Patents

Literature

240results about How to "Reduce pulling force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible display device

PendingCN111508374AIncrease the display areaSmall sizeCasings/cabinets/drawers detailsIdentification meansComputer hardwareComputer graphics (images)

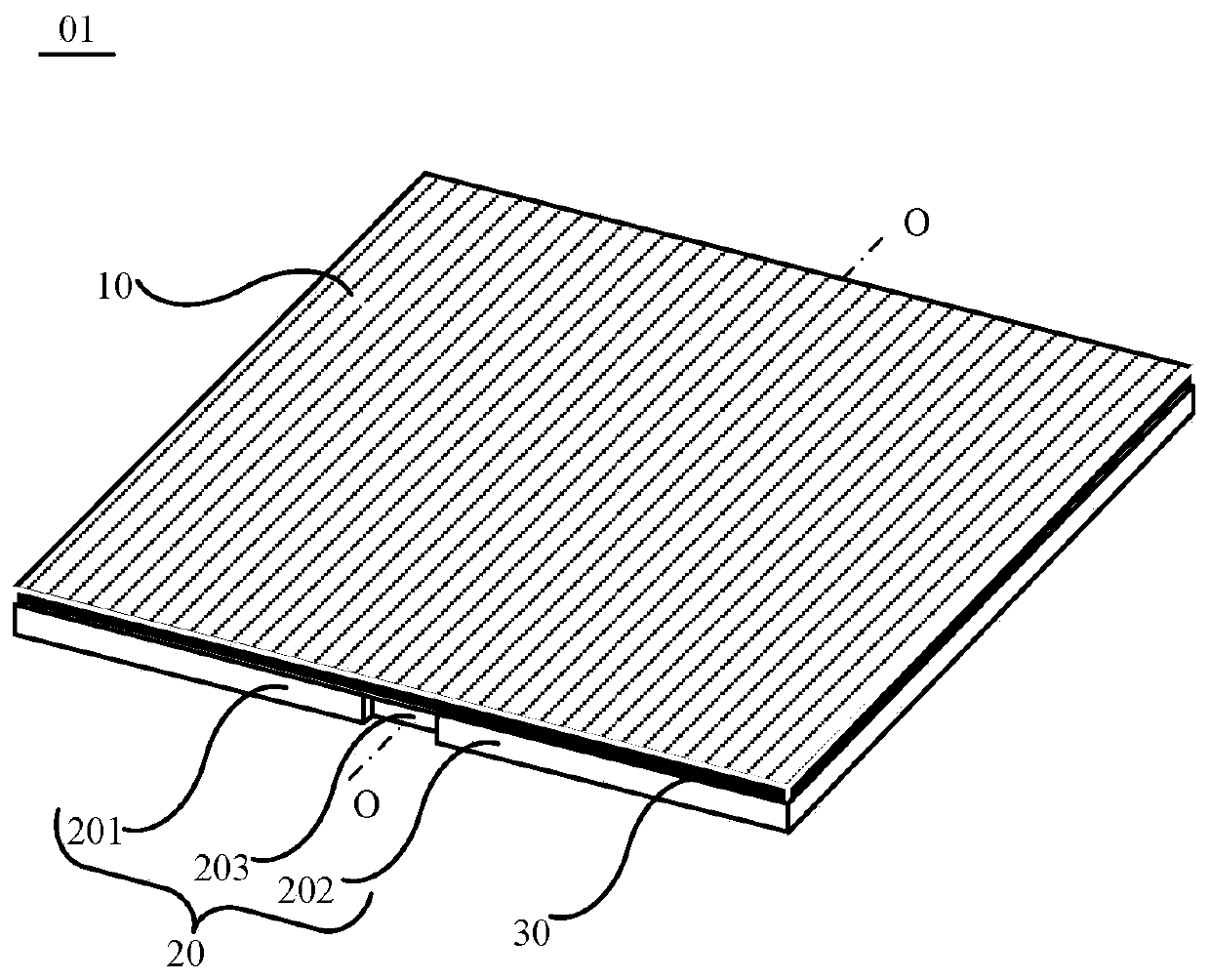

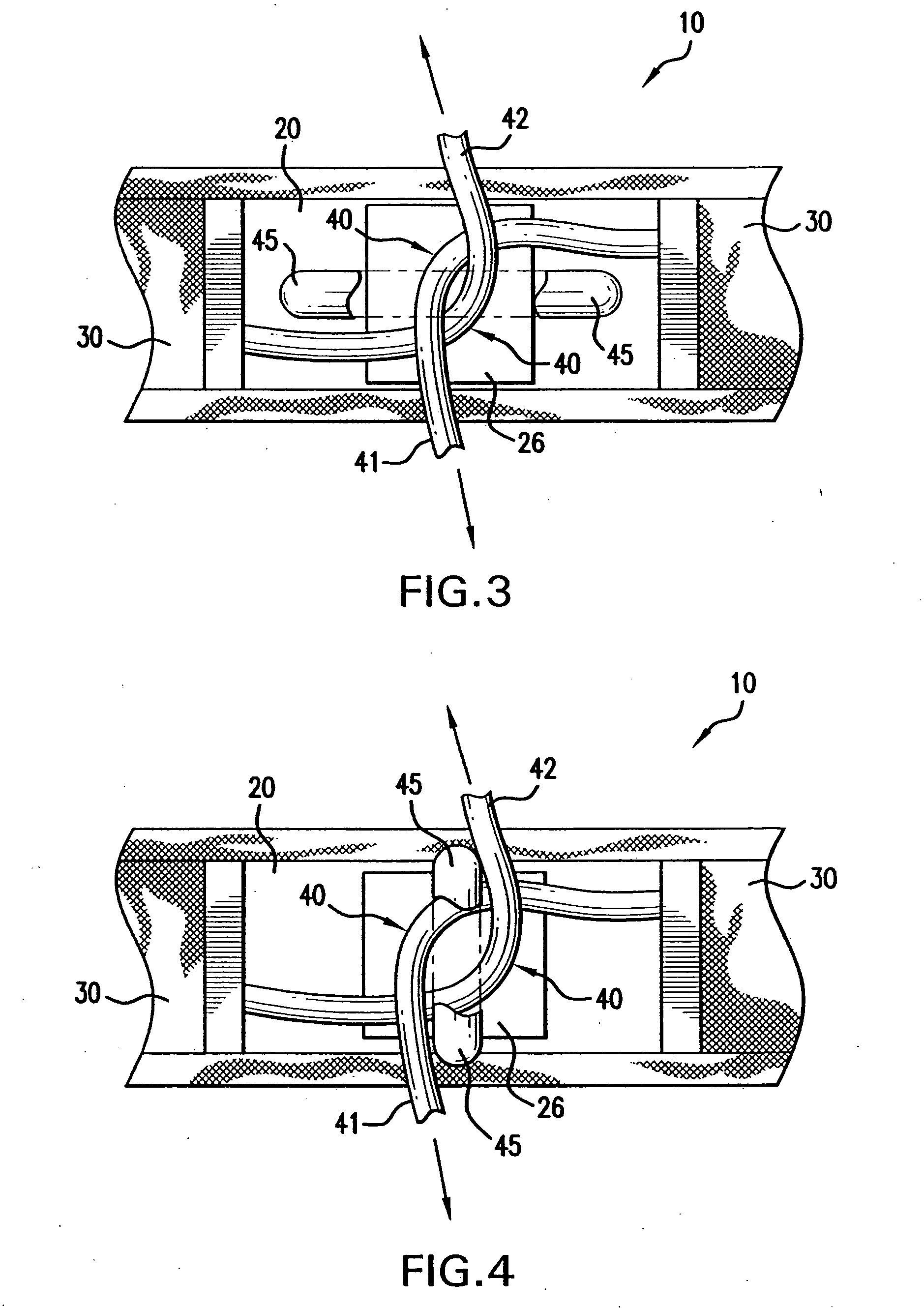

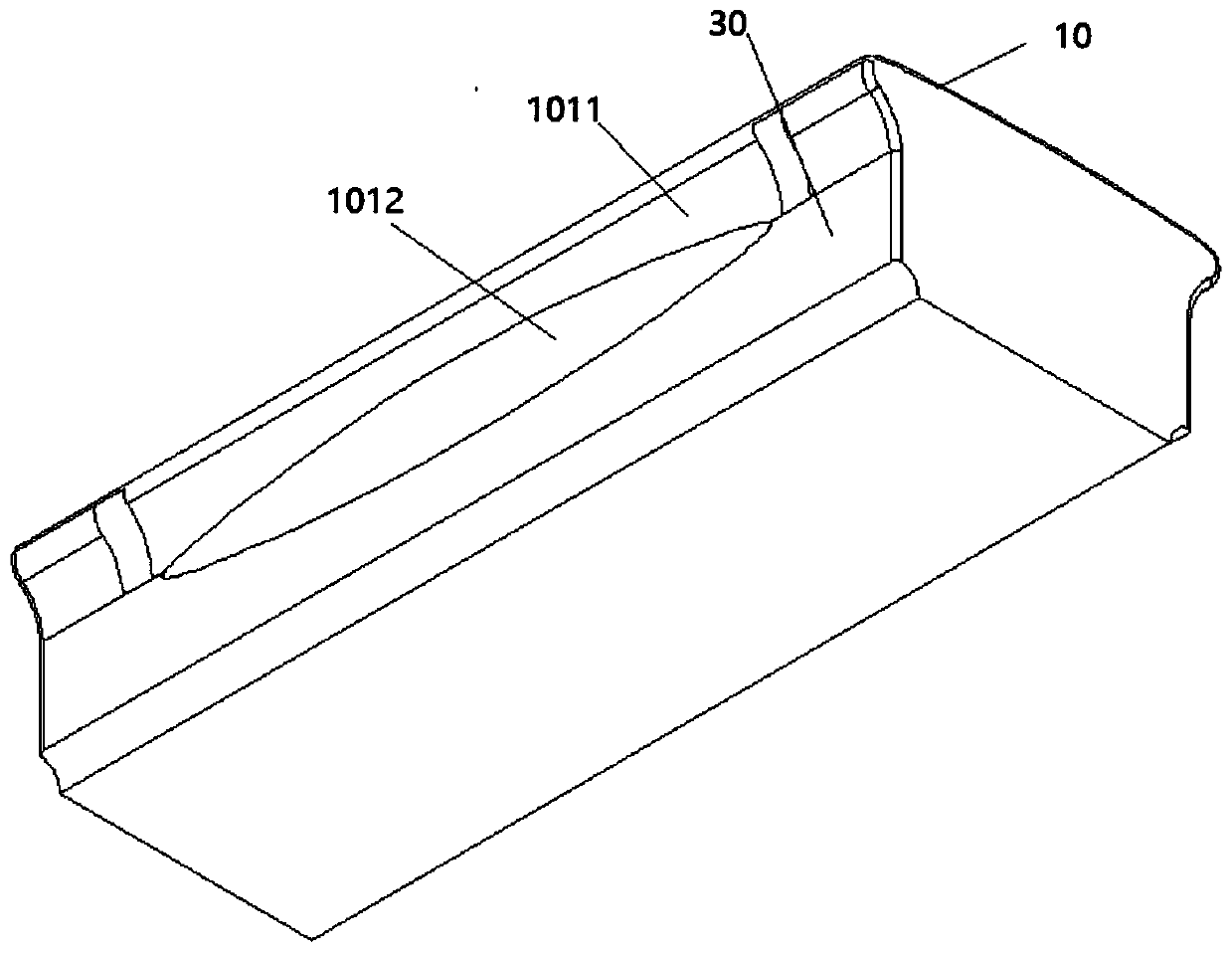

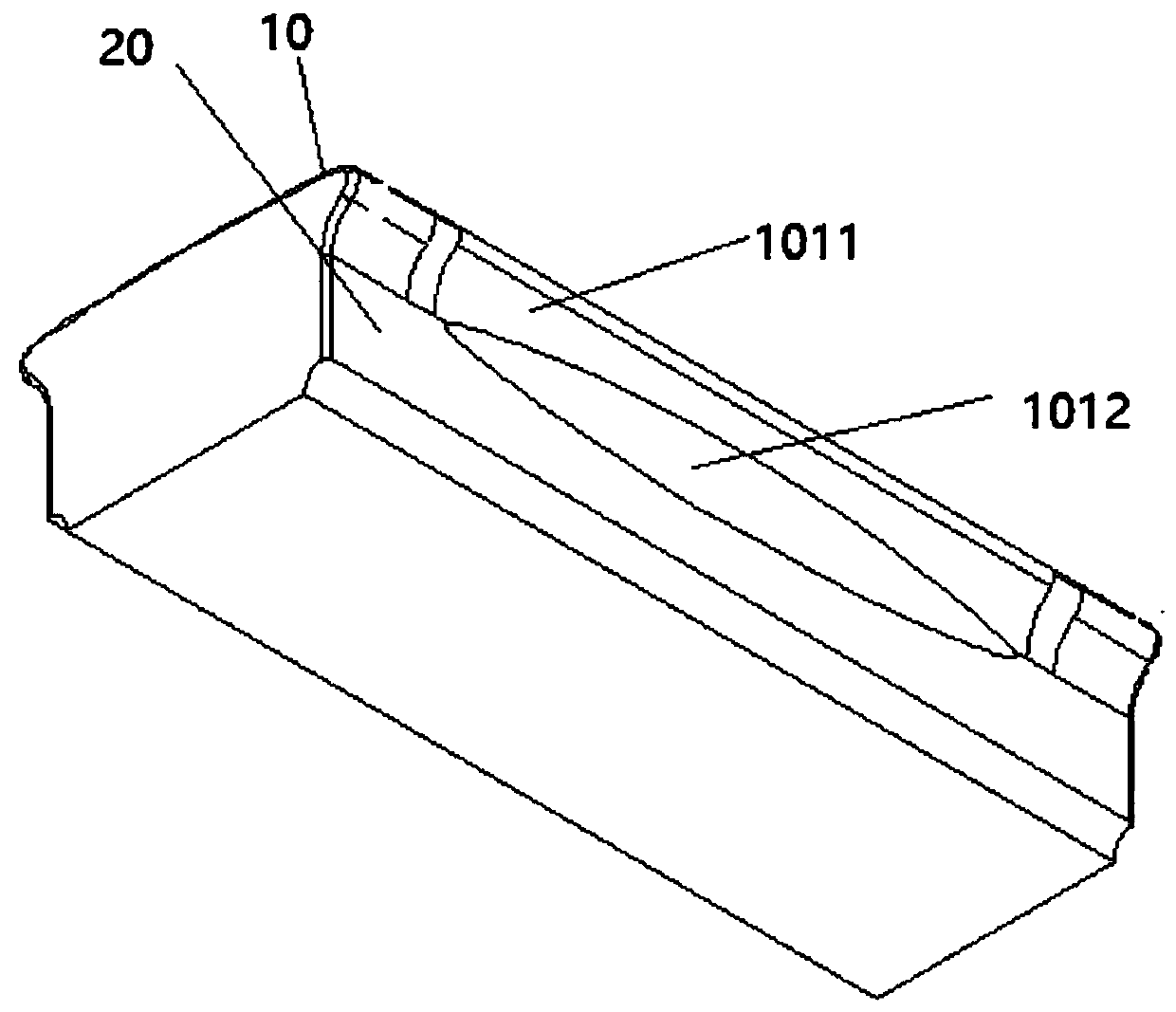

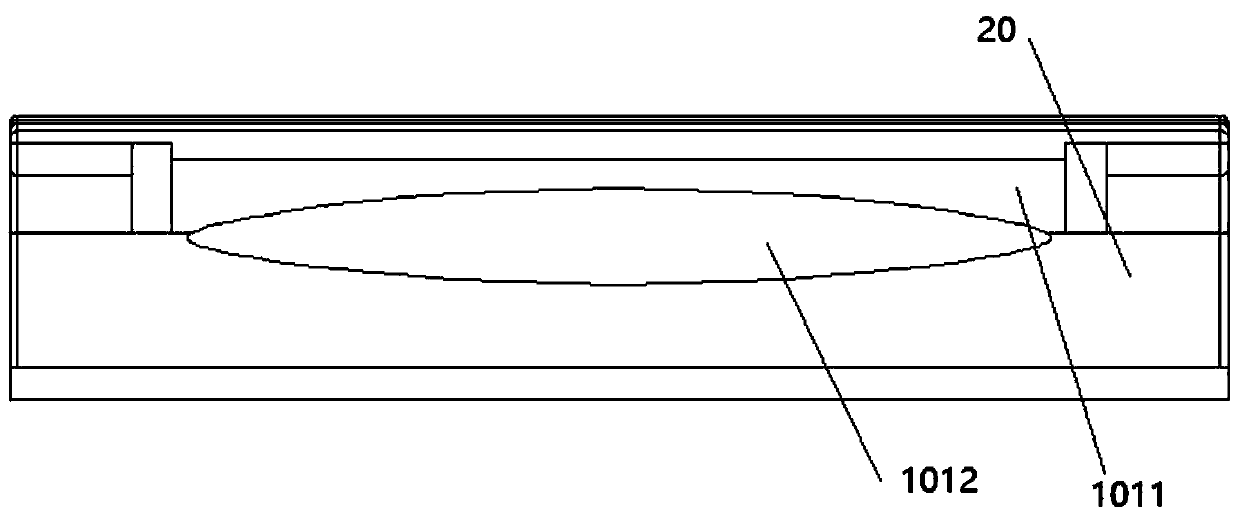

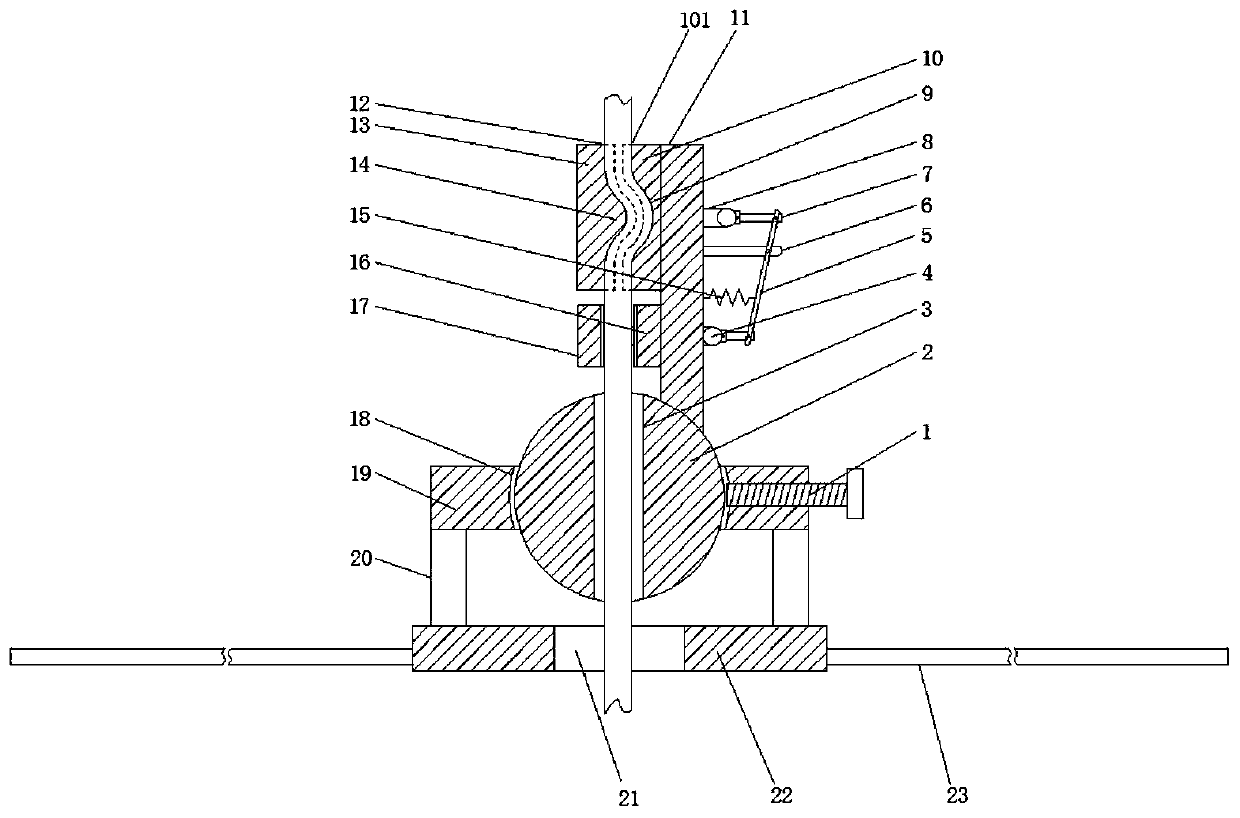

The invention provides a flexible display device. The flexible display device comprises a shell, a first supporting component, a second supporting component, a transmission mechanism and a flexible display screen, wherein the first supporting component is fixedly arranged on the shell; the second supporting component is arranged in a manner of sliding relative to the first supporting component; the flexible display screen is laid on one side of the first supporting component and one side of the second supporting component, the first end of the flexible display screen is connected with the end,away from the first supporting component, of the second supporting component, and the second end of the flexible display screen is connected with the transmission mechanism. When the first supportingcomponent and the second supporting component slide relatively, the two ends of the flexible display screen move by the same motion distance within the same time under the action of the transmissionmechanism. The flexible display device is small in occupied space, and the flexible display screen cannot bear large pulling force in the process of being pulled out of and stored in the shell.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Rotating mechanism and folding display terminal

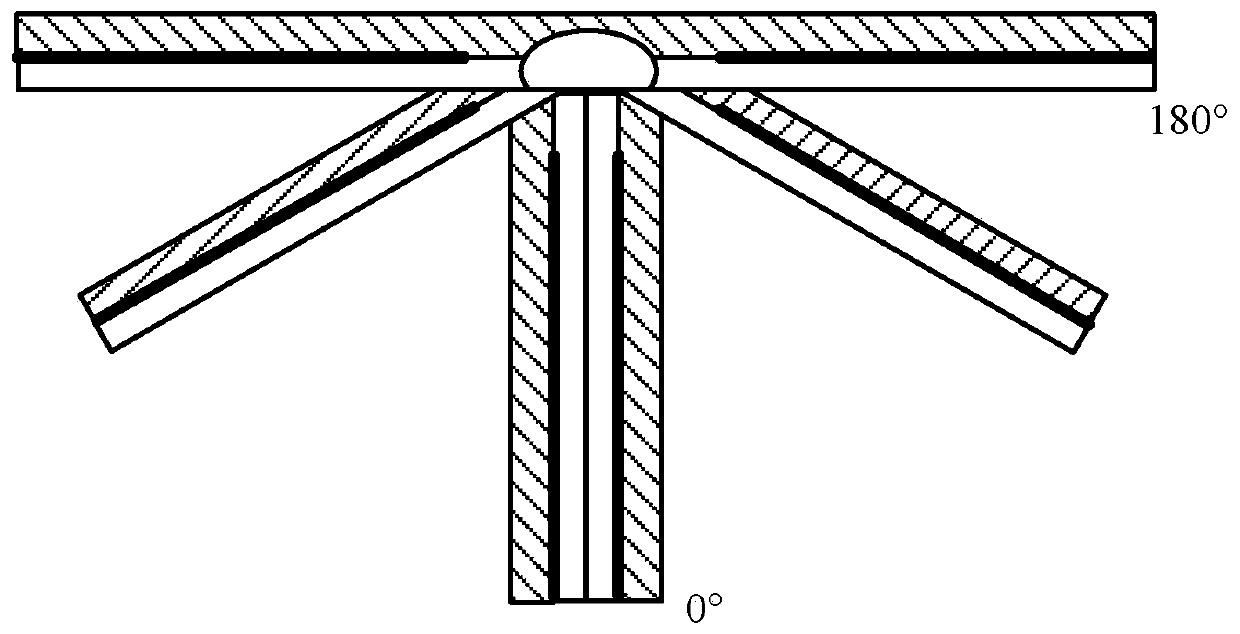

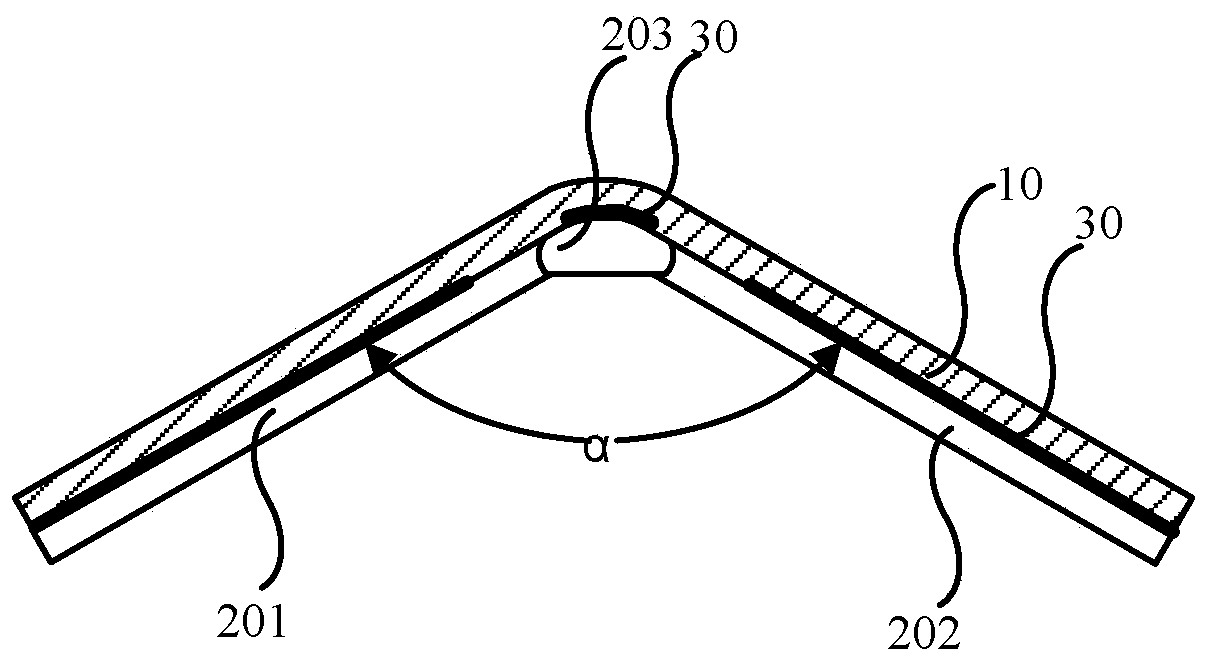

PendingCN110442196AReduce pulling forceImprove flatnessSubstation equipmentDetails for portable computersPull forceEngineering

Owner:HUAWEI TECH CO LTD

Riveting and positioning fixture, PCB riveting method, manufacturing method for PCB and PCB

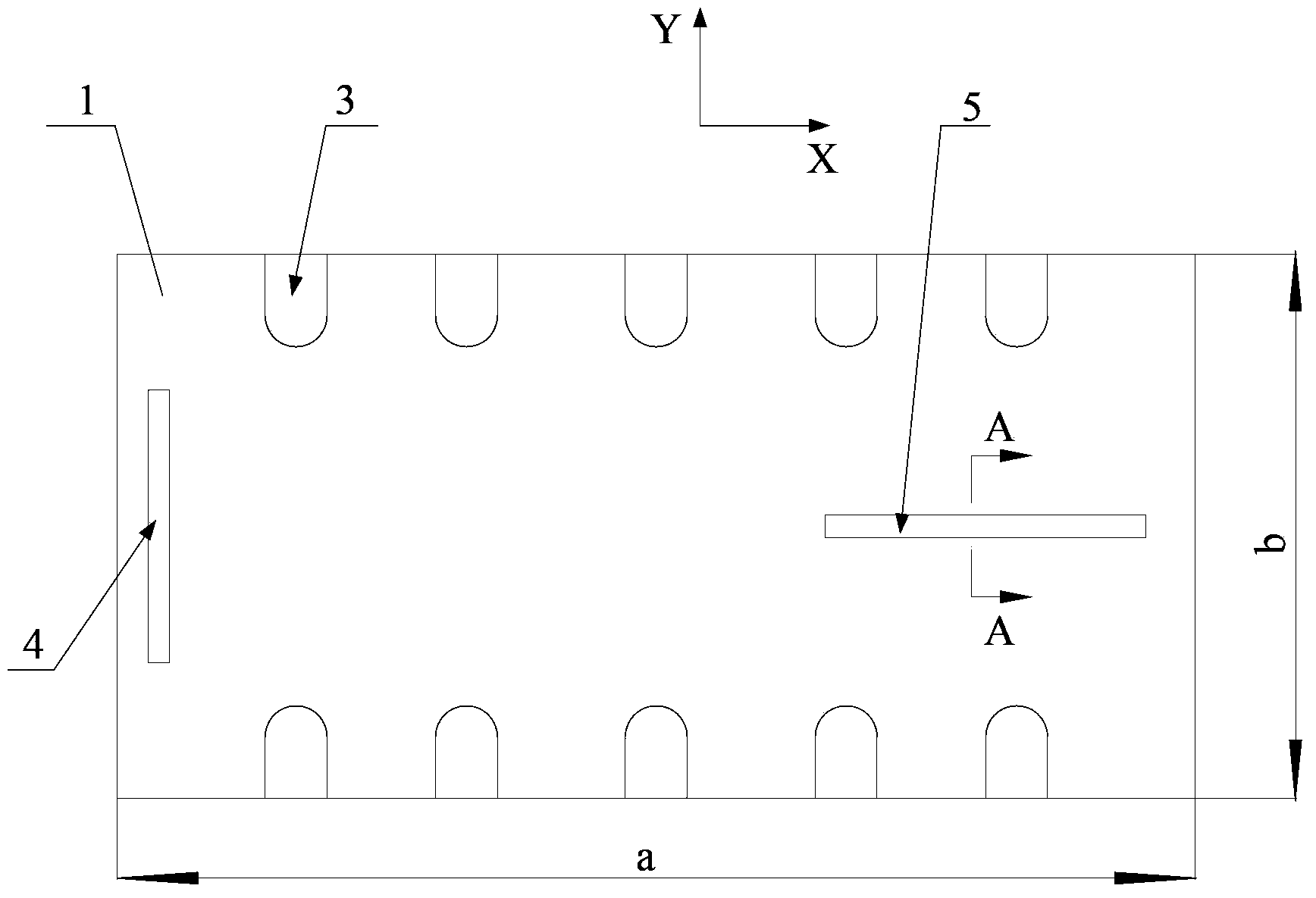

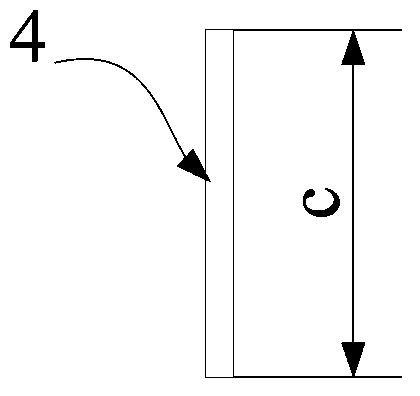

InactiveCN103847097AReduce pulling forceReduce misalignmentWork holdersPrinted circuit manufacturePull forceEngineering

The invention provides a riveting and positioning fixture. The riveting and positioning fixture comprises a fixture body; two opposite sides of the fixture body are respectively provided with a plurality of rivet installation holes; one of the other two opposite sides of the fixture body is provided with a first positioning slide groove extending along a Y-axis direction, and the other of the other two opposite sides of the fixture body is provided with a second positioning slide groove extending along an X-axis direction; and a pin can slide in the first positioning slide groove and the second positioning slide groove and can be fixed at a designated position. The invention also provides a PCB riveting method, a manufacturing method for a PCB and the PCB. According to PCB riveting technology provided by the invention, riveting requirements of all standard jointed board products can be met only by manufacturing one riveting and positioning fixture, so production management is simplified; a pulling force generated in the riveting process can be effectively reduced, thereby avoiding scraping caused by dislocation and improving product yield; after pressing, rivets are drilled out through drilling, so the problems of board separation and delamination at positions where the rivets are located in later processing are overcome.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

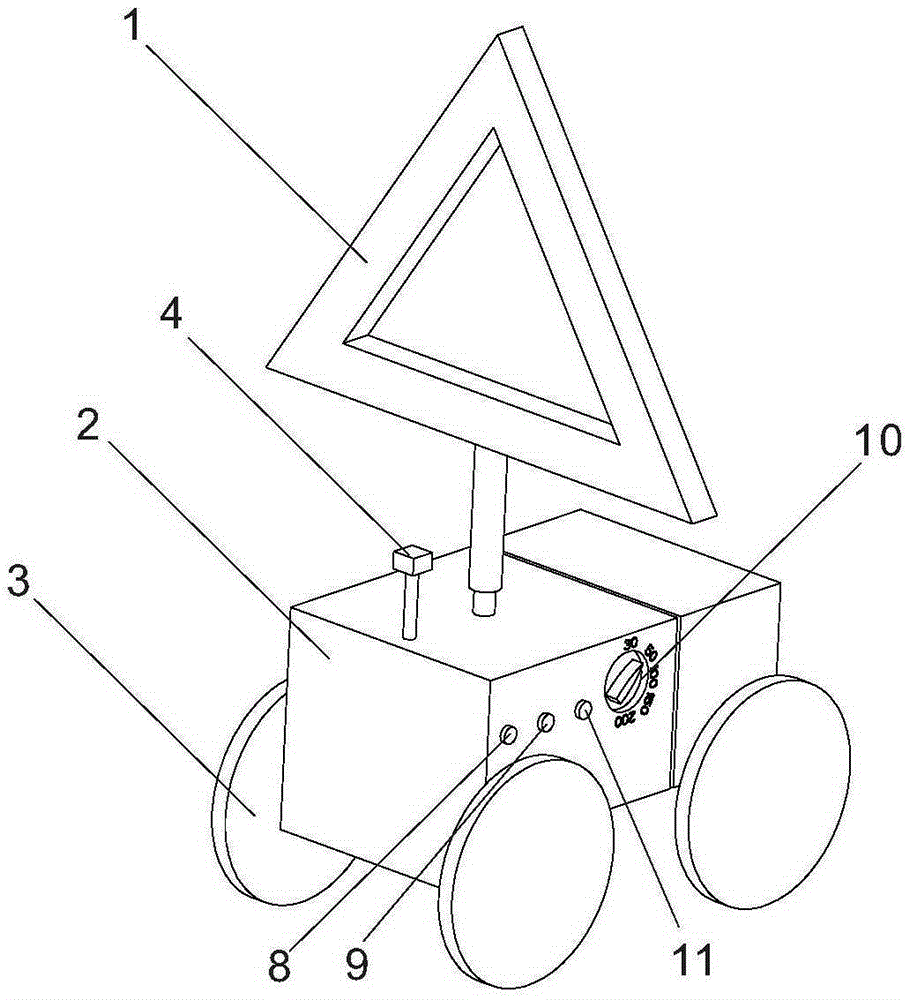

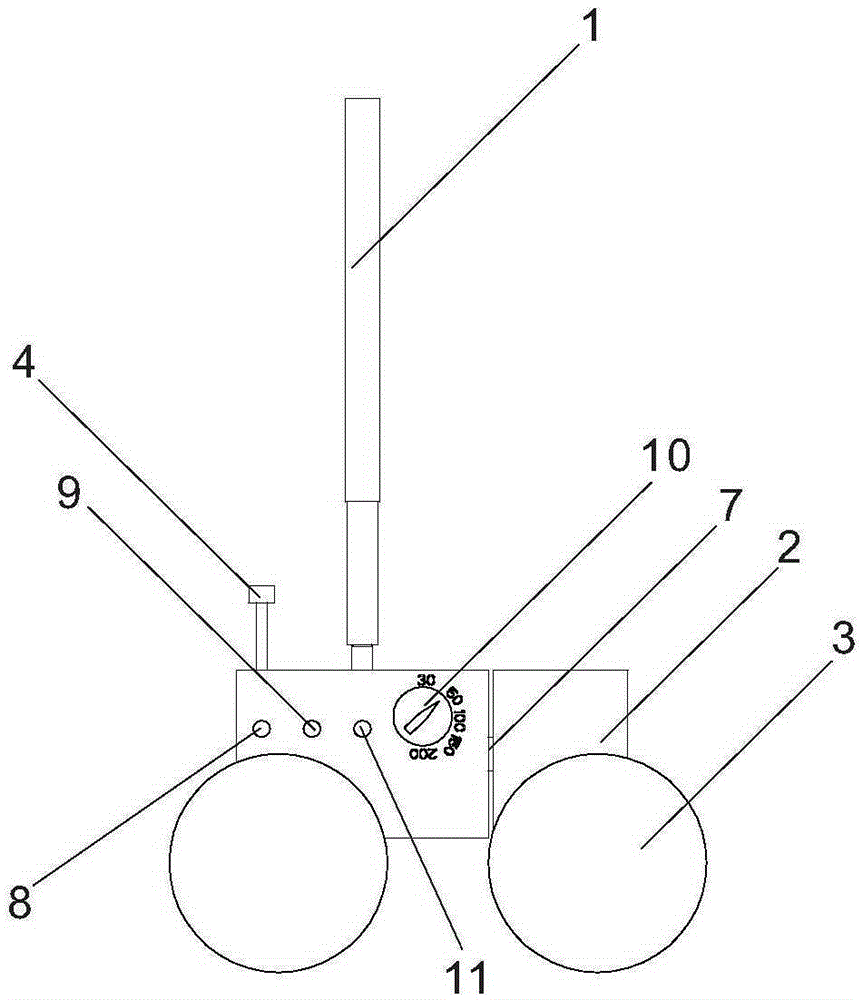

Vehicle warning device capable of automatically detecting highway guardrail position

InactiveCN105200931AAvoid influenceHigh degree of intelligenceTraffic signalsRoad signsElectricityComputer module

The invention discloses a vehicle warning device capable of automatically detecting a highway guardrail position. The vehicle warning device comprises a warning board and a warning board installation base, wherein the warning board installation base is provided with a power supply module, and the vehicle warning device also comprises a distance measurement module capable of measuring a distance from the warning board installation base to the highway guardrail position, and the distance measurement module is electrically connected with the power supply module. The warning board is high in arrangement speed, the intelligence degree is high, the manual intervention is reduced, the moving route is precise, the vehicle warning device can be well adaptive to the unfavorable weather condition and curve road conditions, the windproof performance is good, the warning board is flexible and diversified in transport way and is adaptive to different road conditions and weather situations, the warning board can be rapidly moved to a designated place, the warning board can be automatically restored after rolling over, and the cost is low.

Owner:孙立峰

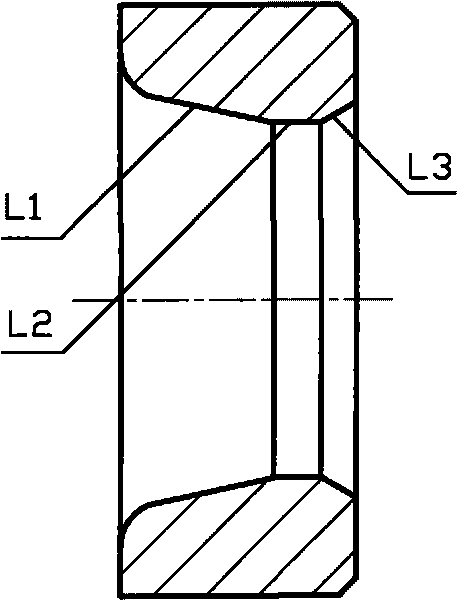

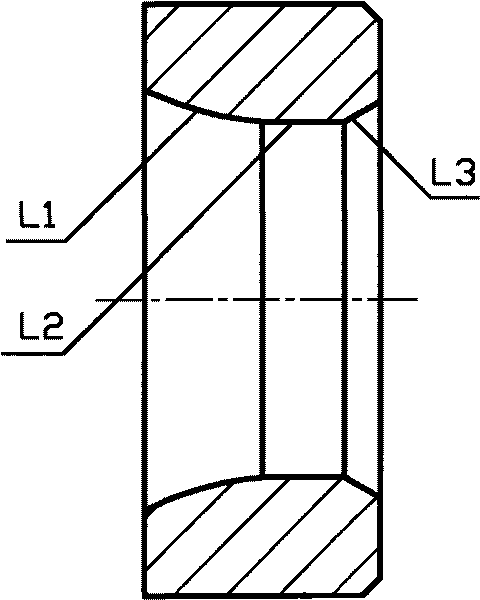

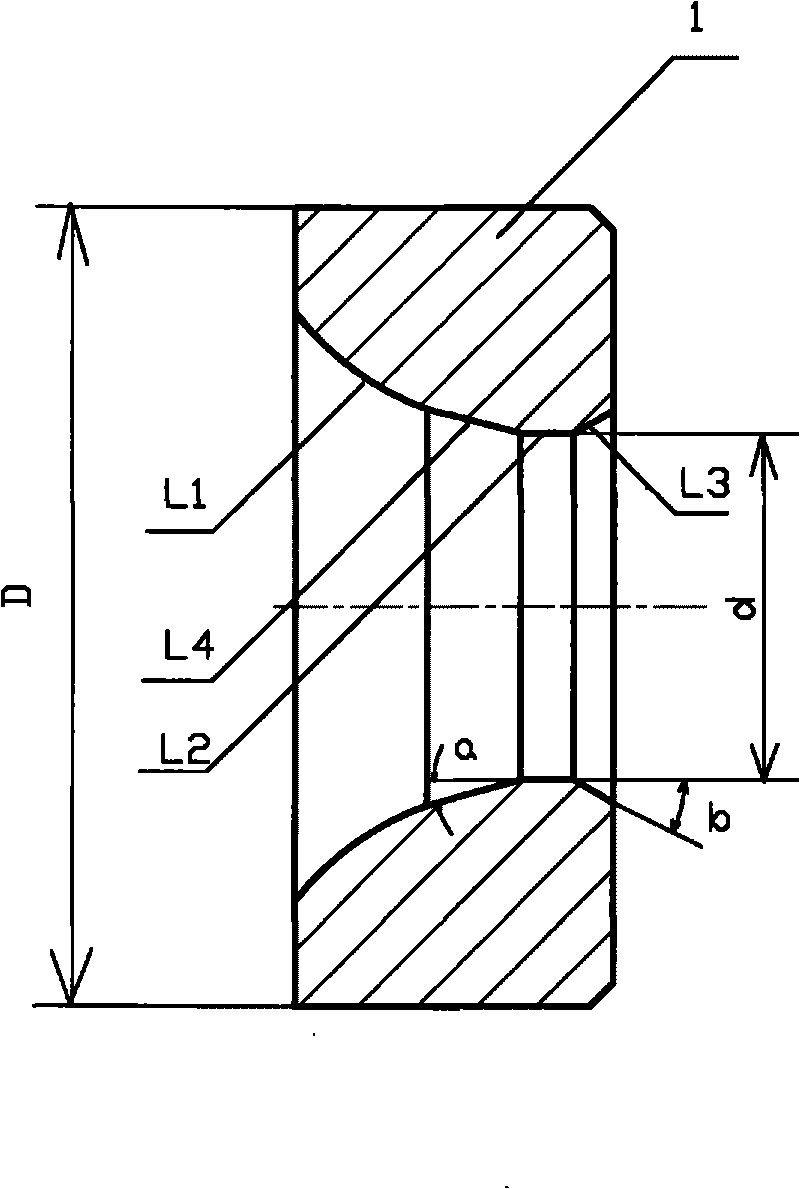

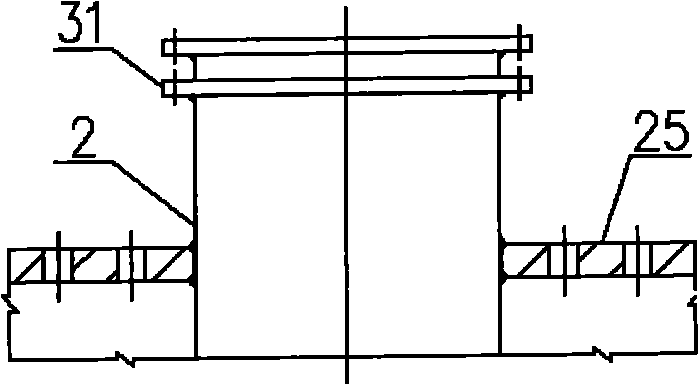

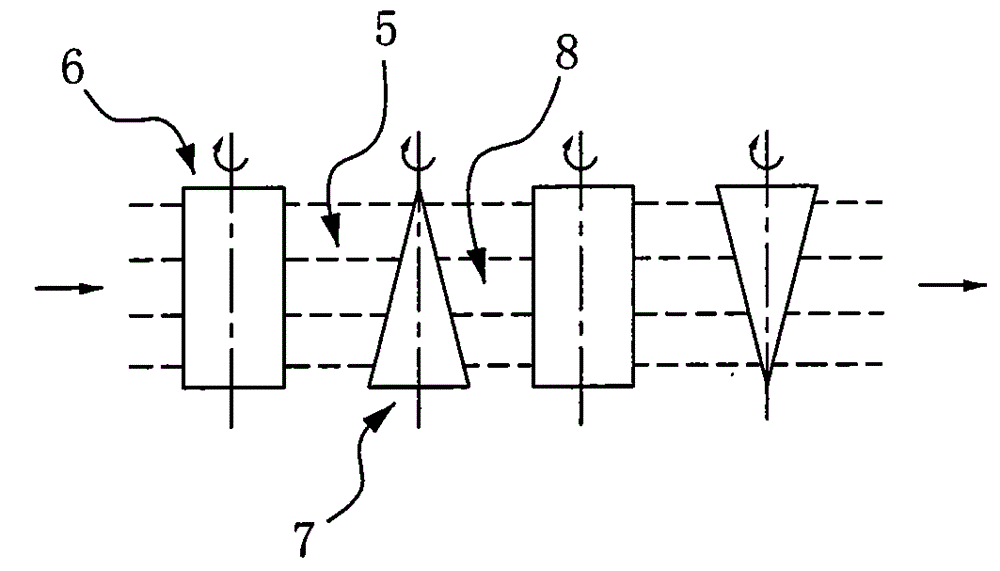

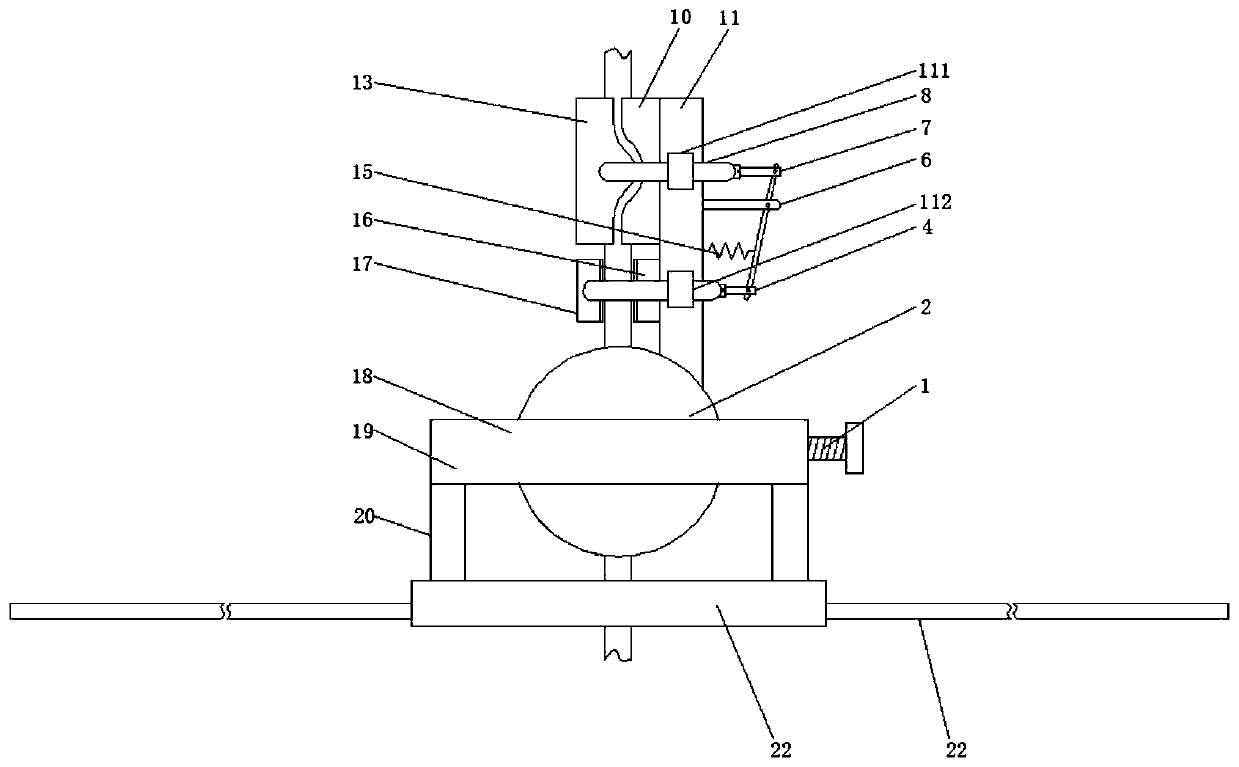

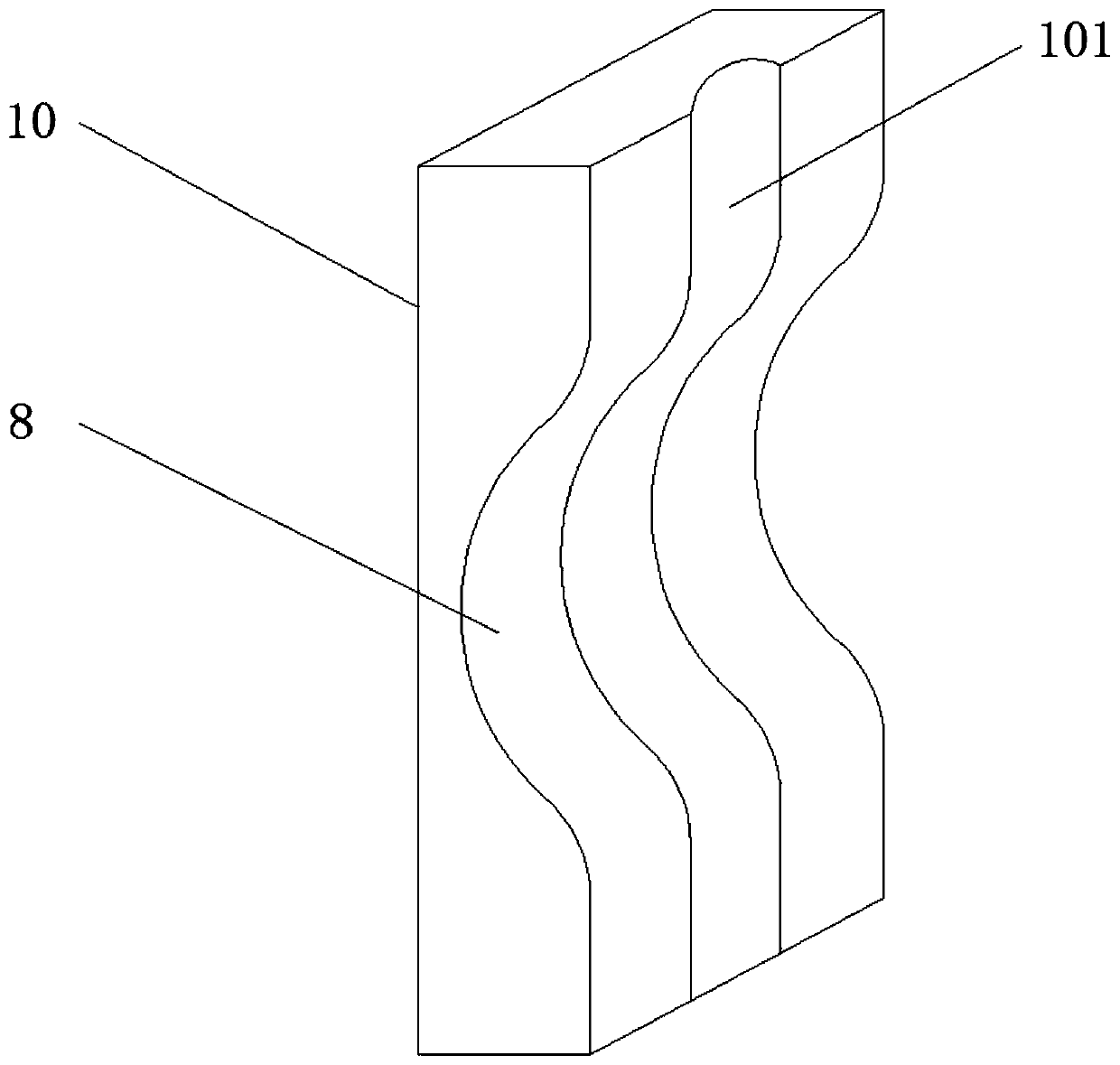

Compound external mold for cold drawing steel tube

The invention relates to a compound external mold for cold drawing a steel tube. The hole types of an external mold body comprise an inlet arc section L1, an inlet arc section L4, a calibrating strap L2 and an outlet cone L3. The arc radius R of the inlet arc section L1 is 30-60 mm. The inlet arc section L4 is arranged between the inlet arc section L1 and the calibrating strap L2; the conicity a of the inlet arc section L4 is 10-15 degrees; and the inlet arc section L4 of the compound external mold is longer so as to play roles of reducing the diameter and the wall. The outlet cone L3 is arranged behind the calibrating strapL2, and the conicity b of the outlet cone L3 is 30-45 degrees. The calibrating strap L2 is shorter than the inlet arc section L4 so as to reduce the friction force during drawing. In order to ensure the surface quality of the drawn steel tube, the inlet arc section L1 and the inlet arc section L4 of the compound external mold, the inlet arc section L4 and the calibrating straight L2, and the calibrating straight L2 and the outlet cone L3 are in smooth transition.

Owner:HENGYANG VALIN STEEL TUBE

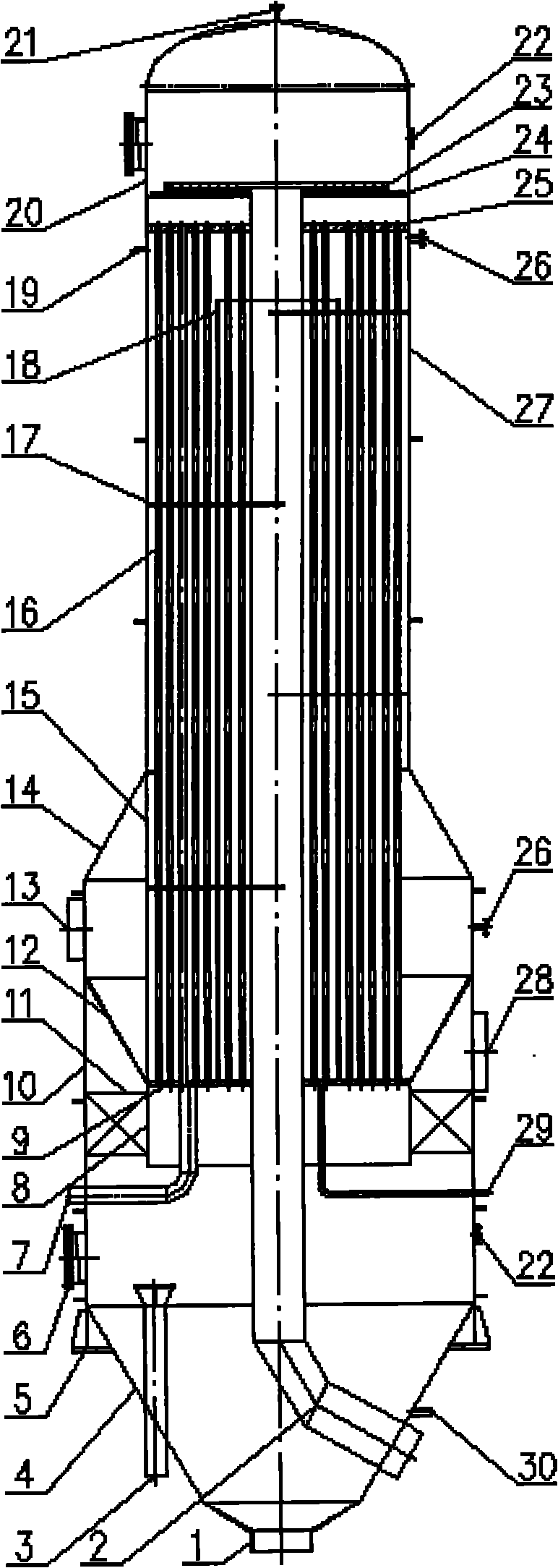

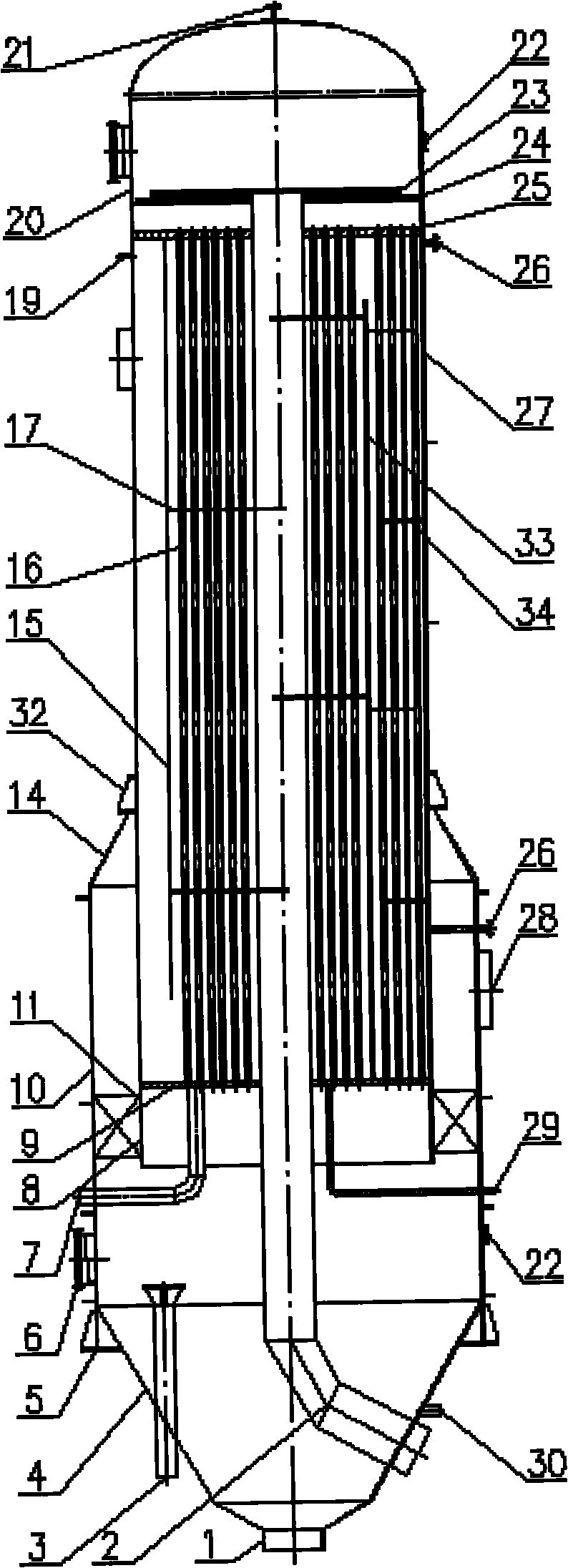

Tubular falling film evaporator

InactiveCN101780341AImprove the rigidityReduce tube sheet thicknessEvaporators with vertical tubesSewageFalling film evaporator

The invention relates to a special type heat exchanger, in particular to a tubular evaporator with a stripper unit, which is used for alkali recovery work in papermaking industry. The evaporator of the invention is arranged in the middle in a shell, namely the position of an axis, a central circulating tube of which an inlet is positioned at the lower part is fixed by an upper tube plate and a lower tube plate, the top part thereof is provided with a fluid dispenser, each heat exchange tube is arranged around the central circulating tube, the central circulating tube is fixed with the upper and the lower tube plates in a welding manner, the lower part of the shell is provided with a chamber which is connected with a steam inlet and provided with an expansion section, the lower chamber wall of the chamber with the expansion section is fixed with the lower tube plate, the lower part of the chamber with the expansion section is connected with a separating chamber in which a demister is arranged, and the lower tube plate is provided with a condense sewage outlet.

Owner:张培洲 +1

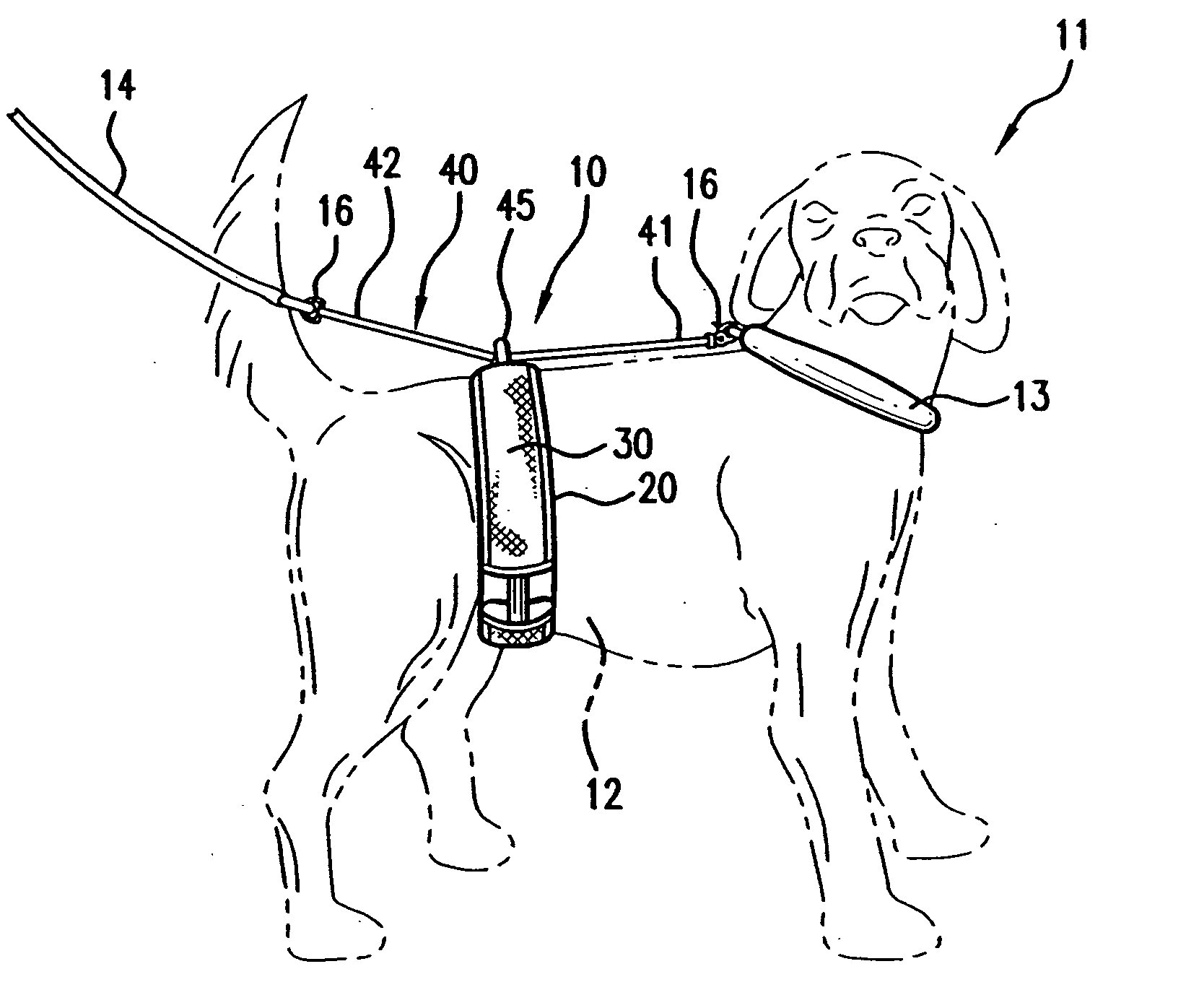

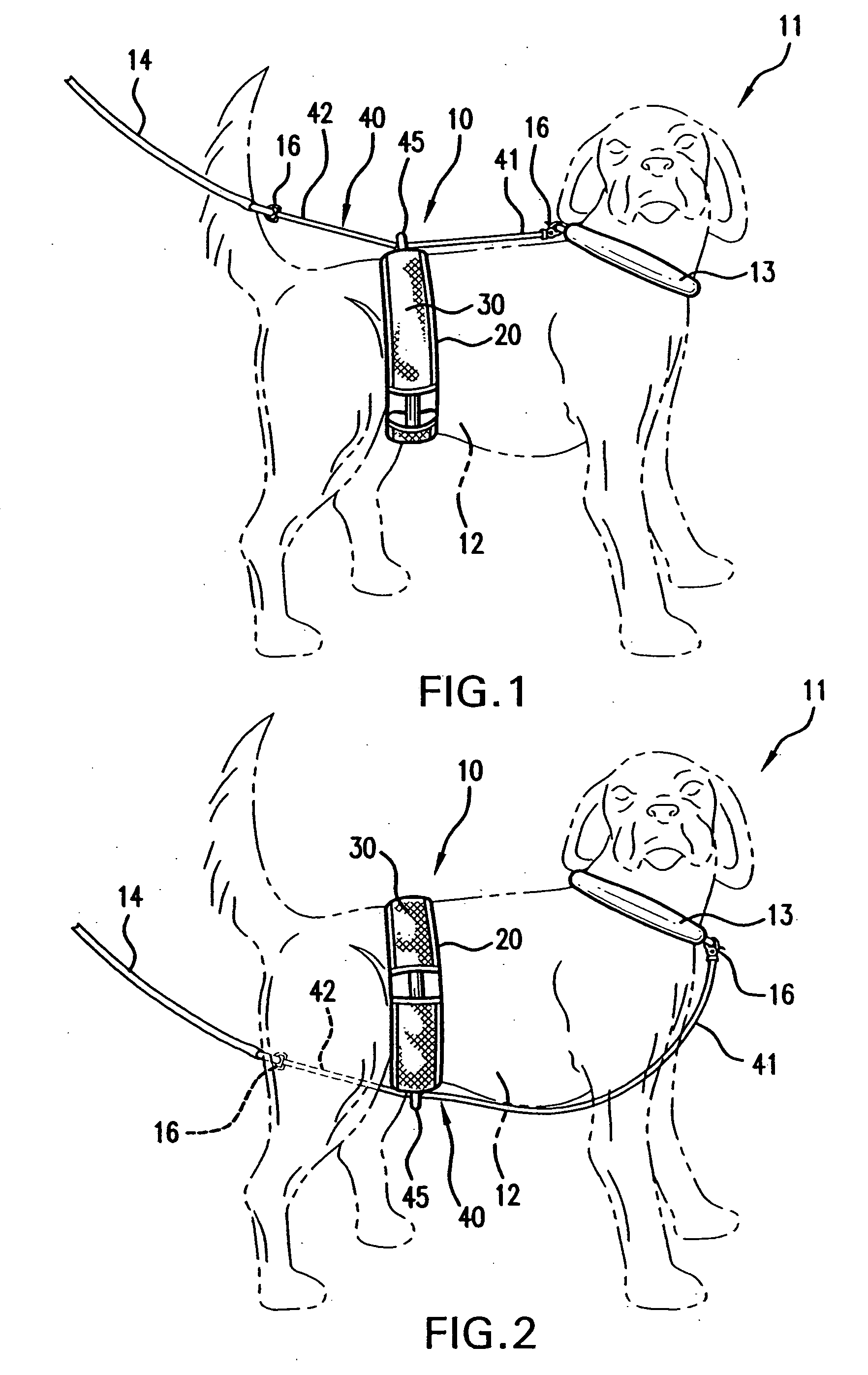

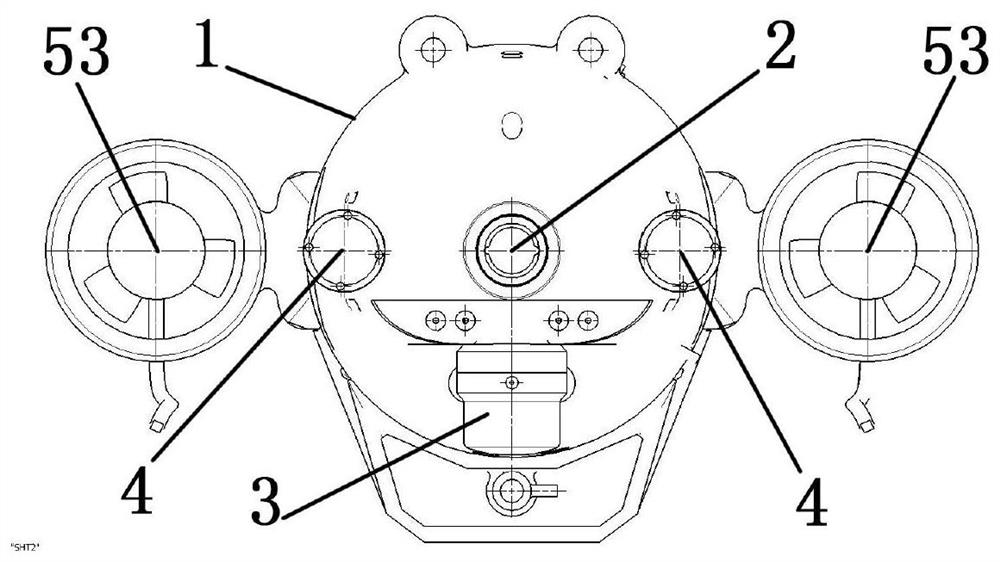

Animal restraining apparatus

InactiveUS20060236954A1Reduces undesirable forceReduce pulling forceTaming and training devicesEngineeringMechanical engineering

Owner:ABINANTI T MICHAEL

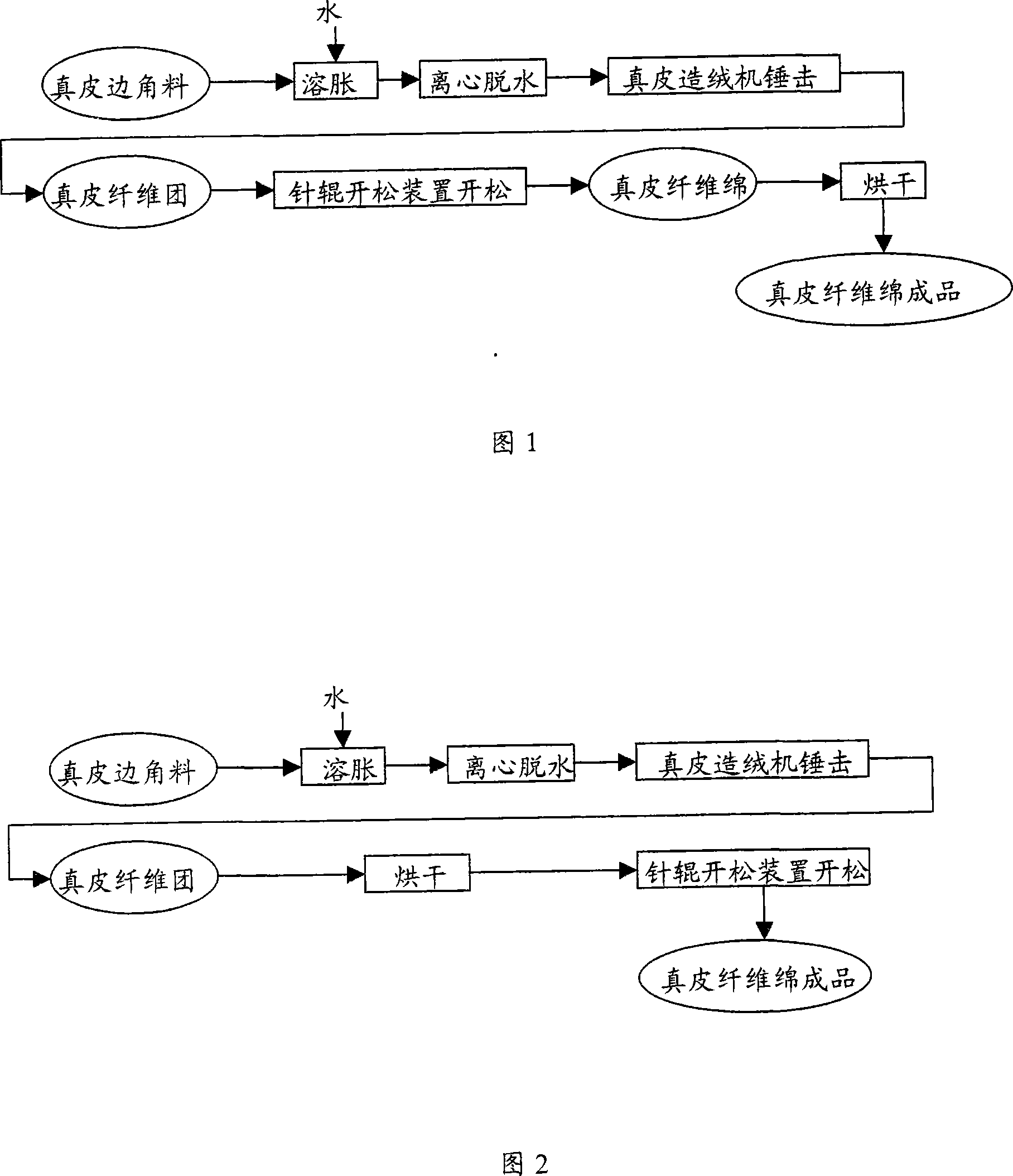

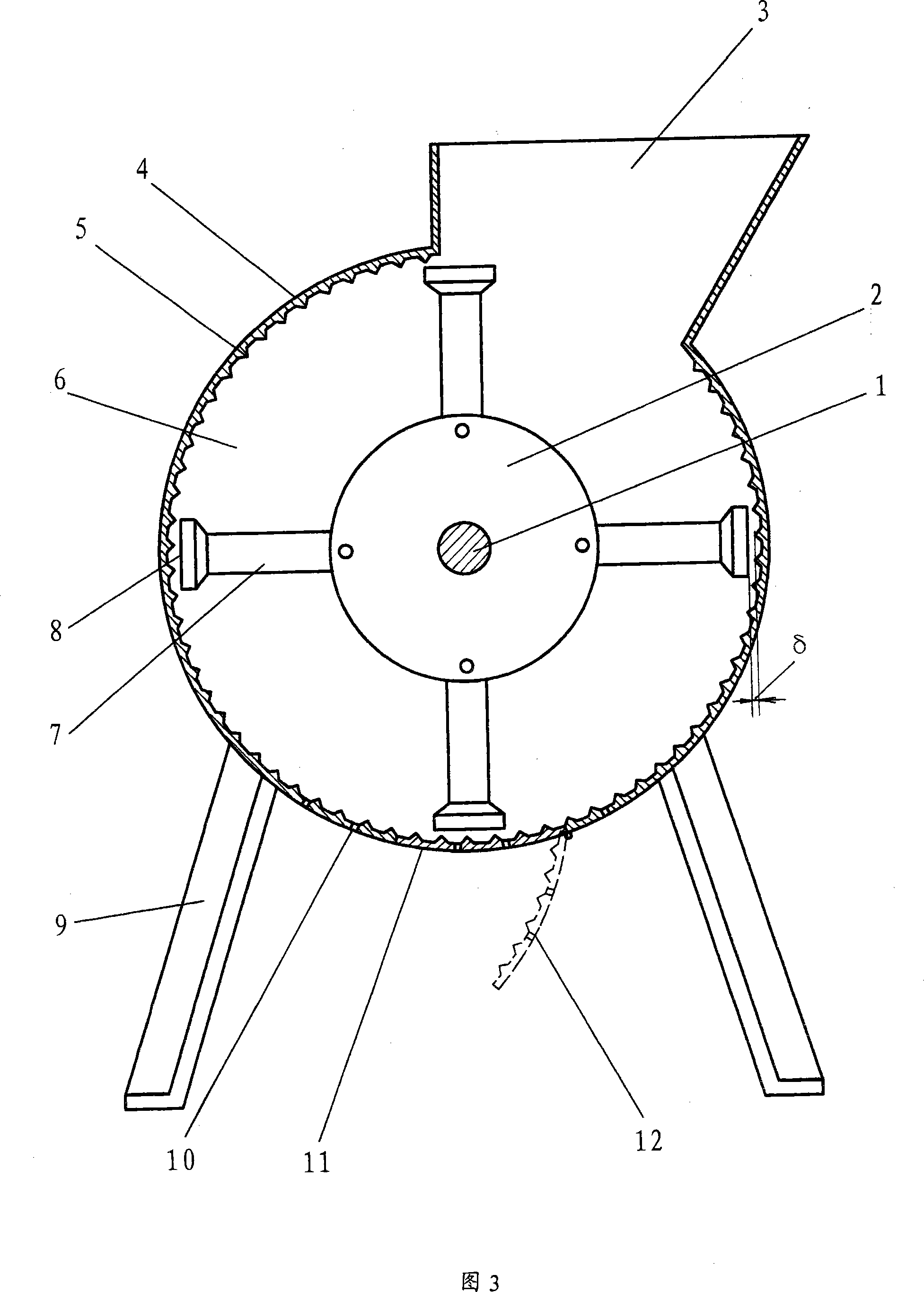

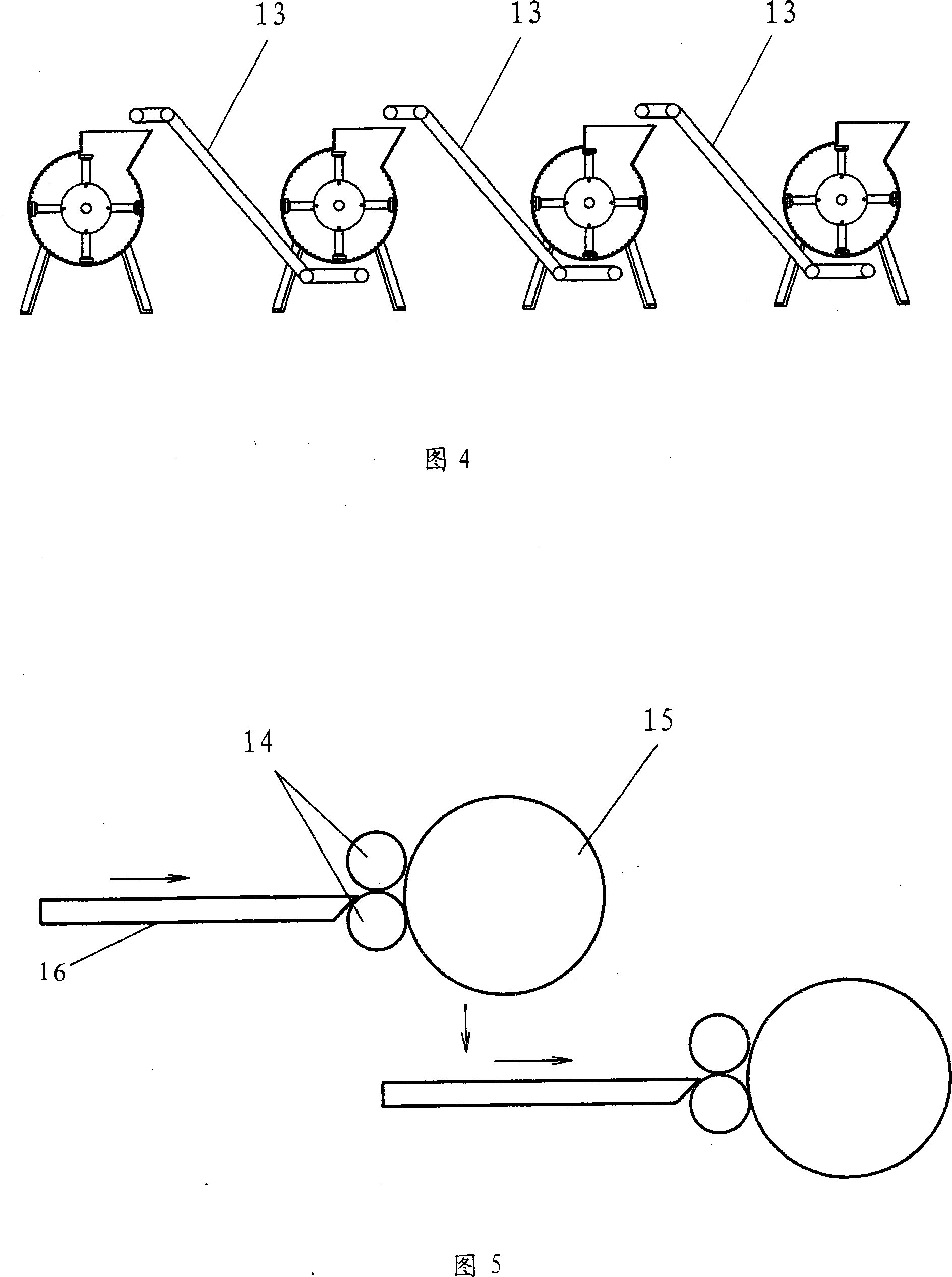

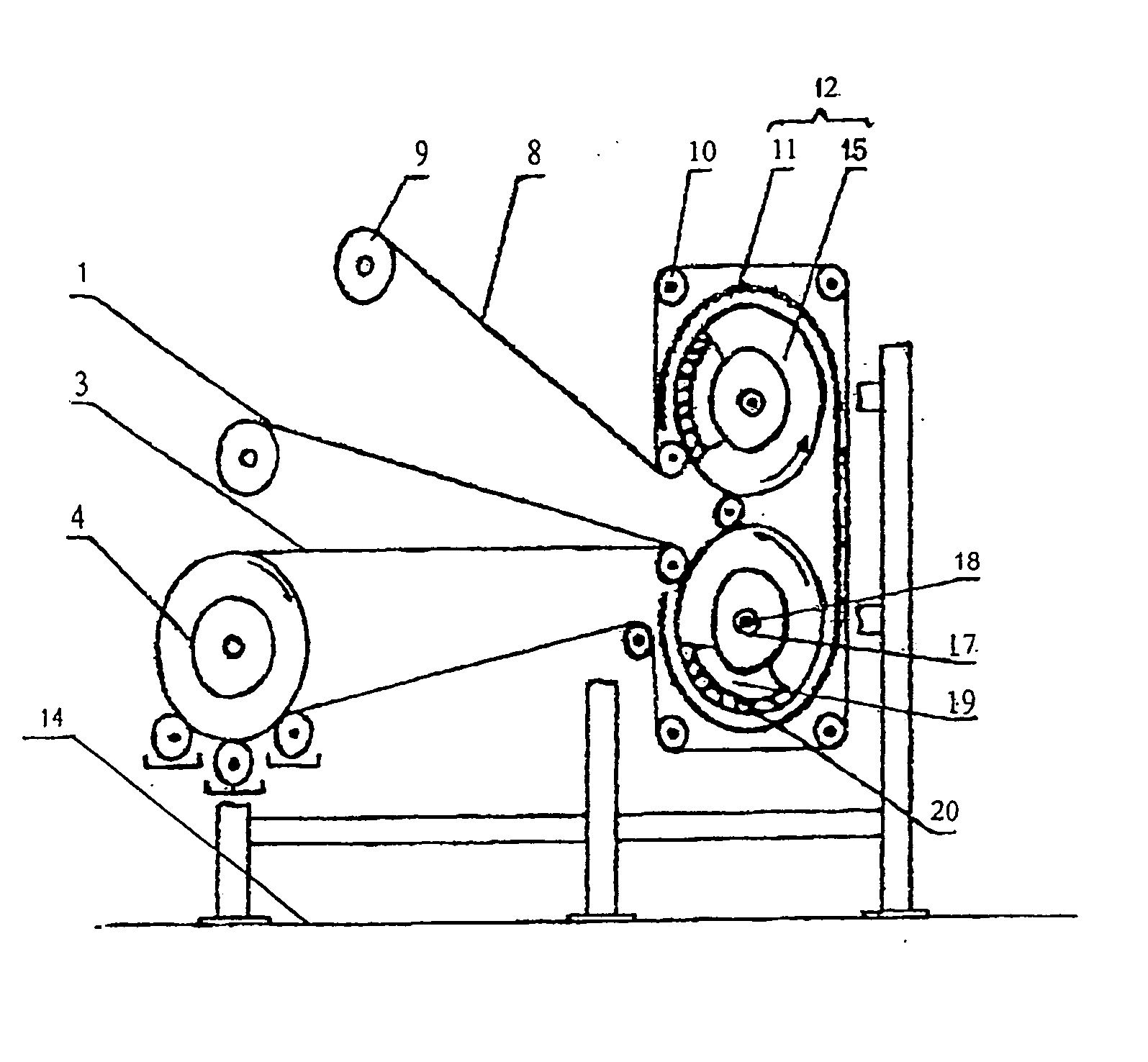

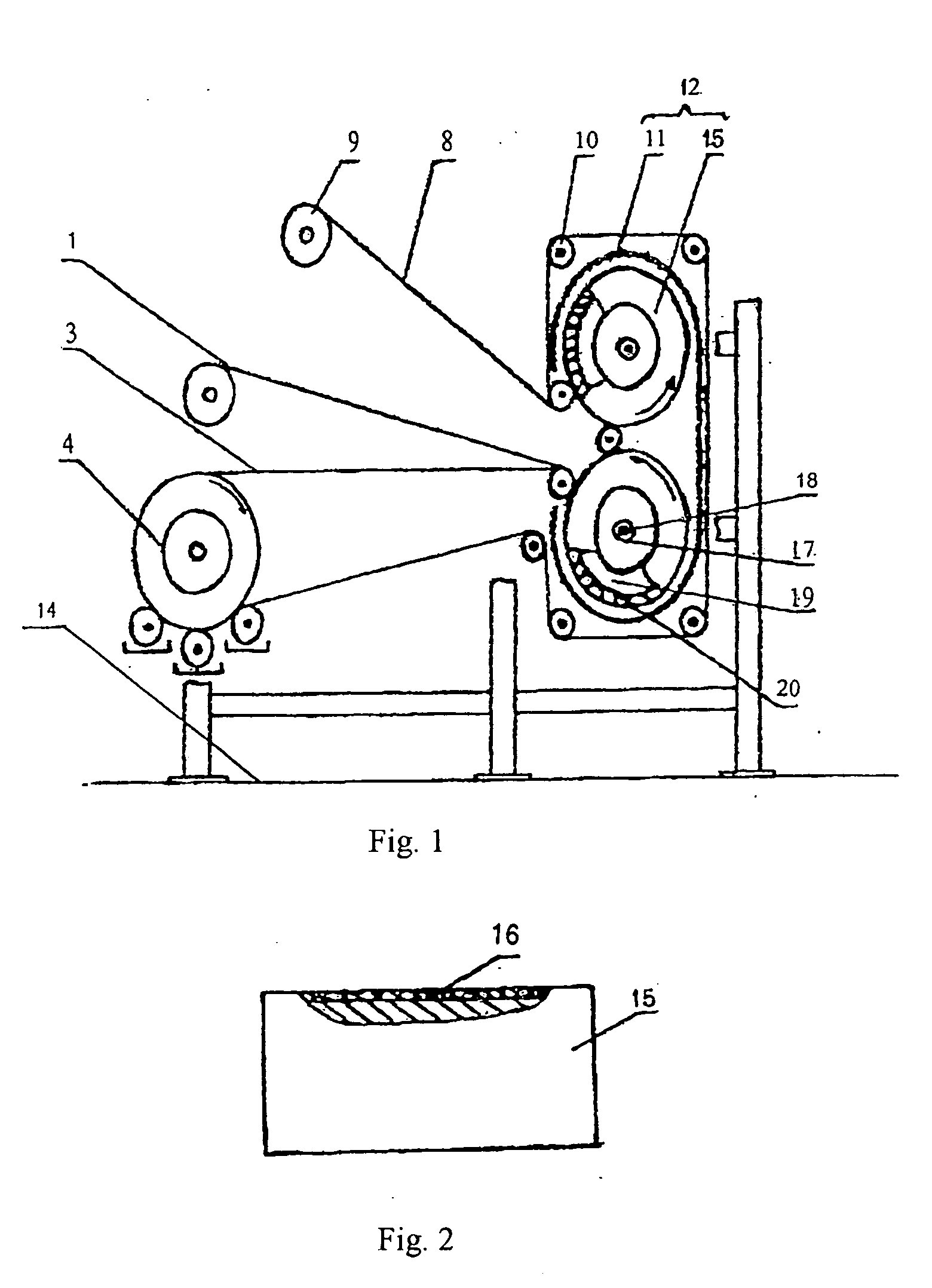

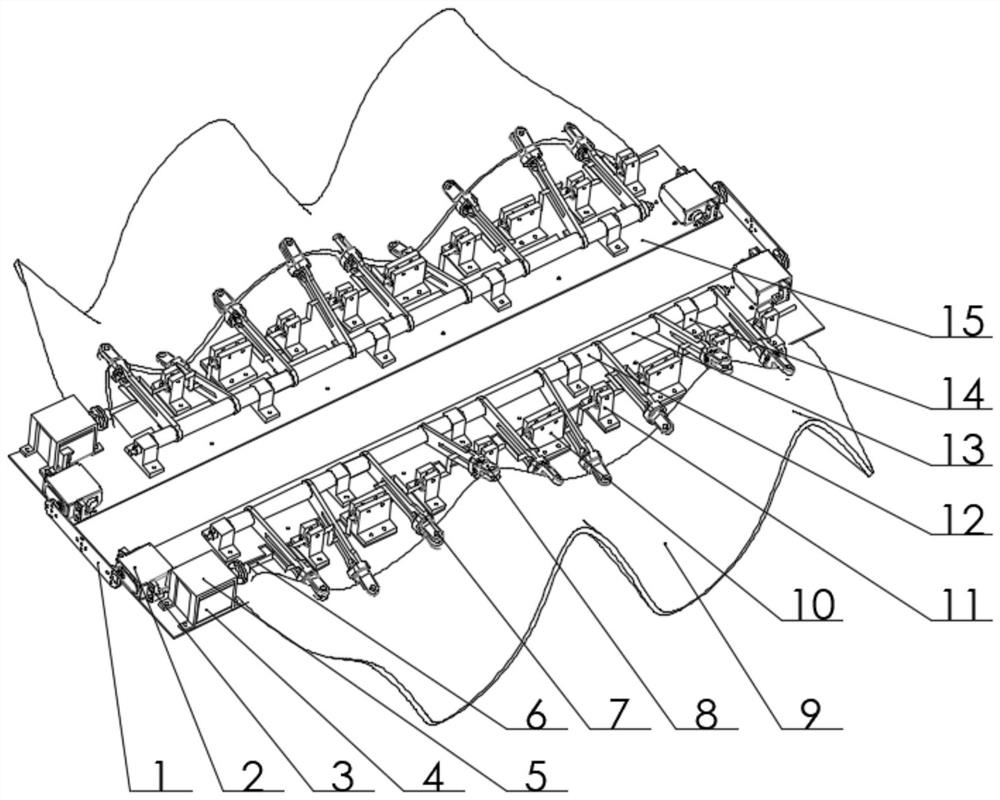

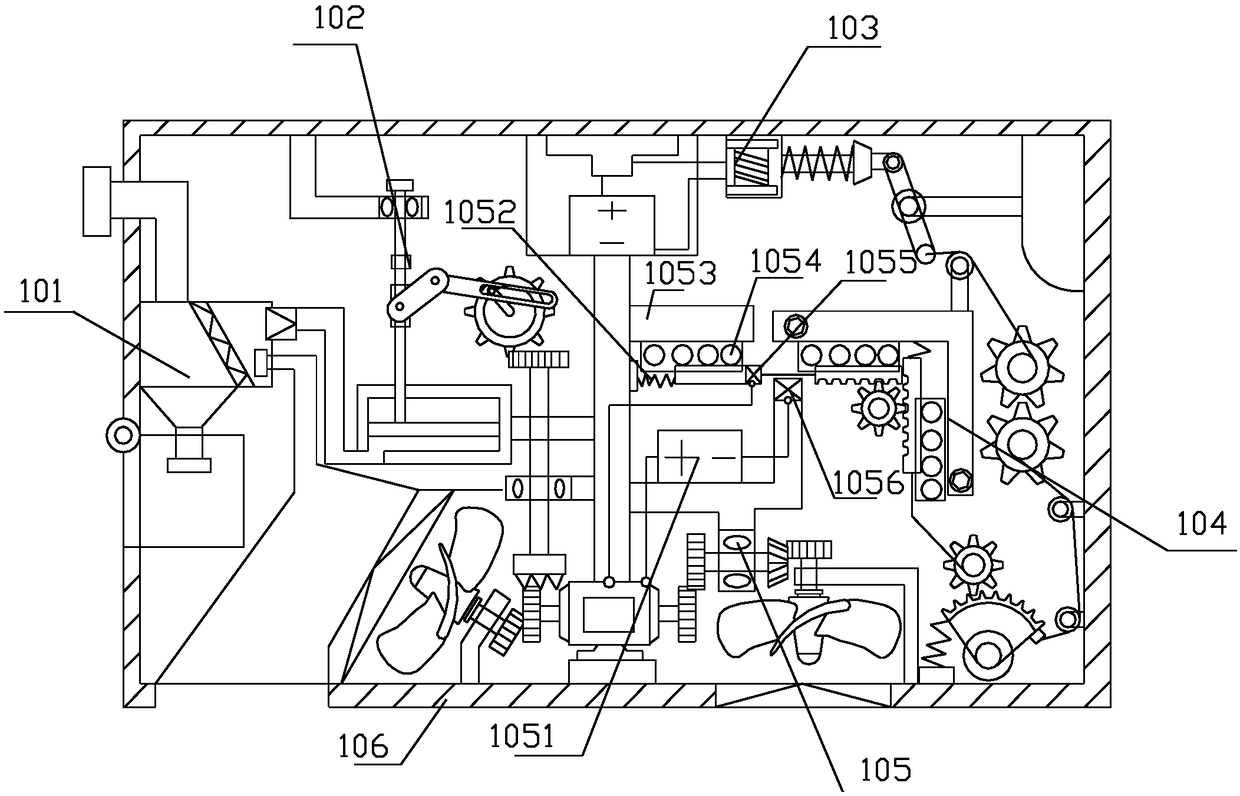

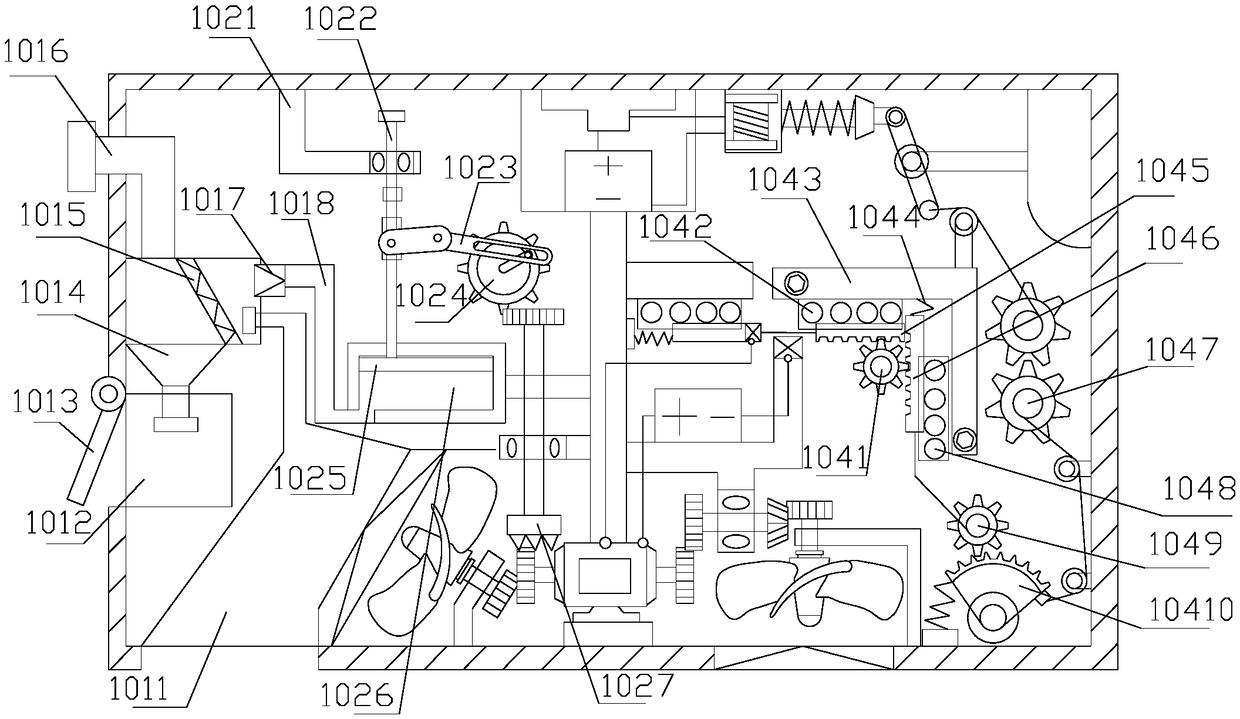

Method for preparing dermal fiber cotton and dermal flocking machine

InactiveCN101235559AQuality improvementAvoid damageCarding machinesTextile disintegration and recoveryEngineeringFiber

A method for manufacturing corium fiber floss comprises the following steps: firstly, soaking the rim leftover of leather in water and fully expanding the rim leftover, secondly, removing water by dewatering centrifuges, thirdly, hammering the rim leftover into flocculent corium fiber agglomerate through corium cashmere-making machines, then opening the corium fiber agglomerate into corium fiber floss by needle roller opening devices, fourthly, drying, wherein the cashmere-making machines comprise shells, main axle(1)s, hammer carriers (2), hammer (7), bases (9), motors and actuating mechanism. ribs with gear form (5) are distributed on the whole inner-wall of the cylindrical surface of the shell, a plurality of weep holes (10) and a discharge hole are mounted on the lower portion of the cylindrical surface, and a can-be opened-and-closed discharging gate (11) is mounted on the discharge hole. Since the method separates the fiber with each other by hammering the leather after the leather is soaked and expended, then opening the fiber by the needle roller opening device, thereby, the manufacturing time is greatly reduced, the opening forces of opening machines are small, the damage is small, and the high quality corium fiber floss can be obtained.

Owner:尹金良

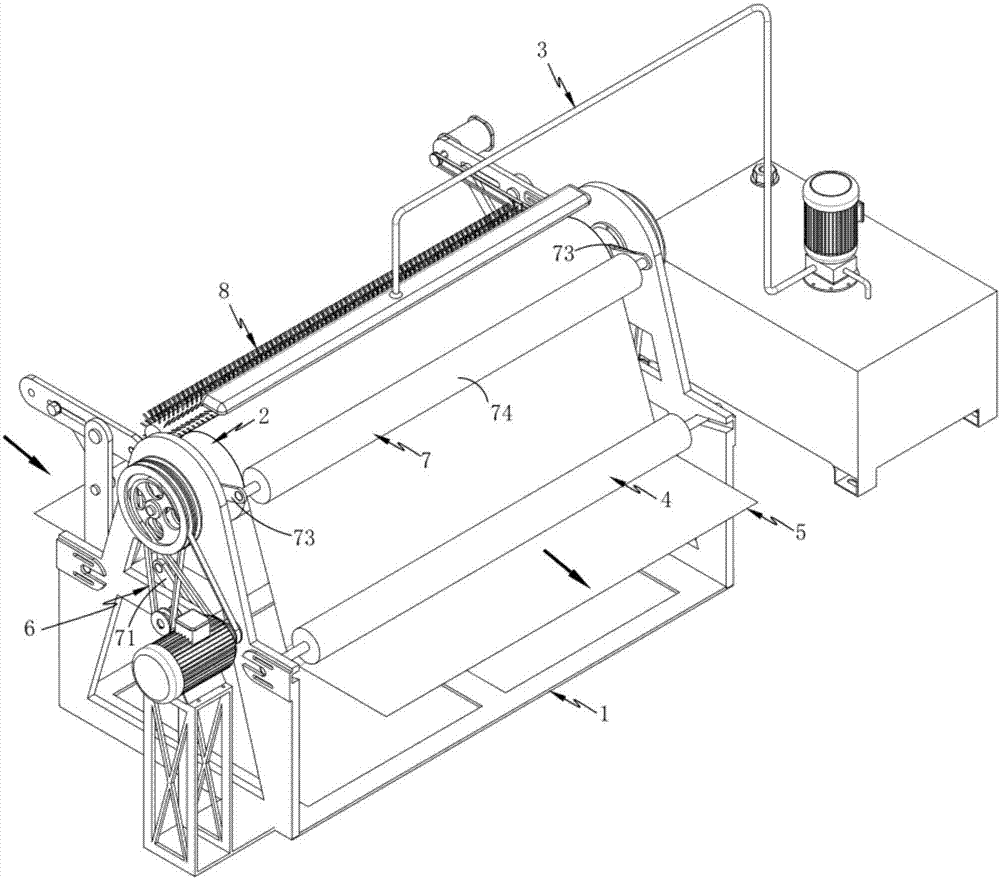

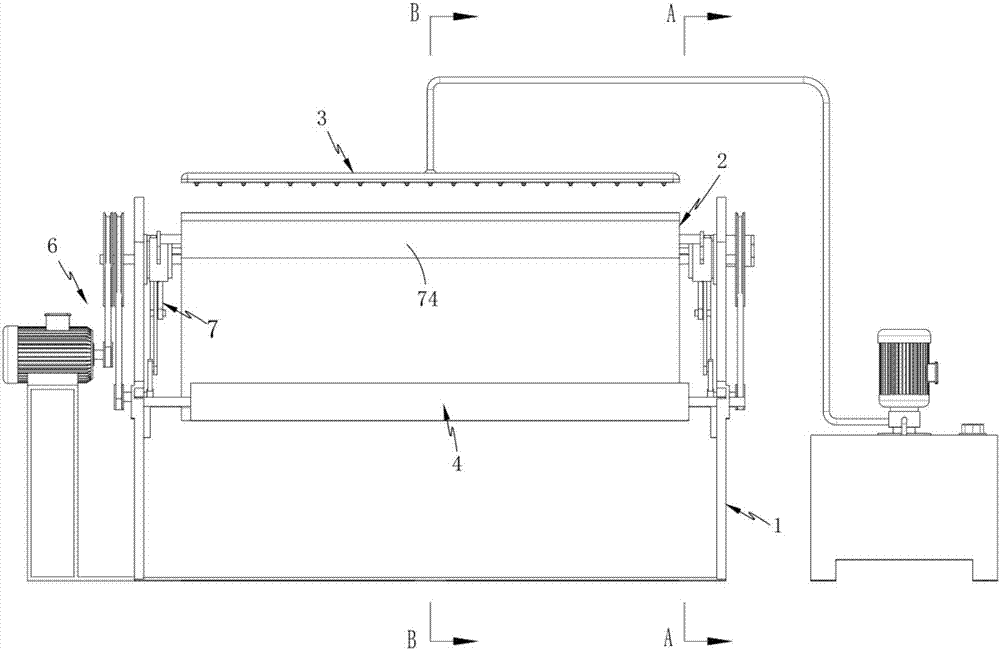

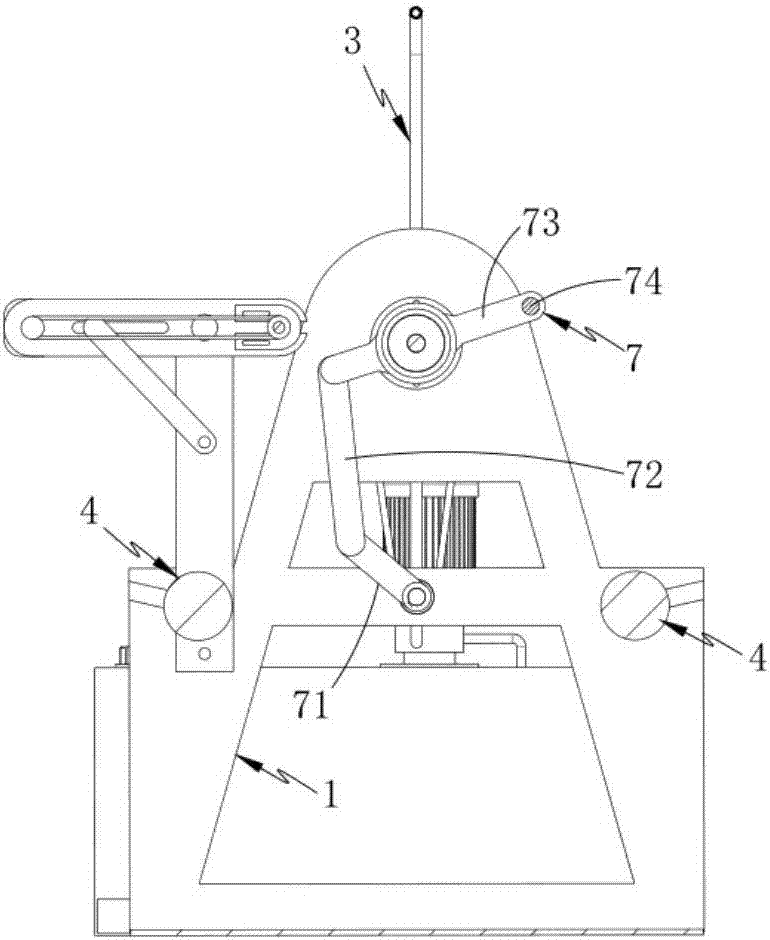

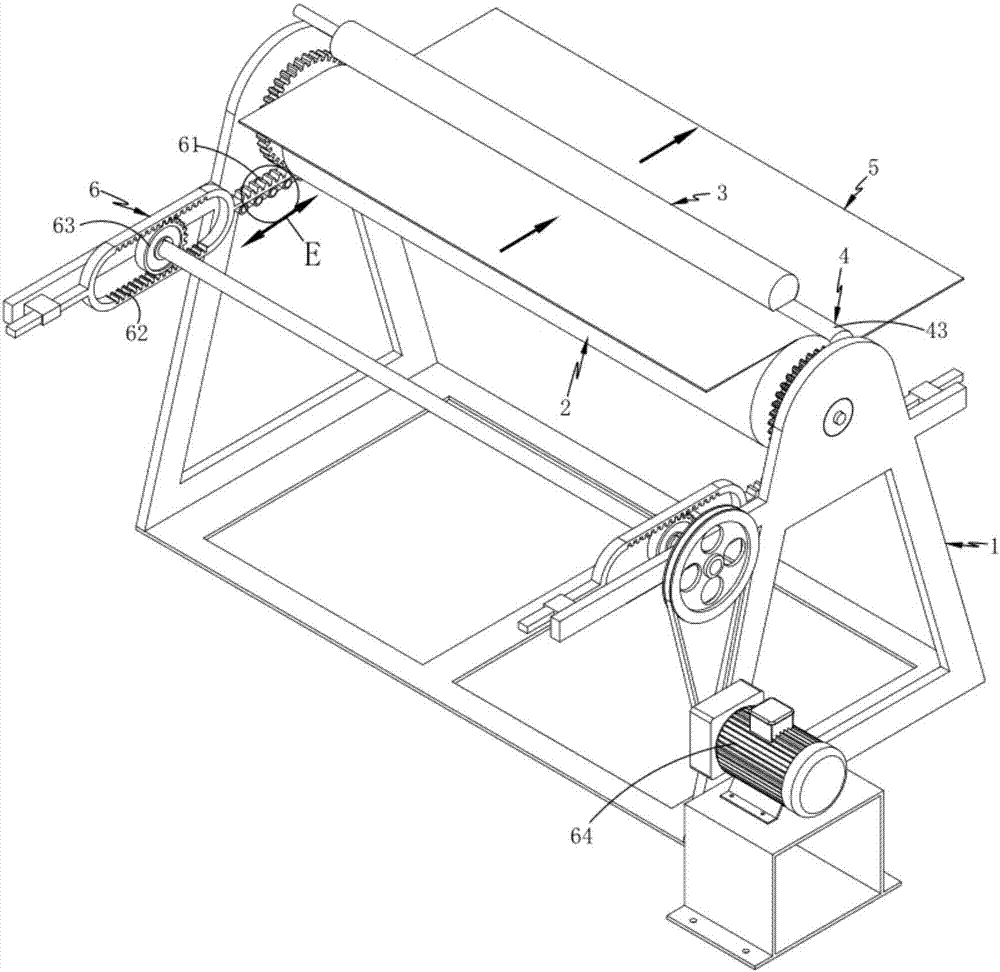

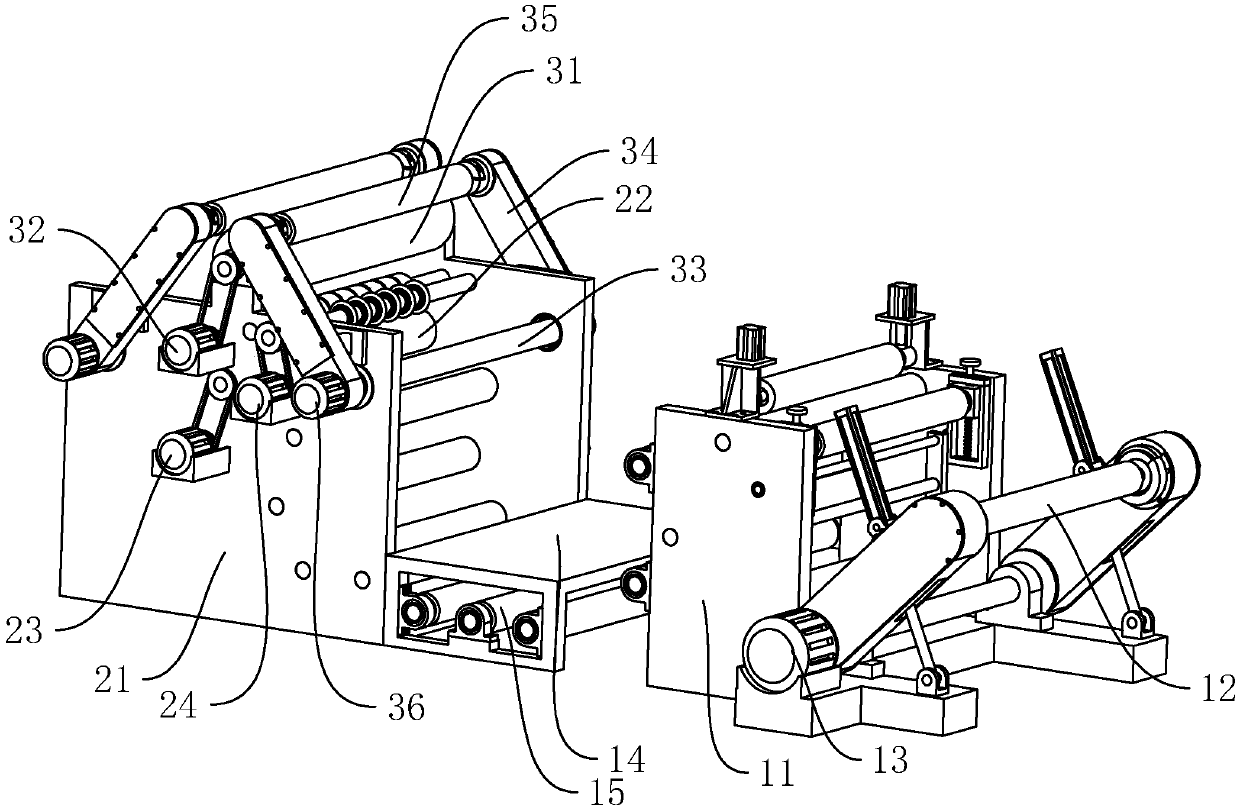

High quality spinning dyeing mechanism

InactiveCN107034606AImprove flatnessReduce pulling forceTextile treatment by spraying/projectingTextile treatment carriersAgricultural engineeringTextile dyeing

The invention relates to a high-quality textile dyeing mechanism, which includes a frame, a transmission roller rotatably mounted on the frame, a spraying and dyeing assembly fixedly arranged above the transmission roller, and a rotatively mounted frame located on both sides of the transmission roller The cloth guide roller and the driving assembly that drives the transmission roller to carry out gray cloth transmission also include a smear assembly that is located on one side of the transmission roller and moves along its outer circumference. The first connecting rod connected to the driving assembly, the second connecting rod connected to the other end of the first connecting rod in rotation, the third connecting rod connected to the second connecting rod at one end and installed on the second connecting rod The smearing roller at the other end of the three connecting rods; the greige cloth is pre-dyed, dyed and polished, and then reciprocated on the conveying roller by the smearing roller to achieve wrinkle removal, color fixation and uniform dyeing of the greige cloth. The technical problems of uneven dyeing and easy fading in the background technology.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

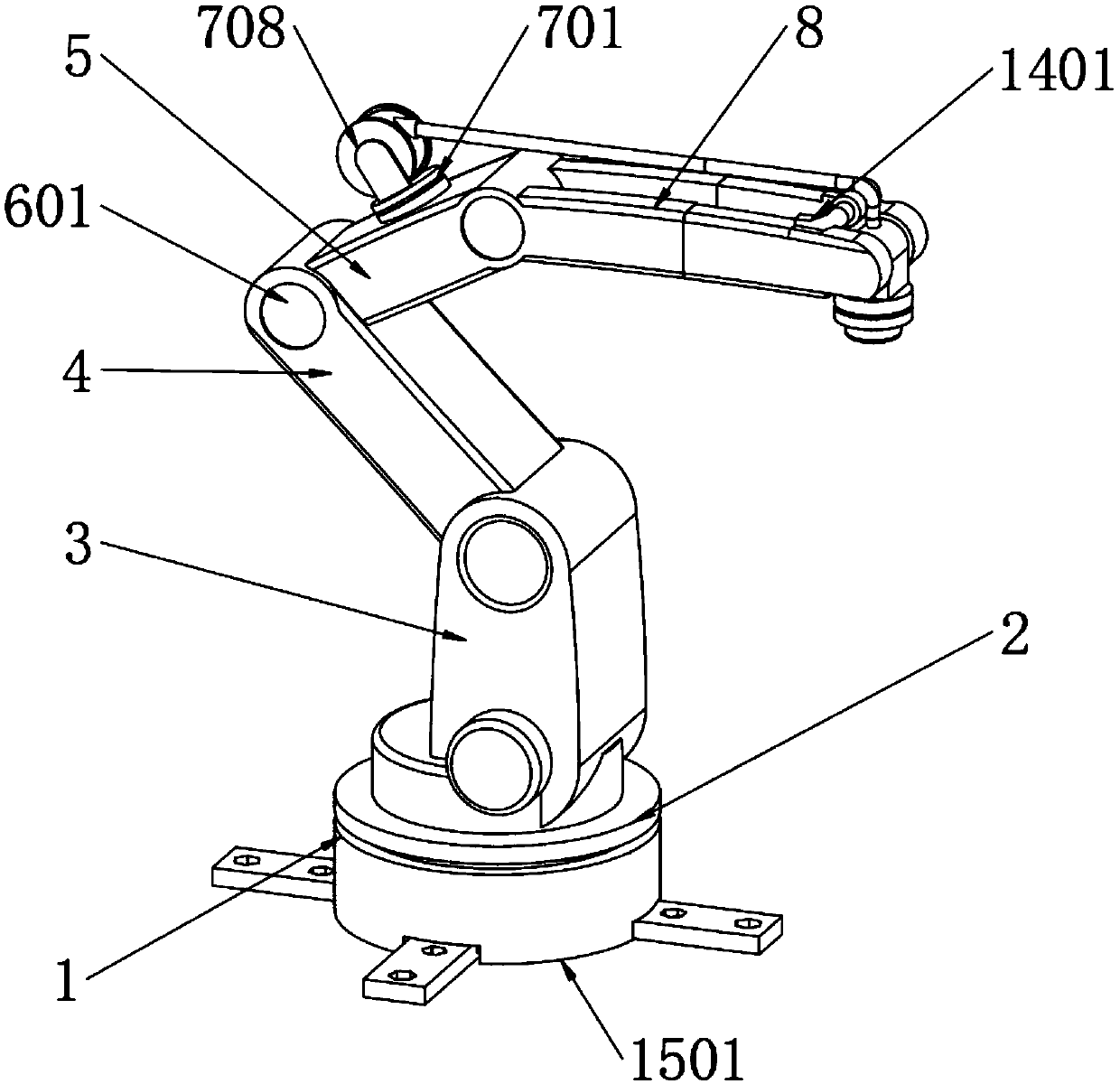

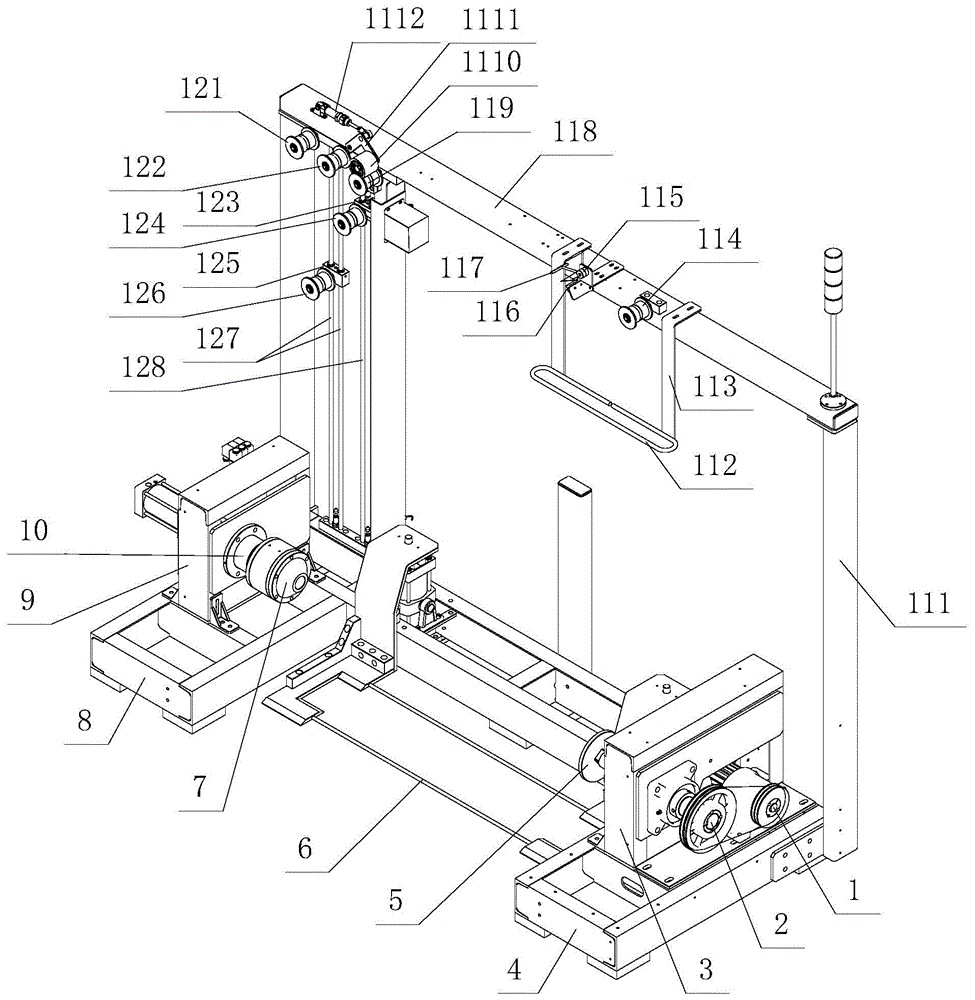

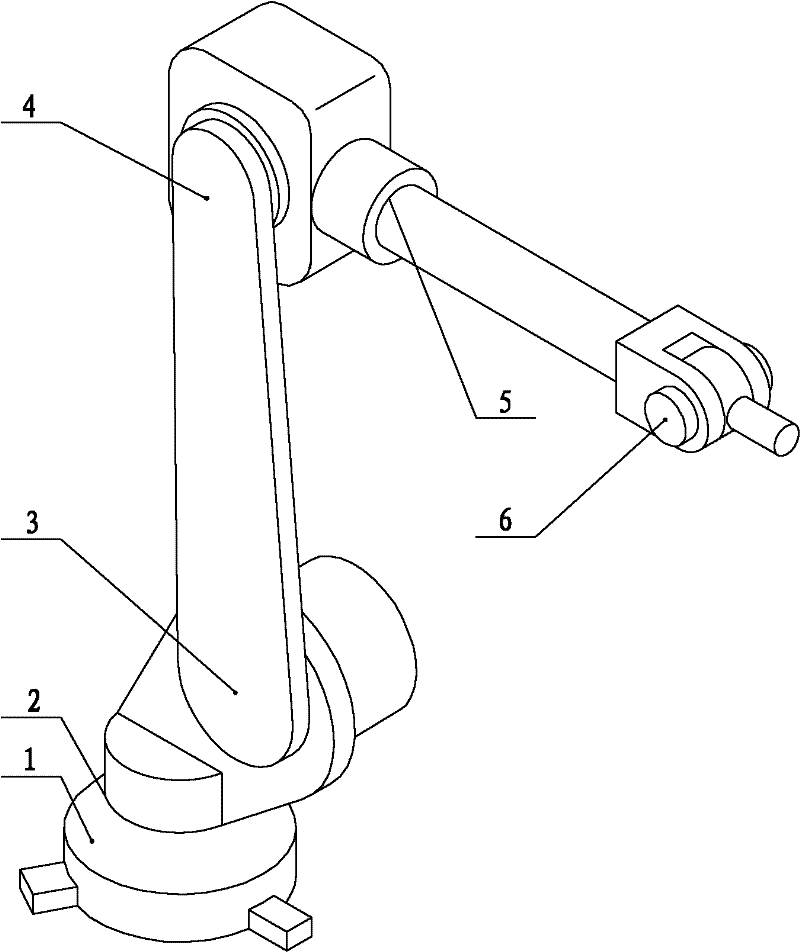

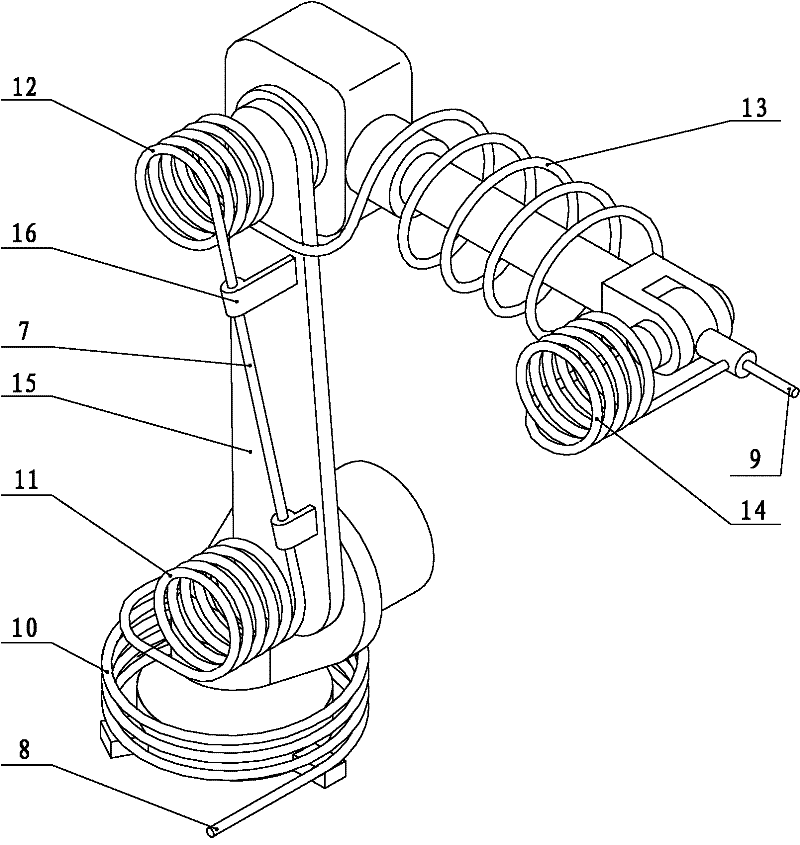

Improved mechanical arm device

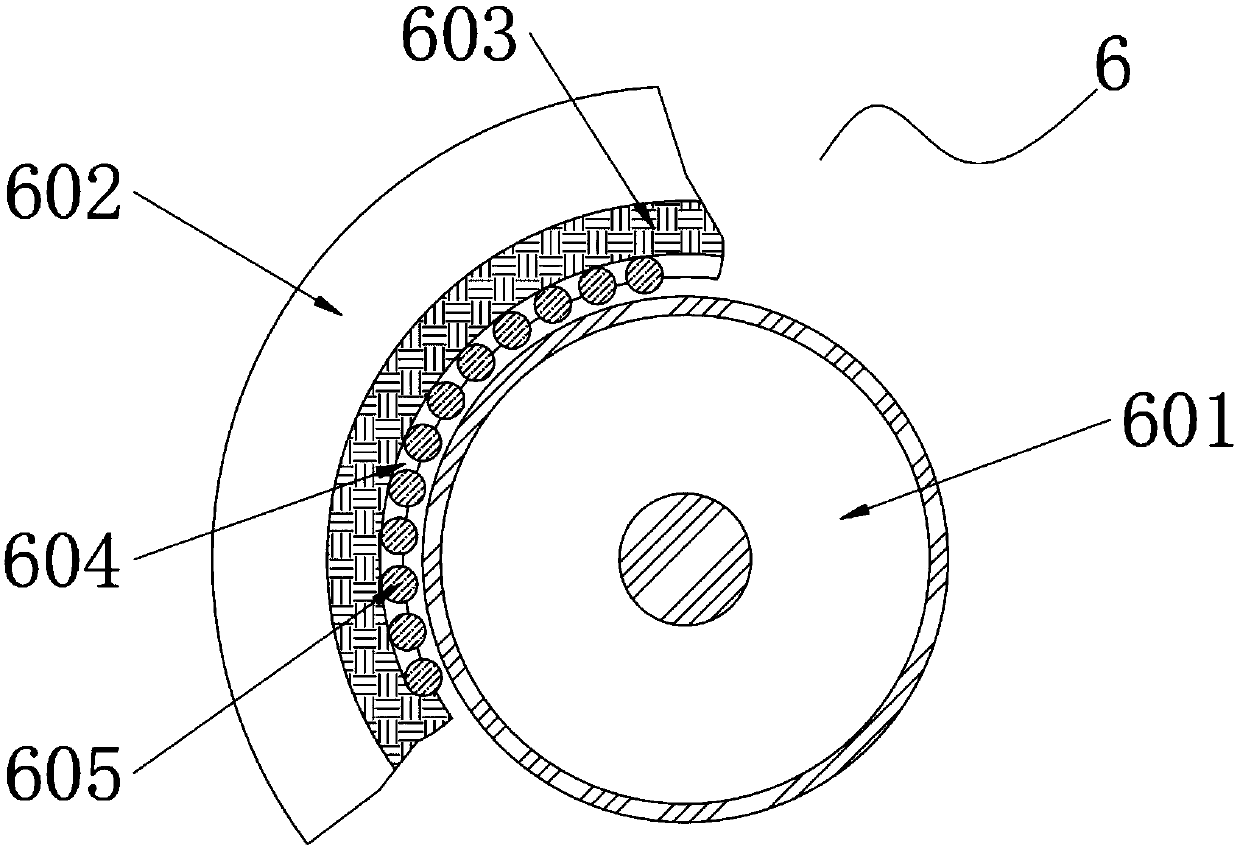

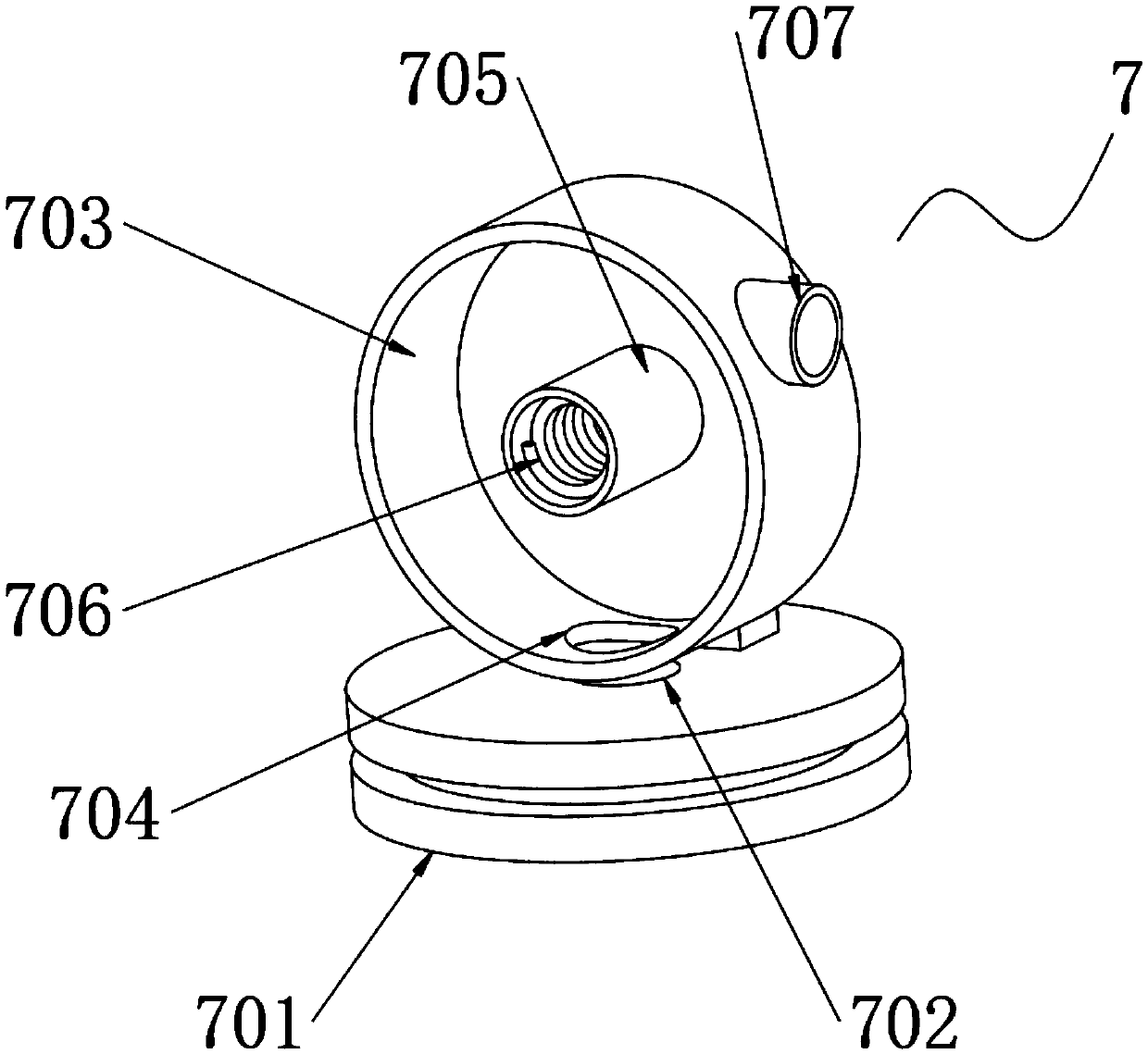

ActiveCN109605334AScientific and reasonable structureEasy to useProgramme-controlled manipulatorJointsEngineeringMechanical engineering

The improved mechanical arm device. The improved mechanical arm device comprises a base, wherein a first connecting arm is arranged at the top end of the base, one end of the first connecting arm is provided with a rotating shaft assembly, one side of the rotating shaft assembly is connected with a second connecting arm, and a take-up assembly is arranged at the top end of the second connecting arm. According to the improved mechanical arm device, the structure is scientific and reasonable, the use is safe and convenient, the take-up assembly is arranged, and the functions of a take-up box, atake-up wheel and a spring are achieved so that the mechanical arm connecting line coils can be conveniently wound into the take-up box to be hidden, abrasion caused by the fact that connecting linesare exposed to be wound or in contact with an external object is avoided; due to the elastic action of the spring, the connecting lines can be automatically tightened; and the rotating shaft assemblyis arranged, through the action of an elastic plate and balls, the balls can be conveniently in contact with a rotating shaft through the rotation of the rotating shaft so that the balls can roll andextrude a sponge layer, lubricating oil inside the sponge layer is guided to the surface of the rotating shaft, the rotating shaft is lubricated, the structure is simple, and the use is convenient andfast.

Owner:久智光电子材料科技有限公司

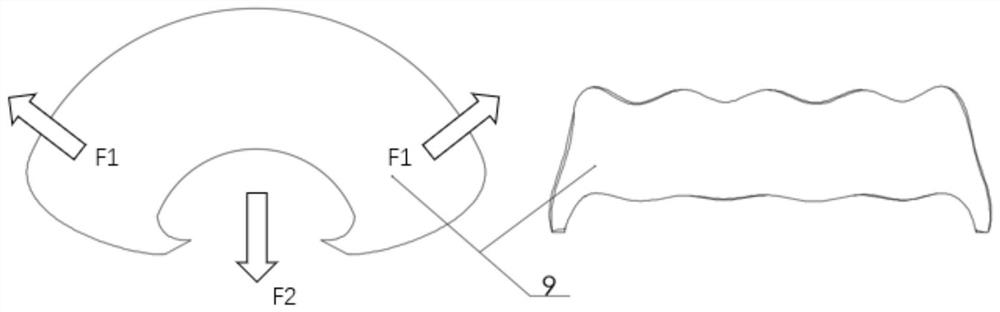

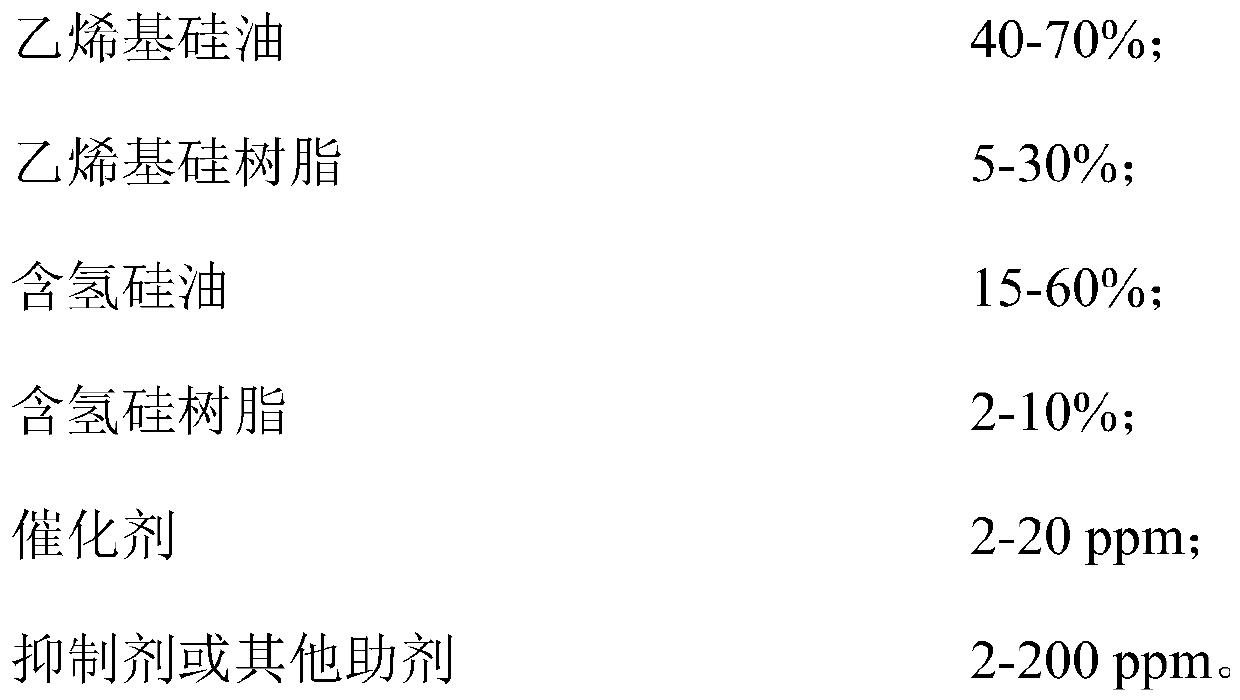

Expansion method and expansion equipment thereof of thermal shrinkage pipe material with large caliber

The invention relates to an expansion method and expansion equipment thereof of a thermal shrinkage pipe material with large caliber, aiming at overcoming the defects of very low expansion speed and low production efficiency caused by such a way that the existing thermal shrinkage pipe material with large caliber adopts a continuous expansion and continuous pipe shrinkage method during expanding. The invention provides an expansion method of a novel thermal shrinkage pipe material with large caliber and adopts the technical concept that expansion and pipe shrinkage are discontinuously carried out circularly; namely, the pipe shrinkage is not carried out at the time of the expansion and the expansion is not carried out at the time of the pipe shrinkage; pulling force to the pipe material can be greatly reduced at the time of the pipe shrinkage because the expansion is not carried out at the time of the pipe shrinkage, and two problems of cooling moulding and tensile deformation of the pipe material are solved; therefore, the expansion speed and the production efficiency can be enhanced lengthening an expansion mould; and simultaneously, the invention also utilizes the concept to design the corresponding expansion equipment, utilizes a time control switch and an electromagnetic valve to carry out discontinuous air suction and exhaust on the expansion mould, utilizes a stroke measurement control switch to control the pipe shrinkage length and realizes that two procedures of expansion and pipe shrinkage are discontinuously carried out circularly.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL

Apparatus for paperless transfer printing and the process thereof

InactiveUS20050139096A1Strong absorption capabilityReduce tensionRecording apparatusTransfer printingMetal foilClose contact

The present invention is related to an apparatus for paperless transfer printing, which includes a printer and a heat transfer printing machine, the printer is connected and assembled with the heat transfer printing machine by an endless metal foil belt, the heat transfer printing machine includes at least a heating transfer printing roller, or a weight bearing crawler belt, or a weight bearing plate the heating transfer printing roller can absorb the belt of metal foil by negative pressure of vacuum or by magnetic means, which result in the close fitting of the belt to the surface of the heating transfer printing roller. The paperless heating transfer printing apparatus also includes a heating device to heat the belt of the metal foil. A set process of printing is also proposed in this invention, which used said apparatus. By using this kind of apparatus and the process, the problem, that the metal foil easier wrinkles than paper does is overcome, and the substrate can close contact with the surface of the roller, the heat can be transferred more uniformly. The patterns the apparatus made are lucidity and less color difference or un-sharpness, the pulling force acting on the foil is also reduced.

Owner:XIANGYANG LU +1

Charging pile device applied to new energy vehicle

InactiveCN109278579ARealize retractable workAvoid breakingCharging stationsElectric vehicle charging technologyNew energyEngineering

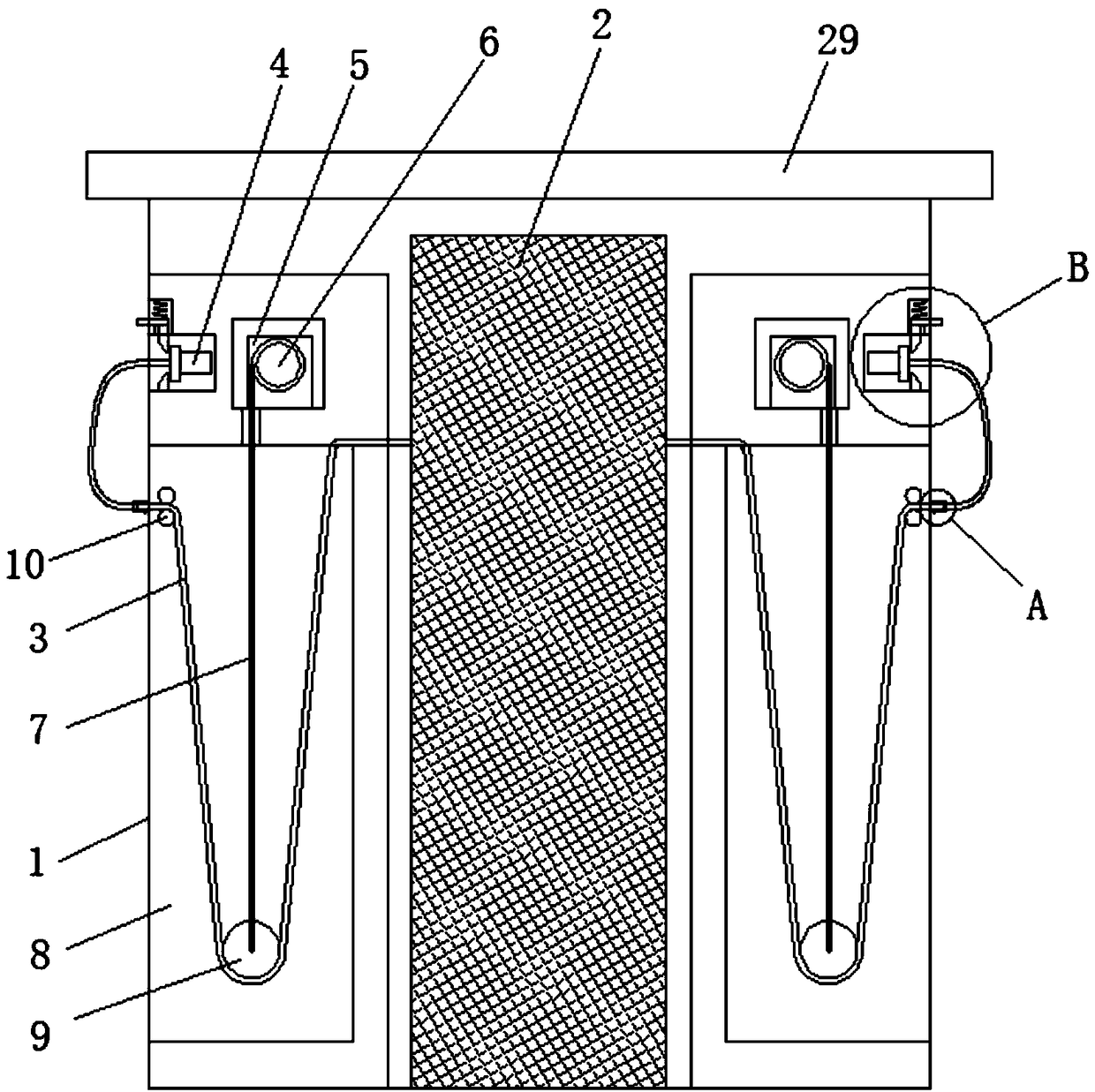

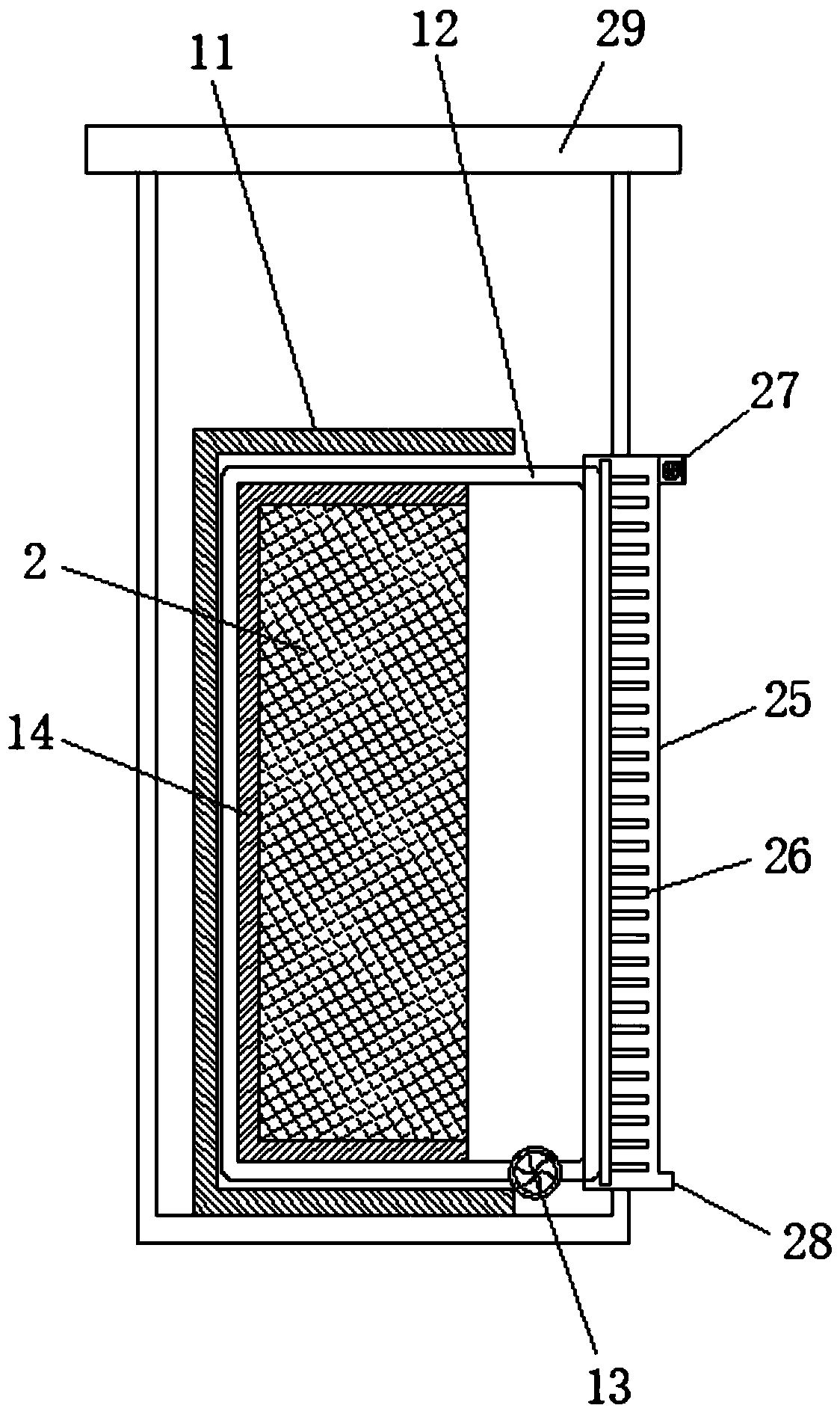

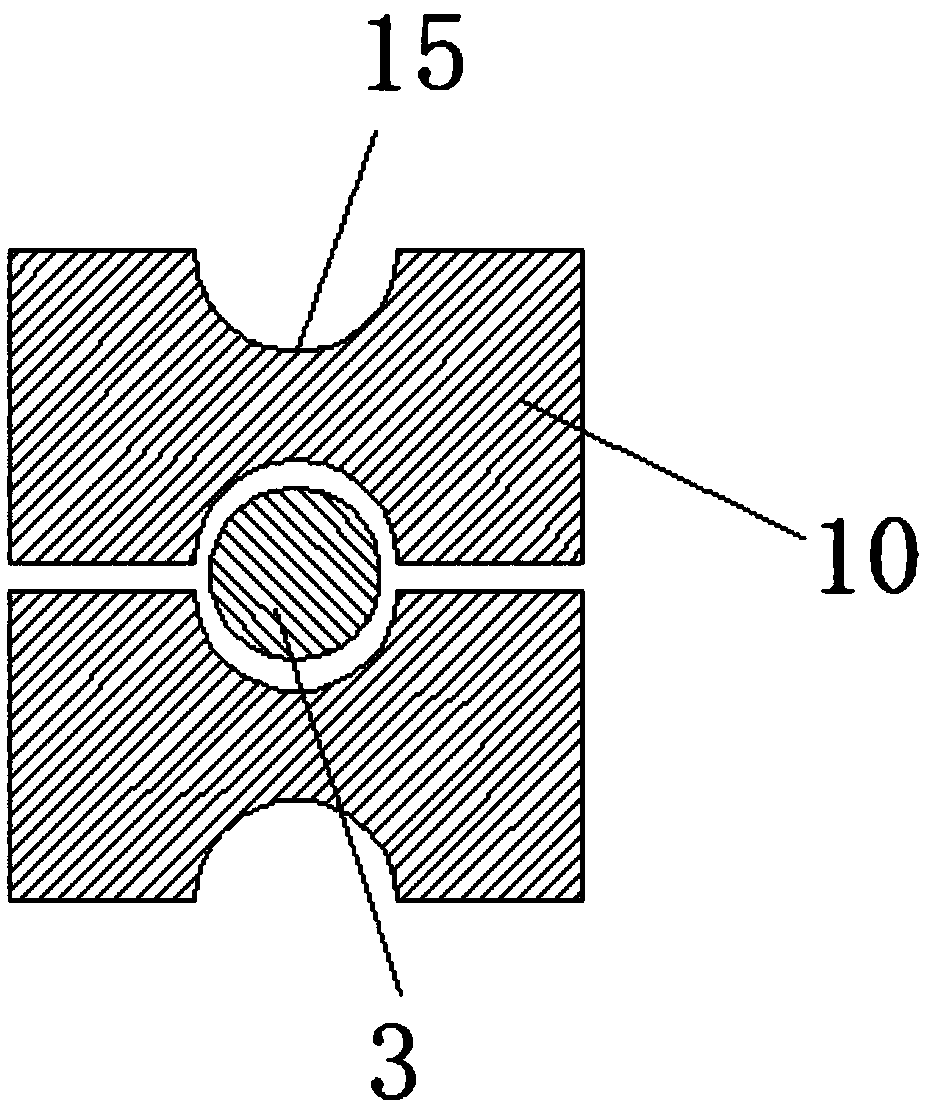

The invention discloses a charging pile device applied to a new energy vehicle. The charging pile device comprises a charging pile shell, a power module, two charging wires and two charging guns; thepower module is connected with the charging guns through the charging wires, the two charging wires and the two charging guns are arranged on the two sides of the charging pile shell correspondingly,winding mechanisms used for winding the charging wires are arranged on the two sides in the charging pile shell correspondingly, and a heat dissipating mechanism used for heat dissipating is arrangedon a back plate of the charging pile shell. According to the charging pile device, the charging wires can be stored, and the situation that an insulation skin exposed outside is damaged and consequently forms a dangerous source that threatens personal safety is avoided; air outside the charging pile shell and air in the charging pile shell are not subjected to convection, the situation that dust and moisture enter the charging pile device and affect subsequent maintenance is avoided, the heat dissipation efficiency is improved, and noise is lowered.

Owner:YANGZHOU GAOSHENG MACHINERY

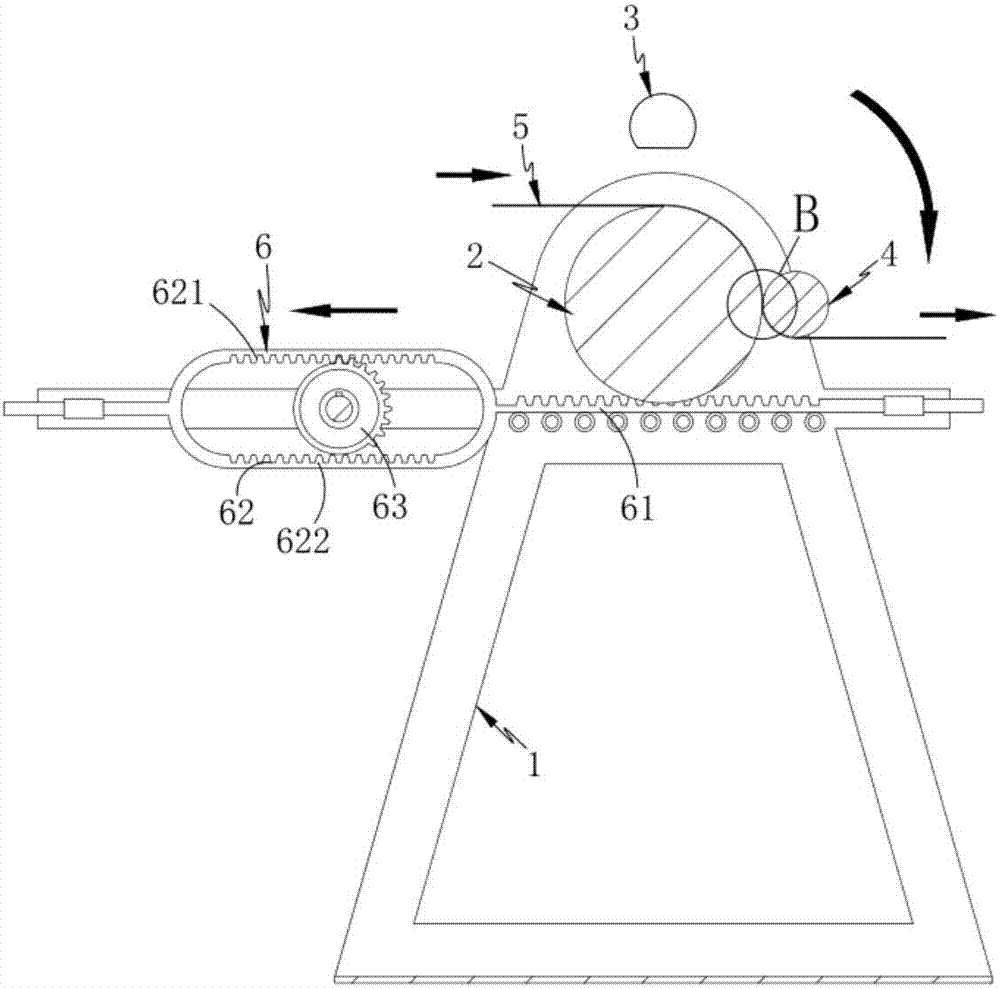

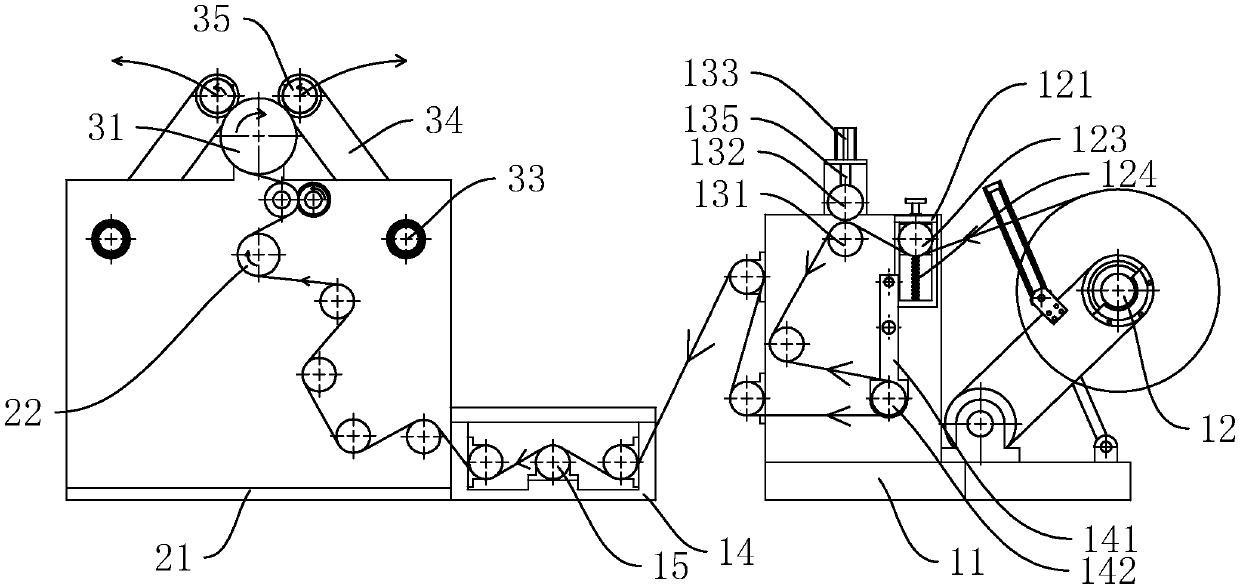

Rolling-type auxiliary device for spray dyeing

InactiveCN107059283AAchieve tautnessImprove flatnessTextile treatment machine arrangementsTextile treatment by spraying/projectingGear driveReciprocating motion

The invention relates to a rolling auxiliary dyeing equipment, which includes a frame, a coloring roller rotatably mounted on the frame, a dyeing spray head arranged above the coloring roller, a smearing assembly located on one side of the coloring roller, and two The transmission channel for gray cloth is formed between them, the drive assembly is symmetrically arranged on the frame and located on both sides of the coloring roller, and the driving assembly drives the smearing assembly to reciprocate along the outer circumferential surface of the coloring roller; The transmission gear ring and the transmission gear, the transmission gear rack is slidably installed on the frame and matched with the smearing component, the transmission gear ring is located at one end of the transmission rack and fixedly connected with it, the transmission gear is rotatably installed on the frame, and is installed in cooperation In the inside of the transmission gear ring, the transmission gear drives the applicator roller to enter the dyed cloth for reciprocating elastic rolling during the rotation process, so as to realize the uniform dyeing treatment and dyeing curing of the gray cloth, and solve the technology of uneven dyeing and easy fading in the background technology question.

Owner:CHANGXING COUNTY DAWEI TEXTILE CO LTD

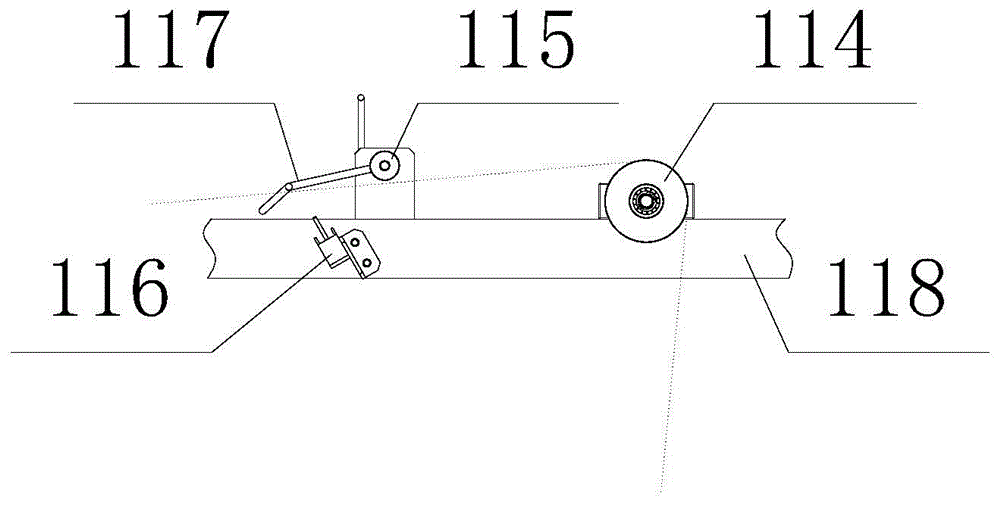

Fin ray-free amphibious propelling device with bionic undulating fins

PendingCN113696685AImprove flexibilityEnough supportAmphibious vehiclesPropulsive elements of non-rotary typeMarine engineeringCam

The invention discloses a fin ray-free amphibious propelling device with bionic undulating fins, which is characterized in that two end fixed type crankshaft swing rod transmission modules are arranged on corresponding bottom plates correspondingly, and the front ends and the rear ends of the two bottom plates are connected with a front waterproof steering engine amphibious mode switching module and a rear waterproof steering engine amphibious mode switching module correspondingly; the front and back waterproof steering engine land and water mode switching module is used for maintaining the state of the bottom plate; each end fixed type crankshaft swing rod transmission module is connected with one flexible fin-ray-free flexible fin through the corresponding drive swing rod mechanism, and the joint of each drive swing rod mechanism and the corresponding flexible fin-ray-free flexible fin is provided with a rotational degree of freedom to drive the fin surface of the corresponding flexible fin-ray-free flexible fin to achieve fluctuating motion. The problems that an existing amphibious robot is complex in transmission mechanism, complex in amphibious mode switching, large in wheel paddle driving noise, low in flexibility and large in environment disturbance, the movement speed of fluctuation fins driven by a conventional steering engine is low, and a traditional cam and crankshaft connecting rod mechanism is low in bearing capacity and cannot conduct amphibious movement are solved.

Owner:XI AN JIAOTONG UNIV

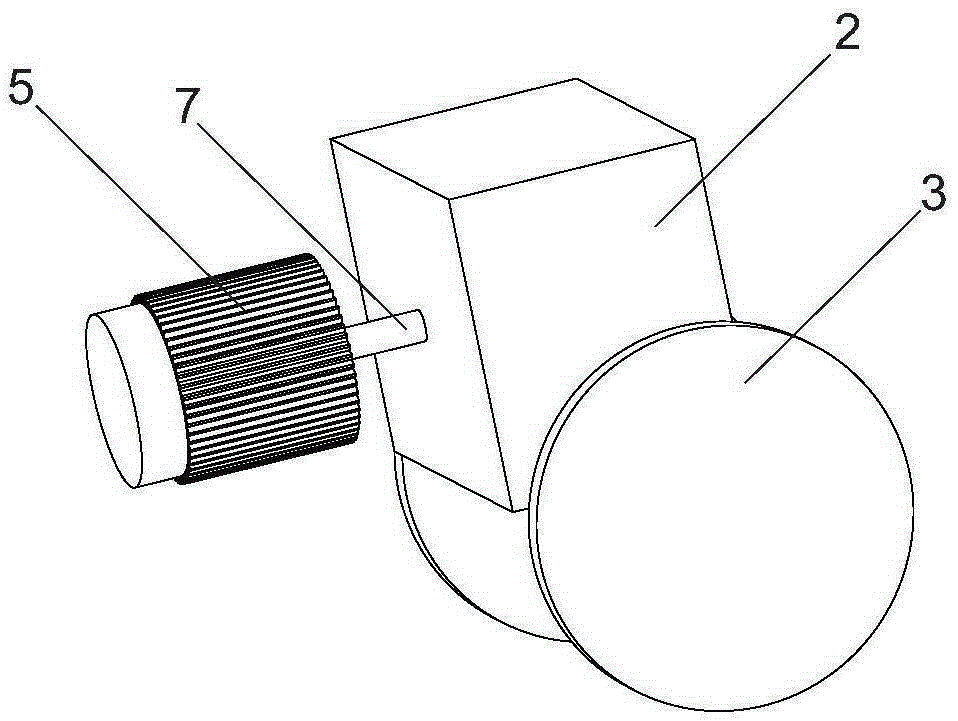

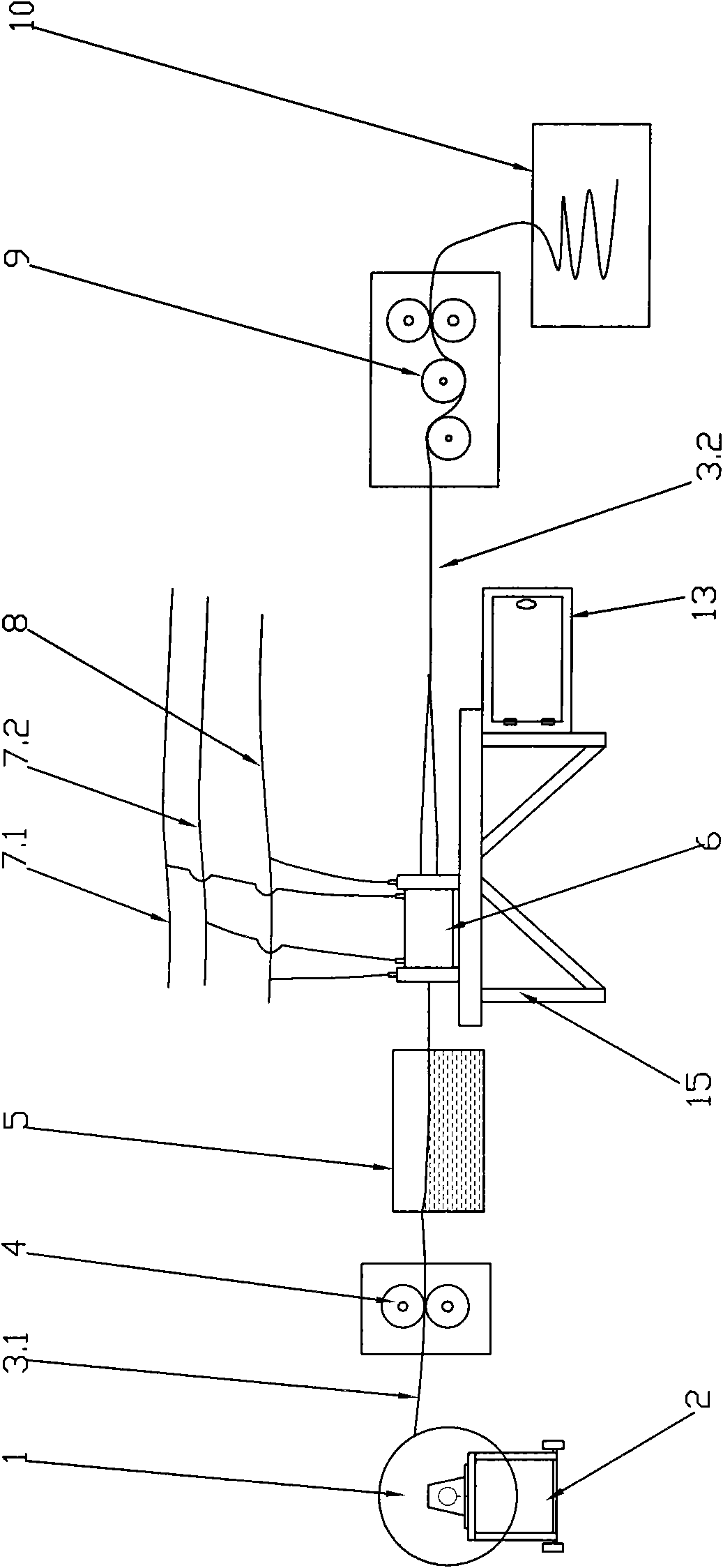

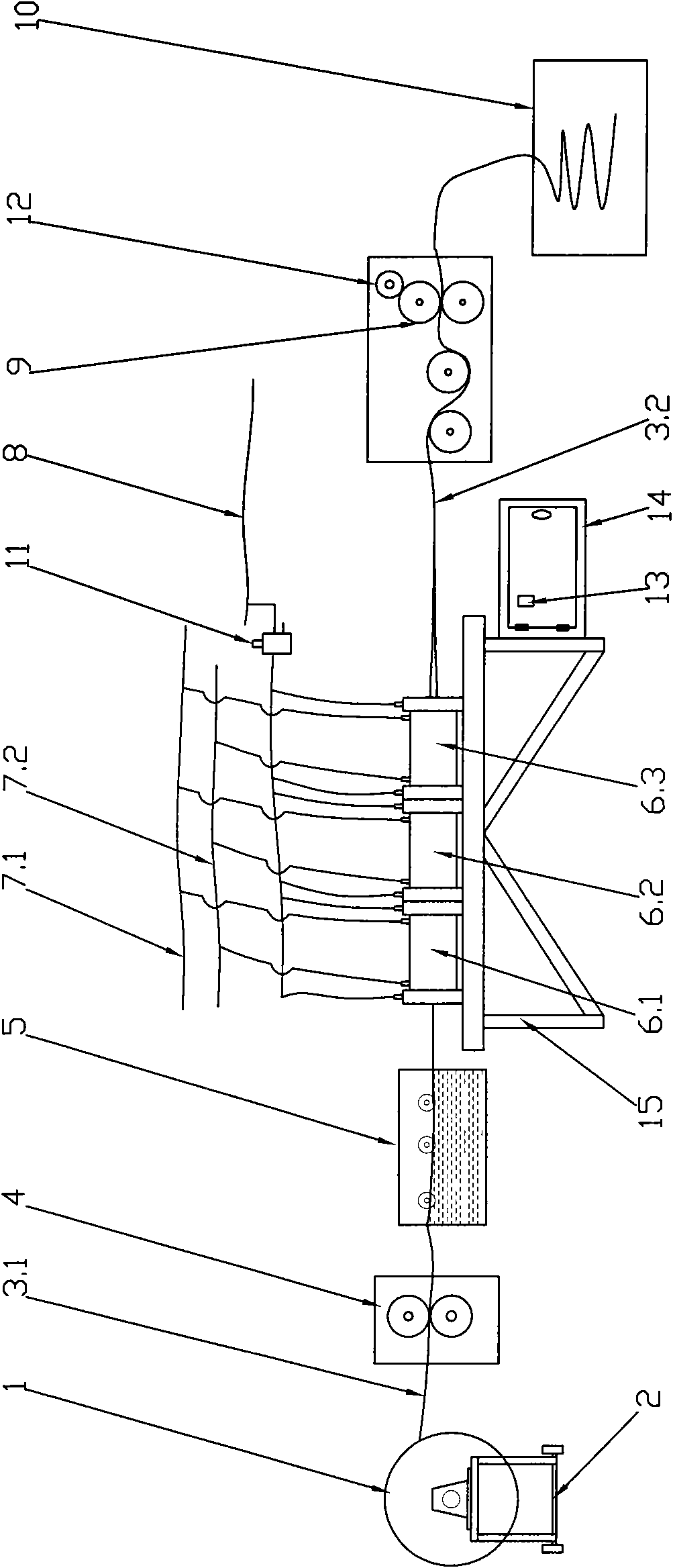

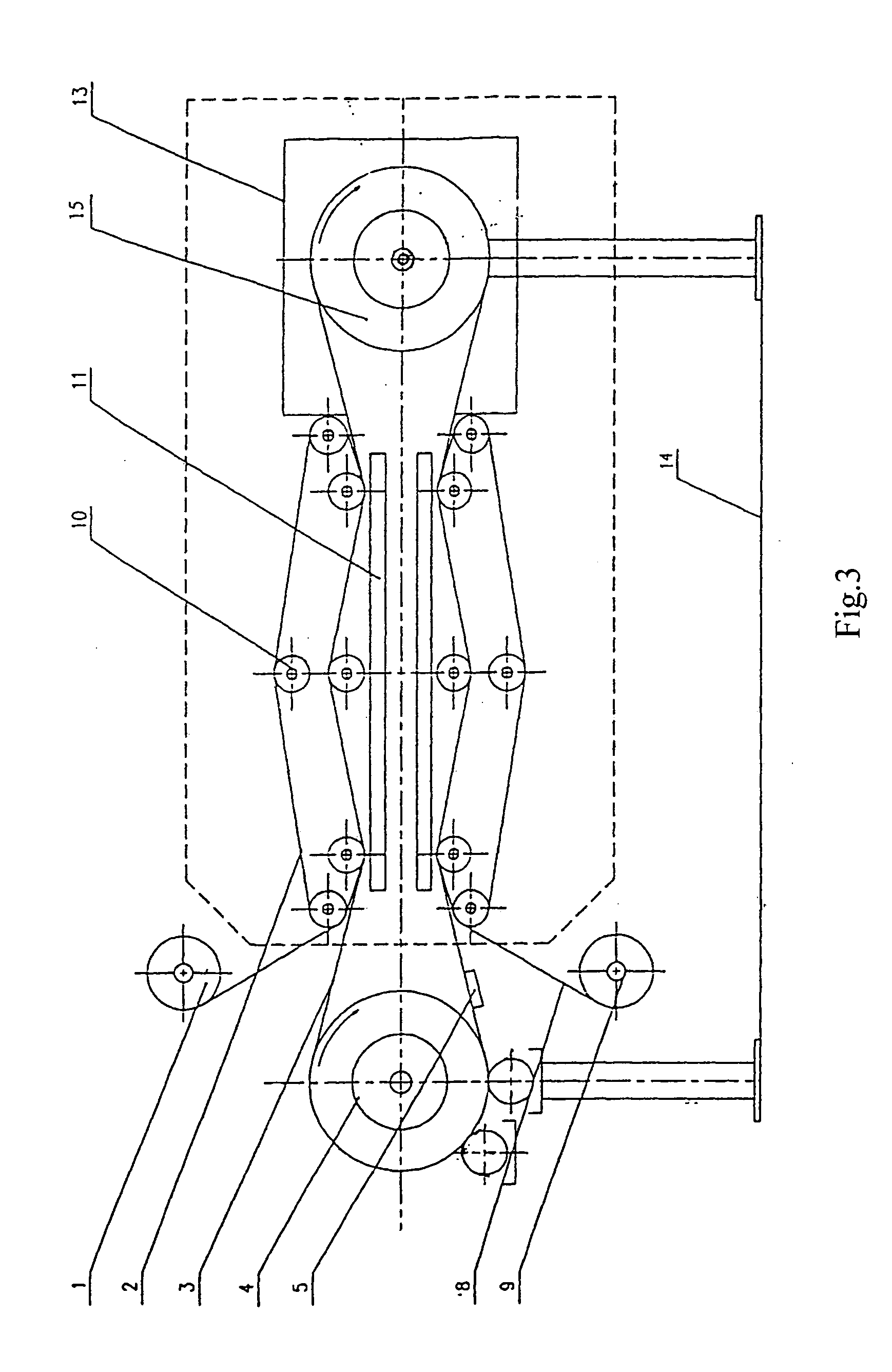

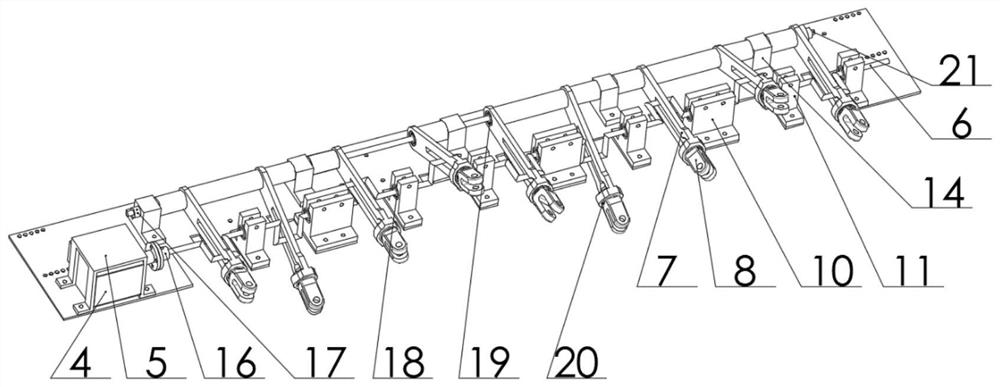

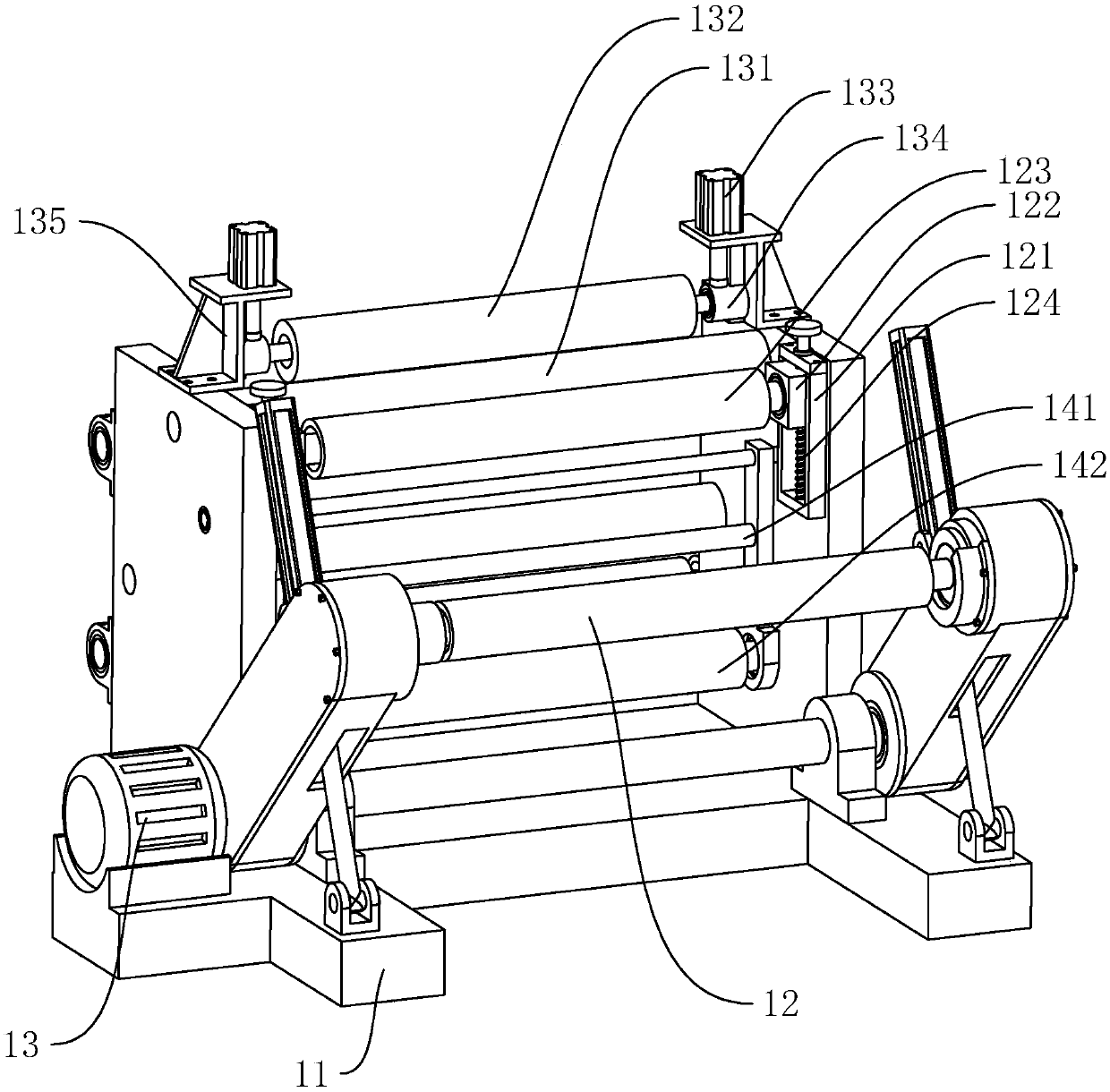

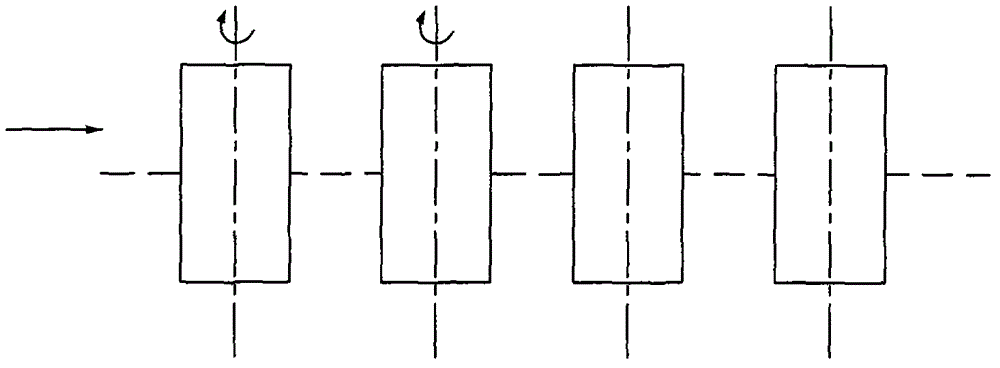

Automatic zipper belt conveying machine

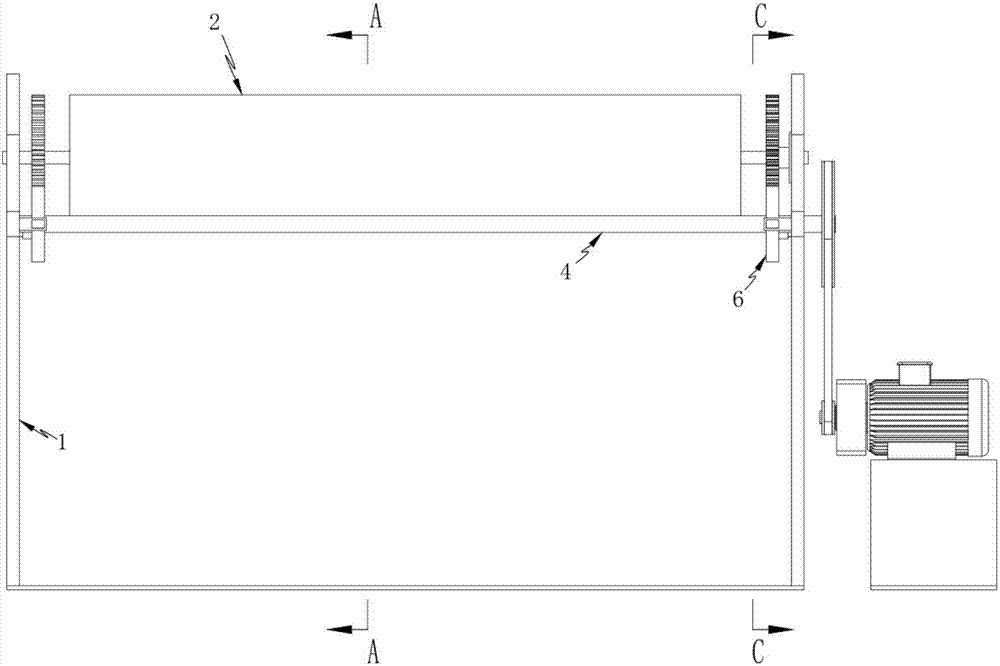

ActiveCN104310099AThe degree of deformation remains consistentImprove product qualityDrying solid materialsArticle deliveryTextileMechanical engineering

The invention relates to the technical field of a belt conveying device of a zipper belt drying machine, and provides an automatic zipper belt conveying machine, which comprises a first mounting frame (3) and a second mounting frame (9), wherein the first mounting frame (3) and the second mounting frame (9) are oppositely arranged, and are respectively provided with a driving rotary shaft (2) and a driven rotary shaft (10), the adjacent front ends of the driving rotary shaft (2) and the driven rotary shaft (10) are respectively and fixedly provided with a left jacking head (5) and a right jacking head (7), the driving rotary shaft (2) and the driven rotary shaft (10) are positioned on the same axis, and the driving rotary shaft (2) is driven by a servo motor (1). The automatic zipper belt conveying machine has the advantages that by matching with the drying machine, the automatic zipper belt conveying is realized, the speed of the drying machine is automatically matched, and the smoothness of zipper teeth is effectively improved; the water shrinkage state of the zipper belt is stabilized, the influence on splicing property of the zipper teeth is avoided, and a cloth belt is sufficiently protected.

Owner:CHENGDU ROCK SOLID AUTOMATION TECH

Inner layer pattern design method for improving copper pull during drilling

ActiveCN108770238AReduce cutting resistanceReduce pulling forcePrinted element electric connection formationPull forceRing pattern

The invention discloses an inner layer pattern design method for improving copper pull during drilling. The method comprises the following steps: setting a drilling location on an inner layer core board, wherein the drilling location is a location that needs to be drilled in subsequent processing; transferring an inner layer pattern on a film to the inner core board by a negative film process, wherein the inner layer pattern comprises a circular ring pattern having an outer diameter larger than the diameter of the drilling location, and the inner diameter of the circular ring pattern is less than the diameter of the drilling location; and removing exposed copper on the inner core board by etching, and then removing the film to form an inner layer circuit via the inner layer pattern and toform a circular ring via the circular ring pattern. By adoption of the method disclosed by the invention, the cutting resistance of a drill bit in the subsequent drilling and the pulling force of thedrill bit to the inner layer copper foil, thereby reducing the copper pull during drilling, effectively reducing the scrap rate of the board and improving the quality of the board.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Manufacturing process of high-strength circular-drawing six-angle steel

InactiveCN110125194AImprove processing efficiencyMeet the needs of deformationDrawing diesExtrusion cleaning devicesLubricationOxide

The invention discloses a manufacturing process of high-strength circular-drawing six-angle steel. The manufacturing process route sequentially comprises the steps of preparation of a blank material,surface cleaning, tip rolling, annealing and solid solution, blank lubrication, cold drawing, straightening, polishing and quality inspection and packaging, wherein a lubricant used for lubricating the blank material is a mixture of liquid paraffin, metal nano-powder and graphene oxide, the diameter of a die hole of a cold-drawing die is 6-14 mm, and the width of a diameter-fixed belt is 5-8 mm. According to the manufacturing process, cold drawing is adopted after surface lubrication treatment, so that the machining efficiency is improved, and the industrial amplification production requirements are met; and meanwhile, the cold drawing die hole is reasonably set, so that the deformation requirement is met, the drawing force is small, drawing is stable, the deformation is uniform, the drawing die is uniformly abraded, the size and the surface smoothness of a cold drawing material are ensured, then the cold-drawn steel has relatively high surface smoothness, and the requirement for the surface quality of the cold-drawn steel in the aerospace industry is met.

Owner:江油华冶特材有限公司

Double-axis high-speed slitting machine for slitting tipping paper

PendingCN109573680AAvoid tearingEnsure Width AccuracyMetal working apparatusArticle deliveryPull forcePulp and paper industry

Owner:JI LONG MACHINERY CO LTD

Safety inspection device for river dam

InactiveCN110487321ASimple structureEasy to operateBreakwatersMeasurement devicesEngineeringMechanical engineering

The invention discloses a safety inspection device for a river dam. The device includes a dam guardrail, a translation cavity with an opening facing the right is set in the dam guardrail, a translation block with a right end located in an external space is in the translation cavity, a connection block is fixed at a right end of the translation block, a moving block whose left end is at an upper end of the dam guardrail is fixed to an upper end of the connection block, a driving cavity is set in the connecting block, a translation mechanism capable of driving the translation block to move backand forth is set in the translation block, the translation block is internally provided with an inspection mechanism capable of inspecting the dam and providing lighting at night, and the driving cavity is internally provided with a transmission mechanism that can transmit the power of the translation mechanism to the inspection mechanism. The device can automatically complete a safe inspection ofthe river dam, the inspection efficiency is improved while labor is saved, the device also can work at night, the lighting is provided during the night work, and the inspection effect is ensured.

Owner:PUJIANG HUIYI INTELLIGENT TECH CO LTD

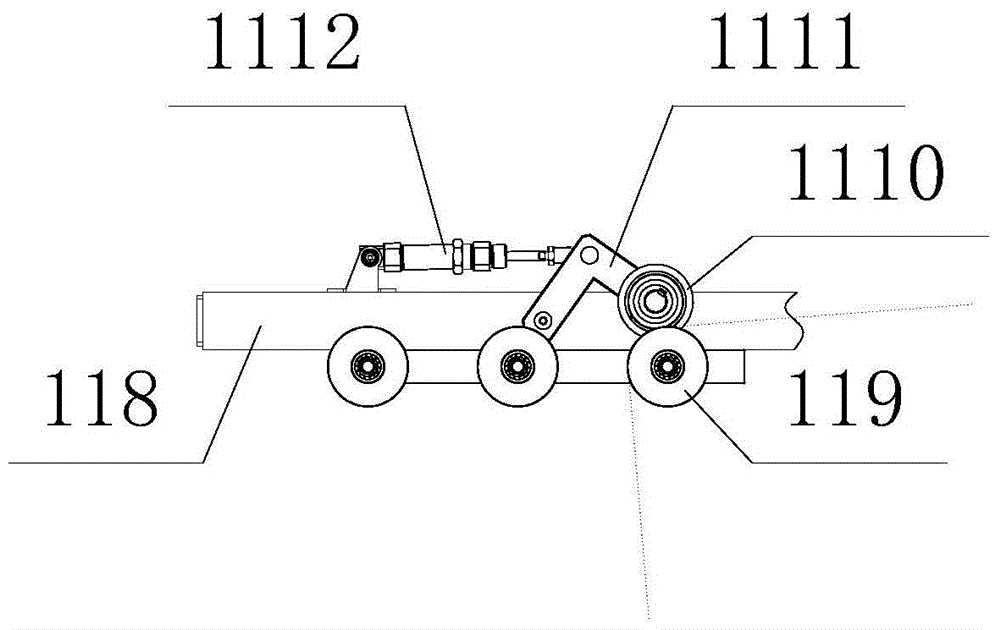

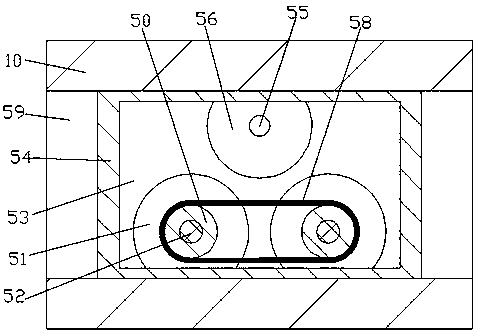

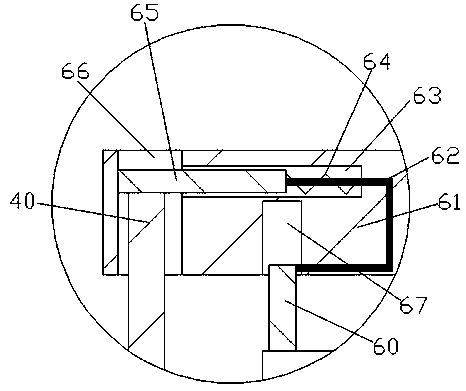

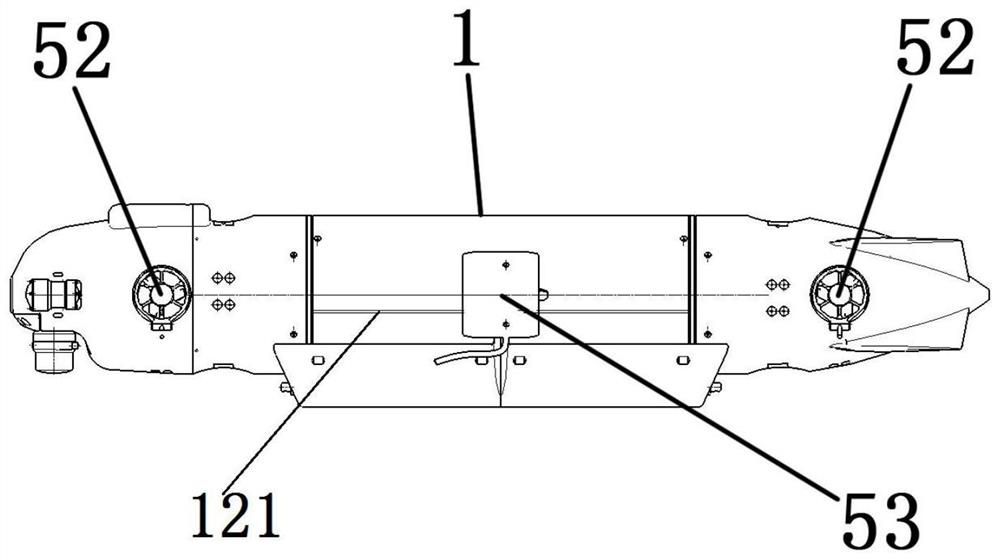

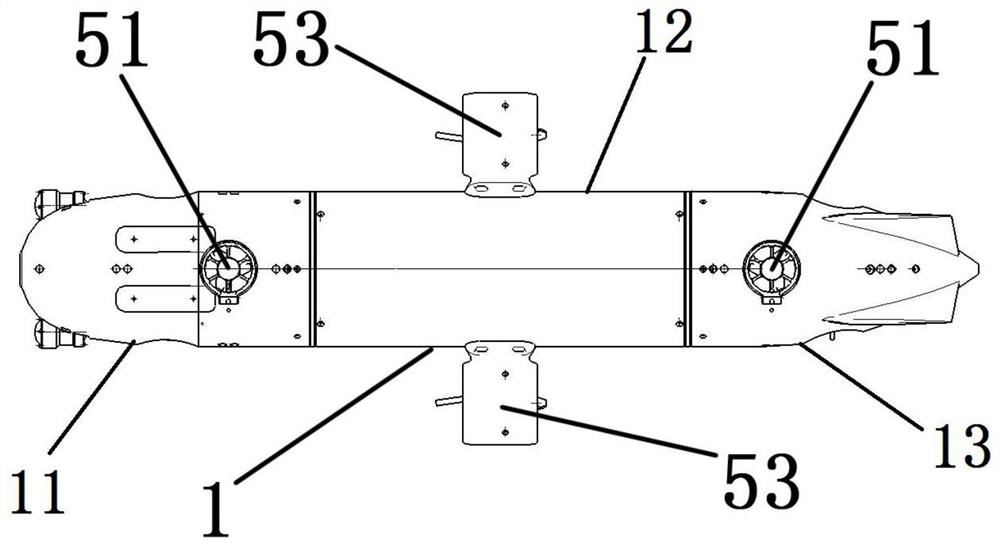

Disposable cableless remote control underwater explosive-handling robot and design method thereof

ActiveCN112025725AIncrease combat radiusOptimized control of volume and weightManipulatorElectrical batteryRemote control

The invention discloses a disposable cableless remote control underwater explosive-handling robot and a design method thereof. The robot comprises a robot body and a communication buoy; the robot bodycomprises a detection head section, an electronic battery cabin section and a tail section; shells between the cabin sections are connected through flange plates, the two ends of the shell of the electronic battery cabin section are completely sealed, except the electronic battery cabin section, the other cabin sections are of water inlet structures, the tail section is detachably connected withthe communication buoy, and the communication buoy is in radio communication with a mother ship. The design method comprises the steps that S1, the overall appearance of the robot is designed, and a propelling device is arranged; S2, a functional sensor is designed; S3, related parameters of the robot are calculated; and S4, the communication buoy is designed; Experiments prove that compared witha traditional underwater explosive-handling tool, the robot designed through the method has the advantages of being long in control distance, small in size, light in weight, accurate in data transmission result and small in dragging force between the communication buoy and the robot body.

Owner:NAVAL UNIV OF ENG PLA

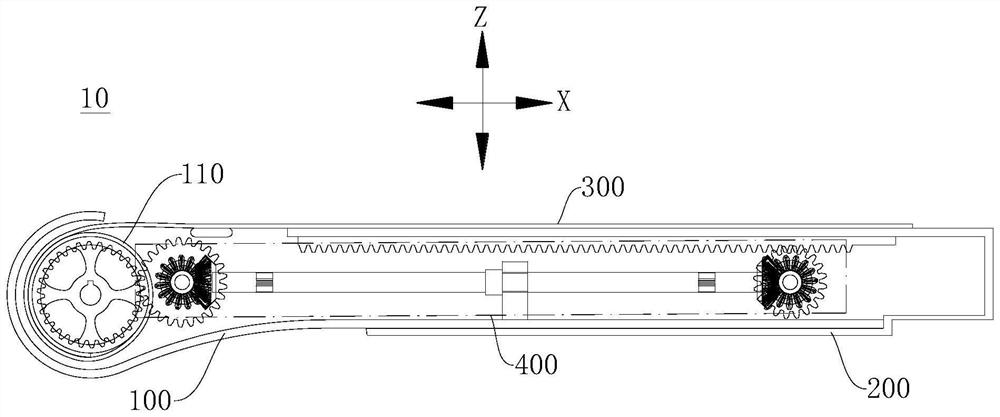

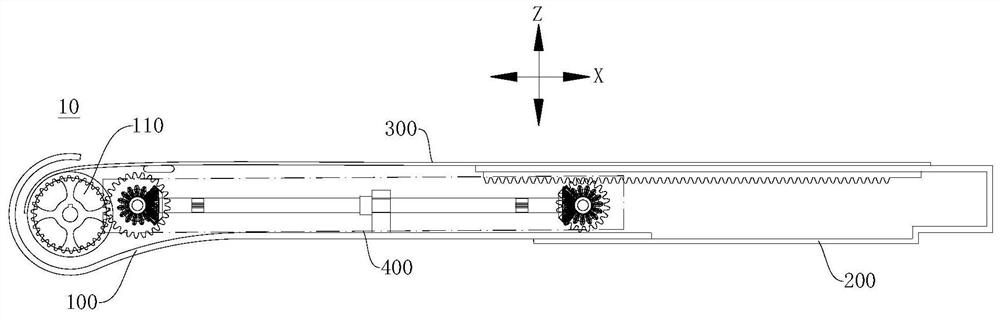

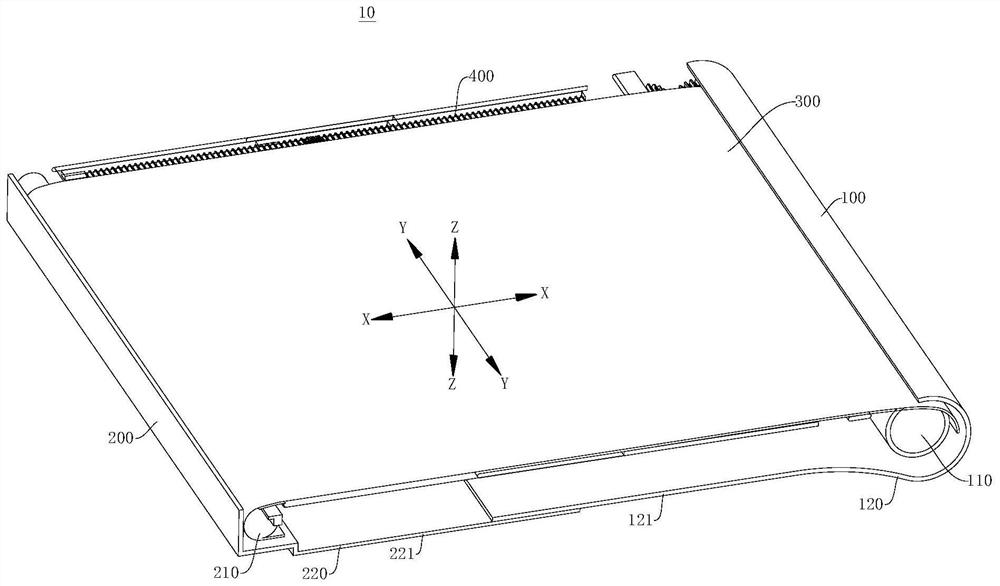

Display device

ActiveCN113129758AReduce pulling forceReduce stressIdentification meansComputer hardwareDisplay device

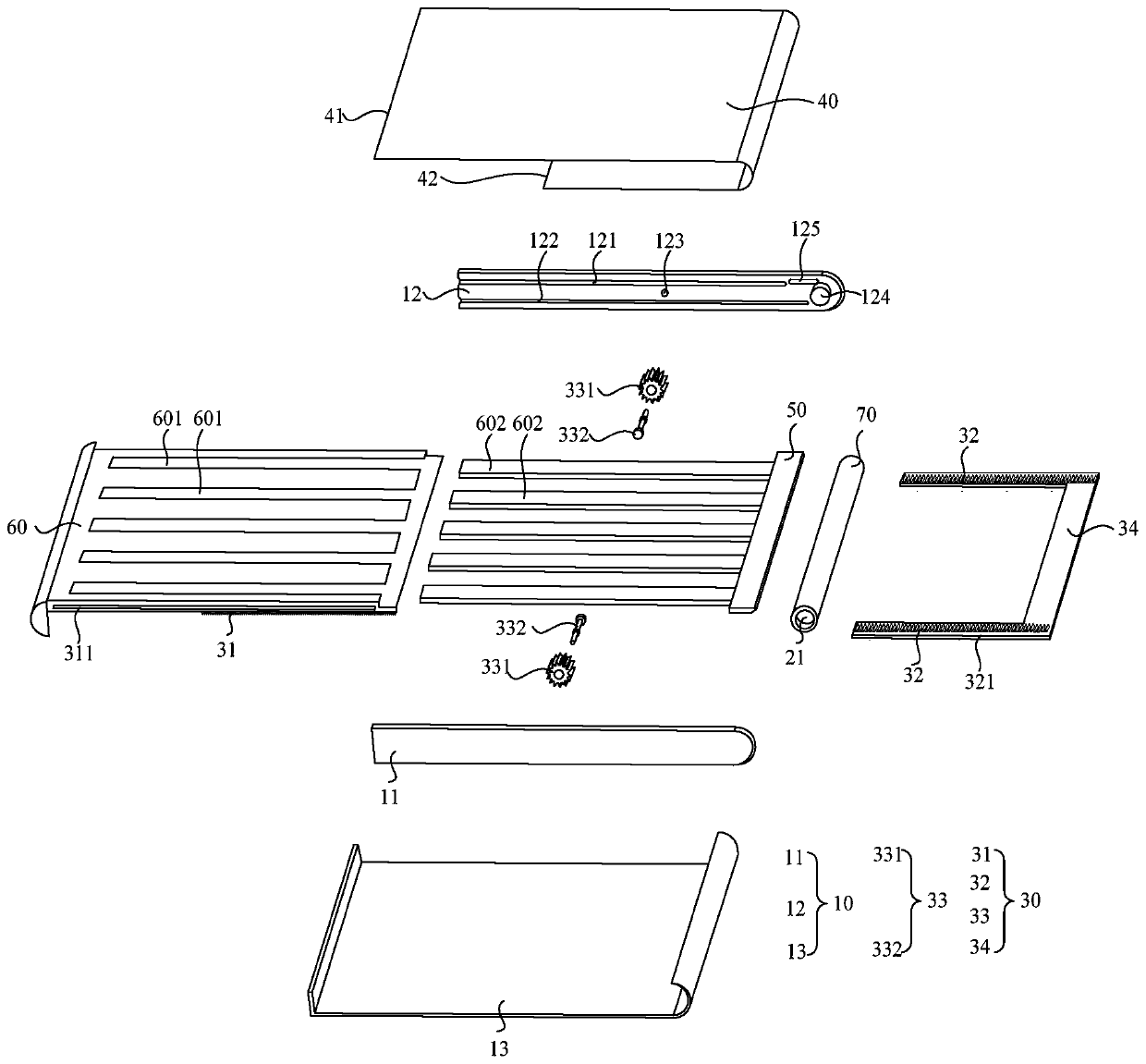

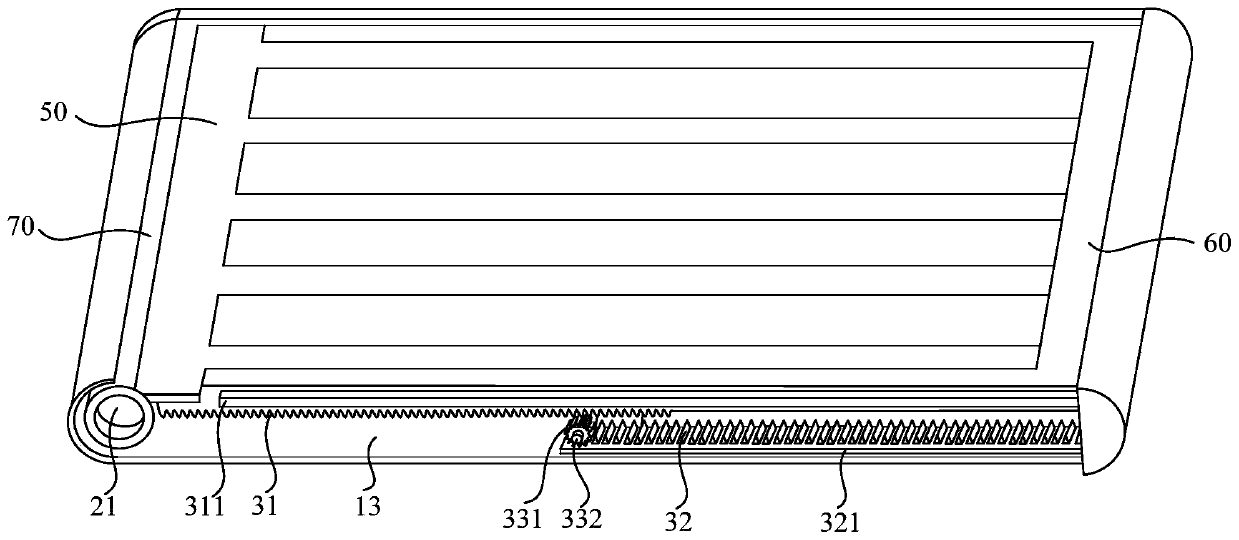

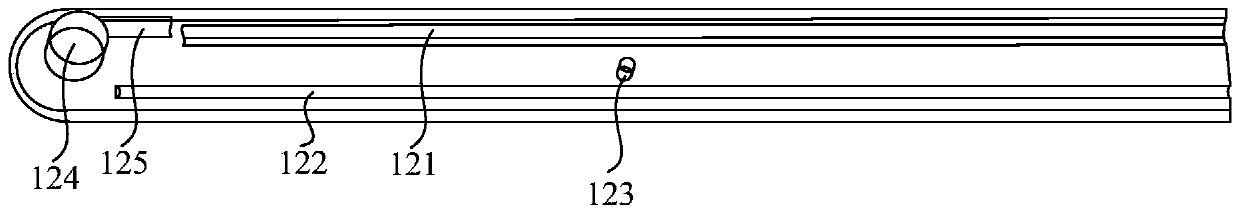

The embodiment of the invention provides a display device which comprises a first supporting part and a second supporting part which are connected with each other, and the second supporting part can slide close to or away from the first supporting part in the first direction; the display device also comprises a first rotating shaft accommodated in the first supporting part; a flexible display panel, wherein one end of the flexible display panel is connected with the first rotating shaft, and the other end of the flexible display panel is connected with the second supporting part; and a transmission part, wherein at least part of the transmission part is fixed on the second supporting part, and at least the other part of the transmission part is linked with the second supporting part and the first rotating shaft; when the second supporting part slides close to or away from the first supporting part in the first direction, the second supporting part drives the first rotating shaft to rotate through the transmission part, and then the flexible display panel is driven to be wound or unfolded. According to the display device, external force does not directly act on the flexible display panel, so that the stress of the flexible display panel can be reduced, and the service life of the flexible display panel is prolonged.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

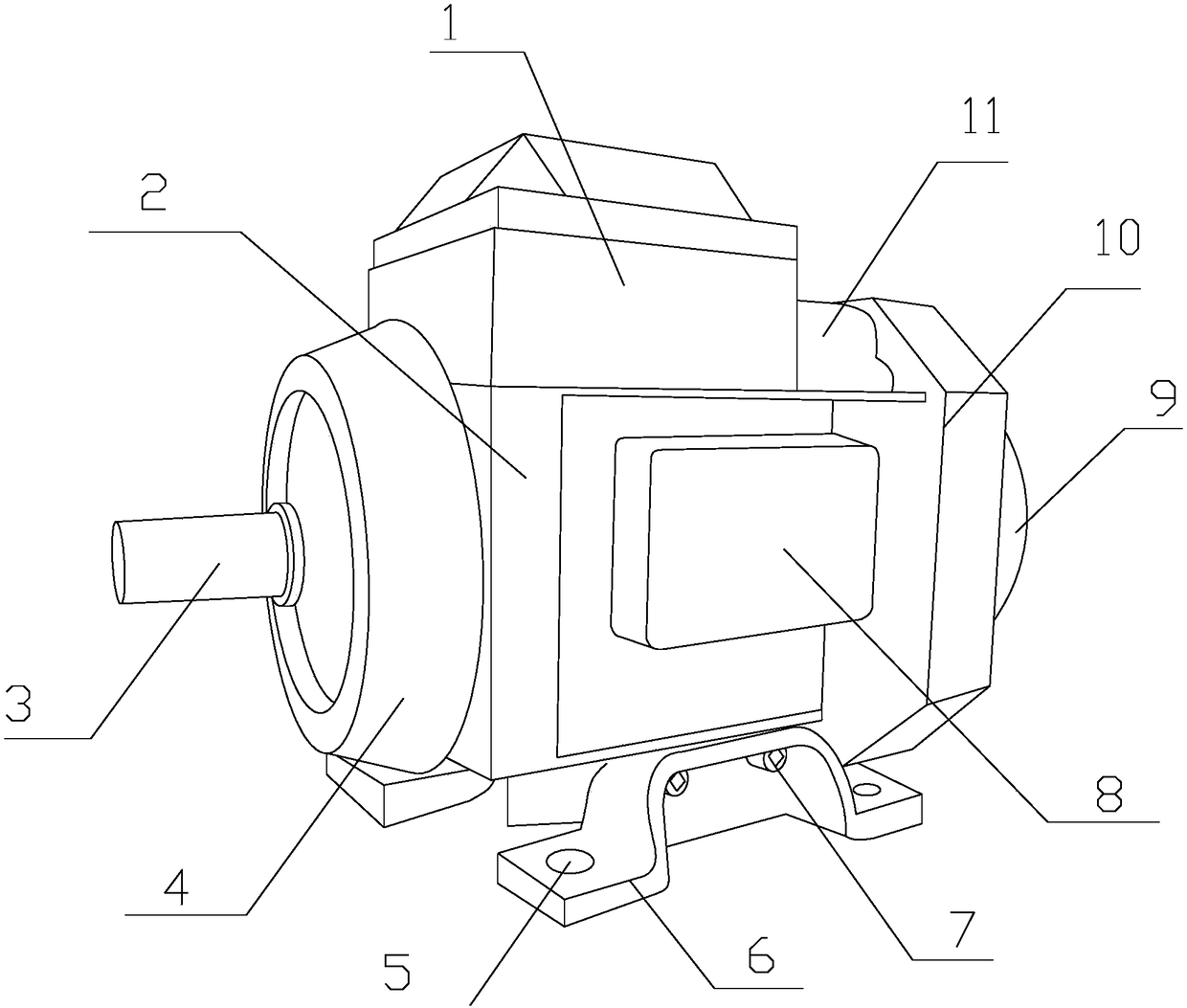

Efficient radiating dust-proof motor

ActiveCN108649746ASpeed up the flowEasy to moveCooling/ventillation arrangementEngineeringFront cover

The invention discloses an efficient radiating dust-proof motor, and the structure thereof comprises a radiator, a main frame of the motor, a rotating shaft, a front cover, a through hole, a motor fixing seat, a hexagon socket screw, a junction box, a back cover, a commutator and a clamping block, wherein the left end of the main frame of the motor is fixedly connected with the right end of the front cover by screws, the left end of the main frame of the motor is perpendicular to the right end of the rotating shaft, the right end of the rotating shaft is mechanically connected to the inside ofthe main frame of the motor, the right end of the rotating shaft is connected with the middle end of the front cover, and the bottom of the main frame of the motor is fixedly connected with the rearend of the motor fixing base by the hexagon socket screw. The efficient radiating dust-proof motor provided by the invention effectively improves the effect of cooling and radiating by structurally setting a radiator and mounting an exhaust fan and an air suction fan, effectively reduces the wear between the parts by the mechanical transmission of the transmission device to reduce the pulling force, and reduces environmental pollution as the dust removing device may effectively humidify and filter the dust and exhaust gas generated by the motor during work.

Owner:南理工泰兴智能制造研究院有限公司

Helical spring high pressure water pipe for high pressure water cutting machine having multi-degree of freedom

InactiveCN102161210AImprove the forceImprove deformationMetal working apparatusCoil springMulti degree of freedom

The present invention provides a helical spring high pressure water pipe for a high pressure water cutting machine having multi-degree of freedom, wherein the water pipe belongs to a seamless metal pipe. From the output end of an ultrahigh pressure presser to the input end of a nozzle, the water pipe is winded with a helical spring structure at each joint position, and the axis of the helical spring structure is coincident with or parallel to or approximately parallel to the axis of the rotation or / and moving of the joint. The diameter or / and the number of loops of the helical spring structure is compatible with the rotation or / and moving scope of the joint. The water pipe is a stainless steel seamless pipe. With the helical spring structure, the high pressure water pipe can realize compatible angle change or length change while maintains the normal function of high pressure water conveying under the condition that the joint rotates or moves. The usage of the helical spring high pressure water pipe for the high pressure water cutting machine having the multi-degree of freedom can guarantee that the high pressure water pipe rotates or moves with the joint freely, no wear part exists, no leakage occurs, and technology performance of the high pressure water cutting machine having the multi-degree of freedom is improved.

Owner:CHONGQING SHEPING TECH

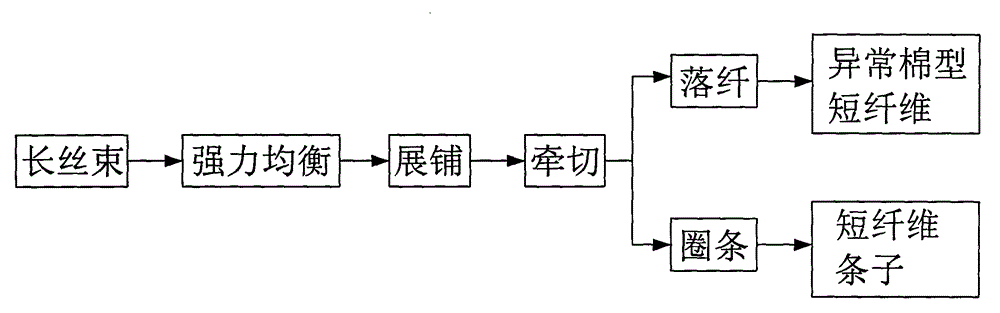

Cotton type fiber stretch-breaking strip making method

The invention discloses a cotton type fiber stretch-breaking strip making method, which comprises the following steps that (1) tows requiring stretch-breaking strip making are prepared; (2) stretch-breaking strip making treatment is carried out: 1) the tows led out from a tow box are fed into a stretch-breaking device provided with four stretching regions and four groups of stretch-breaking rollers, and first-time stretch-breaking processing is firstly carried out through a first stretch-breaking region; 2) the tows subjected to the first-time stretch-breaking processing enter a second stretching region for second stretch-breaking processing; 3) the tows subjected to the second stretch-breaking processing enter a third stretching region for third stretch-breaking processing; 4) the tows subjected to the third stretch-breaking processing enter a fourth stretching region for fourth stretch-breaking processing; (3) coiling processing is carried out. The method has the advantages that cotton type short fiber strips can be directly manufactured, and the severe carding effect of a cotton carding machine can be avoided, and the cotton type short fiber strips can be directly mixed with other fiber strips in the drawing work procedure.

Owner:湖北立天生物工程有限公司

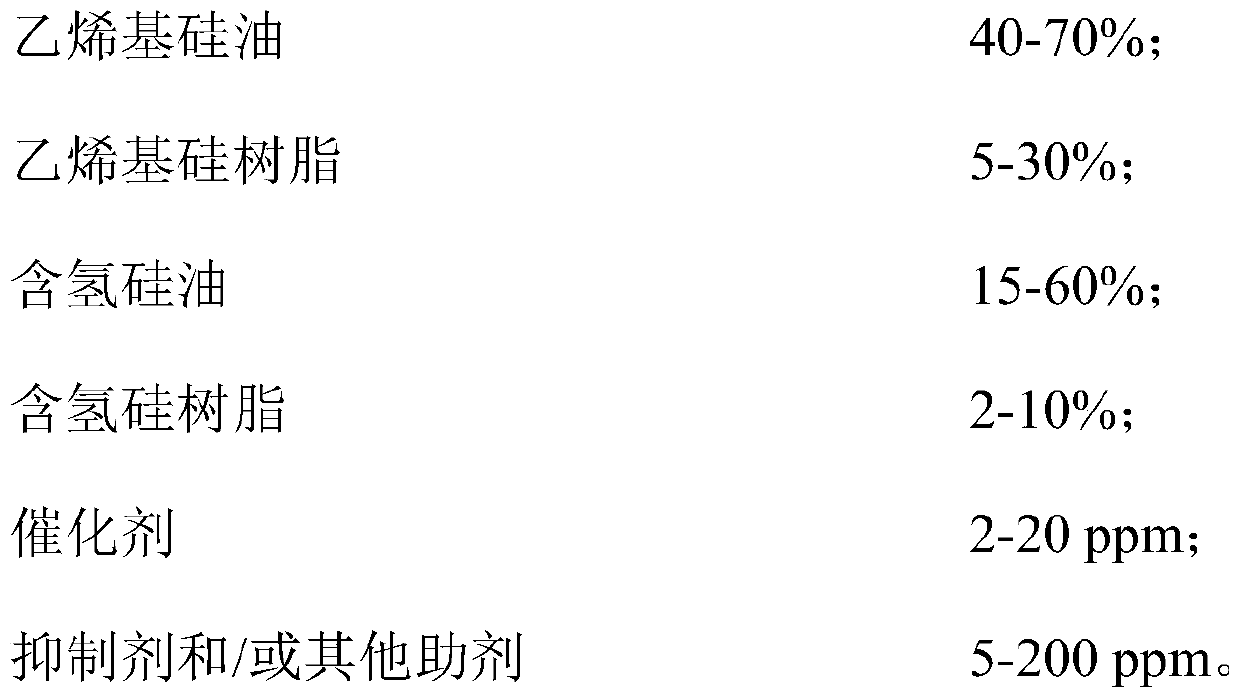

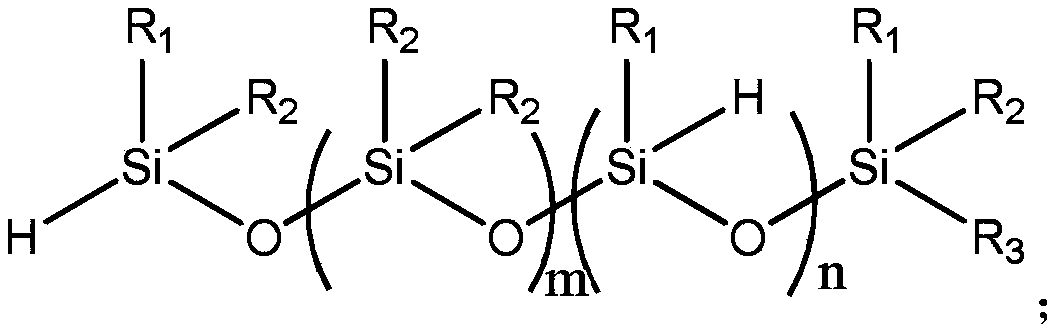

Thermosetting liquid optical adhesive composition and application thereof

ActiveCN111154451AStable PenetrationImprove heat stabilityNon-macromolecular adhesive additivesNeedle penetrationPolymer science

The invention provides a thermosetting liquid optical adhesive composition and an application thereof; the thermosetting liquid optical adhesive composition is tested according to a GB / T 4509-2010 asphalt needle penetration determination method, and the needle penetration of the thermosetting liquid optical adhesive composition is 160-250 mm. The thermosetting liquid optical adhesive provided by the invention has proper needle penetration after being cured, is easy to repair, does not greatly fluctuate along with the influence of temperature, humidity, UV aging irradiation and the like, and has higher cohesion strength, better binding power and excellent binding power for a binding material of a display module.

Owner:DONGGUAN POWERBOND NEW MATERIALS TECH DEV

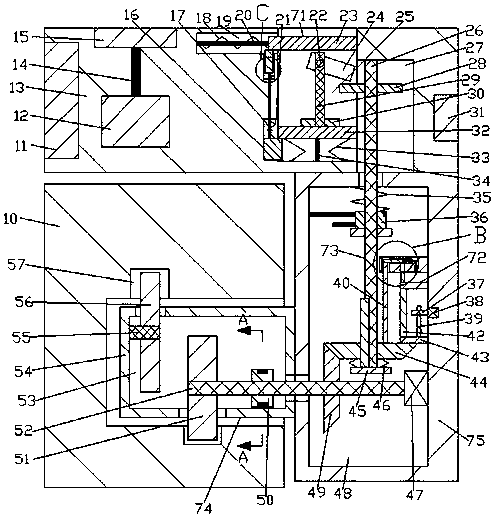

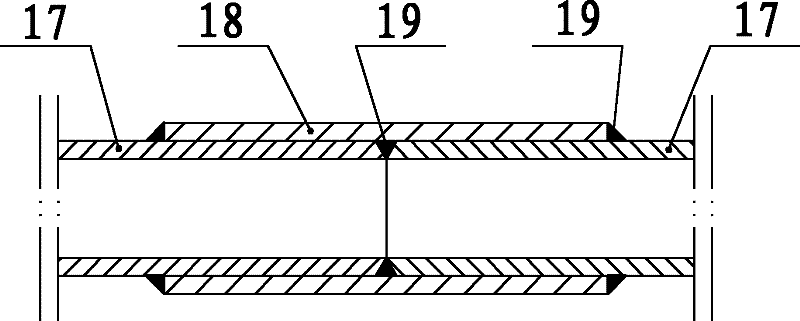

Low-strength fiber stretch-breaking and slivering device

The invention discloses a low-strength fiber stretch-breaking and slivering device. The low-strength fiber stretch-breaking and slivering device comprises a stretch-breaking device which is composed of multiple sets of stretch-breaking roller set and provided with a feeding end and a discharging end, a stretch-breaking area is formed between each set of the stretch-breaking roller set, each set of the stretch-breaking roller set is composed of a pair of stretching rollers and a pair of stretch-breaking rollers which are meshed with each other respectively, a stretch-breaking transition area is formed by the stretching roller and the stretch-breaking roller which are located between adjacent stretch-breaking roller sets, the stretching roller and the stretch-breaking roller are both composed of two roller bodies, and the size of the horizontal distance between the stretching roller and the stretch-breaking roller in the axial direction of the roller body in each stretch-breaking area is changeable. Through arranging tapered or trapezoid structure, the tractive force of the stretch-breaking areas is greatly reduced, the diameters of the stretch-breaking rollers are decreased, the distance of the stretch-breaking areas formed by the stretch-breaking roller sets is shortened, the distance between the stretching roller and the stretch-breaking roller can be set to be small enough, stretch-breaking can be conducted on short fiber with smaller cotton fiber level, and the production efficiency is greatly improved. The low-strength fiber stretch-breaking and slivering device has the advantages that the structure is simple and compact, the occupied area is small, the cost is low, and popularization and application are applicable.

Owner:QINGDAO UNIV

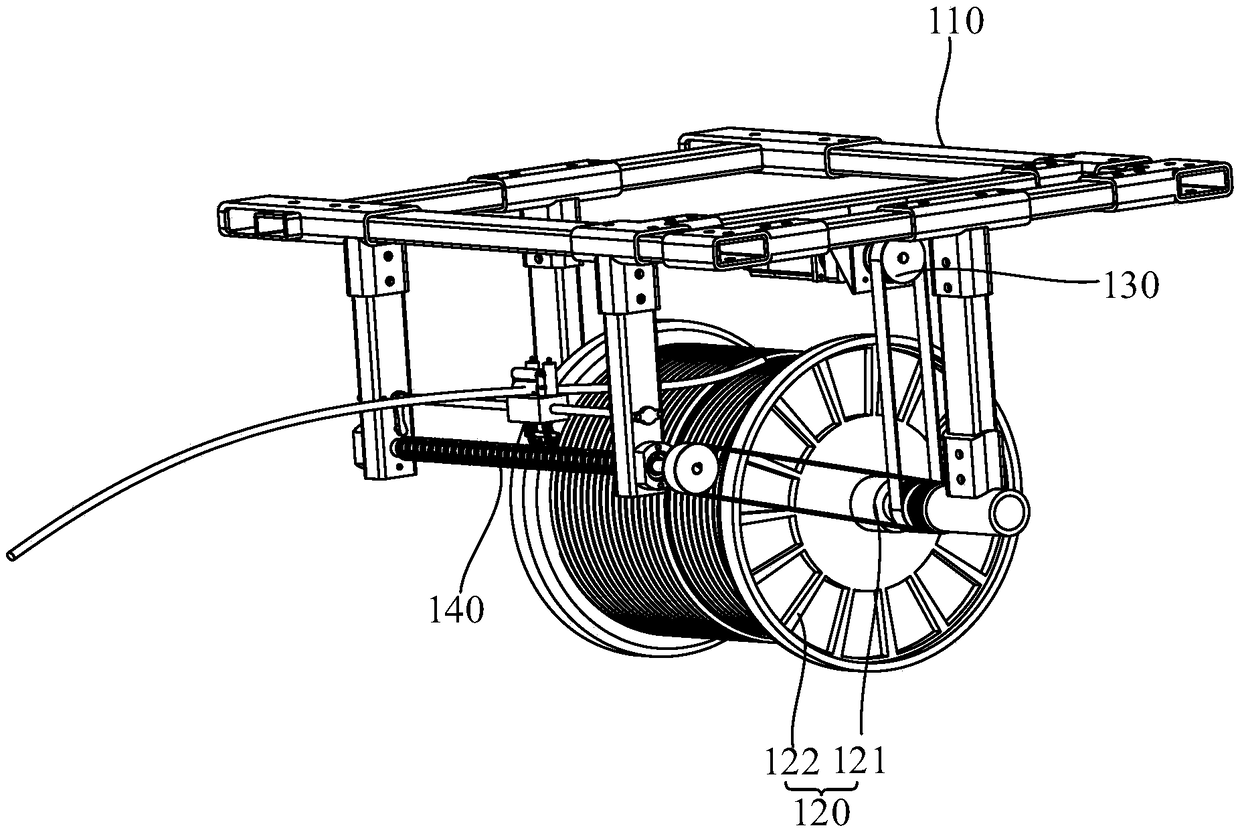

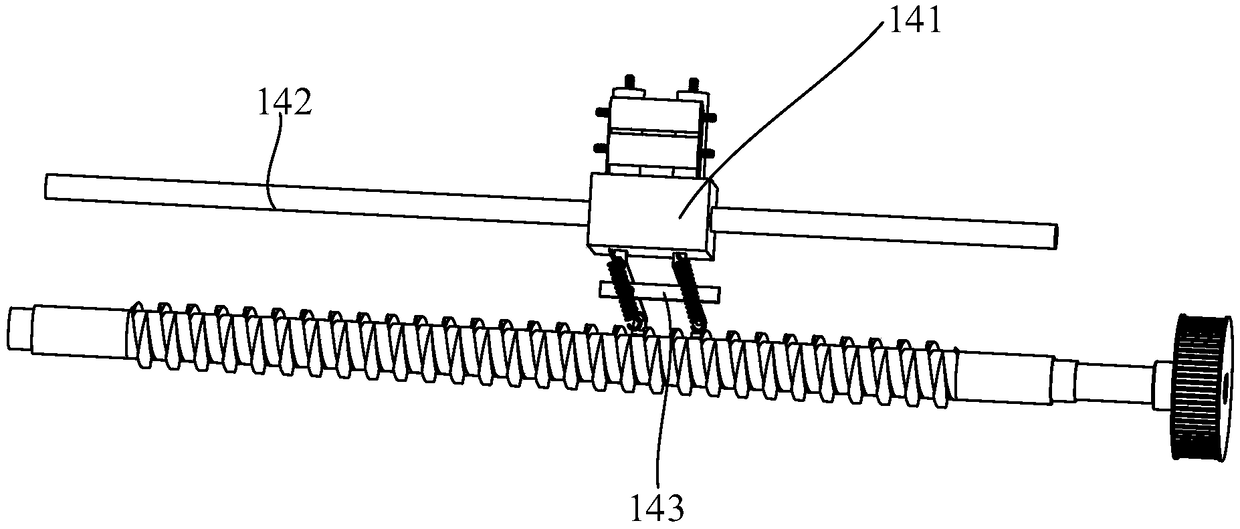

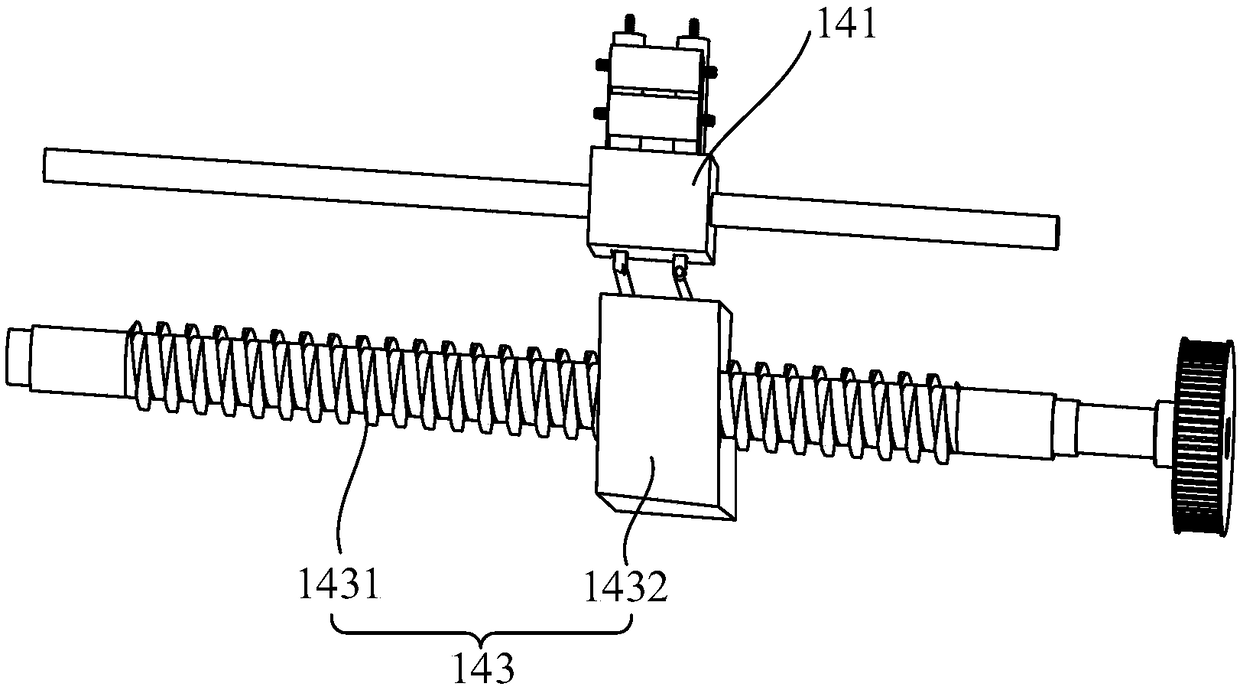

Cable paying-off device and cable laying device of unmanned aerial vehicle

PendingCN109132695AReduce pulling forceImprove construction qualityFilament handlingApparatus for laying cablesTransmission performancePetroleum engineering

The invention provides a cable paying-off device and a cable laying device of an unmanned aerial vehicle, belonging to the technical field of cable laying. The cable paying-off device comprises a mainframe, a cable winding reel and a driver, wherein the driver and the cable winding reel are connected with the main frame, and the driver is drivingly connected with the cable winding reel are connected with the main frame, and the driver is in transmission connection with the cable winding reel. The cable laying device of the unmanned aerial vehicle (UAV) comprises the UAV and the cable paying-off device, wherein the cable paying-off device is connected with the UAV. The invention provides the cable paying-off device and the cable laying device of the unmanned aerial vehicle, which can actively pay off the cable through the cable paying-off device provided with the driver and the cable winding reel, thereby reducing the pulling force of the cable and further guaranteeing the signal transmission performance of the optical fiber which can be damaged by an external force inside the cable.

Owner:SHENYANG HENGTONG OPTICAL COMM CO LTD

Functional part, attaching jig and attaching method

ActiveCN111300947AReduce the amount of expansion in the middleSlow down the bonding speedLaminationLamination apparatusTarget surfaceCrazing

The embodiment of the invention discloses a functional part, an attaching jig and an attaching method, the functional part comprises a target surface, the target surface is provided with a first profiling surface used for being attached to a to-be-attached part, the target surface comprises a first curved surface, a second curved surface and a third curved surface which are smoothly connected in sequence, the first curved surface and the third curved surface are located on the two sides of the second curved surface and extend in the first direction, the first direction is the direction, away from the second curved surface, of the first curved surface or the third curved surface, the first curved surface and the third curved surface are each provided with a concave contour groove extendingin the second direction, and the second direction is perpendicular to the first direction. According to the embodiment of the invention, the probability that the functional part is used for laminatingthe to-be-laminated part can be reduced, the pressure and the pulling force of the edge area of the to-be-laminated part can reduce the middle expansion amount of the functional part and reduce the laminating speed of the to-be-laminated part from the middle to the two sides in the laminating process, so that the problems of laminating bubbles and laminating cracks are avoided.

Owner:BOE TECH GRP CO LTD +1

Dialysis tube fixing device for nephrology department

InactiveCN110420362AEasy to useEasy to operateDialysis systemsCatheterHemodialysisIntensive care medicine

The invention discloses a dialysis tube fixing device for the nephrology department. The dialysis tube fixing device comprises a positioning part and a fixing part, the positioning part comprises a positioning block, binding bands, supporting rods, rotating ball fixing seats, a limiting screw and a rotating ball, a through hole is formed in the middle of the positioning block, and the binding bands are arranged on the two sides of the positioning block correspondingly. When a dialysis tube penetrates through a first arc-shaped channel of a first clamping block and a second arc-shaped channel of a second clamping block, the dialysis tube is bent in a certain arc shape, when bent to a certain extent, the dialysis tube is not blocked, thus using of the dialysis tube is not affected, but whenthe dialysis tube is bent in the certain arc shape, the contact area between the dialysis tube and the first clamping block as well as the contact area between the dialysis tube and the second clamping block can be increased, friction force is increased, thus the dialysis tube is fixed more firmly by the first clamping block and the second clamping block, and meanwhile, if large force is generatedcarelessly to involve the blood dialysis tube, a second locking block moves towards one side of a first locking block to clamp and lock the dialysis tube.

Owner:张伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com