Patents

Literature

103 results about "Source surface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

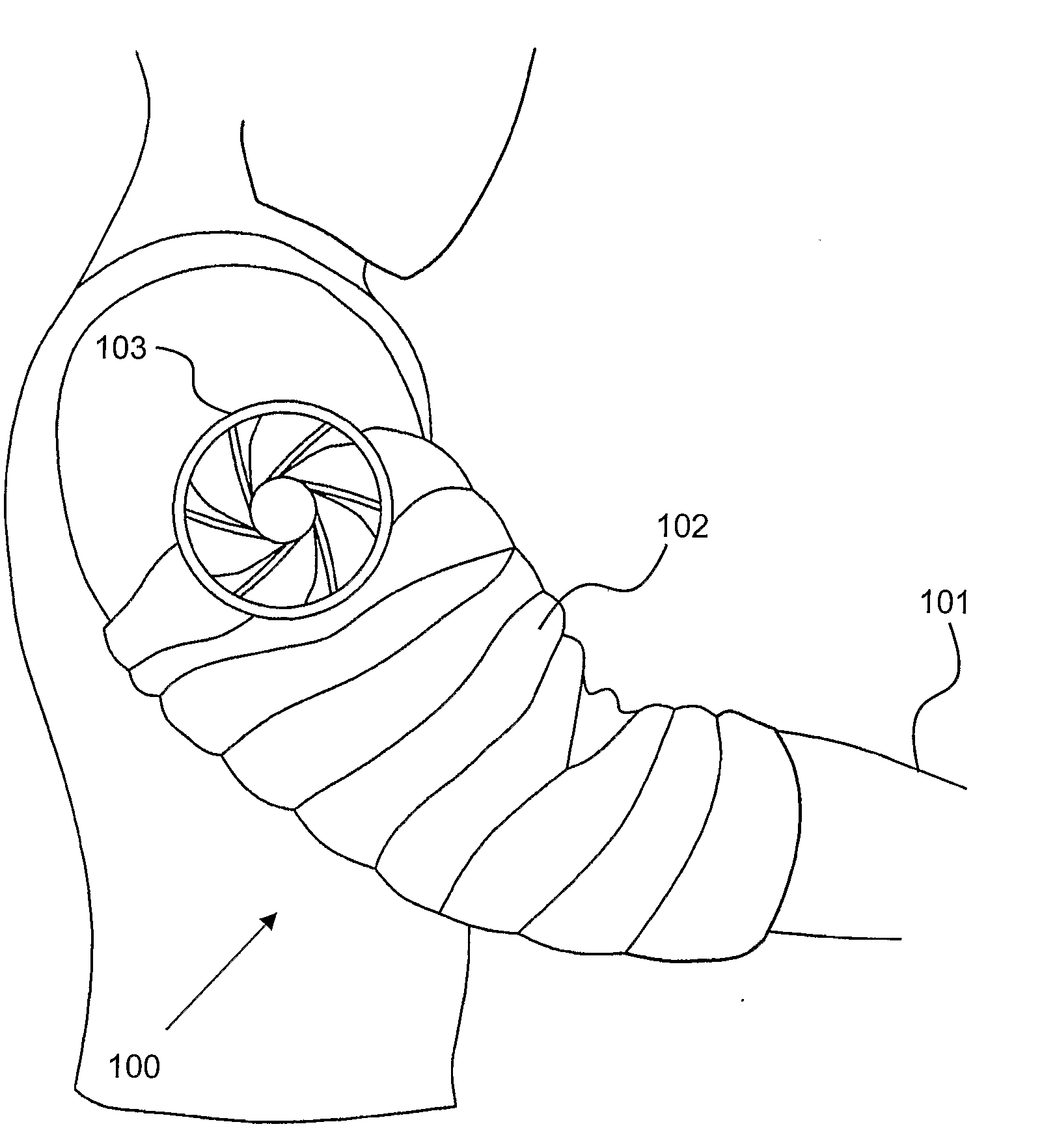

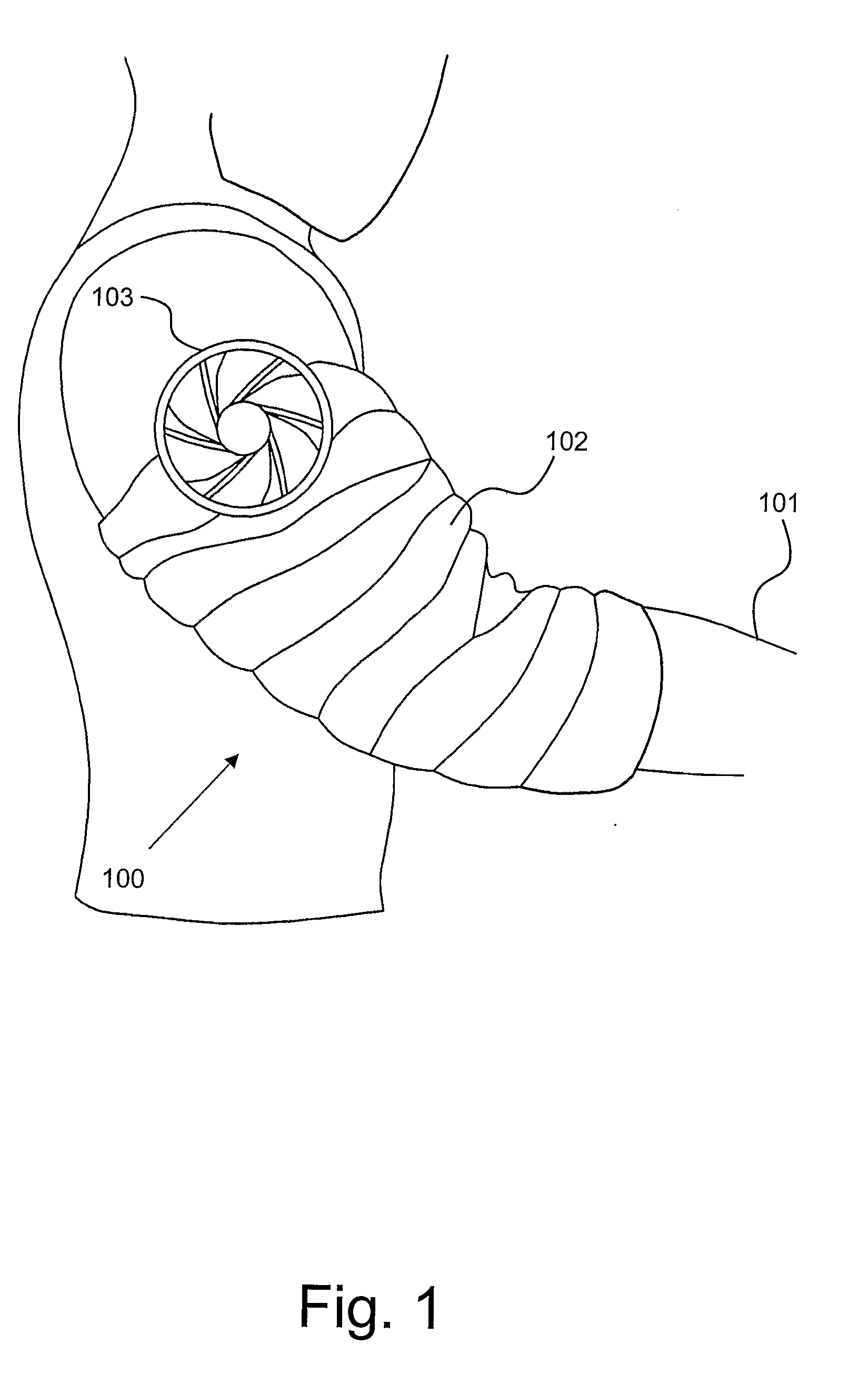

Apparatus For Providing A Heating And Cooling Effect

InactiveUS20080188915A1Increase surface areaEasy to controlTherapeutic coolingTherapeutic heatingFluid controlCooling effect

A device configured to treat a human or animal body part or limb by providing a heating and / or cooling effect in addition to a compressive force. A metallic conductive material is positioned in thermal contact with at least one Peltier cell whereby the heating and cooling effect generated at an active face of the Peltier cell is conducted and distributed over the surface area of the conductive material. The conductive material comprises a significantly greater surface area than the active face of the Peltier cell. A compressive force may be applied to the human or animal body part or limb by the control of a fluid into an expandable sack secured with the conductive material to the body part by suitable strap means.

Owner:SWELLAWAY

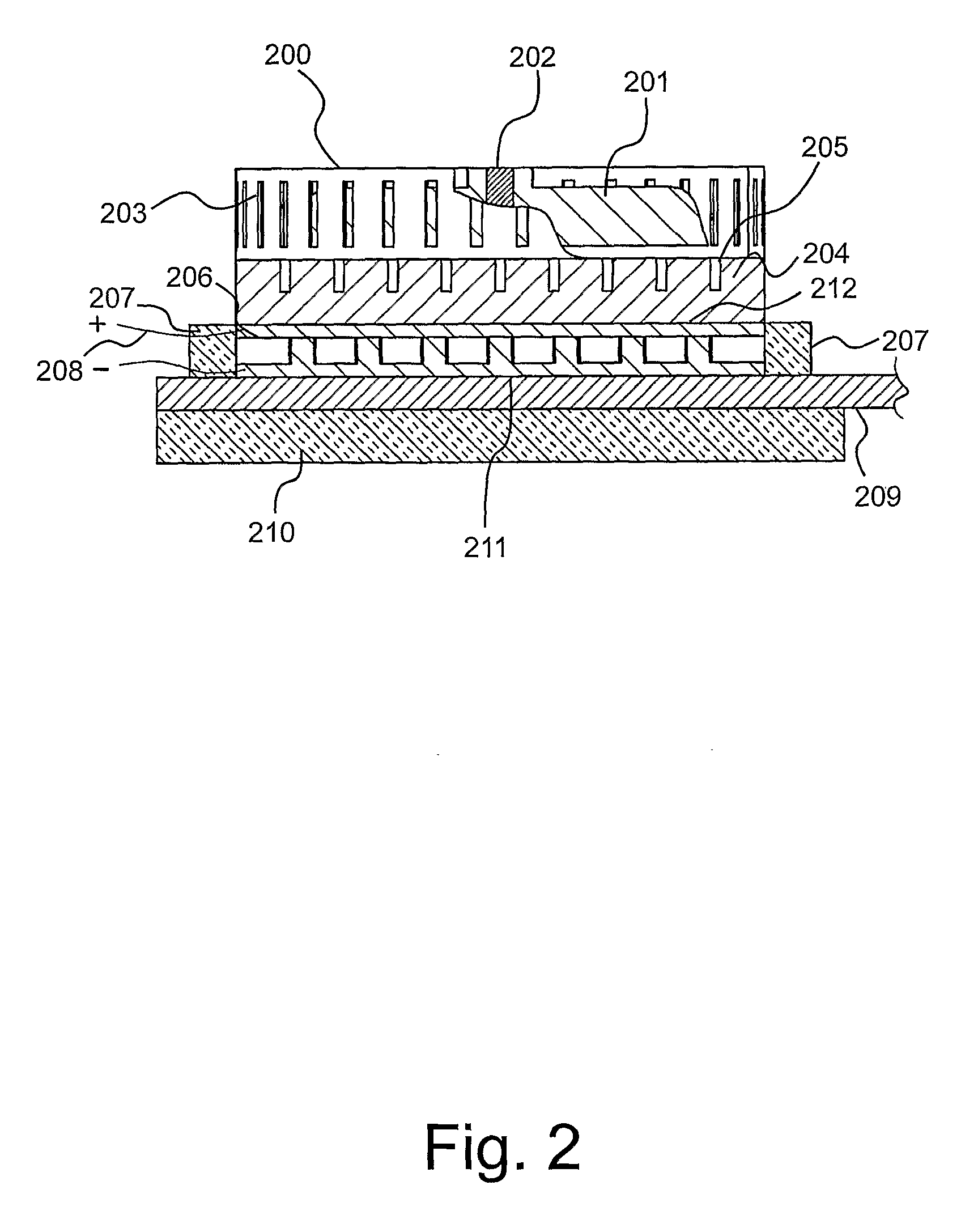

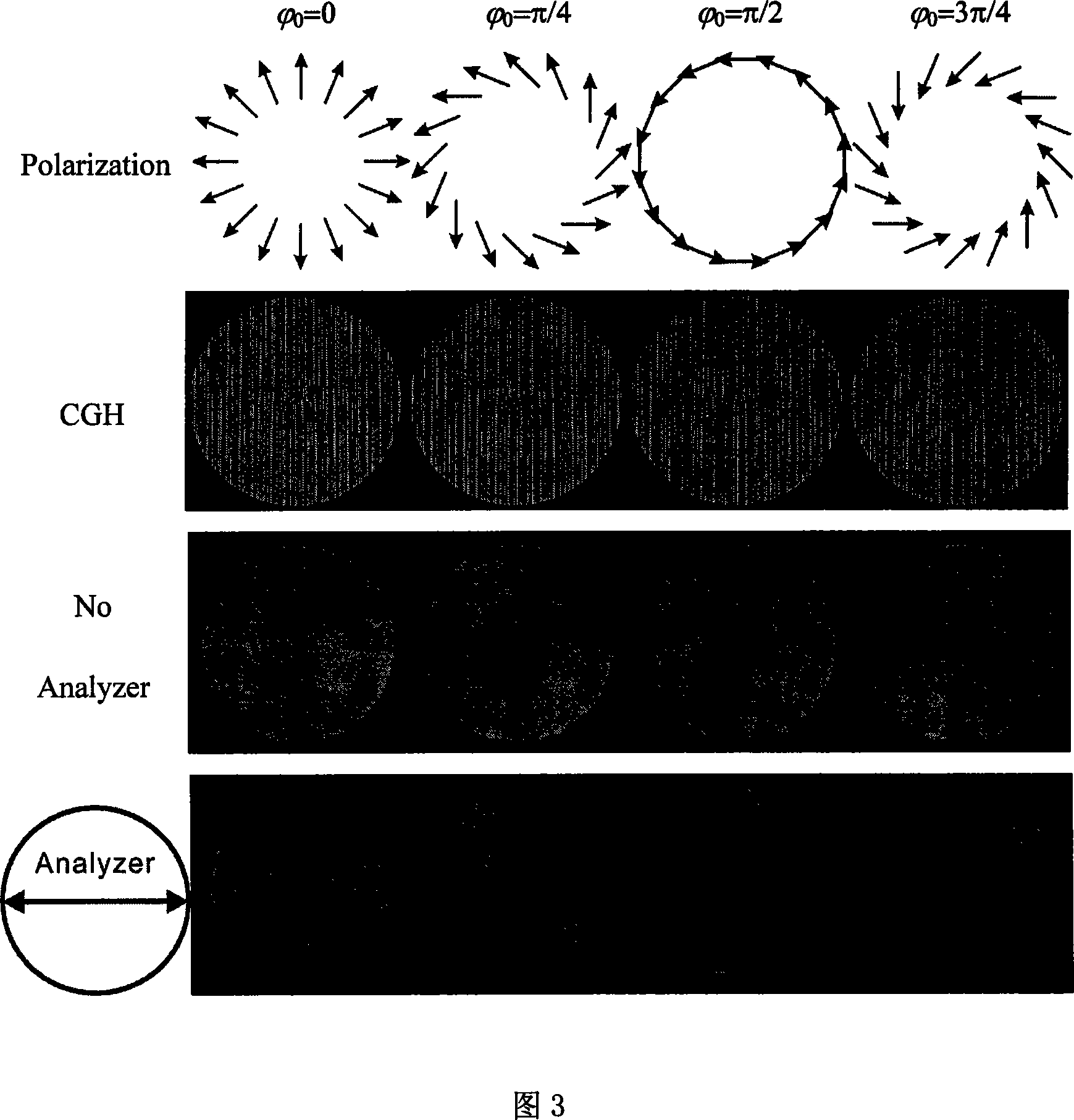

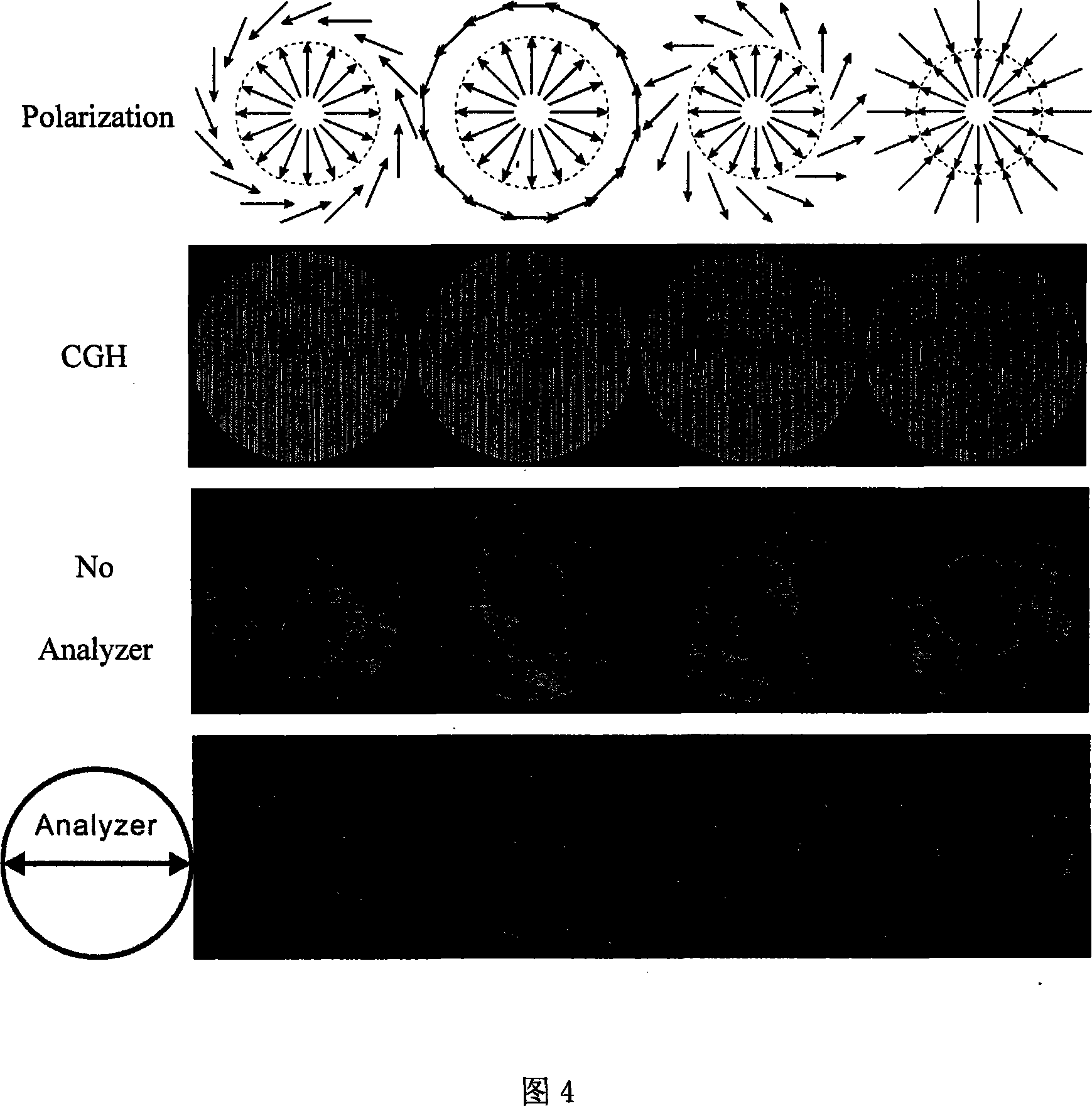

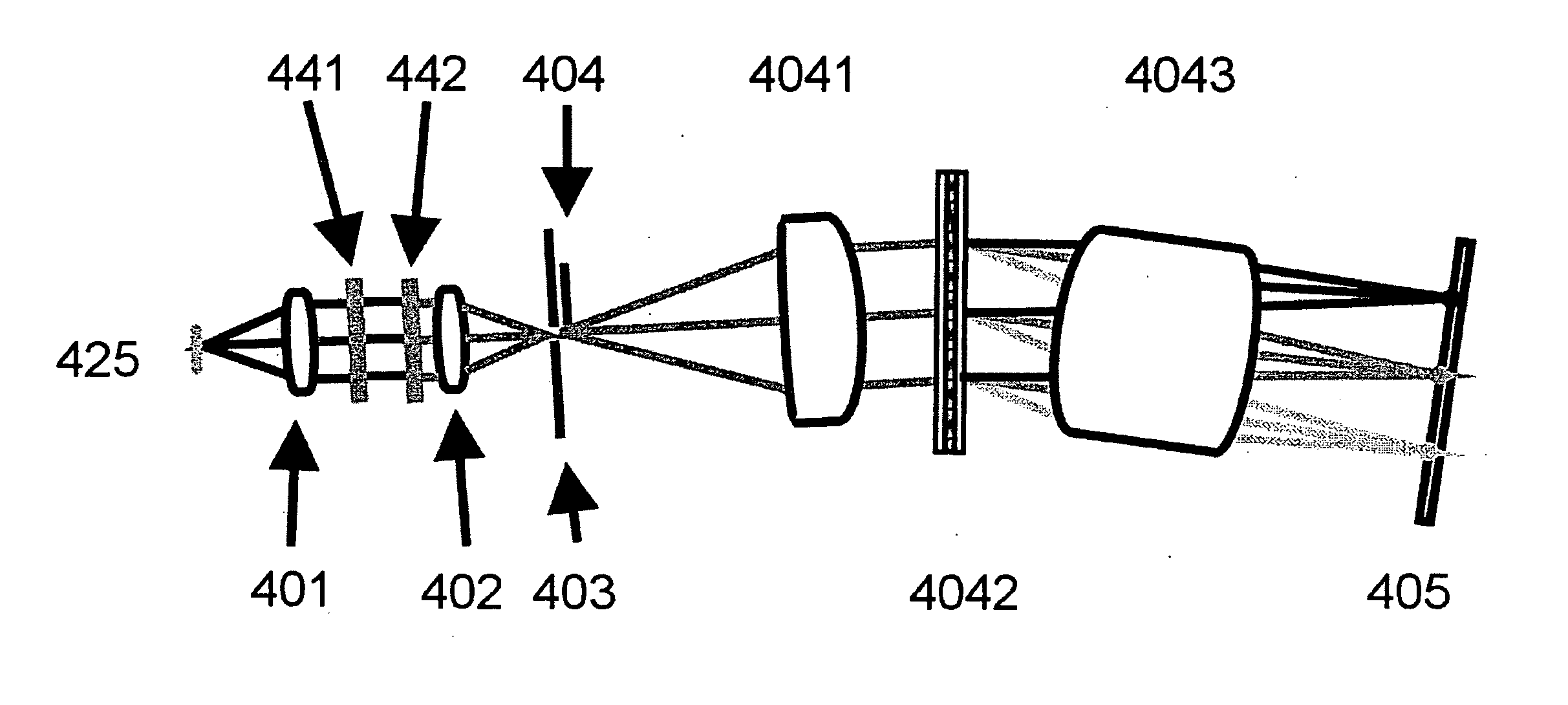

Generation device of random polarization distributing vector light beam

InactiveCN101178484AGenerate real-time newsReduce the impactNon-linear opticsOptical elementsSpatial light modulatorGrating

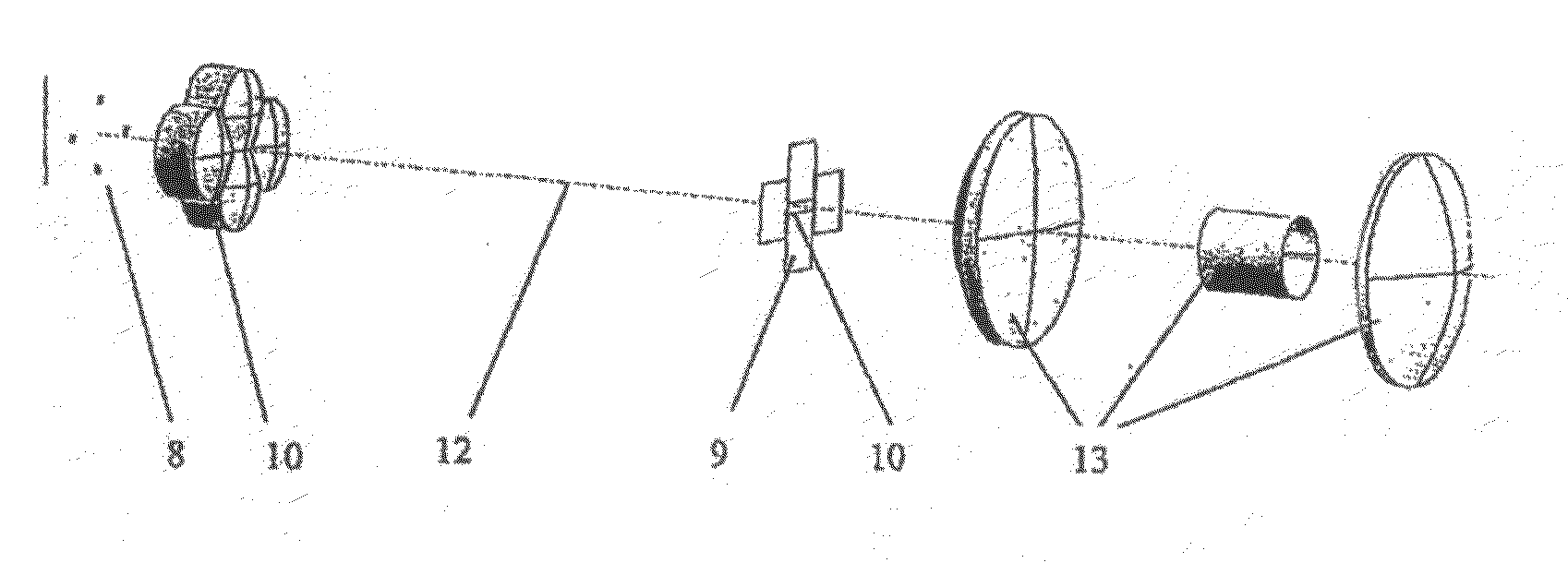

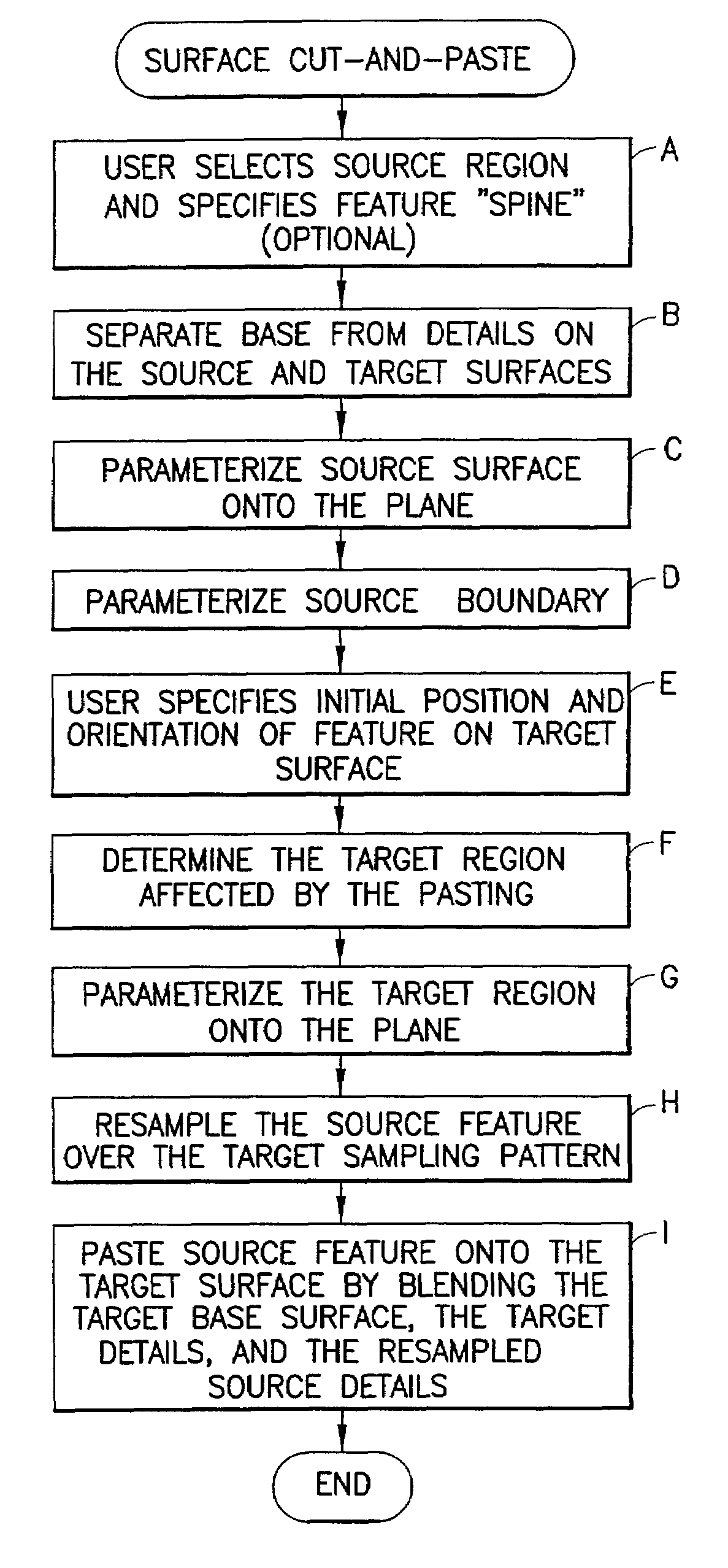

The invention provides a generation device of an arbitrary polarization distribution vector light beam, and is in turns provided with a spatial light modulator controlled by a computer, a first lens, a wave filter, two quarter wave plates, a second lens and a Rochi grating along the light direction of the light source producing linearly polarized light. The spatial light modulator is positioned on a front focal plane of the first lens, a back focal plane is provided with the wave filter, and the wave filter is synchronously positioned on a front focal plane of the second lens. Rochi grating is positioned on a back focal plane of the second lens. Two quarter wave plates are placed by closely depending on the backlight source surface of the wave filter. The invention has the advantage of producing arbitrary vector light beam, and to be important, the device of the invention can produce the vector light beam in real time and dynamic manner. Moreover, the device greatly reduces the effect to the light beam quality caused by coherent noise, and can produce the high-quality vector light beam, and the producing manner is real time and dynamic.

Owner:NANJING UNIV

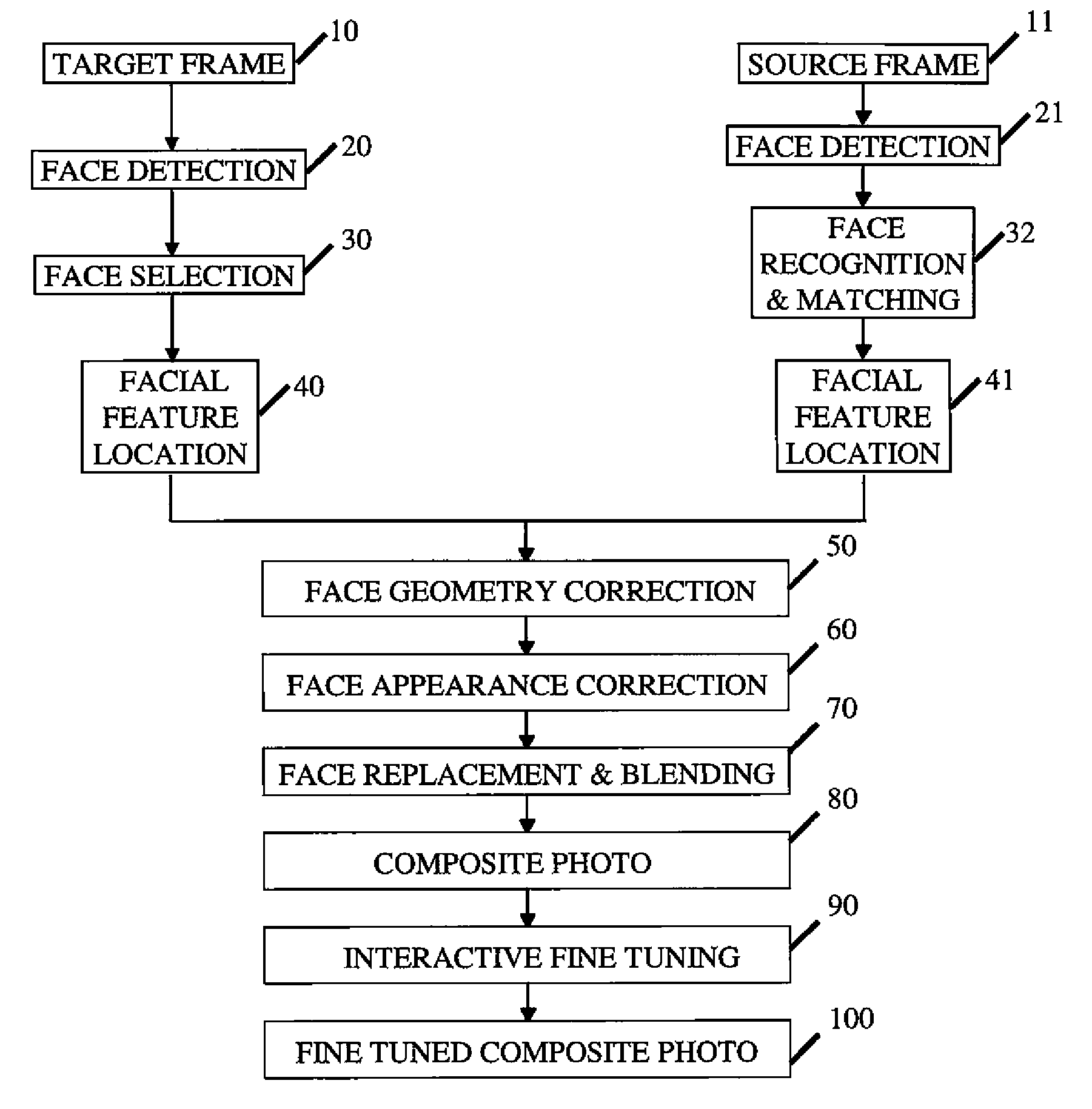

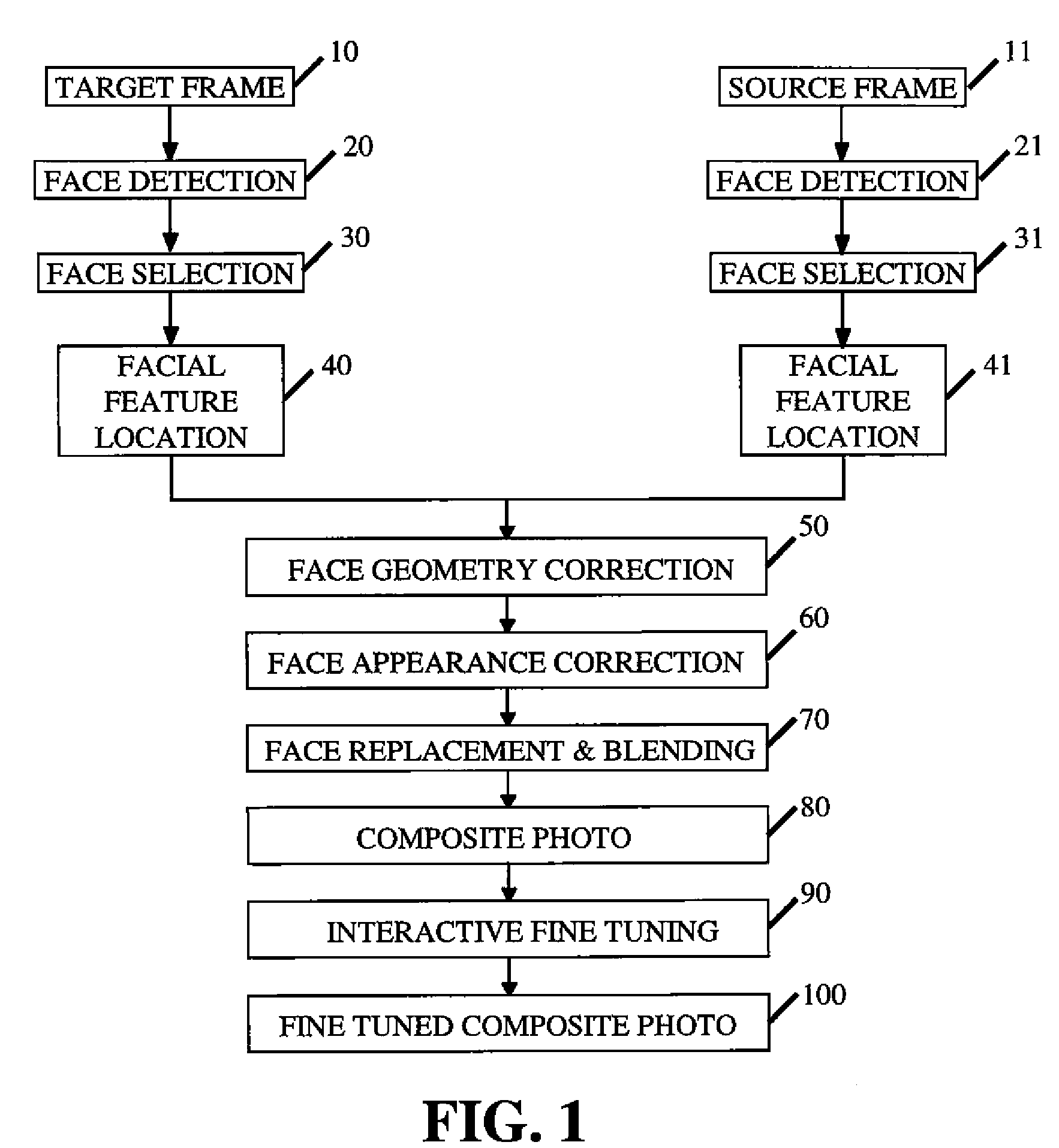

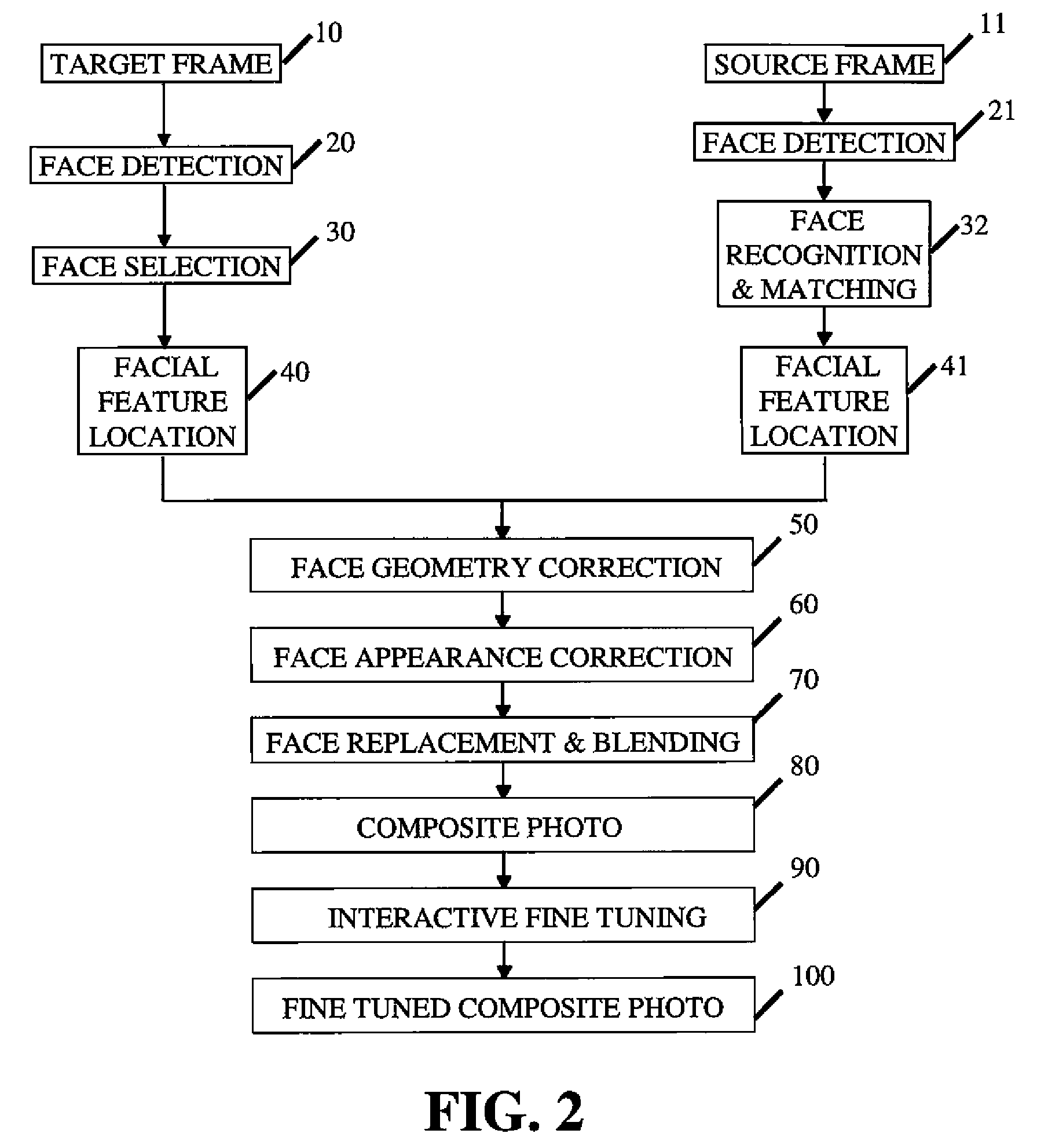

Recomposing photographs from multiple frames

InactiveUS7787664B2Character and pattern recognitionEditing/combining figures or textPattern recognitionMultiple frame

A method for replacing a face in a first digital image with a face from a second digital image including automatically detecting one or more faces in the first digital image; identifying at least one target face from the detected faces that needs to be replaced; automatically detecting one or more faces in the second digital image; identifying at least one source face from the second image detected faces for replacing the target face; using features from the target and source faces to perform facial geometry and appearance corrections to the source face; and replacing the target face with the corrected source face and blending the corrected source face into the first digital image.

Owner:MONUMENT PEAK VENTURES LLC

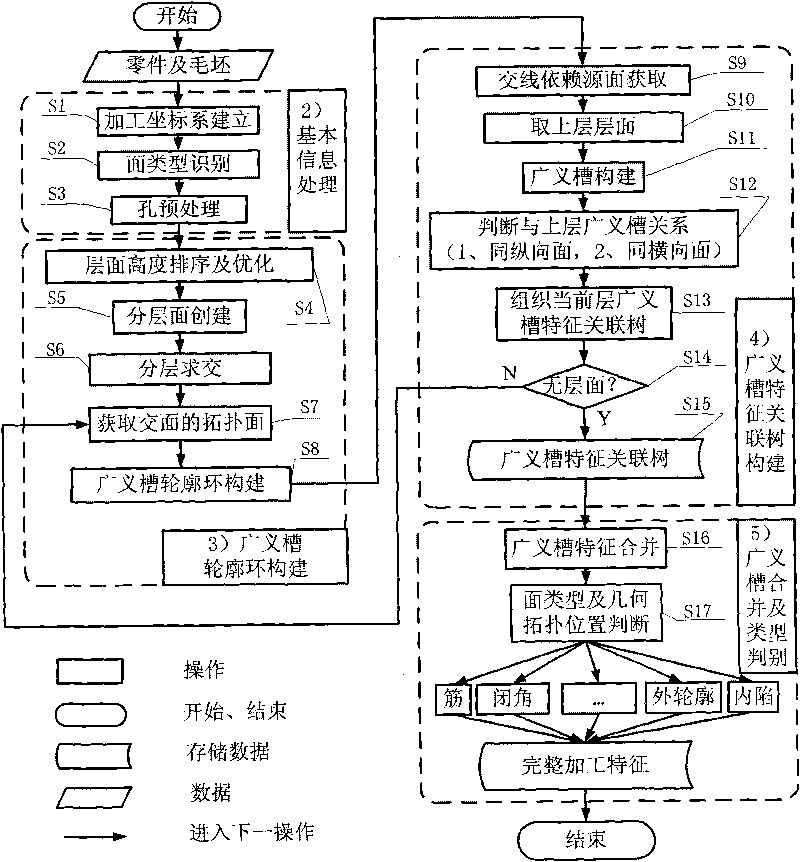

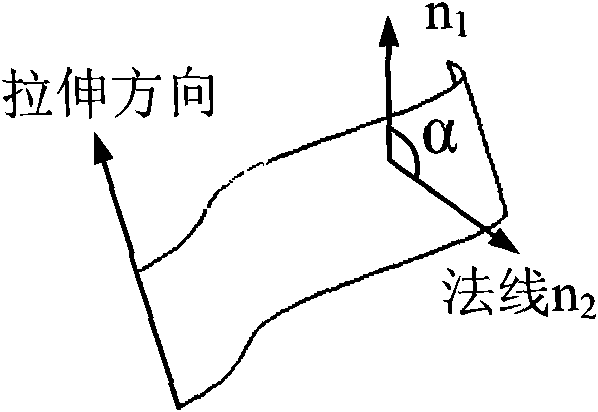

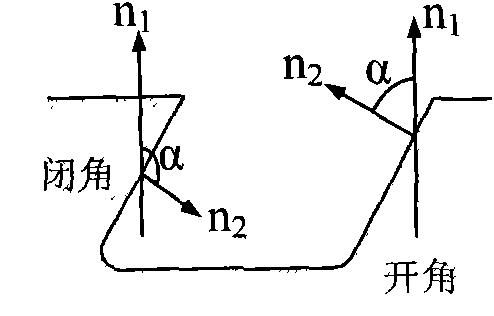

Identification method of machining characteristics of complex parts of airplane

InactiveCN101763069AShorten the manufacturing cycleReduce workloadProgramme controlComputer controlNumerical controlCharacteristic type

The invention provides an identification method of the machining characteristics of complex parts of an airplane, which comprises steps of: firstly, setting a machining coordinate system, identifying a machining surface and preprocessing a hole to complete basic information process; secondly, layering and intersecting to obtain intersecting line rings in each layer of intersecting result and relationships among the intersecting line rings to complete the construction of outline rings of generalized grooves; building the generalized grooves according to the outlines of the generalized grooves and the source surface depended by the intersecting lines; building the characteristics relevance tree of the generalized grooves according to the lengthways relationship of the outlines of the generalized grooves; and emerging the generalized grooves and identifying the characteristics types to complete the identification of the machining characteristics of a whole part. The method has the characteristics of high identification accuracy rate, high speed and small space usage, and the like; can be used for designing and developing systems for programming the complex parts of the airplane by means of intelligent numerical control, analyzing a machining technical scheme, and automatically generating blanks, and the like; and has good application foreground.

Owner:SHENYANG AIRCRAFT CORP +1

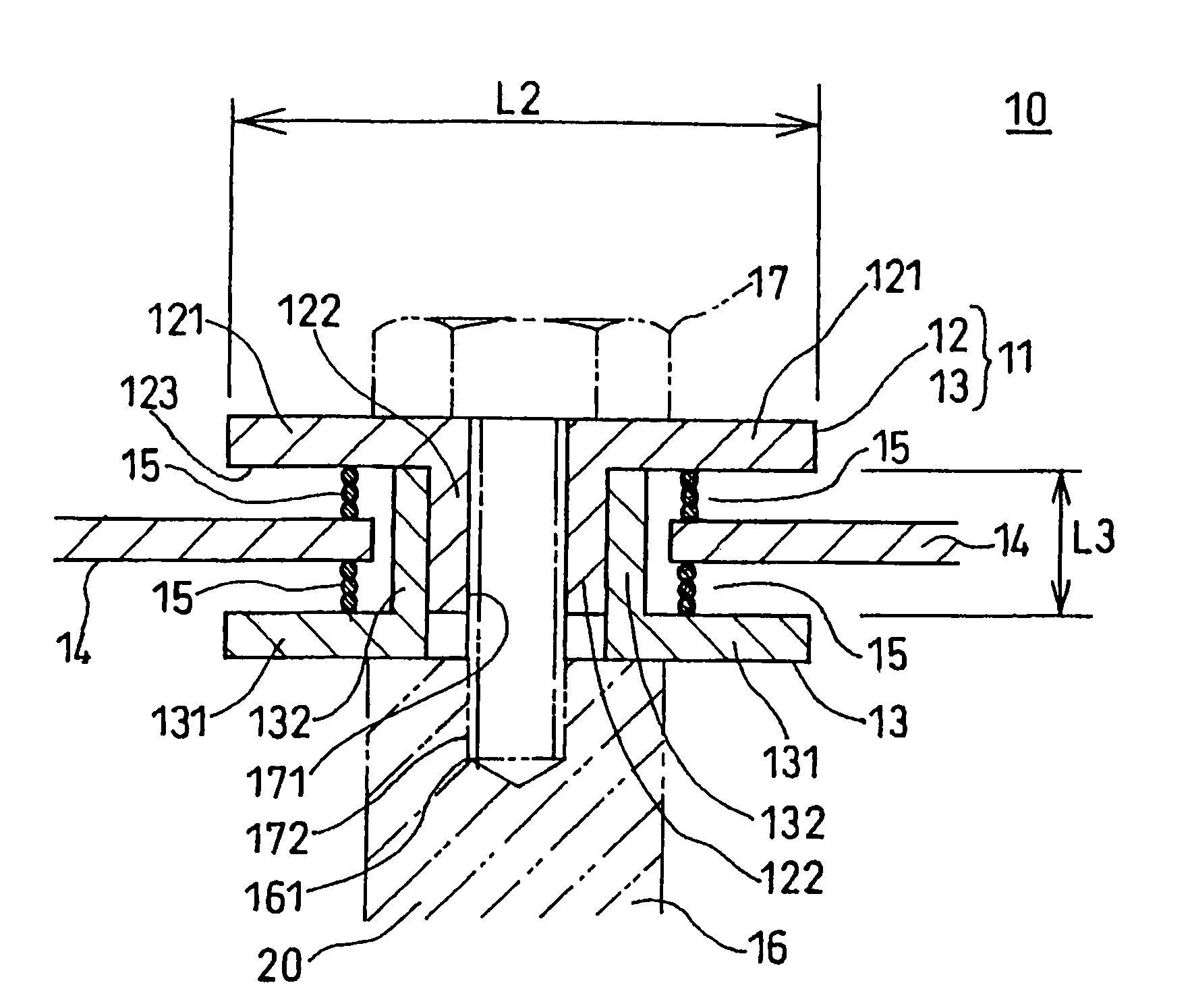

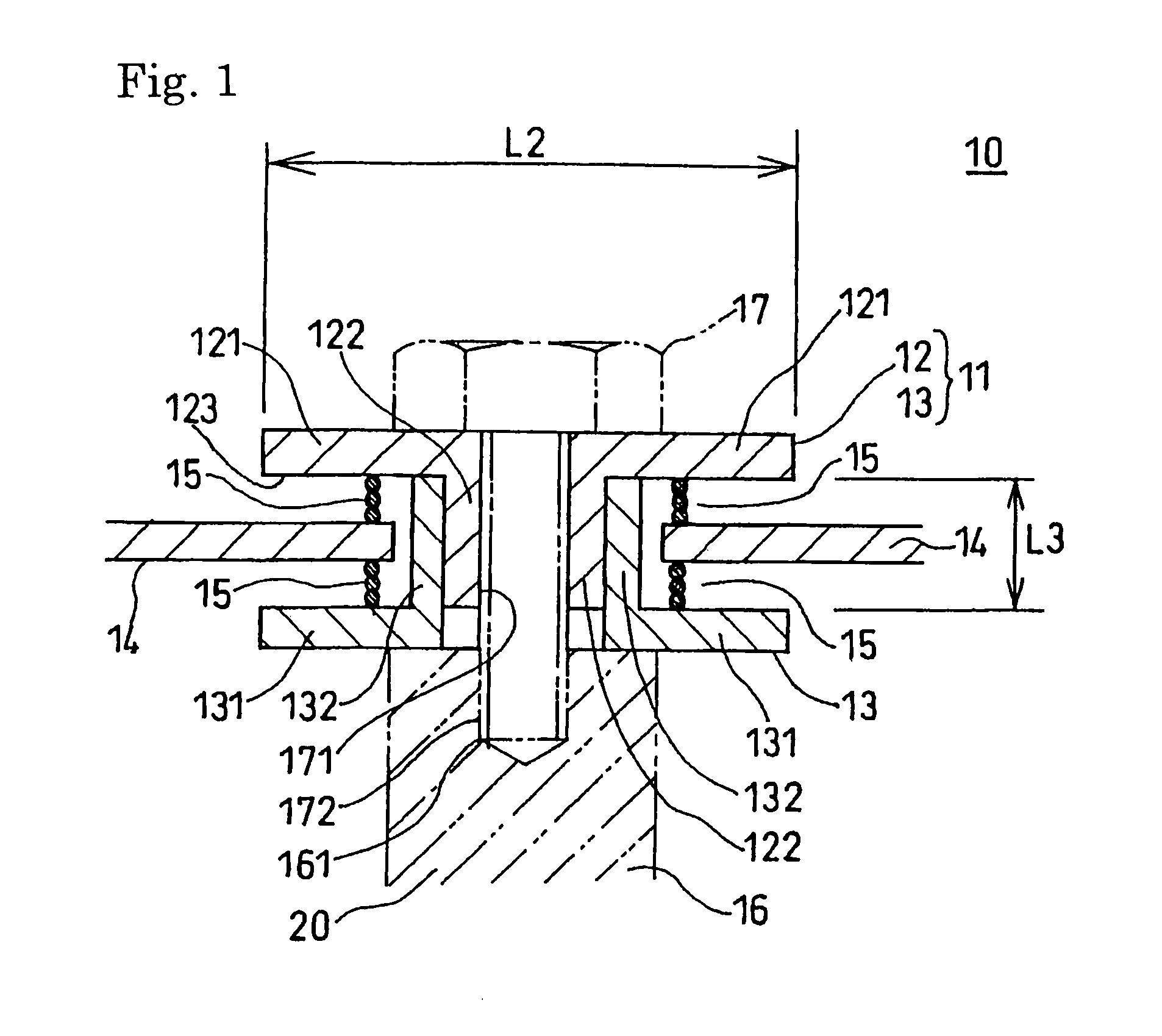

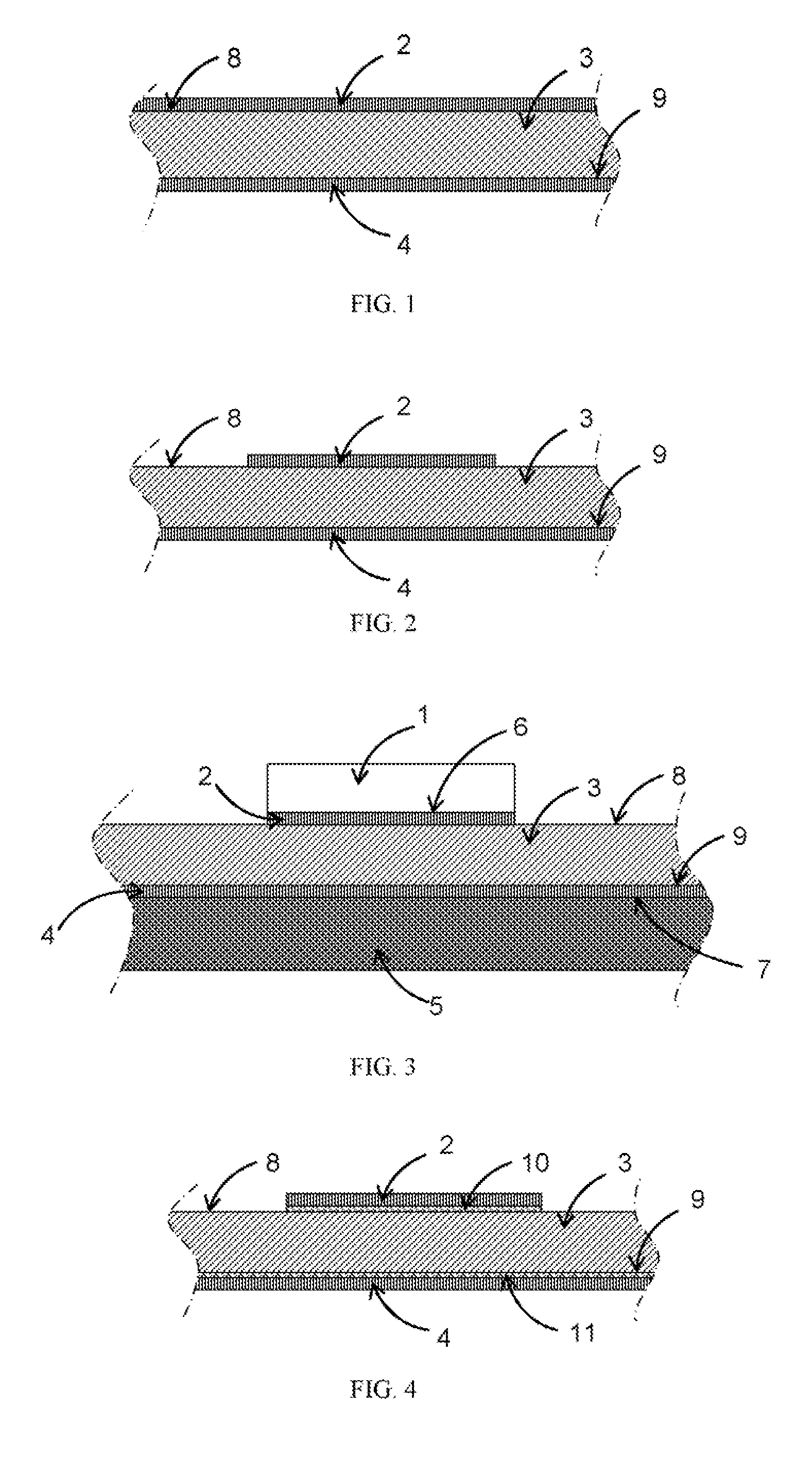

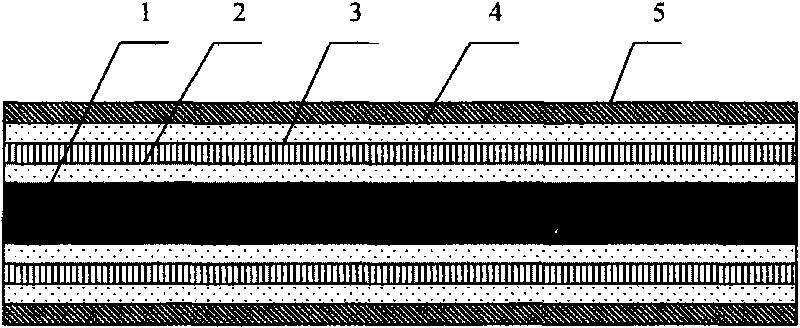

Vibration and heat insulating board

ActiveUS7065963B2Efficient processReduce in quantityExhaust apparatusNon-rotating vibration suppressionSource surfaceVibration source

A vibration and heat insulating board fixed so as to cover at least part of a heat source while forming a gap against the heat source surface, in order to lessen diffusion of heat from the heat source fixed in a vibration source, in which the heat source and the vibration and heat insulating board are coupled by means of a collar member having a pair of locking pieces fitted to the vibration and heat insulating board main body and bolted to a mounting part of the heat source, and ring-shaped coil members interposed between the pair of locking pieces of the collar member and the vibration and heat insulating board main body.

Owner:NICHIAS CORP

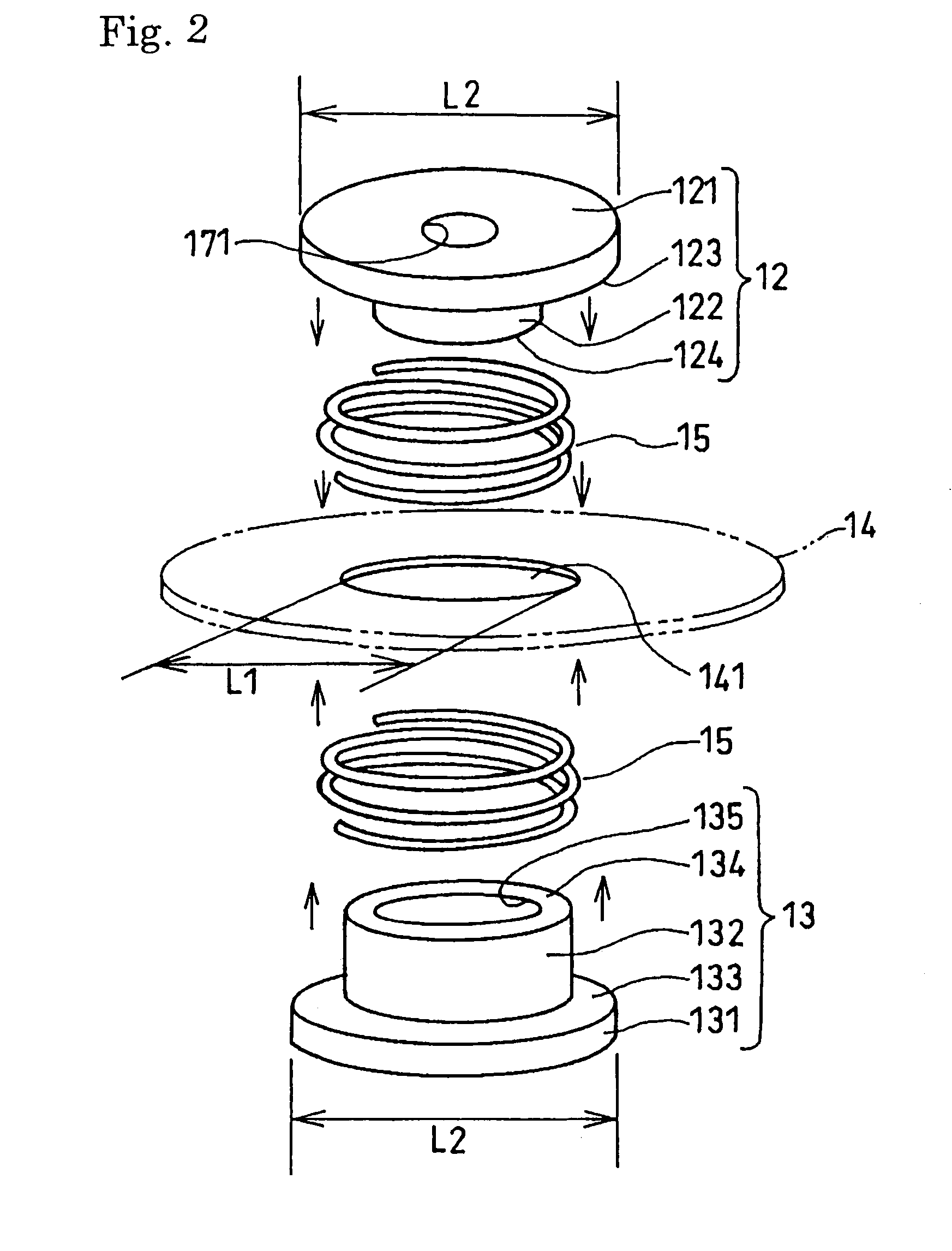

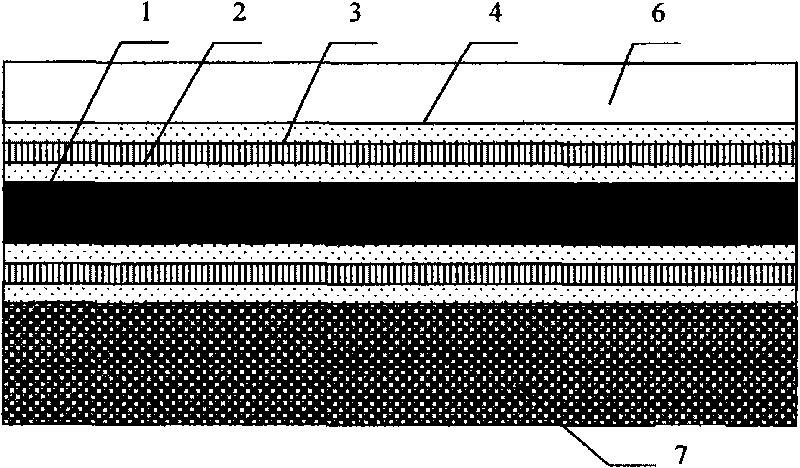

Heat Dissipation Structure With Aligned Carbon Nanotube Arrays and Methods for Manufacturing And Use

ActiveUS20080001284A1Improve thermal conductivitySimplify the manufacturing processNanotechSemiconductor/solid-state device detailsCarbon nanotubeAdhesive materials

A heat dissipation structure with aligned carbon nanotube arrays formed on both sides. The carbon nanotube arrays in between a heat source and a cooler are used as thermal interface material extending and dissipating heat directly from a heat source surface to a cooler surface. In some embodiments, an adhesive material can be used to dispense around carbon nanotube arrays and assemble the heat dissipation structure in between a heat source and a cooler. In some other embodiments, carbon nanotube arrays are formed on at least one of a heat source surface and a cooler surface and connect them together by further growing. The carbon nanotube arrays can be exposed to the environment instead of being in between a heat source and a solid cooler, and can serve as fins to enlarge heat dissipation area and improve thermal convection.

Owner:THE HONG KONG UNIV OF SCI & TECH

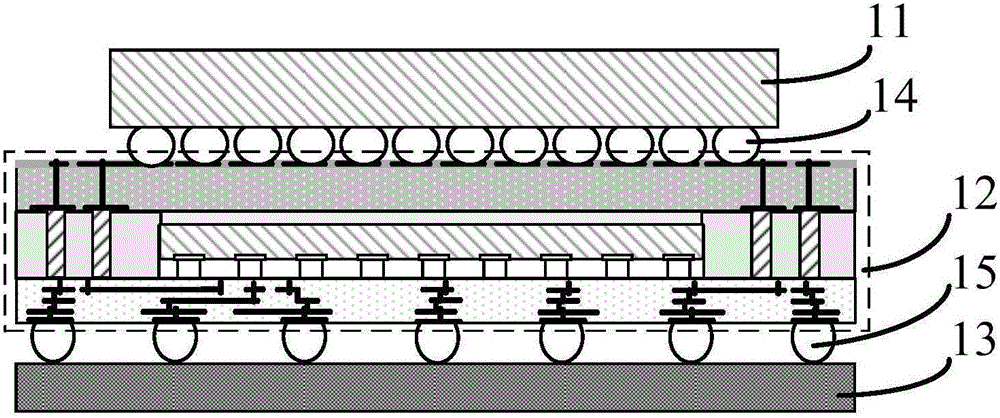

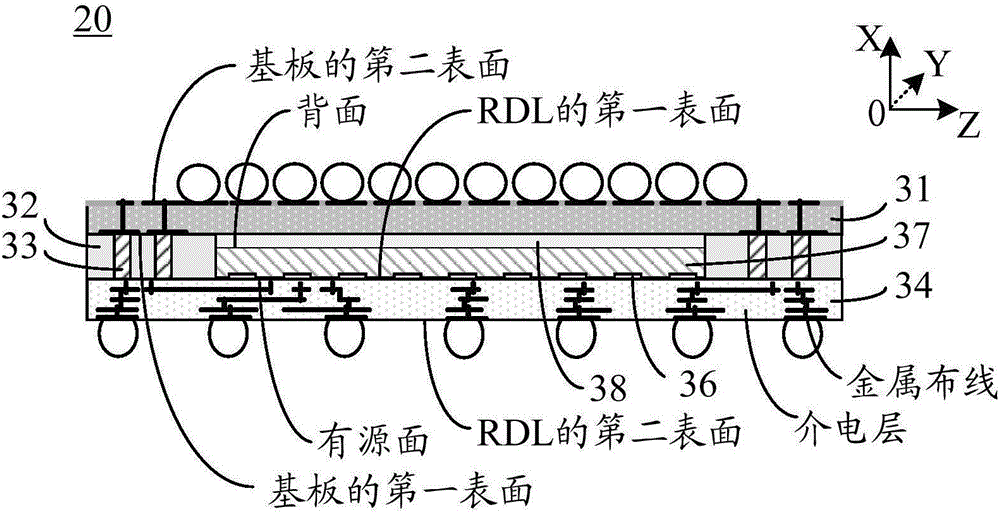

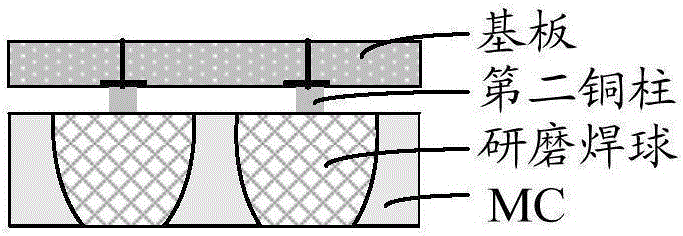

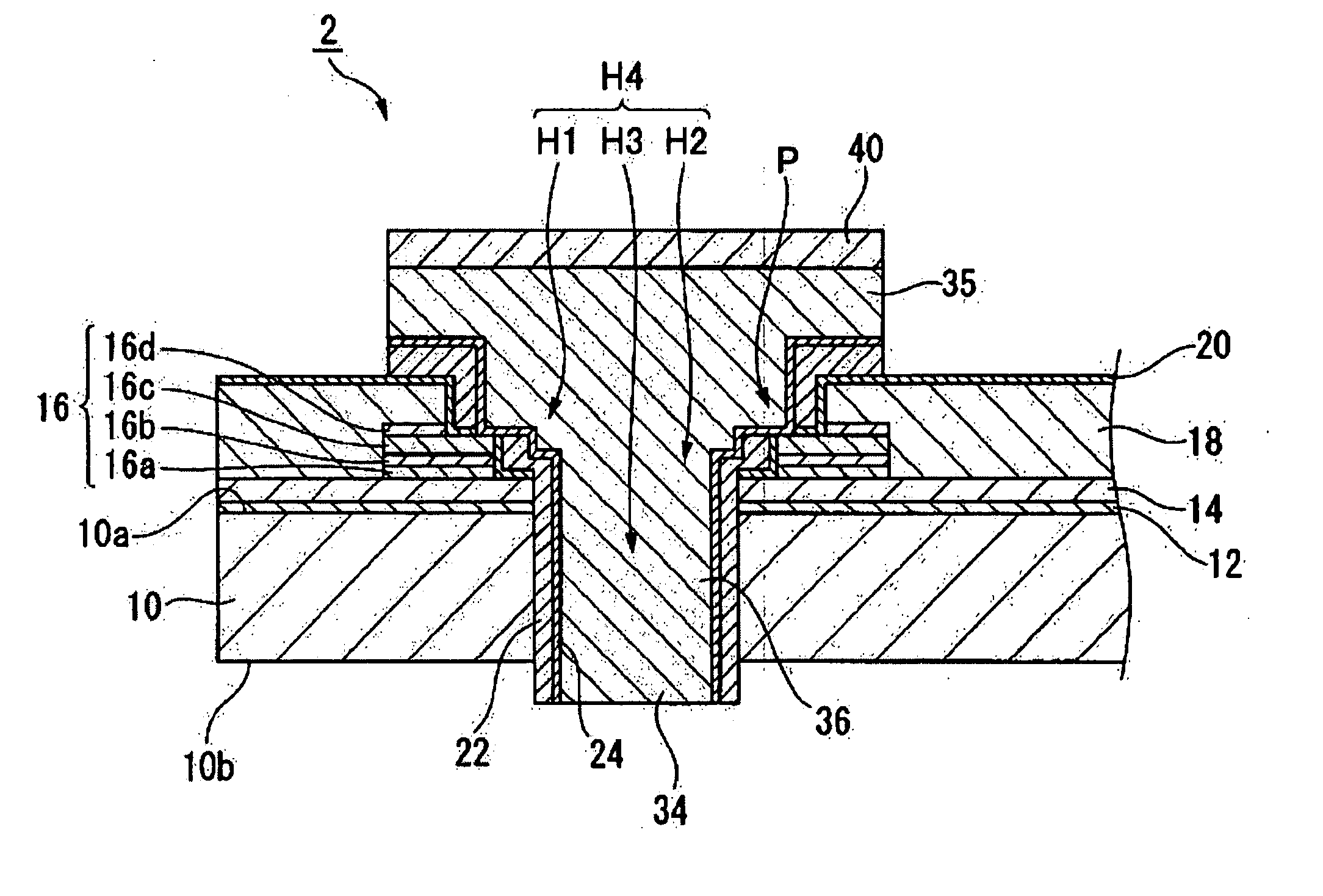

Chip package structure and method

InactiveCN106558574AHigh densityHigh bandwidthSemiconductor/solid-state device detailsSolid-state devicesRedistribution layerInterconnection

The embodiment of the invention discloses a chip package structure and method. The chip package structure and method can reduce the thickness of the package structure, improve the density of a base pin, add the number of the interconnection channels and increase the bandwidth of the top chip. The chip package structure comprises: a redistribution layer (RDL); a target chip including a source surface and a back surface, wherein the source surface of the target chip is connected with the first surface of the RDL; a substrate, wherein the first surface of the substrate is opposite to the back of the target chip; and an interconnection channel located around the target chip, one end of the interconnection channel is connected with the first surface of the RDL, and the other end of the interconnection channel is connected with the first surface of the substrate.

Owner:HUAWEI TECH CO LTD

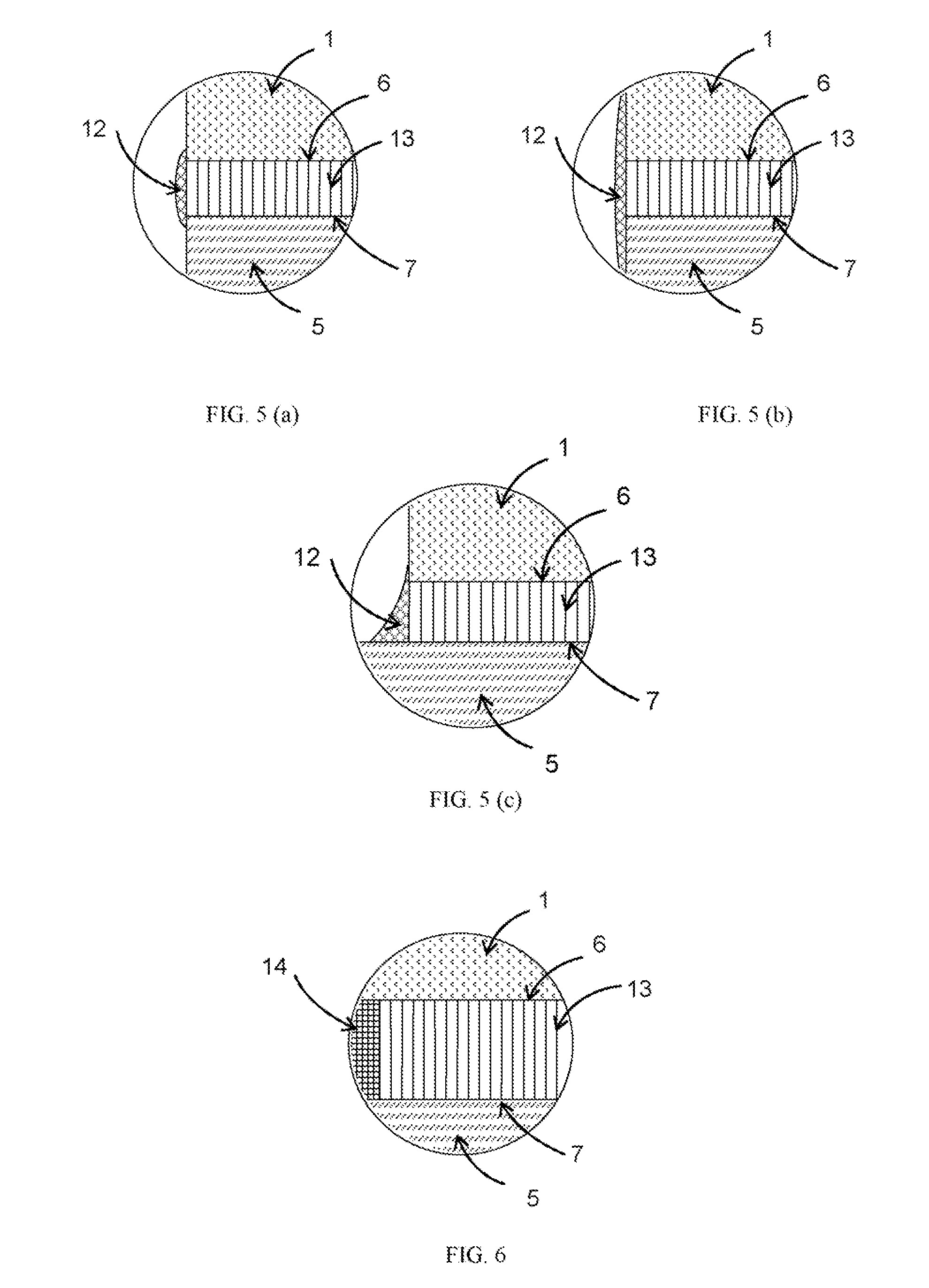

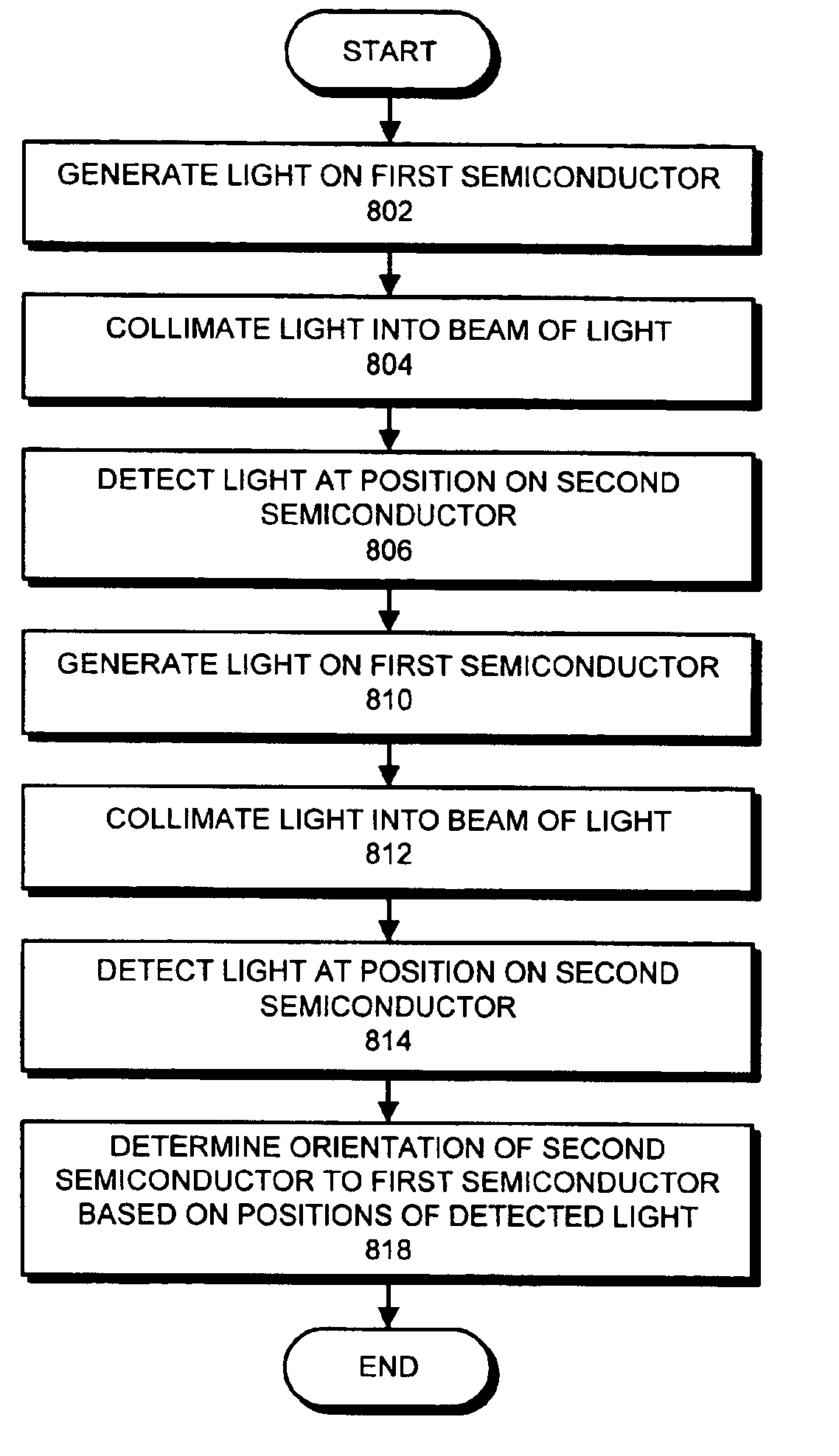

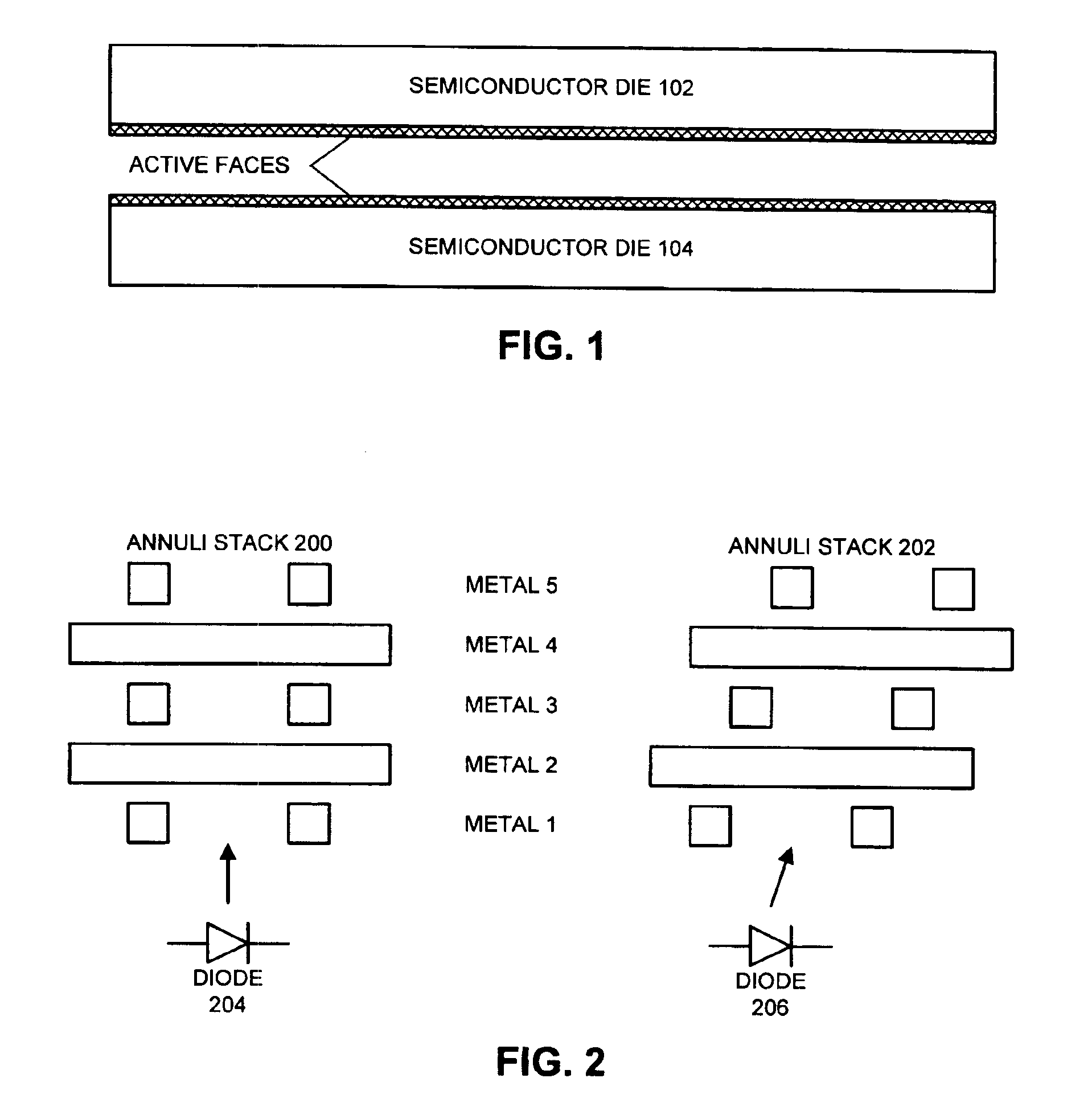

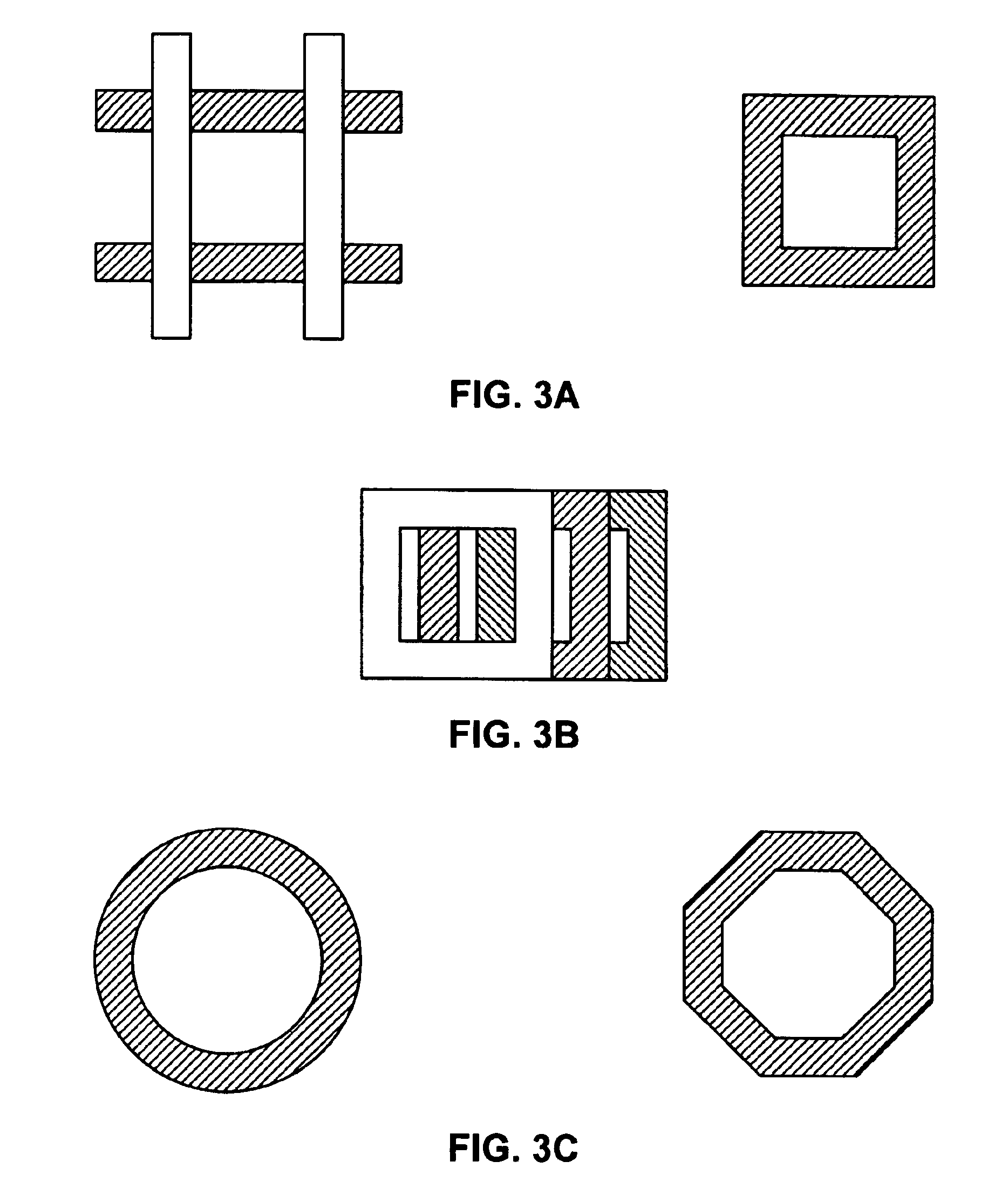

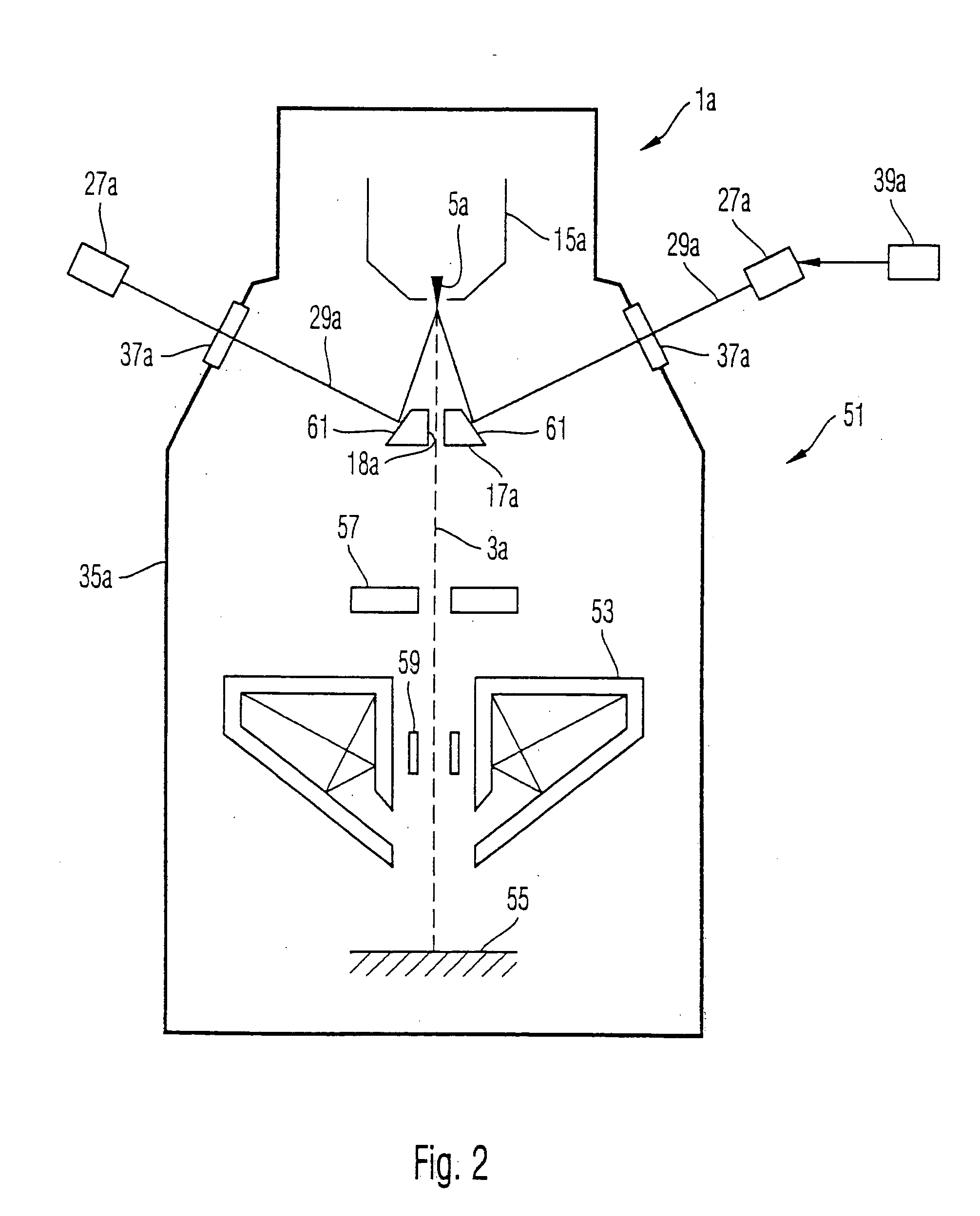

Method and apparatus for optically aligning integrated circuit devices

ActiveUS6949406B2Easy alignmentSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringSemiconductor

One embodiment of the present invention provides a system that facilitates aligning a first semiconductor die with a second semiconductor die, wherein the first semiconductor die and the second semiconductor die are arranged active face to active face. Note that the active face contains circuitry for communicating between semiconductor dies. The system starts by generating light on an active face of the first semiconductor die. The system then collimates the light within the active face of the first semiconductor die to form a first beam of light which is projected onto the second semiconductor die. Next, the system receives the first beam of light on an active face of the second semiconductor die and determines a position of the first beam of light on the active face of the second semiconductor die. Finally, the system determines an alignment of the second semiconductor die relative to the first semiconductor die based on the determined position of the first beam of light.

Owner:ORACLE INT CORP

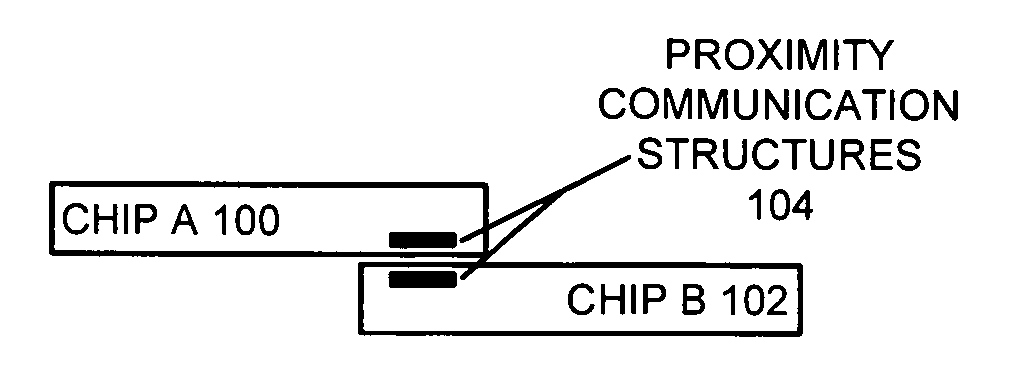

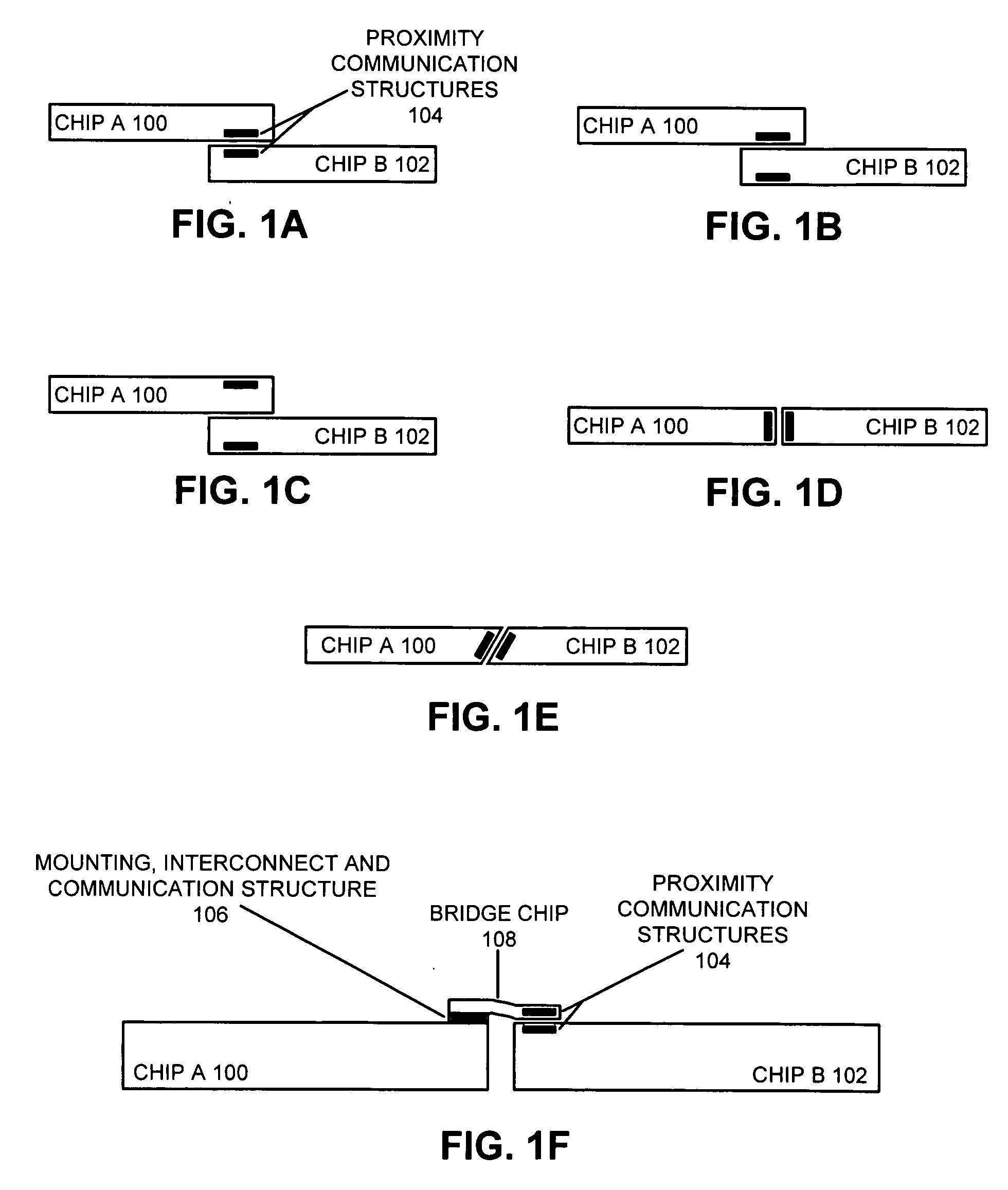

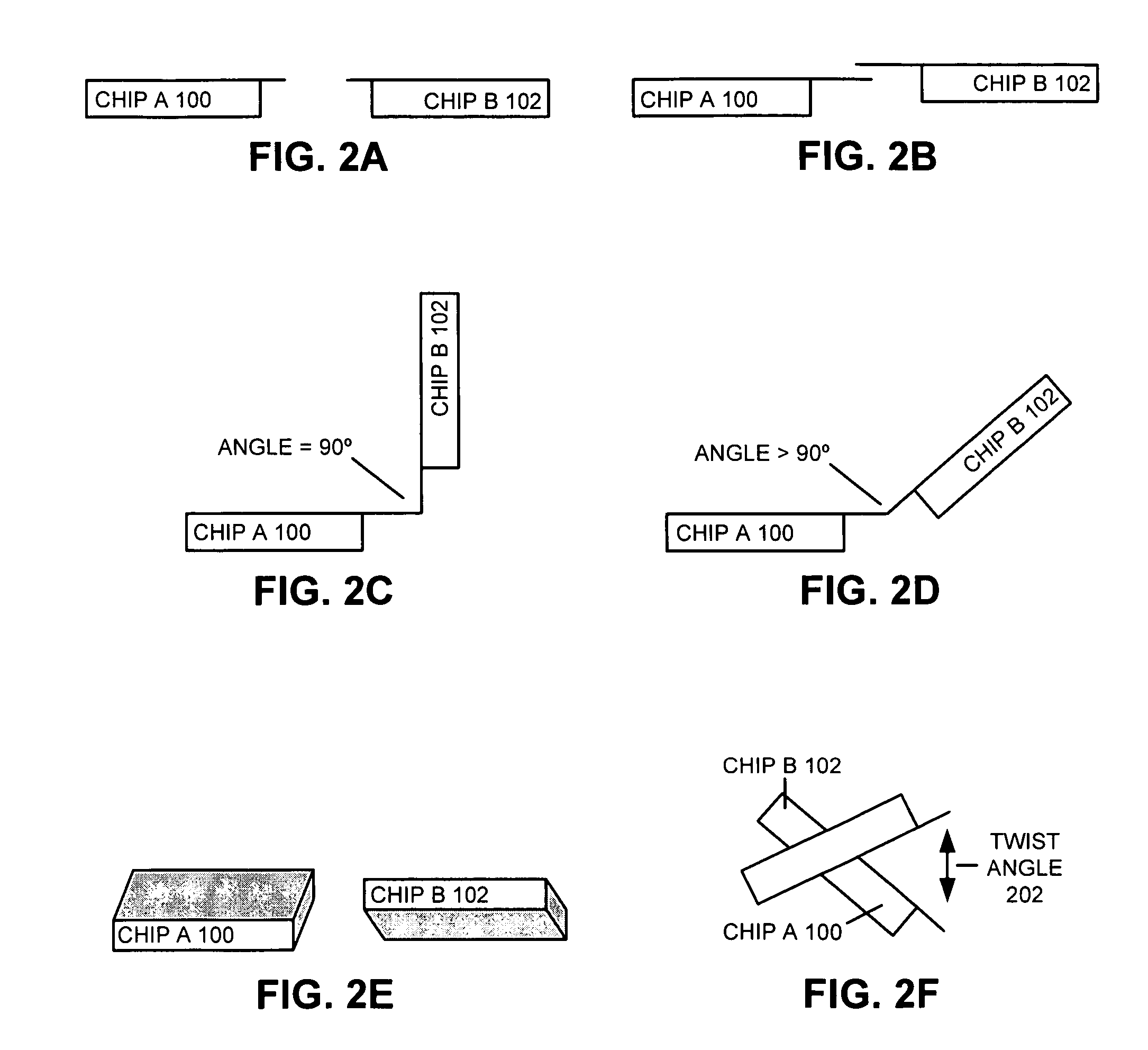

Structures and methods for a flexible bridge that enables high-bandwidth communication

ActiveUS20070043894A1Easy to optimizeAlleviating wireabilitySemiconductor/solid-state device detailsSolid-state devicesHigh bandwidthBandwidth limitation

One embodiment of the present invention provides a system that facilitates high-bandwidth communication using a flexible bridge. This system includes a chip with an active face upon which active circuitry and signal pads reside, and a second component with a surface upon which active circuitry and / or signal pads reside. A flexible bridge provides high-bandwidth communication between the active face of the chip and the surface of the second component. By matching the wire line size in the flexible bridge to the size of circuits and / or signal pads on the chip and on the second component, the system allows signals to be sent between the circuits on the chip and the second component without having to change the scale of the interconnect, thereby alleviating wireability and bandwidth limitations of conventional chip packaging technologies.

Owner:ORACLE INT CORP

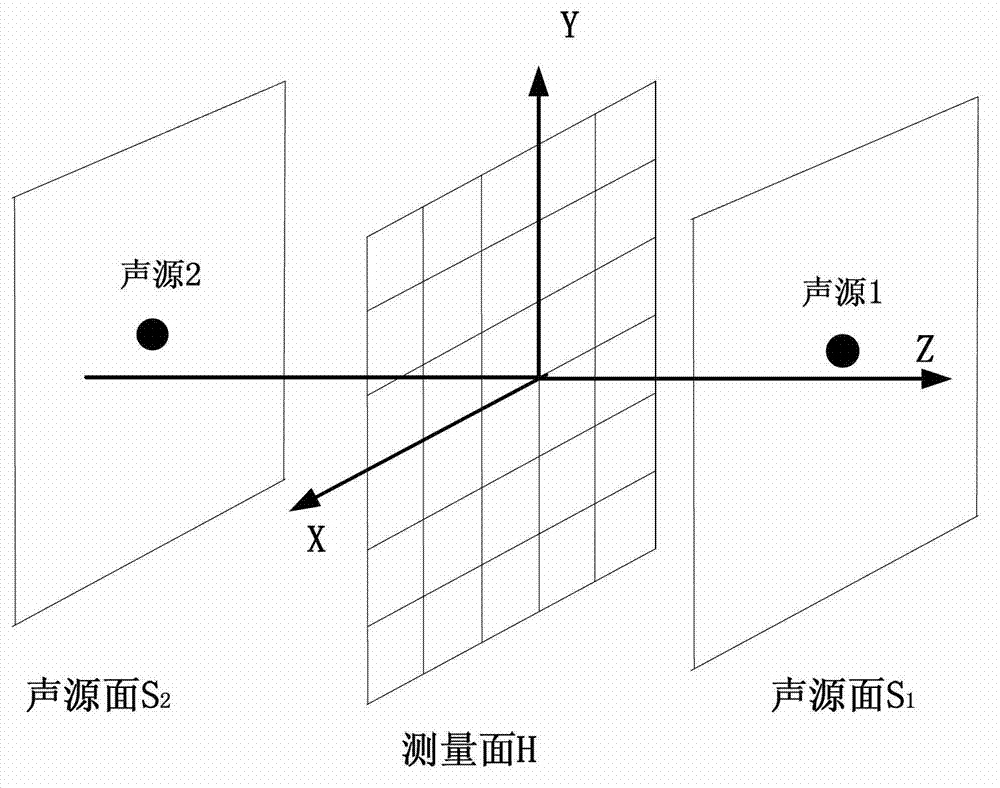

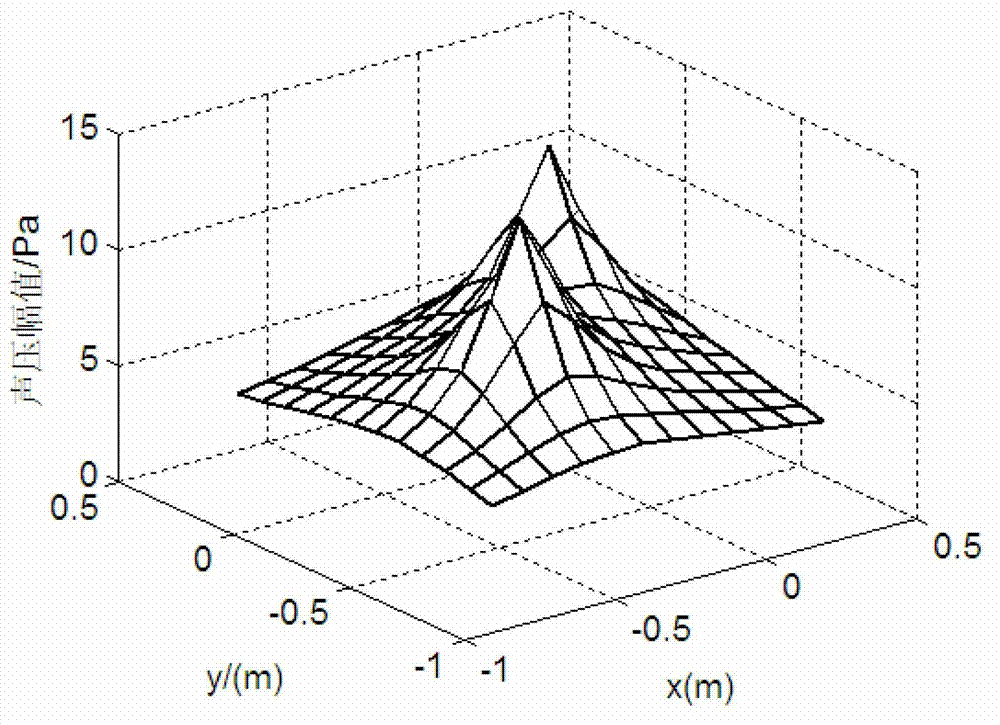

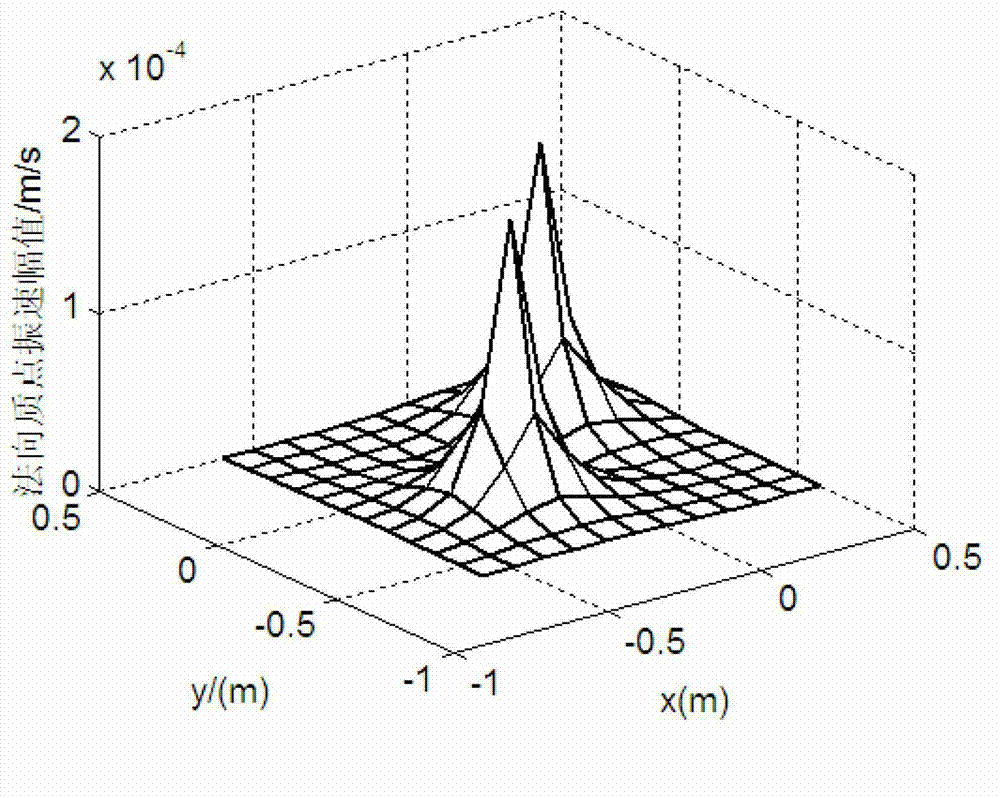

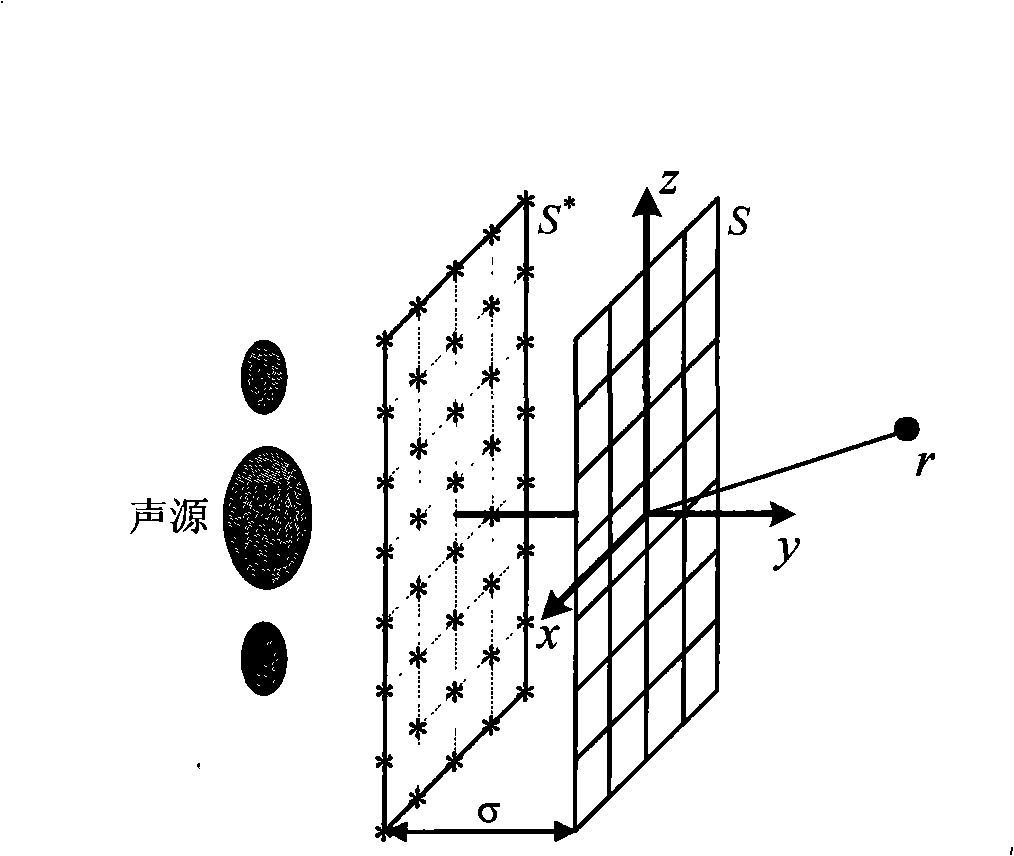

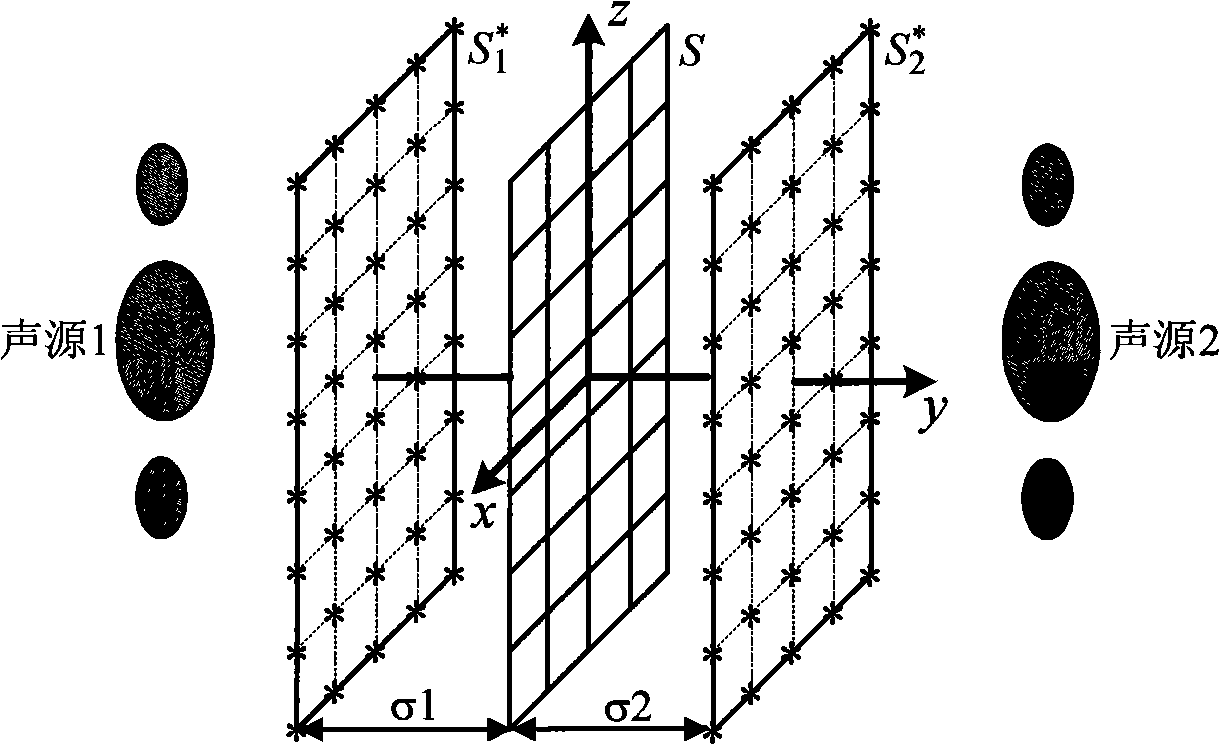

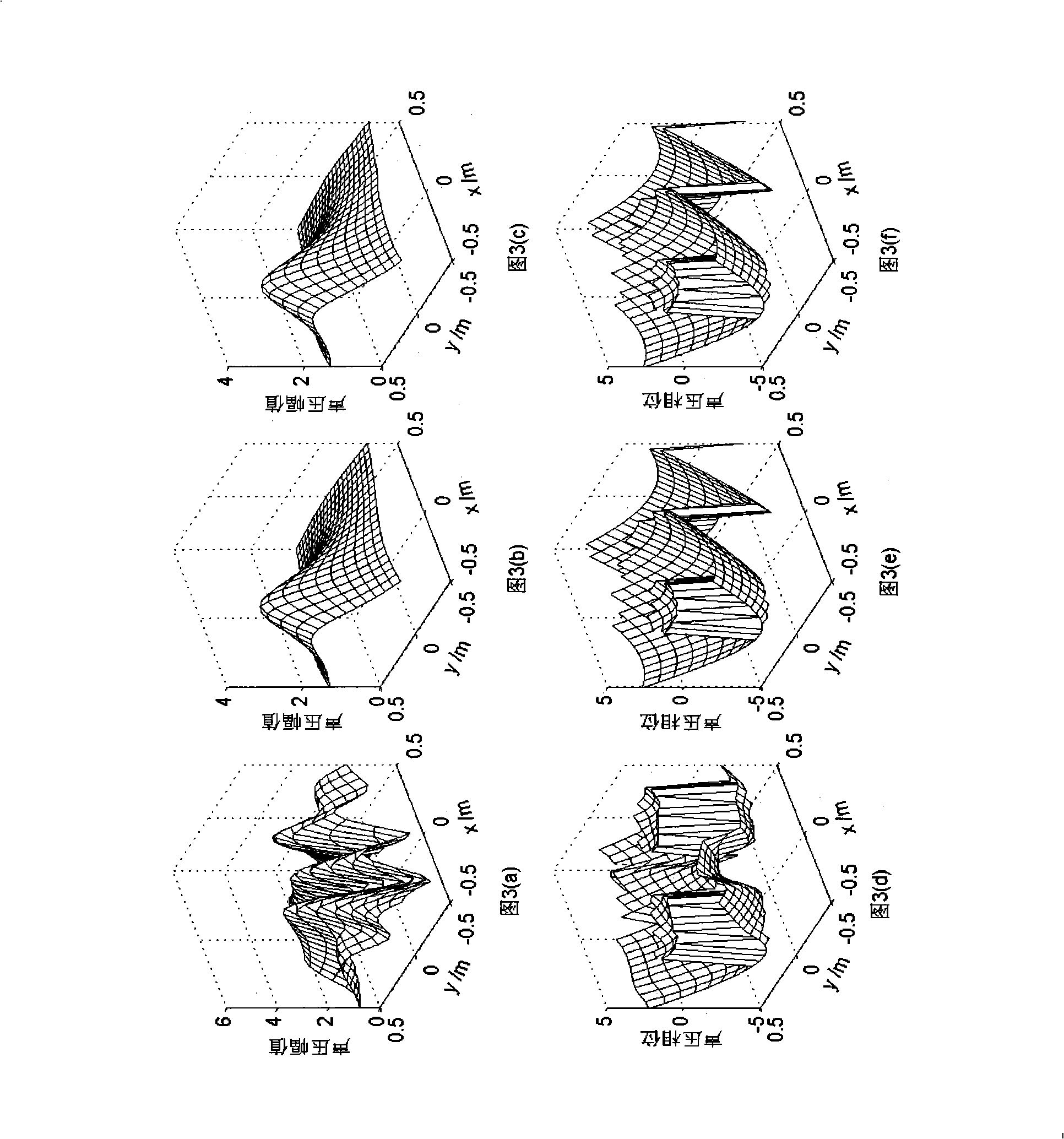

Sound field separating method based on single-surface measurement and local acoustical holography method

InactiveCN102901559ASimple methodShort calculation timeSubsonic/sonic/ultrasonic wave measurementSound sourcesReconstruction method

The invention relates to the field of noise, in particular to a sound field separation and reconstruction method applicable to sound field separation and reconstruction of large sound sources. The sound field separation and reconstruction method comprises the following steps of: acquiring sound pressure and normal particle vibration velocity on a measuring surface; performing zero filling extension on the measuring surface positioned between two sound sources; acquiring transfer matrixes between the extended measuring surface and surfaces of the two sound sources, namely sound source faces; building a transitive relation between the sound pressure and the normal particle vibration velocity on the measuring surface; and acquiring the sound pressure and the normal particle vibration velocity of the first sound source face and the sound pressure and the normal particle vibration velocity of the second sound source face. A sound field is separated and reconstructed by using the single-measurement-surface and local near-field acoustical holography method. The sound field separation and reconstruction method has the characteristics of simplicity, short calculation time and high calculation efficiency, and can be widely applied to the measurement of near-field acoustical holography, the measurement of material reflecting coefficients, the separation of scattering sound fields and the like of large-size sound-source sound fields.

Owner:三亚哈尔滨工程大学南海创新发展基地

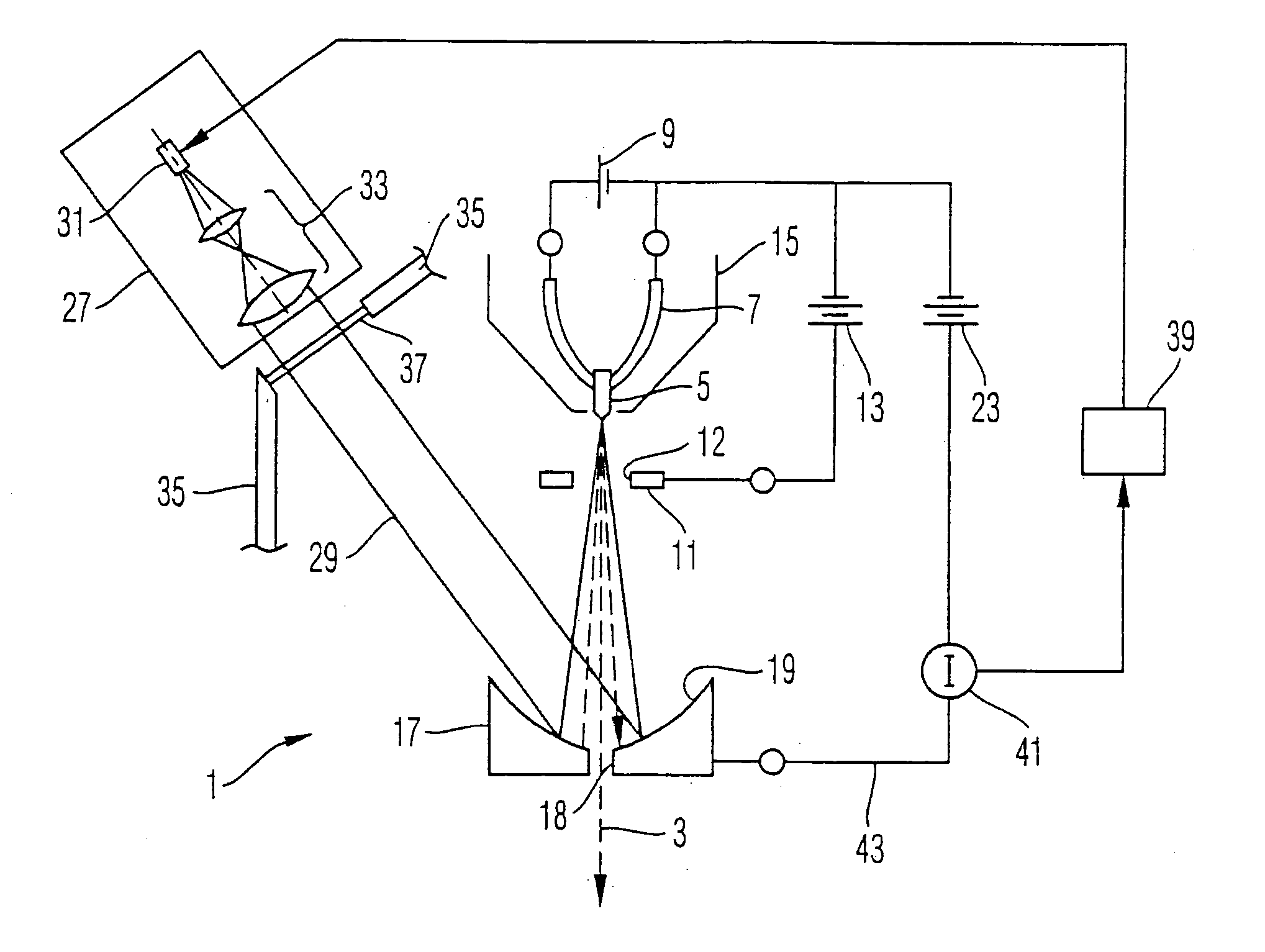

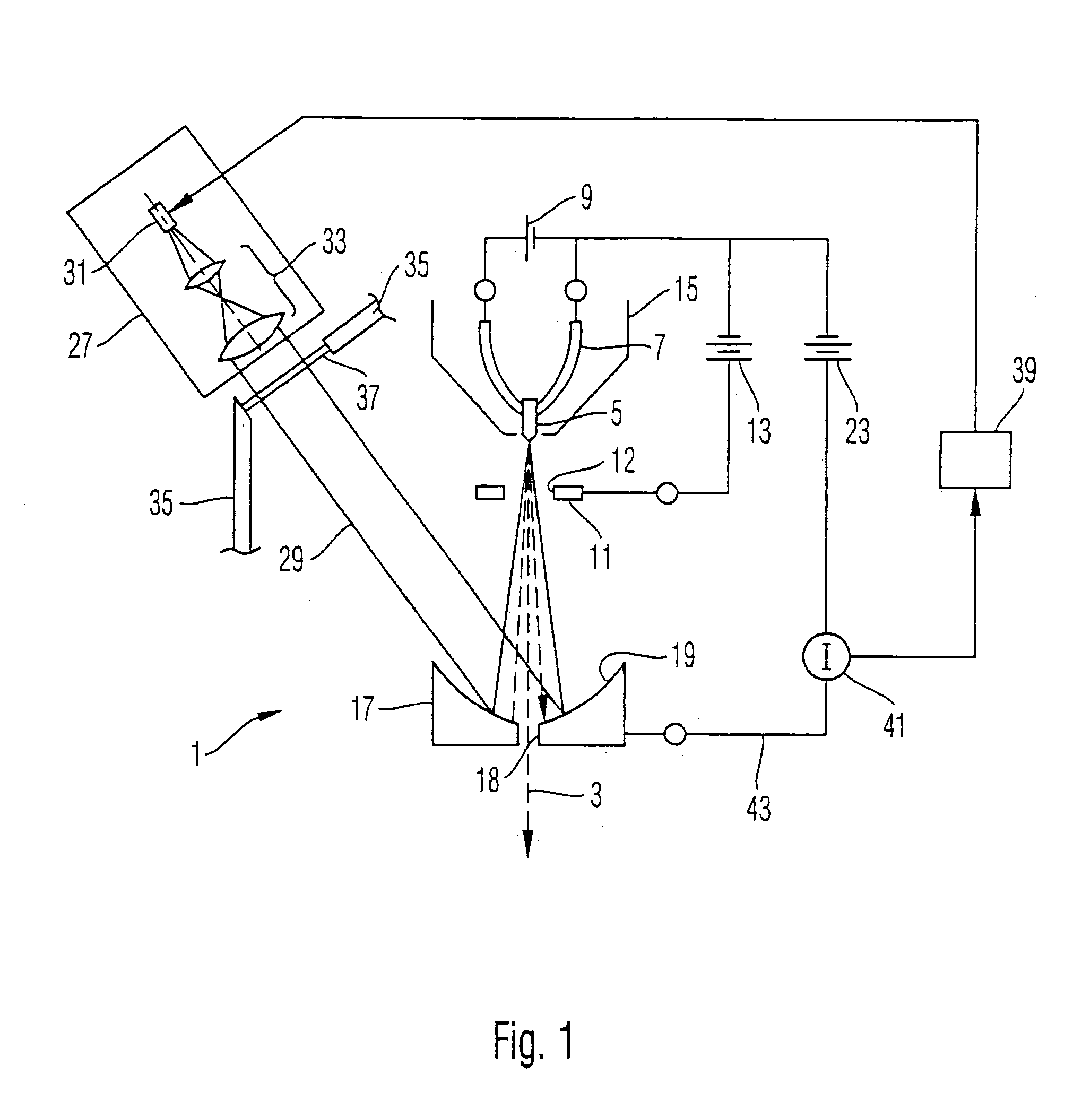

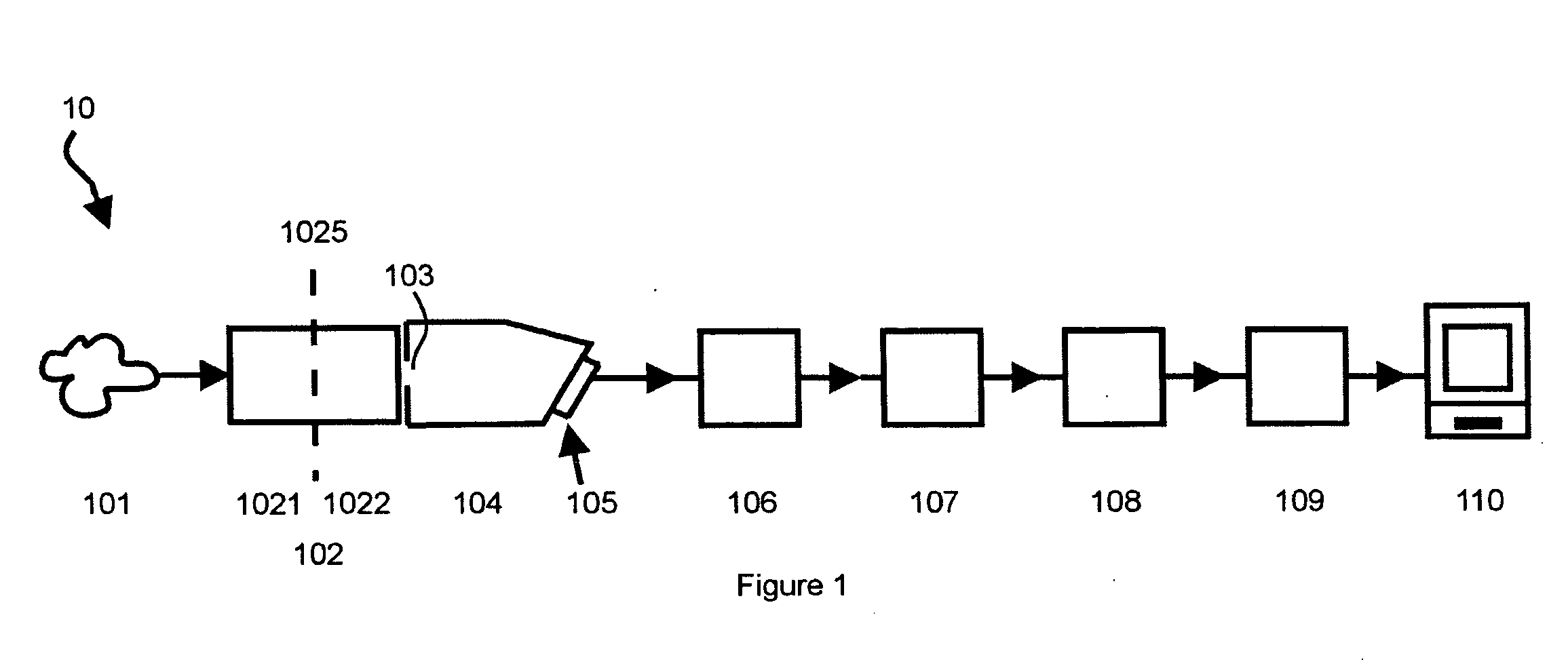

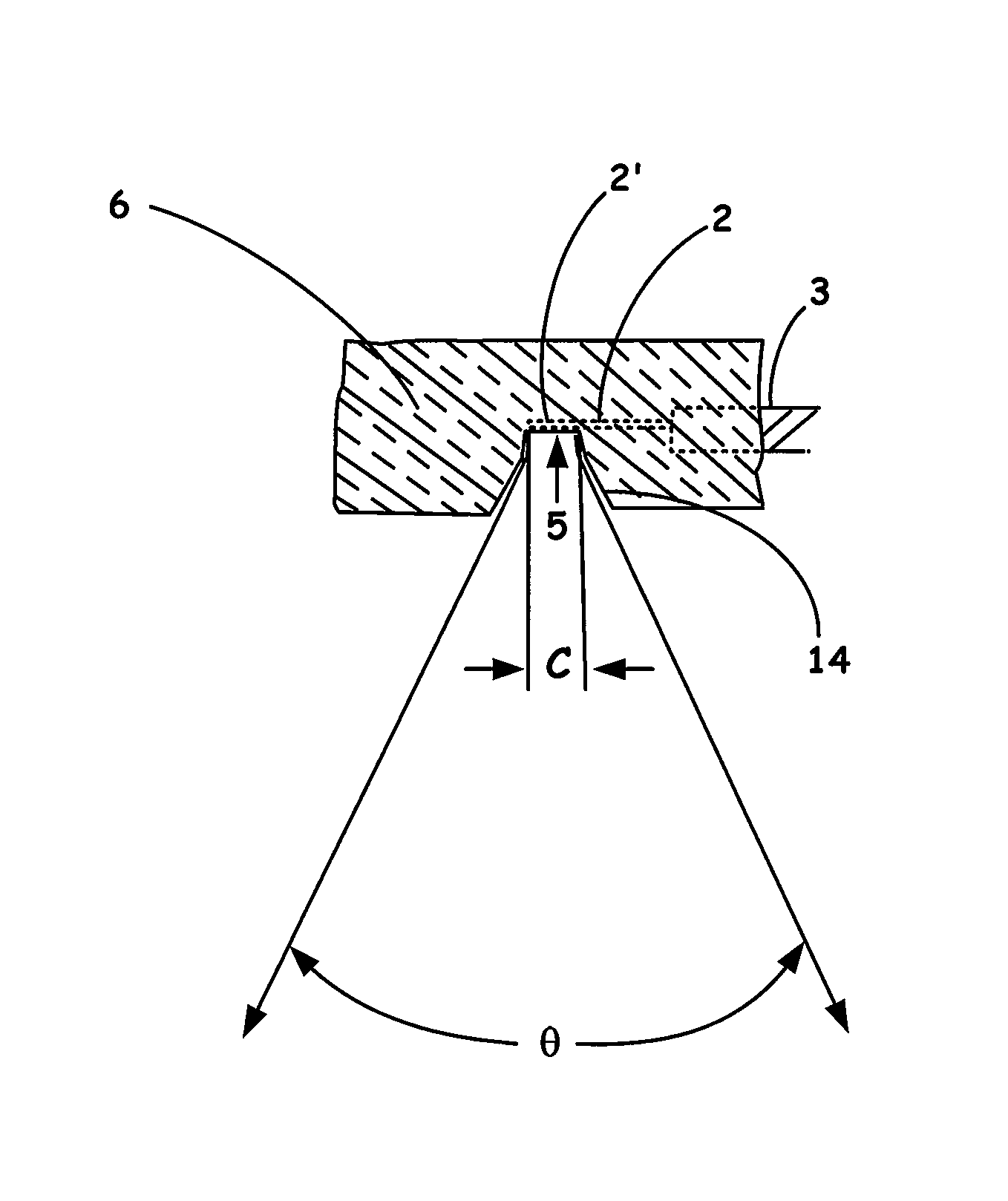

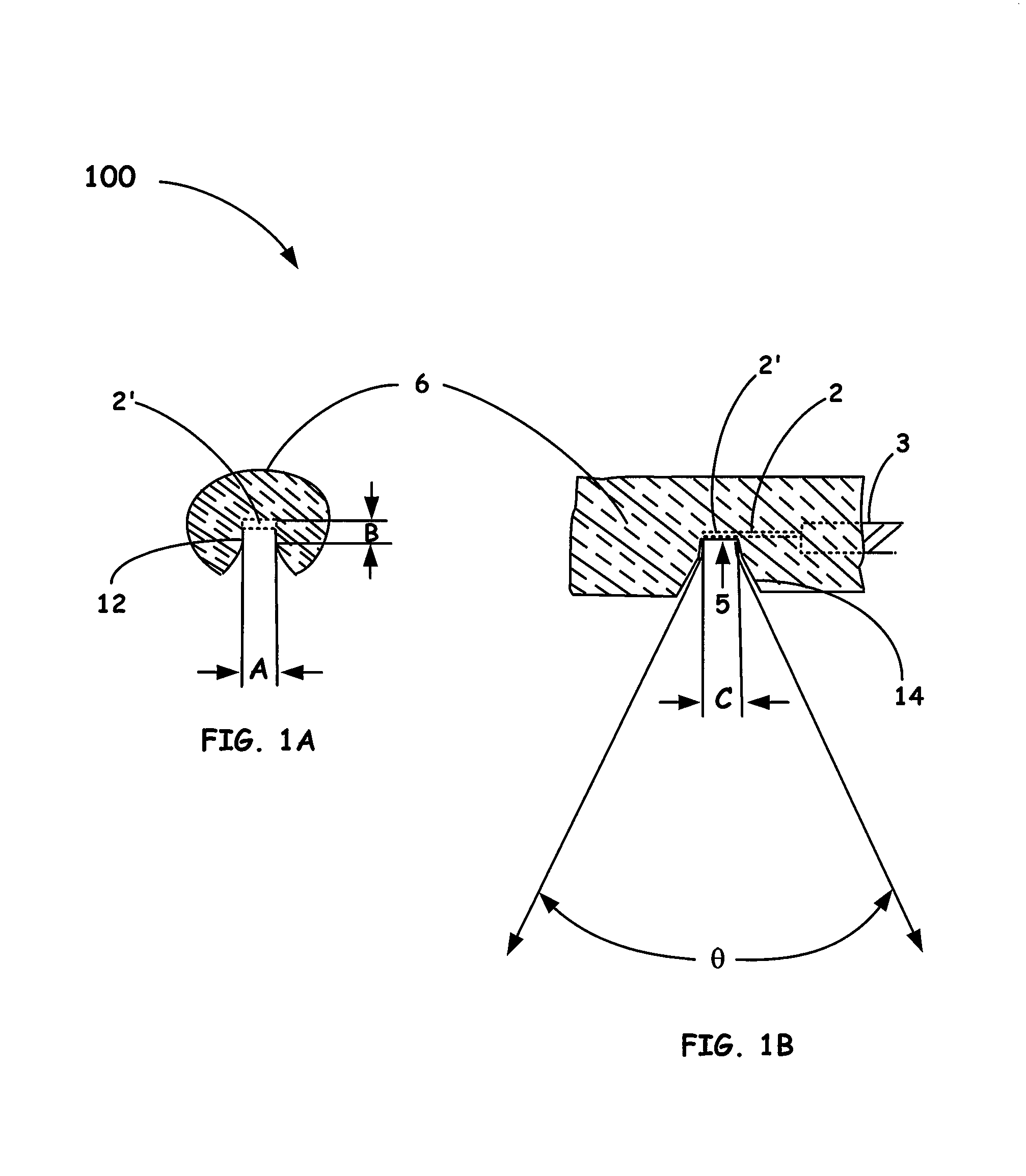

Electron beam source, electron optical apparatus using such beam source and method of operating an electron beam source

InactiveUS20040124365A1Reduce widthImprove adjustabilityMaterial analysis using wave/particle radiationSemiconductor/solid-state device manufacturingBeam sourcePhoton beam

An electron beam source comprises a source surface illuminated with a photon beam of adjustable intensity. The photon beam assists emission of electrons from the source surface due to a photo effect. An electric extraction field further assists in electron emission. Further, a heater is provided for further assisting in electron emission by a thermionic effect. An electron beam current is measured, and the intensity of the photon beam is adjusted based on the measured electron beam current.

Owner:CARL ZEISS SMT GMBH

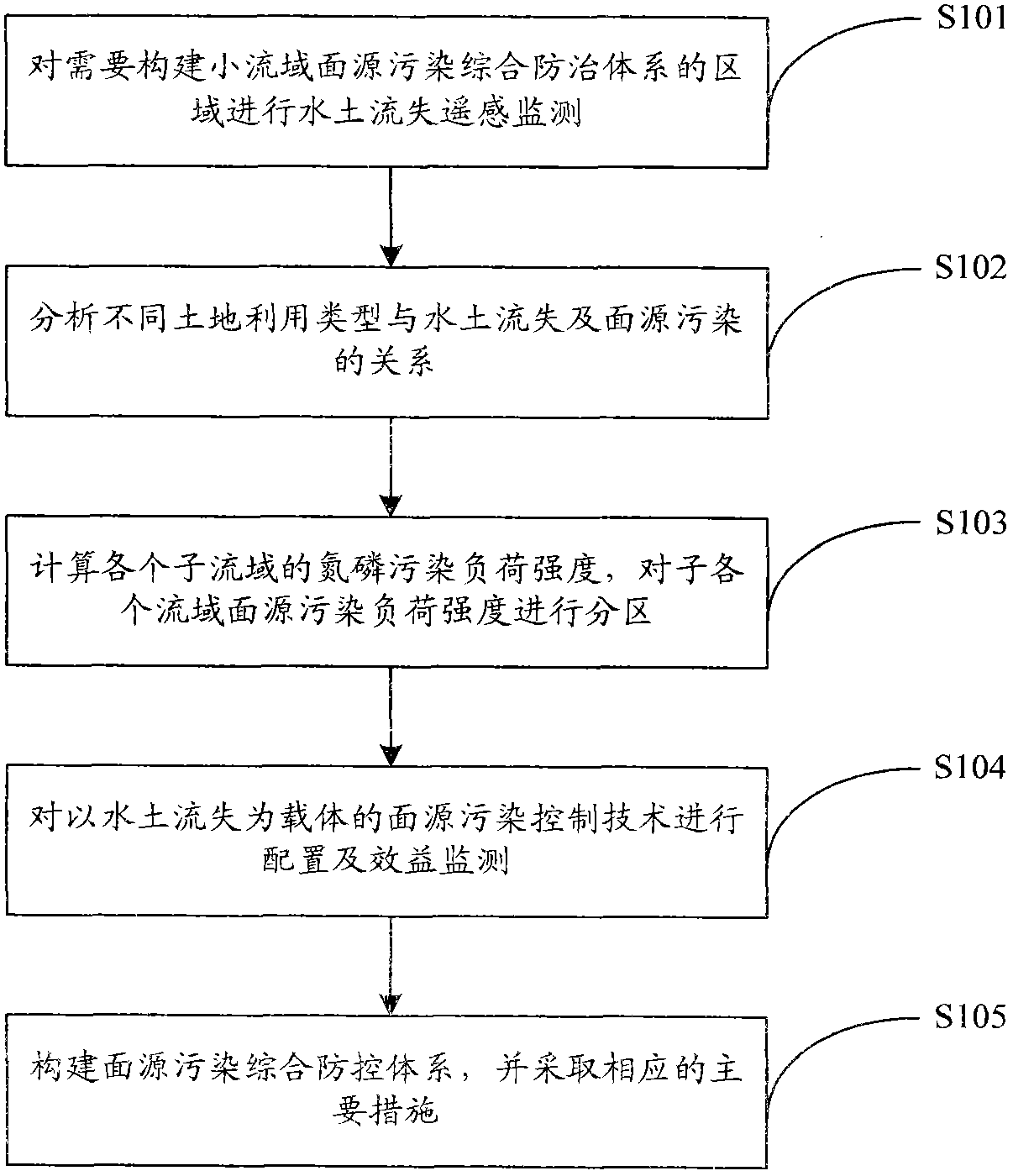

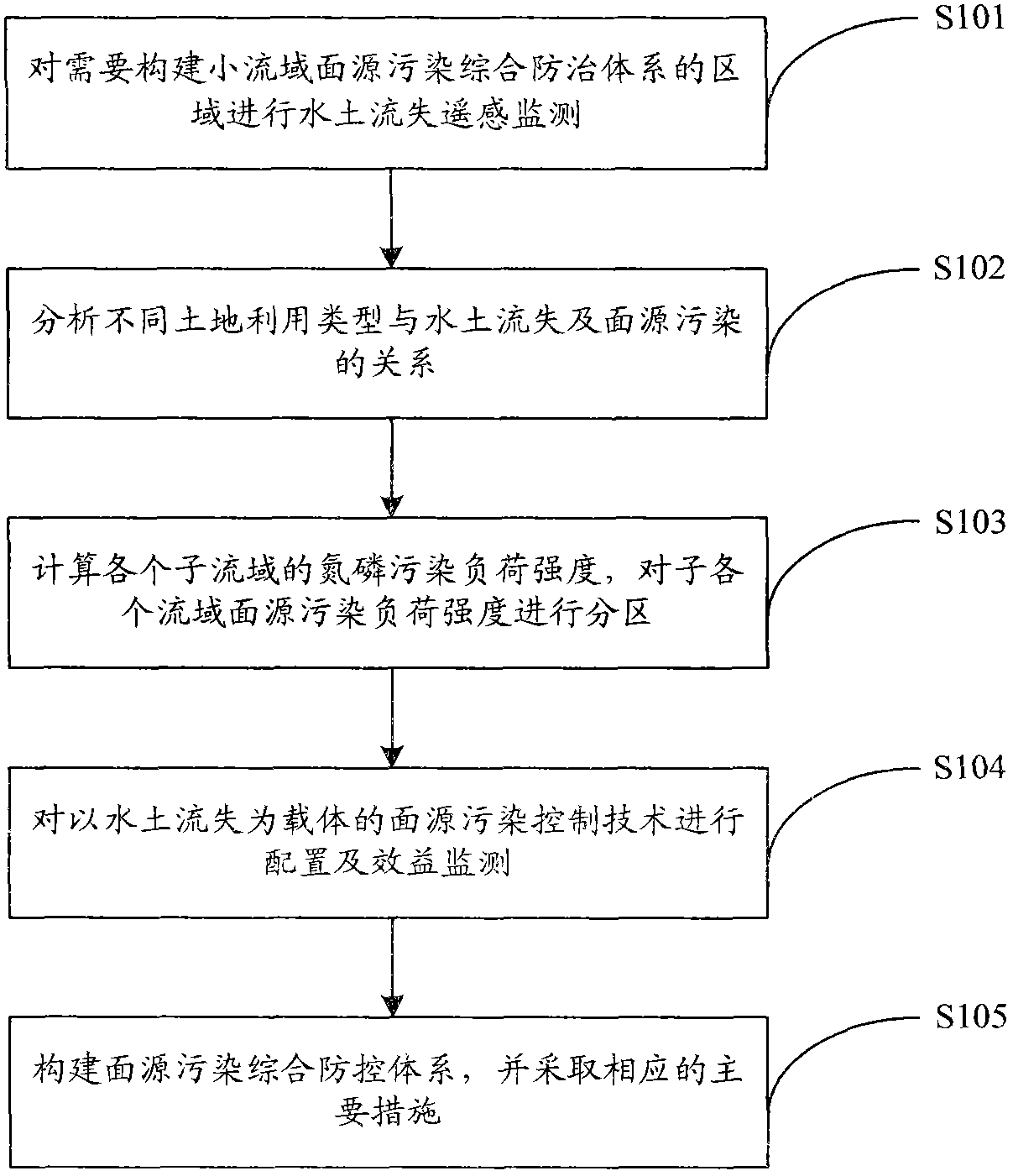

Method for constructing comprehensive control system for small-watershed surface source pollution

The invention belongs to the technical field of researching of an ecological system and provides a method for constructing a comprehensive control system for small-watershed surface source pollution. The method comprises the following steps of: firstly, carrying out remote sensing monitoring on water loss and soil erosion; then carrying out field positioning observation and manually-simulated rainfall; analyzing radial water loss and soil erosion of different land utilization types and an output rate of surface source pollutants including nitrogen, phosphorus and the like through the field positioning observation and the manually-simulated rainfall; calculating a nitrogen and phosphorus source surface pollution load strength and partitioning; carrying out control technology configuration and biological measure benefit monitoring on the surface source pollution which takes the water loss and soil erosion as a carrier; and finally, establishing the comprehensive control system of the small-watershed surface source pollution. The invention provides main measures needing to be adopted and provides evidences for guaranteeing the safety of a main water source land and planning work for supporting water and soil maintenance of a drainage basin, therefore, the method has stronger popularization and application values.

Owner:LINYI UNIVERSITY

Method for sound field separation by pressure velocity method

InactiveCN101403634AGood calculation stabilityImprove calculation accuracyVelocity propogationEquivalent source methodSound sources

The invention discloses a pressure speed method sound field separation method, a measured sound field is provided with a measuring surface S; a sound pressure sensor is adopted to measure the sound pressure on the measuring surface S, and a particle velocity sensor or a sound intensity probe is adopted to measure the particle speed on the measuring surface S; both sides of the measuring surface S are provided with the imaginary source surfaces S1 <*> and S2 <*> which are provided with the equivalent sources; the transfer relationship between the equivalent sources and the sound pressure and the particle speed on the measuring surface S is constructed; the separation of sound source radiation sound pressure and the particle speed of both sides on the measuring surface according to the transfer relationship is realized; the sound field separation is realized by measuring the speed relation of sound pressure and particle on each surface; and the equivalent source method is adopted as the sound field separation arithmetic, the calculation stability is good, the calculation precision is high, and the implement is simple. The method can be widely applicable to the near-field acoustic holography measurement in the environments of internal sound field or noisy sound, the sound intensity method sound source identification in the noisy environment, the material reflection coefficient measurement, and the separation of the scattering sound field.

Owner:HEFEI UNIV OF TECH

Multi-channel spectrum analyzer

ActiveUS20050162649A1High refractive indexEliminate the effects ofRadiation pyrometrySpectrum investigationSpectral bandsFrequency spectrum

A spectrum analyzer for the simultaneous analysis of electromagnetic radiation delivered to it from either multiple sources or from a linear segment along a source surface, and arranged as either continuous or discrete set of points along a short piece of a straight line referred to herein as a slit. In one embodiment of the invention, the optical design of the dispersing part of the analyzer provides essentially stigmatic spots for any spectral band up to one octave wide in the spectral range of about 400 nm to about 2500 nm.

Owner:P&P OPTICA

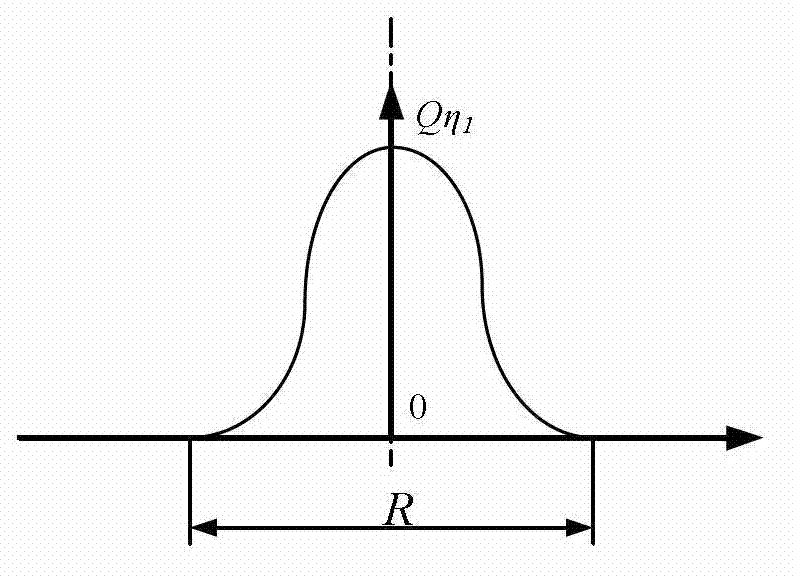

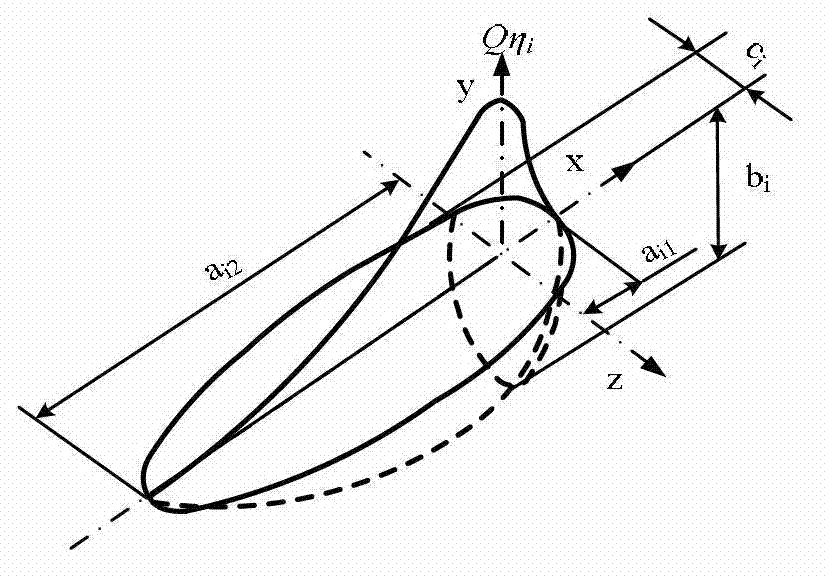

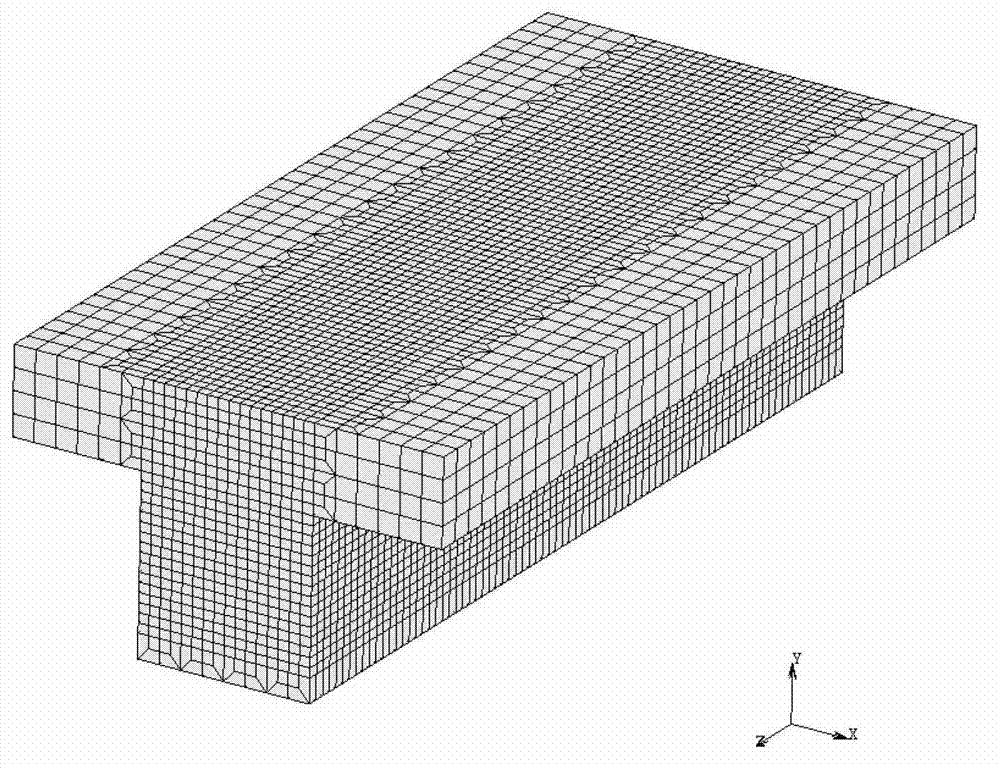

Building method for laser welding heat source model

ActiveCN103049623AEfficiency is obviousImprove efficiencySpecial data processing applicationsCouplingOpen source

The invention relates to a building method for a welding heat source model, in particular to a building method for a laser welding heat source model. The method solves the problem in laser welding simulation of large-scale complex construction members that laser heat source achieving difficulty is large, and calculating efficiency is low. The method includes: step 1, building a three-dimensional finite element grid model; step 2, building a Gaussian heat source mode of a heat source surface; step 3, expanding welding energy along the laser welding pool depth direction; and step 4, solving a governing equation based on finite element software and conducting heat-machine coupling calculation, namely building of the laser welding heat source model is finished. The building method is applied to the field of welding.

Owner:HARBIN INST OF TECH

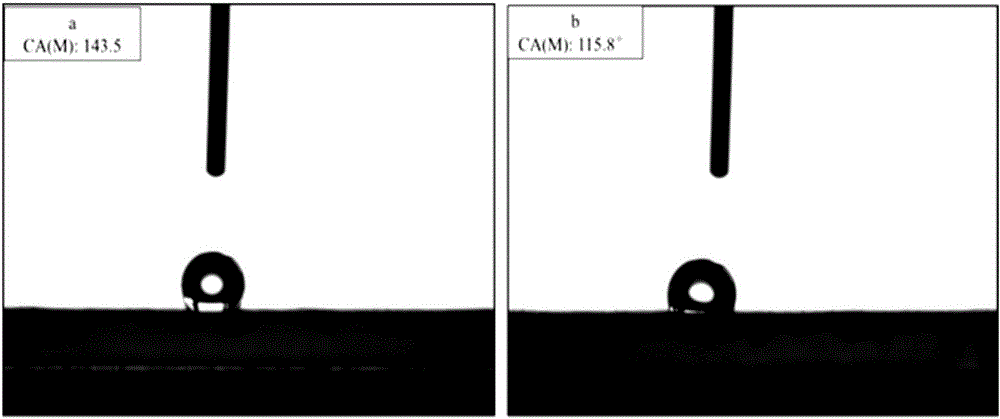

Chopped fiber dispersion and preparation method thereof

ActiveCN105818398AImprove surface activityImprove hydrophilicityCleaning using liquidsCelluloseFiber

The invention discloses chopped fiber dispersion and a preparation method thereof and belongs to the field of fiber fabric materials. A bio-based source surface modifier and a bio-based thickener are adopted for synergistically acting to facilitate dispersion of chopped fibers in water. The bio-based source surface modifier is dopamine. The bio-based thickener is one or more of methylcellulose, hydroxyethyl cellulose, hydroxy propyl cellulose, hydroxypropyl methyl cellulose, sodium carboxymethylcellulose, gelatin and sodium lignin sulfonate. According to the chopped fiber dispersion and the preparation method thereof, the content range of hydroxyl and amidogen on the surfaces of the fibers is adjusted and controlled effectively, so that the surface activity hydrophilia of the fibers are improved significantly, and thus the dispersibility of the fibers in the water is improved greatly. The dopamine and the bio-based thickener are both environmentally friendly low-cost materials; and when the dopamine and the bio-based thickener are used for fiber surface modification, the conditions are mild, control is easy, and the production efficiency is high. The dispersibility of the prepared chopped fibers in the water is excellent, and preparation of fiber paper or fibrofelt and other products with the uniform structure is facilitated.

Owner:BEIJING UNIV OF CHEM TECH +1

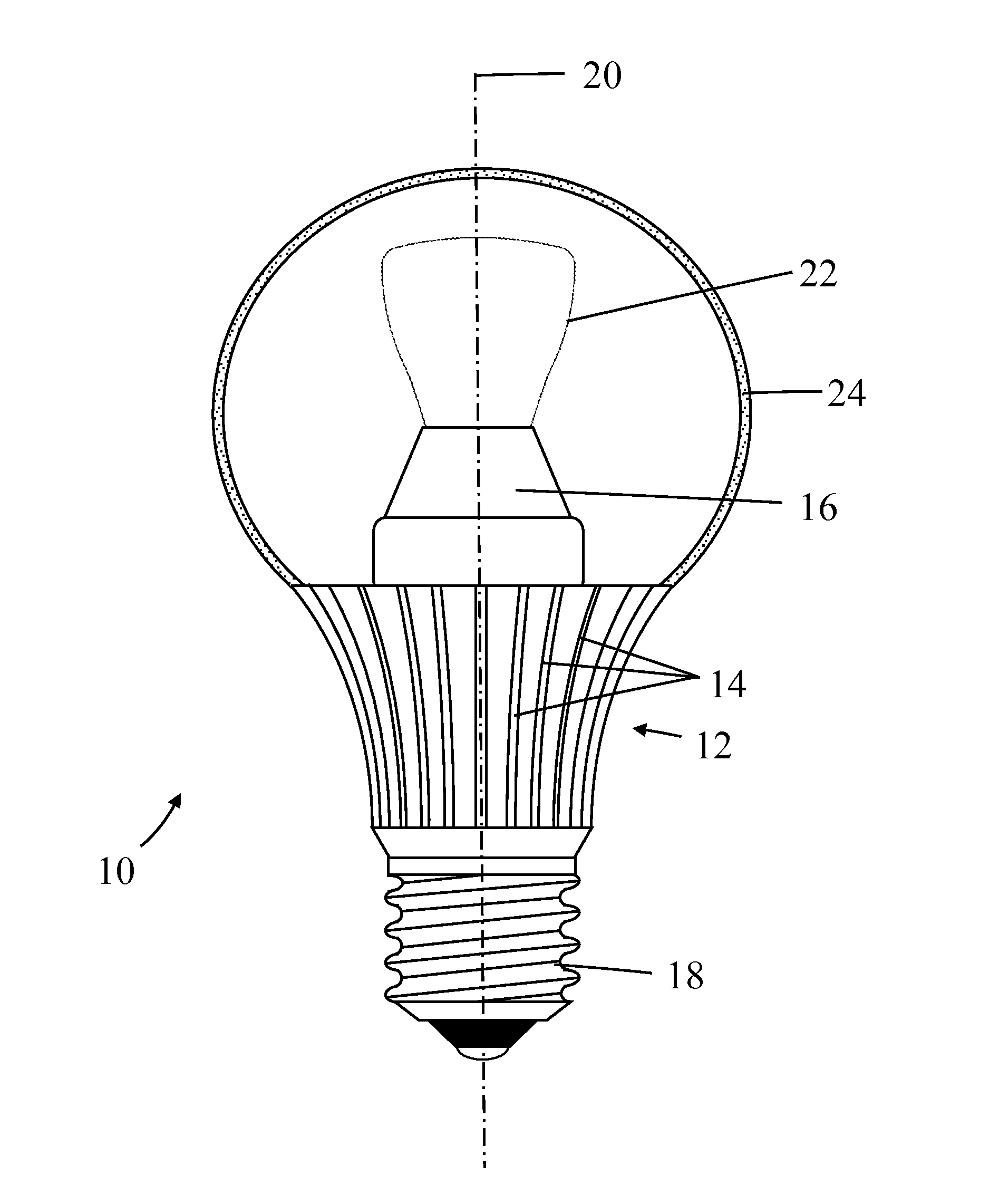

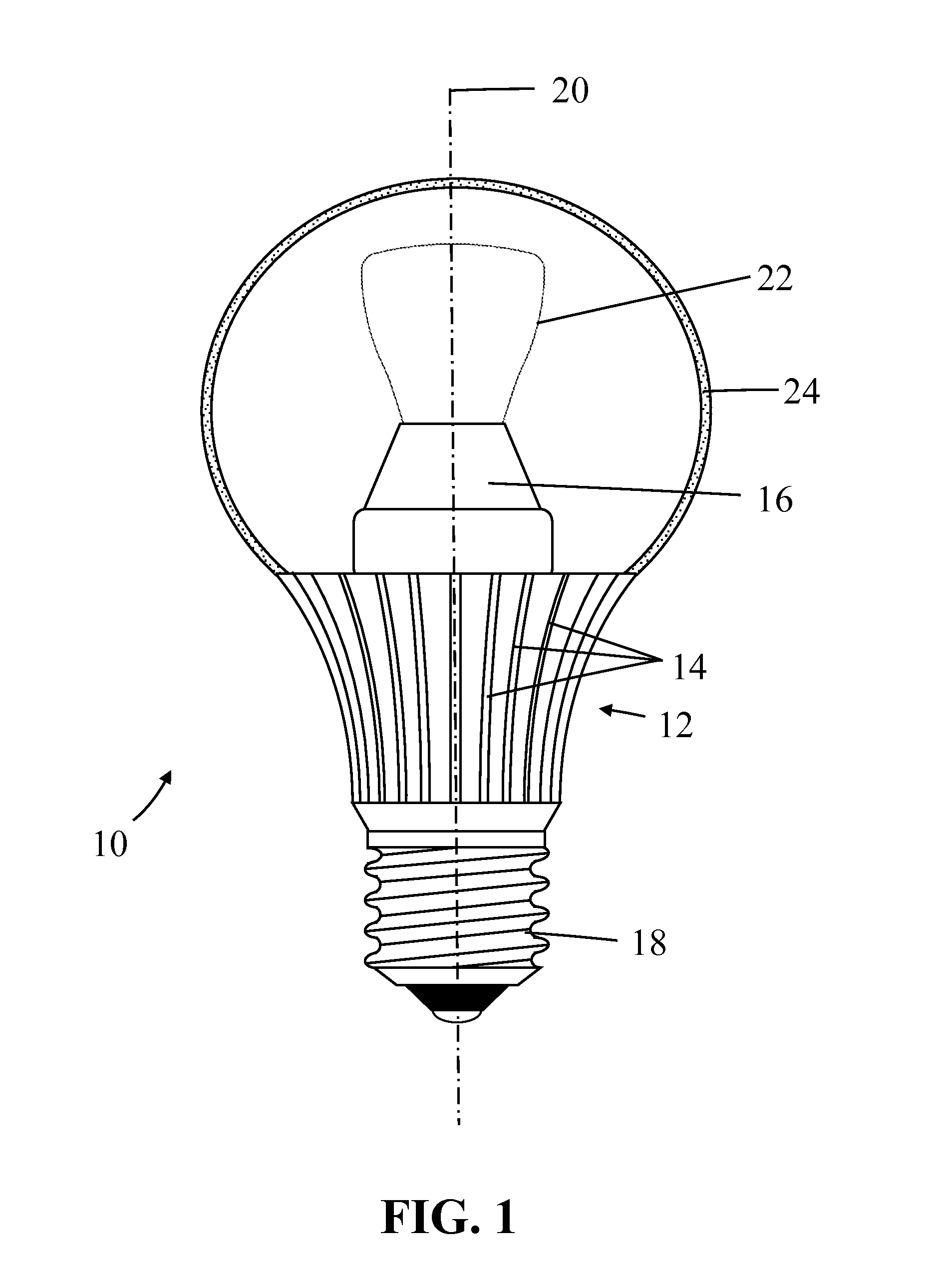

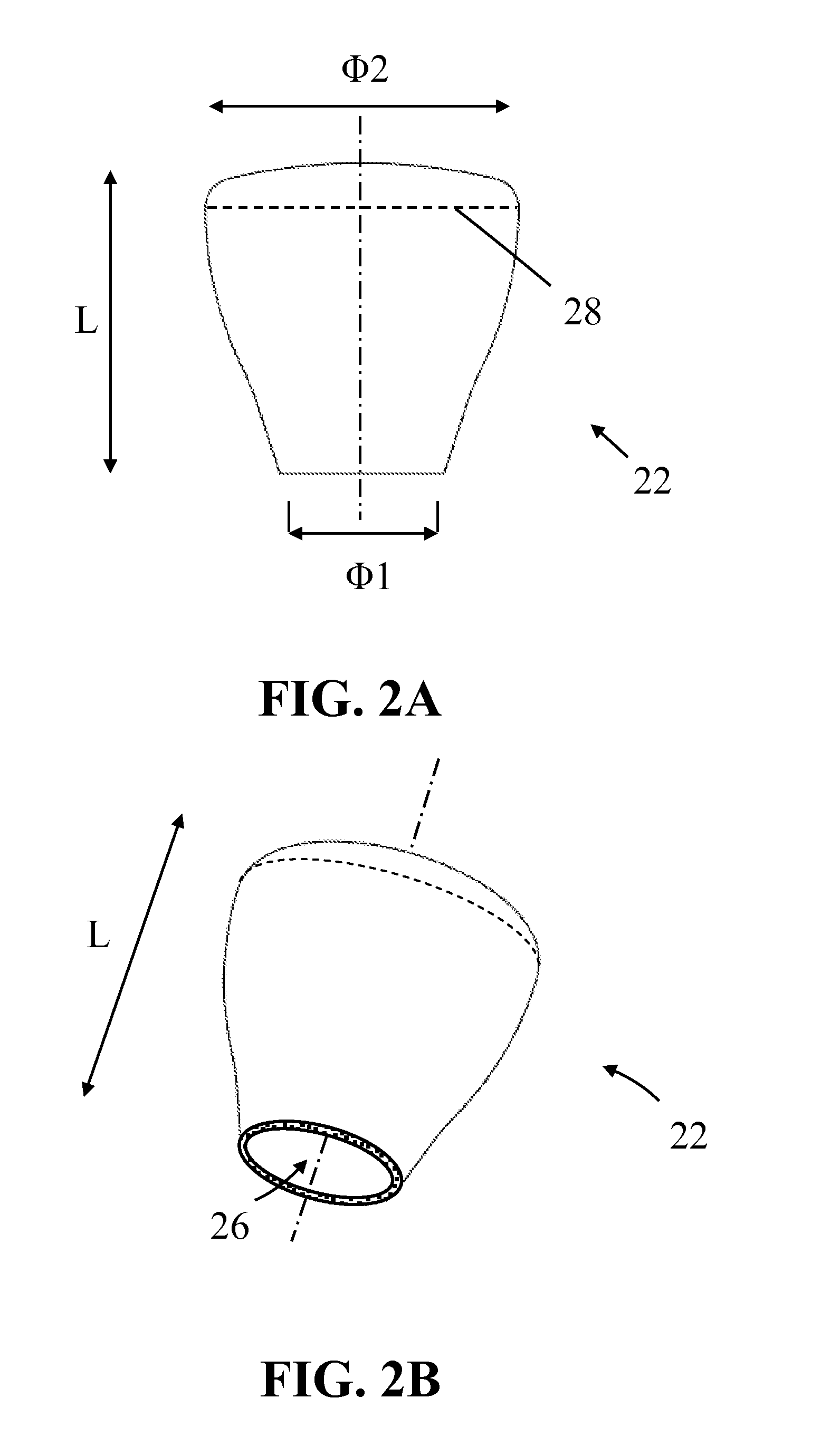

Solid-state lamps with improved emission efficiency and photoluminescence wavelength conversion components therefor

InactiveUS20130214676A1Reduce in quantityImprove white appearanceEnvelopes/bags making machineryDischarge tube luminescnet screensPhotoluminescenceWavelength

A solid-state lamp comprising: an array of solid-state excitation sources and a photoluminescence wavelength conversion component comprising a layer of photoluminescence material and a coupling optic. The layer of photoluminescence material is remote to the excitation sources and the coupling optic is disposed between the excitation sources and the layer of photoluminescence material. The ratio of the photoluminescence material surface area of the layer of the photoluminescence material to the excitation source surface area for the array of solid-state excitation sources is at least 3 to 1.

Owner:INTEMATIX

Multi-channel spectrum analyzer

ActiveUS7315371B2Minimize negative impactEasy to produceRadiation pyrometrySpectrum investigationSpectral bandsFrequency spectrum

A spectrum analyzer for the simultaneous analysis of electromagnetic radiation delivered to it from either multiple sources or from a linear segment along a source surface, and arranged as either continuous or discrete set of points along a short piece of a straight line referred to herein as a slit. In one embodiment of the invention, the optical design of the dispersing part of the analyzer provides essentially stigmatic spots for any spectral band up to one octave wide in the spectral range of about 400 nm to about 2500 nm.

Owner:P&P OPTICA INC

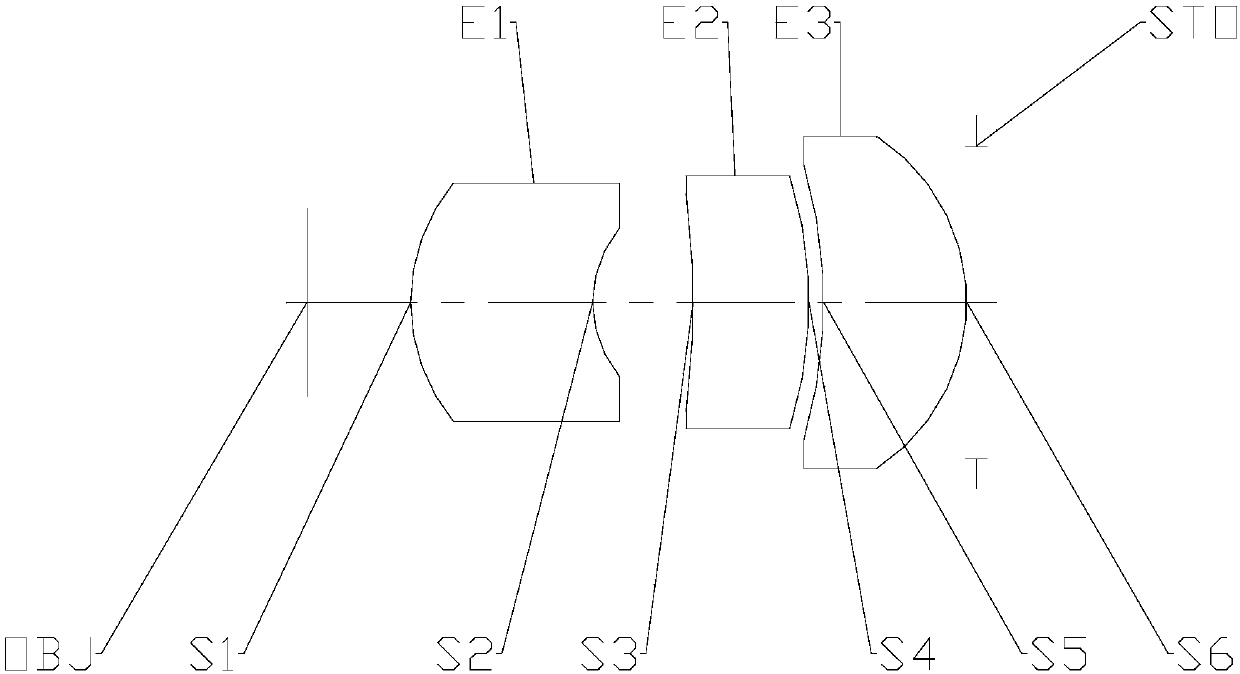

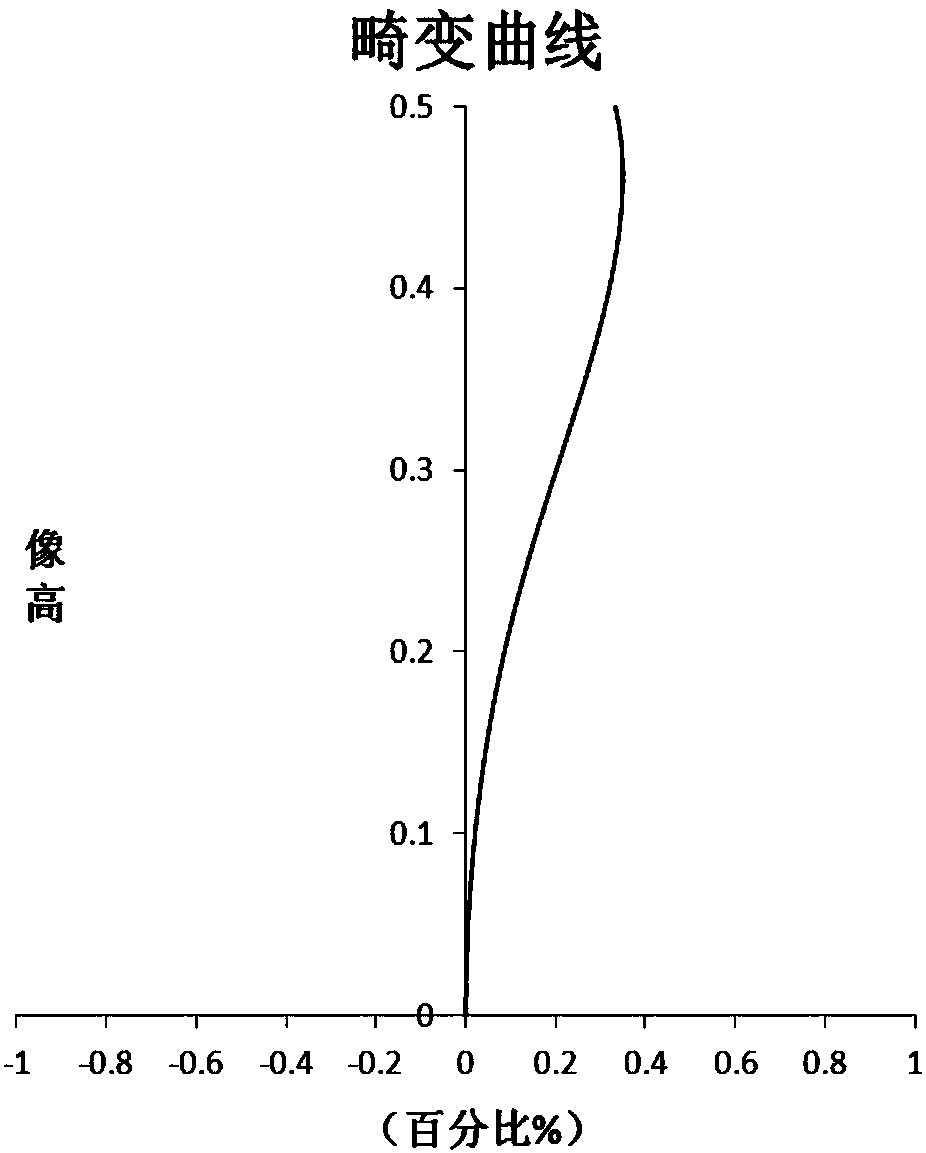

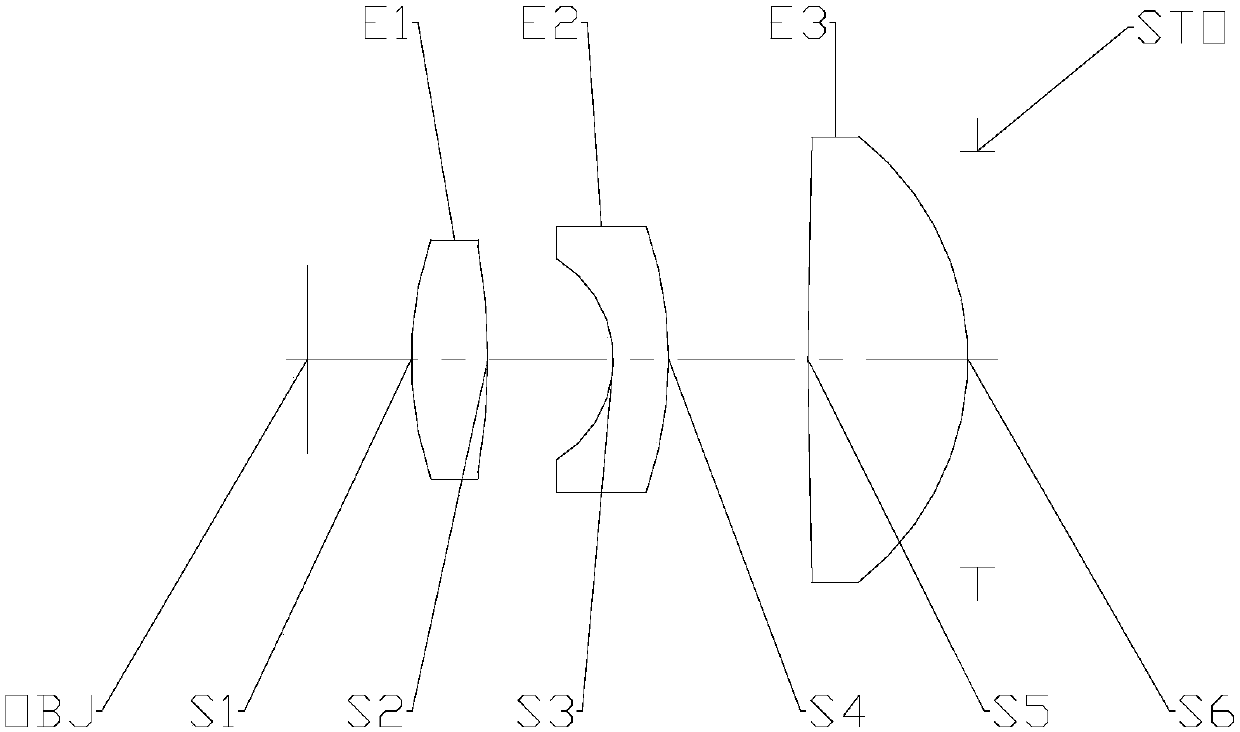

Projection lens

ActiveCN107861316AWith miniaturizationHigh image qualityProjectorsOptical elementsCamera lensOptical axis

The invention discloses a projection lens which sequentially comprises a first lens, a second lens and a third lens from an image source side to an imaging side along an optical axis. The first lens has positive focal power or negative focal power, the second lens has positive focal power or negative focal power, the third lens has positive focal power, and the surface of the imaging side of the third lens is a convex surface. The distance TTL between the image source surface of the projection lens and the surface of the imaging side of the third lens on the optical axis and the total effective focal distance f of the projection lens meet the formula TTL / f<1.4, and the effective focal distance f3 of the third lens and the total effective focal distance f of the projection lens meet the formula 0<f3 / f<18.0.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

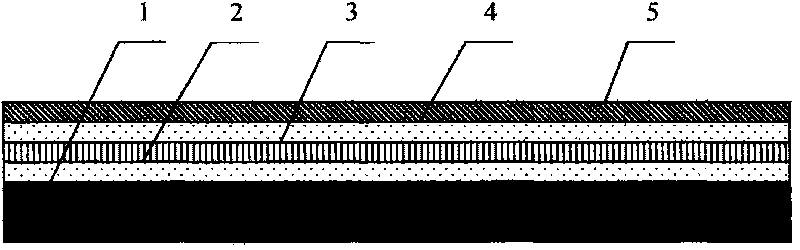

Thermally-conductive graphite interface material and production process thereof

InactiveCN101712217AEasy to useImprove thermal conductivityLamination ancillary operationsSynthetic resin layered productsGraphiteFilm material

The invention relates to a thermally-conductive graphite interface material and a production process thereof. The thermally-conductive graphite interface material is characterized by attaching films to at least one surface of a flexible graphite sheet by adhesives, coating high temperature resistant pressure-sensitive adhesives on the films and attaching separation materials to the other surfacesof the pressure-sensitive adhesives respectively. The production process comprises the procedures of coating, heating and drying, film covering, hot pressing, pressure-sensitive adhesive coating, release material sticking and rolling, etc. The film materials attached to the thermally-conductive graphite interface material on the one hand have the effect of surface insulation and on the other handcan effectively prevent the surface of the heat-exchange graphite material from being scratched, thereby obtaining the thermally-conductive interface material which is stable in use and has good thermal conductivity. The material of the invention is convenient to use. When the material is used, the release paper on the two surfaces is only stripped and is stuck to the heat source surface and the heat-dissipating assembly respectively, thus the heat source (electronic device) surface and the heat-dissipating material or assembly can be tightly coupled.

Owner:DALIAN LICHANG NEW MATERIAL CO LTD

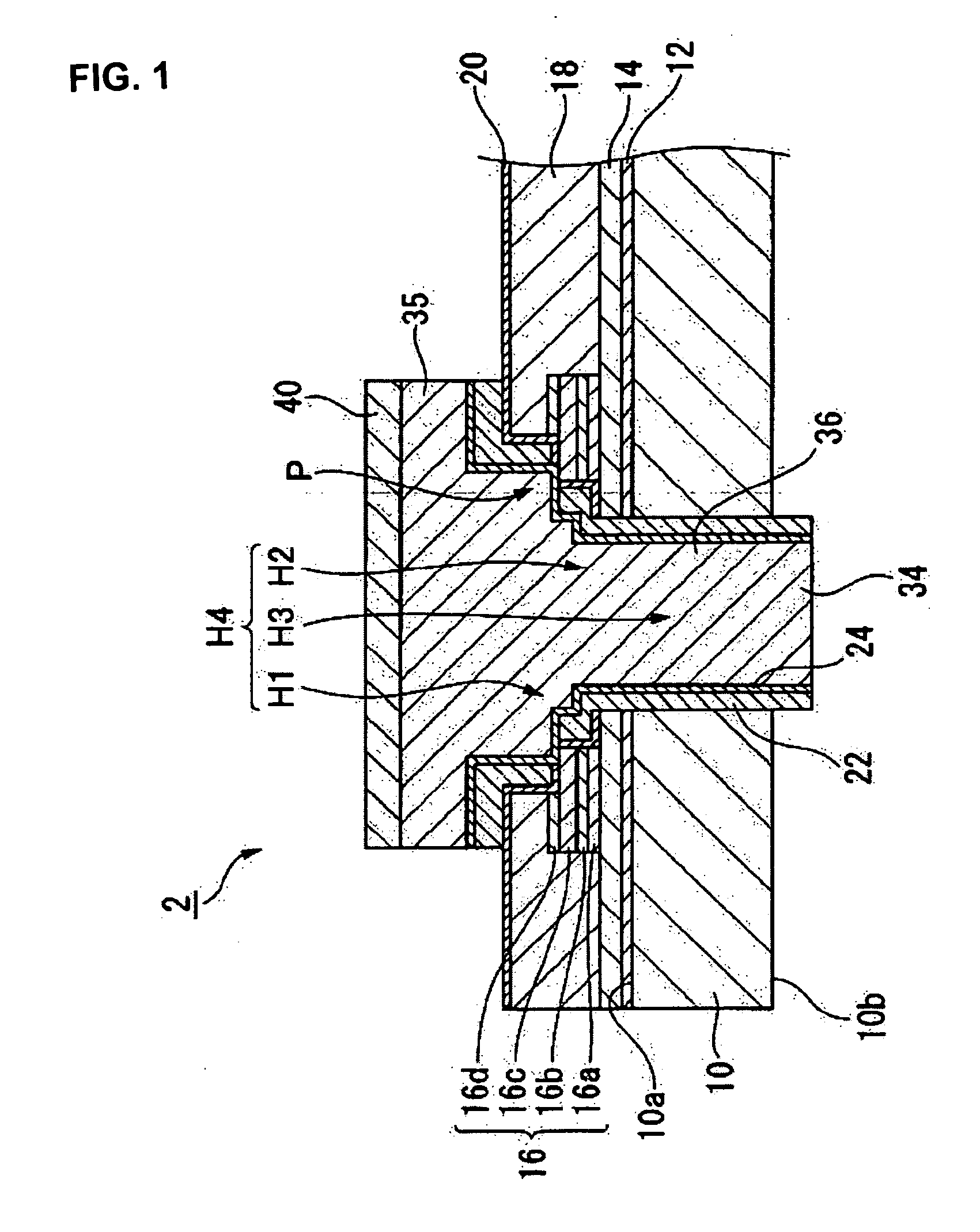

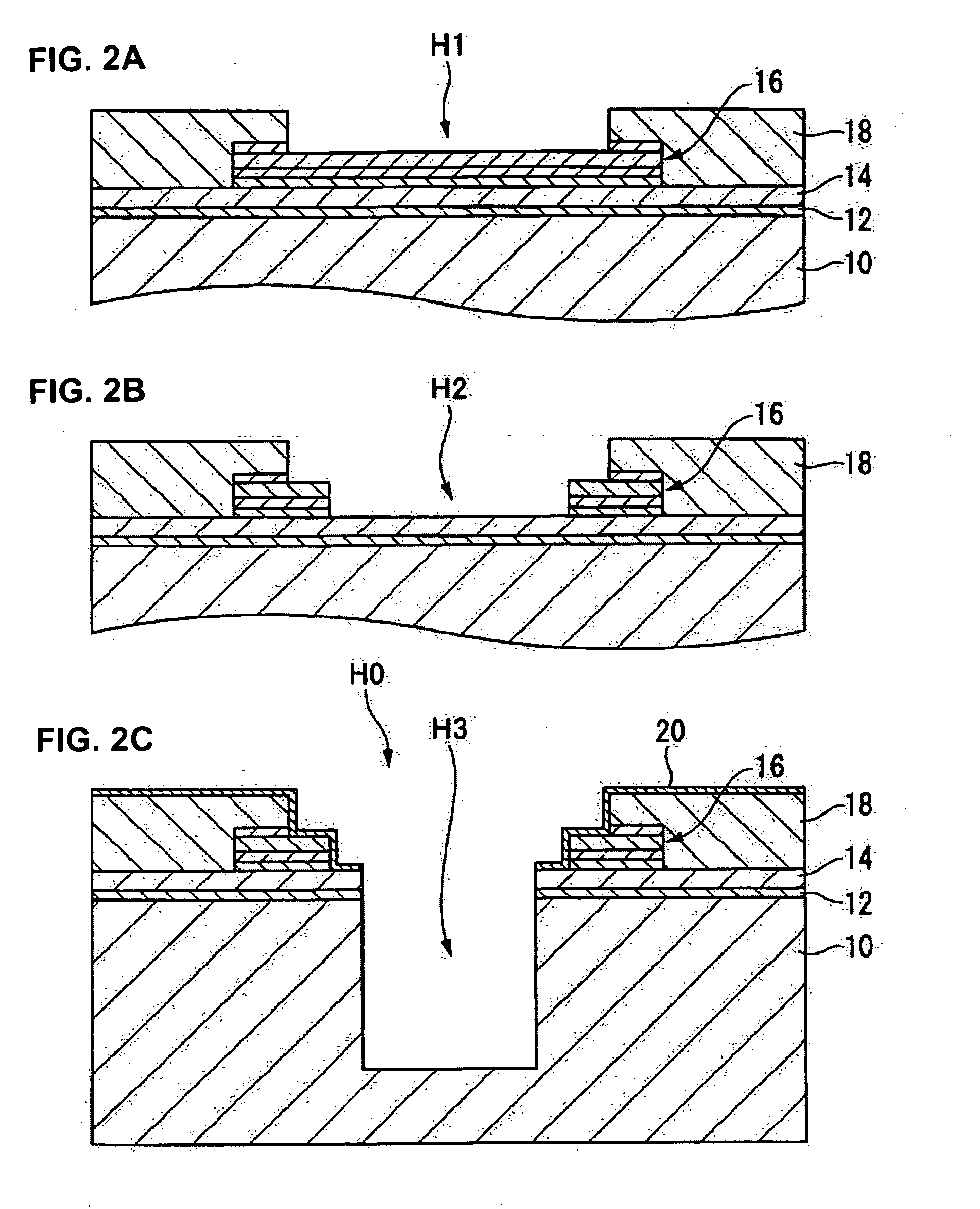

Semiconductor device, method for producing the same, circuit board, and electronic apparatus

InactiveUS20050230805A1Avoid warpingEnsure insulationSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorDevice material

A method for making a semiconductor device having an electrode penetrating a substrate includes (a) forming a concavity in an active face of the substrate; (b) forming an insulating layer on the active face of the substrate and the interior of the concavity; (c) removing at least part of the insulating layer formed outside the concavity; (d) forming the electrode by filling the interior of the concavity with a conductor; and (e) exposing the electrode from a rear face of the substrate opposite to the active face by milling the substrate from the rear face side. In this method, (a) to (e) are performed in that order.

Owner:SEIKO EPSON CORP

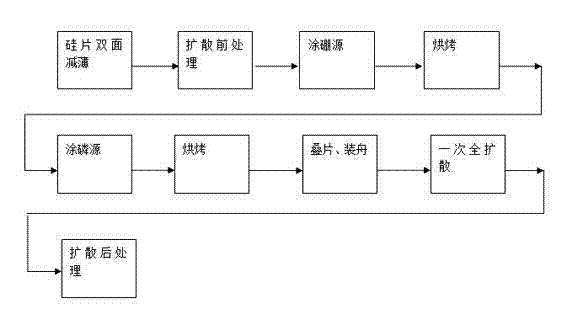

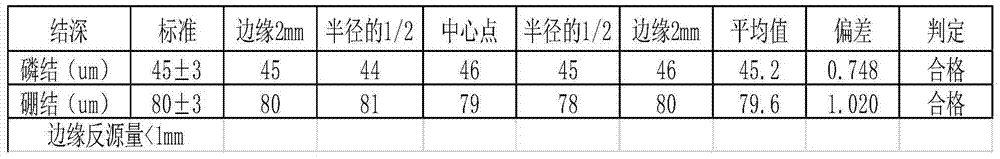

Phosphorus and boron liquid source one-shot perfect diffusion process

ActiveCN104766790ASmall amount of feedbackImprove effective area utilizationSemiconductor/solid-state device manufacturingConcentration gradientProcessing cost

The invention discloses a phosphorus and boron liquid source one-shot perfect diffusion process. The process is mainly implemented through the following steps that one surface of each silicon wafer with two thinned sides is rotated to be coated with a liquid boron source, baked and then rotated again to be coated with a liquid phosphorus source, lamination is conducted after baking, the silicon wafers are stacked on a silicon boat pairwise to be subjected to one-shot perfect diffusion in the mode that each phosphorus source surface is opposite to the corresponding phosphorus source surface and each boron source surface is opposite to the corresponding boron source surface. Diffused junction depth is even, and reverse breakdown voltage of a product can be stable and good in uniformity; the diffusion concentration gradient is reduced, PN junction field intensity can be effectively improved, discharging-resistant capacity of the product is improved, and the reverse surge capacity of the product can be effectively improved; meanwhile, the source return quantity of the edge of the silicon wafer is small, the number of intra defects is small, and product reliability is high. Processing cost is low, the process is simple, and production is easy.

Owner:SUZHOU QILAN POWER ELECTRONICS

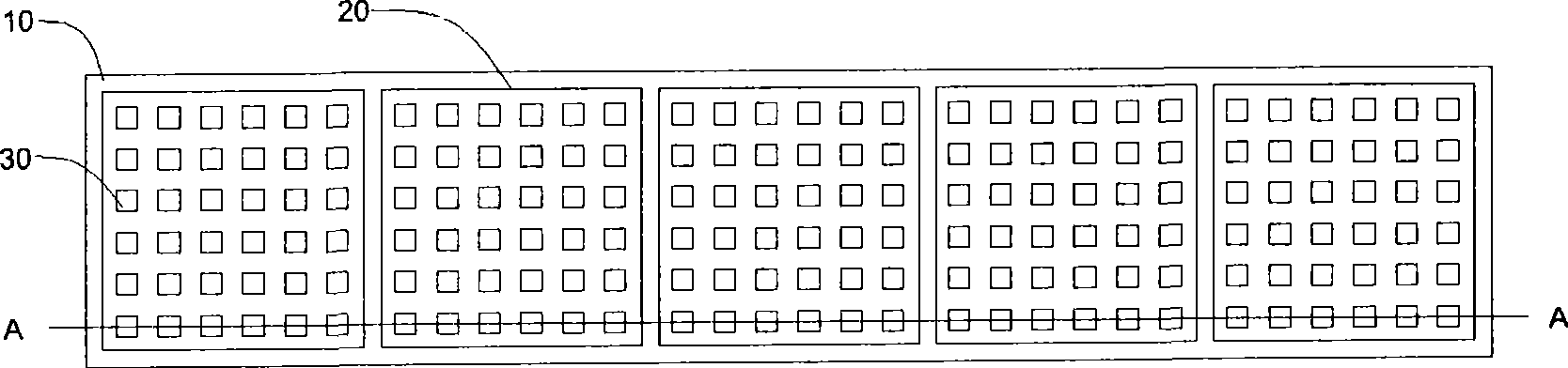

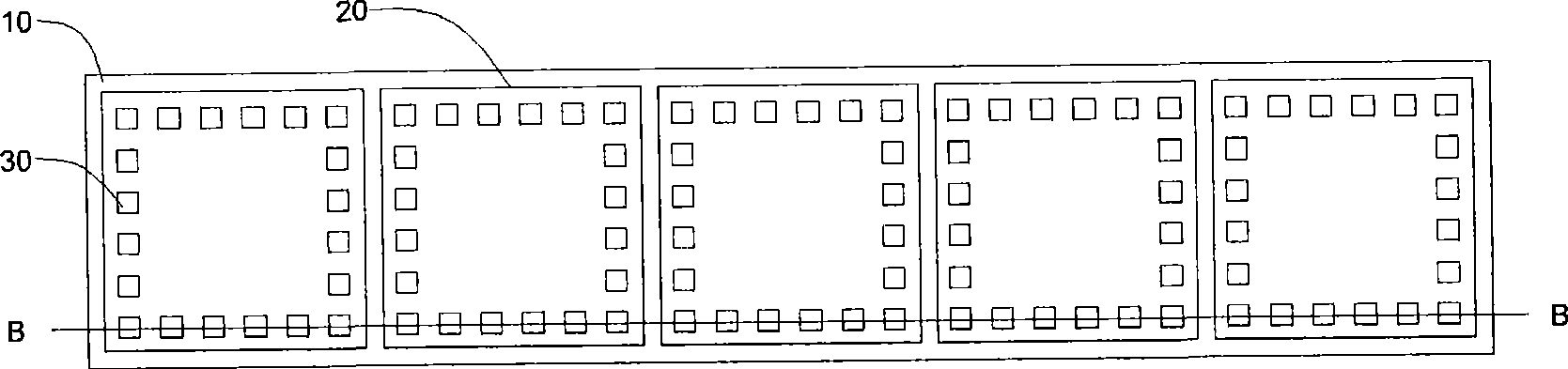

Illumination Device, In Particular for Microscopes

InactiveUS20090224694A1High strengthDischarge tube luminescnet screensLamp detailsGlobal illuminationBrightness perception

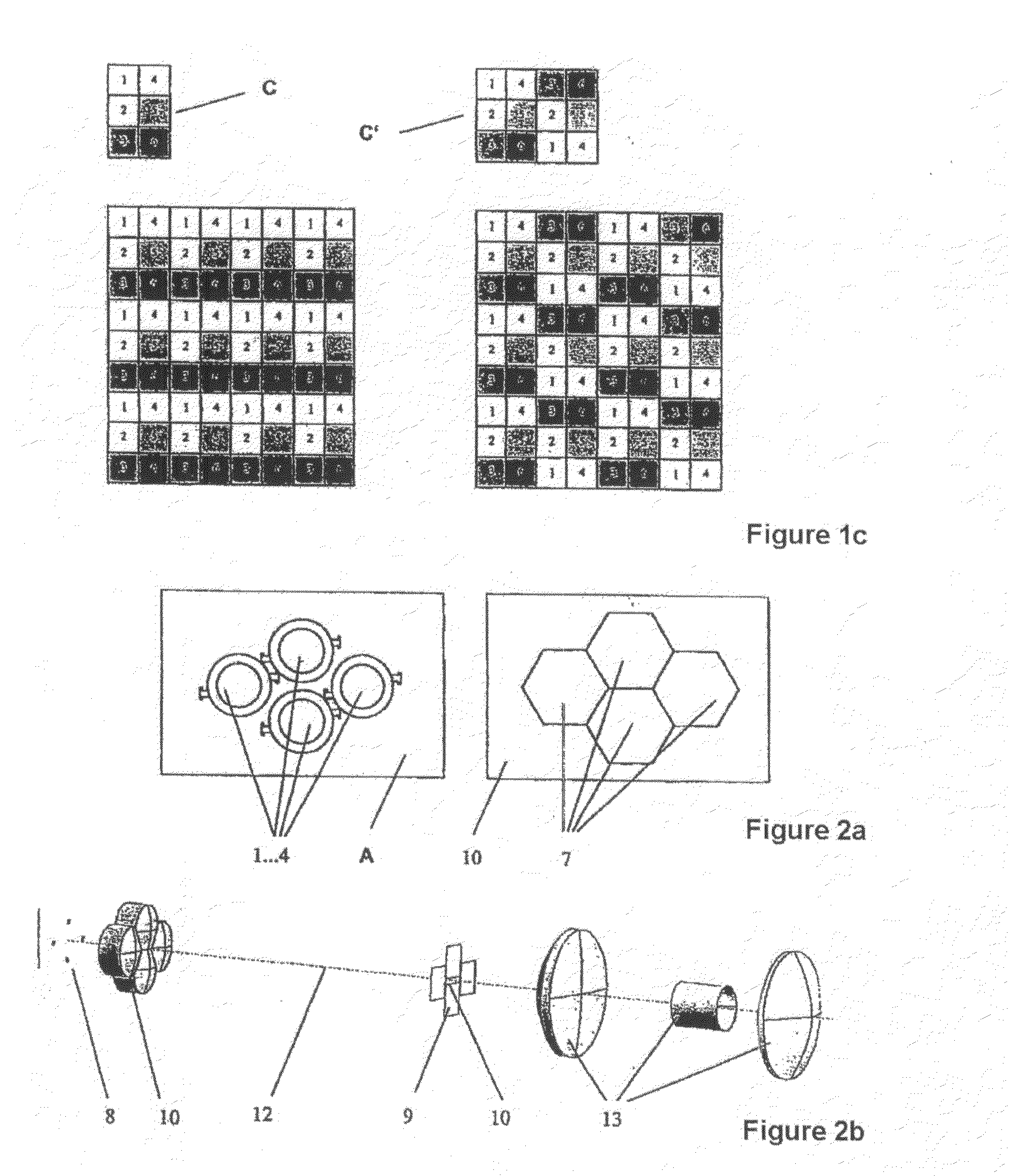

The present invention is directed to a controllable microscope illumination within a microscope system by which all essential contrasting methods in microscopy can be realized. The illumination device according to the invention comprises a plurality of individual light sources which can be regulated with respect to brightness, wherein these individual light sources are formed as unit cells and form a luminous surface by a periodic arrangement. In an advantageous arrangement, imaging optics are associated with each individual light source in order to magnify the image of the source surface of the individual light source so that the images of the source surfaces of adjacent individual light sources touch. Illumination variants for all of the essential contrasting methods in microscopy can be generated by means of the proposed solution. The proposed LED illumination is electronically switchable, can be regulated with respect to brightness, supplies all colors, is long-lasting and economical. LEDs have a long life and are very robust and insensitive to vibrations. The spatial light distribution and the color temperature are adjustable.

Owner:CARL ZEISS MICROSCOPY GMBH

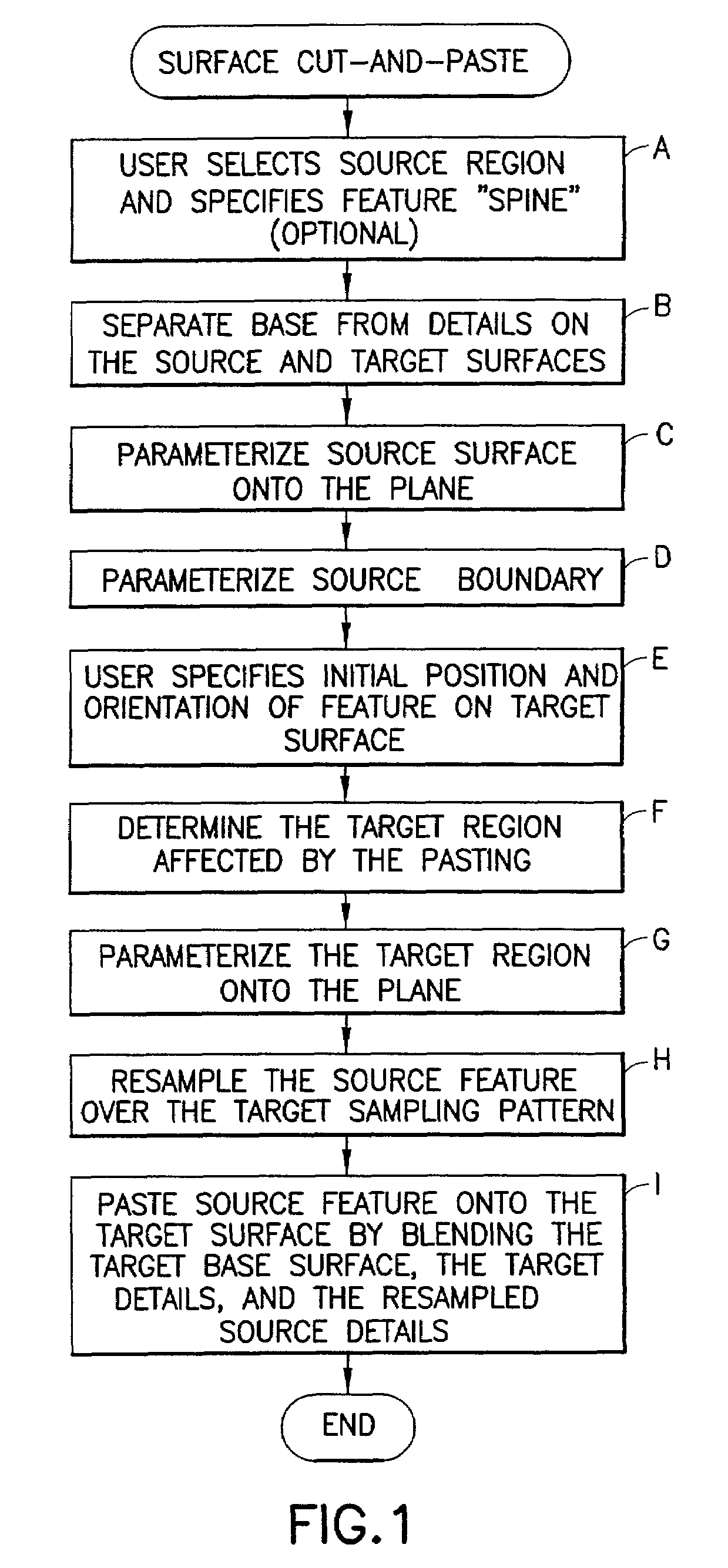

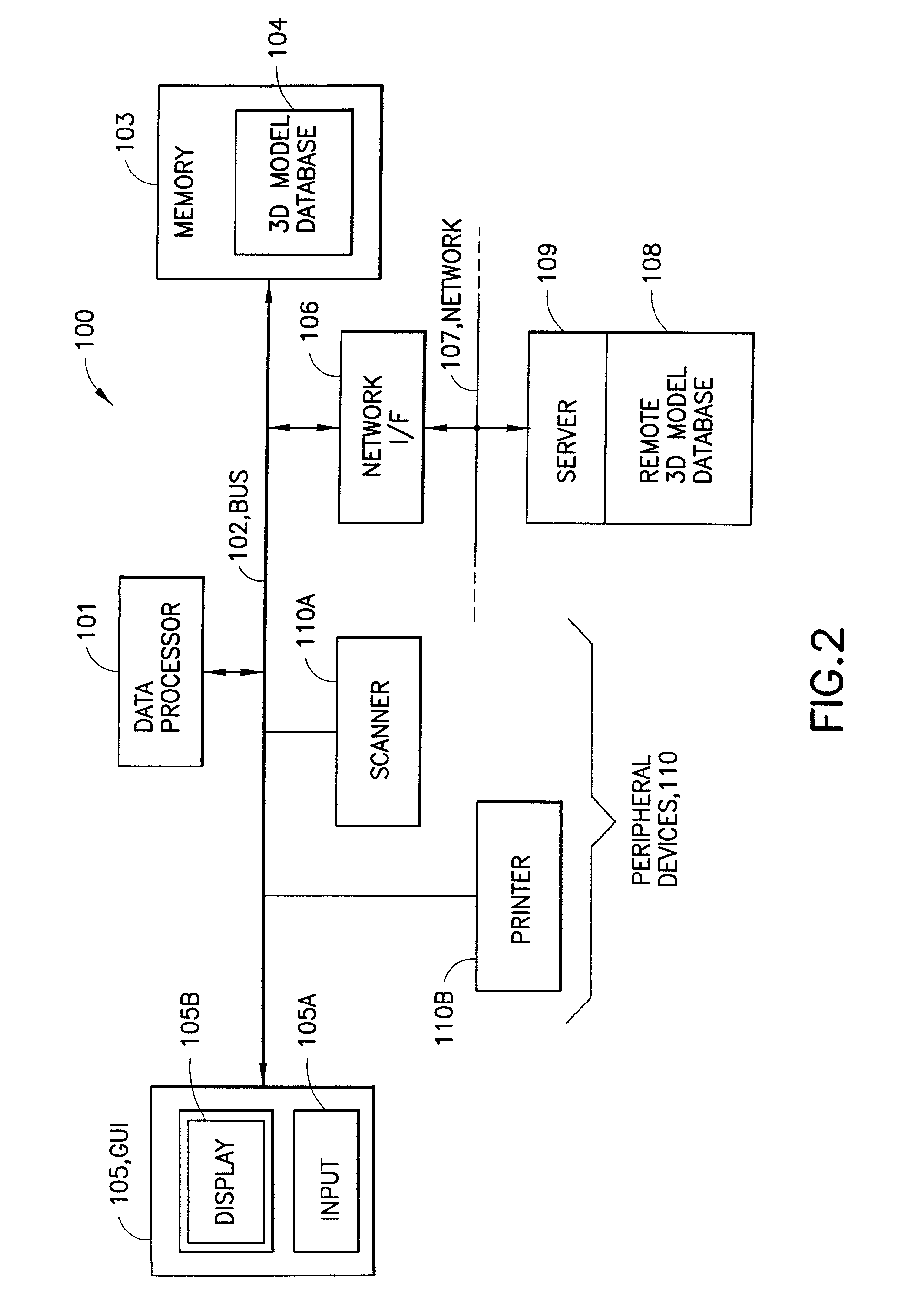

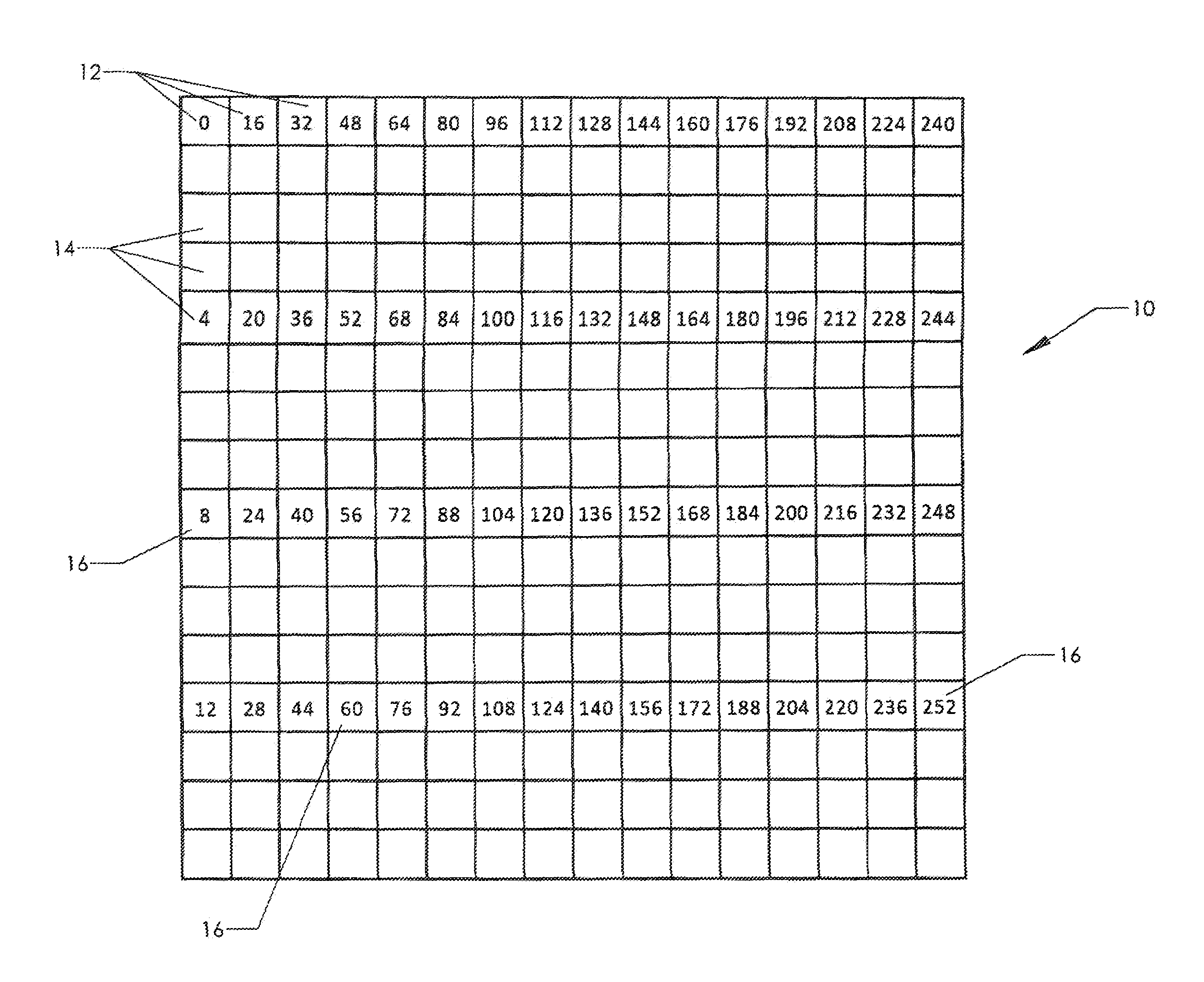

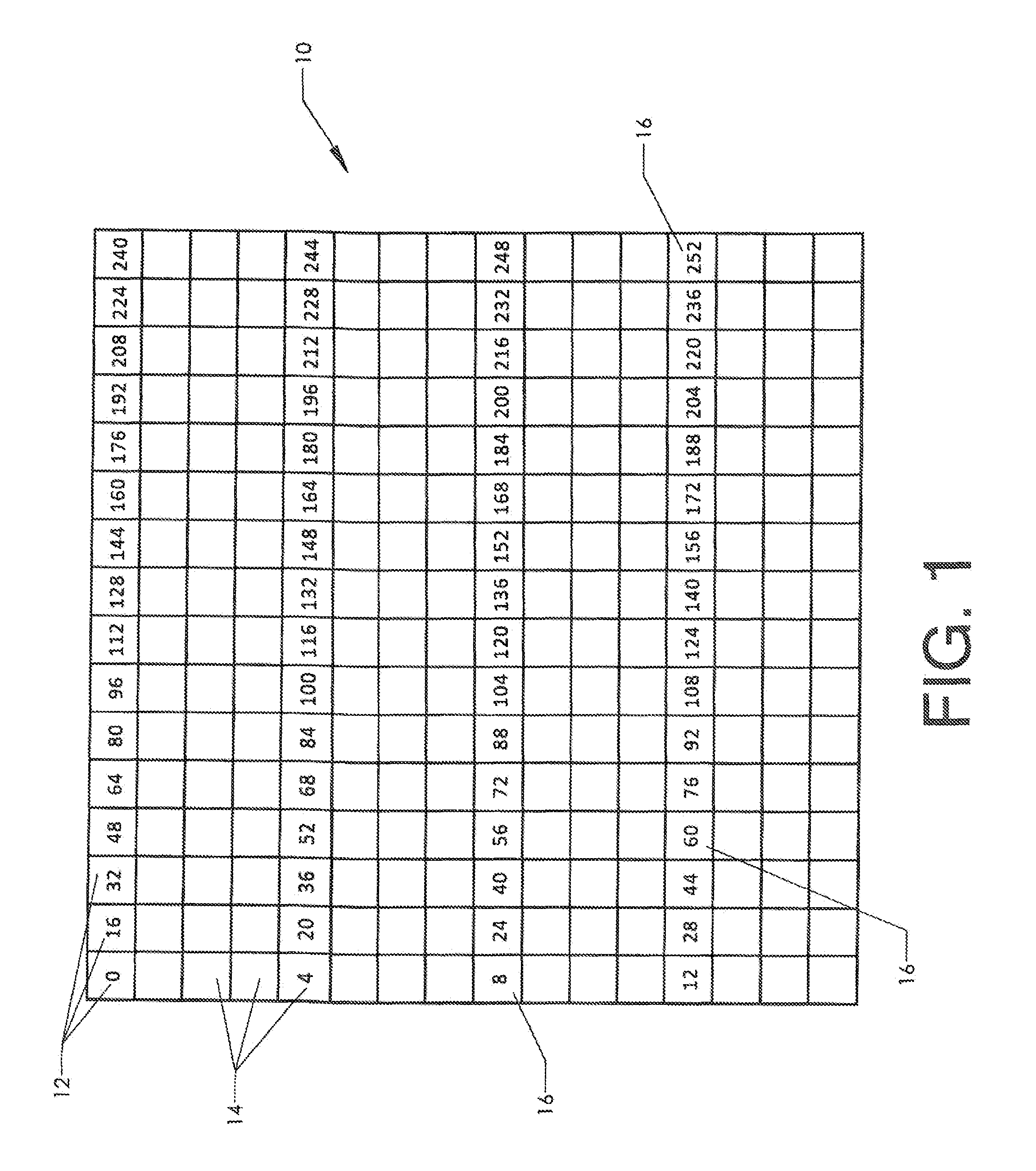

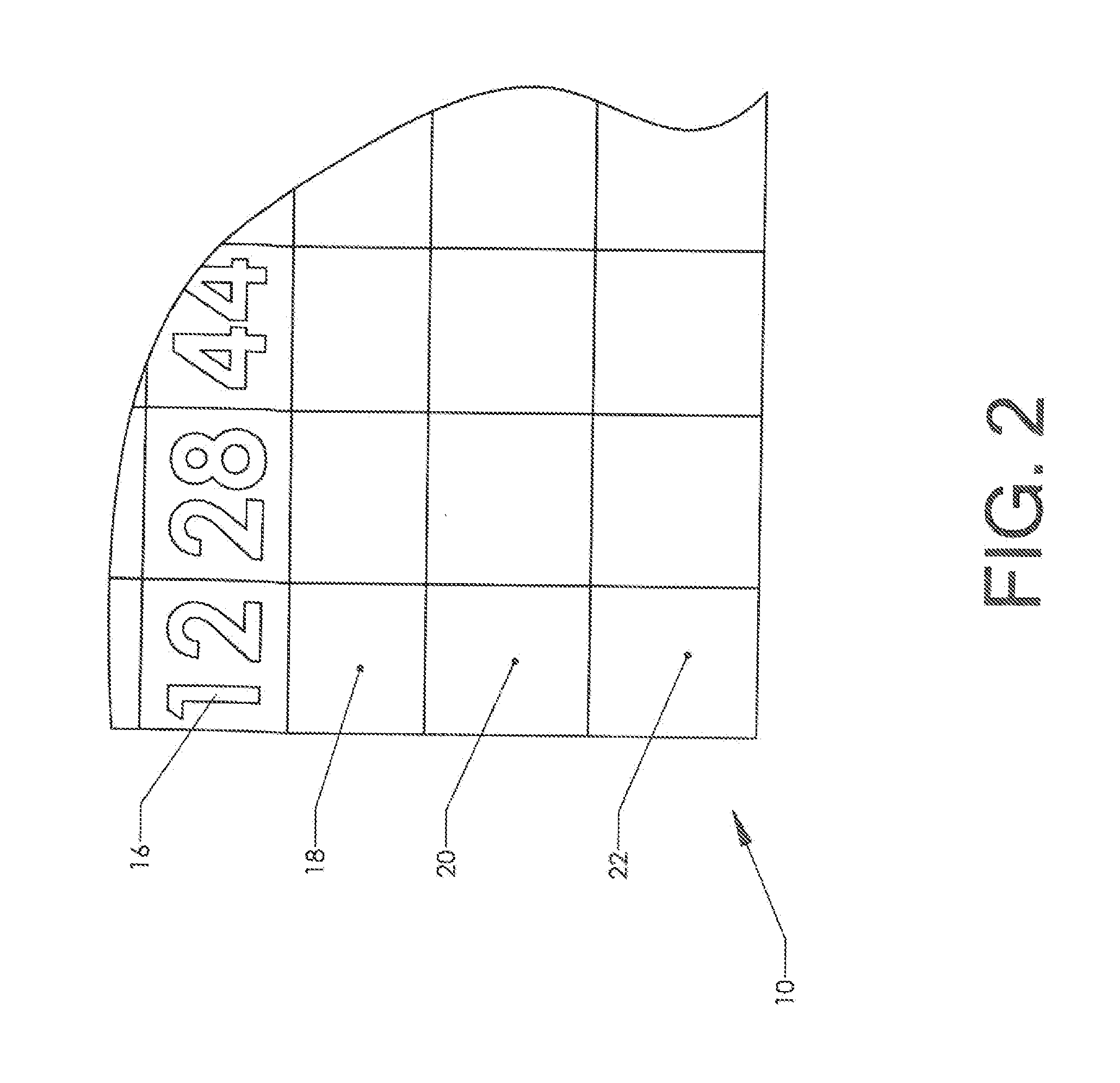

Methods and apparatus for cut-and-paste editing of multiresolution surfaces

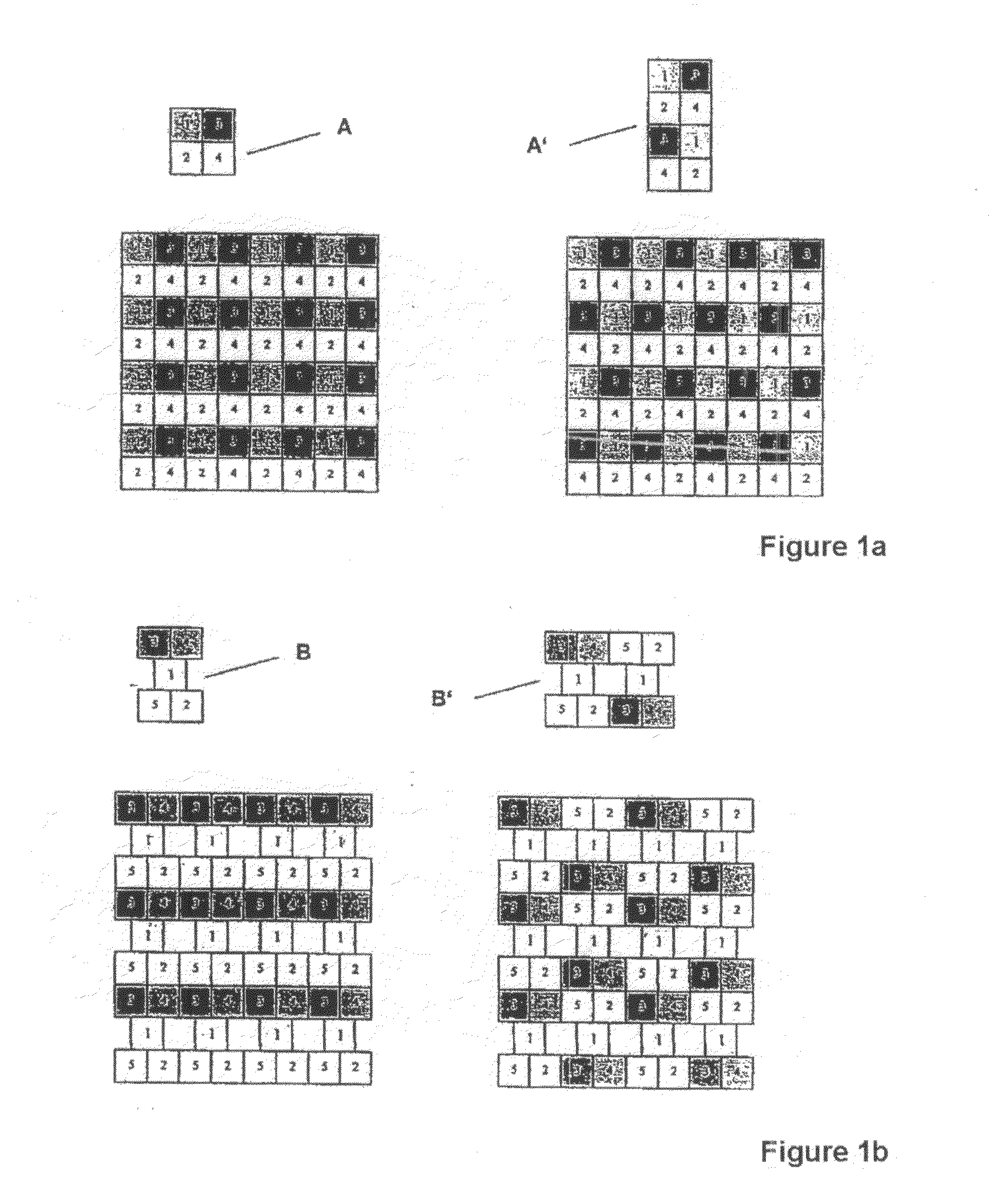

In this invention there are described a set of algorithms based on multiresolution subdivision surfaces that perform at interactive rates and enable intuitive surface cut-and-paste operations. The method includes separating a source region of interest of a source surface into a source base surface and a source detail surface; separating a target region of interest of a target surface into a target base surface and a target detail surface; and pasting the source detail surface onto the target base surface in accordance with a mapping. The step of pasting includes parameterizing and mapping the parameterized regions of interest of the source and target surfaces into an intermediate plane, and aligning the parameterizations using a linear transformation that compensates for first order distortions.

Owner:TWITTER INC

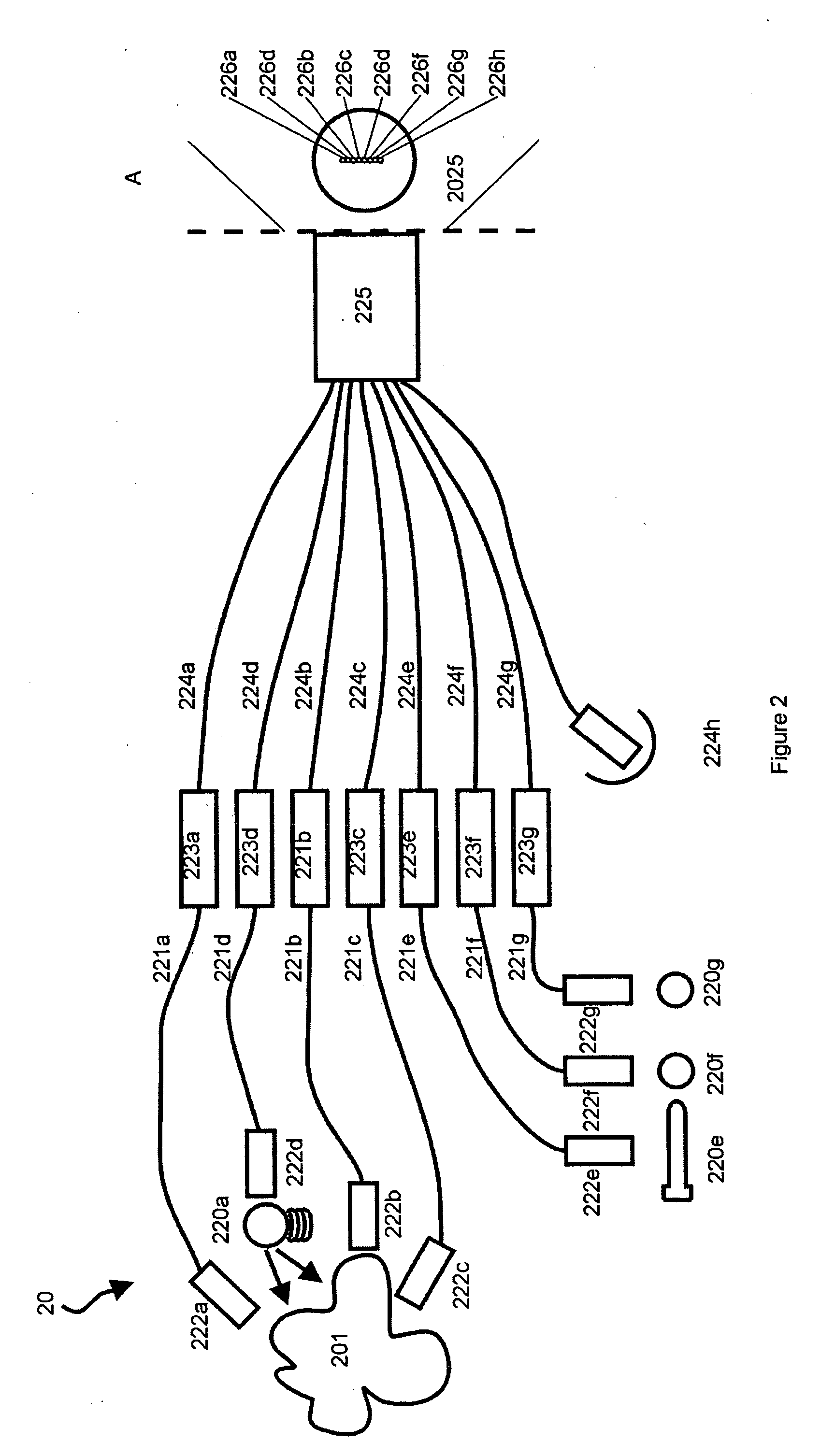

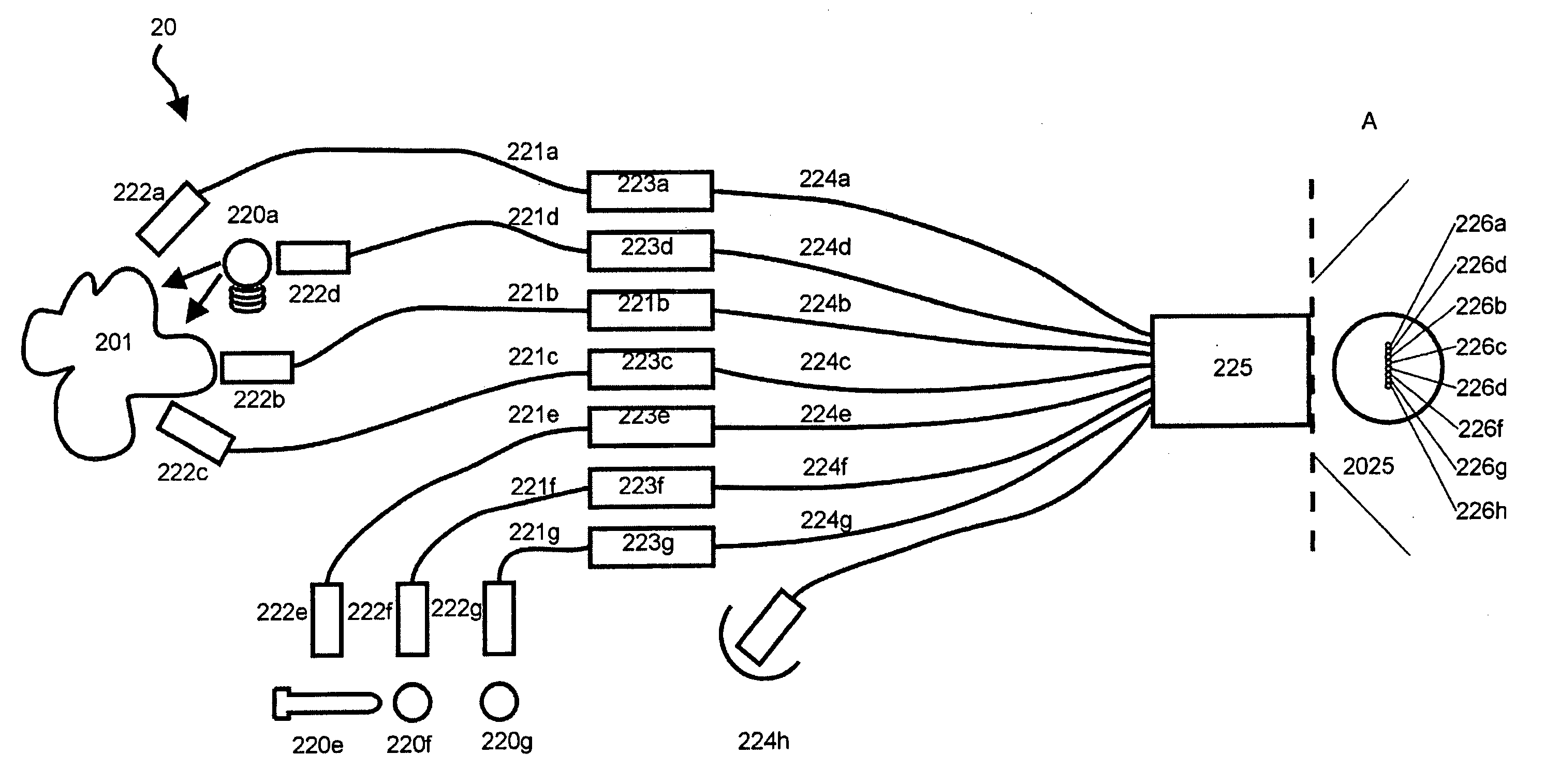

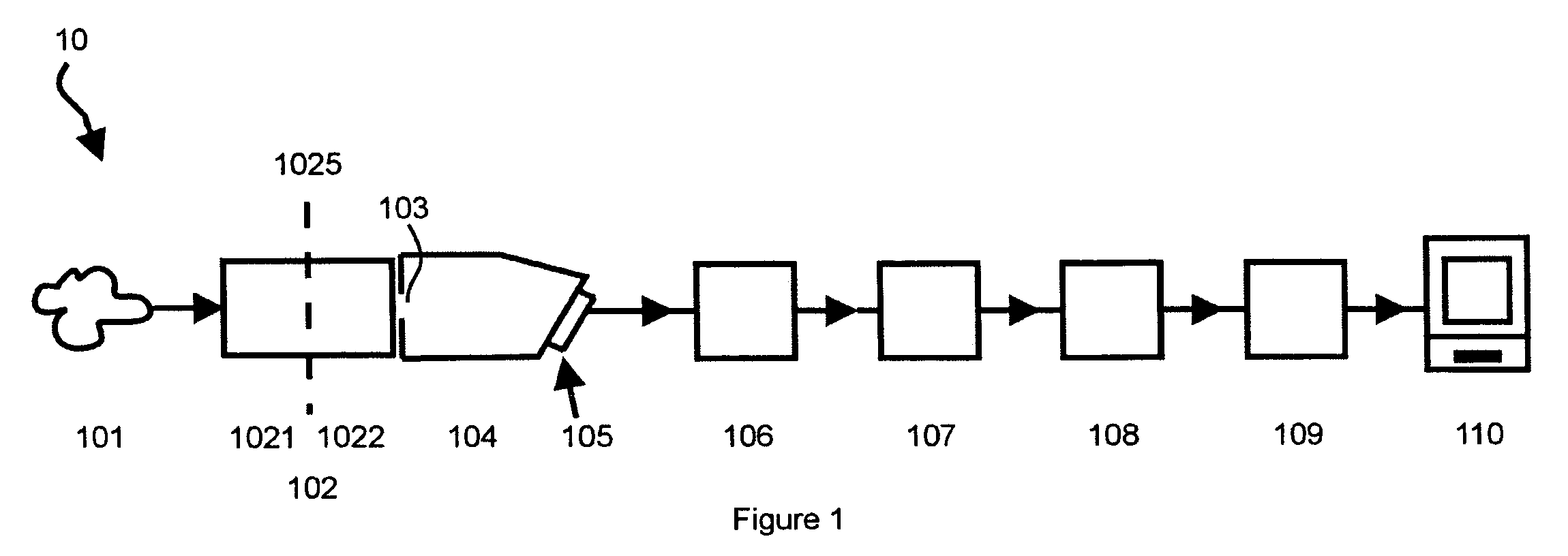

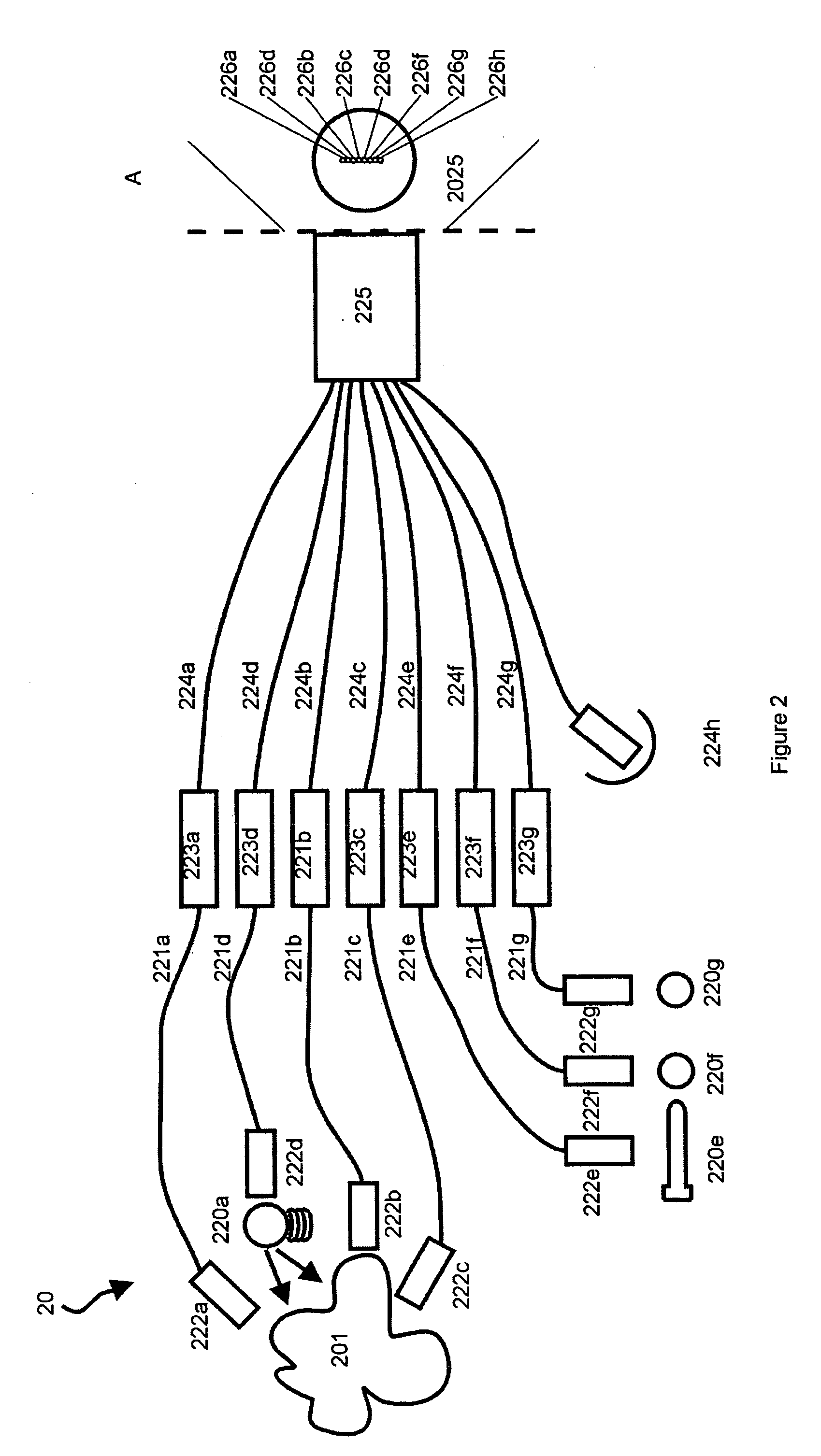

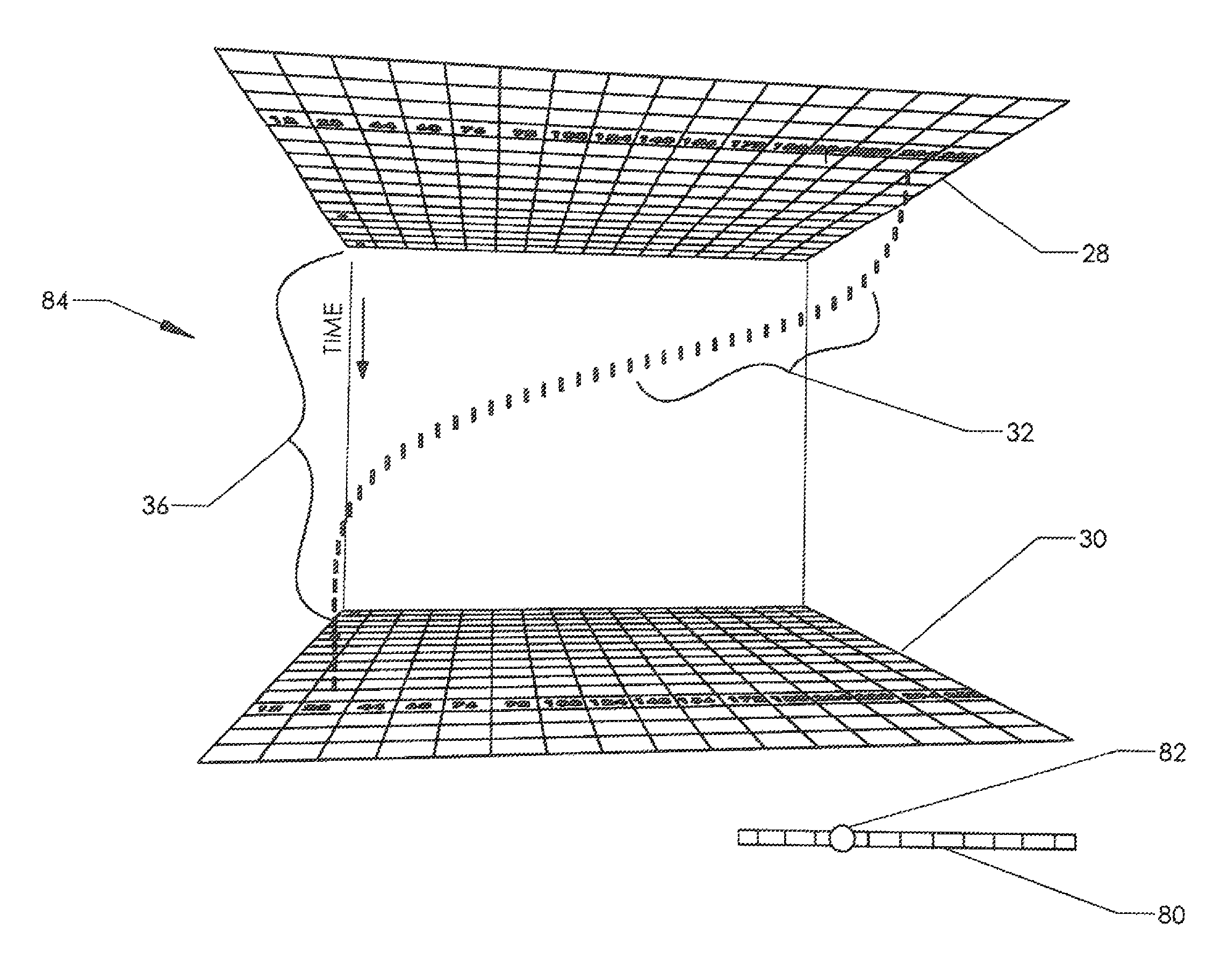

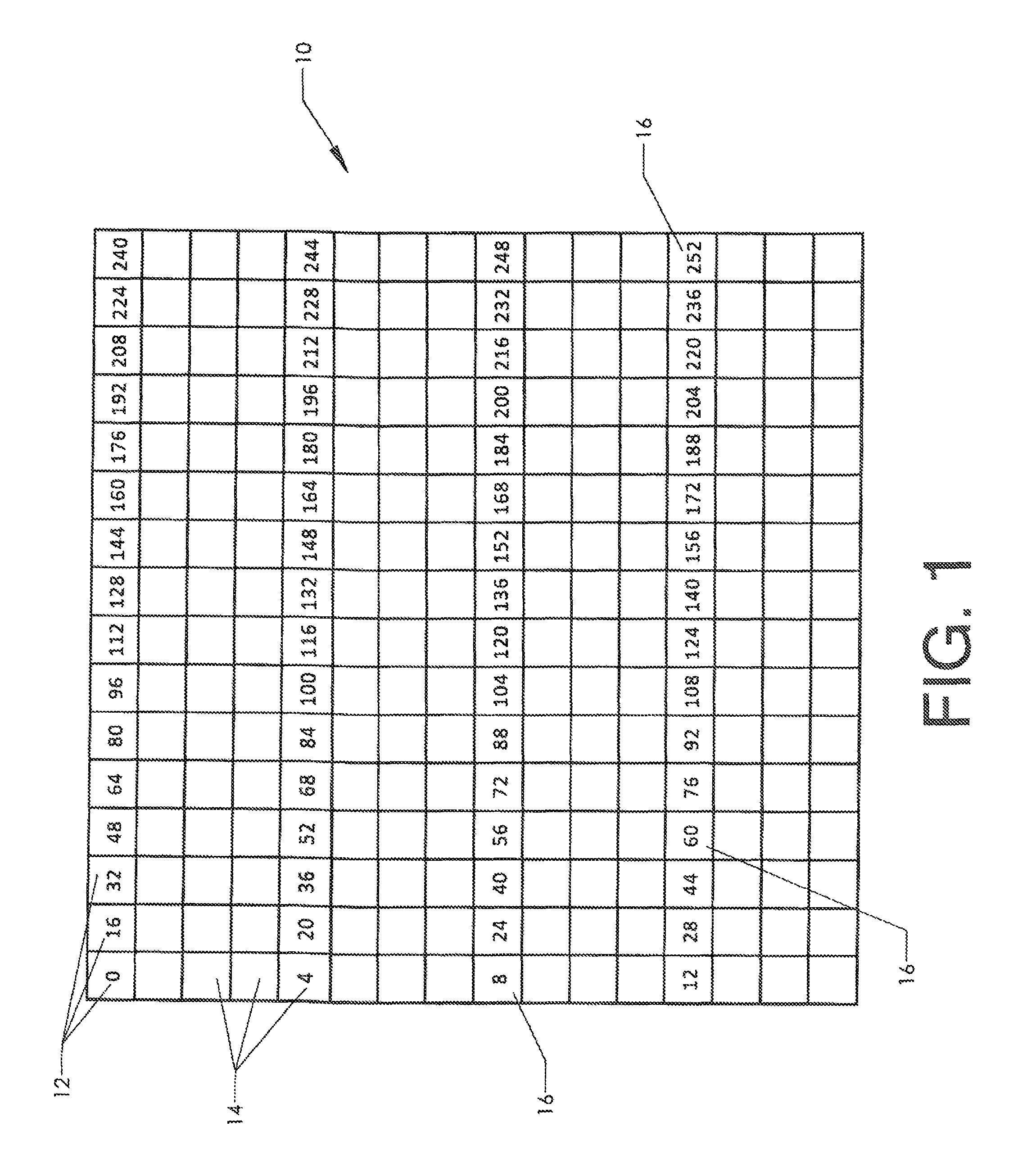

Event data visualization tool

A method for visually depicting complex events. Software agents are preferably employed to assist the human operator by collecting, enriching, selecting, aggregating, and analyzing data so that patterns of interest can be visually flagged or otherwise emphasized in the visual display. Events are depicted as an “event flow” from a source surface to a destination surface. Intervening surfaces may also be defined. The point of origin on the source surface reveals some information about the event flow, as does the point of impact on the destination surface. The event flow may be mapped to one or more intervening surfaces in order to visually depict other characteristics of the event. The entire depiction is rendered in a simulated three-dimensional view. The user is preferably given the ability to pan, zoom, and reorient the vantage point from which the user “views” the depiction on the computer display.

Owner:FLORIDA INST FOR HUMAN & MACHINE COGNITION

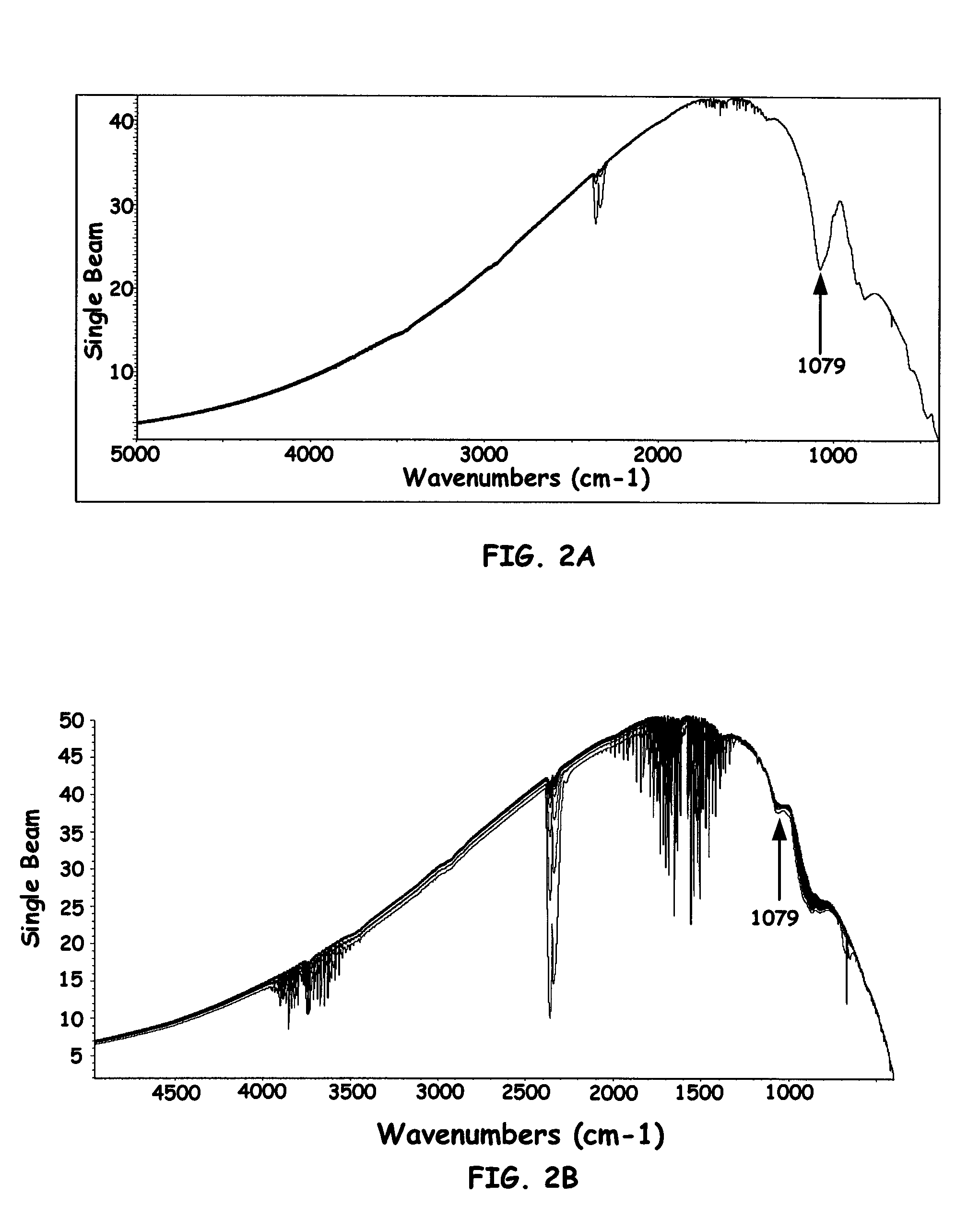

Emissivity enhanced mid IR source

ActiveUS8975604B2High emissivityAccelerate emissionsSolid-state devicesMaterial analysis by optical meansSpectral emissionEmissivity

An infrared (IR) source apparatus that includes a desired infrared source element coupled to an insulating housing so to minimize overall source inefficiency at desired optical bandwidths is introduced. The insulation itself is machined or configured in a way so that the infrared source element is in contact with a designed cavity in the insulation so that the IR source image becomes the average of the insulation material and the infrared element. Such an arrangement of the present invention increases the emissivity of the IR source below about 1500 wave numbers, more often, below about 1100 wave numbers, and even more particularly, at about 1079 wave numbers. Accordingly, the combined emissivity of the infrared source and the insulation substantially enhances spectral emission and eliminates or reduces spectral artifacts from the formation of oxides on the infrared source surfaces.

Owner:THERMO ELECTRONICS SCI INSTR LLC

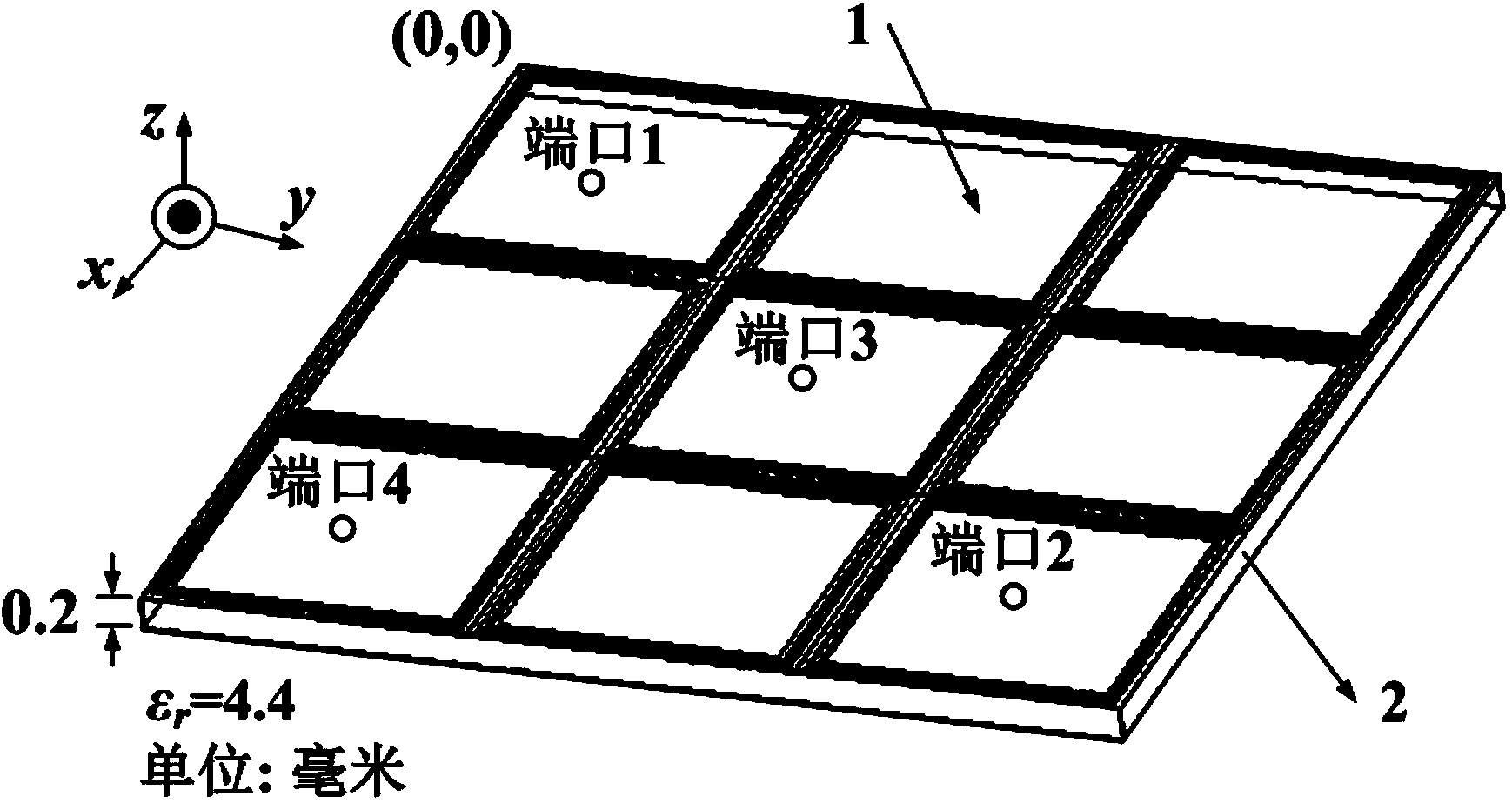

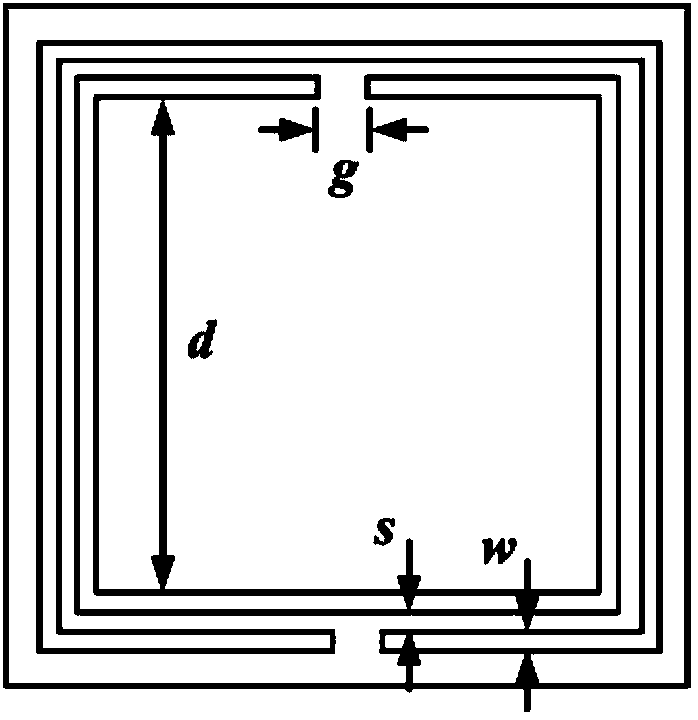

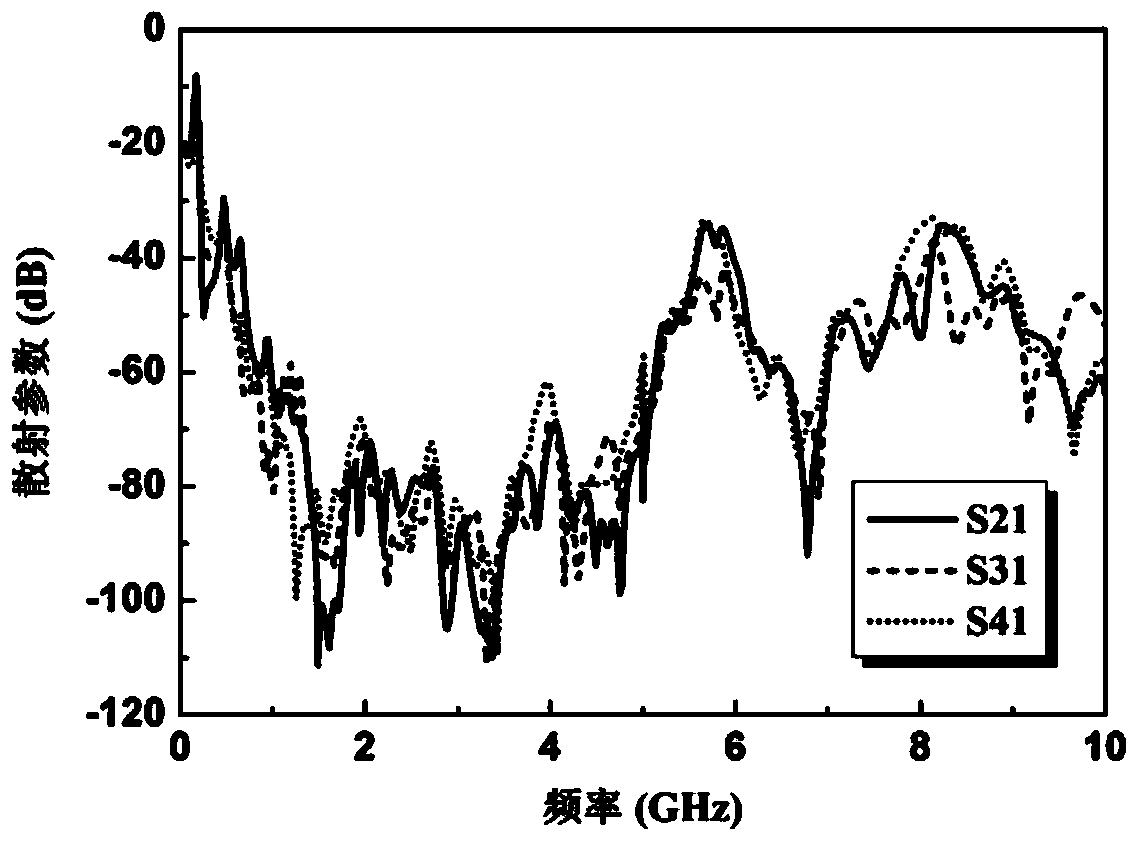

Power source distribution network with small electromagnetic band gap structure units

InactiveCN103683904ASmall sizeReduce the impact of continuityPower conversion systemsMiniaturizationUnit structure

The invention discloses a power source distribution network with small electromagnetic band gap structure units. An electromagnetic band gap structure is etched on a power source surface of the power source distribution network, the ground keeps complete based on the consideration of completeness of signals, and basic units of the plane electromagnetic band gap structure are composed of complementary split ring resonators. The power source distribution network with the small electromagnetic band gap structure units effectively resolves the problem of noise suppression of a synchronous switch in a mixing circuit system, and compared with other typical plane electromagnetic band gap structures, the size of the unit structure can be reduced. In addition, the noise suppression performance of the power source distribution network is hardly influenced by the tiny variation of the size, and the power source distribution network is good in robustness and can be effectively applied to a high-speed multi-layer circuit design.

Owner:SHANGHAI JIAO TONG UNIV

Event Data Visualization Tool

A method for visually depicting complex events. Software agents are preferably employed to assist the human operator by collecting, enriching, selecting, aggregating, and analyzing data so that patterns of interest can be visually flagged or otherwise emphasized in the visual display. Events are depicted as an “event flow” from a source surface to a destination surface. Intervening surfaces may also be defined. The point of origin on the source surface reveals some information about the event flow, as does the point of impact on the destination surface. The event flow may be mapped to one or more intervening surfaces in order to visually depict other characteristics of the event. The entire depiction is rendered in a simulated three-dimensional view. The user is preferably given the ability to pan, zoom, and reorient the vantage point from which the user “views” the depiction on the computer display.

Owner:FLORIDA INST FOR HUMAN & MACHINE COGNITION

Encapsulation structure and method for semi-conductor

InactiveCN101504919AImprove reliabilityImprove packaging benefitsSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipBall grid array

The invention relates to a ball grid array packaging structure and a packaging method thereof. The packaging structure comprises a circuit board provided with an upper surface and a lower surface. The method comprises the following steps that: firstly, the upper surface is provided with patterned conductive contacts, while the lower surface is provided with corresponding metal endpoints which are electrically connected with the patterned conductive contacts; secondly, a plurality of welding pads on the active surface of a semiconductor chip are electrically connected with the patterned conductive contacts; thirdly, a packaging body is used for coating the semiconductor and the upper surface of the circuit board; and finally, a plurality of conducting elements are electrically connected with the metal endpoints on the lower surface of the circuit board.

Owner:叶秀慧

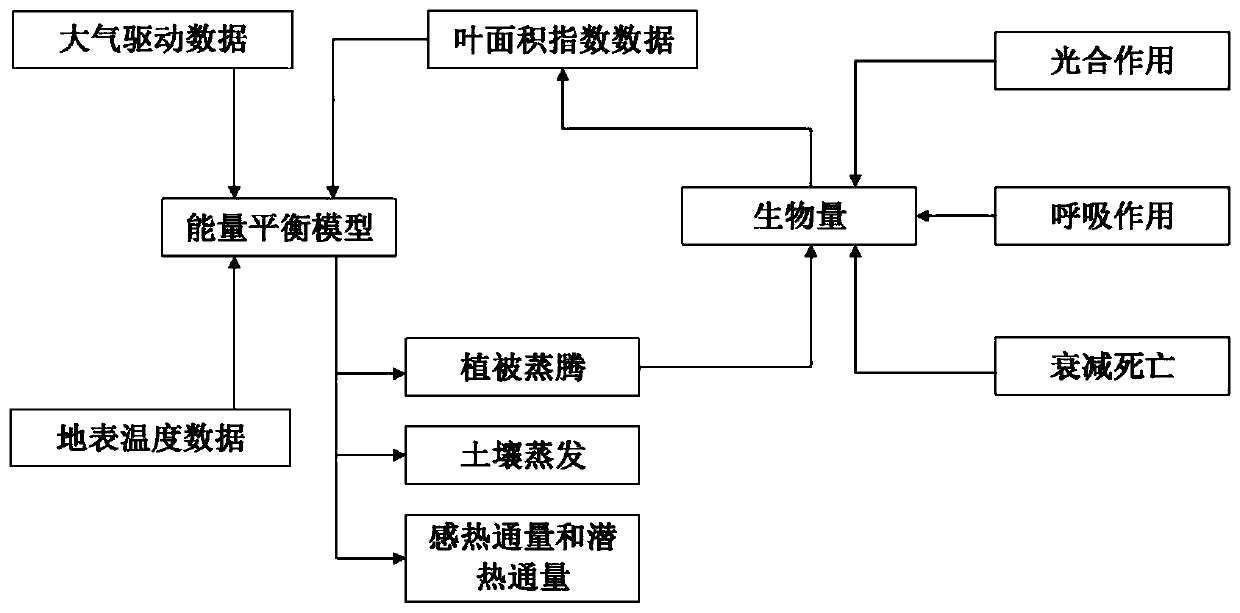

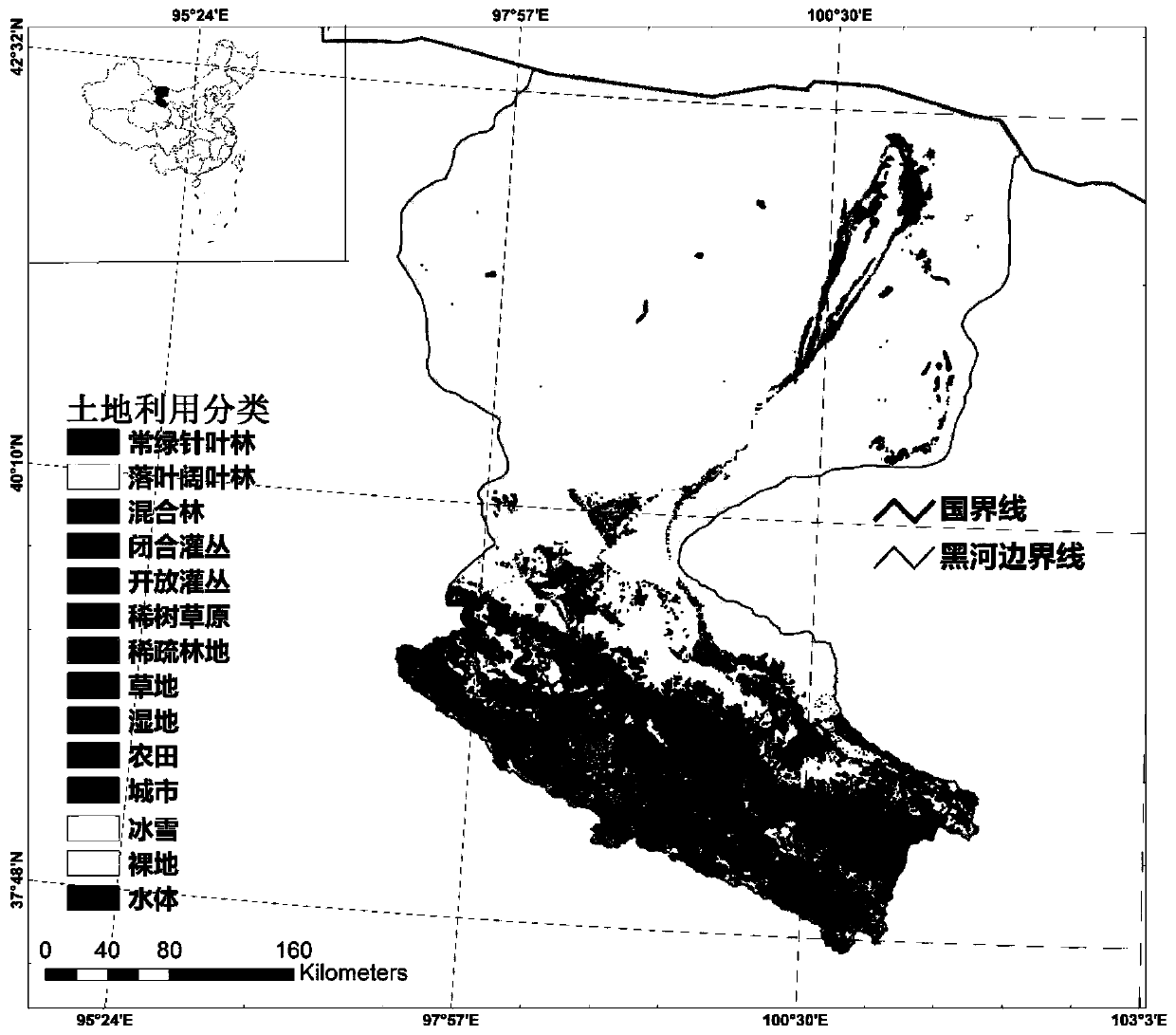

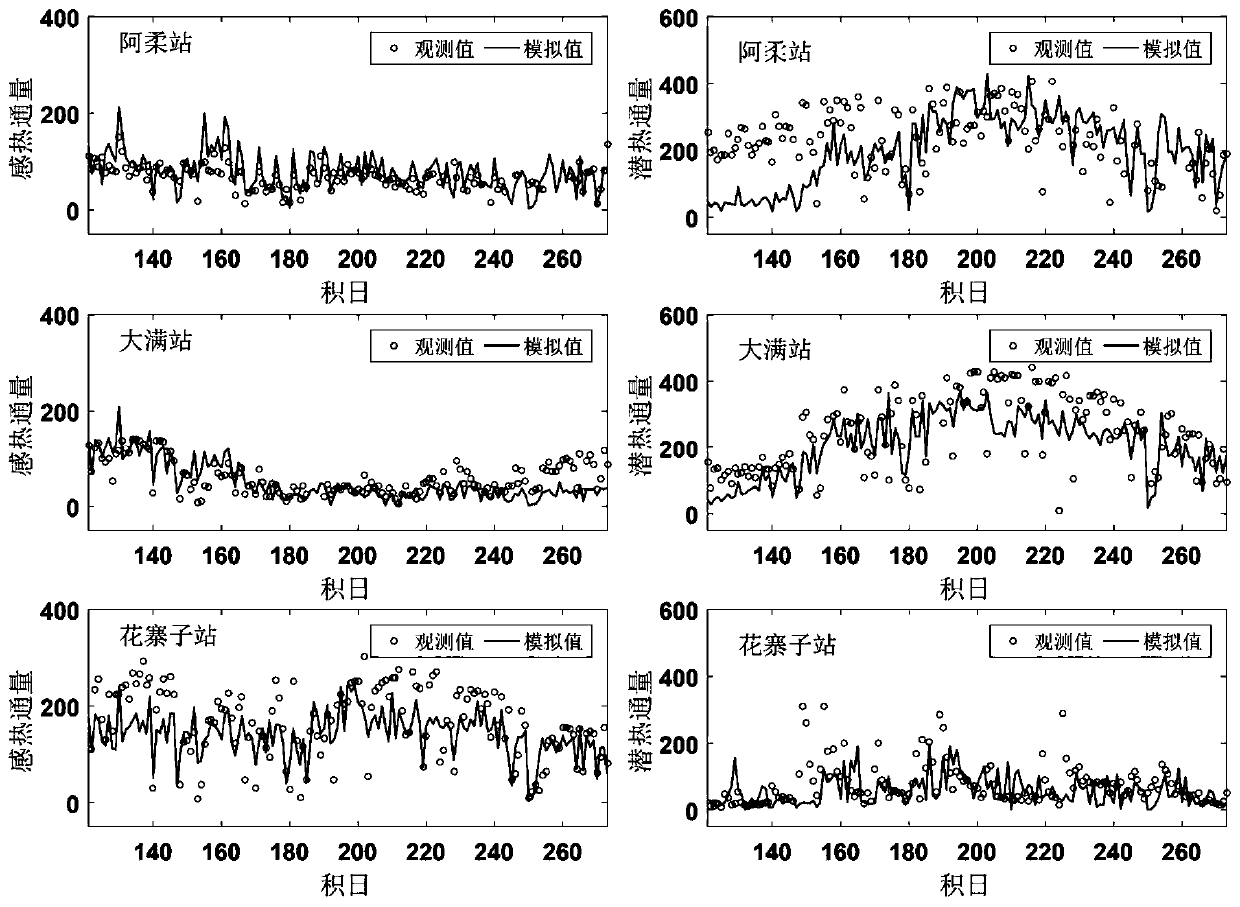

Data assimilation method for estimating space-time continuous surface water heat flux

ActiveCN110472281AImprove simulation accuracyImprove forecast accuracySpecial data processing applicationsHeat fluxDynamic models

The invention provides a data assimilation method for estimating space-time continuous surface water heat flux. The method mainly comprises the following steps: S1, establishing a double-source surface energy balance model; S2, establishing a vegetation dynamic model, and obtaining the dynamic change of the vegetation according to the vegetation dynamic model; S3, establishing a relationship according to the vegetation dynamic model and the specific leaf area established in the step S2 to obtain an LAI dynamic model; S4, coupling the double-source earth surface energy balance model establishedin the step S1 with the vegetation dynamic model established in the step S2; S5, constructing a data assimilation framework based on the double-source earth surface energy balance model and the vegetation dynamic model coupled in the S4; and S6, estimating the heat flux of the surface water according to the data assimilation framework constructed in the S5. According to the method, the model state variables are optimized. Errors caused by observation data loss or model parameters of a traditional model are reduced. Therefore, the simulation precision and the prediction precision of the modelare improved.

Owner:BEIJING NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com