Catalyst for preparing styrene by ethylbenzene dehydrogenation and preparing method thereof

A catalyst technology for the dehydrogenation of ethylbenzene, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of low compressive strength of catalysts and catalyst bed Problems such as high resistance drop and poor anti-powdering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

[0036] 290.8 grams of red iron oxide, 76.3 grams of potassium carbonate, 6.5 grams of cerium oxide, 67.5 grams of persimmon nitrate, 6.5 grams of ammonium molybdate and 15.0 grams of carboxymethyl cellulose (see Table 1) were stirred in a kneader for 1 hour, and the Add water, stir for another half an hour, take out the extruded strips, extrude them into cylindrical strips with a diameter of 3 mm and a length of 5-10 mm, put them in an oven, bake at 80°C for 4 hours, then place them in a muffle furnace, and bake them at 850°C Catalyst was produced in 4 hours. Embodiment 2, embodiment 3, embodiment 4, embodiment 5, embodiment 6, embodiment 7, the preparation method of embodiment 8 are the same as embodiment 1, just add different proportions.

[0037] Table 1 Fe-K-Ce-Mo catalysts with different proportions of porogens and composition Fe-K-Ce-Mo catalyst preparation dosage and physical properties

[0038]

[0039] * : The percentage of the difference between the accurately w...

Embodiment 9~17

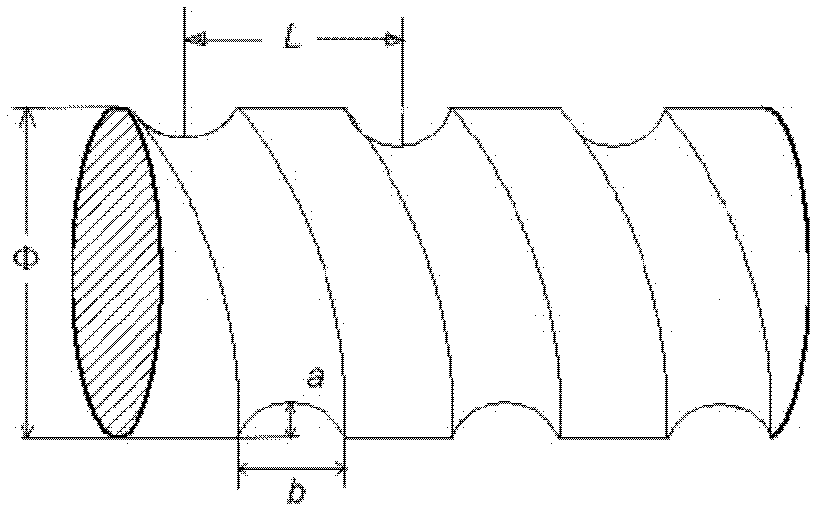

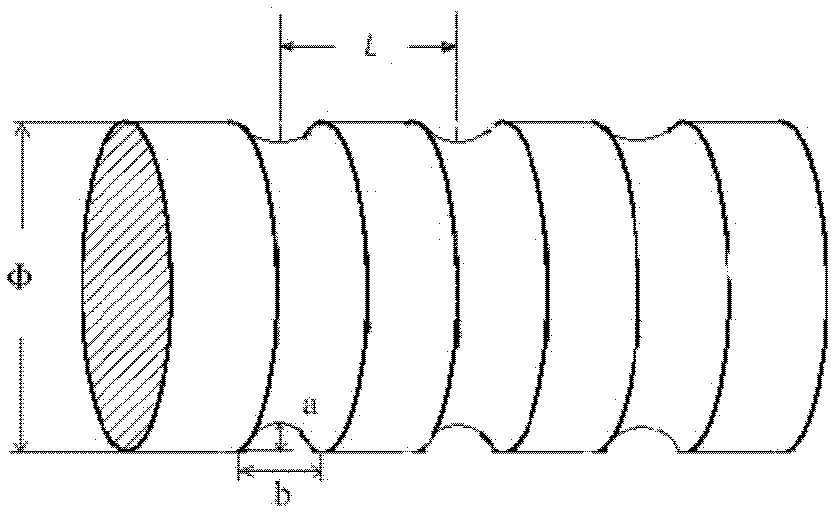

[0042]Extrude the wet-kneaded paste blocks with the same components as in Example 5 on extruders equipped with different shapes of flower boards and different propulsion processes to make straight lines, threads or rings with different widths, depths, and shapes on the axial outer surface. The strip of shape flute, then pelletize, dry, the physical performance of the prepared catalyst of roasting is shown in Table 2:

[0043] Table 2 Physical properties of different fluted catalysts

[0044]

[0045] It can be seen from the table that the axial thread or annular groove on the outer surface of the catalyst is equivalent to the linear groove in terms of compressive strength and specific surface area, but the wear resistance is obviously improved.

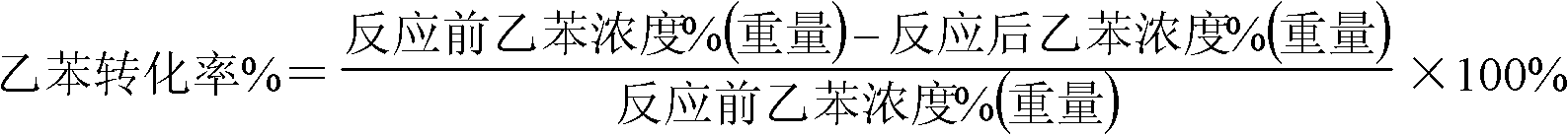

[0046] Respectively with the embodiment in table 1,2, comparative example catalyst take pure ethylbenzene as raw material ethylbenzene dehydrogenation styrene performance see table 3:

[0047] Table 3 Catalyst ethylbenzene dehydro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com