Building method for laser welding heat source model

A laser welding and heat source model technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of difficult realization of laser heat source and low calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] Specific embodiment one: the establishment method of a kind of laser welding heat source model of this embodiment is realized according to the following steps:

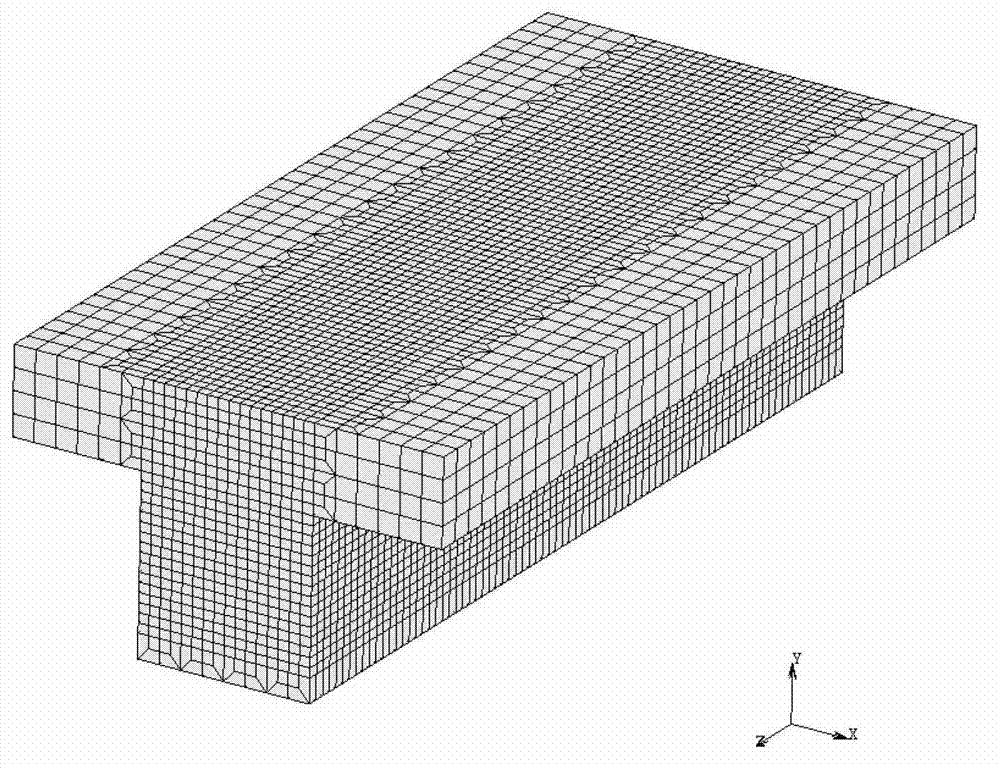

[0038] Step 1: Establish a 3D finite element mesh model:

[0039] Establish the geometric model of the workpiece in the 3D modeling software, and use meshing software or finite element calculation software to mesh the workpiece;

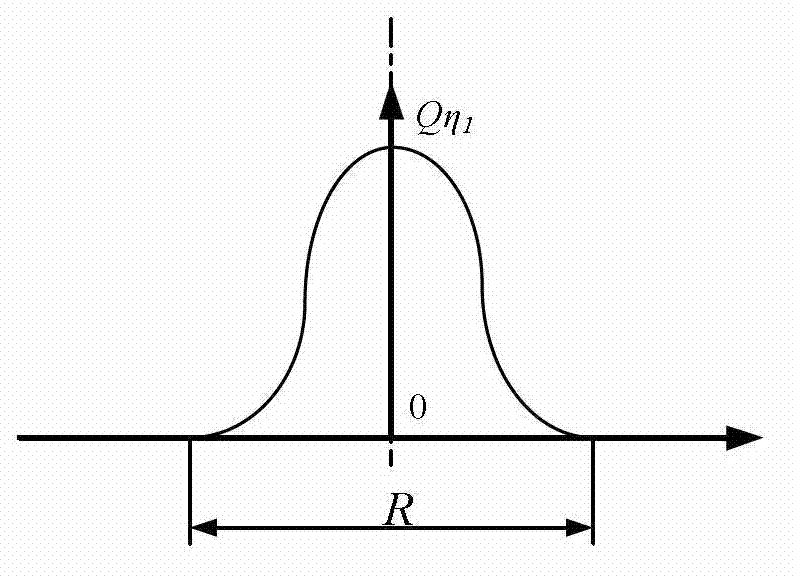

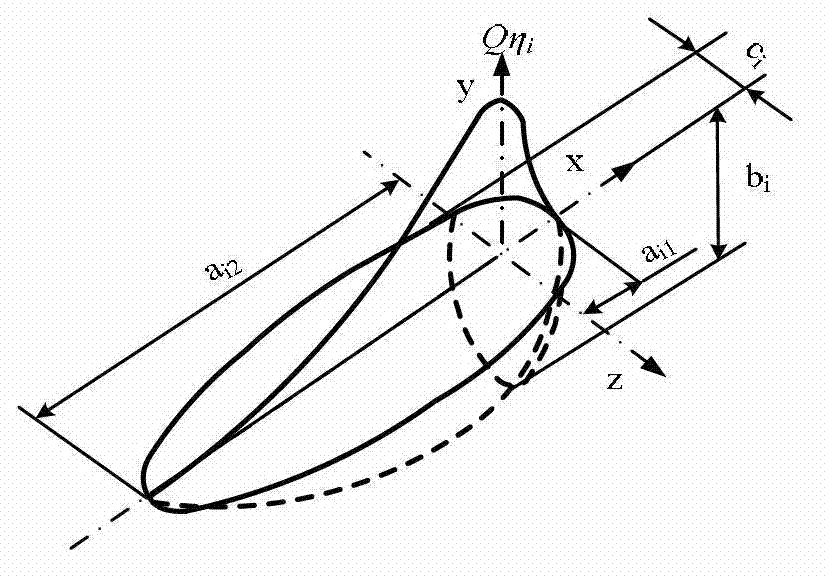

[0040] Step 2: Establish a Gaussian heat source model on the surface of the heat source:

[0041] q ( x , y , t ) = 3 Q η 1 π R 2 exp ( - 3 ( x ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com