Phosphorus and boron liquid source one-shot perfect diffusion process

A liquid source and full diffusion technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of poor anti-surge capability of devices, multiple reverse sources at the edge of silicon wafers, and uneven diffusion junction depth, etc., to achieve Small amount of reverse source, improved discharge resistance and reverse surge resistance, and the effect of reducing the concentration gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The primary total diffusion process of phosphorus and boron liquid sources according to the present invention will be further described in detail through specific examples below.

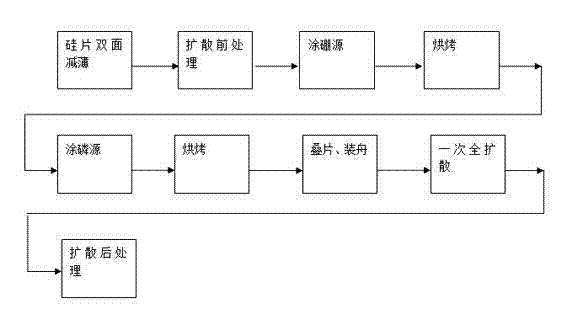

[0021] Such as figure 1 As shown, a phosphorus, boron liquid source once total diffusion process includes the following steps:

[0022] 1) Double-sided thinning of the silicon wafer: use nitric acid, hydrofluoric acid, and glacial acetic acid to etch the original silicon wafer on both sides according to the ratio of 3:1:1, and remove the surface damage layer;

[0023] 2) Cleaning before diffusion: chemically treat the surface of silicon wafers through acid, alkali and deionized water ultrasonic cleaning process;

[0024] 3) Coating boron source: place the cleaned silicon wafer on the rotator, drop the boron source on the center of the surface of the silicon wafer, start the rotator to rotate the silicon wafer, the rotation speed of the rotator is 3000-4000 rpm, The concentration of the Peng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com