Chopped fiber dispersion and preparation method thereof

A short-cut fiber and dispersion technology, which is applied in the field of fiber fabric materials, can solve problems such as easy agglomeration, poor hydrophilicity, and poor dispersion, and achieve the effects of high production efficiency, improved dispersion, and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of chopped fiber dispersion of the present invention and preparation method thereof, it is characterized in that comprising following operation steps:

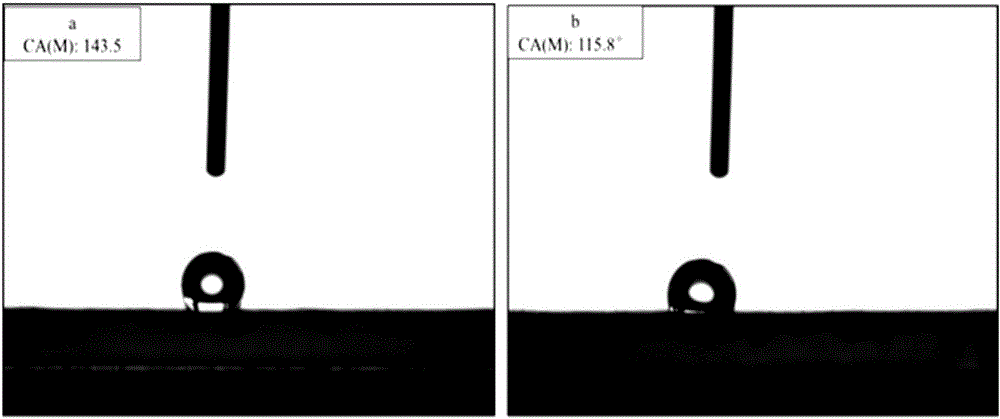

[0026] (1) Surface modification process: First, immerse the chopped carbon fiber (fiber length: 4mm) in water and ultrasonicate for 40min. Sonicate for 10 seconds, and add a dopamine modifier, the amount of which is 5% of the amount of chopped carbon fiber added, and use Tris-HCl to adjust the pH value of the solution to 8.5, and ultrasonically react at room temperature (25°C) for 6h to obtain Dopamine modified chopped carbon fiber; wherein, after dopamine modified chopped carbon fiber, its surface hydroxyl content is 0.1% (mass percentage content, the same as the following examples), and the amino content is 0.05% (mass percentage content, the same as the following examples); and Carbon fiber and carbon fiber contact angle characterization after dopamine modification, the contact angle of carbon fiber and water ...

Embodiment 2

[0029] A kind of chopped fiber dispersion of the present invention and preparation method thereof, it is characterized in that comprising following operation steps:

[0030] (1) Surface modification process: first, immerse chopped glass fiber (fiber length: 8mm) in water and ultrasonicate for 20min, the ultrasonic power is 400w, then reduce the ultrasonic power to 150w, add dopamine modifier, its addition amount is 50% of the added amount of chopped glass fiber, and adjust the pH value of the solution to 9.0 with Tris-HCl, and react ultrasonically at room temperature (25° C.) for 12 hours to prepare dopamine-modified chopped fiber. Ultrasound is used for 10 seconds every 50 seconds; wherein, the surface hydroxyl content of the dopamine-modified chopped glass fiber is 4.5%, and the amino group content is 1.0%; and the chopped glass fiber and the chopped glass fiber modified by dopamine are contacted The contact angle between glass fiber and water is 130.3°, and the contact angl...

Embodiment 3

[0033] A kind of chopped fiber dispersion of the present invention and preparation method thereof, it is characterized in that comprising following operation steps:

[0034] (1) Surface modification process: first, immerse the chopped polyimide fiber (fiber length: 0.05 mm) in water and ultrasonicate for 5 minutes, the ultrasonic power is 200w, ultrasonic for 10 seconds every 40 seconds, and then reduce the ultrasonic power to 50w, ultrasonication for 10 seconds every 60 seconds, then add dopamine modifier, its addition is 10% of the addition of chopped polyimide fibers, and adjust the pH value of the solution to 8.0 with Tris-HCl, at room temperature ( 22 ℃) ultrasonic reaction 10h, make dopamine modified chopped polyimide fiber; Wherein, its surface hydroxyl content after dopamine modified chopped polyimide fiber is 0.23%, amino content is 0.09%; And to short The contact angle of cut polyimide fiber and dopamine-modified chopped polyimide fiber was characterized. The contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com