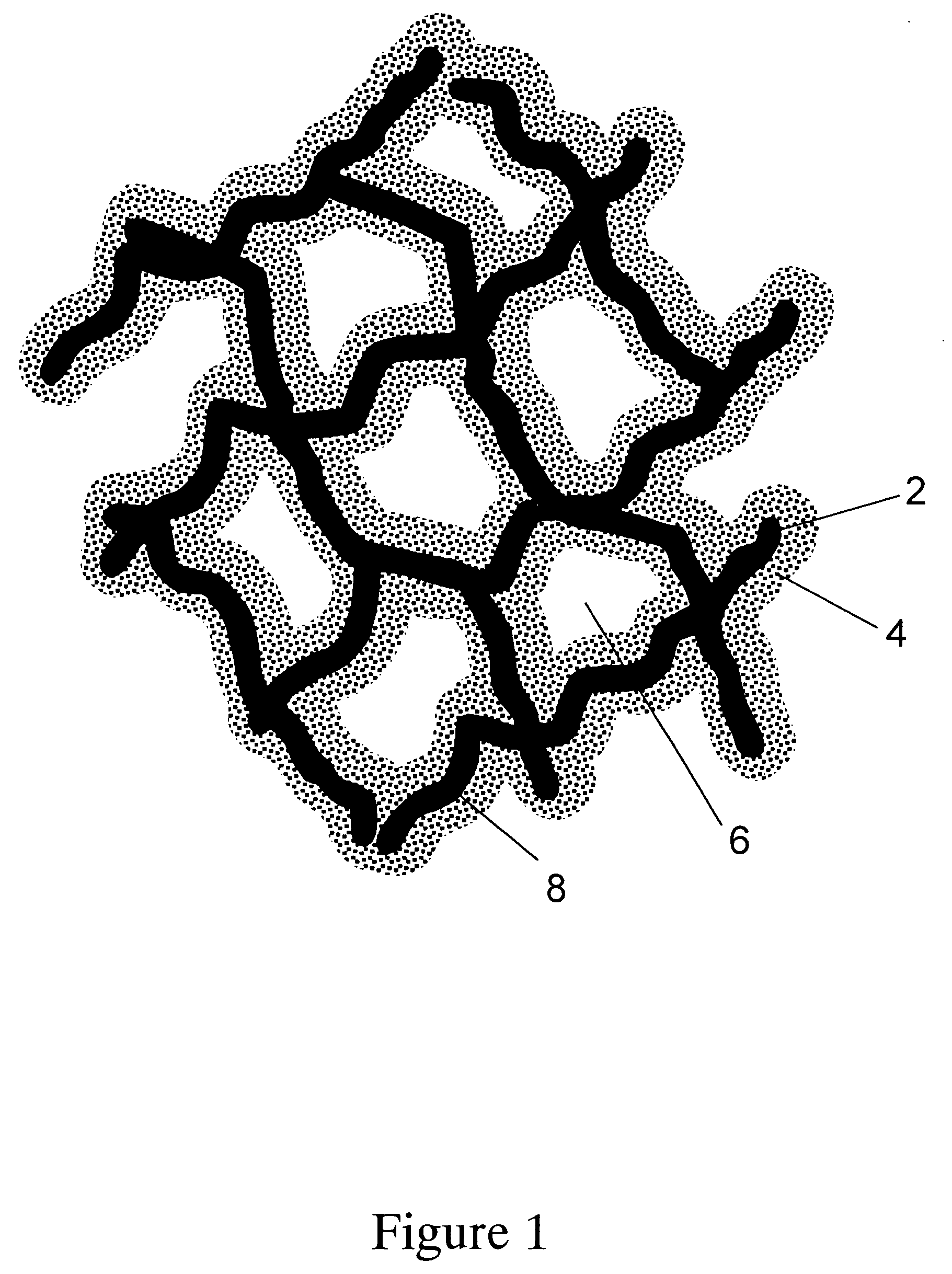

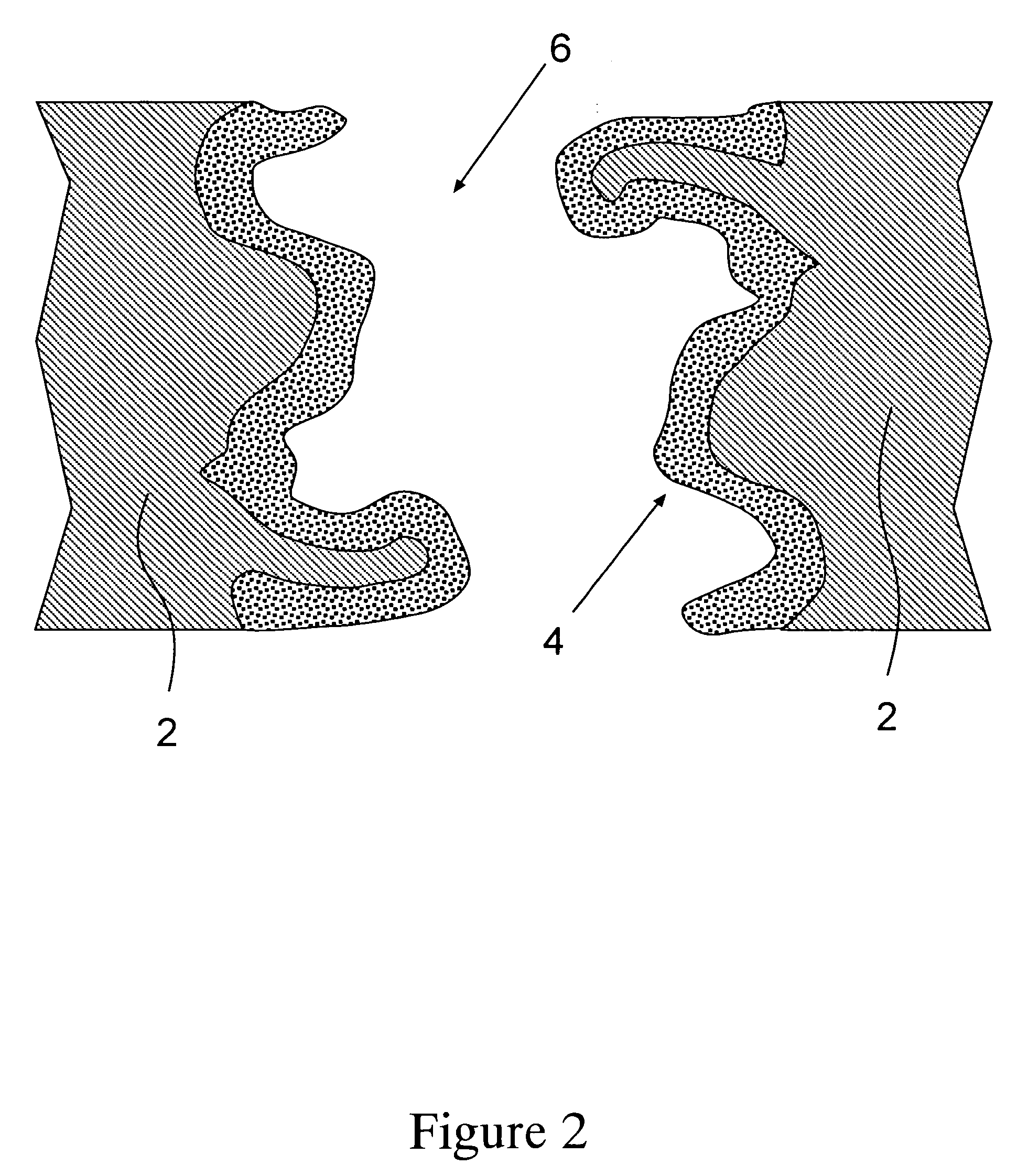

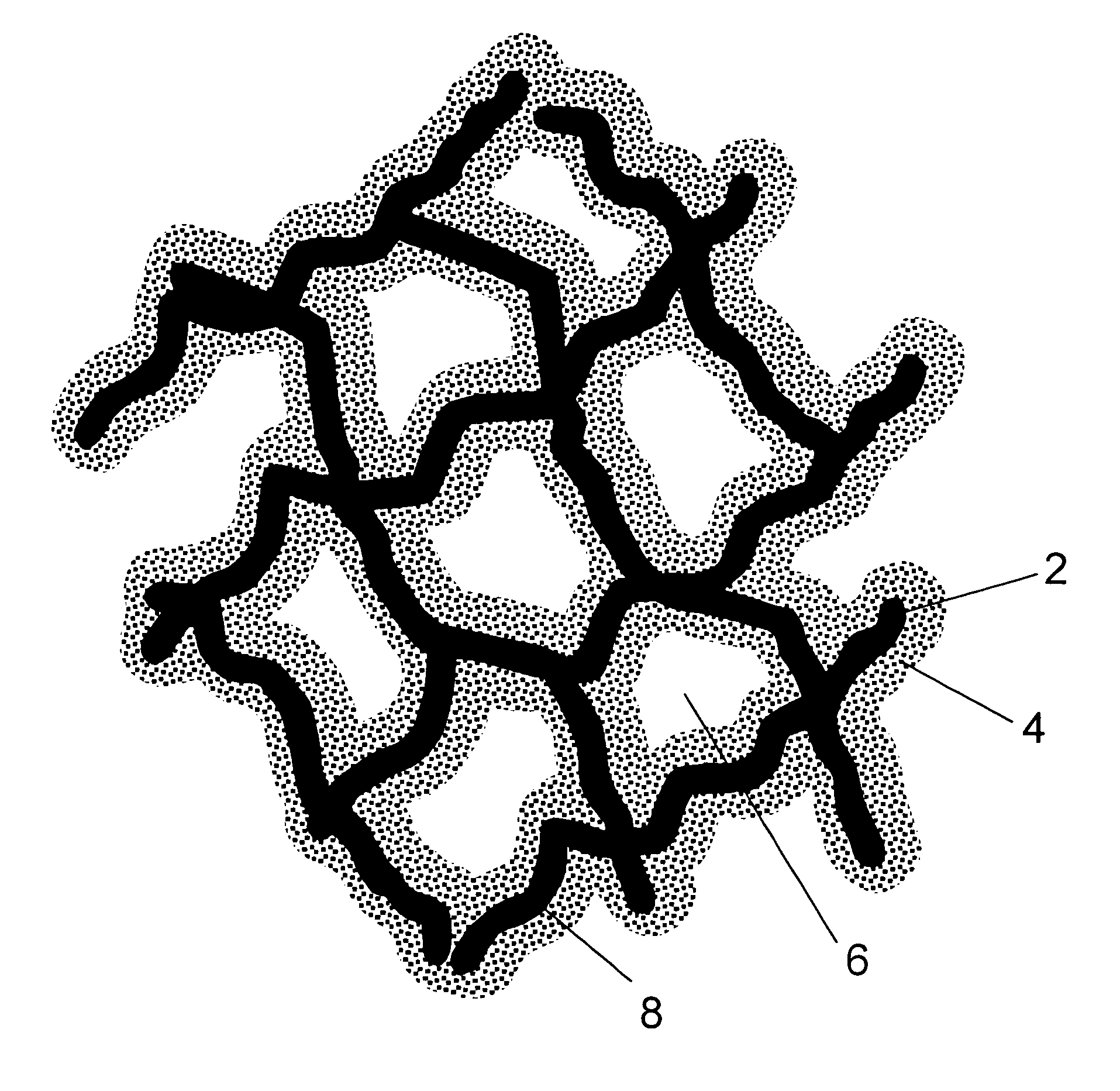

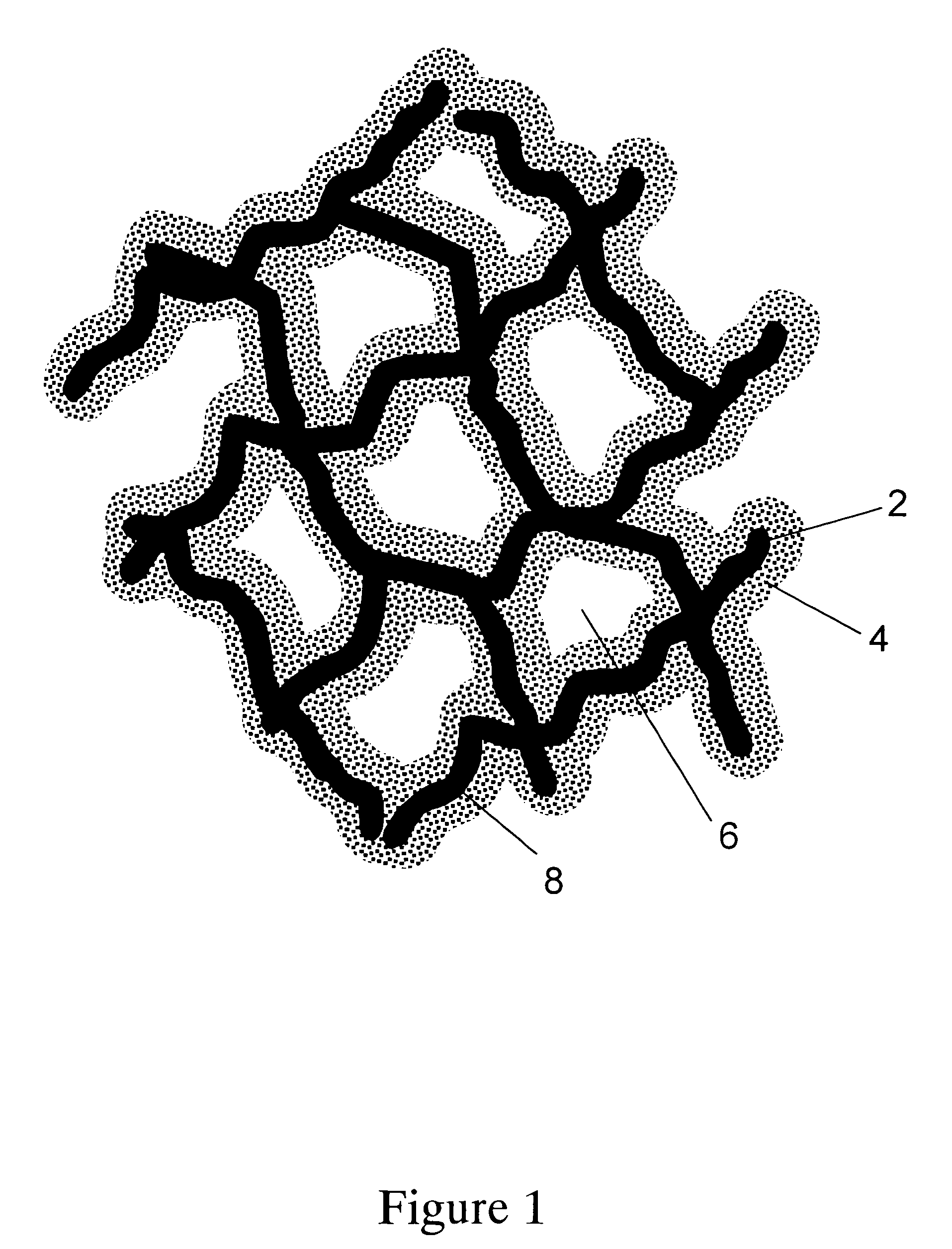

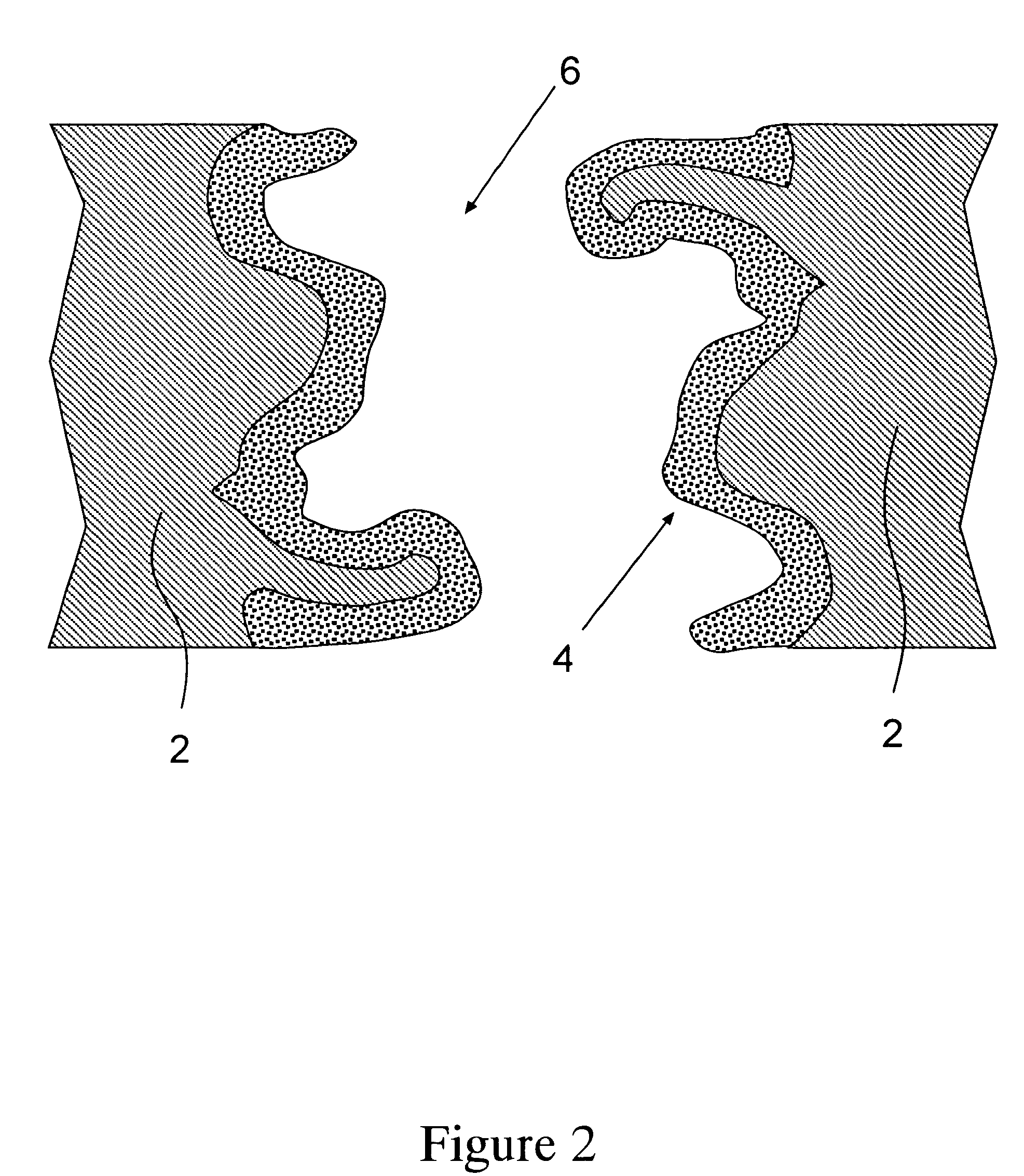

Porous adsorptive or chromatographic media

ActiveUS20050211615A1High dynamic capacityGood convective and diffusional flow characteristicsIon-exchange process apparatusOther chemical processesPorous substrateFiltration

A porous substrate capable of adsorptive filtration of a fluid having a porous self-supporting substrate and one or more porous, adsorptive polymeric coatings comprising from about 1 to about 80% of the void volume of the pores of the substrate. The resultant substrate has good convective and diffusive flow and capacity. The substrate may be cross-linked, have one or more capture chemistries attached to it and is useful as a chromatography media for the selective filtration of desired species including biomolecules such as proteins and DNA fragments.

Owner:MILLIPORE CORP

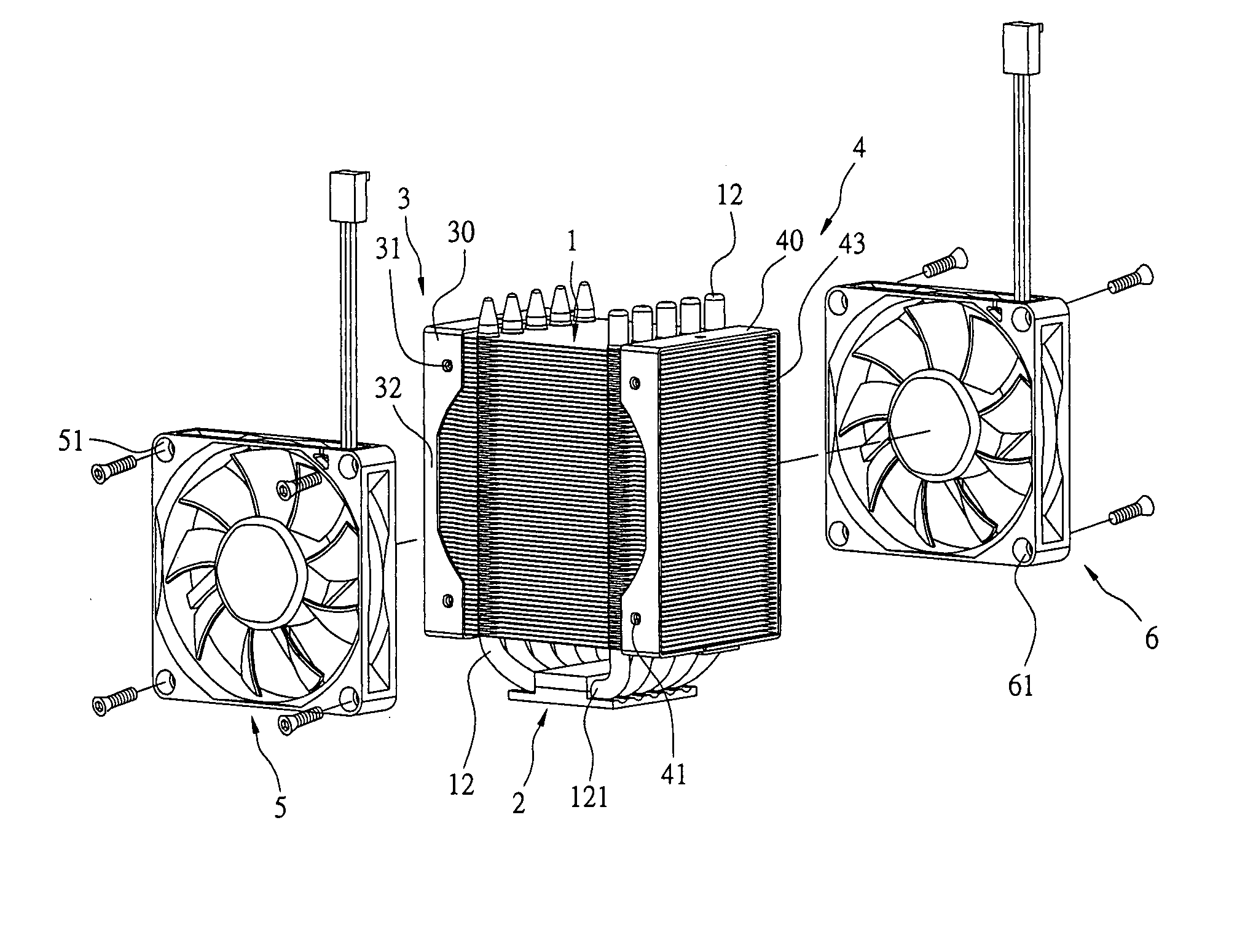

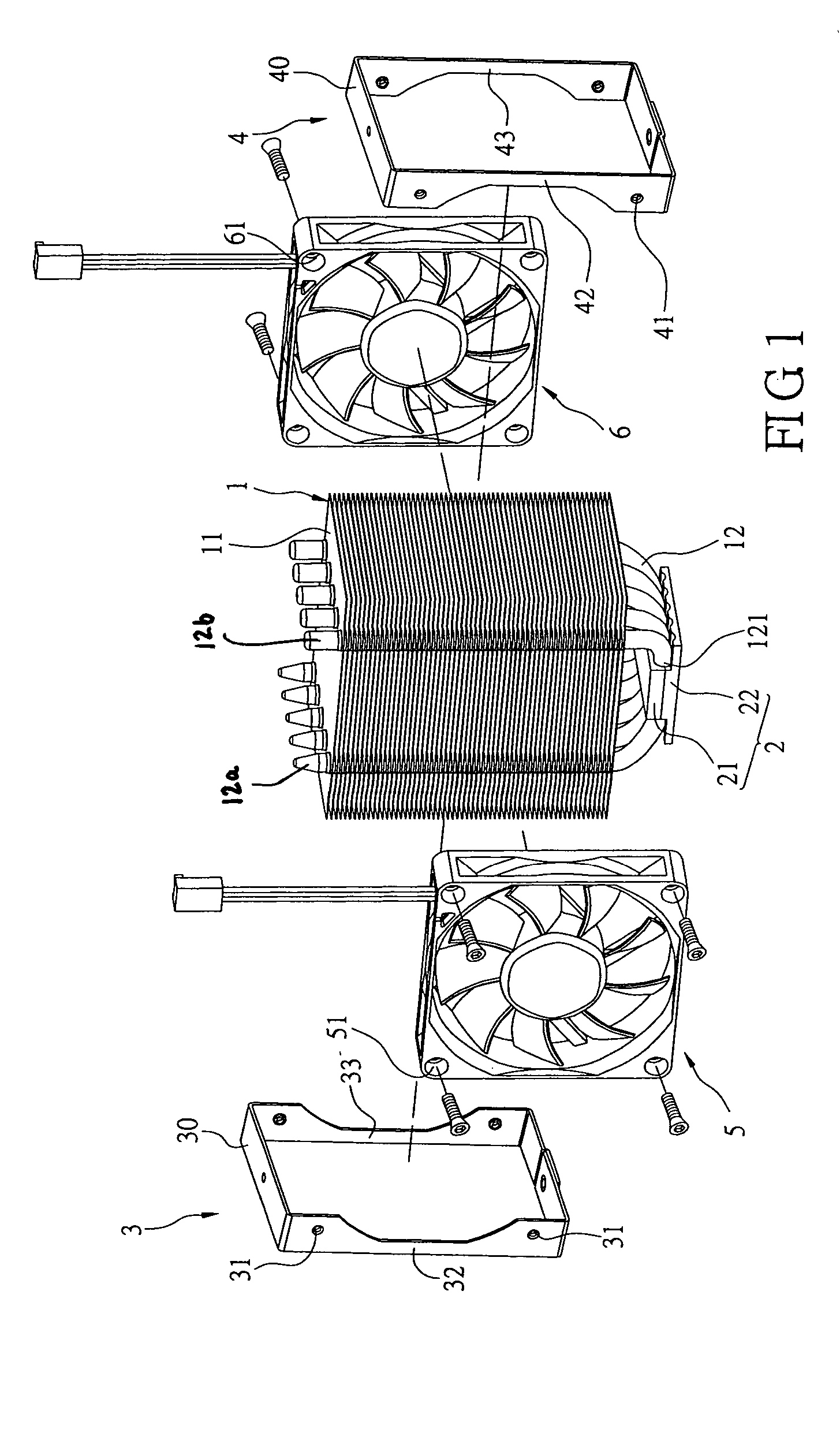

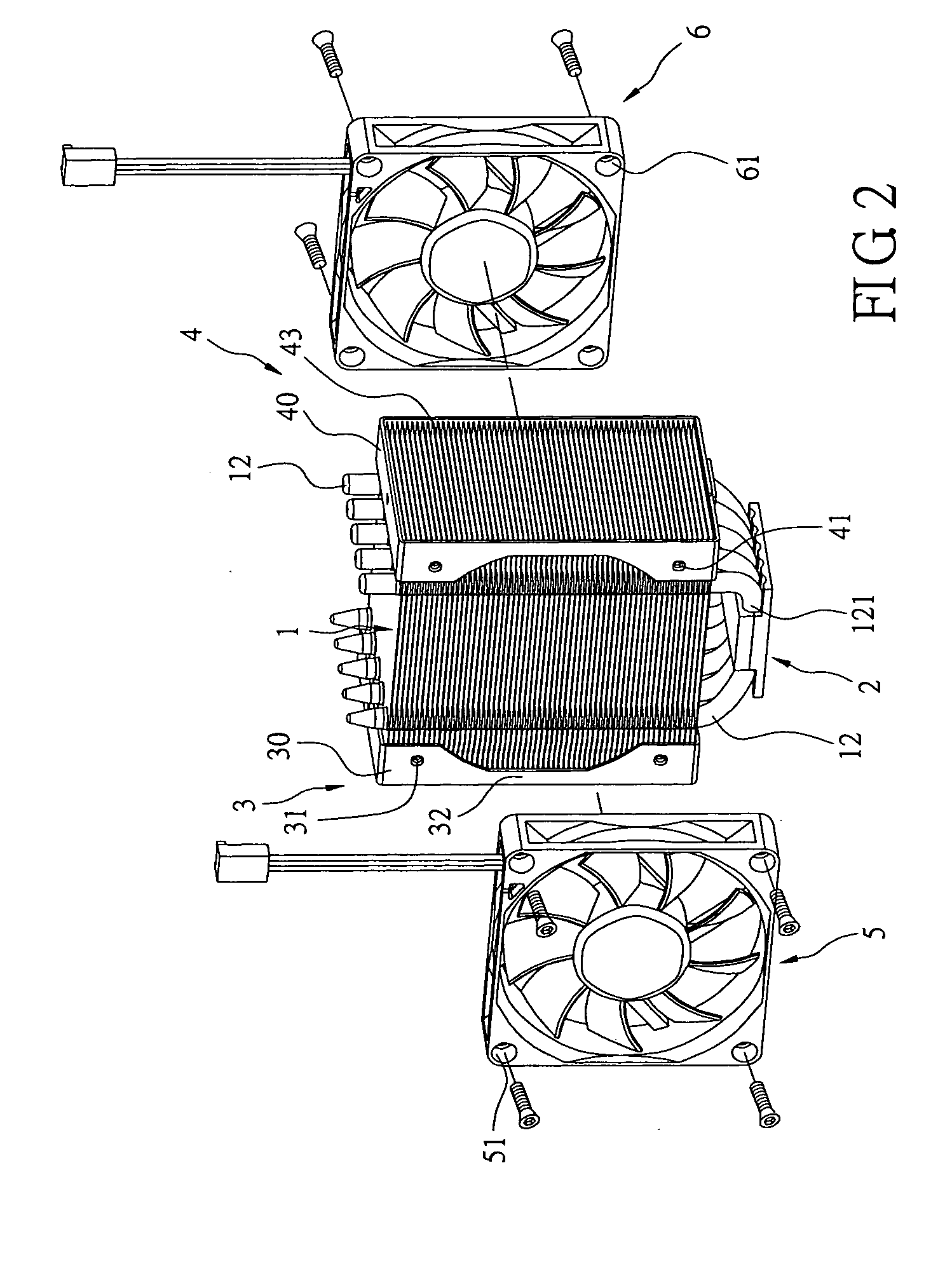

Heat dissipation module with a pair of fans

InactiveUS20050087329A1Improve convection efficiencyEnhanced convectionSemiconductor/solid-state device detailsSolid-state devicesHeat pipeElectrical and Electronics engineering

A heat dissipation module with a pair of fans is described. The heat dissipation module has a heat dissipation fin, a heat pipe and a pair of fans. The present invention enhances heat dissipation efficiency. The present invention has a fin group having a plurality of heat dissipation fins in stack. A first and a second supporting mechanism with a plurality of threaded holes are set on opposite sides of the fin group. A first and a second fans are individually set on opposite sides of the fin group. Each of the first and the second fans has holes corresponding to the threaded holes of the first and the second supporting mechanism. Therefore, the first and the second fans can be built at opposite sides by using the first and the second supporting mechanism.

Owner:MOLEX INC

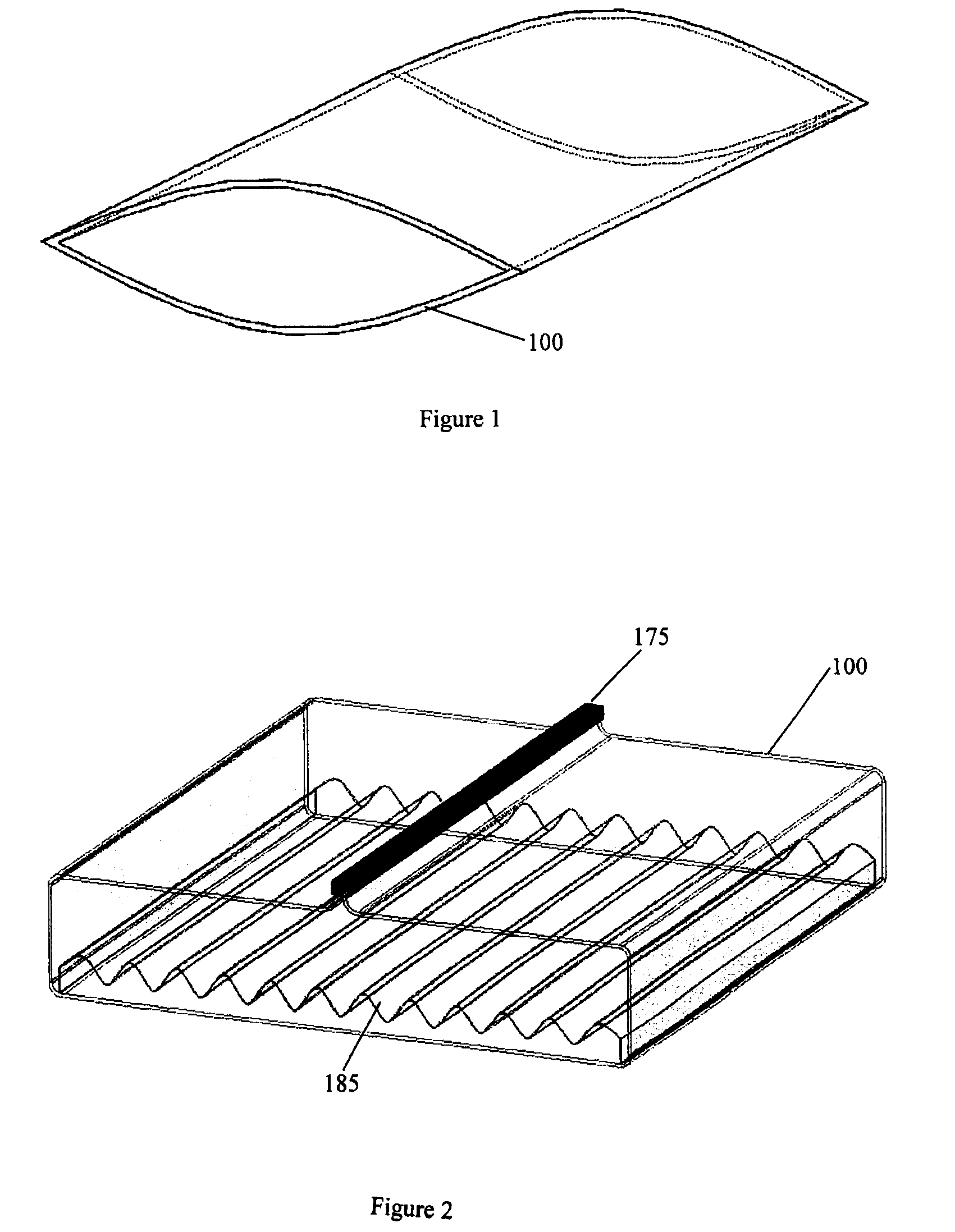

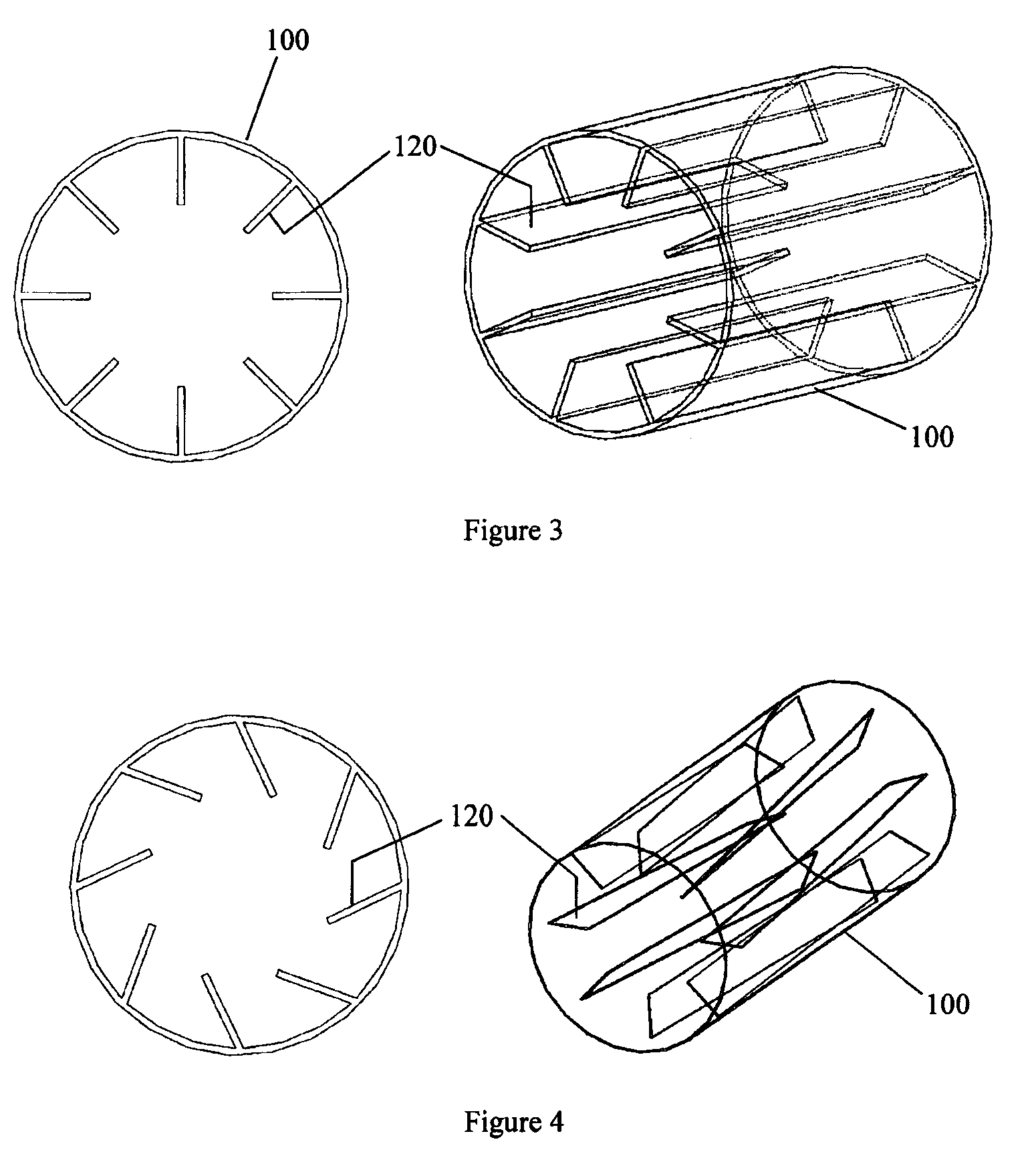

High surface cultivation system bag

InactiveUS20080206862A1Increase of available surfaceIncrease gas exchangeBioreactor/fermenter combinationsBiological substance pretreatmentsParticulatesMulticellular organism

An exemplary embodiment of a reversibly closable bag suitable for the cultivation of cells and / or tissues can be provided. The exemplary bag can comprise at least one reversibly closable aperture in the bag wall, and a surface-increasing convection arrangement inside the bag. The convection arrangement is capable to generate and / or modify a convection in a fluid within said bag when at least one of the fluid, the bag, and the convection arrangement is agitated. For example, the surface increasing convection arrangement can be at least one blade, at least one particulate filler and / or at least one surface-increasing substrate being made of a single mould. A system can also be provided comprising at least two bags, whereas the bags may be interconnected via at least one aperture in their bag wall, and a cultivation process using such a bag or system, in which at least one type of cells, tissue, tissue-like cell cultures, organs, organ-like cell cultures, or multicellular organisms are cultivated in the presence of at least one fluid or solid medium provided for growing and / or cultivating the aforesaid culture.

Owner:CINVENTION AG

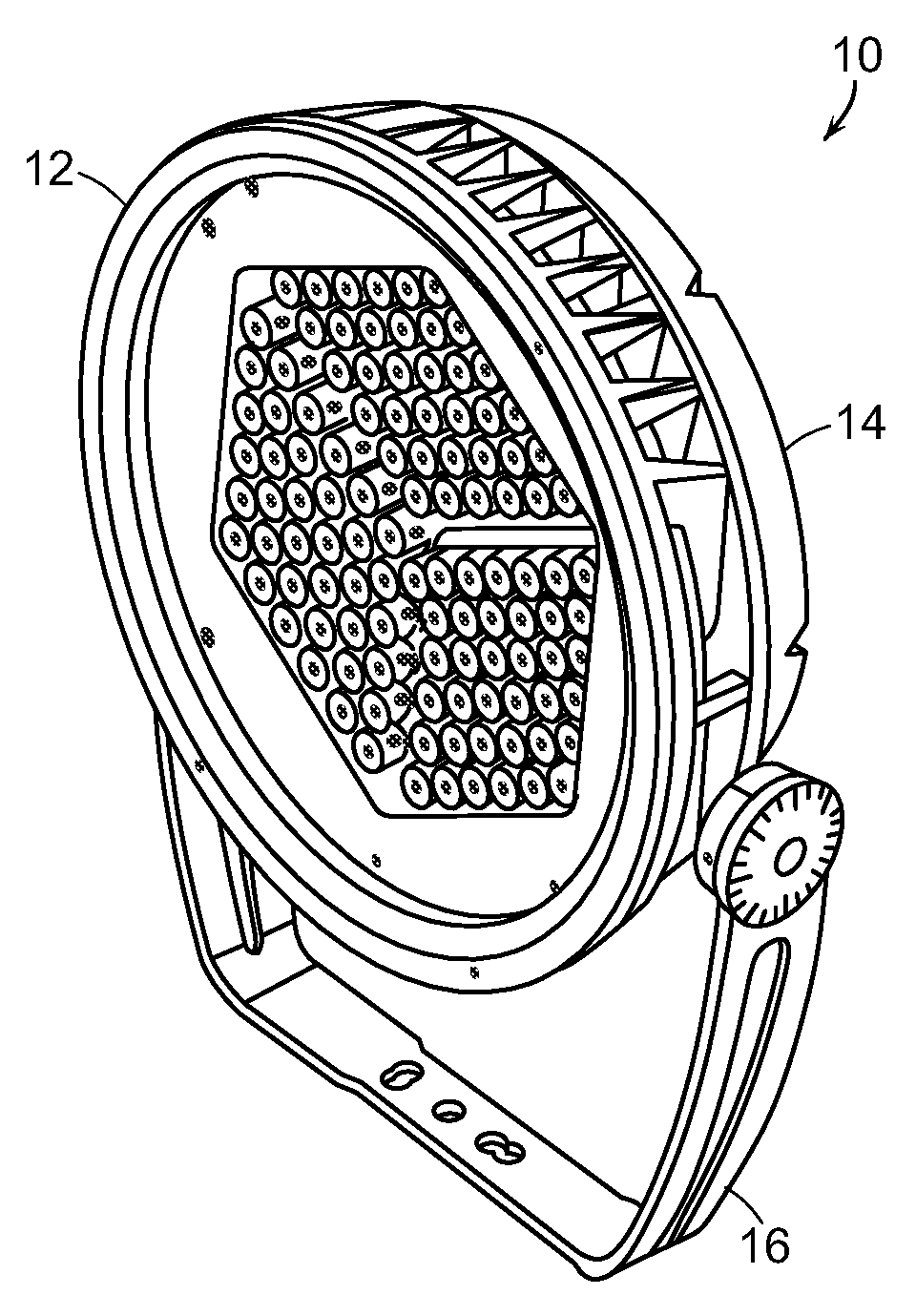

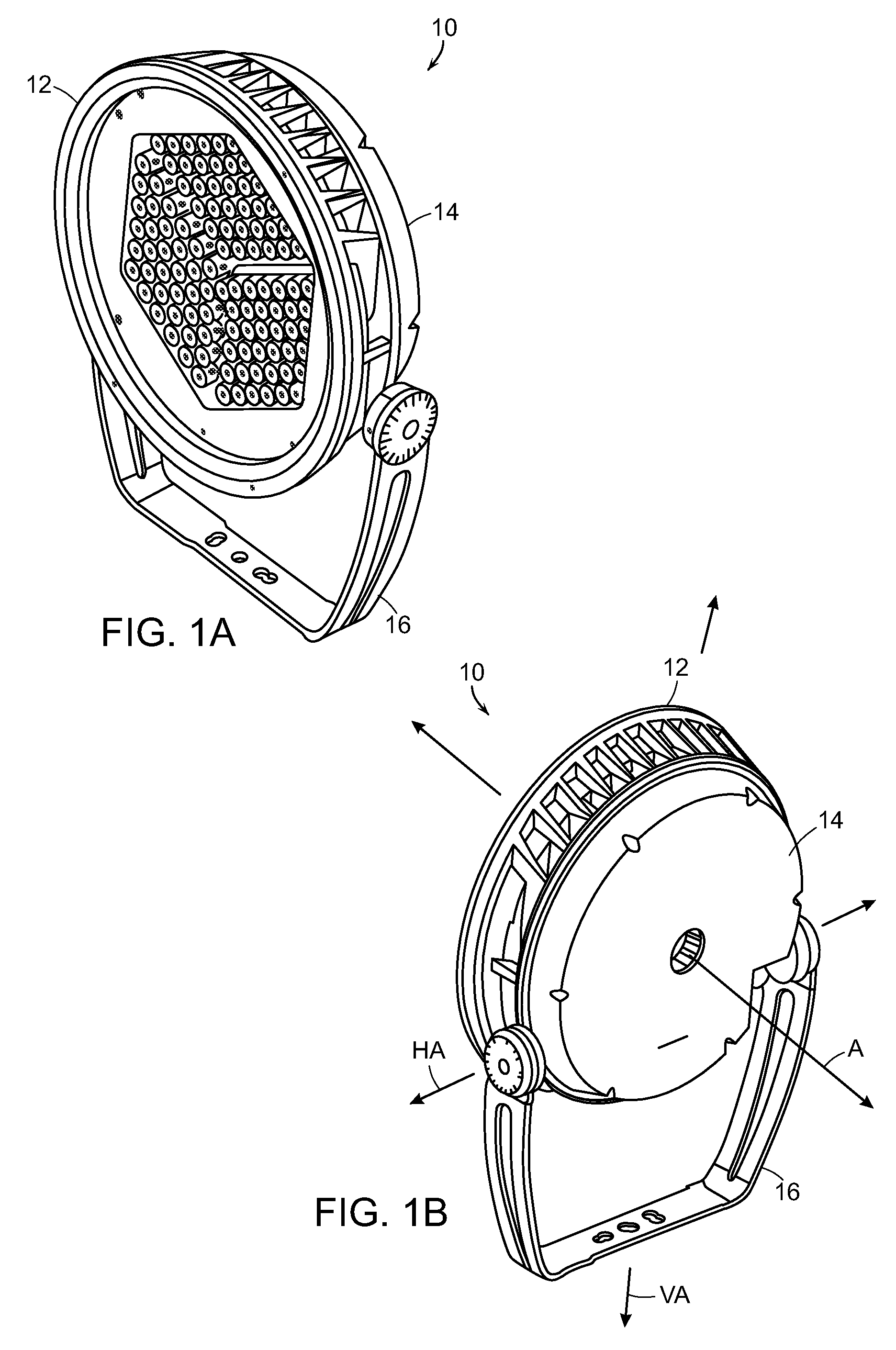

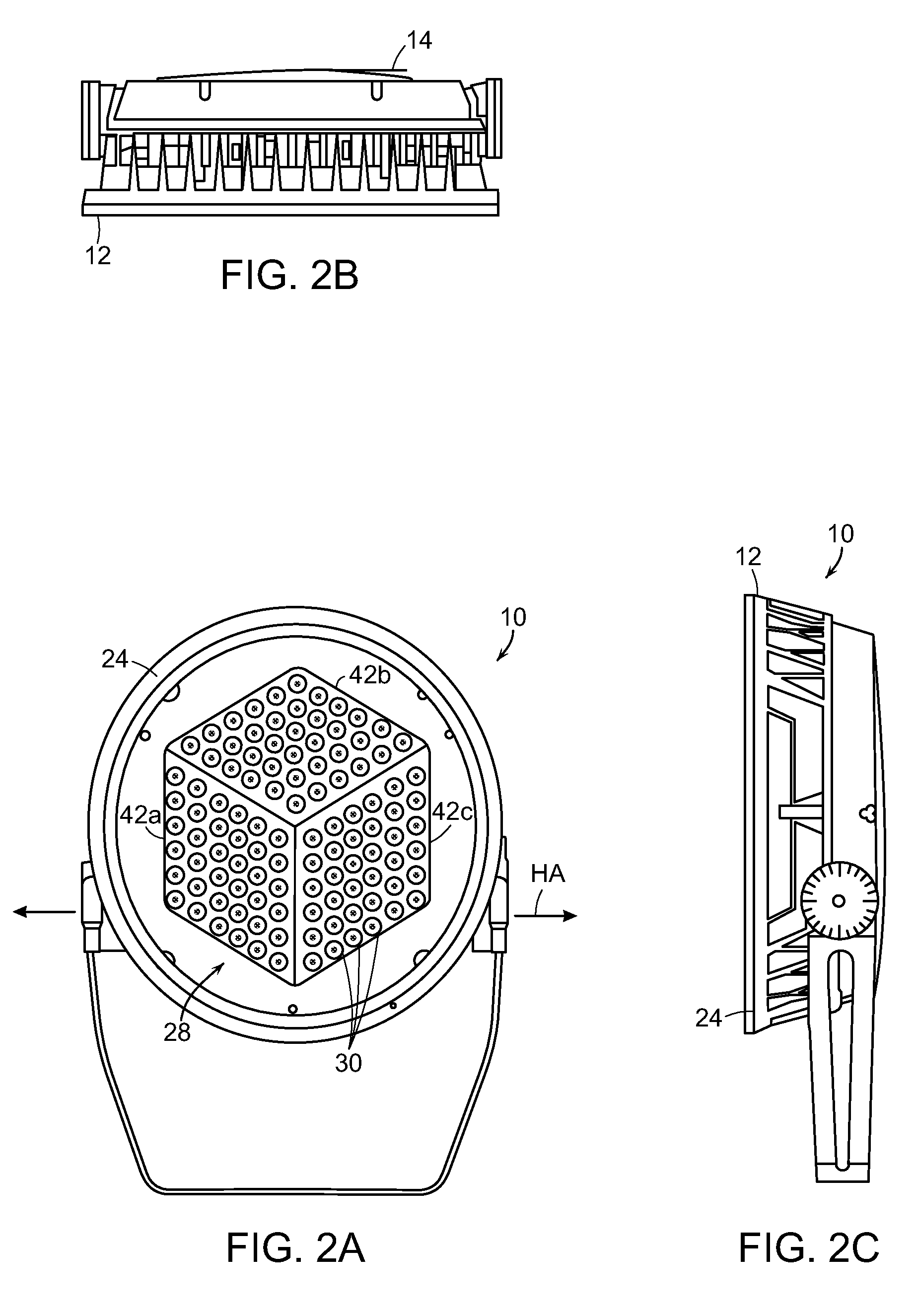

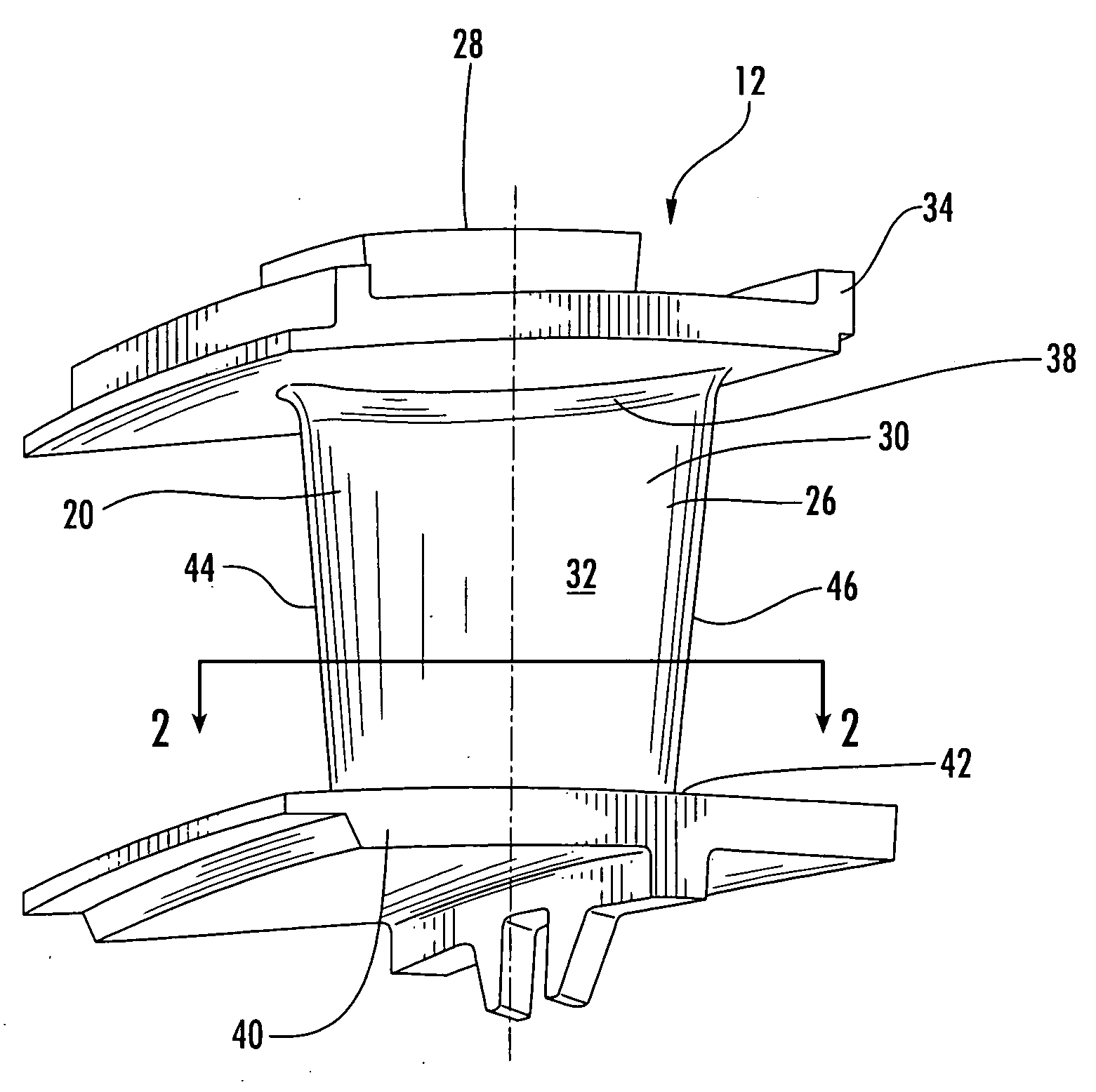

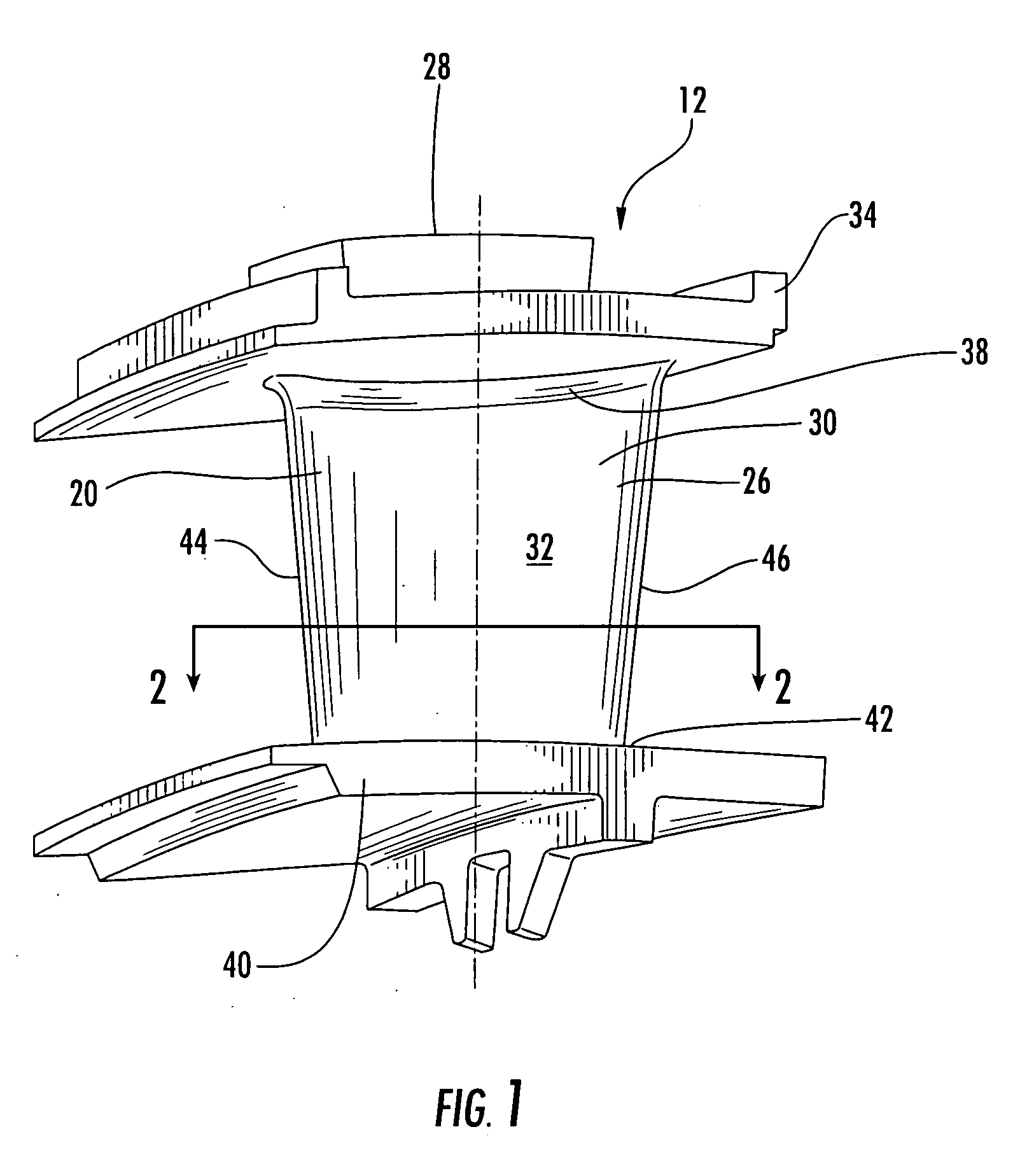

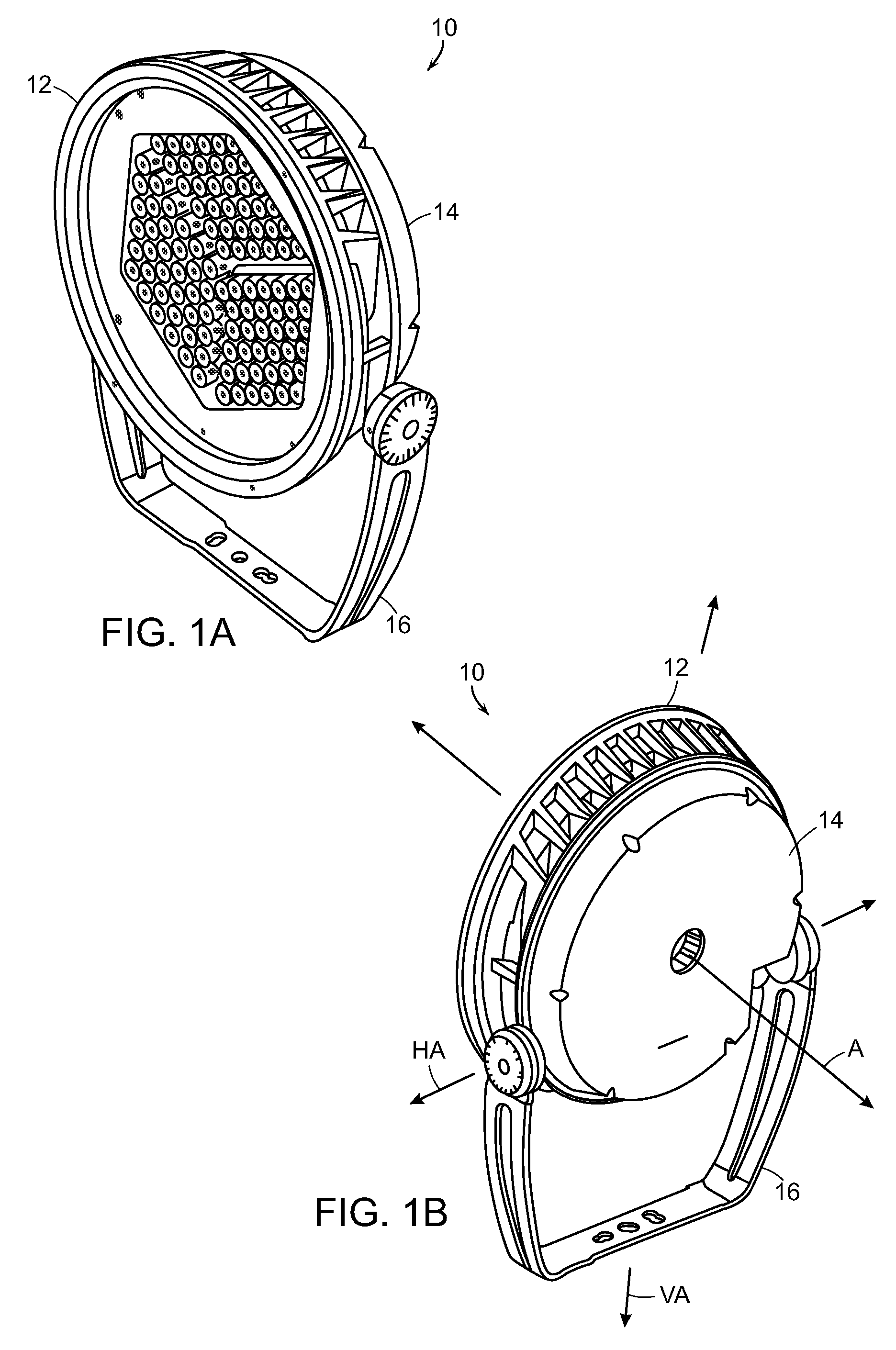

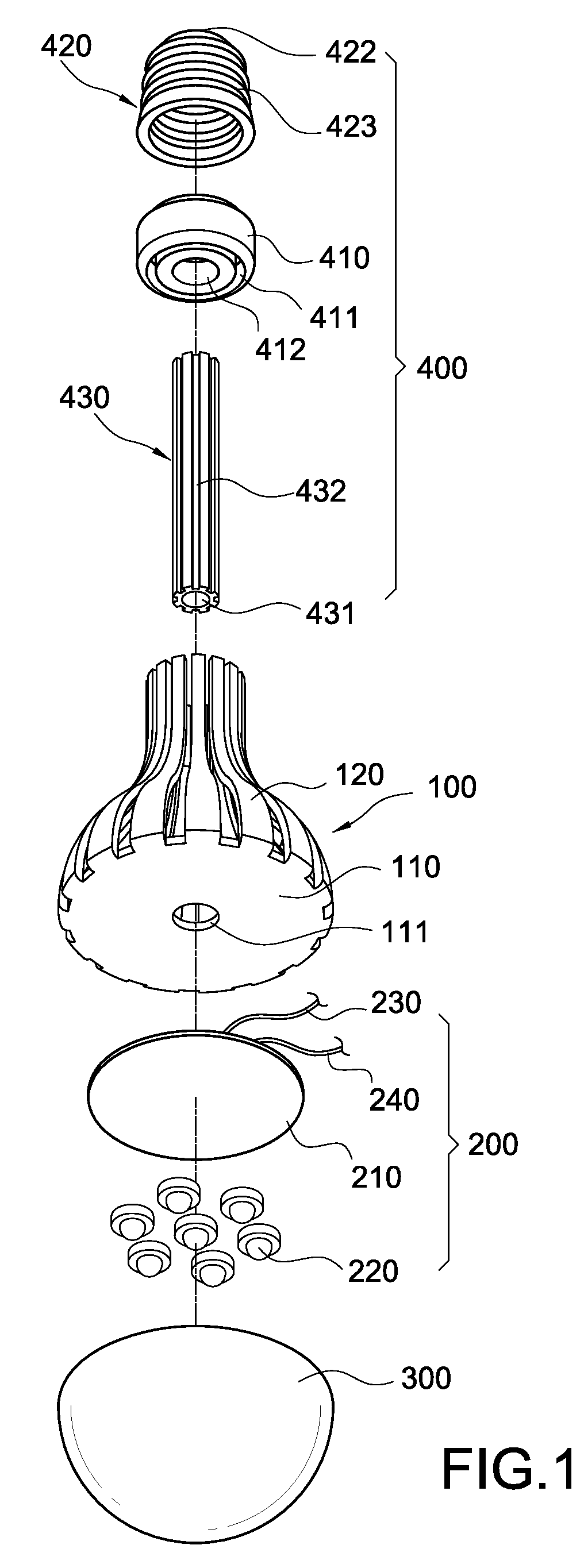

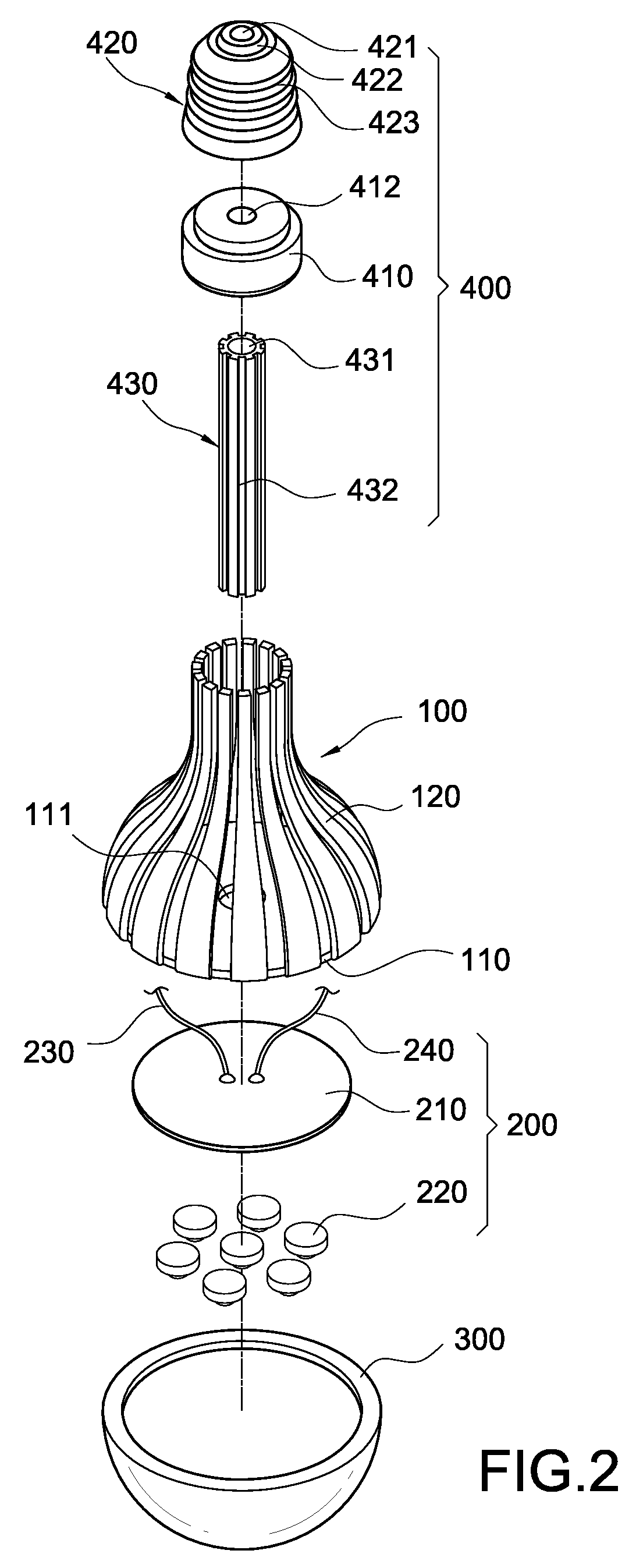

High powered light emitting diode lighting unit

ActiveUS20120287613A1Facilitate removal of heatReduce pressurePlanar light sourcesPoint-like light sourcePrinted circuit boardAirflow

A light emitting diode (LED) lighting unit including power supply housing accommodating a power supply and an LED array housing defining an internal compartment and a lens sealing the internal compartment. An LED array and an LED control circuit are mounted on a printed circuit board, which is accommodated within the compartment. The rear surface of the LED array housing includes a heat transfer element. At least one of the LED array and power supply housings has a chimney extending therethrough from a front to rear surface. The rear surface of the LED array housing is spaced from the front surface of the power supply housing to define and airflow space therebetween. During operation of the LED lighting unit, air flows into the airflow space and toward a central axis of the LED lighting unit before flowing out through the chimney to facilitate removing heat from the LED lighting unit.

Owner:LUMENPULSE GRP INC

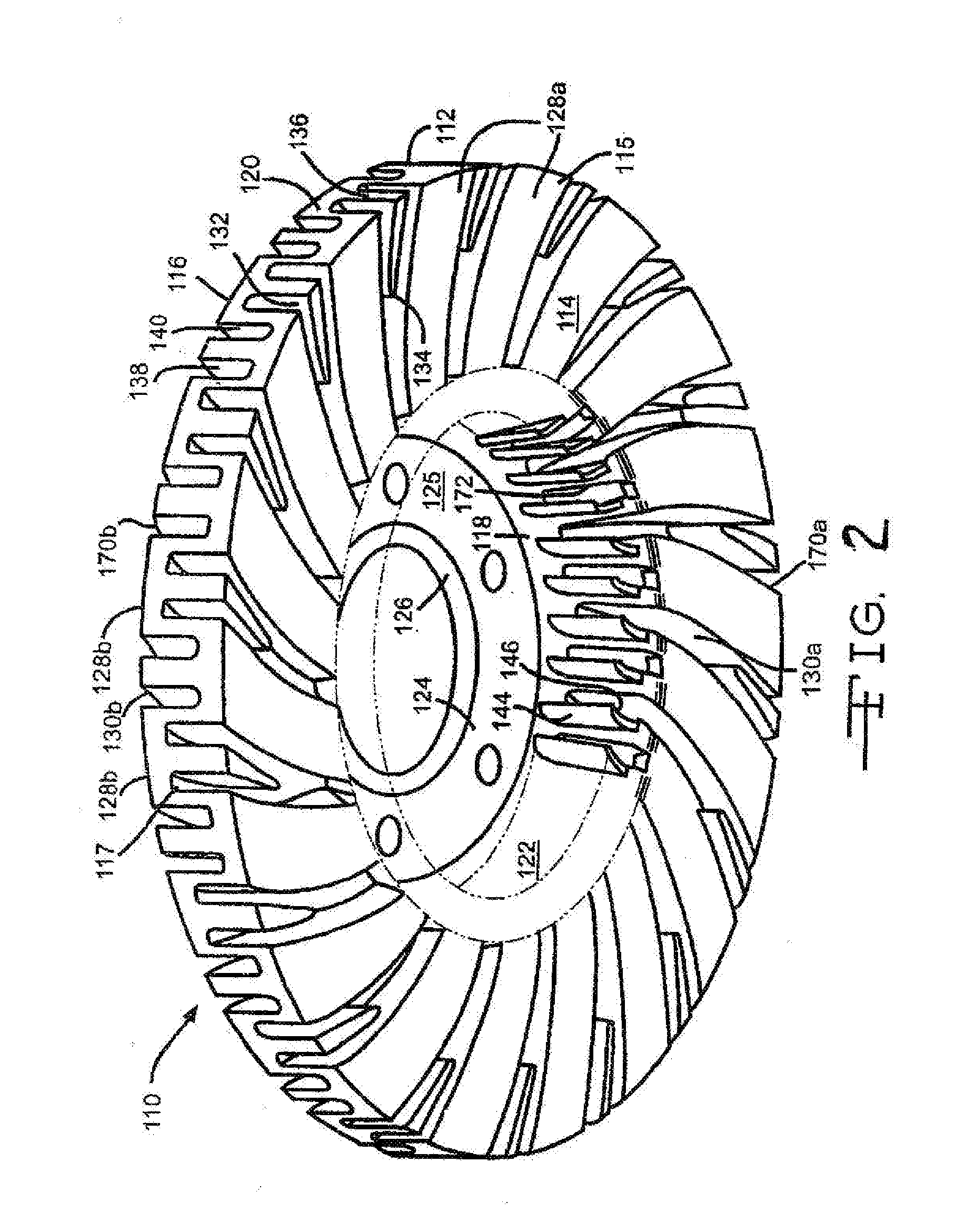

Turbine airfoil with near wall multi-serpentine cooling channels

InactiveUS20090104042A1Improve design flexibilityRaise the potentialPropellersEngine manufactureCooling chamberTurbine

A turbine airfoil usable in a turbine engine and having at least one cooling system. At least a portion of the cooling system may be positioned in an outer wall of the turbine airfoil and be formed from at least one suction side serpentine cooling chamber and at least one pressure side serpentine cooling chamber. Each of the suction and pressure side serpentine cooling channels may receive cooling fluids from a cooling fluid supply source first before being passed through other components of the cooling system. The cooling fluids may then be passed into a mid-chord cooling chamber to cool internal aspects of the turbine airfoil, yet prevent creation of a large temperature gradient between outer surfaces of the turbine airfoil and inner aspects.

Owner:SIEMENS ENERGY INC

Heat Dissipation Structure With Aligned Carbon Nanotube Arrays and Methods for Manufacturing And Use

ActiveUS20080001284A1Improve thermal conductivitySimplify the manufacturing processNanotechSemiconductor/solid-state device detailsCarbon nanotubeAdhesive materials

A heat dissipation structure with aligned carbon nanotube arrays formed on both sides. The carbon nanotube arrays in between a heat source and a cooler are used as thermal interface material extending and dissipating heat directly from a heat source surface to a cooler surface. In some embodiments, an adhesive material can be used to dispense around carbon nanotube arrays and assemble the heat dissipation structure in between a heat source and a cooler. In some other embodiments, carbon nanotube arrays are formed on at least one of a heat source surface and a cooler surface and connect them together by further growing. The carbon nanotube arrays can be exposed to the environment instead of being in between a heat source and a solid cooler, and can serve as fins to enlarge heat dissipation area and improve thermal convection.

Owner:THE HONG KONG UNIV OF SCI & TECH

Flow direction control mechanism

InactiveUS20060073783A1Enhanced convectionIncrease heatDomestic cooling apparatusLighting and heating apparatusElectronic systemsEngineering

A flow direction control mechanism is provided, which includes at least a rotatable means provided in a passage of an electronic system or apparatus. The rotatable means moves to an open position by means of a force generated from fluids flowing through the passage and returns to a close position in the absence of the force. Further, a restrictor is disposed adjacent to the rotatable means for restricting movement of the rotatable means between the open position and the close position.

Owner:TSAI I HSUAN +3

Multi-outlet soft frozen dessert apparatus for a self-service restaurant

A multi-outlet soft frozen dessert apparatus for a self-service restaurant with multiple freezers attached to the wall dividing the client area of the restaurant from the kitchen area is provided. The freezers of apparatus may include an evaporation tube comprised of an aluminum alloy micro-channel parallel flow extruded tape. The mix vats of the apparatus may include circulating water in a hydraulic system having added antifreeze to suppress a freezing temperature in the range of −2° C. to −5° C. to assure adequate approach temperature to cool a mix in the mix vat. The apparatus may include scrape blades mounted on a helical part of the beater-scraper that scrape a thin layer of ice crystals from an internal surface of the inner cylinder and fold the ice crystals inside the mix bulk.

Owner:REICH DANIEL +1

Planting method for tea-oil trees

InactiveCN103081671AReasonable planting structureNutritiousHorticultureCamellia oleiferaFarmyard manure

The invention discloses a planting method for tea-oil trees. The method comprises the following steps of: (1) selecting soil and an area, building horizontal steps on a slope around a mountain, digging drainage ditches on the inner sides of the steps, and digging pits at fixed points according to a planting distance, wherein the pits are arranged to form delta shapes; (2) after the pits are dug, properly applying garbage tankage, rice straws, dicranopteris pedata and farmyard manure, wherein base fertilizers are required to be deeply applied; (3) during the blossoming of the tea-oil trees, marking early blossoming type plants of a selected tea-oil tree variety, selecting high-yield and high-premonition plants from the marked plants when fruits are matured in the next type, and picking mature and full tea-oil tree seeds; (4) sowing the seeds from every early November to February of the next year, wherein germination is accelerated and the seeds are sown after the seeds are sterilized; (5) after the seeds come up, selecting seedlings, and filling gaps with the seedlings; and (6) after the tea-oil trees are fruited, applying the farmyard manure and a compound fertilizer or a phosphate fertilizer, a potash fertilizer and urine in every May to July. The problems of irrational structure of a planting structure, low oil yield, shortage of scientific management and the like of the conventional tea-oil tree planting process are solved.

Owner:永州锦溁新能源开发有限公司

Maze conformal cooling method and structure of mold

The invention provides a maze conformal cooling method and structure of a mold, and aims to solve the problem that the conventional mold cooling method cannot meet efficient and uniform cooling requirement of a complex mold. Compared with three traditional mold cooling method including a straight hole flow channel, a built-in bent pipe flow channel and a common tubular shape follow-up flow channel, the maze conformal cooling method is high in cooling efficiency and good in cooling effect. According to the structure, a hollow layer nearly parallel to the inner surface of a cavity is arranged in the position, having certain thickness distance from the cavity, in the mold, a maze type partition wall is arranged in the hollow layer, and a cooling medium flows in a channel formed by partition wall gapes in a cooling layer. The maze conformal cooling method and the structure of the mold have the advantages that the cooling state of the cooling medium in the gaps of the maze type partition wall is turbulence, and the contact area between the cooling medium and the mold is increased, so that the cooing efficiency is high, the service life of the mold is long, an injection molding process period is shortened, and the injection molding manufacturing cost is reduced. A 3-dimensional laser printing technology is adopted to directly manufacture the mold with the layered maze flow channel conformal cooling structure, components in the mold are uniform, the molding process is simple, the mold manufacturing period is short, and the mold manufacturing cost is low.

Owner:HUAZHONG UNIV OF SCI & TECH

High powered light emitting diode lighting unit

ActiveUS8485691B2Fast heat conductionEnhanced convectionPlanar light sourcesLighting support devicesLed arrayEffect light

A light emitting diode (LED) lighting unit including power supply housing accommodating a power supply and an LED array housing defining an internal compartment and a lens sealing the internal compartment. An LED array and an LED control circuit are mounted on a printed circuit board, which is accommodated within the compartment. The rear surface of the LED array housing includes a heat transfer element. At least one of the LED array and power supply housings has a chimney extending therethrough from a front to rear surface. The rear surface of the LED array housing is spaced from the front surface of the power supply housing to define and airflow space therebetween. During operation of the LED lighting unit, air flows into the airflow space and toward a central axis of the LED lighting unit before flowing out through the chimney to facilitate removing heat from the LED lighting unit.

Owner:LUMENPULSE GRP INC

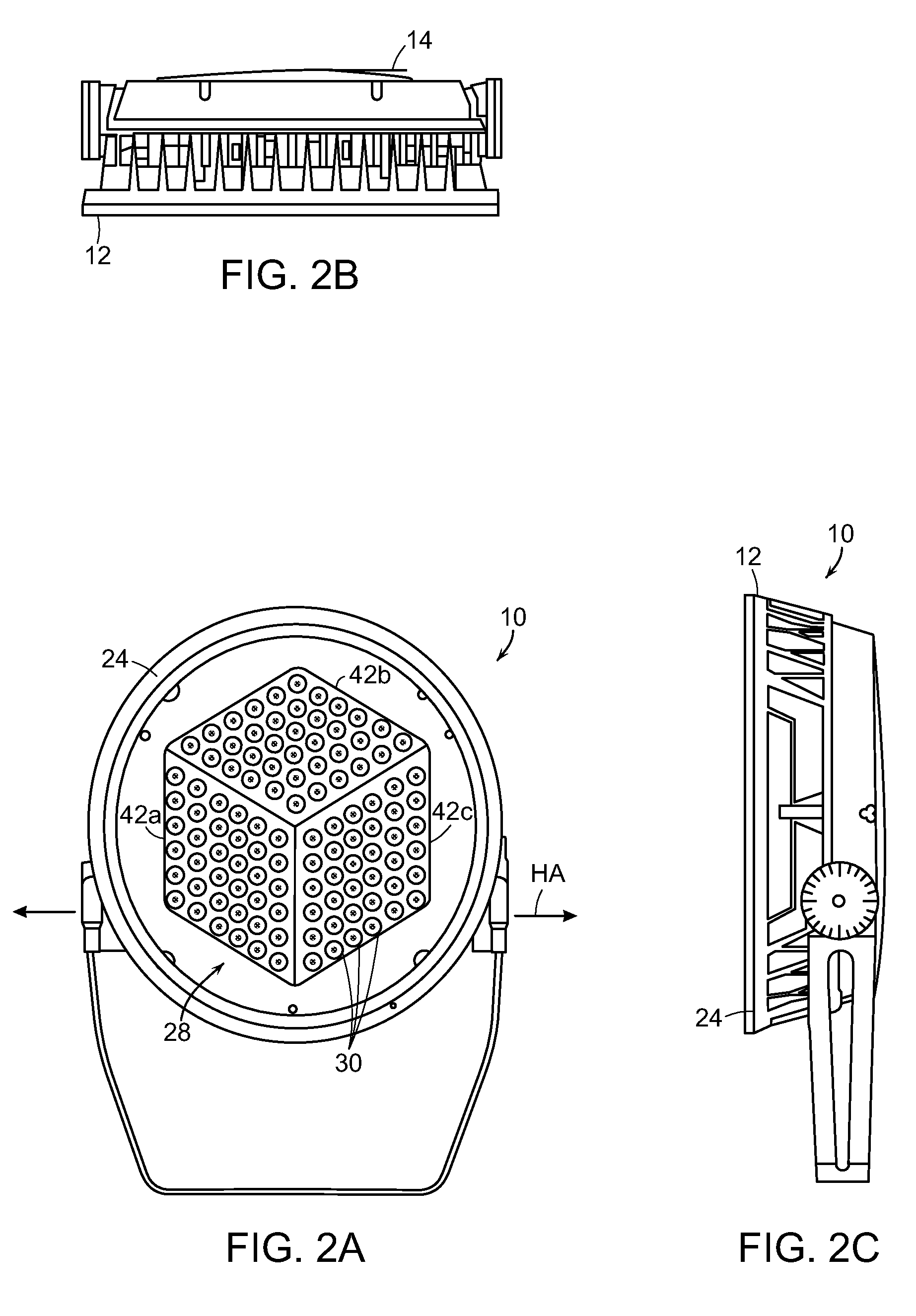

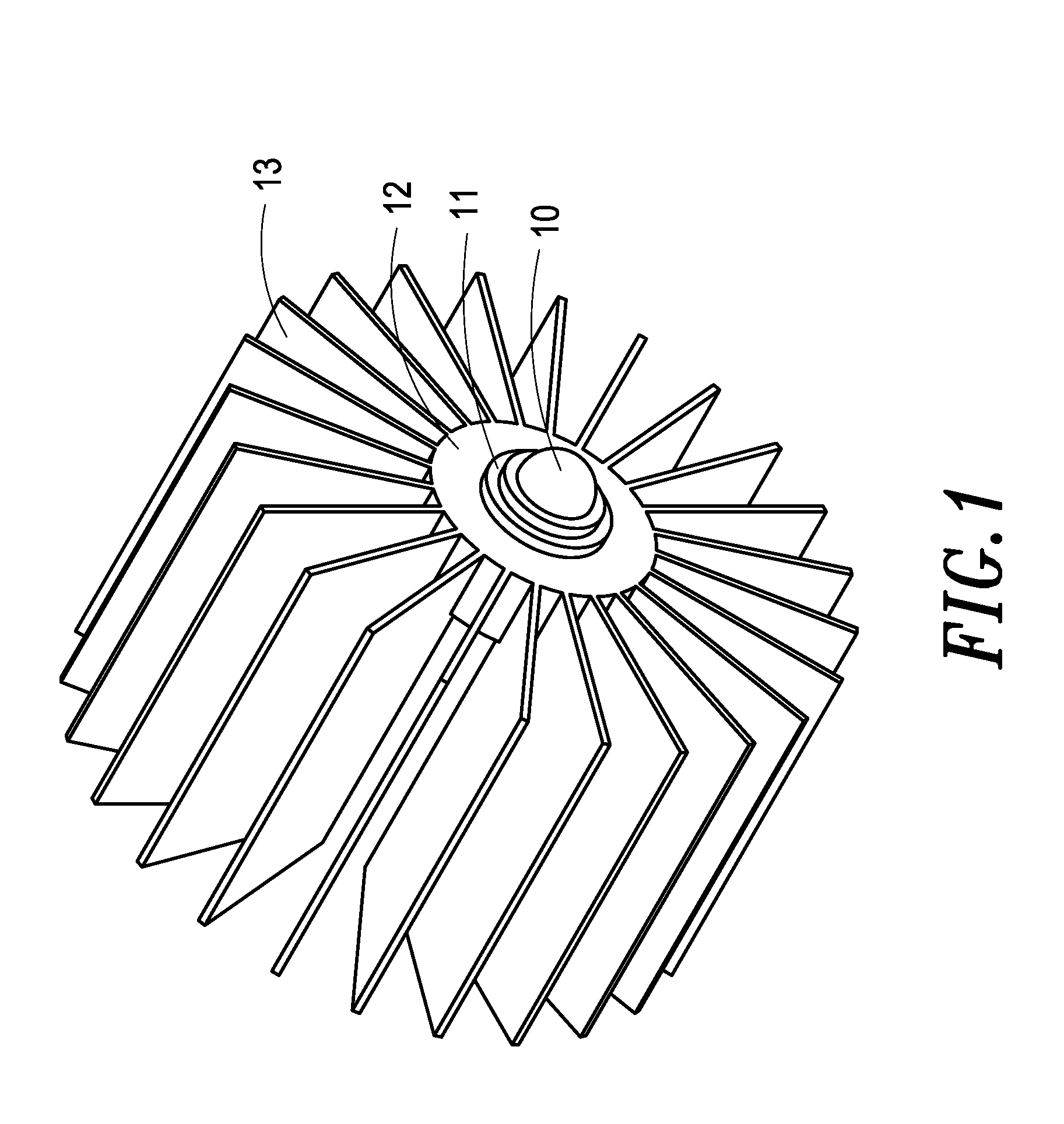

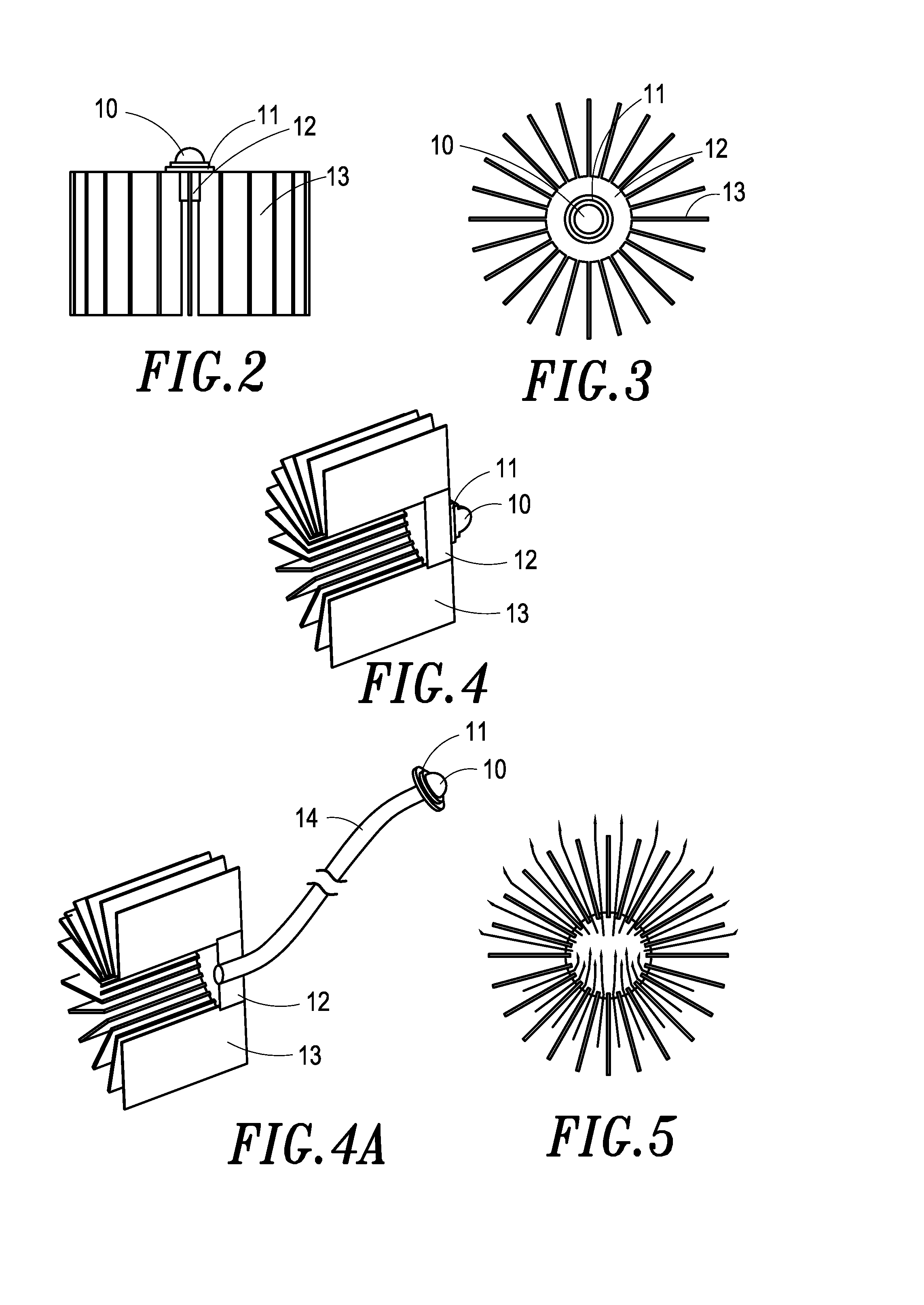

Heat Sink Structure for High Power LED Lamp

InactiveUS20080149305A1Good convection effectEnhanced convectionLighting heating/cooling arrangementsHeat exchange apparatusOmnidirectional antennaHeat conducting

A heat sink structure for high power LED lamp includes a heat conducting lamp holder, a heat conductor and a heat sink. The heat conducting lamp holder is made of highly heat-conductive material to provide a smooth surface for firmly holding an LED lamp. The heat conductor is made of highly heat-conductive material for linking the heat conducting lamp holder and the heat sink. The heat sink includes a plurality of heat sink fins made of highly heat-conductive material. The plurality of heat sink fins are arranged radially to form a porous center structure with no occluding junction, thereby implementing a heat sink structure which can provide omnidirectional heat dissipating capability and good convection capability to let hot air to rise naturally for high power LED lamps.

Owner:CHEN TE CHUNG +1

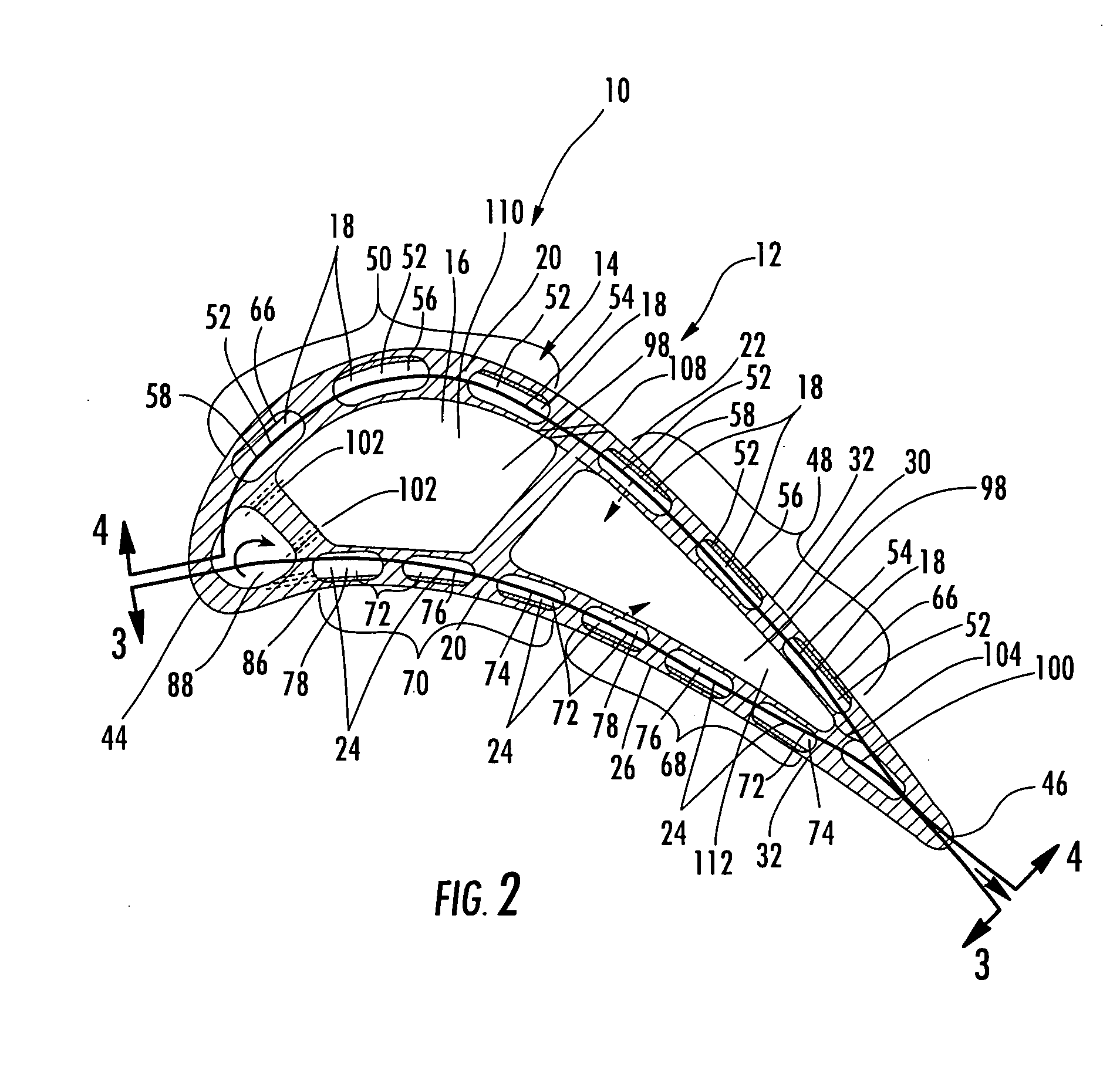

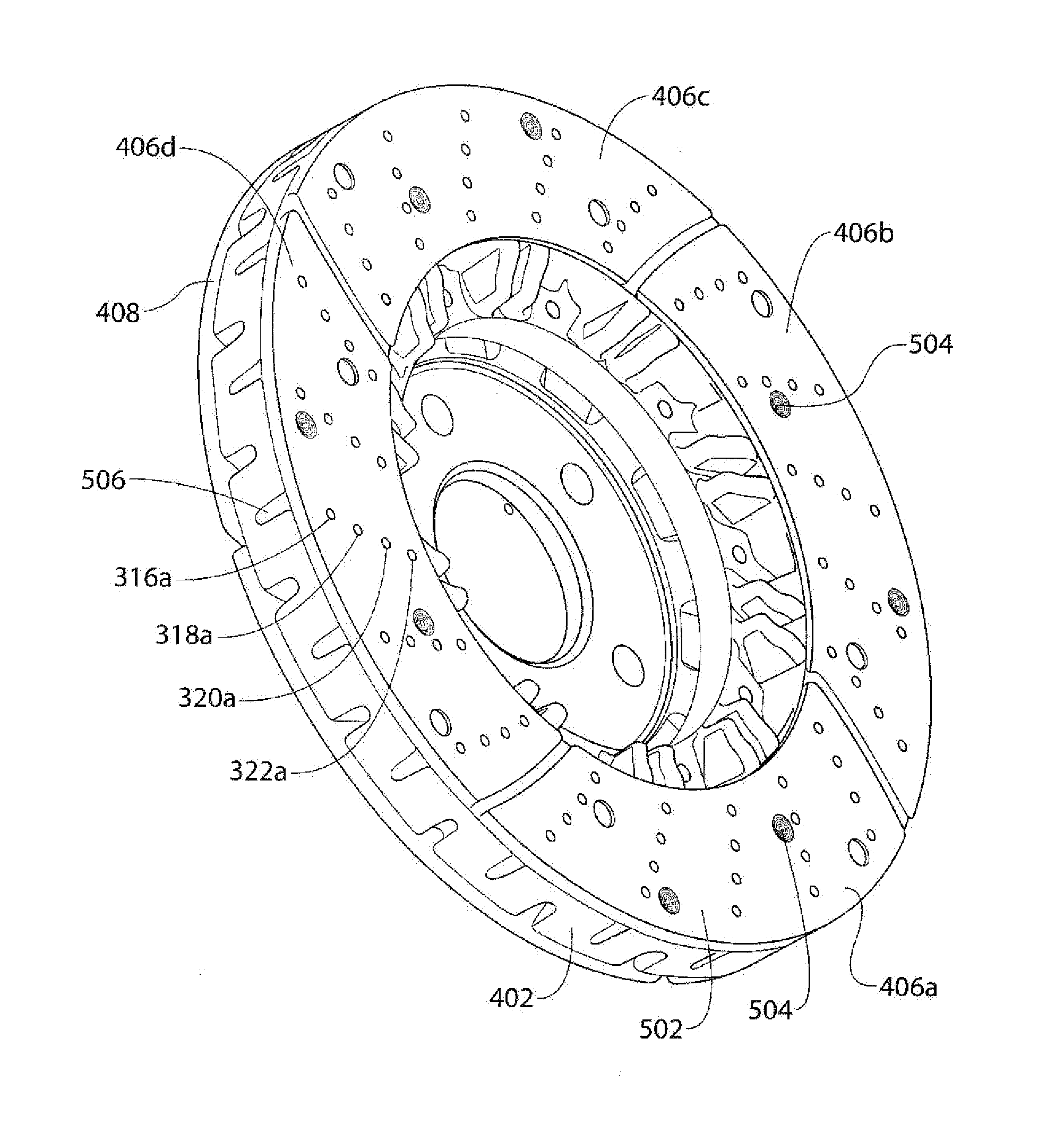

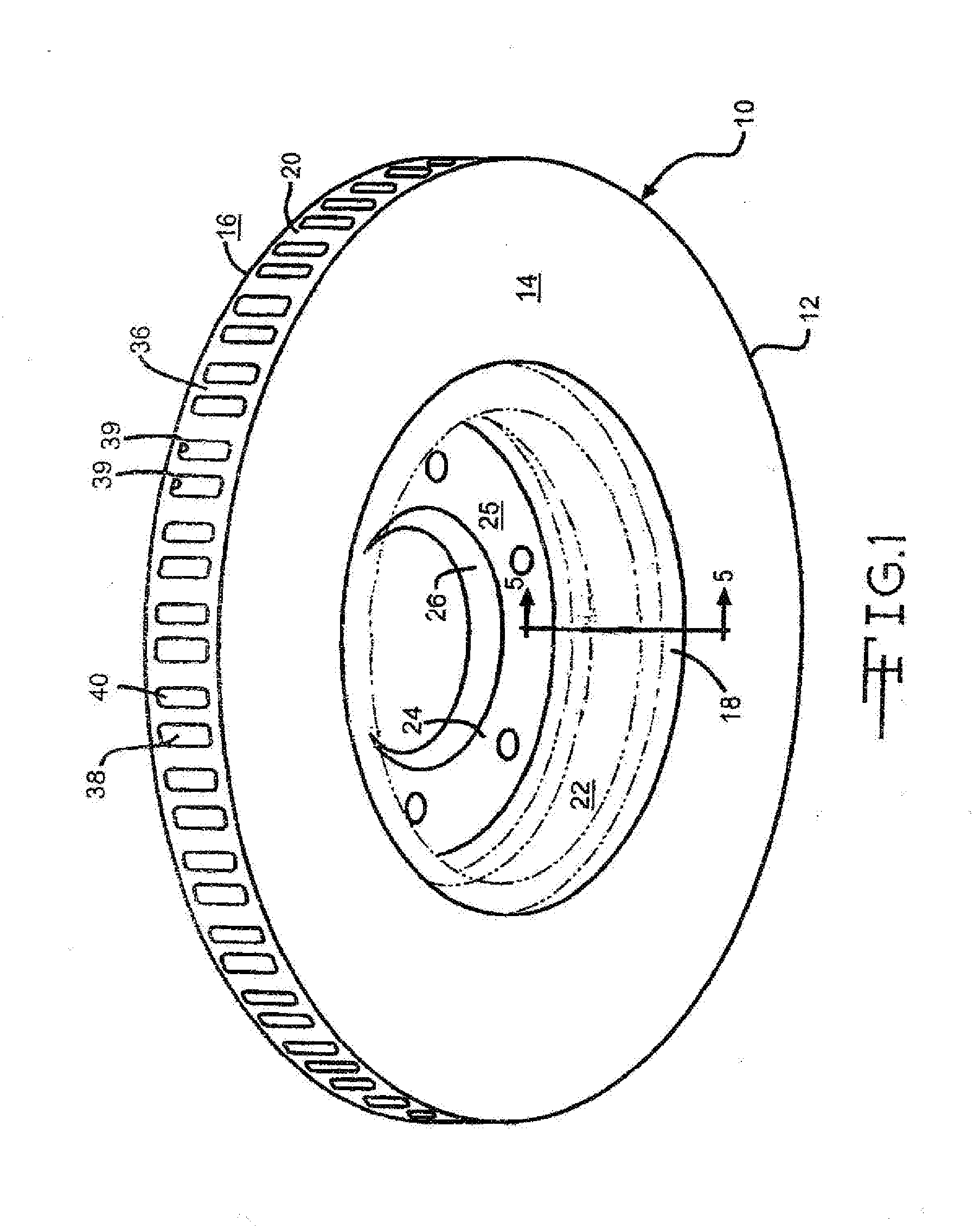

Segmented brake rotor with externally vented carrier

InactiveUS20120255820A1Improve effectivenessFunction increaseBraking discsFriction liningBrakeThermal force

An externally vented brake rotor (EVR) core design, such as exemplified by U.S. Pat. No. 6,536,564, is being used to improve the function and effectiveness of a segmented brake rotor (SBR) through more efficient management of the thermal forces created in the segmented rotor. Specifically, segmented friction plates are attached to the EVR core to form friction surfaces. Air flow through the vents contacts the back side of the friction plates. At least one segmented friction plate may be provided with a tab or protrusion that engages a corresponding receiving recess in the carrier surface of the EVR core, thereby relieving lateral stress forces.

Owner:MCCORD GEOFFREY K +1

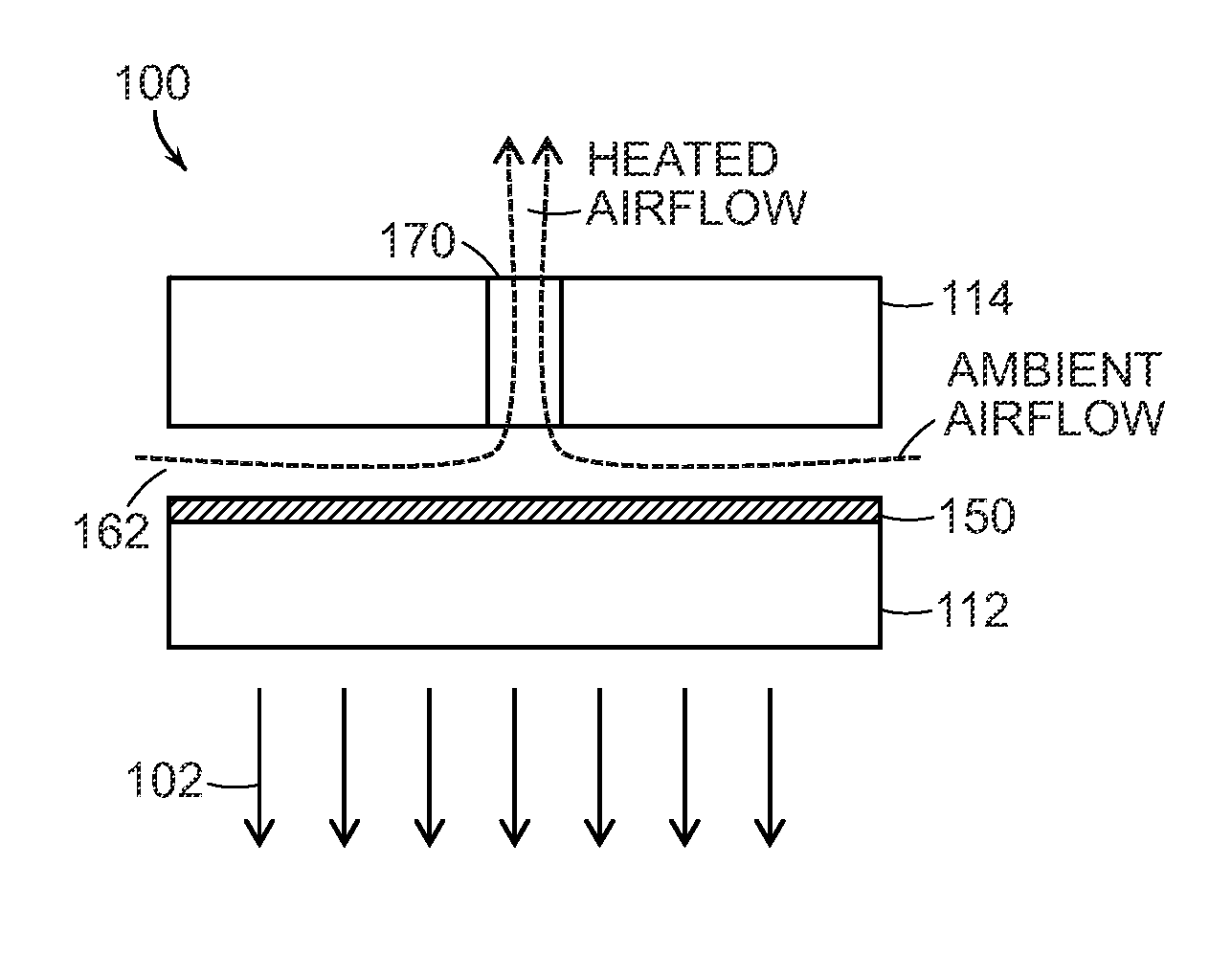

Two-phase-flow, panel-cooled, battery apparatus and method

InactiveUS20100252238A1Eliminate needEnhancing free convectionSemiconductor/solid-state device detailsSolid-state devicesHeat fluxWorking fluid

Two-phase, boiling heat transfer in confined channels close to a source of heat, such as an electrical component or device, carries the latent heat of vapors away to remote locations where “real estate” demands of air convection are tolerable operationally, economically, and technologically. Liquid-to-vapor, phase-change, heat transfer in a narrow channel (e.g., typically less than 0.200 inches total thickness, and often less than 0.150 in the channel itself) improves by several hundred percent the heat extraction from modest temperature (e.g., about 120 degree F.) devices, when compared to heat fluxes in pool boiling. Saturated working fluids provide nearly isothermal conditions in the working fluid. Minimal conduction paths provide minimal temperature gradients, and capillary action may maintain nearly constant temperature conditions about a surface of a heat source, while carrying heat of vaporization away to a condensation location.

Owner:BATTY J CLAIR +1

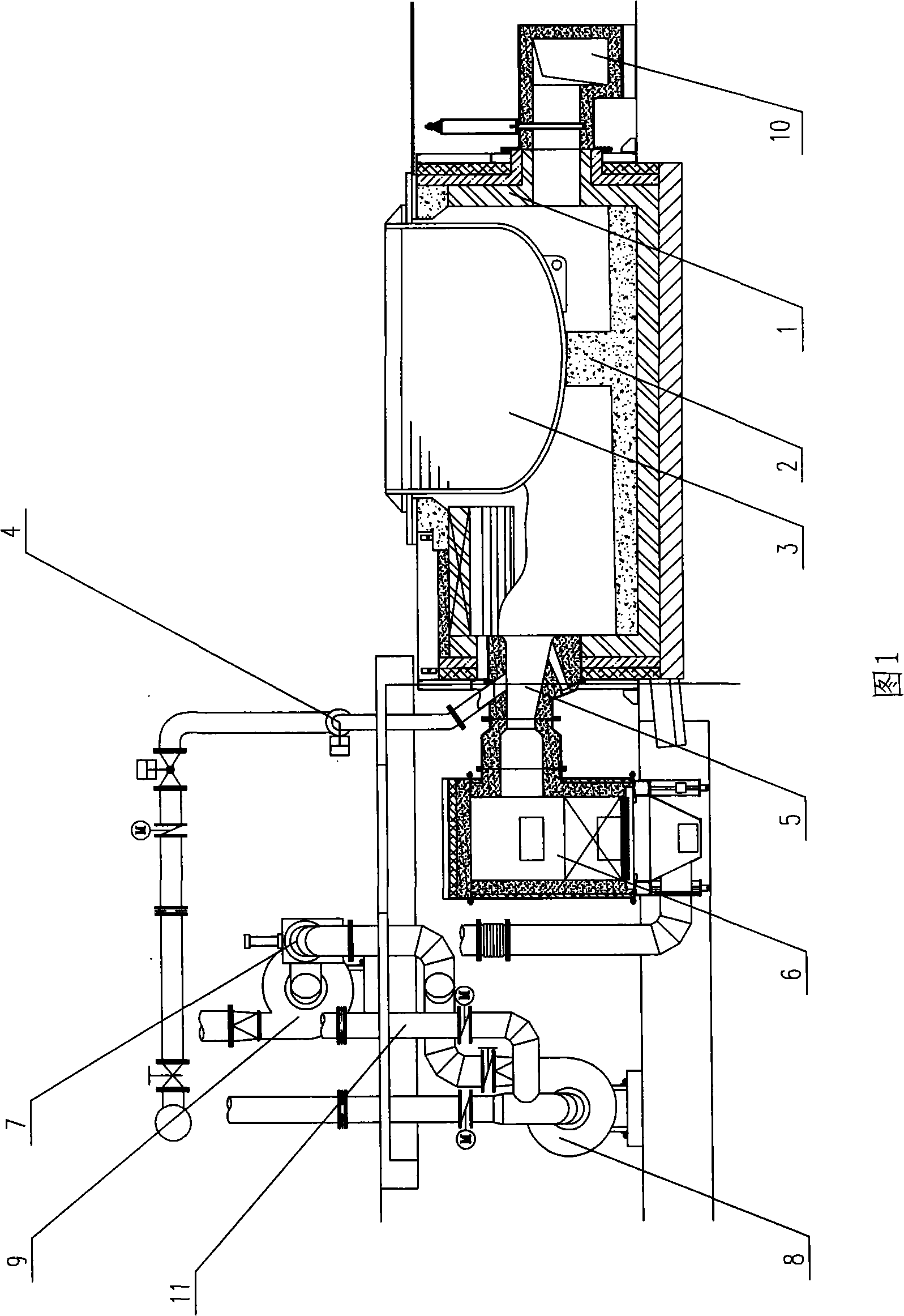

Kiln for melting high-alkali aluminosilicate glass

InactiveCN102503076AIncrease the maximum temperatureImprove efficiencyGlass furnace apparatusGlass productionThroatHeating system

The invention discloses a kiln for melting high-alkali aluminosilicate glass. The kiln is used for manufacturing cover plate glass of a touch screen. The kiln comprises a heating system which is matched with the kiln; the key points are that: a glass kiln structure comprises a pre-melting tank for melting glass, a horizontal flame melting tank which is connected with the pre-melting tank, and a throat which is connected with the melting tank and a material supply channel; and a kiln weir which can divide a zone for accommodating glass liquid flow in the melting tank into a fusion zone and a clarification zone is arranged in the melting tank; and stirring units are arranged in the material supply channel. Energy resources of the kiln are utilized reasonably, the temperature of molten glass rises quickly, homogenization and defoaming efficiencies are high, the high quality requirement of a glass product can be met, and the energy-saving requirement of the kiln can be met.

Owner:HENAN GUOKONG YUFEI ELECTRONICS GLASS

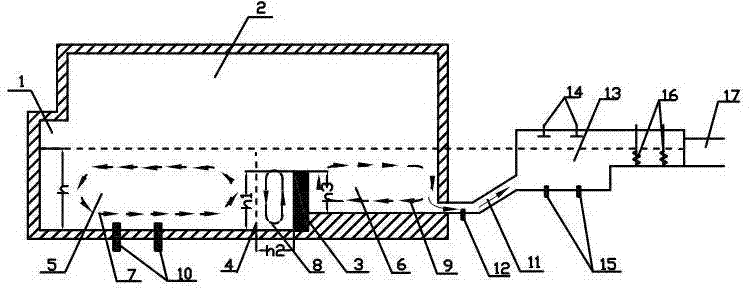

Laser micro-processing device and method thereof

InactiveCN104942442AEnhanced convectionImprove transmission efficiencyLaser beam welding apparatusSpray nozzleUltrasound

The invention relates to a laser micro-processing device and method. The laser micro-processing device comprises a rotating table and a container located on the rotating table, a lower ultrasonic vibrating table is installed at the bottom of the container, an upper ultrasonic vibrating table is fixed to the lower ultrasonic vibrating table, a workpiece is placed on the upper ultrasonic vibrating table, a laser source and a lens are arranged above the upper ultrasonic vibrating table, laser beams penetrate through the lens and reach the surface of the workpiece, an ultrasonic horn is arranged on the upper side of the upper ultrasonic vibrating table and sends ultrasonic waves to the surface of the workpiece, an outer container is connected with the container through a liquid inflow pipe and a liquid outflow pipe, and a spraying nozzle on the liquid inflow pipe faces the surface of the workpiece. When the surface of the workpiece in liquid is immersed in laser irradiation, the ultrasonic horn irradiates the surface of the workpiece or the workpiece is made to generate ultrasonic vibration in the vertical direction and the horizontal direction. Laser and the ultrasonic waves ideally act on the first surface of the workpiece at the same time, different processing effects are achieved, the ultrasonic cavitation phenomenon and the water jetting phenomenon can be intensified, the surface of the workpiece can be cleaned again, and heat-affected zones of processing, cracks and deposition of chippings are reduced.

Owner:WENZHOU UNIVERSITY

Porous adsorptive or chromatographic media

ActiveUS7479222B2Good convective and diffusional flow characteristicsIncrease capacityIon-exchange process apparatusOther chemical processesPorous substrateFiltration

A porous substrate capable of adsorptive filtration of a fluid having a porous self-supporting substrate and one or more porous, adsorptive polymeric coatings comprising from about 1 to about 80% of the void volume of the pores of the substrate. The resultant substrate has good convective and diffusive flow and capacity. The substrate may be cross-linked, have one or more capture chemistries attached to it and is useful as a chromatography media for the selective filtration of desired species including biomolecules such as proteins and DNA fragments.

Owner:EMD MILLIPORE CORP

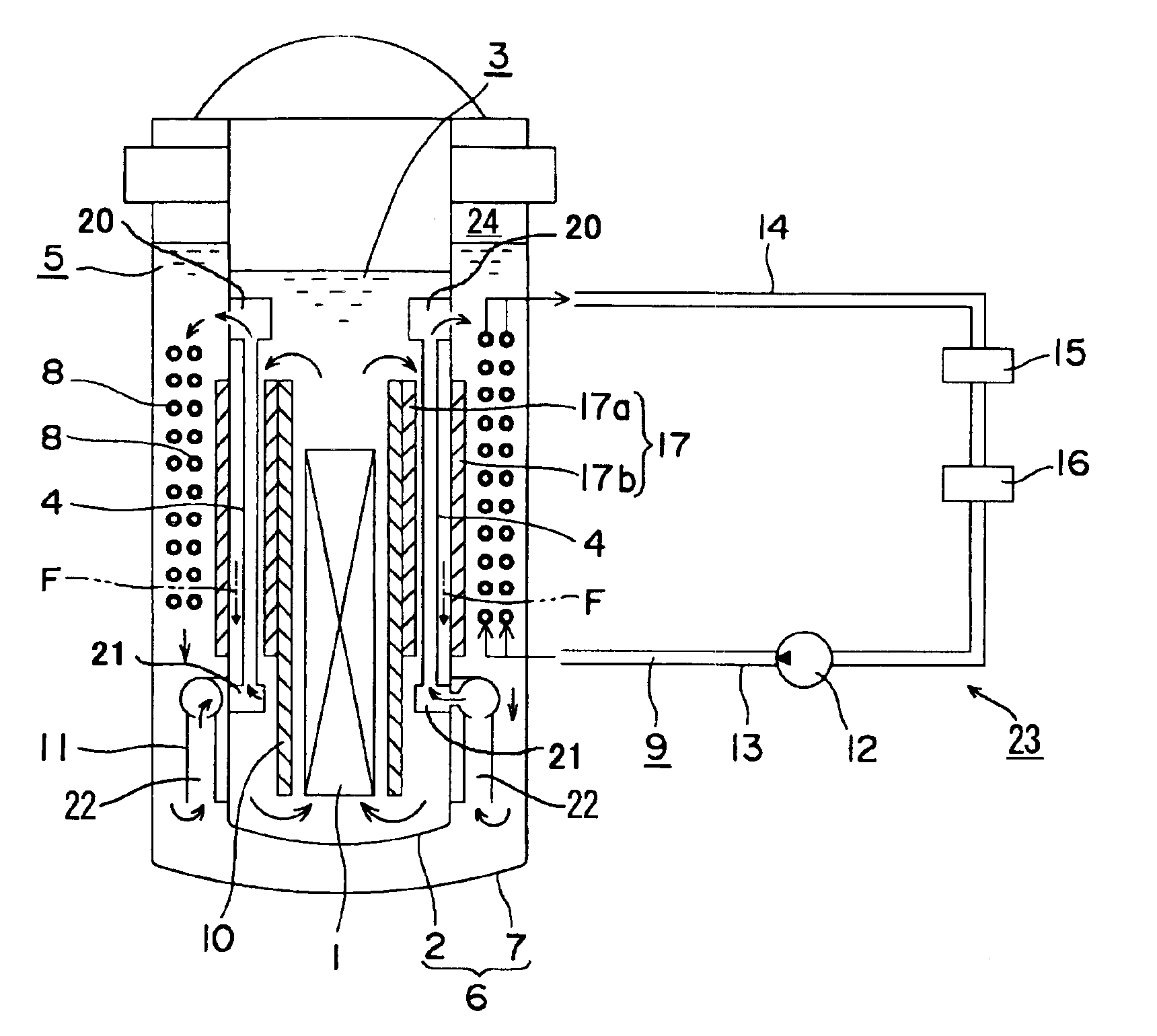

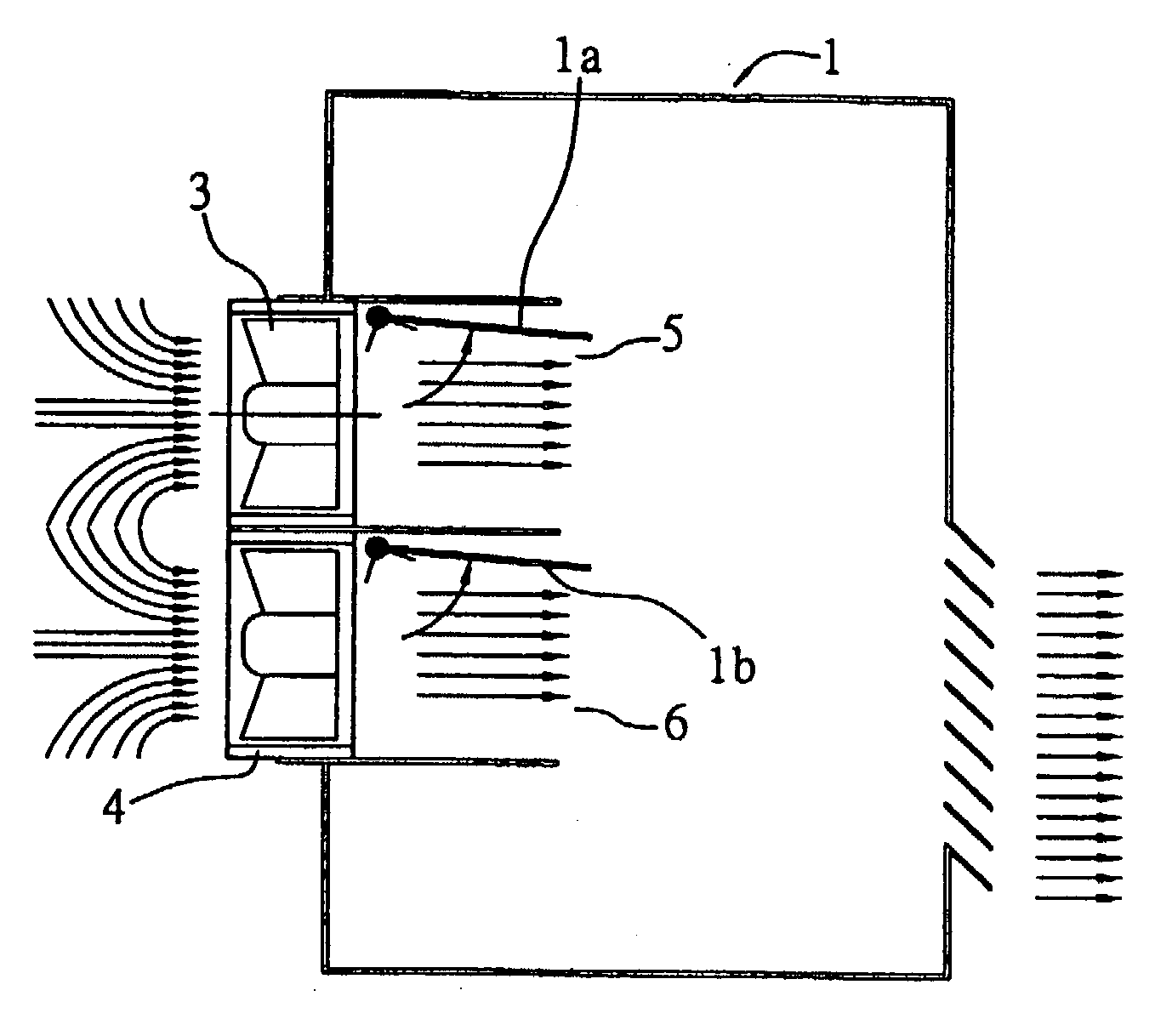

Nuclear reactor

InactiveUS20040247067A1SimplifyReduce in sizeIntegral reactorsNuclear energy generationHeat transfer tubeNuclear reactor

A nuclear reactor in which a secondary or tertiary coolant system of a nuclear steam supply system is simplified, comprising: a reactor vessel (2) which integrates a reactor core (1); a first coolant (3) which is stored in the reactor vessel (2) and heated by the reactor core (1) to convect; a first heat transfer tube (4) which is arranged in the reactor vessel (2) and comes into contact with the first coolant (3); and a second coolant (5) which is supplied from the outside of the reactor vessel (2) to the first heat transfer tube (4), cools the first coolant (3) and led to the outside of the reactor vessel (2).

Owner:CENTRAL RESEARCH INSTITUTE OF ELECTRIC POWER INDUSTRY

Porous adsorptive or chromatographic media

ActiveUS7479223B2Good convective and diffusional flow characteristicsIncrease capacityIon-exchange process apparatusOther chemical processesPorous substrateFiltration

A porous substrate capable of adsorptive filtration of a fluid having a porous self-supporting substrate and one or more porous, adsorptive coatings comprising from about 1 to about 80% of the void volume of the pores of the substrate. The resultant substrate has good convective and diffusive flow and capacity. The substrate may be crosslinked, have one or more capture chemistries attached to it and is useful as a chromatography media for the selective filtration of desired species including biomolecules such as proteins and DNA fragments.

Owner:MILLIPORE CORP

Light emitting diode lamp

InactiveUS20120236593A1Improve cooling efficiencySimple structureMechanical apparatusPoint-like light sourceHeat conductingLight guide

A light emitting diode (LED) lamp includes a heat dissipation module, a circular light guide plate (LGP), and LED light sources. The heat dissipation module includes a heat dissipation element and a heat-conducting base that has a containing concave. The heat dissipation element connecting and surrounding the heat-conducting base is distant from the circumference of the heat-conducting base. The circular LGP in the containing concave has a top surface, a bottom surface, and an annular side surface. The top surface faces the heat-conducting base and has concentric annular trenches. The LED light sources are configured in the containing concave and face the annular side surface. The LED light sources are suitable for emitting a light beam which is capable of passing through the annular side surface to enter the circular LGP and capable of being reflected by the annular trenches and emitted from the bottom surface.

Owner:CORETRONIC

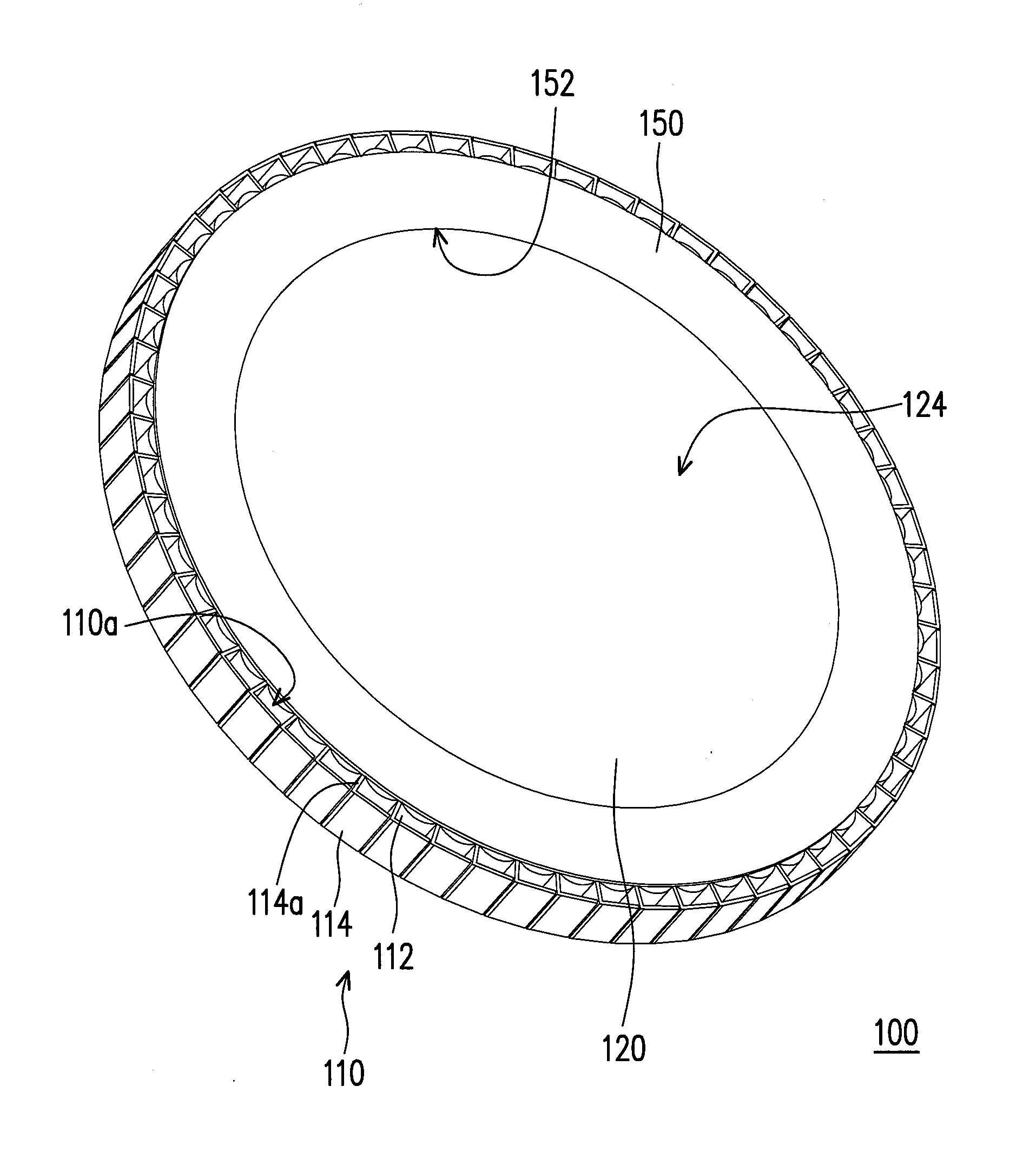

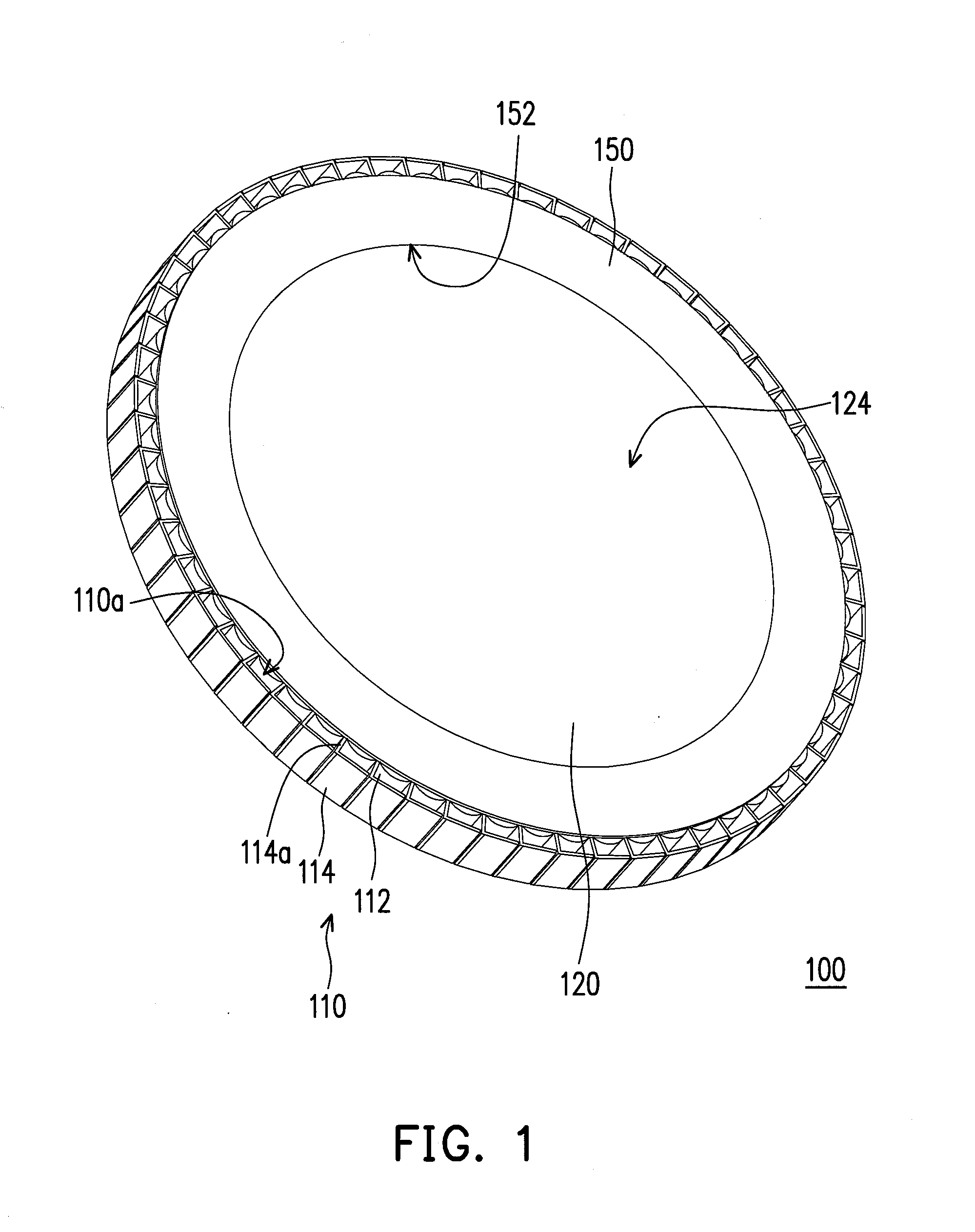

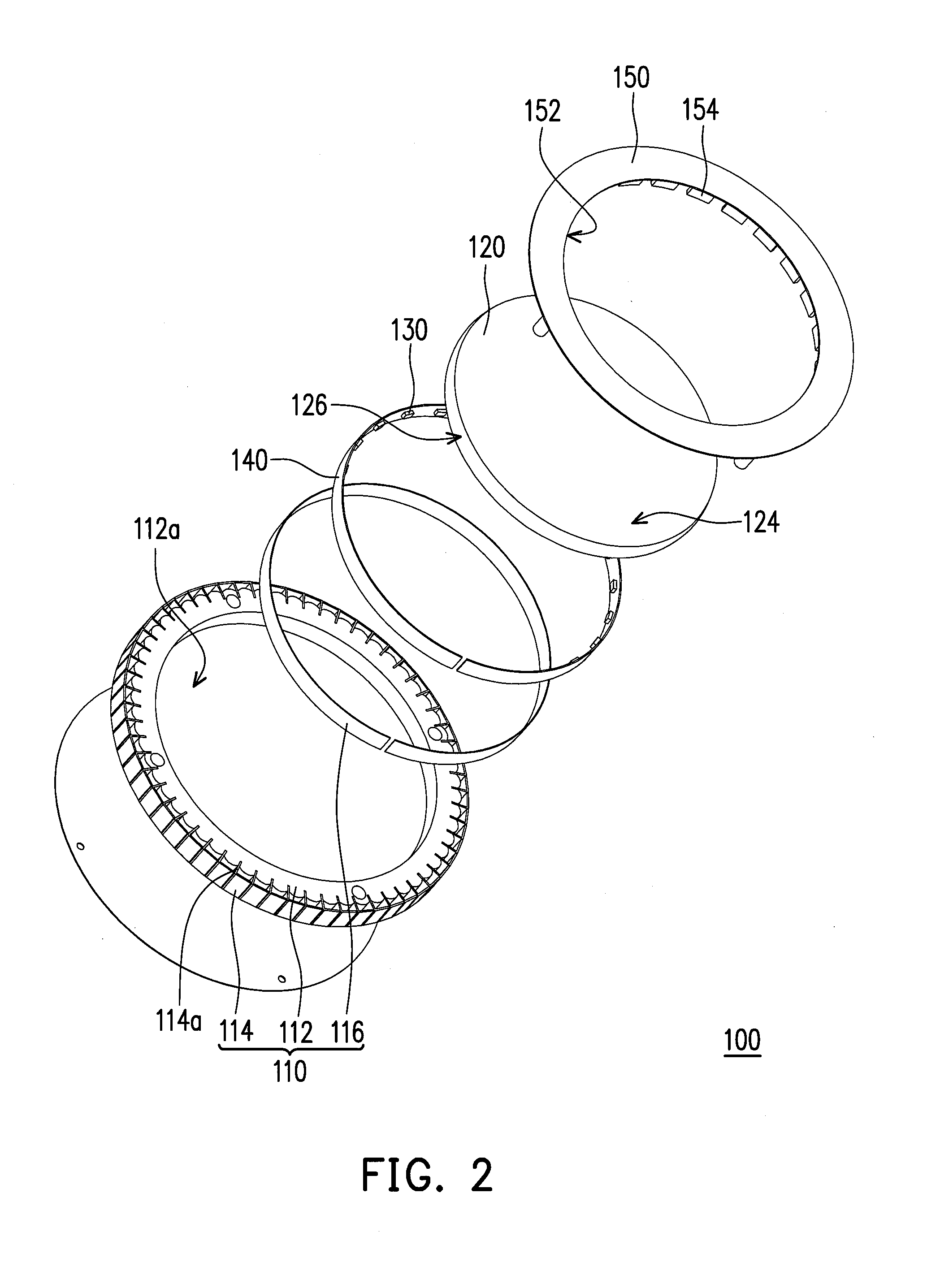

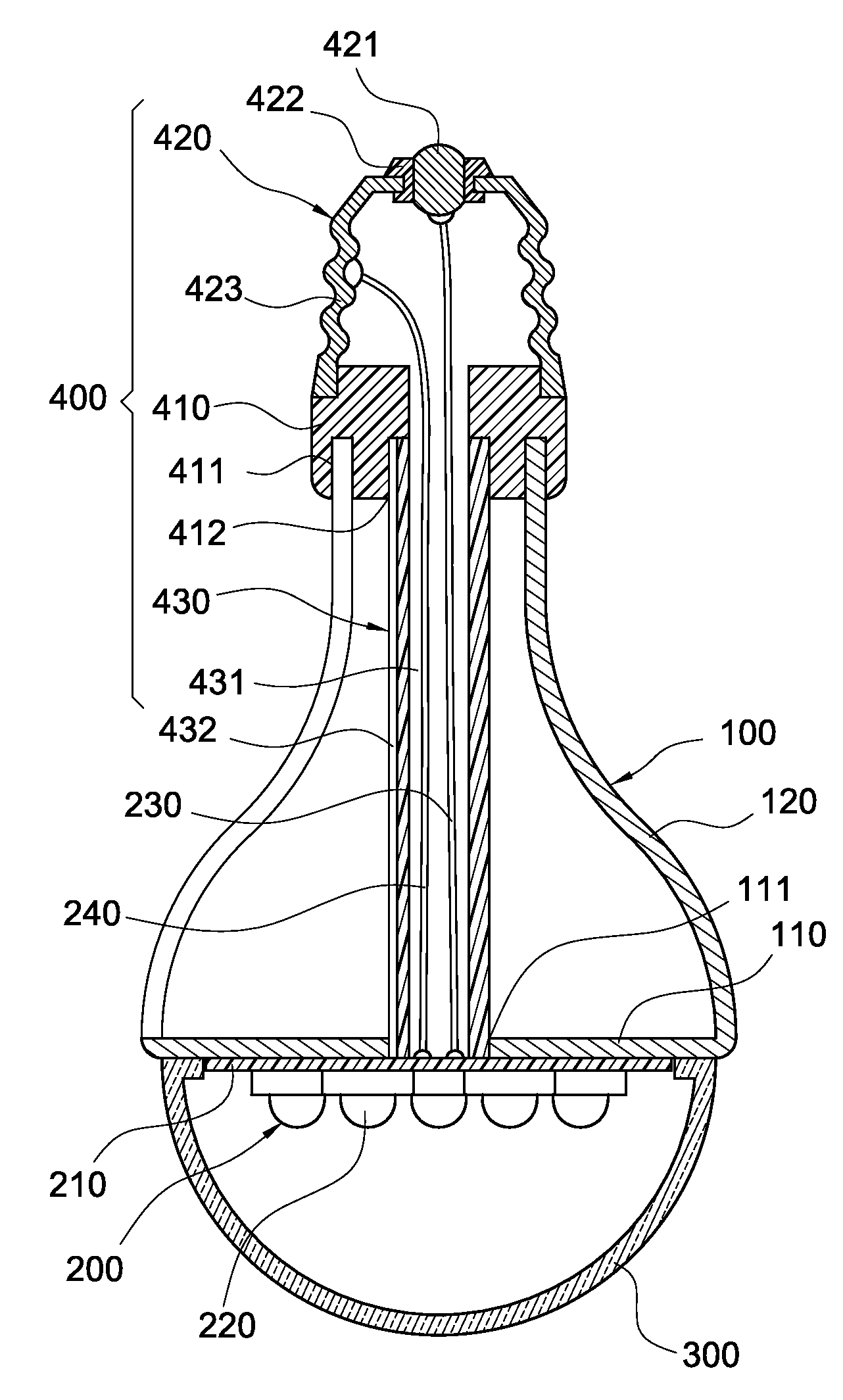

Bulb-type LED lamp

InactiveUS8058782B2Enhanced convectionImprove cooling efficiencyFurnace componentsPoint-like light sourceEngineeringHeat sink

A bulb-type LED lamp includes a cooling structure, an LED module, a transparent shade and a lamp head. The cooling structure includes a thermally conductive plate and a plurality of cooling fins configured by being bended upwardly from a periphery of the thermally conductive plate, and each cooling fins are disposed by being interspaced to each other. The LED module is attached onto a bottom face of the thermally conductive plate. The transparent shade covers the LED module correspondingly and is connected fixedly to the thermally conductive plate. The lamp head is fitted and connected to each cooling fin and electrically connected to the LED module. Thereby, the thermal convection is enhanced and the cooling efficiency is further promoted.

Owner:CHICONY POWER TECH CO LTD

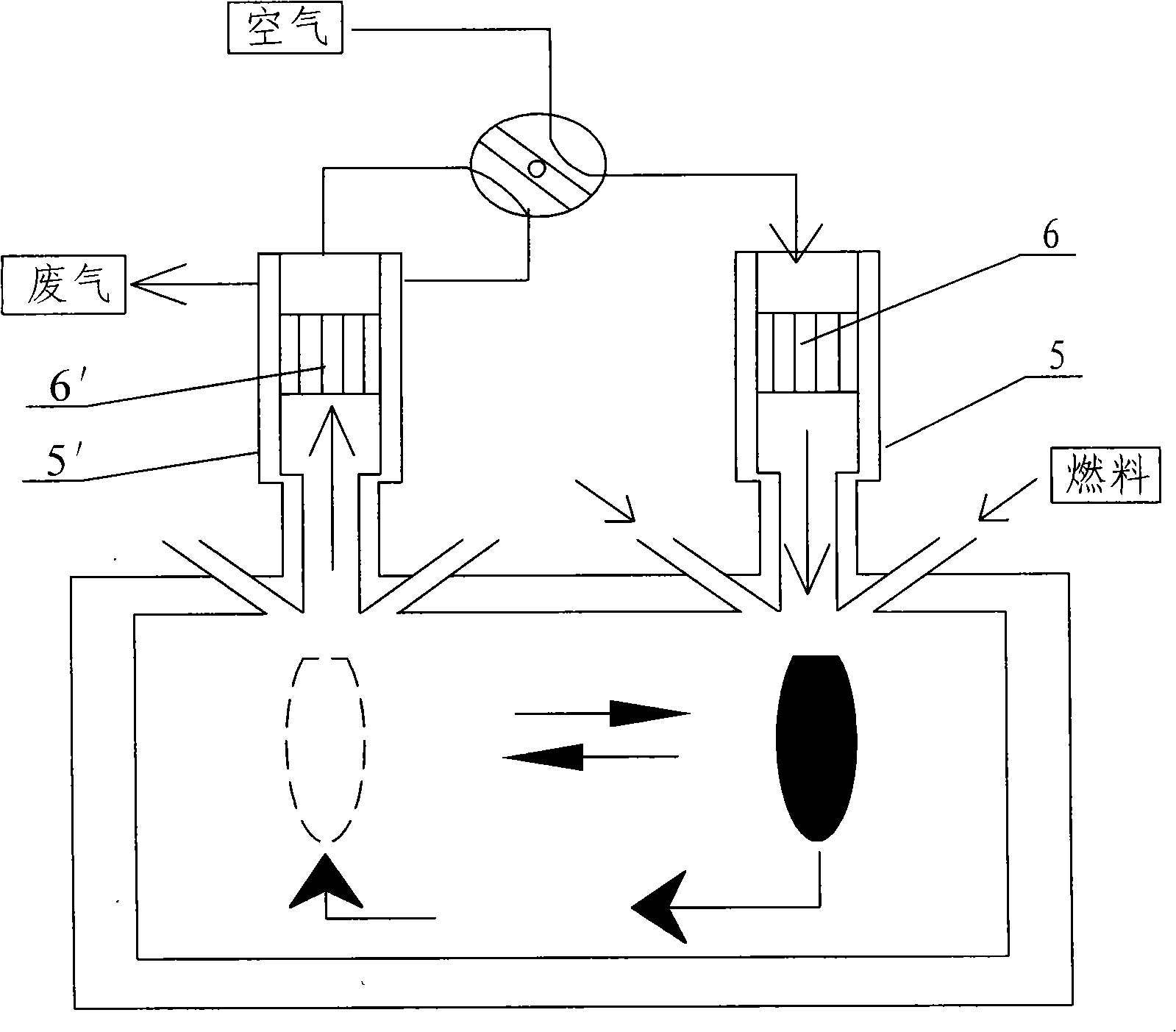

Heat accumulated type lead-melting furnace

InactiveCN101514871AEliminate high temperature zonesUniform furnace temperatureCrucible furnacesIndirect carbon-dioxide mitigationSmokeControl system

The invention discloses a heat accumulated type lead-melting furnace, which includes a furnace body, a heat accumulated type combustion system and a automatic combustion control system, wherein the heat accumulated type combustion system mainly includes heat accumulated type burners, a combustion gas pipeline, a smoke evacuation system and a air supplying system, the heat accumulated type burners are arranged at one side of the furnace body in pair, a main pipeline of the combustion gas pipeline extends to heat accumulated type burner tips of the two heat accumulated type burners through a combustion gas reversing valve and two branch pipelines, heat accumulated bodies of the heat accumulated type burners are respectively connected with a blower exhaust pipeline of the air supplying system and a draught fan smoking pipeline of the smoke evacuation system through the pipeline and a triple valve, and the triple valve is used for controlling air inlet or smoke evacuation. The invention can reduce fuel consumption, save energy, reasonably control combustion status in the furnace and increase operation security performance of the furnace.

Owner:ZHUZHOU FLASHLIGHT IND FURNACE

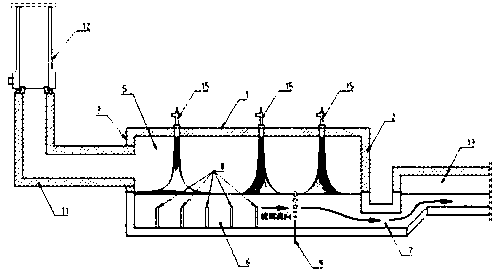

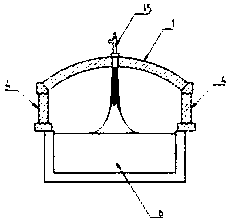

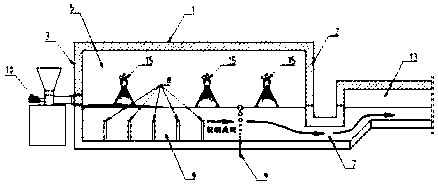

Glass fiber tank furnace structure and glass smelting method

ActiveCN103508652AHigh heat transfer efficiencyReduce erosionCharging furnaceTank furnacesCorrosionSmoke

The invention discloses a glass fiber tank furnace structure and a glass smelting method. The glass fiber tank furnace structure comprises a smelting part and a passage. The smelting part comprises a feeding tank for feeding a glass raw material, and a smelting pool for receiving the supplied materials and forming a glass liquid. A glass liquid separation device of the smelting pool and the passage is a throat or a baffle brick structure. The upper part of the smelting pool is provided with a crown, two side breast walls, a front wall, a back wall and a smoke flue. The smelting pool is divided into a zone A as a raw material zone, a zone B as a foam zone and a zone C as a clarification zone C along a glass melt flowing direction. The smelting pool is provided with at least one combustor, the combustor is installed on the crown or the breast walls, the combustor sprays flame to glass batch and the sprayed flame forms an included angle of 0-80 degrees with the two side breast walls and forms an included angle of 0 degree with the front wall or the back wall. The glass smelting method adopting the glass fiber tank furnace structure comprises that above the smelting pool of the glass fiber tank furnace structure, the at least one combustor is arranged on the crown or the breast walls; a gaseous oxidant and a gaseous, liquid or solid fuel fluid are supplied to the combustor; and the combustor sprays flame to the glass batch. The glass fiber tank furnace structure has the advantage of high heat transfer efficiency, small corrosion on a refractory material, long tank furnace service life, and energy saving.

Owner:JUSHI GRP CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com