Single-track railway high-gas tunnel face bench shift forward device

A single-track railway and face technology, which is used in transportation and packaging, earth drilling, underground transportation, etc., can solve the problems of damage to the mechanical equipment of the side station workers, easy falling of construction tools, and inaccurate positioning of the bench. To achieve the effect of reducing the hidden dangers of machinery and equipment and the probability of construction personnel injury accidents, reducing the incidence of accidents, and reducing the probability of gas accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

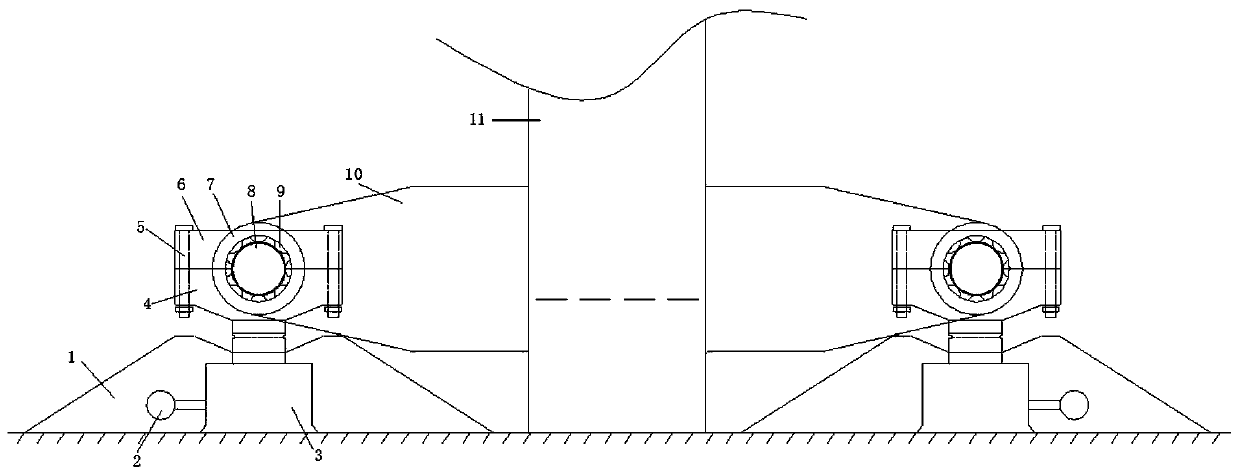

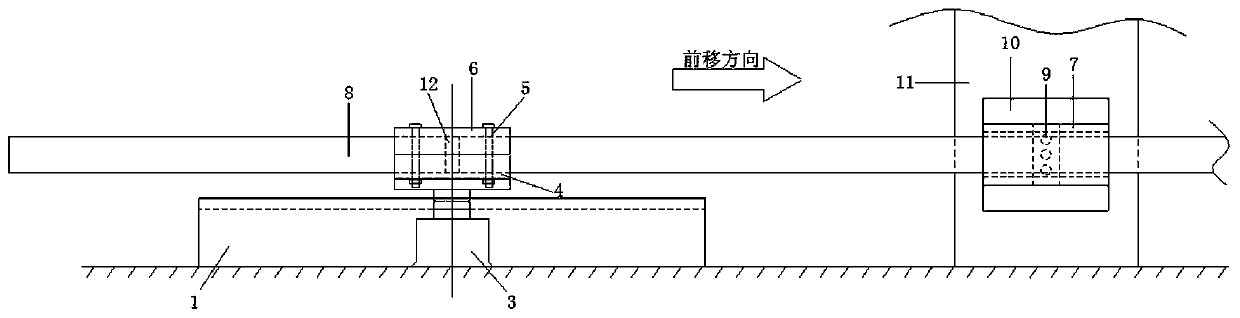

[0016] The invention discloses a forward moving device for the face platform of a single-track railway high-gas tunnel, which includes a lifting part and a forward sliding part of the platform, and the sliding part is designed by adopting the principle that steel pipes are locked as the sliding track of the platform. The specific structure is as figure 1 , 2 As shown, it includes a stand column 11, and multiple sets of clamps are arranged symmetrically on both sides of the stand column 11. The clamps include a clamp base 10 welded to the stand column 11, and a ball bearing outer ring is installed in the clamp base 10. 7. The outer ring 7 of the ball bearing installs the ball 9 through the ball cage, and the ball 9 of the outer ring 7 of the ball bearing is set with cement mortar and pours the galvanized steel pipe 8 inside. The stand lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com