Identification method of machining characteristics of complex parts of airplane

A technology of processing features and recognition methods, applied in computer control, instruments, simulators, etc., can solve problems such as automatic acquisition, tool selection and tool path calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings. This implementation example is carried out on the premise of the technical solution of the invention. This paper provides detailed implementation methods and specific implementation processes, but the protection scope of the present invention is not limited to the following implementation examples.

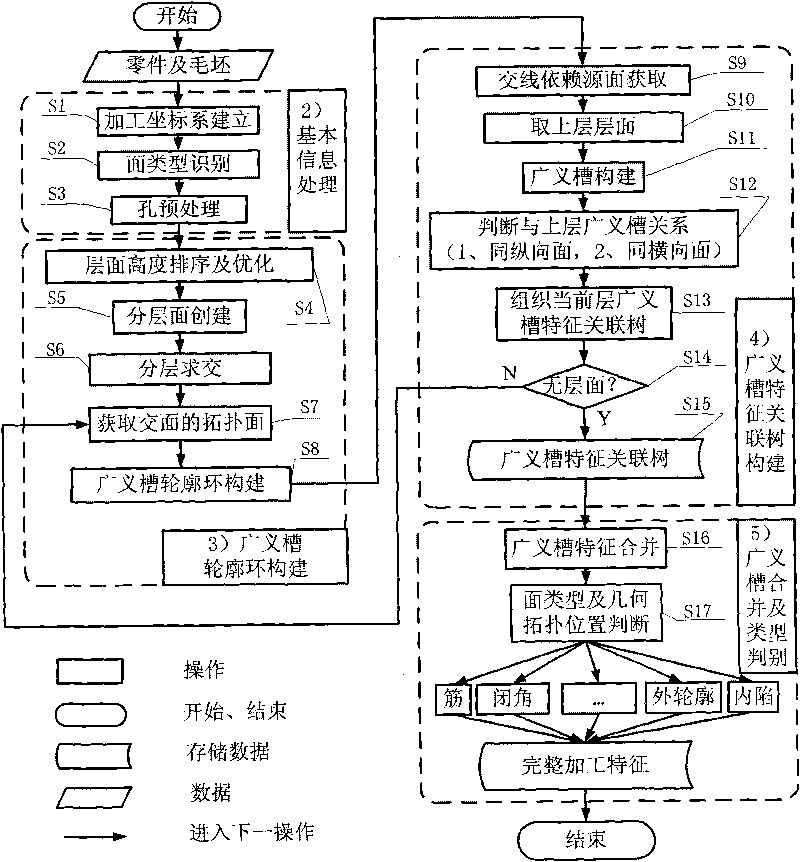

[0079]figure 1 Shown is the specific flow of the realization of the processing feature recognition method proposed by the present invention, and its realization steps are: 1) loading of parts and blank models; 2) basic information processing; 3) construction of generalized groove contour ring; 4) generalized groove feature association Tree construction; 5) generalized slot feature merging and type discrimination; where:

[0080] Step 1): Part and blank model loading, that is, loading the part and blank model into the existing CAD / CAM system; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com