Thermally-conductive graphite interface material and production process thereof

An interface material, graphite heat conduction technology, used in cooling/ventilation/heating transformation, synthetic resin layered products, lamination devices, etc. The effect of surface scratches, ease of use, and good thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

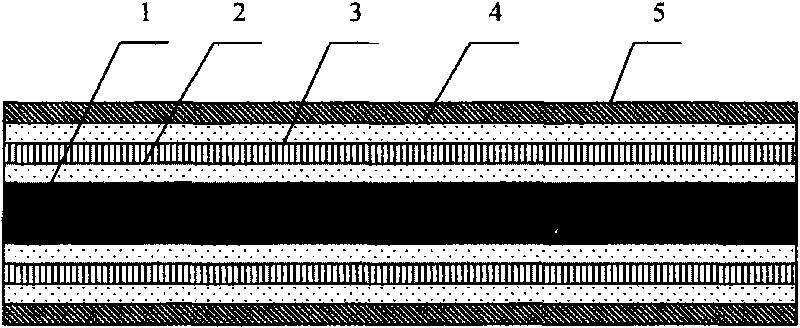

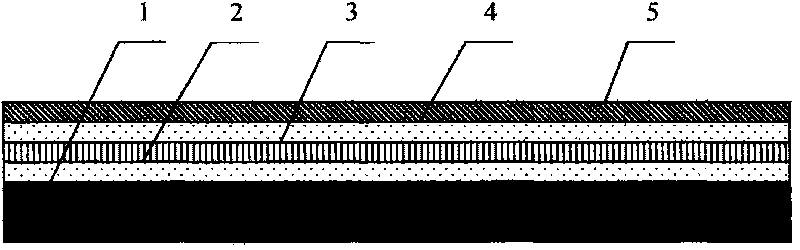

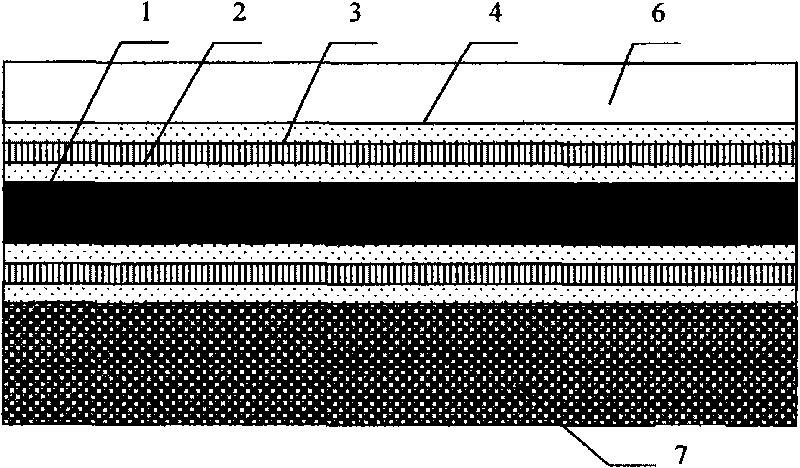

[0030] Such as figure 1 As shown, the graphite composite material of the present invention includes: flexible graphite sheet 1, polyurethane adhesive 2, PET film 3, high temperature pressure sensitive adhesive 4 and separation material 5.

[0031] In this embodiment, a flexible graphite sheet 1 with a thickness of 1mm is selected, and the flexible graphite sheet 1 is evenly coated with a layer of polyurethane adhesive 2 on the surface in contact with the graphite sheet through the rubber roller on the grid, and the adhesive is controlled. The thickness of the liquid is between 2 μm and 3 μm; then heat the graphite sheet 1 coated with the adhesive under infrared rays for two minutes, take it out and dry it, and cover the surface with a layer of PET film 3 with a thickness of 0.012 mm; pass it through a hot pressing roller Hot pressing at 60°C, where the control pressure is 0.5MPa, to complete the single-sided lamination of the flexible graphite sheet. According to repeating th...

Embodiment 2

[0034] Such as figure 1 As shown, the graphite composite material of the present invention includes: a flexible graphite sheet 1 , a polyurethane adhesive 2 , a polyimide film 3 , a high-temperature pressure-sensitive adhesive 4 and a separation material 5 .

[0035]In this embodiment, a flexible graphite sheet 1 with a thickness of 0.15 mm is selected, and the surface of the flexible graphite sheet 1 that is in contact with the graphite sheet is evenly coated with a layer of polyurethane adhesive 2 by scraper coating, and the glue is controlled. The thickness is between 2 μm and 3 μm; after the graphite sheet 1 coated with the adhesive is heated and dried by constant temperature hot air, the surface is covered with a layer of polyimide film 3 with a thickness of 0.006 mm; Hot pressing, wherein the control pressure is 0.8MPa, to complete the single-sided lamination of the flexible graphite sheet. Repeat the above steps to adhere a layer of polyimide film 3 on the other side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Heat resistant | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com