Compound external mold for cold drawing steel tube

A steel pipe and cold drawing technology, applied in wire drawing dies and other directions, can solve the problems of small diameter reduction, high cost, and many cold drawing passes, and achieve the effect of large diameter reduction, low friction resistance and good surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

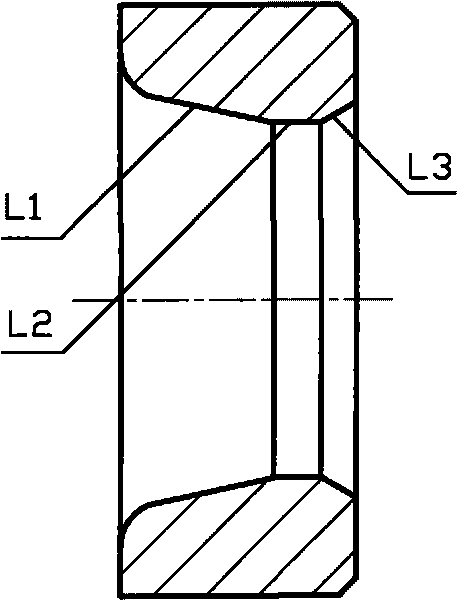

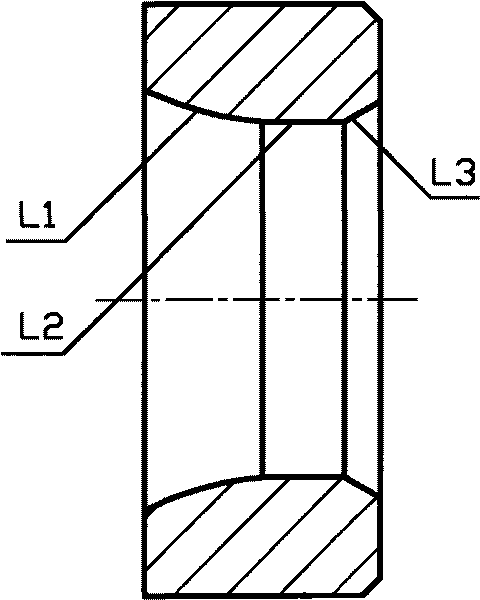

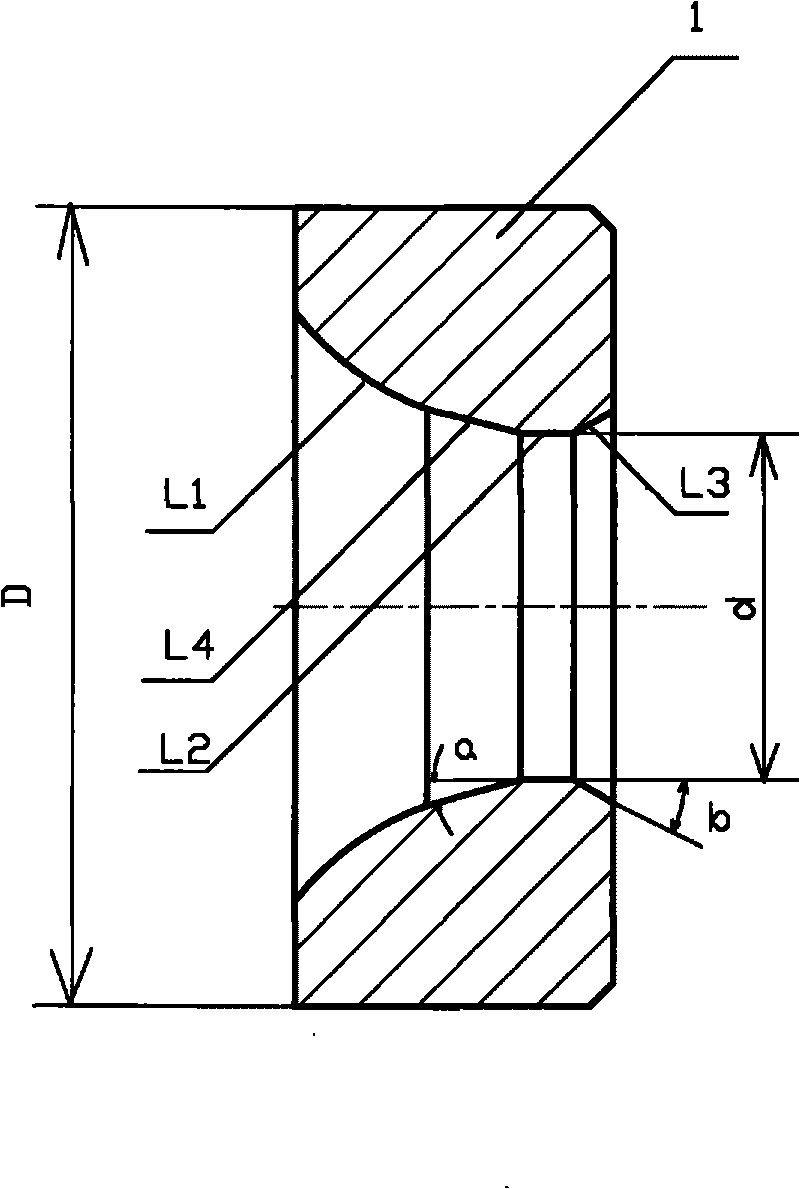

[0015] As shown in the accompanying drawings: a cold-drawn steel pipe composite outer mold, a cold-drawn steel pipe composite outer mold, which includes an outer mold body 1, the outer diameter D of the outer mold body 1 is 108mm, and the length is 50mm. The pass pattern of the outer mold body 1 is composed of four parts: the inlet arc section L1, the inlet cone section L4, the sizing belt L2, and the outlet cone L3. The arc radius R of the inlet arc segment L1 is 40 mm, and the length is 20 mm. The entrance conical section L4 is set between the entrance arc section L1 and the sizing zone L2, the length of the entrance conical section L4 is 15 mm, and the taper a is 12 degrees. The length of the sizing belt L2 is 10mm, and the diameter d is 51mm. The exit cone L3 is set behind the sizing belt L2, the length of the exit cone L3 is 5mm, and the taper b is 30 degrees.

[0016] In order to ensure the surface quality of the drawn steel pipe, the transition between the entrance ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com