Patents

Literature

90 results about "Inlet cone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Inlet cones (sometimes called shock cones or inlet centerbodies) are a component of some supersonic aircraft and missiles. They are primarily used on ramjets, such as the D-21 Tagboard and Lockheed X-7. Some turbojet aircraft including the Su-7, MiG-21, English Electric Lightning, and SR-71 also use an inlet cone.

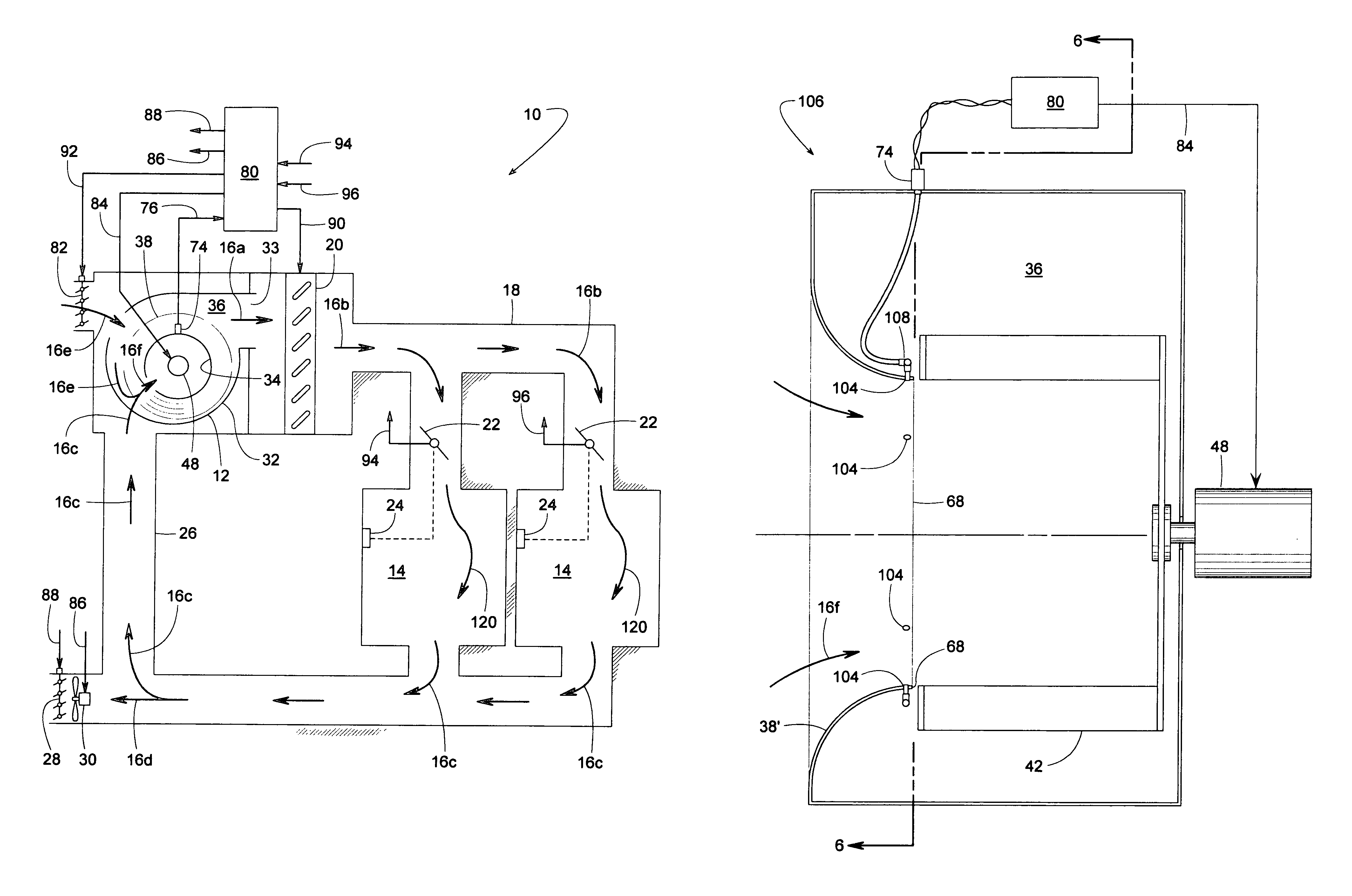

In-line centrifugal fan

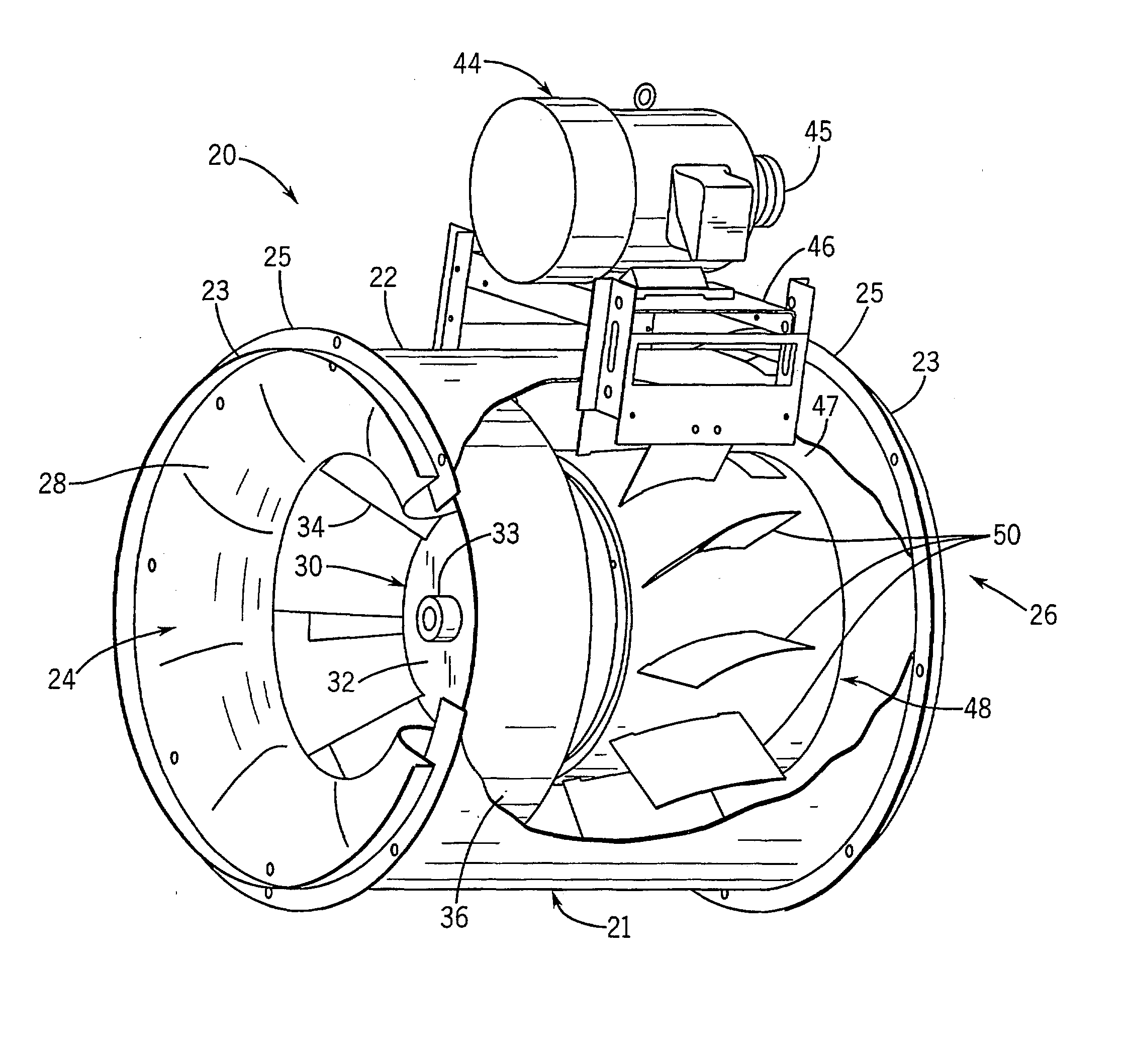

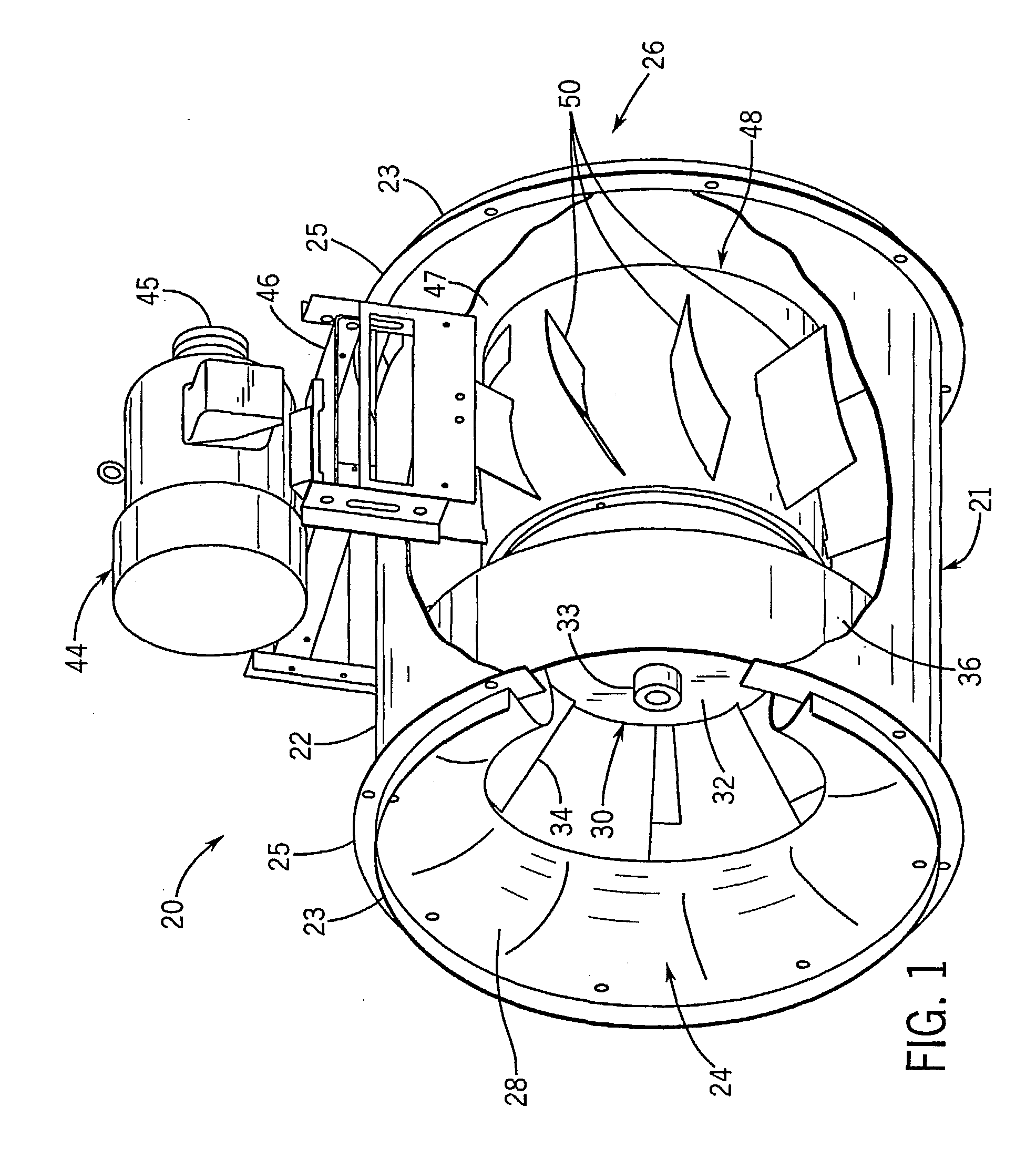

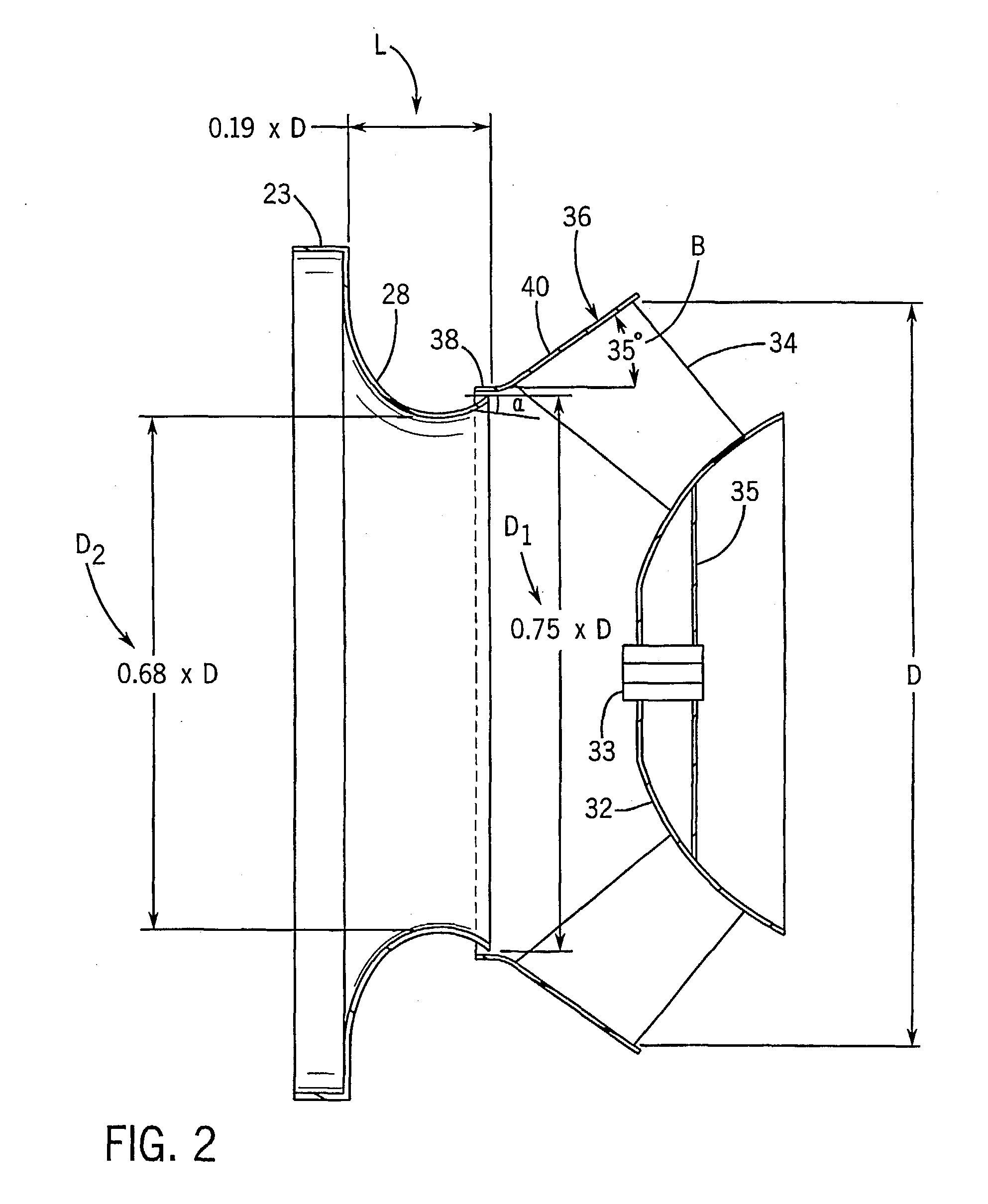

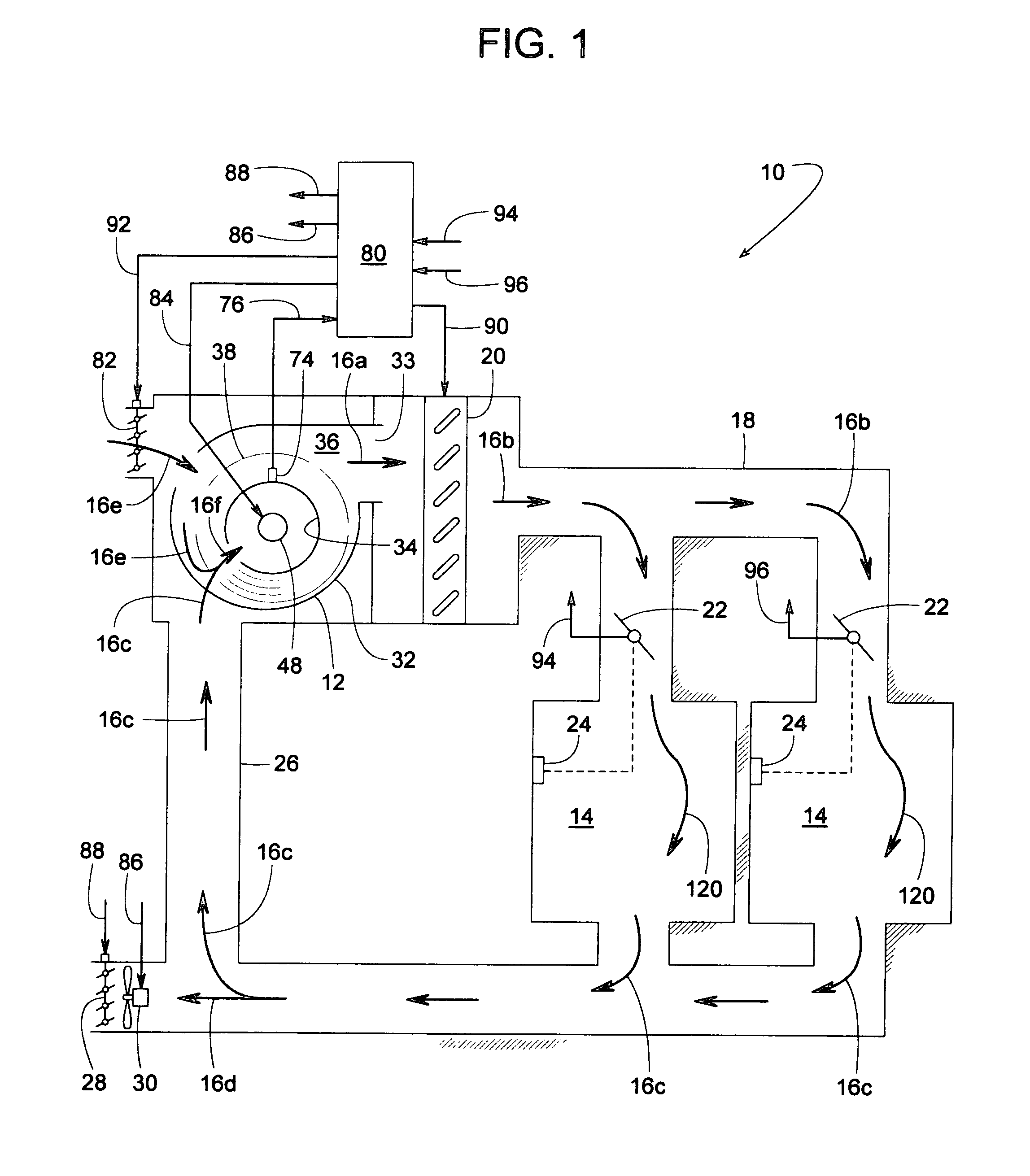

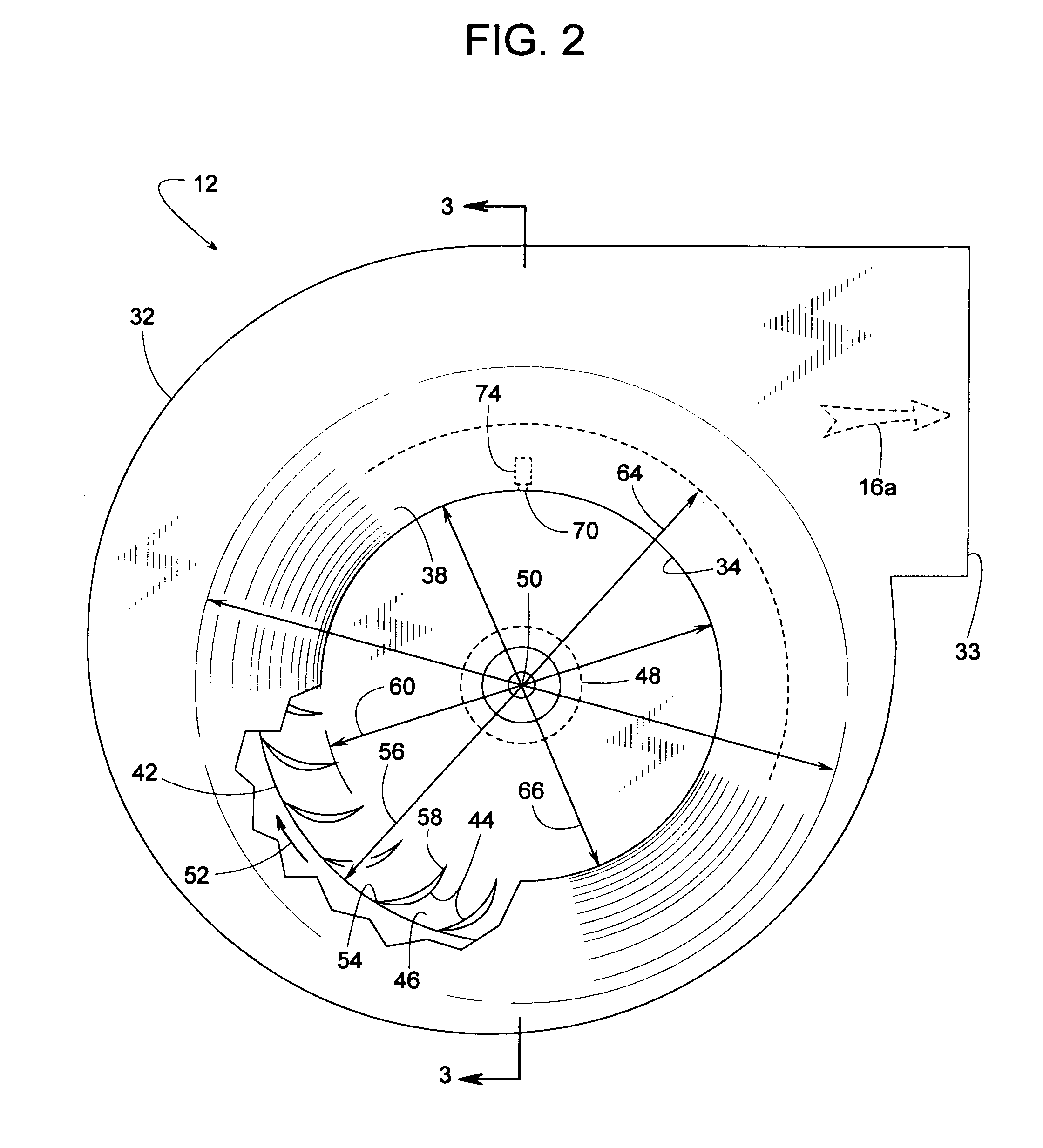

InactiveUS20030206800A1Easy to installEfficient and less noisyPropellersRotary propellersImpellerMixed flow

An inline centrifugal mixed flow fan (20) includes an axially extending intake conduit (22). An inlet cone (28) is disposed at an intake end (24). An impeller (30) is disposed downstream of the inlet cone and includes a centrally disposed wheel-back (32) rotated by an electric motor (44), plural fan blades (34) extending radially outwardly from the wheel-back and a wheel cone fixedly (36) attached to and circumscribing the wheel blades. A driver chamber (48) downstream of the impeller includes plural radially extending straight vanes (50) to direct air to an outlet end (26). The fan is configured to achieve reduced sound level and increased efficiency.

Owner:GREENHECK FAN

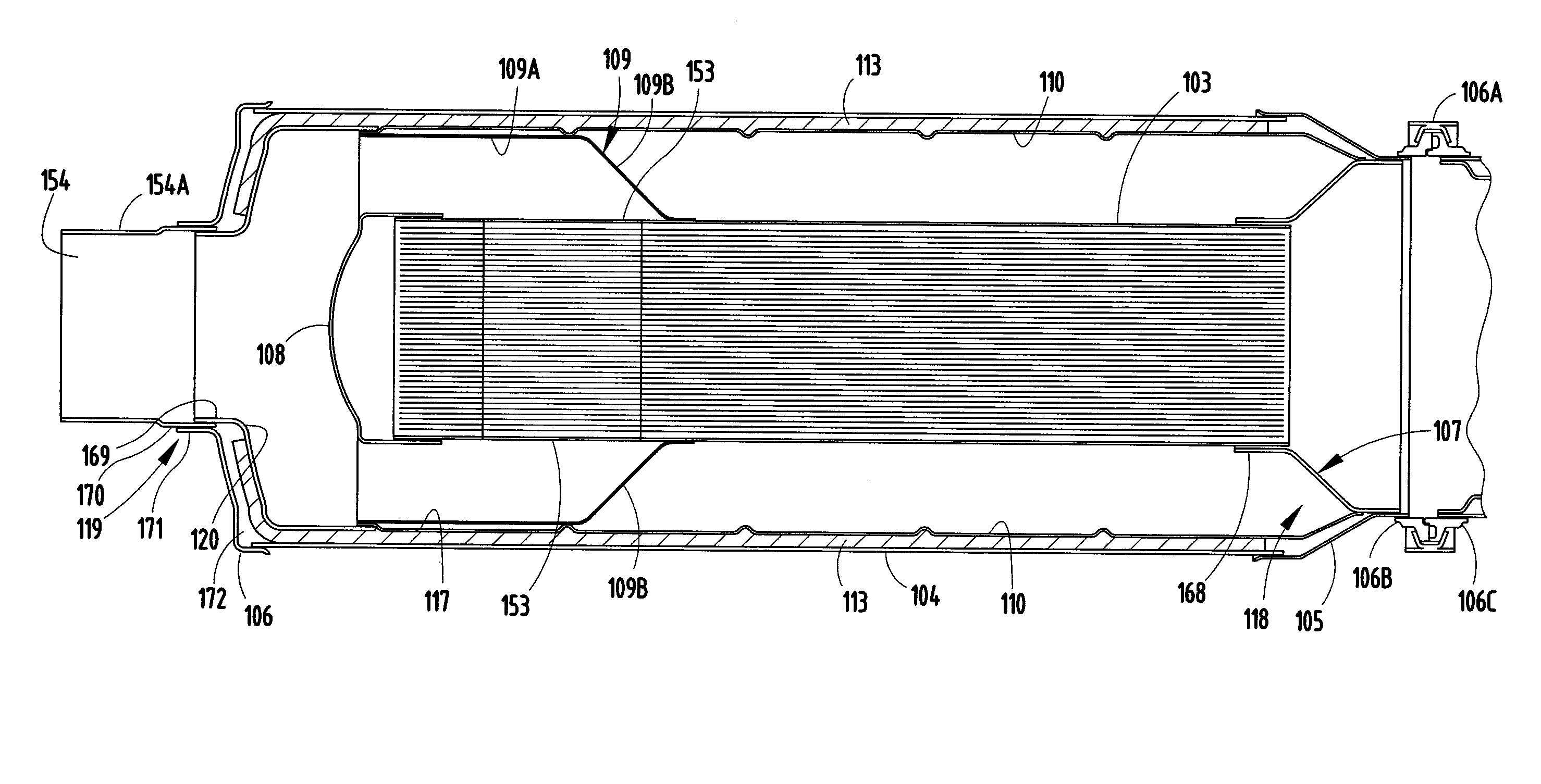

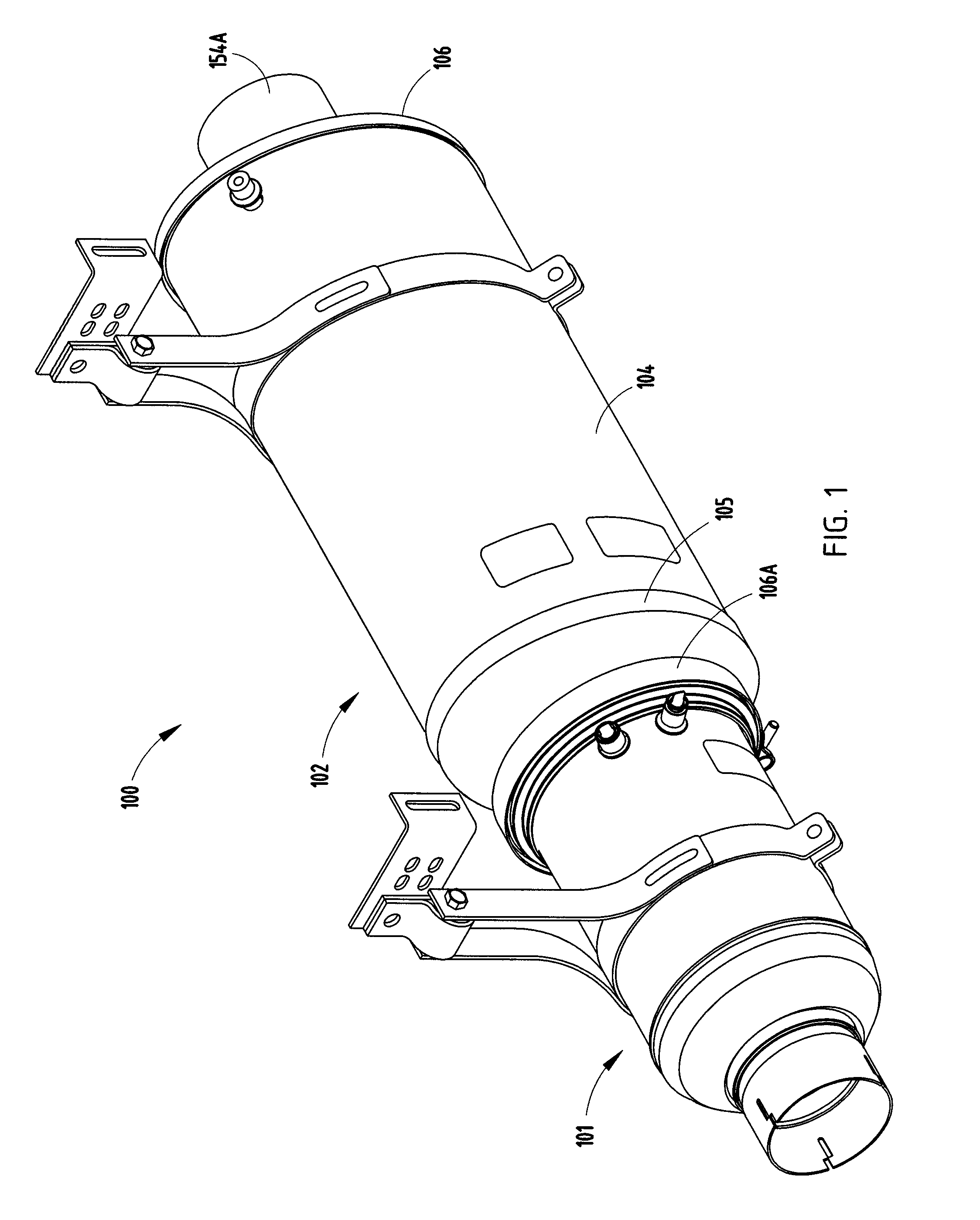

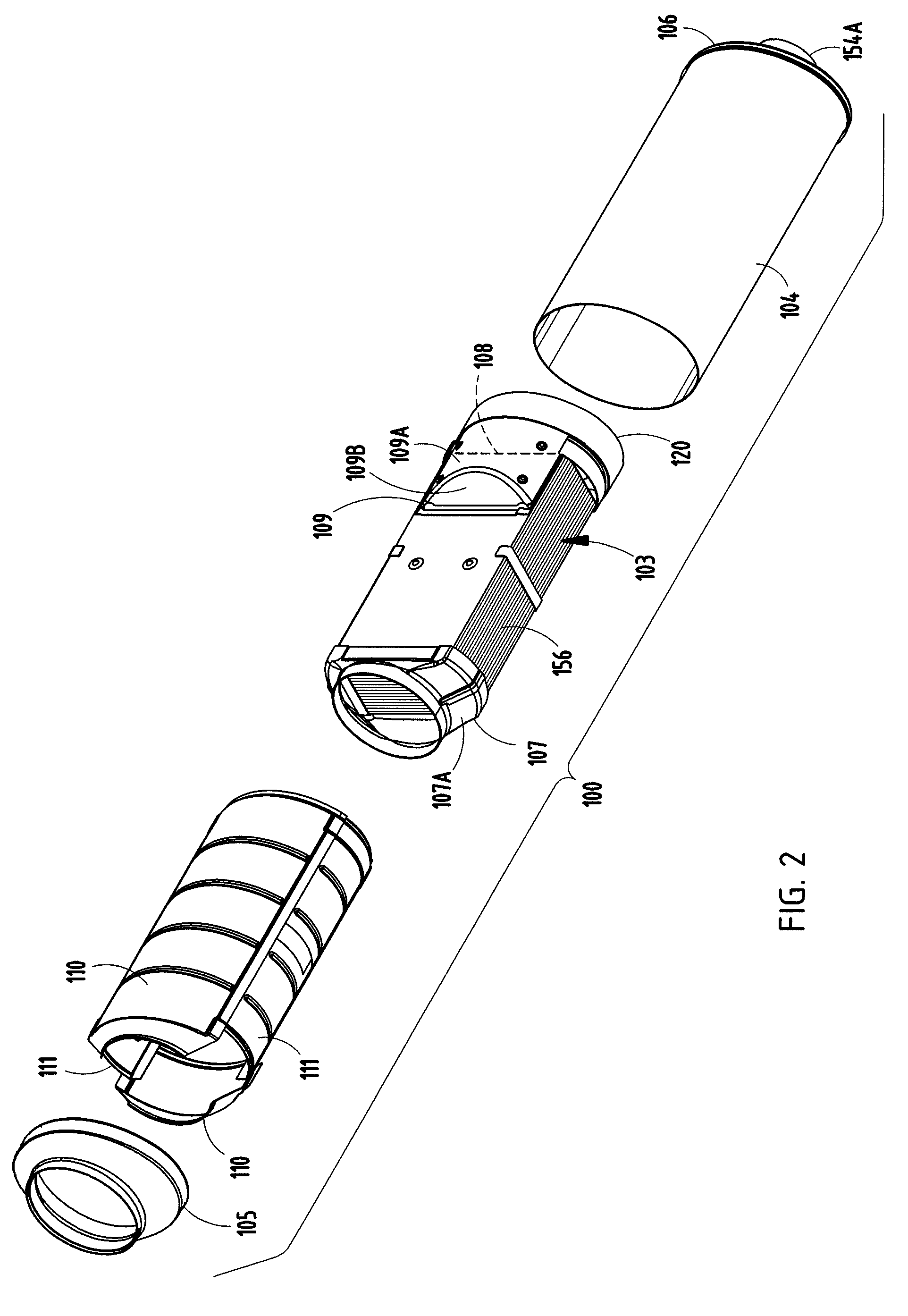

Diesel exhaust filter construction

InactiveUS7611561B2Reduce surface temperatureReduce in quantityCombination devicesInternal combustion piston enginesExhaust fumesThermal expansion

Owner:BENTELER AUTOMOTIVE CORP

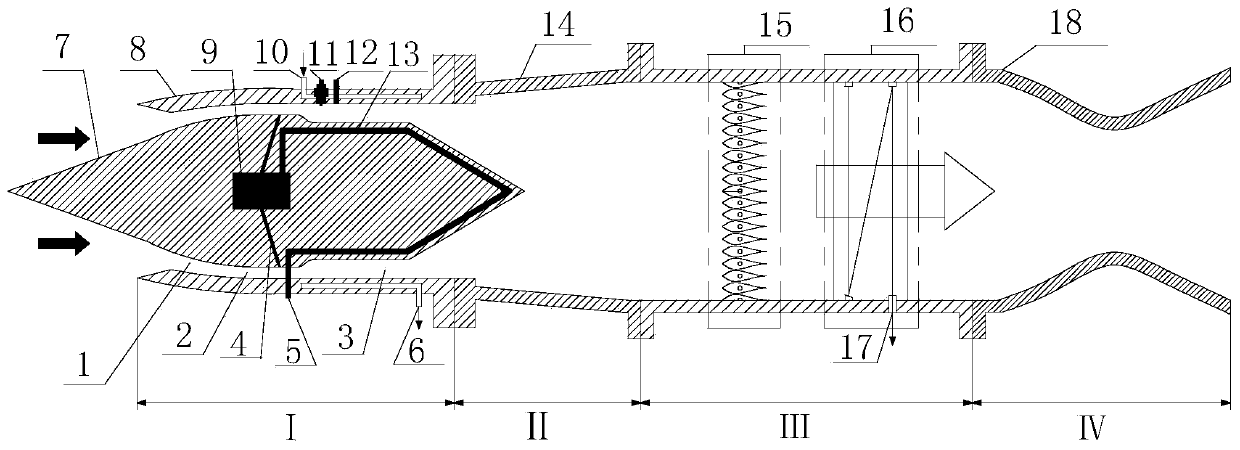

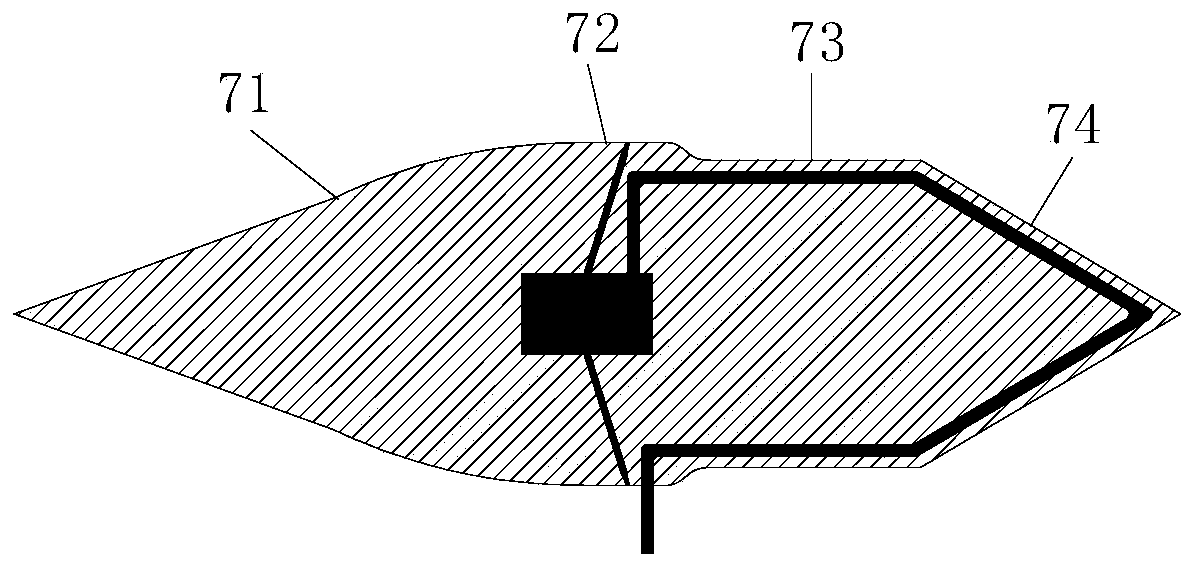

Air inlet of air-breathing pulse detonation engine

The invention discloses an air inlet of an air-breathing pulse detonation engine. The housing of the engine constitutes the circular air inlet, wherein an inlet cone is arranged on the medial axis at the rear end of the air inlet; a cylindrical structure at the rear part of the inlet cone and the housing of the engine constitute a ring-shaped channel; the air flow is fed into a special-shaped channel having a special-shaped structure via the ring-shaped channel; the special-shaped channel is evenly distributed on the circumference of the air inlet with the distance between the central symmetrical curve of the special-shaped channel and the medial axis of the engine remaining unchanged but deviating along the circumference; a fuel channel is arranged on the medial axis of the inlet cone, and the two ends of the fuel channel are connected with the fuel inlet and a fuel injection lever located on the medial axis outside the rear end of the cylindrical structure; the fuel injection lever is particularly a hollow oil tube with one end thereof being closed; a plurality of fuel injection holes are formed on the lateral surface of the fuel injection lever; the housing of the engine and the rear end surface of the cylindrical structure constitute a mixing chamber; and an igniter is located on the lateral wall of the mixing chamber. The invention can improve the atomization and evaporation of the fuel and reduce the impact of reversed fuel on the air inlet.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

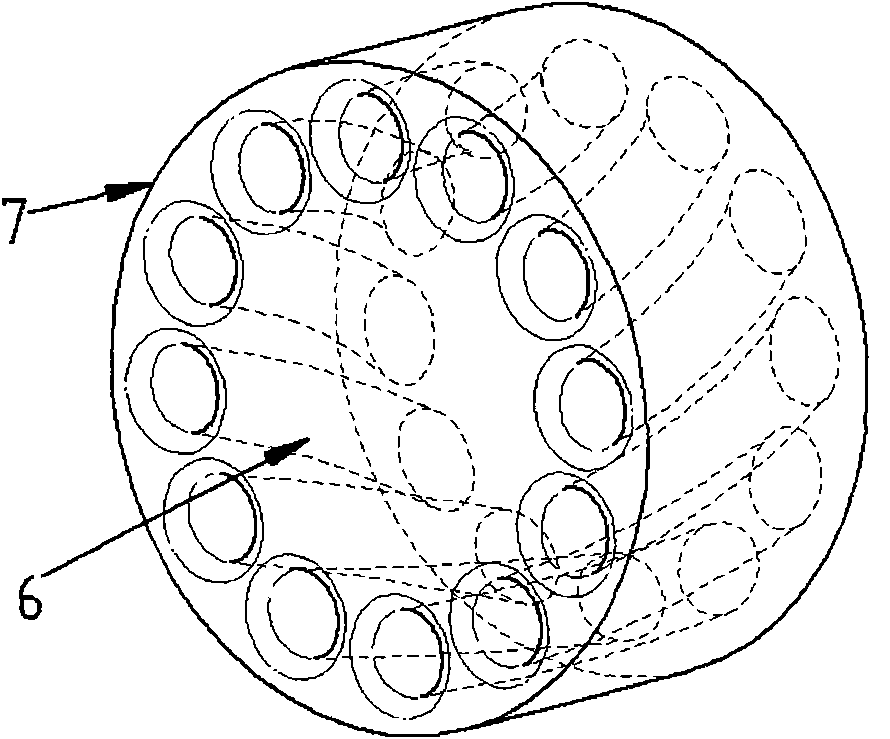

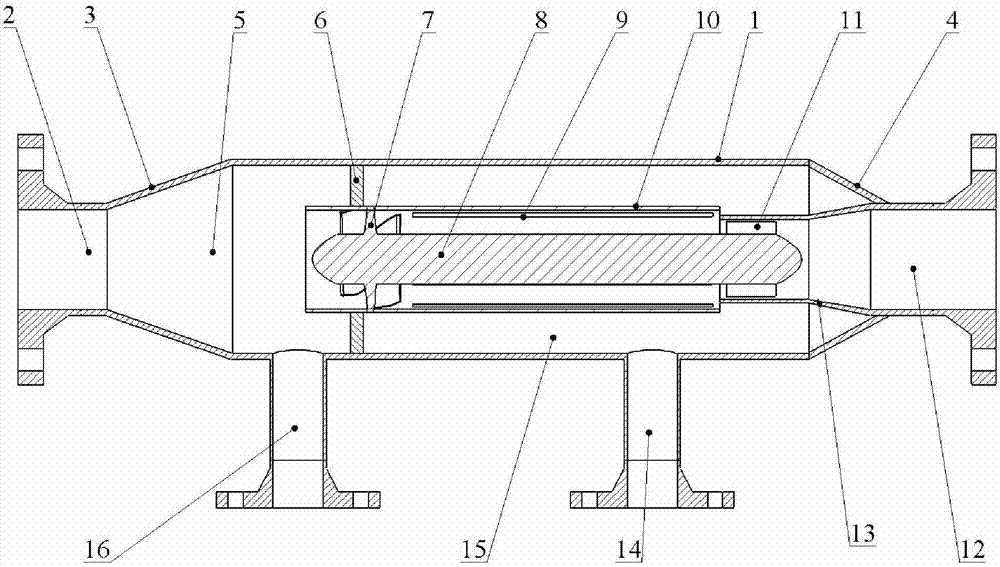

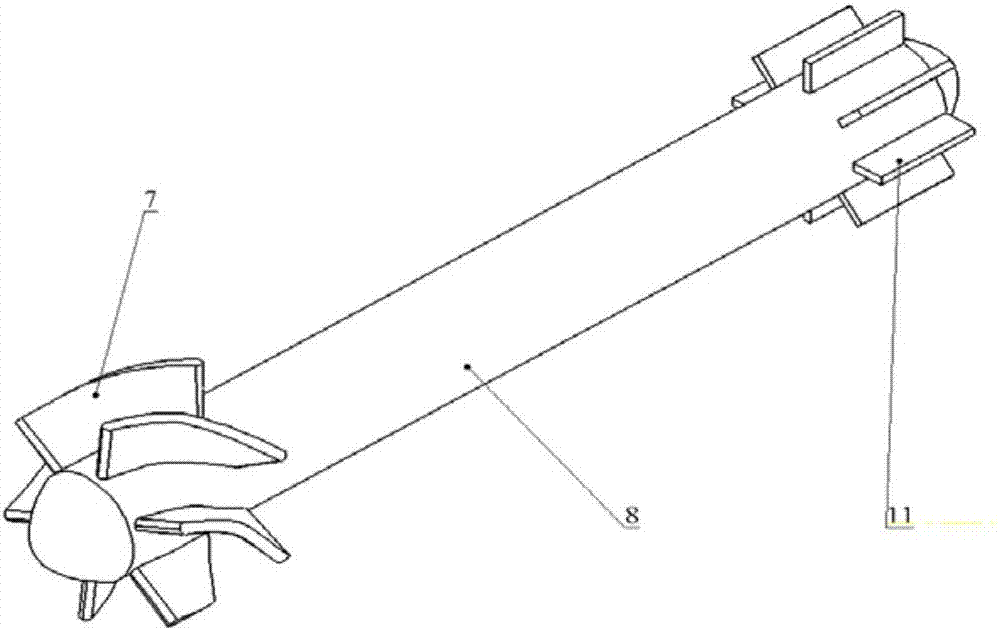

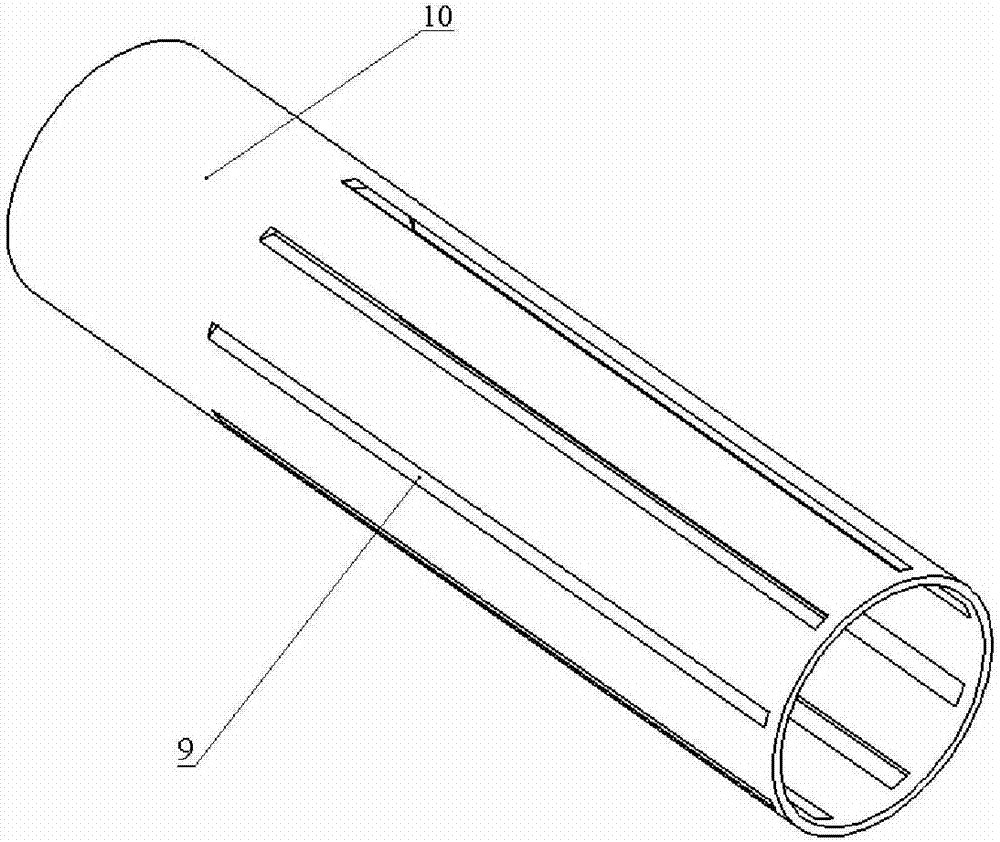

Pipeline type natural gas condensed liquid rotating flow separator

ActiveCN106861296AReduce the strength of the rotationReduce breakageGaseous fuelsDispersed particle separationNatural-gas condensateEngineering

The invention relates to a pipeline type natural gas condensed liquid rotating flow separator, which comprises a cylinder tube body, an axial inlet, an inlet cone section, an outlet cone section, an axial outlet, a front liquid discharging pipe, a back liquid discharging pipe, an annular plate, an inner tube, a flow guide body, an inlet guide blade and a support blade, wherein the inside of the separator is divided into a pre-separation region and a main separation region by the annular plate; the inner tube passes through the annular plate to extend in the separator and forms an annular cavity with the flow guide body; the inlet guide blade is formed by combining a smoothly transiting circular arc-shaped and linear blades; the outer edge and the inner edge of the inlet guide blade are respectively and fixedly connected with the inner tube and the flow guide body; a longitudinal seam is formed in the wall surface of the inner tube; the tail part and the outlet gradual expansion section form an annular opening; the inner edge of the support blade is connected with the tail end of the flow guide body; the outer edge of the support blade is connected with the linear pipe section of the outlet gradual expansion section. The pipeline type natural gas condensed liquid rotating flow separator has the advantages that the integral structure is compact; the two ends are provided with standard flanges; the pipeline connection with the pipeline and the dismounting from the pipeline are convenient; the separation efficiency is high; the pressure drop loss is small; a pre-separation region is installed; a good separation effect is achieved on the high-liquid-contact gas liquid incoming flow.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

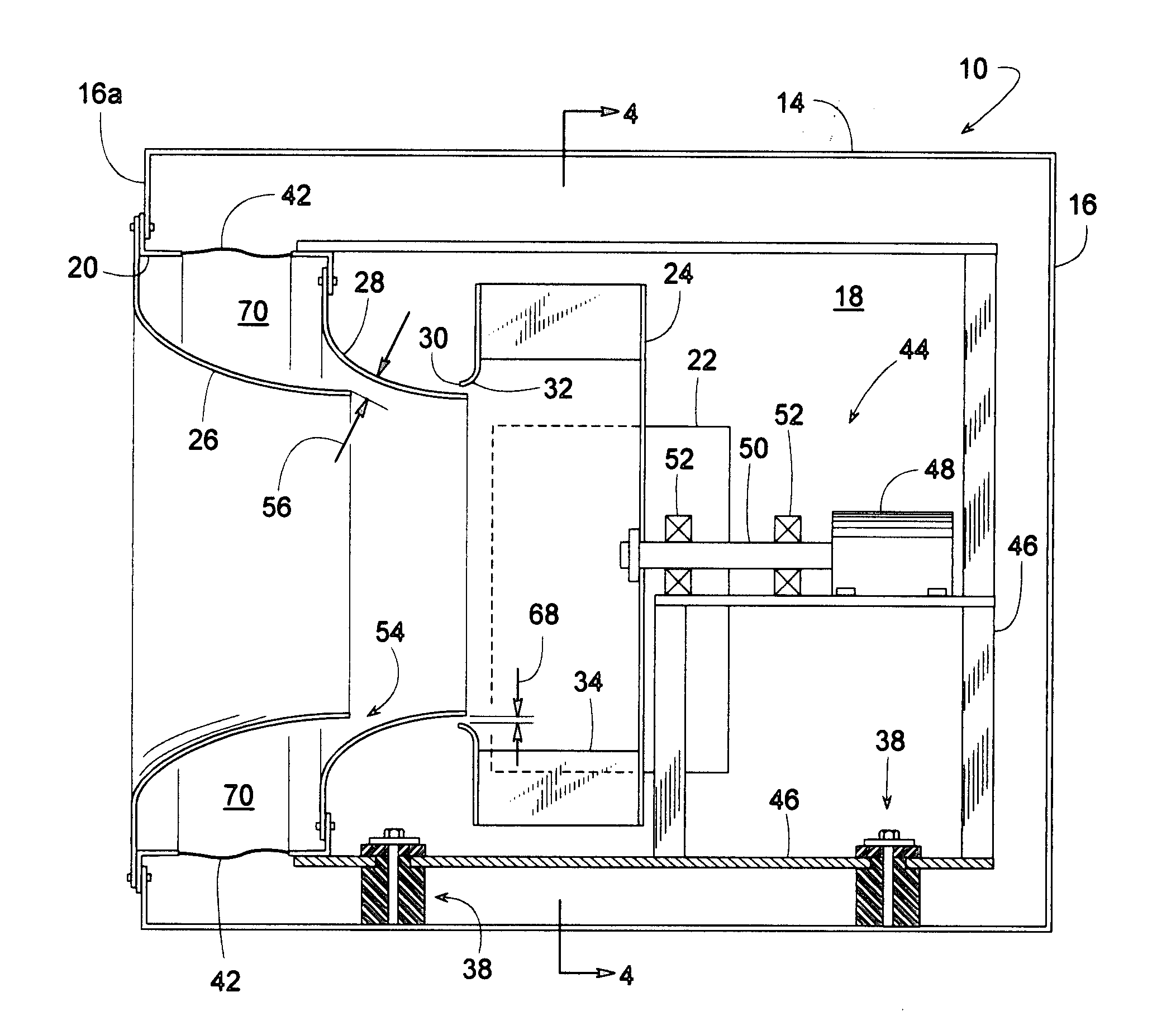

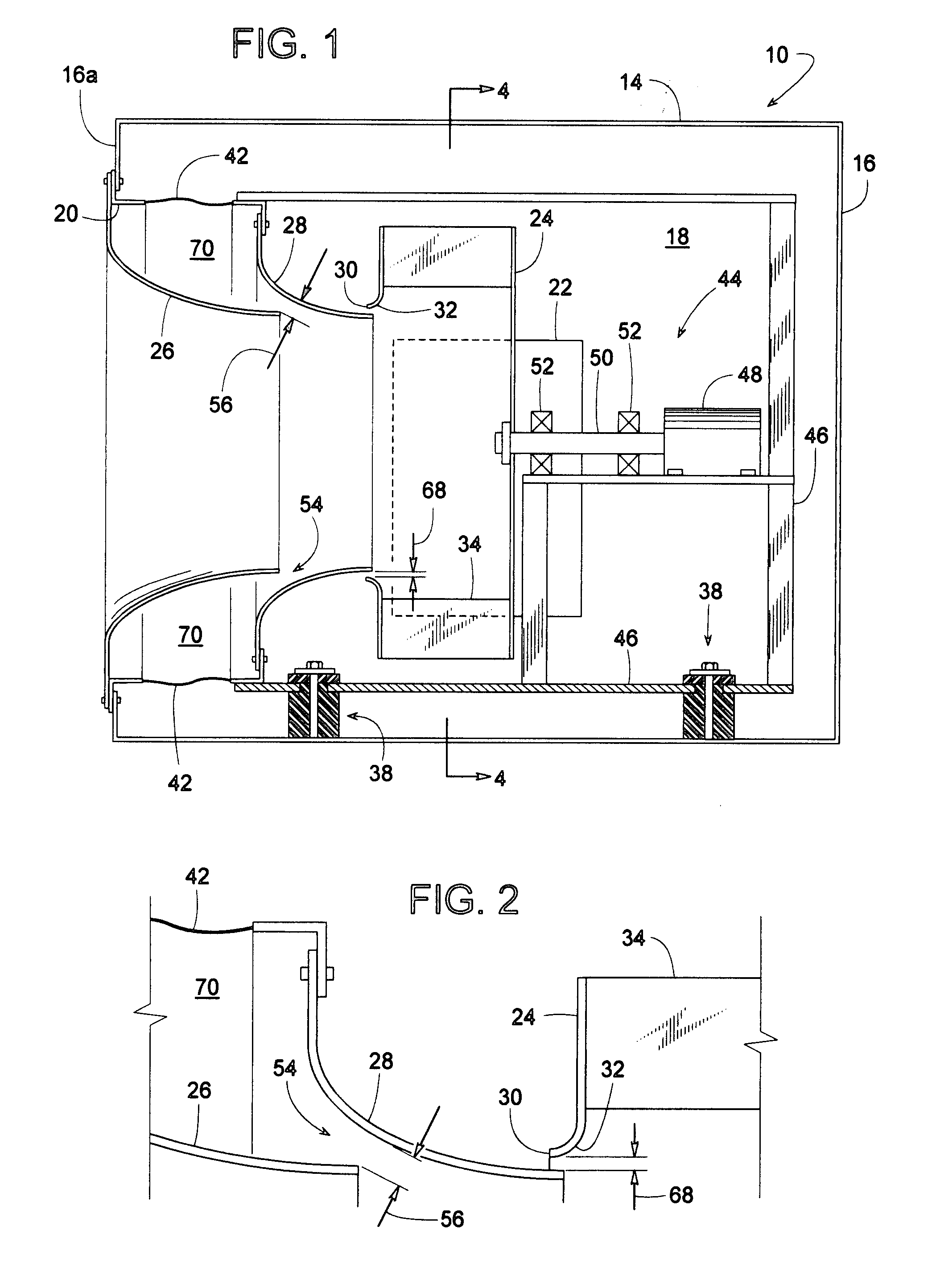

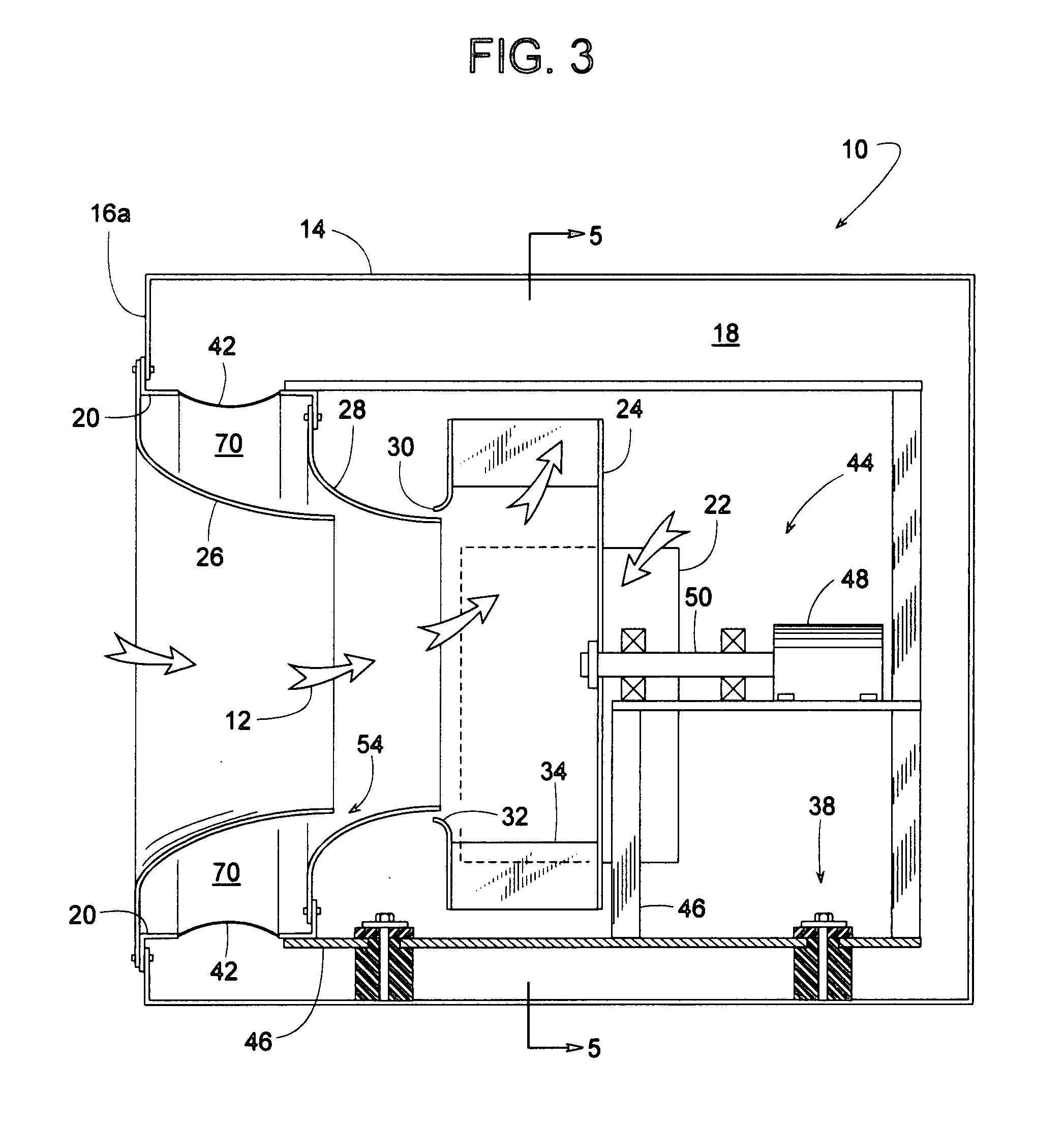

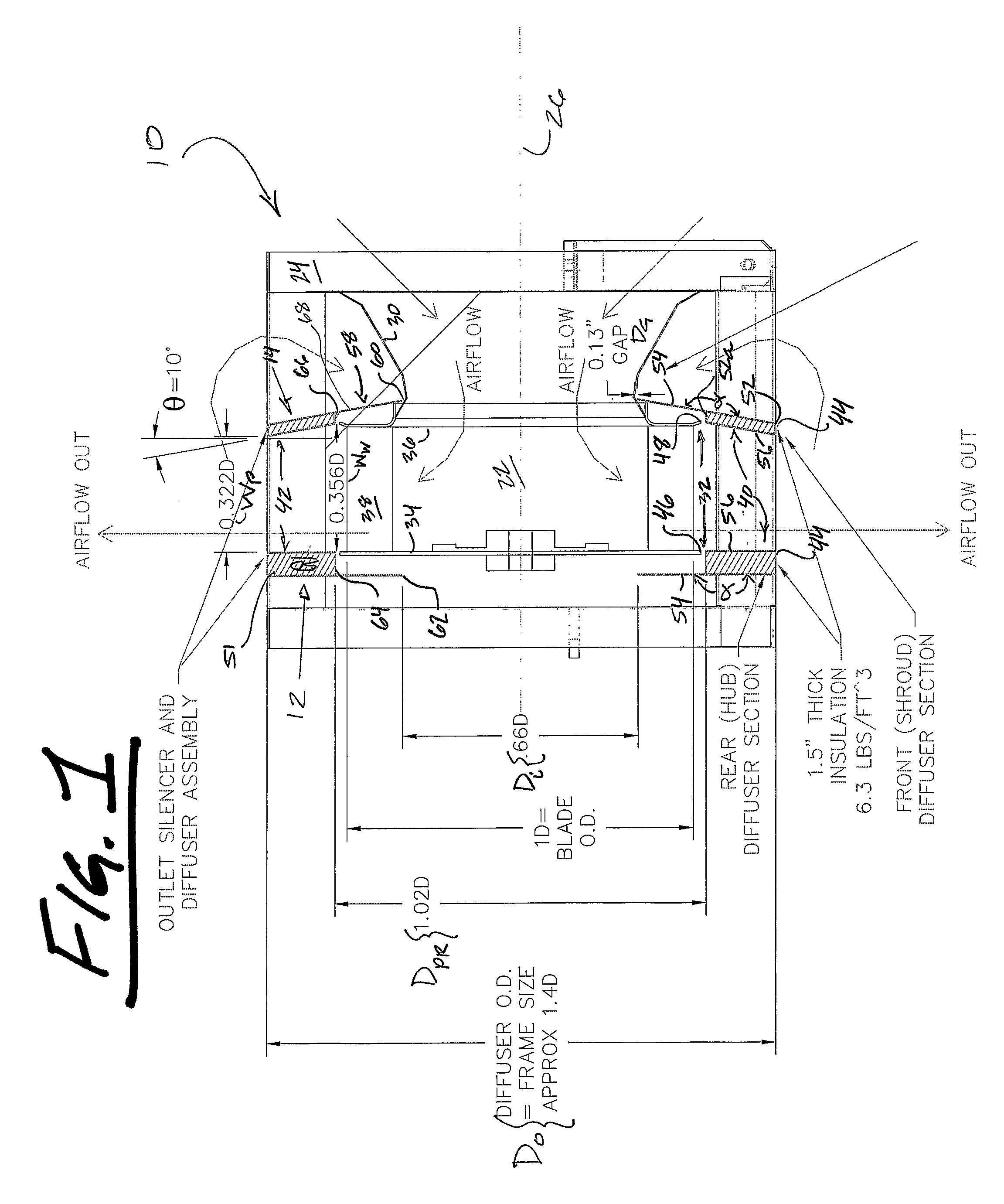

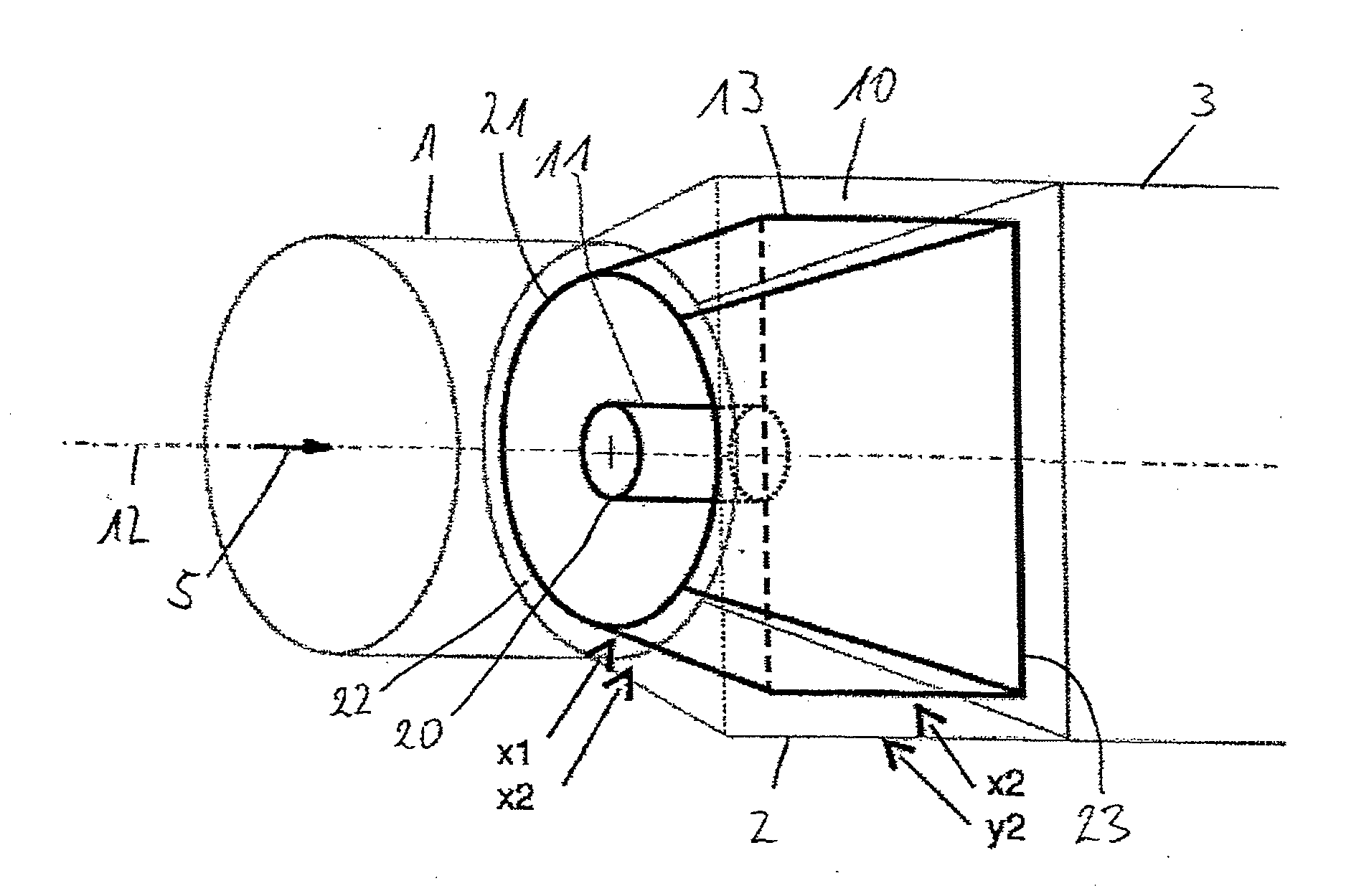

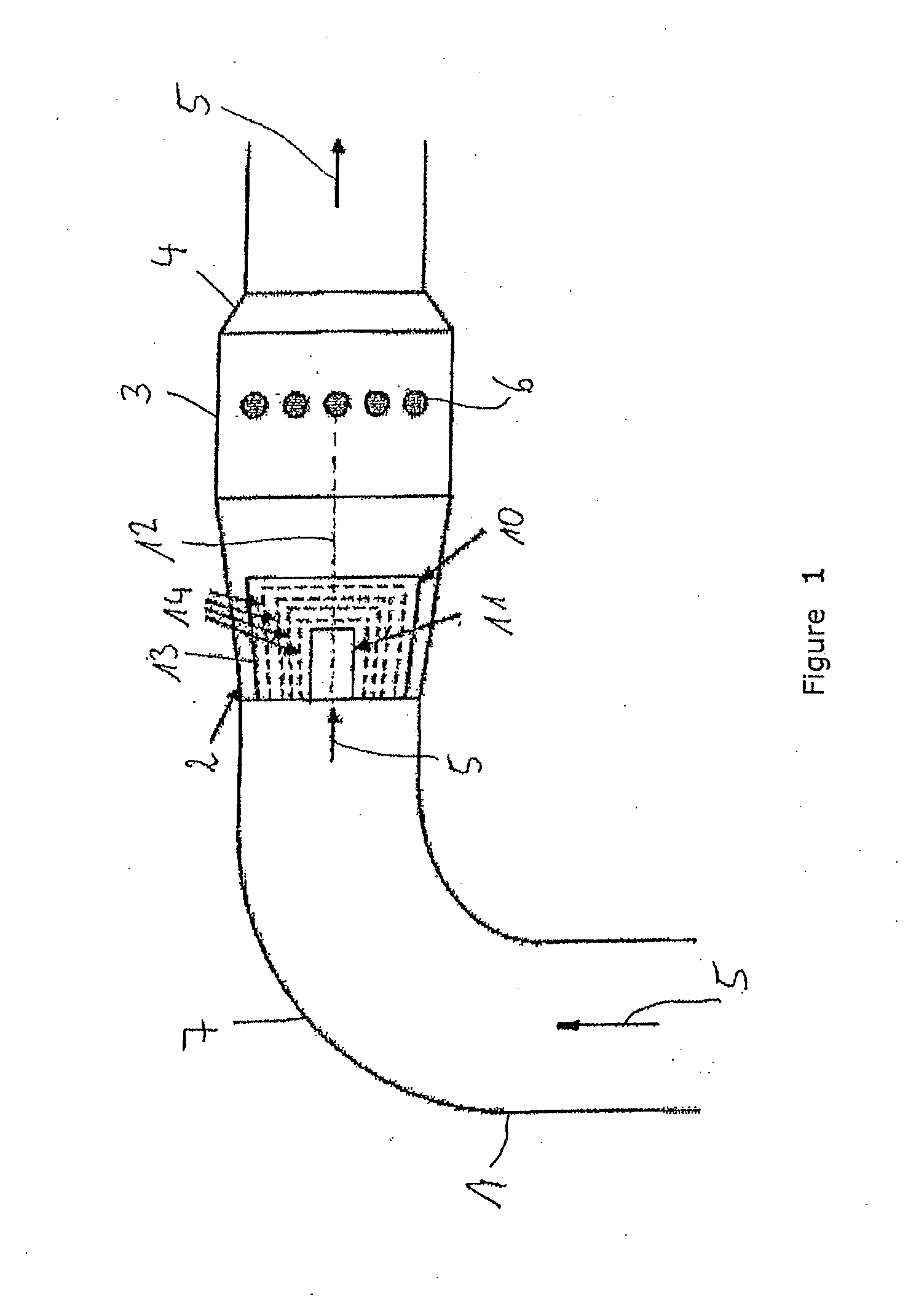

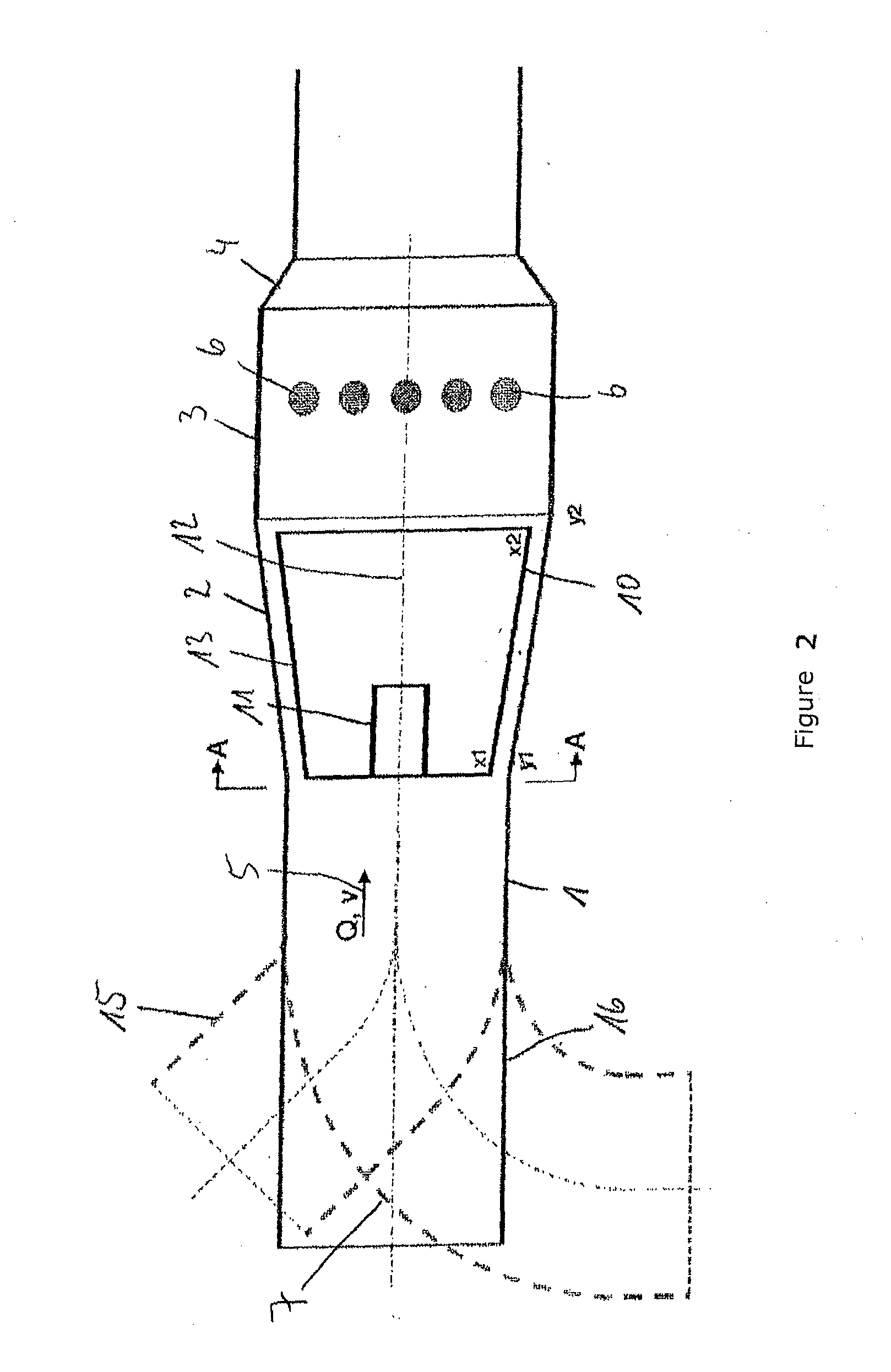

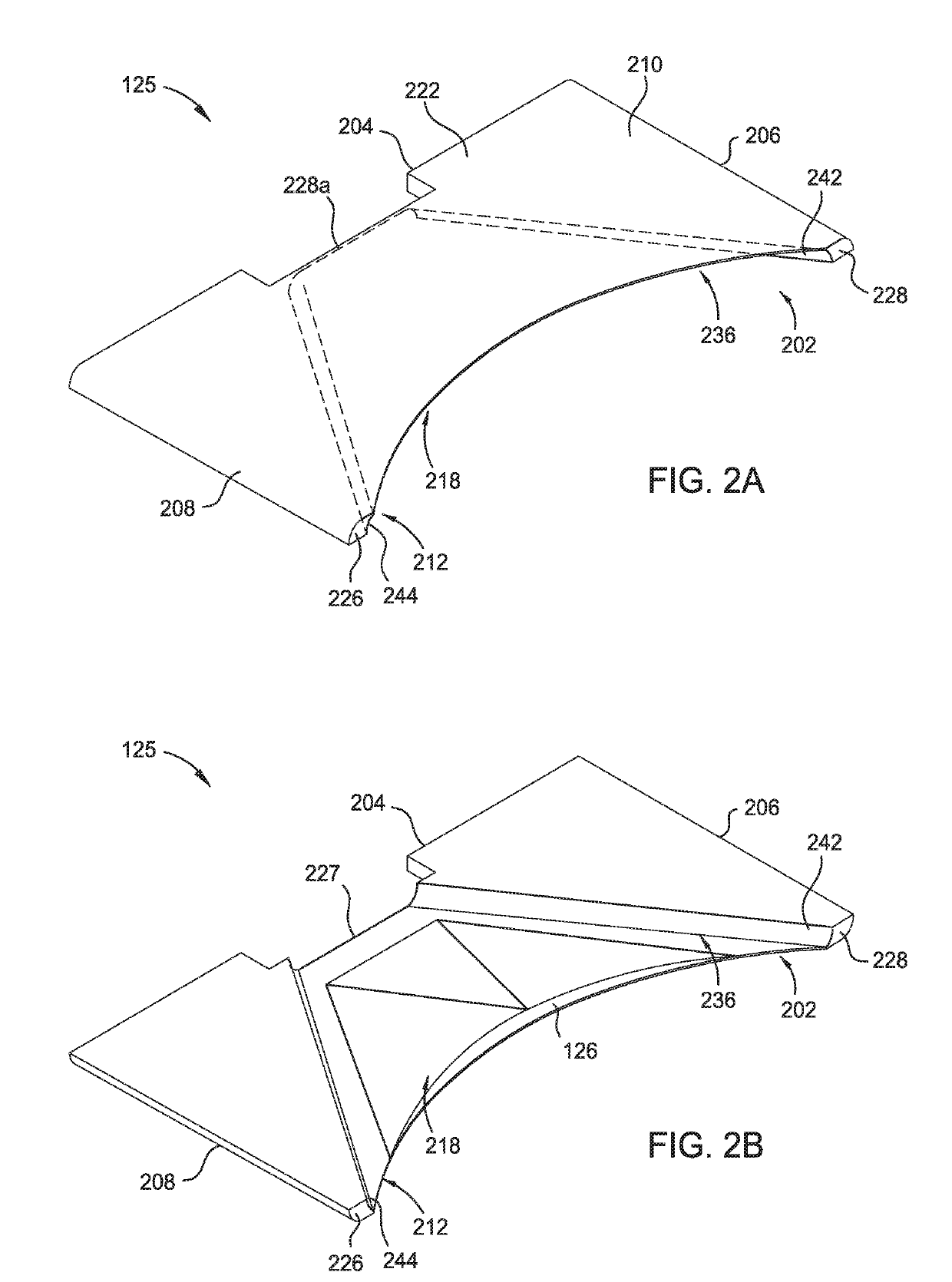

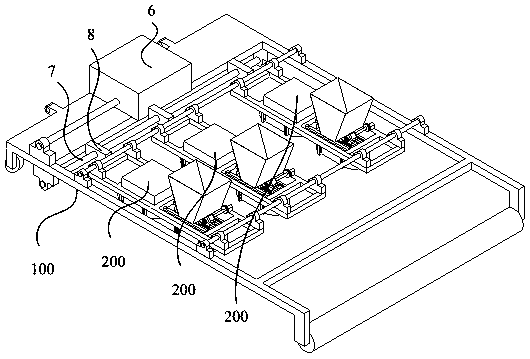

Secondary Inlet Cone for a Plenum Fan

ActiveUS20110064571A1Vibration isolationTight radial clearanceEngine manufacturePump componentsImpellerAirflow

A plenum fan comprising a fan wheel disposed within a box-like enclosure includes a secondary inlet cone, a primary inlet cone, and a flexible duct. The two inlet cones convey air to the mouth of the fan wheel. A frame supports the fan wheel and the primary inlet cone such that the frame, the fan wheel and the primary inlet cone comprise a fan assembly. If the fan assembly shifts due to fan thrust or vibration, the fan assembly moves as a unit. The flexible duct connects the primary inlet cone to an inlet of the enclosure while isolating the fan assembly's vibration from the enclosure. The secondary inlet cone extends from the inlet of the enclosure, protrudes into or toward the primary inlet cone and provides a smooth airflow path over the abrupt shape of the flexible duct.

Owner:TRANE INT INC

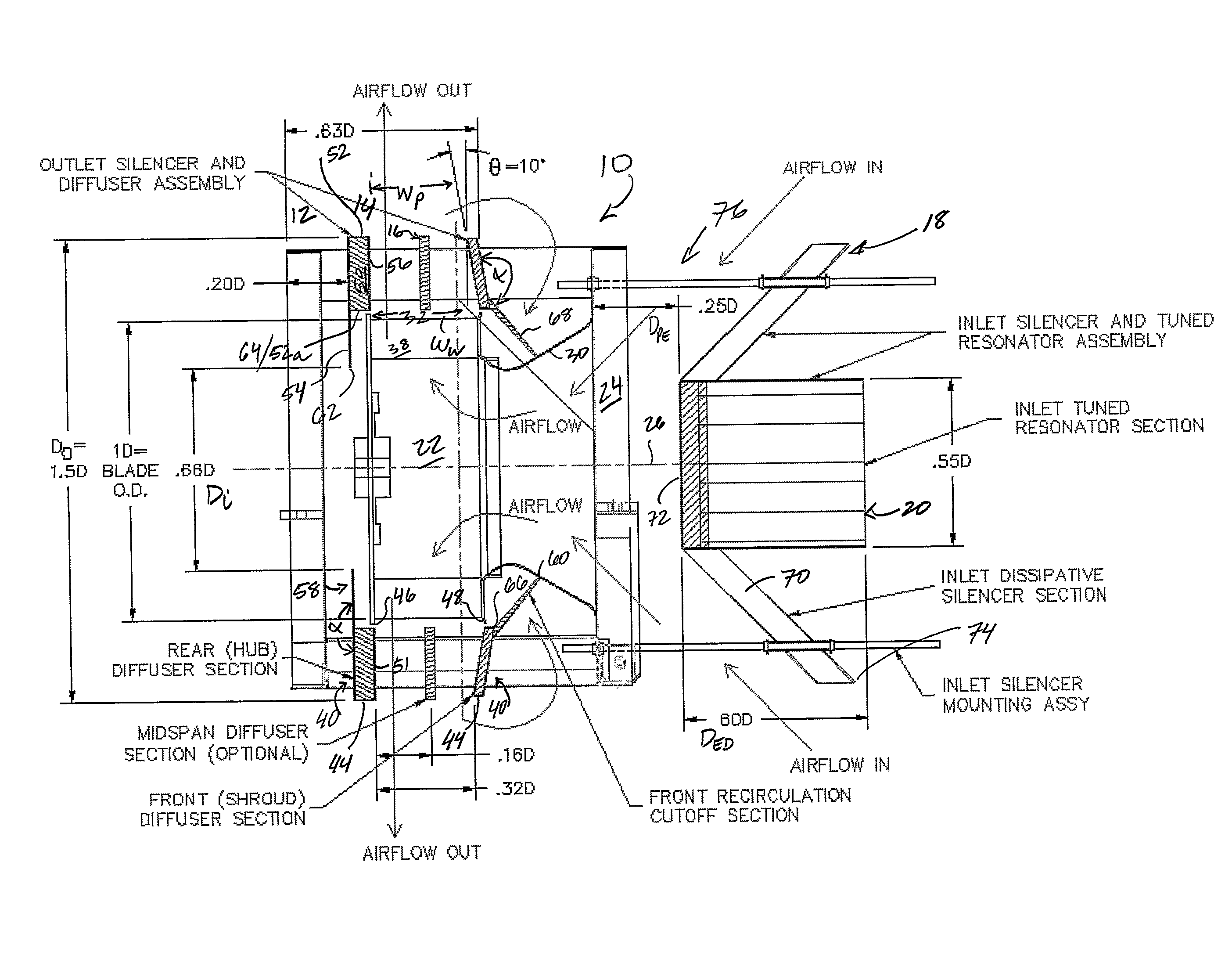

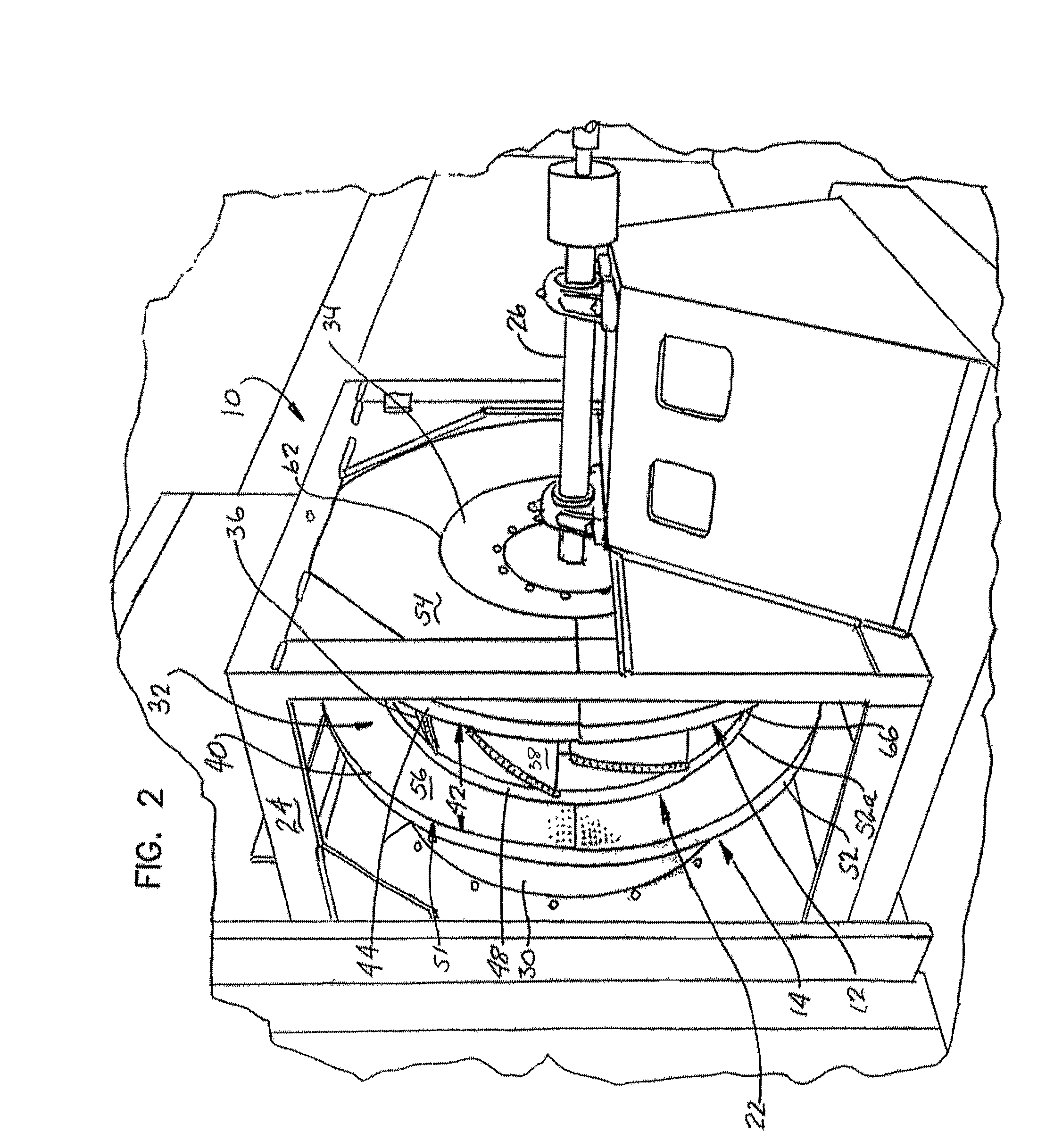

Plenum/plug fan assembly

An aero acoustic fan assembly is provided and generally includes a fan wheel, a frame, and first and second air outlet diffusing structures. The fan wheel generally, and typically includes an axial air inlet delimited by an air inlet cone, an annular air outlet, a back plate, and front plate opposite the back plate. The frame within supports the fan wheel for rotation about a central axis thereof. The first air outlet diffusing structure is supported by a portion of the frame, adjacent the back plate of the fan wheel and includes a peripheral region. The second air outlet diffusing structure is similarly supported by a portion of the frame, adjacent the front plate of the fan wheel, and also includes a peripheral region, air exiting the annular air outlet of the fan wheel passing between the peripheral regions of the diffusing structures.

Owner:TWIN CITY FAN CO LTD

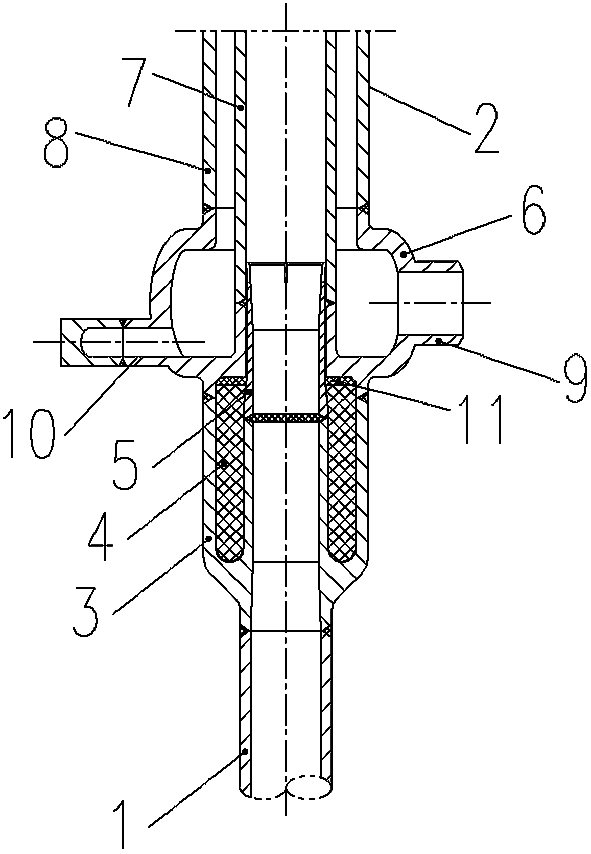

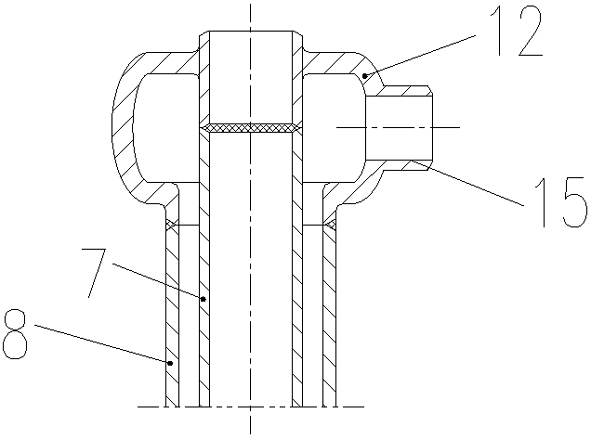

Linear quenching heat exchanger inlet connecting piece and quenching heat exchanger thereof

ActiveCN101975527AGood forming qualityImprove welding strengthHeat exchanger casingsSteam generation using hot heat carriersQuenchingEngineering

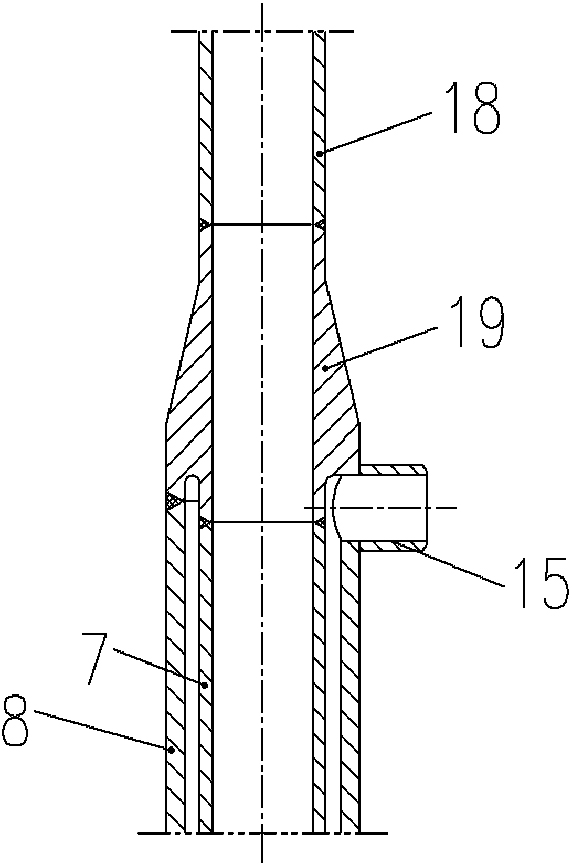

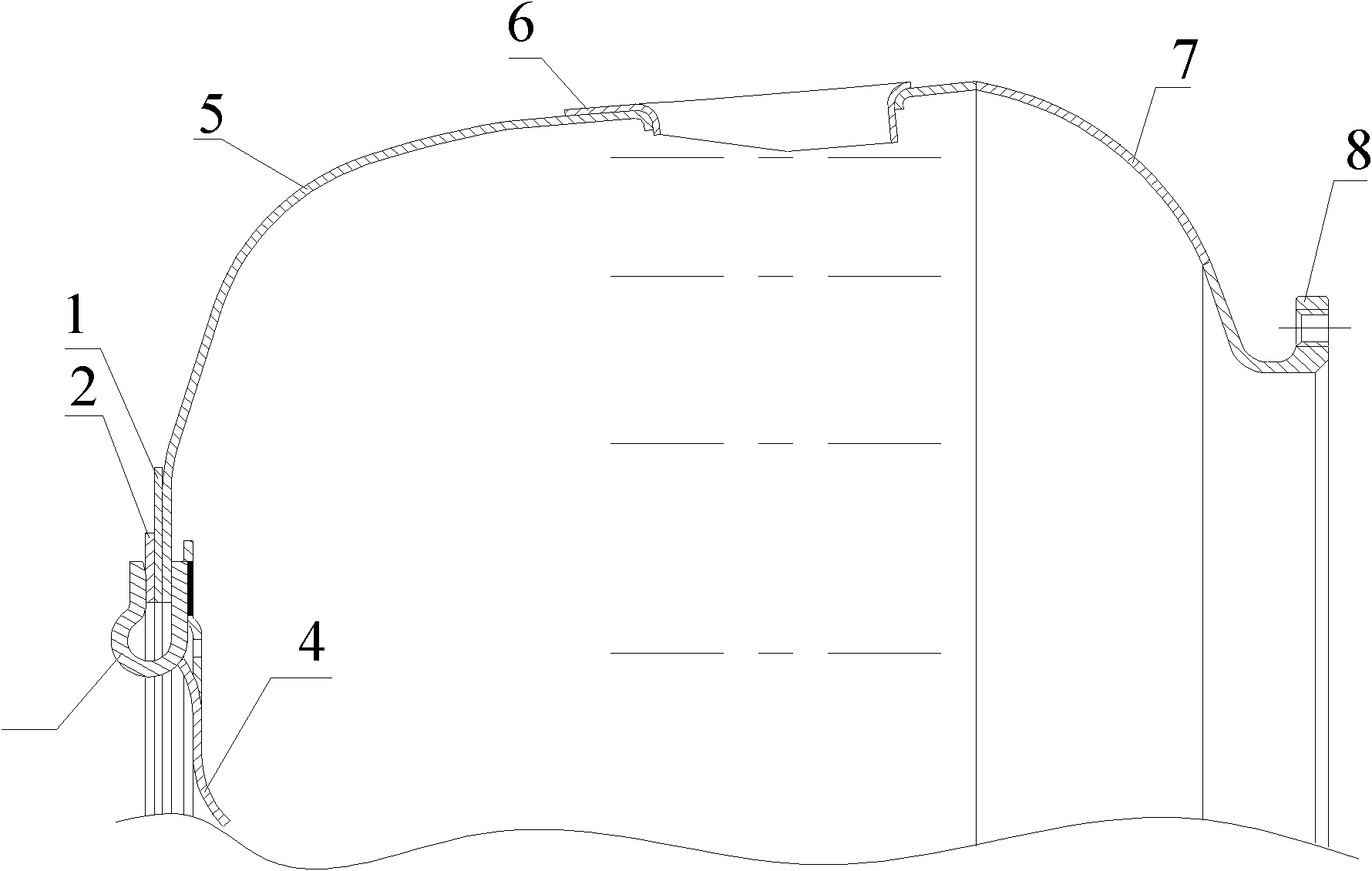

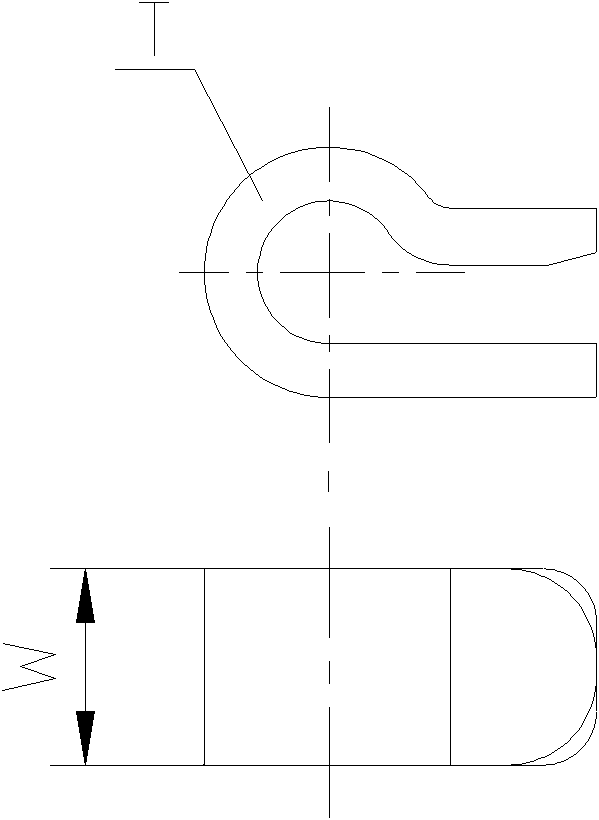

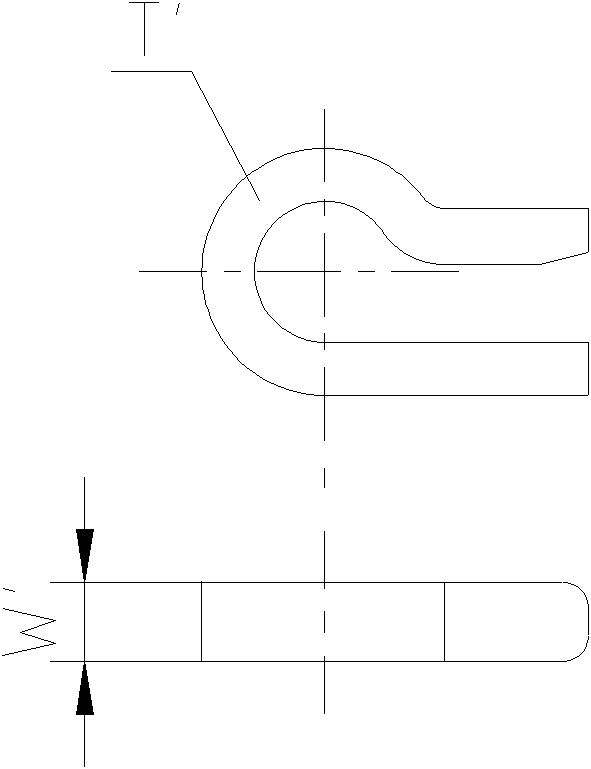

The invention provides a linear quenching heat exchanger inlet connecting piece and a quenching heat exchanger thereof. The inlet connecting piece comprises an inlet cone (3), a heat insulating piece (4), a sealing piece (11), a protective sleeve (5) and a cooling medium connecting piece (6), wherein the cooling medium connecting piece (6) is a revolution body of which the cross section shape is a convex curve surface and can be used for better absorbing heat expansion difference stress between an inner pipe (7) and an outer pipe (8) of a double-sleeve heat exchanger element (2); and the protective sleeve (5) has good heat protection effect on a deep-hole welding head and the cooling medium connecting piece (6). The invention has the advantages of simple structure, long service life and short cracked gas retention time, and not only can be used for newly building a linear quenching heat exchanger of an ethylene cracking device, but also can be used for reforming a service linear quenching heat exchanger inlet connecting piece.

Owner:CHINA PETROLEUM & CHEM CORP +1

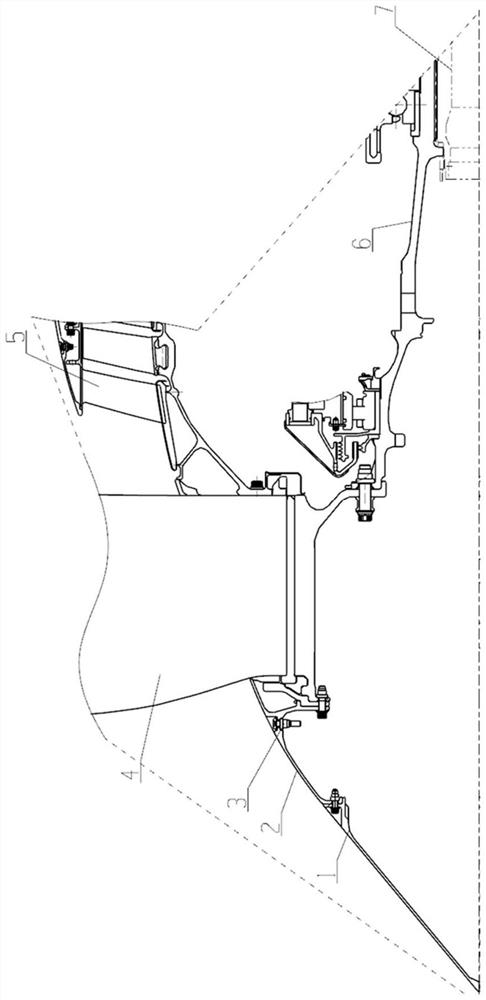

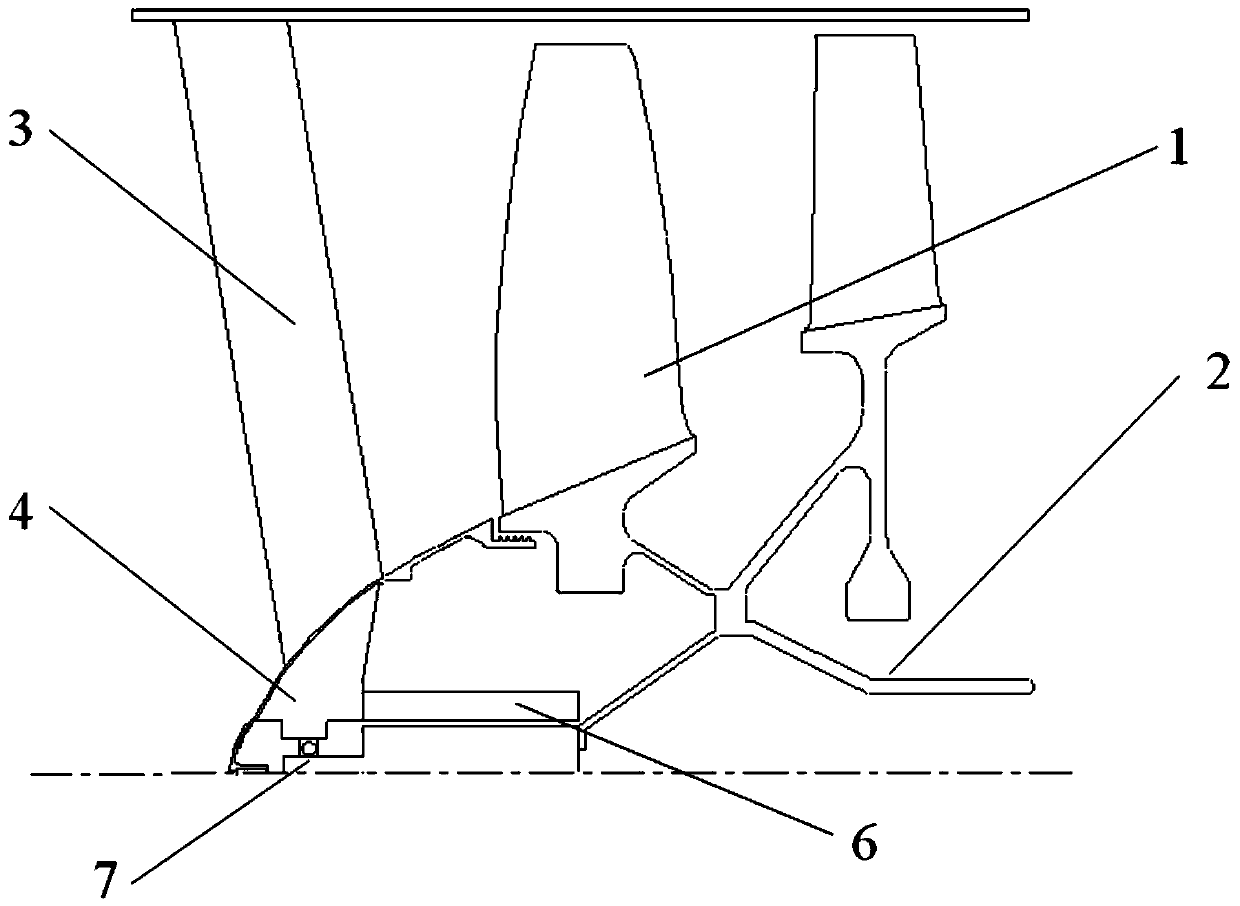

Shell structure for flame tube of aircraft engine

InactiveCN102032596AReduce the maximum temperatureImprove uneven temperature distributionContinuous combustion chamberFuel gasAero engine

The invention relates to a shell structure for a flame tube of an aircraft engine. The shell structure comprises a reinforcing ring of a shell of the flame tube, a fixed ring, a fixed hook, a front air inlet cone, a front section of the shell of the flame tube, an air inlet hopper, a rear section of the shell of the flame tube and a rear mounting edge of the flame tube, wherein the front section of the shell of the flame tube and the rear section of the shell of the flame tube are connected into a whole by welding so as to form the shell of the flame tube, and the reinforcing ring of the shell of the flame tube is welded at the front end of the front section of the shell of the flame tube so as to form an inner mounting edge of the front air inlet cone. The rear mounting edge of the flame tube is welded at the rear end of the rear section of the shell of the flame tube; the air inlet hopper is welded in a long circular hole punched at the front section of the shell of the flame tube; the fixed hook is welded on the front air inlet cone; and the width of the fixed hook is changed from the original 11mm to 4.5mm, the thickness of the fixed hook is changed from 1.8mm to 3mm, the placement angle of the fixed hook is changed to the placement along the direction of air flow, and an included angle between the fixed hook and the radial axial line of the flame tube is 30 degrees. The shell structure can effectively reduce the temperature on the wall surface of the shell of the flame tube; and excess materials on the gasward side surface of the air inlet hopper can be cut off, and the problem of occurrence of cracks on the air inlet hopper can be solved.

Owner:BEIHANG UNIV

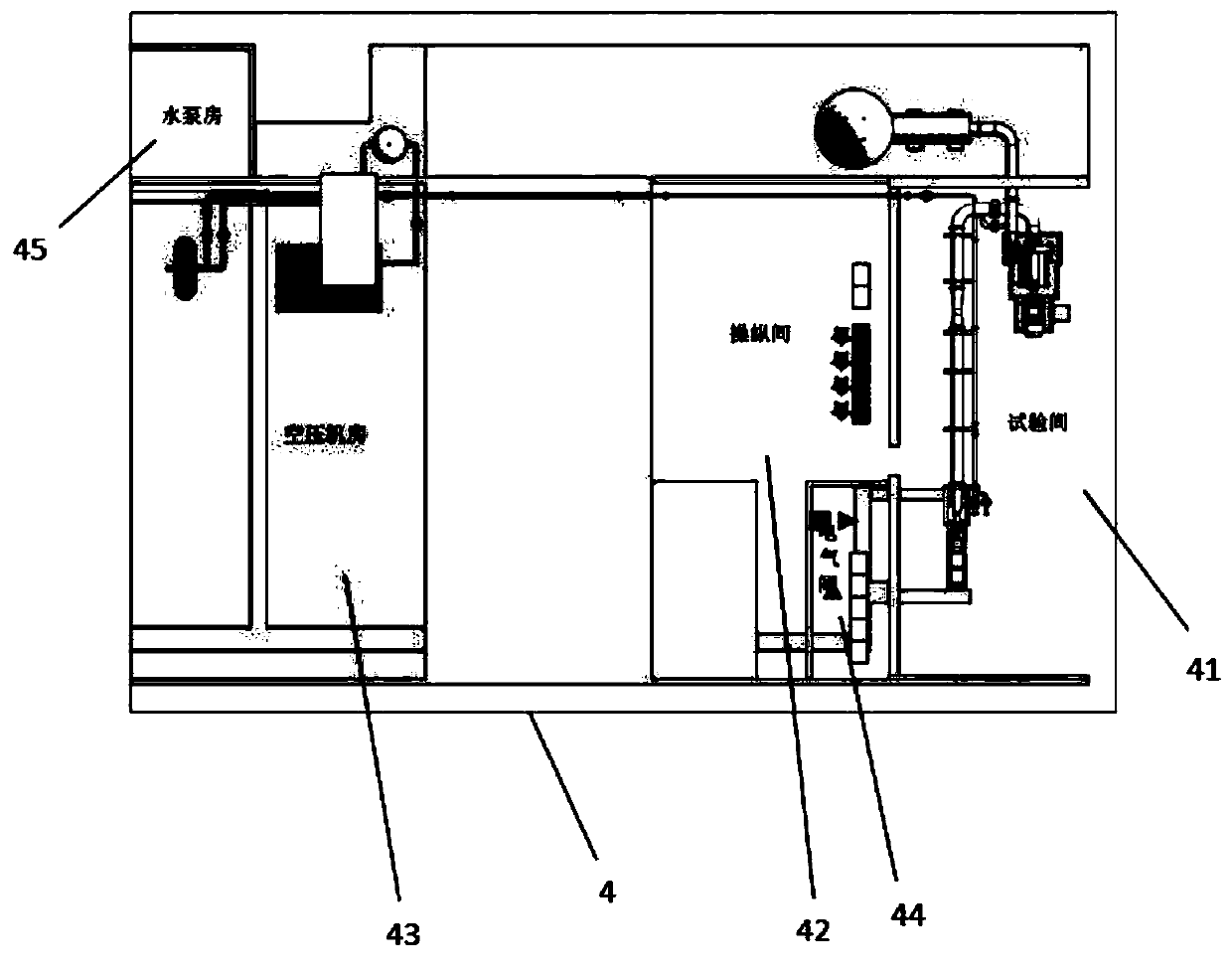

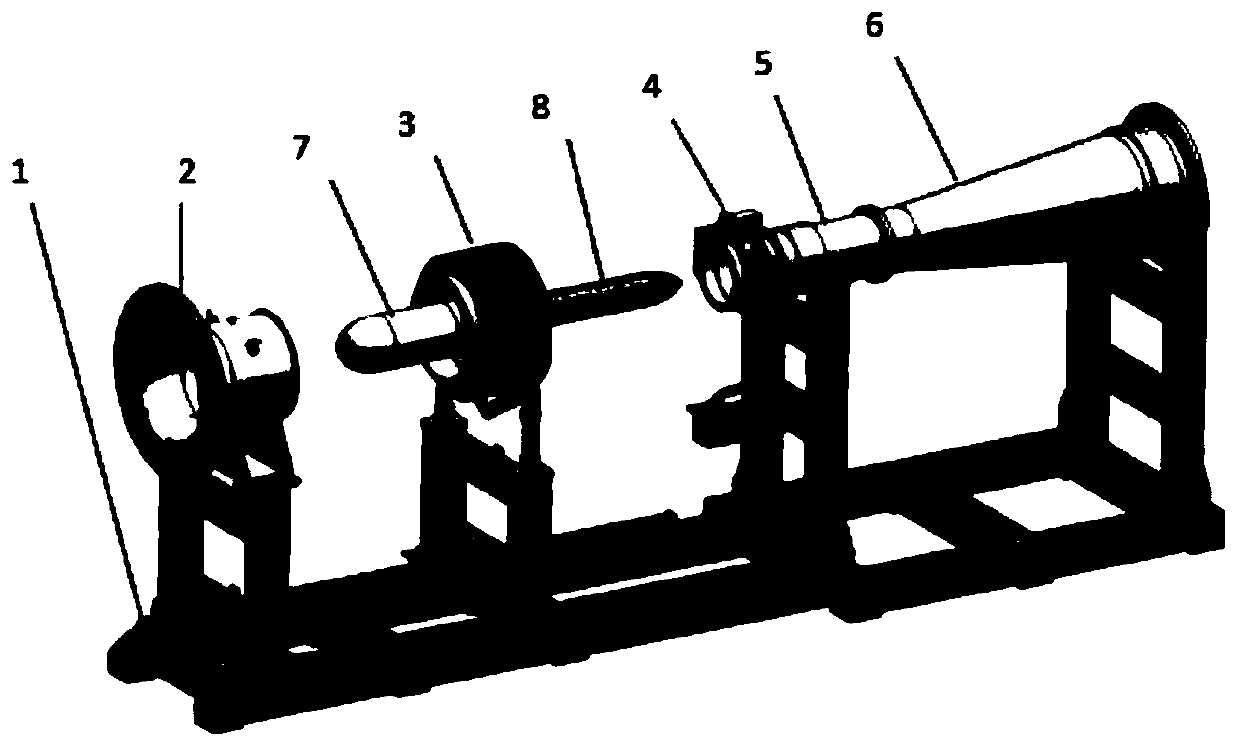

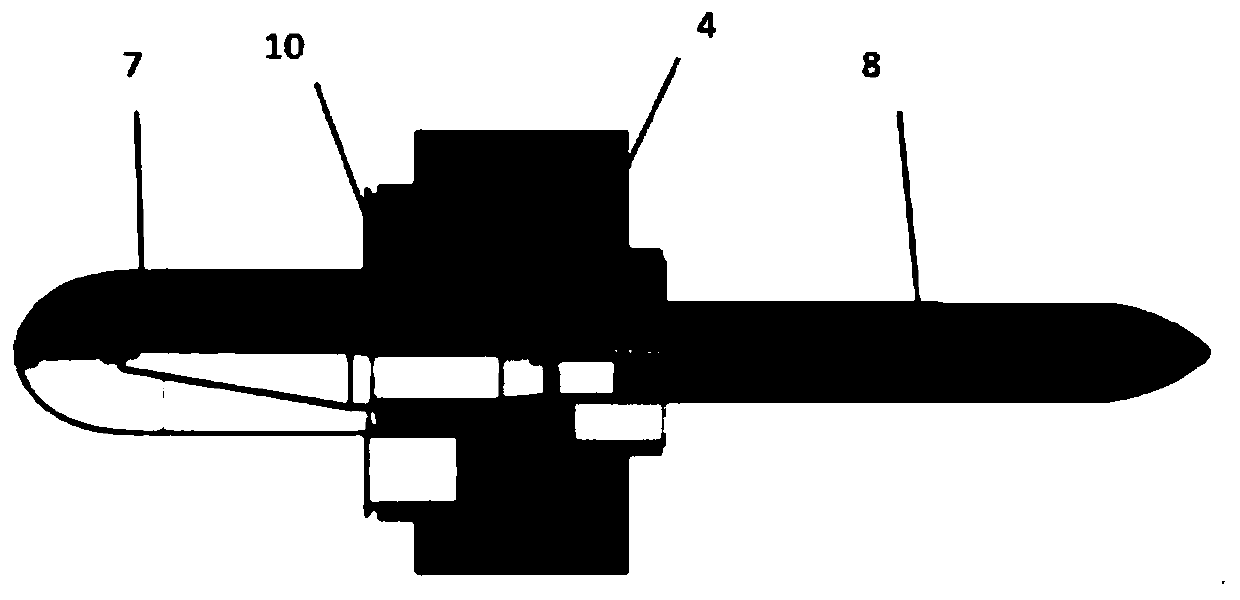

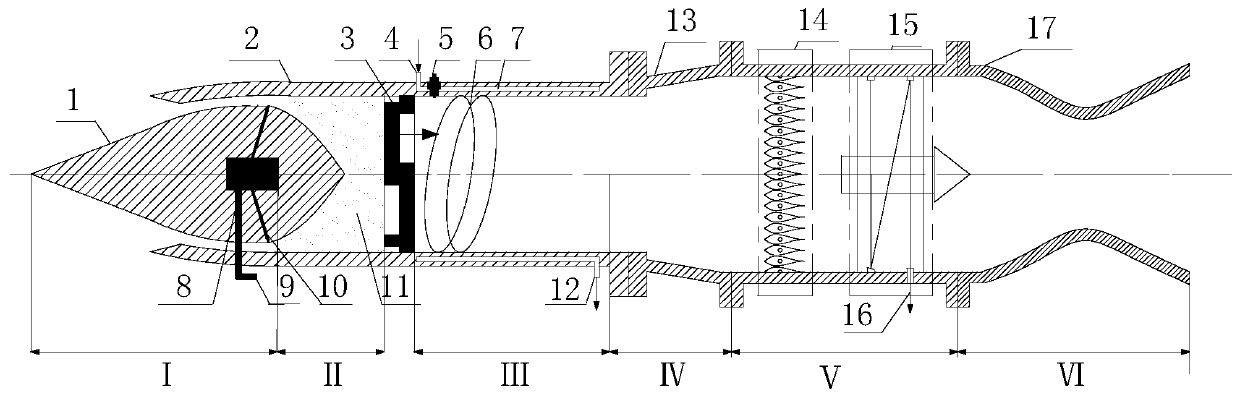

Aero-engine part comprehensive test bed and test method

ActiveCN111044296AAccurately reflectThe test data is accurateGas-turbine engine testingJet-propulsion engine testingStraight tubeStructural engineering

An aero-engine part comprehensive test bed comprises a test piece mounting system, a main airflow pipeline system and an anti-icing air entraining flow system. The test piece mounting system comprisesan annular straight pipe section, a test piece mounting mechanism, a rotary measuring mechanism, an exhaust straight pipe section and an expansion section which are connected in sequence, the annularstraight pipe section comprises an air inlet fairing and an air inlet cone arranged inside the air inlet fairing, and a pressure testing device is arranged on the air inlet fairing; the test piece mounting mechanism is used for mounting a test piece; the rotary measuring mechanism and the exhaust straight pipe section are sequentially connected to form a straight pipe, the exhaust cone assembly is installed in the straight pipe, and the rotary measuring mechanism is provided with a total pressure probe and a static pressure measuring hole; the rear part of the straight exhaust pipe section isconnected with an expansion section; the main airflow pipeline system is connected to the rear end of the test piece mounting system and is used for extracting air out of the test piece; and the anti-icing air entraining flow system is connected to the test piece mounting system through an anti-icing air entraining interface. The test bed can meet two test items, and has the advantages of low cost and high test precision.

Owner:湖南汉能科技有限公司

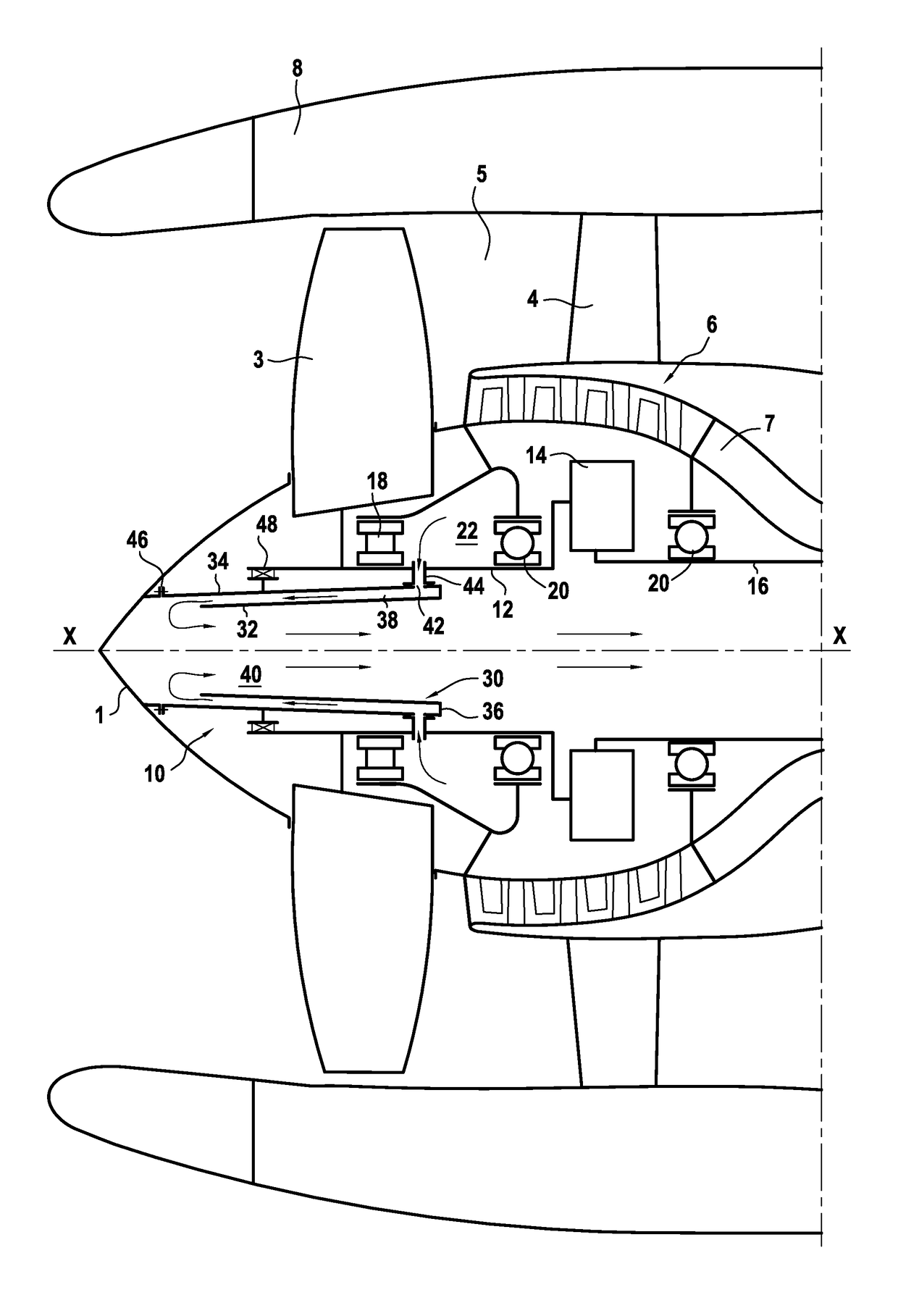

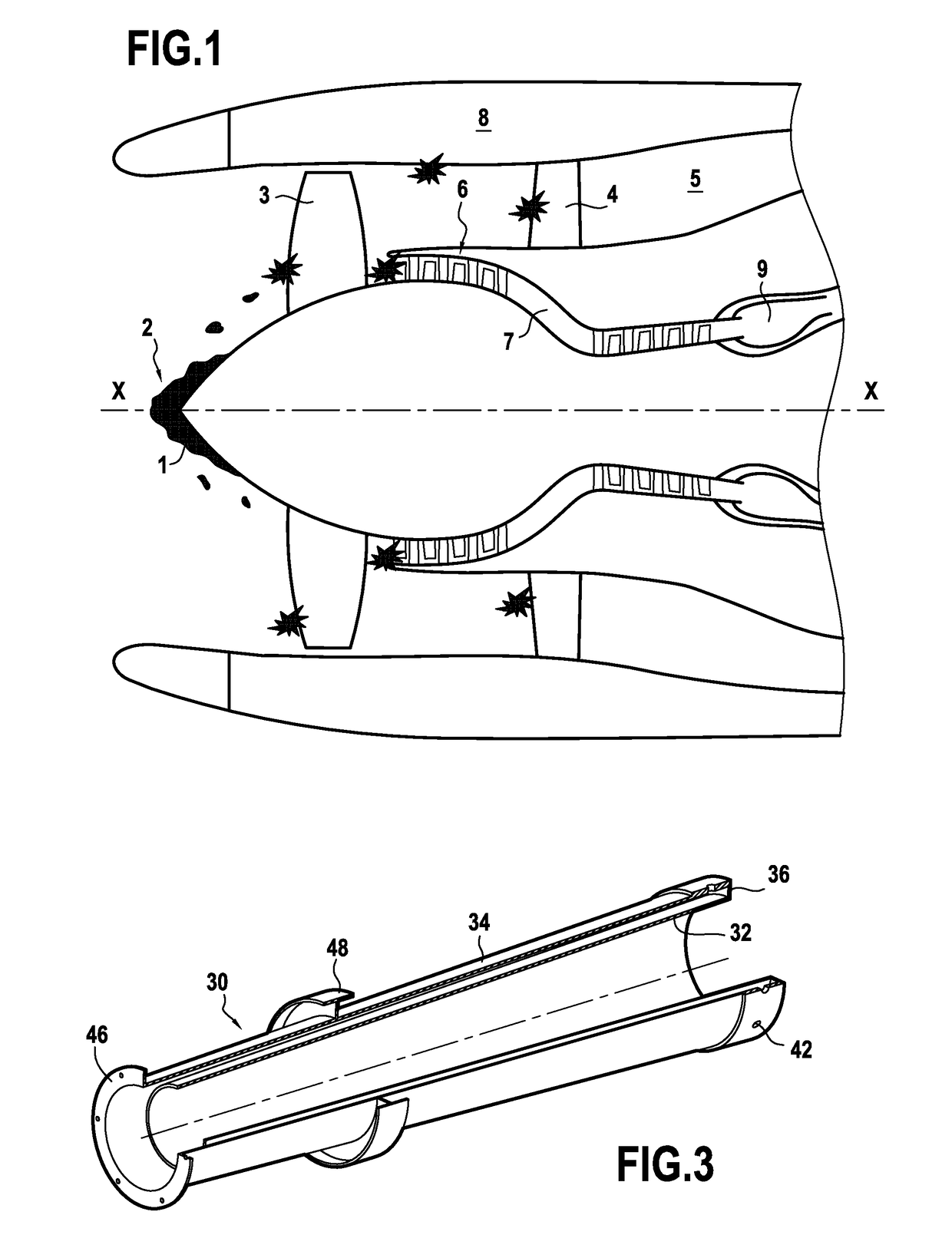

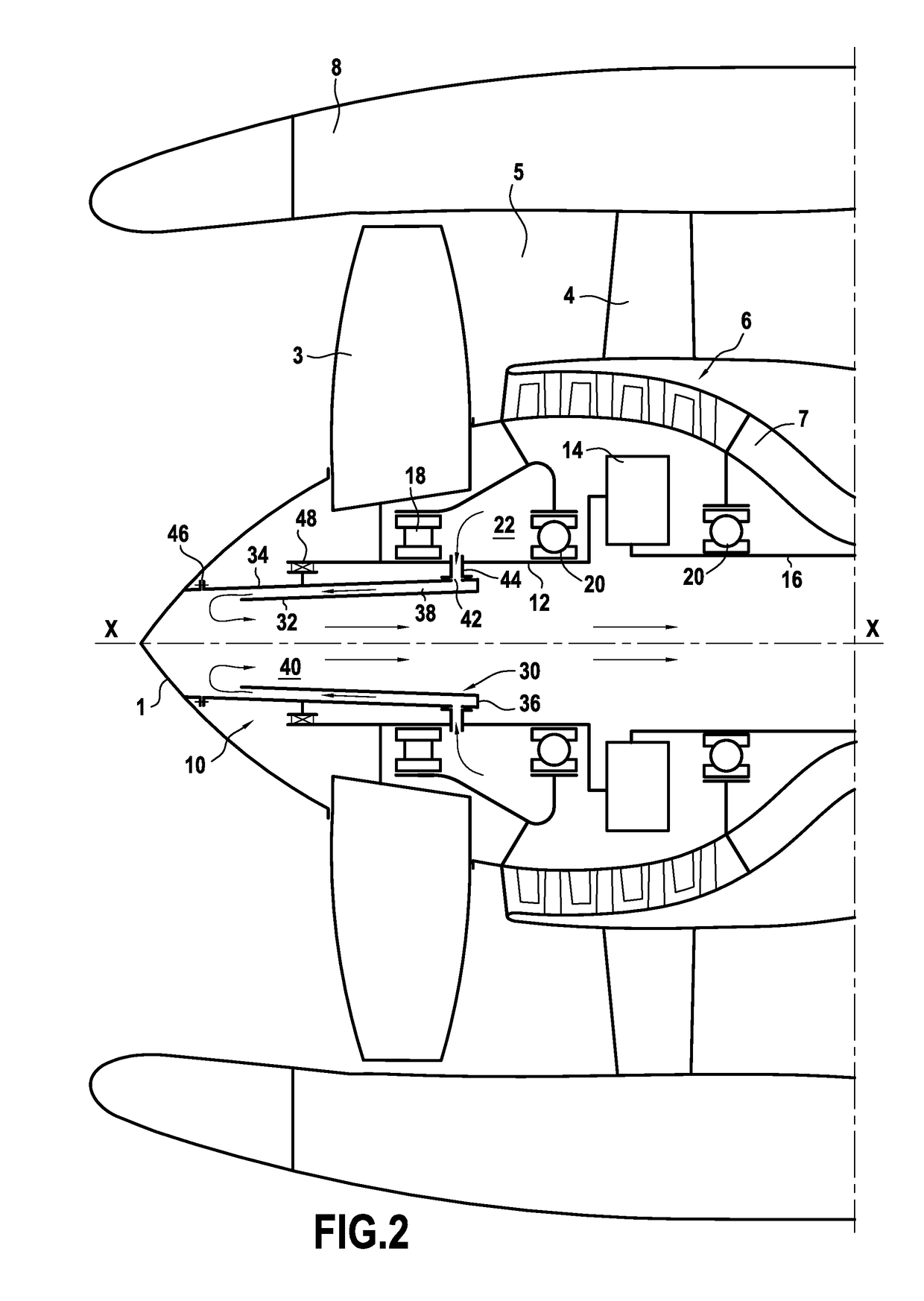

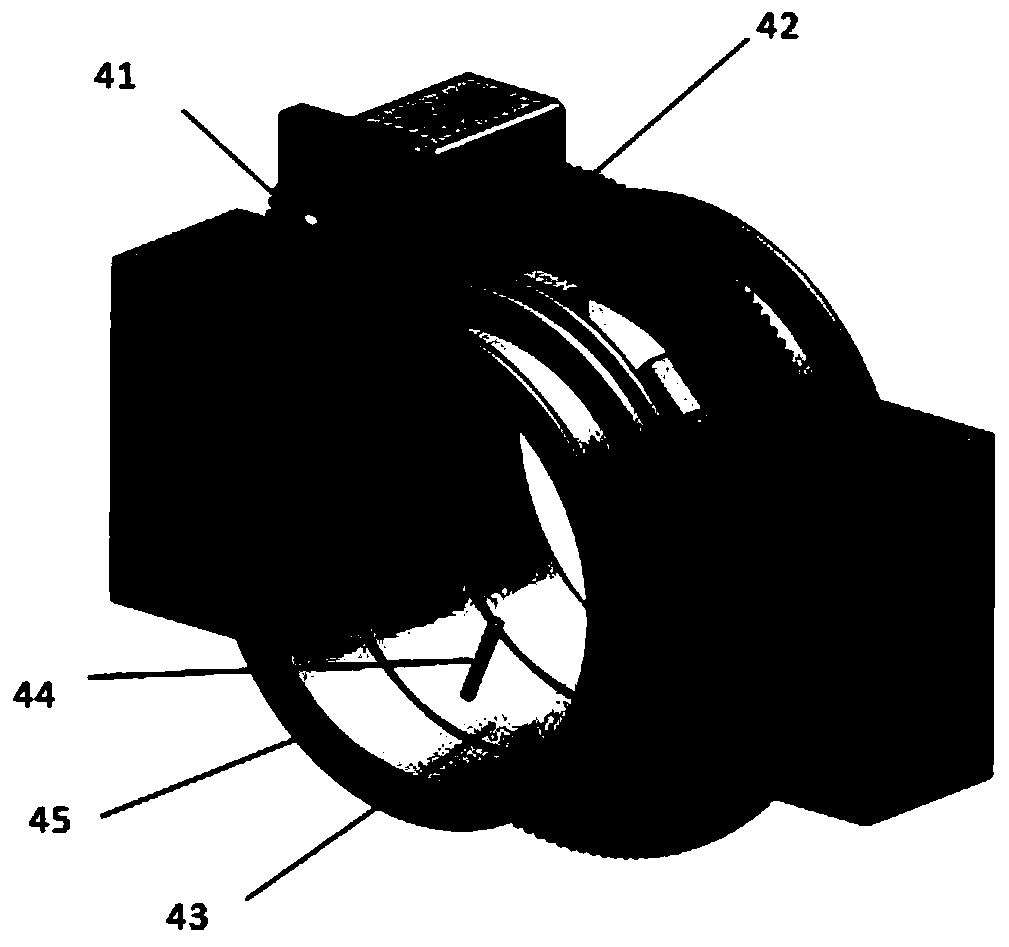

Turbine engine fan module including a turbine engine inlet cone de-icing system, and a de-icing method

ActiveUS20180128173A1Mitigate such drawbackImprove performanceEngine fuctionsDe-icing equipmentsAviationOne-hot

The invention relates to an aviation turbine engine fan module including a de-icing system (10) for de-icing an inlet cone (1) and comprising a sheath (30) placed inside an inside space defined upstream by the inlet cone, said sheath comprising a first duct (38) having at least one hot air admission orifice (42), said first duct being configured to convey hot air from a bearing enclosure (22) of the engine towards a wall of the inlet cone in order to heat it from the inside, the sheath further comprising a second duct (40) having at least one outlet situated downstream from the admission orifice of the first duct, said second duct being configured to discharge air from the first duct towards the downstream end of the engine. The invention also provides a method of de-icing a turbine engine inlet cone.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

Air-breathing premixed carbon dioxide pneumatic laser driven by continuous rotary detonation combustion

ActiveCN110718843ADetonation combustion achievedDetonation combustion hasLaser detailsCombustion chamberFlight vehicle

The invention discloses an air-breathing premixed carbon dioxide pneumatic laser driven by continuous rotary detonation combustion. The laser comprises an air-breathing continuous rotary detonation combustion device, a transition section, a CO2 pneumatic laser generation device and an exhaust section. The air-breathing continuous rotary detonation combustion device is used for generating a high-temperature and high-pressure fuel gas heat source serving as total energy for downstream output laser, and comprises a center body and a cylindrical shell. The center body comprises an air inlet cone part, a large cylinder part, a small cylinder part and a tail cone part which are sequentially arranged from front to back. An air inlet channel is formed by a gap between the air inlet conical part and the front-end conical shell, and a rotary detonation combustion chamber is formed by a gap between the small cylindrical part and a rear-end cylindrical shell. The laser is applied to an air-breathing aircraft, and the air-breathing continuous rotary detonation combustion device is adopted as a pumping source; the generated laser is high in efficiency, and energy is saved. The same air-breathingcontinuous rotary detonation combustion device is adopted without increasing the load, so not only can thrust be generated, but also laser can be generated.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Flow rectifier for closed pipelines

ActiveUS20130320233A1Stable speedScattering properties measurementsFluid dynamicsEngineeringIrradiation

A channel for a UV irradiation device, in which the UV irradiation device is disposed in a closed channel and an inlet cone is provided in the direction of flow upstream of a UV reactor, which, as part of the wall of the channel, increases the cross section of the channel from an incoming pipeline cross section to a cross section of the reactor, in which a flow rectifier with at least one inner first guide element and at least one outer second guide element is disposed in the inlet cone, wherein the inner guide element is a substantially circular, cylindrical pipe and the outer guide element runs substantially parallel to the outer wall and is disposed at a distance from the outer wall.

Owner:XYLEM IP HLDG

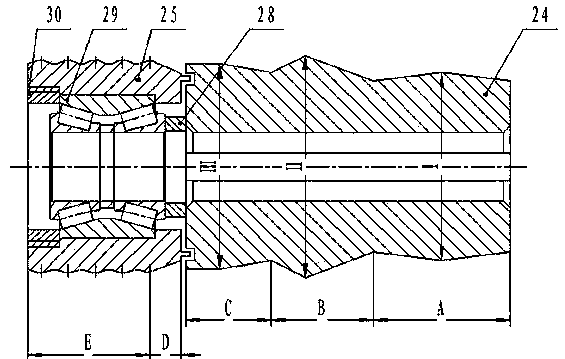

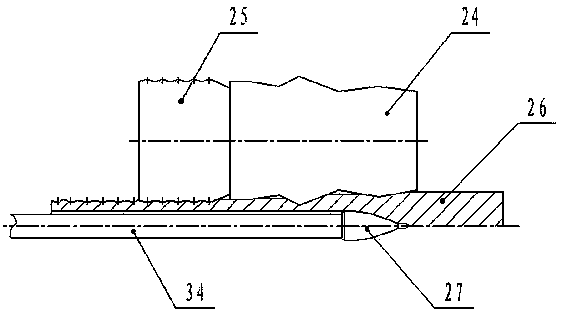

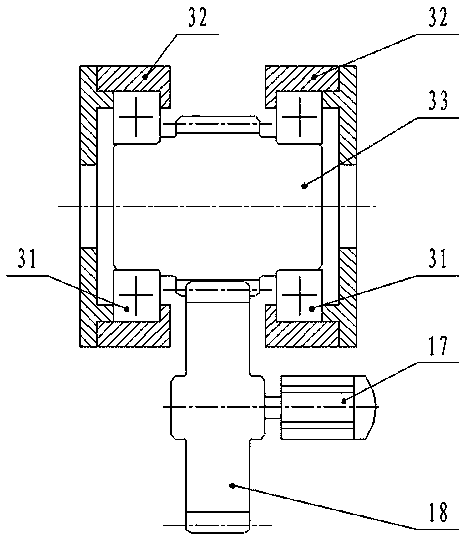

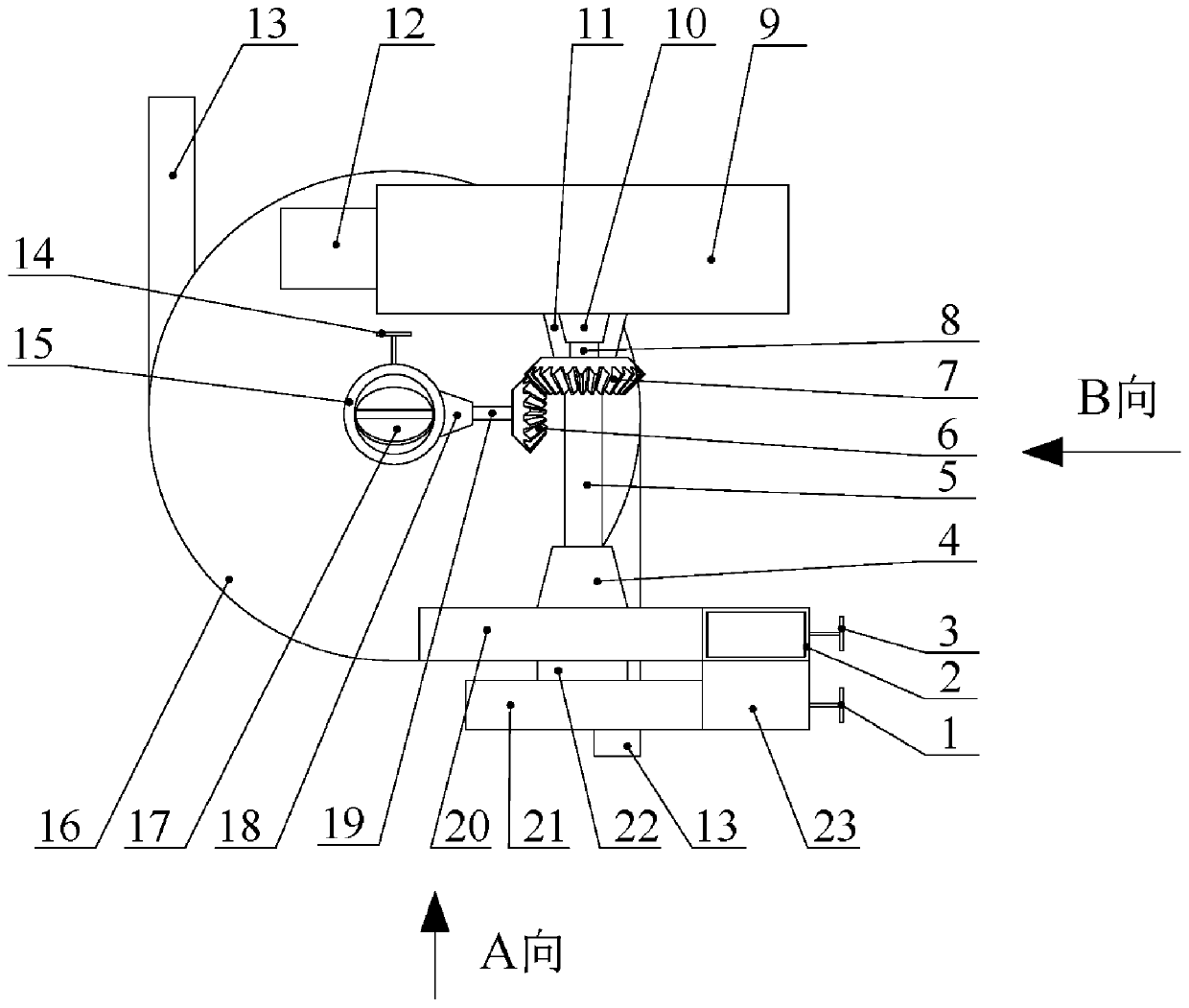

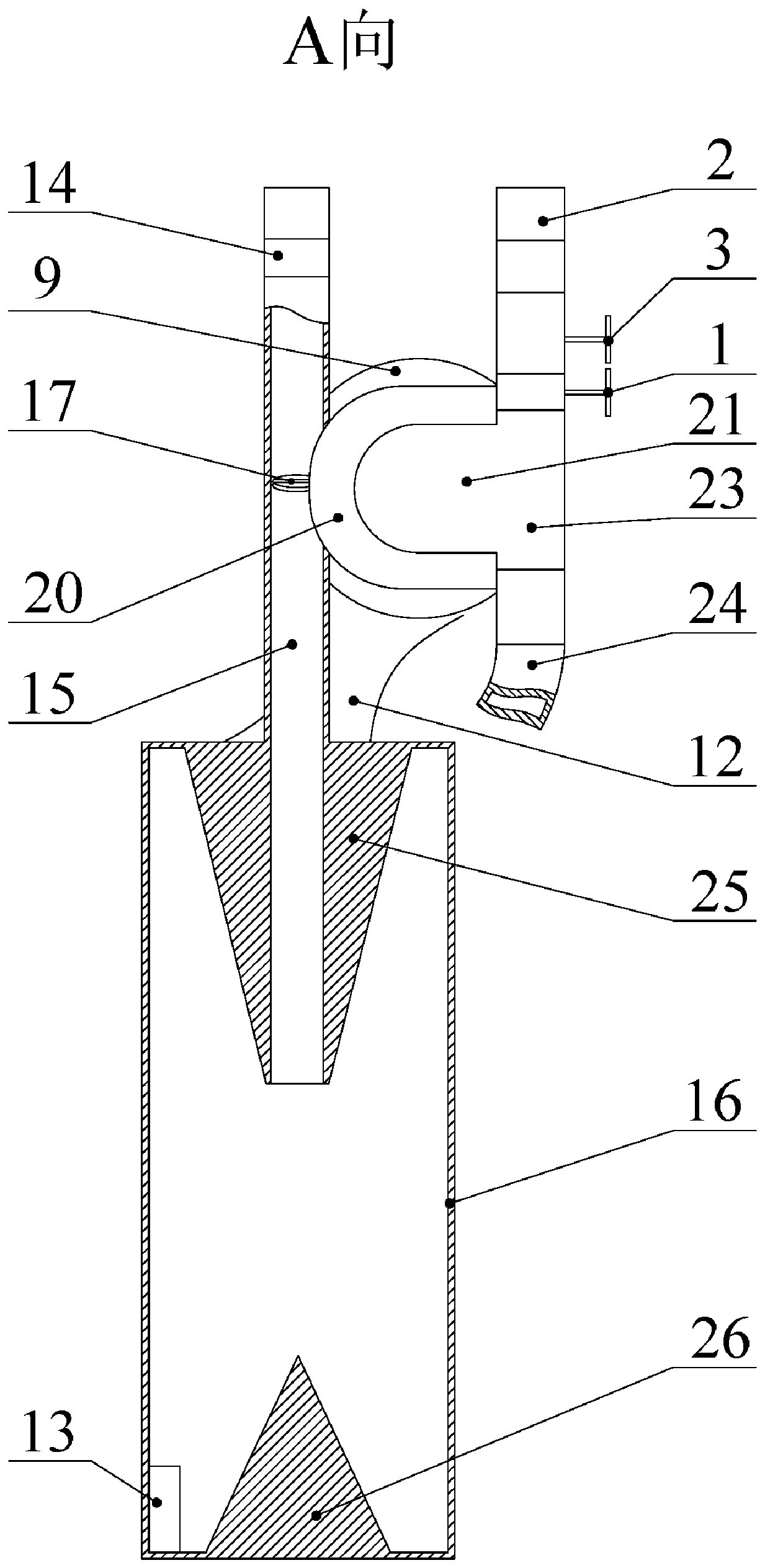

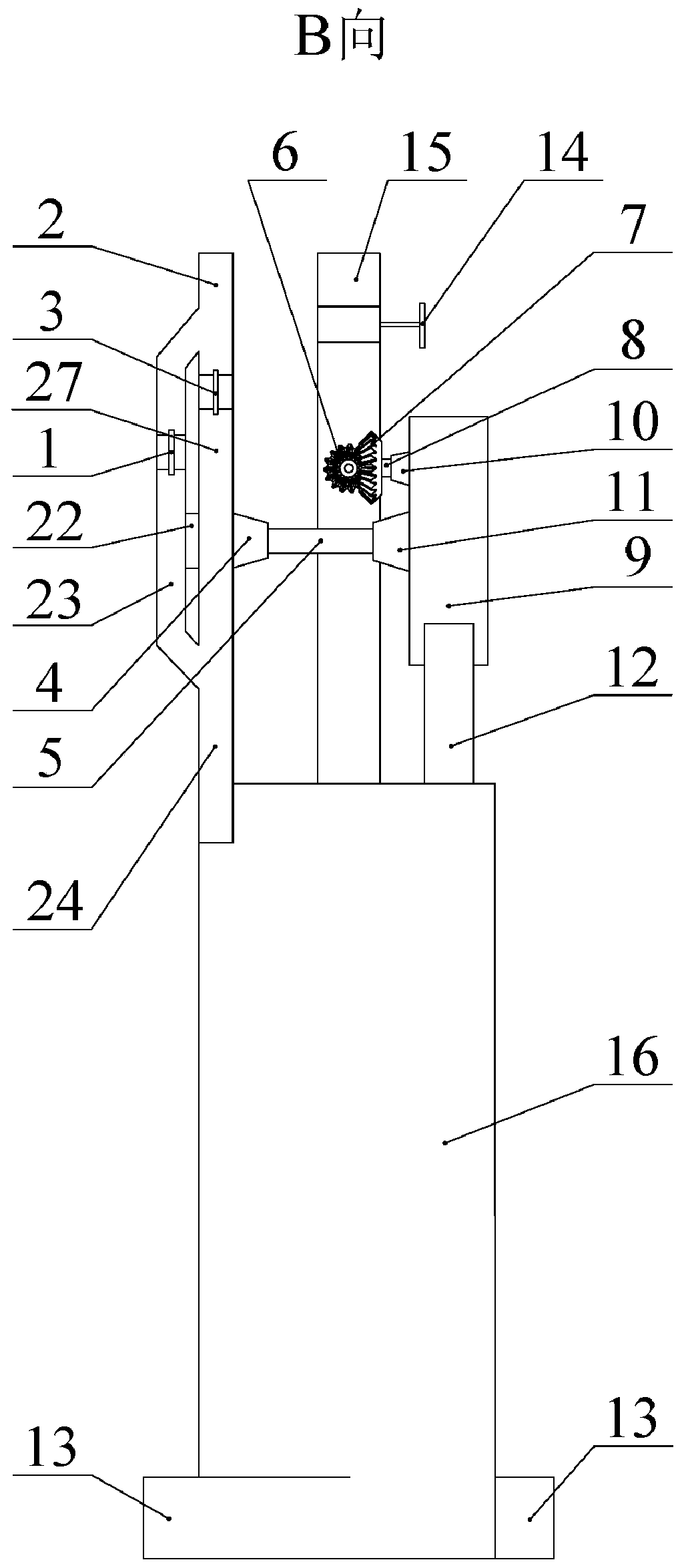

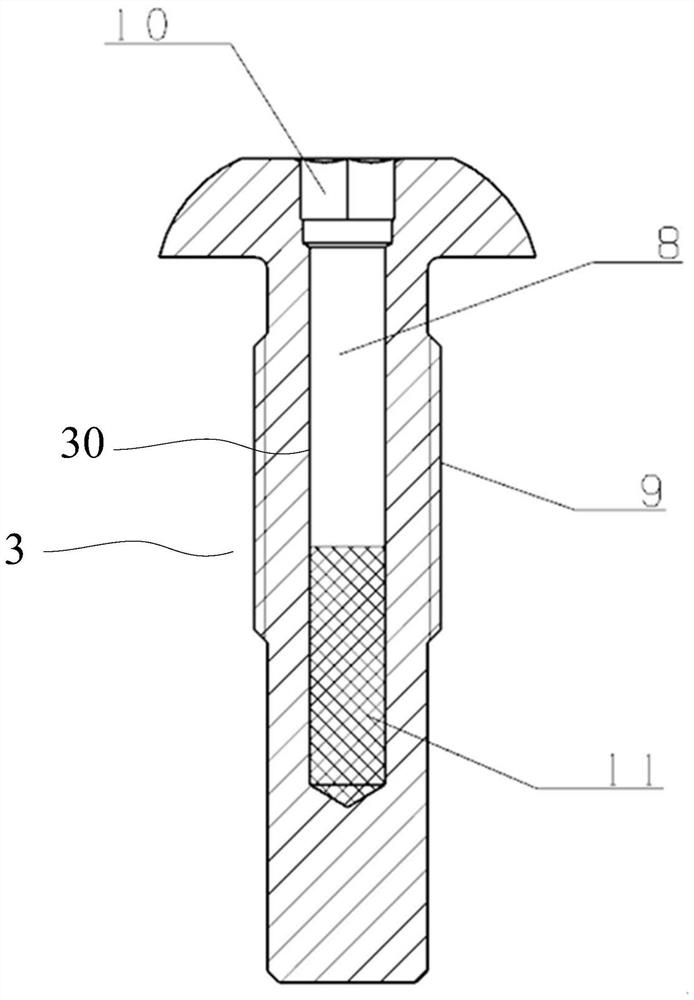

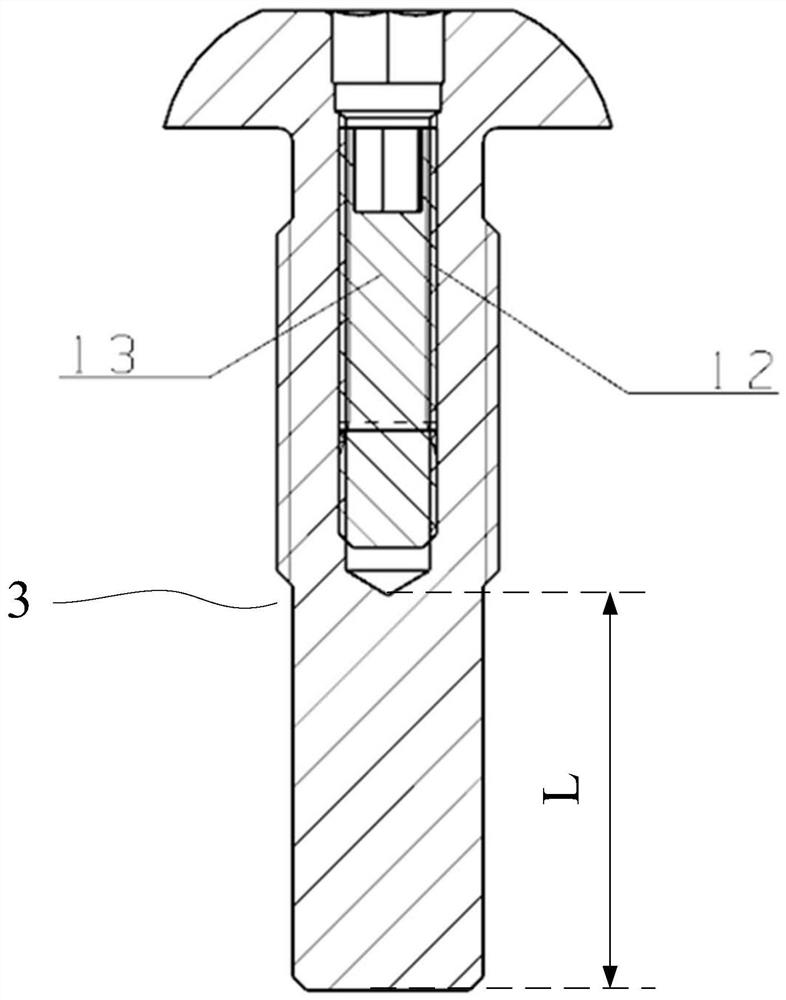

Equipment and technology for piercing and rolling anchor rod integrally

InactiveCN104174652AIncrease productivityLow costScrew-threads articlesMetal rolling arrangementsEngineeringScrew thread

The invention belongs to the technical field of anchor rod rolling, and provides equipment and a technology for piercing and rolling an anchor rod integrally. The equipment for piercing and rolling the anchor rod integrally comprises a heating device and a piercing and rolling machine (9), wherein the piercing and rolling machine (9) comprises a front table, a main frame and a rear table; each roller comprises an inlet section roller (24) and an outlet section roller (25) which are nested on a roller shaft, and the inlet section roller (24) is in key connection with the roller shaft and is provided with a perforation section A, a diameter-reducing and wall-reducing section B and a diameter-fixing section C; each outlet section roller (25) adopts a structure driven by the rolled anchor rod to rotate and is provided with an inlet cone D and a thread forming section E; and the equipment further comprises a mandrel (12) matched with the rollers. According to the equipment and the technology for piercing and rolling the anchor rod integrally, the solid bar material is subjected to perforating, diameter reducing, wall reducing, diameter fixing and thread forming on the same rolling machine to obtain the finished product of the anchor rod, the production steps are reduced, the cost is reduced, and the anchor rod production efficiency is improved.

Owner:LUOYANG DINGRUI MATERIAL TECH

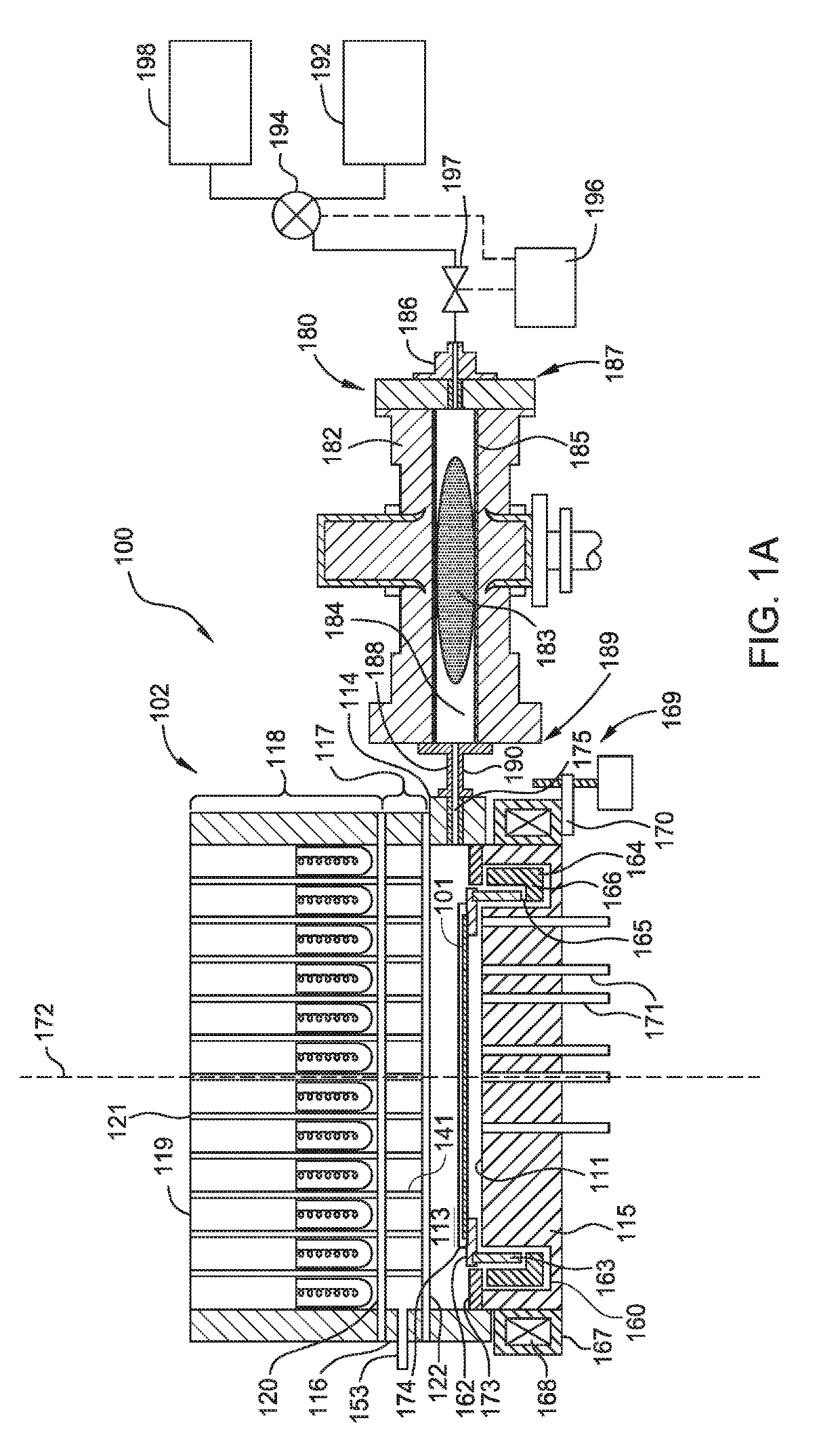

FC fan flow measurement system using a curved inlet cone and pressure sensor

ActiveUS8366377B2Simple meansProtection from damagePump componentsWind motor controlImpellerDischarge measurements

An airflow volume sensing system for determining the flow rate through a fan includes a curved inlet cone with a pressure sensor at the minimum diameter of the cone, wherein the flow volume sensing system is particularly suited for FC centrifugal fans (centrifugal fans with forward curved fan blades). With an FC fan, the minimum diameter of the inlet cones interior surface is adjacent the fan wheel, and the static pressure there is at a minimum value. A predetermined relationship between the static gage pressure at that point and the volume flow rate through the fan is applied regardless of variables such as fan speed, fan housing geometry, supply air duct configurations, return air duct configurations, location of various heat exchangers or filters, etc. In some examples, a single pressure sensor senses an average of a plurality of pressure taps wherein each tap is at approximately the same minimum pressure.

Owner:TRANE INT INC

Test piece anti-icing air entraining flow device and test method

ActiveCN111044295AAccurately reflectThe test data is accurateGas-turbine engine testingJet-propulsion engine testingStraight tubeStructural engineering

A test piece anti-icing air entraining flow device comprises a test piece installation system, a compressed air source system and an exhaust pipeline; and the test piece installation system comprisesan annular straight pipe section, a test piece installation mechanism, a rotary measurement mechanism, an exhaust straight pipe section and an expansion section which are connected in sequence. The annular straight pipe section comprises an air inlet fairing and an air inlet cone arranged inside. The test piece installation mechanism is used for installing a test piece; the rotary measurement mechanism and the exhaust straight pipe section are sequentially connected to form a straight pipe, an exhaust cone assembly is installed in the straight pipe, and the rotary measuring mechanism is provided with a total pressure probe and a static pressure measuring hole; the rear part of the straight exhaust pipe section is connected with an expansion section; a compressed air source system is connected with an anti-icing air entraining pipe connector of the test piece and comprises a compressor, an air storage tank, an air dryer, a filter and an adjusting valve which are connected through a pipeline. The exhaust pipeline is connected to the rear end of the test piece installation system. The device has the advantages of high test accuracy and real simulation environment.

Owner:湖南汉能科技有限公司

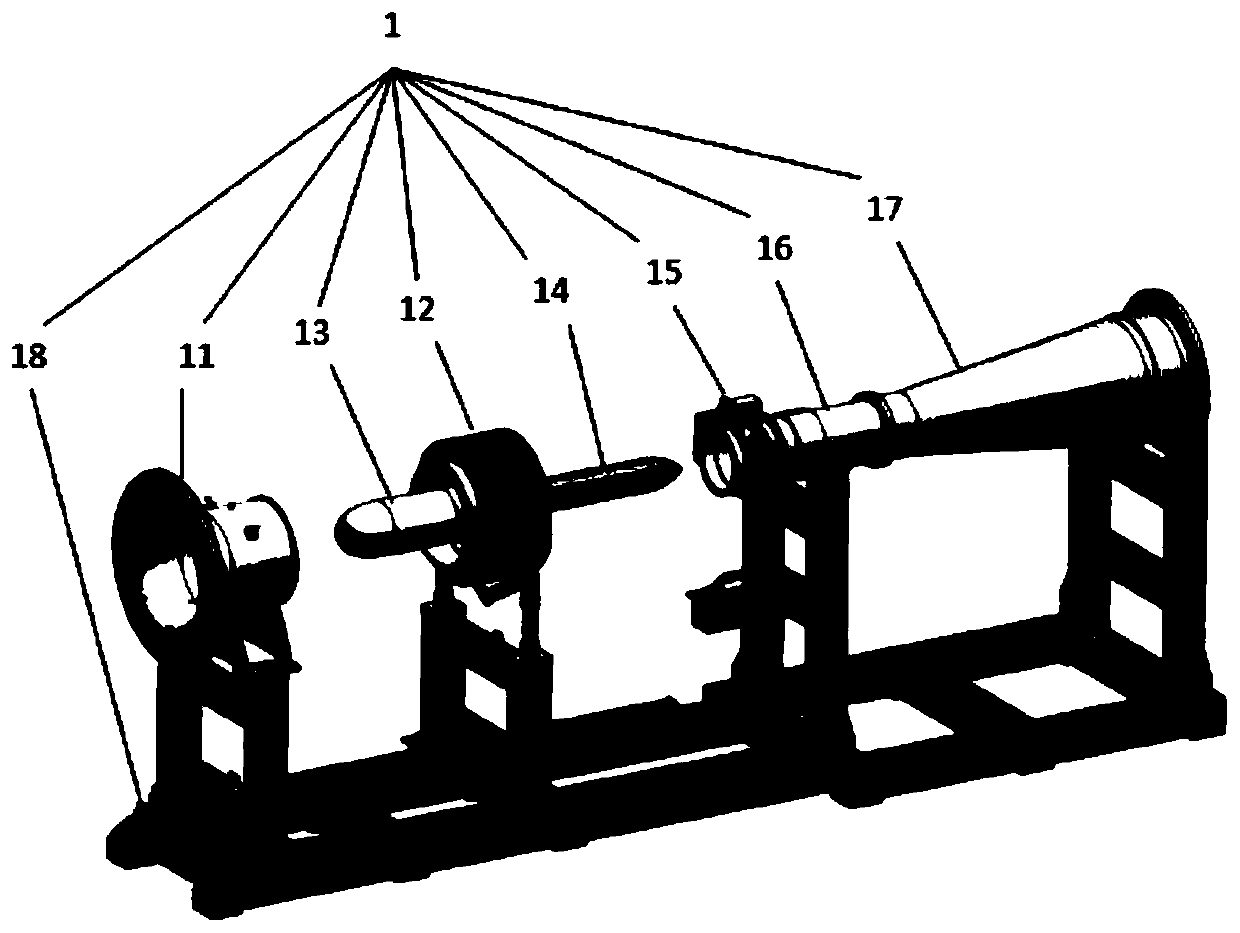

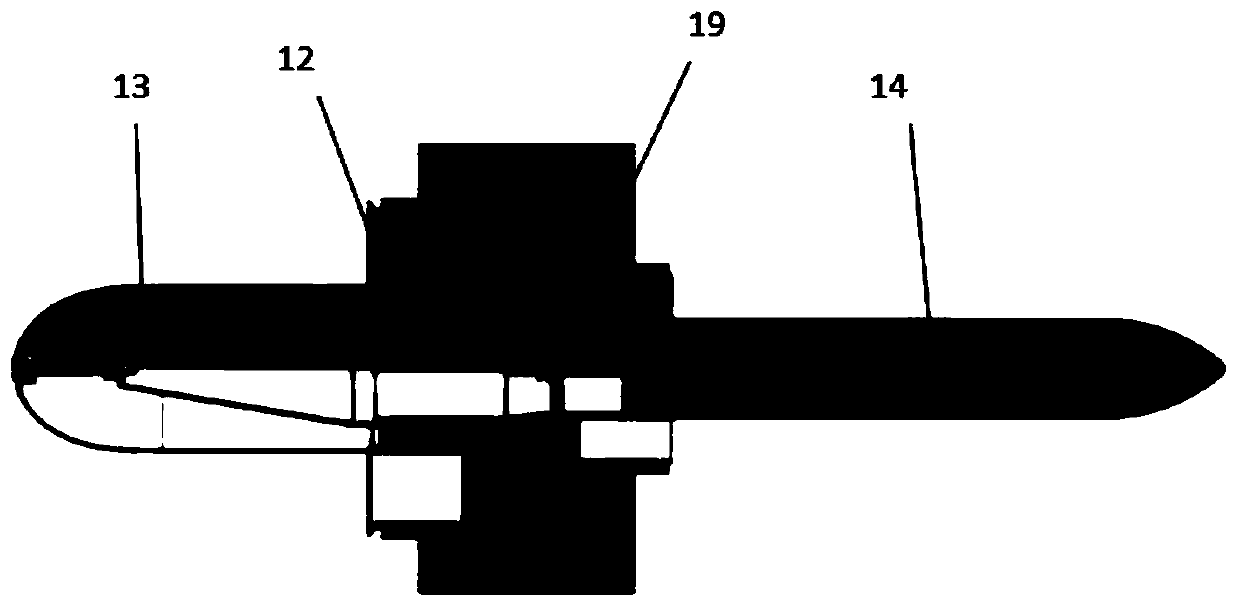

Aero-engine test bed mounting system

ActiveCN111024402AImprove installation accuracyImprove disassembly efficiencyGas-turbine engine testingJet-propulsion engine testingEngine test standMarine engineering

An aero-engine test bed mounting system comprises a test bed frame, an air inlet fairing mounted on the test bed frame, a test piece mounting mechanism, a rotary measuring mechanism and an exhaust pipe. The exhaust pipe comprises an exhaust straight pipe and an expansion pipe, an air inlet cone is arranged in the air inlet fairing, and an exhaust cone is arranged in the exhaust pipe; an air pressure measuring device is arranged in the air inlet fairing, and a plurality of air pressure measuring devices are arranged in the rotary measuring mechanism; a movable connecting unit and an air inlet fairing are arranged on the mounting rack; and the test piece mounting mechanism moves through the movable connecting unit. The installation system has the advantages of real simulation environment andaccurate measurement data.

Owner:湖南汉能科技有限公司

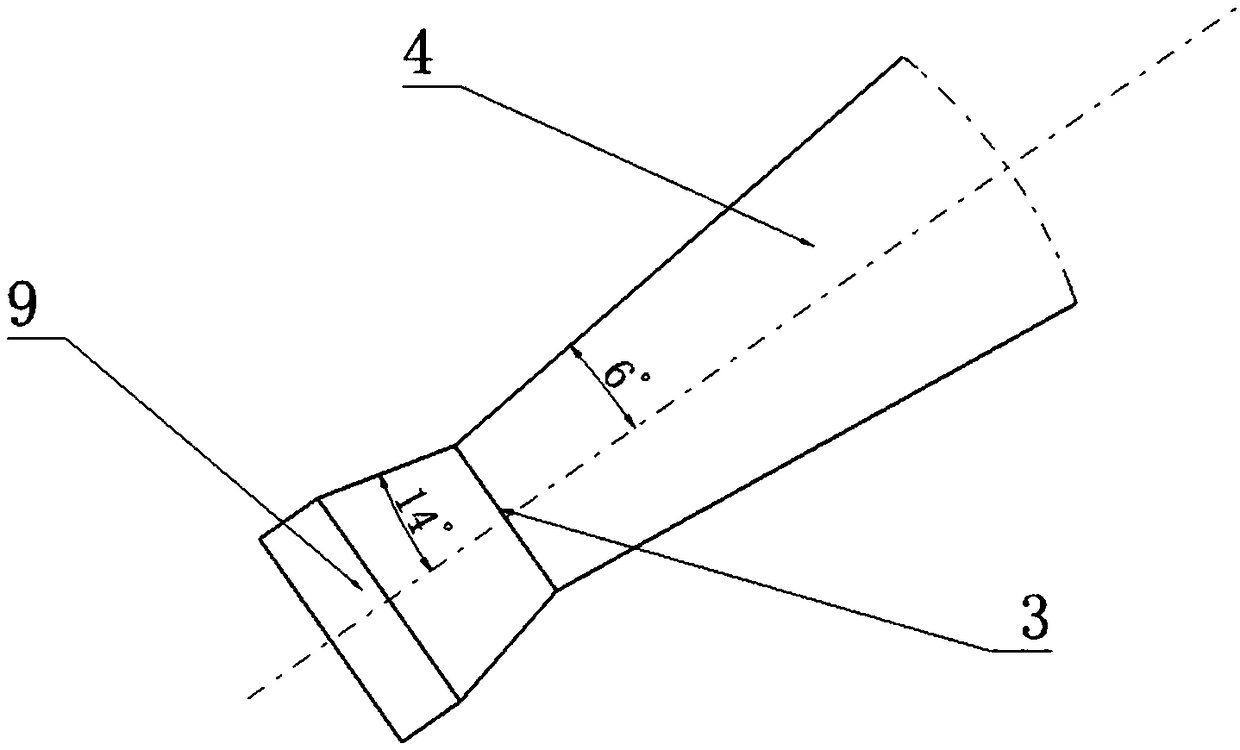

Formula car engine air intake system

PendingCN109209614AImprove performanceImprove air intake efficiencyInternal combustion piston enginesAir intakes for fuelNumerical controlResonant cavity

The invention discloses a formula car engine air intake system, which comprises an air filter, a throttle valve, a flow limiting opening, a diffusion tube, a resonant cavity, a variable air intake manifold and a manifold length regulator, wherein the inlet cone angle and the outlet cone angle of the flow limiting opening are respectively 14 degrees and 6 degrees, the outlet of the flow limiting opening is connected with the diffusion tube, the outlet of the diffusion tube is connected with the resonant cavity, the diffusion angle of the diffusion tube is 6 degrees, the length is 220mm, the resonant cavity is molded by an ABS material through upper and lower die separating and numerical control milling, the volume is 3L, and the internal part of the resonant cavity is equipped with the manifold length regulator. The working length of the air intake manifold is enabled to meet manifold characteristic requirements that the air intake manifold needs to be thin and long at a low speed and needs to be short and thick at a high speed of the engine through additionally arranging the manifold length regulator, the variable length of the air intake manifold can better utilize a resonant airintake effect of the engine in different speed ranges, the air intake efficiency is improved, and the overall performance of the variable air intake manifold is better than that of the traditional non-variable air intake manifold structure.

Owner:HEFEI UNIV OF TECH

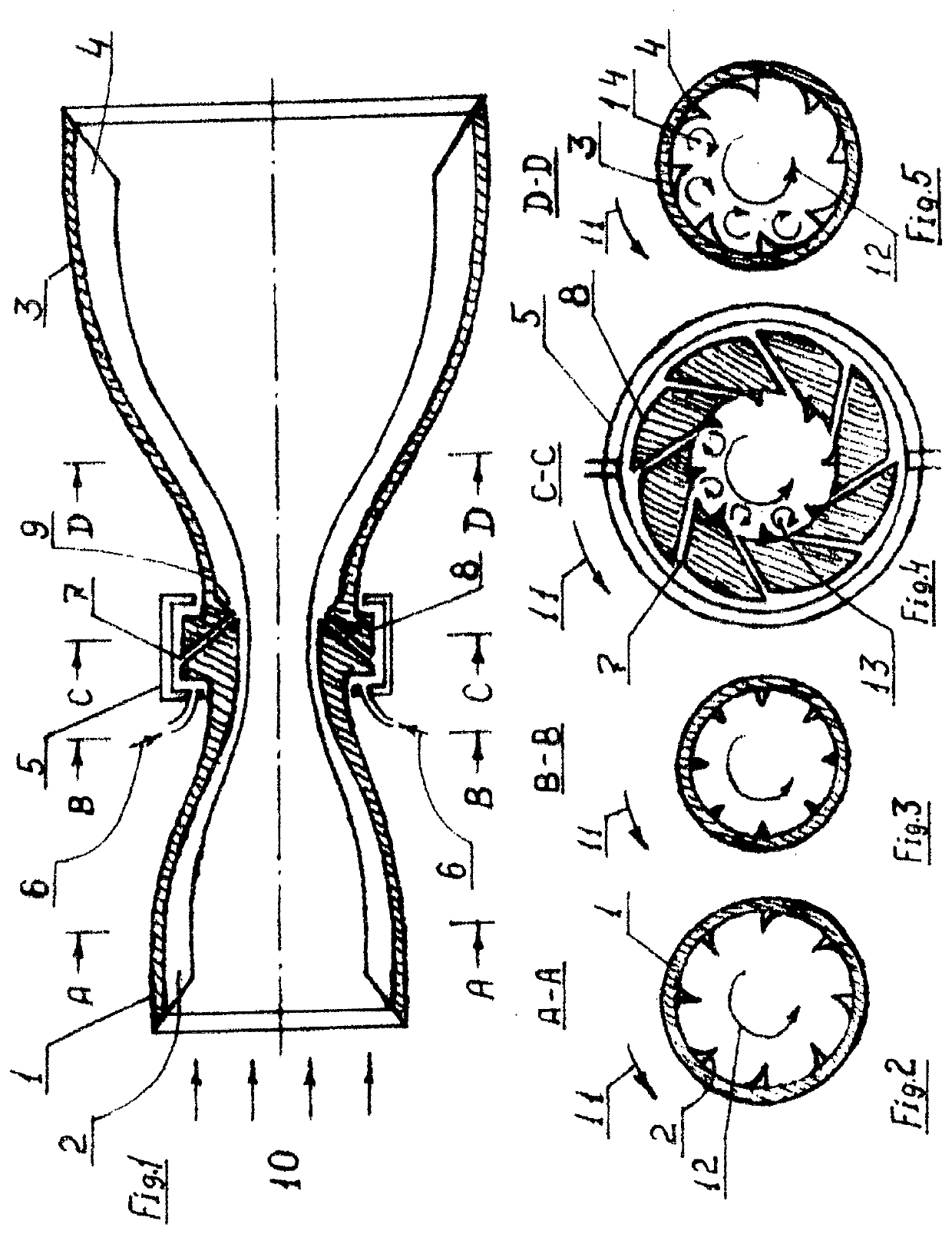

Ram-jet and turbo-jet detonation engine

InactiveUS20190338664A1Effectively run continuously with shiftsIncrease air velocityEngine manufactureBlade accessoriesDetonationHigh pressure

A ram-jet and turbo-jet detonation engine includes an inlet part and a discharge part both shaped as axis-symmetrical round hollow rotating cones interconnected by a narrow middle part, having vanes, mounted on the internal surfaces of the cones, not completely overlapping a central part of a channel, and form spirals, twisted about a common central axis of the channel. The inlet cone with vanes serves as a ventilator / compressor, and the discharge cone with vanes serves as a turbine and discharge nozzle. The middle part and the discharge cone are built as one integral component. A centripetal pump supplies fuel to a mixing section. The engine includes a firing system, generating short high-voltage electrical pulses, providing for burning of combustible mixture in a detonation mode. The invention enables an independent horizontal take-off of flying apparatus and a possibility of varying / alternating the speed within a range from subsonic to hypersonic.

Owner:KOZHEVNIKOV DMITRY DMITRIEVICH

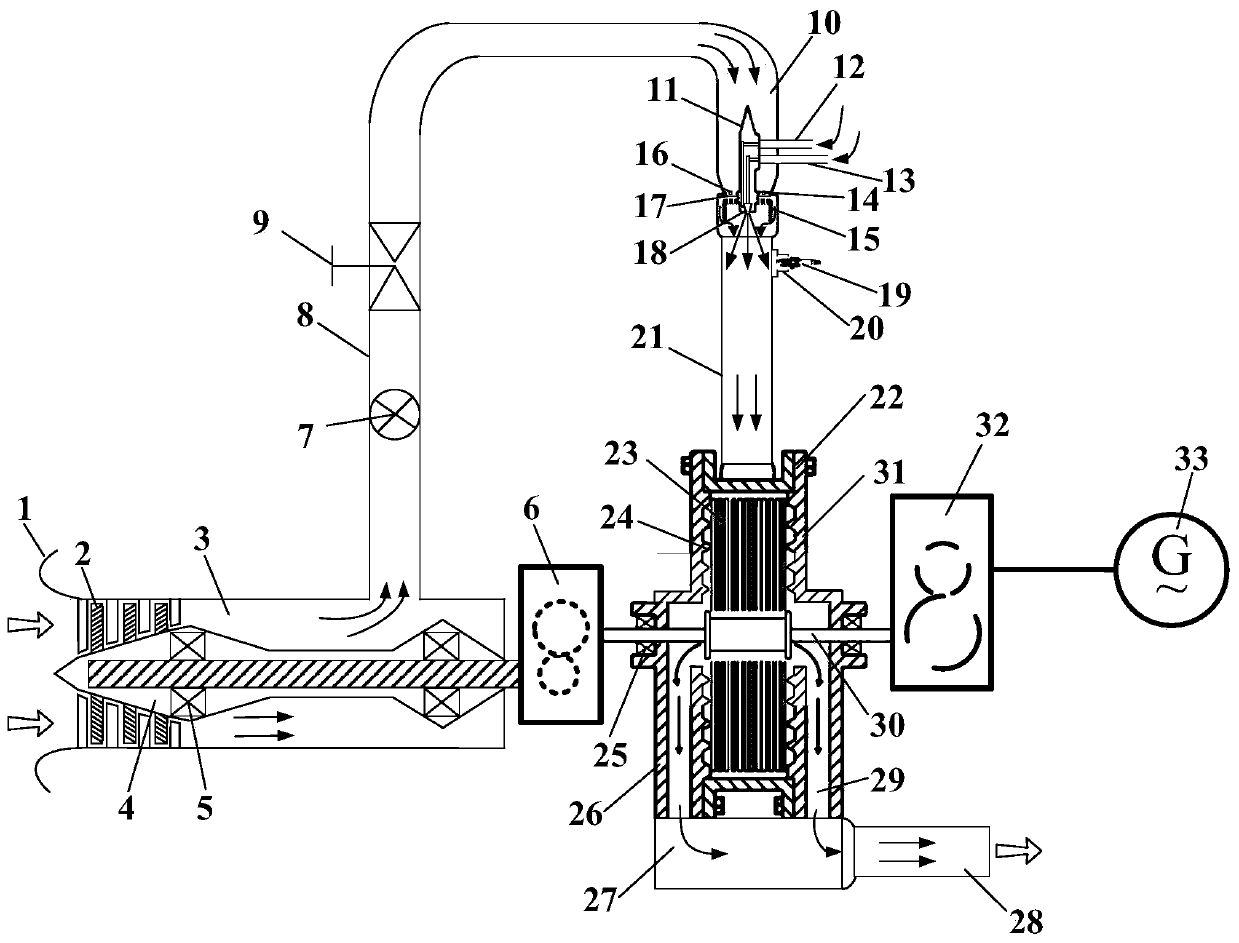

Gas turbine power generation device acting through pulse detonation fuel gas viscous force

ActiveCN111577459AIncrease output generating powerImprove cycle thermal efficiencyContinuous combustion chamberGas turbine plantsCombustion chamberGas compressor

The invention discloses a gas turbine power generation device acting through pulse detonation fuel gas viscous force. The gas turbine power generation device comprises a gas inlet channel, a gas compressor and the like. The gas inlet channel is located at the forefront end of a gas turbine, the gas compressor is connected with the gas inlet channel, and a gas storage chamber is arranged on the downstream portion of the gas compressor. An exhaust pipe of the gas compressor is connected with the gas storage chamber and a combustion chamber gas inlet channel. A combustion chamber gas inlet cone is arranged in the combustion chamber gas inlet channel, and a combustion chamber pneumatic valve is mounted on the combustion chamber gas inlet cone. A pulse detonation combustion chamber is connectedwith the combustion chamber gas inlet channel, a spark plug is arranged on the head of the pulse detonation combustion chamber, and a telsa turbine is arranged at an outlet of the pulse detonation combustion chamber. A gas collection cavity is arranged on the side of the telsa turbine. The exhaust pipe is connected with the gas collection cavity. The left end of a gas compressor transmission is connected with a gas compressor rotor, and the right end of the gas compressor transmission is connected with a turbine rotor. The left end of a generator transmission is connected with the turbine rotor, and the right end of the generator transmission is connected with a generator. According to the gas turbine power generation device, the problems happening after the pulse detonation combustion chamber replaces an isobaric combustion chamber in a ground gas turbine and other power generation power devices are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD

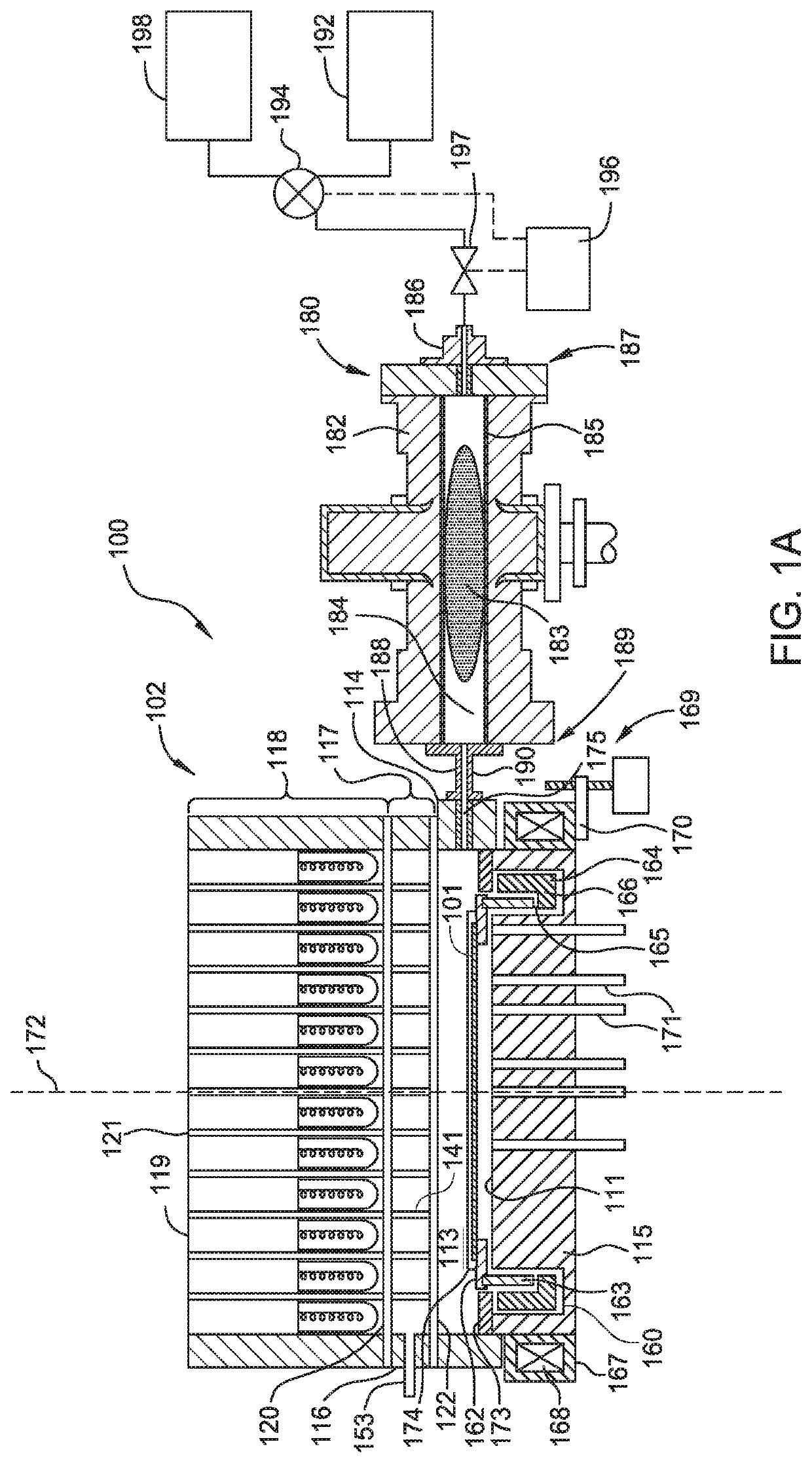

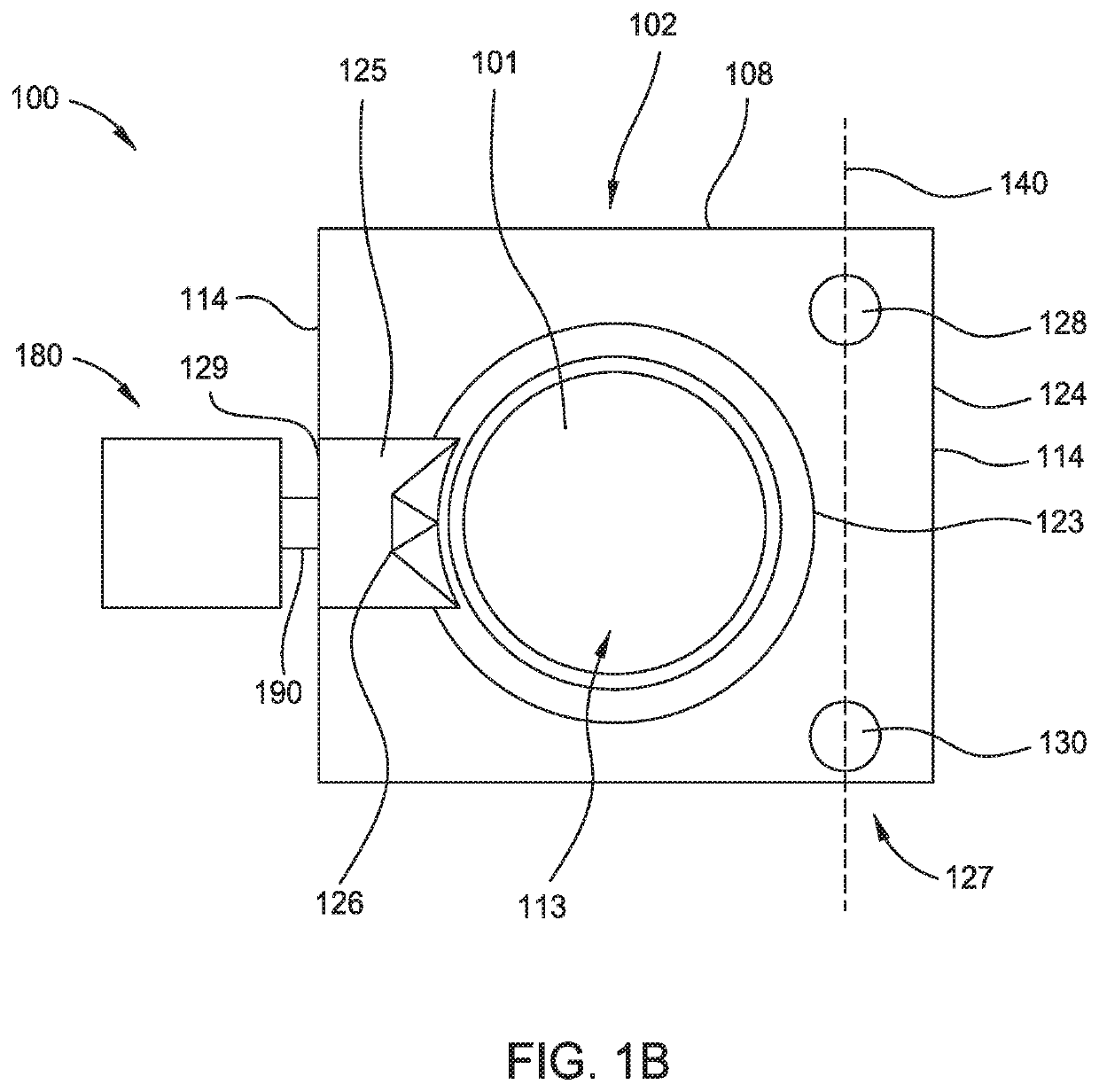

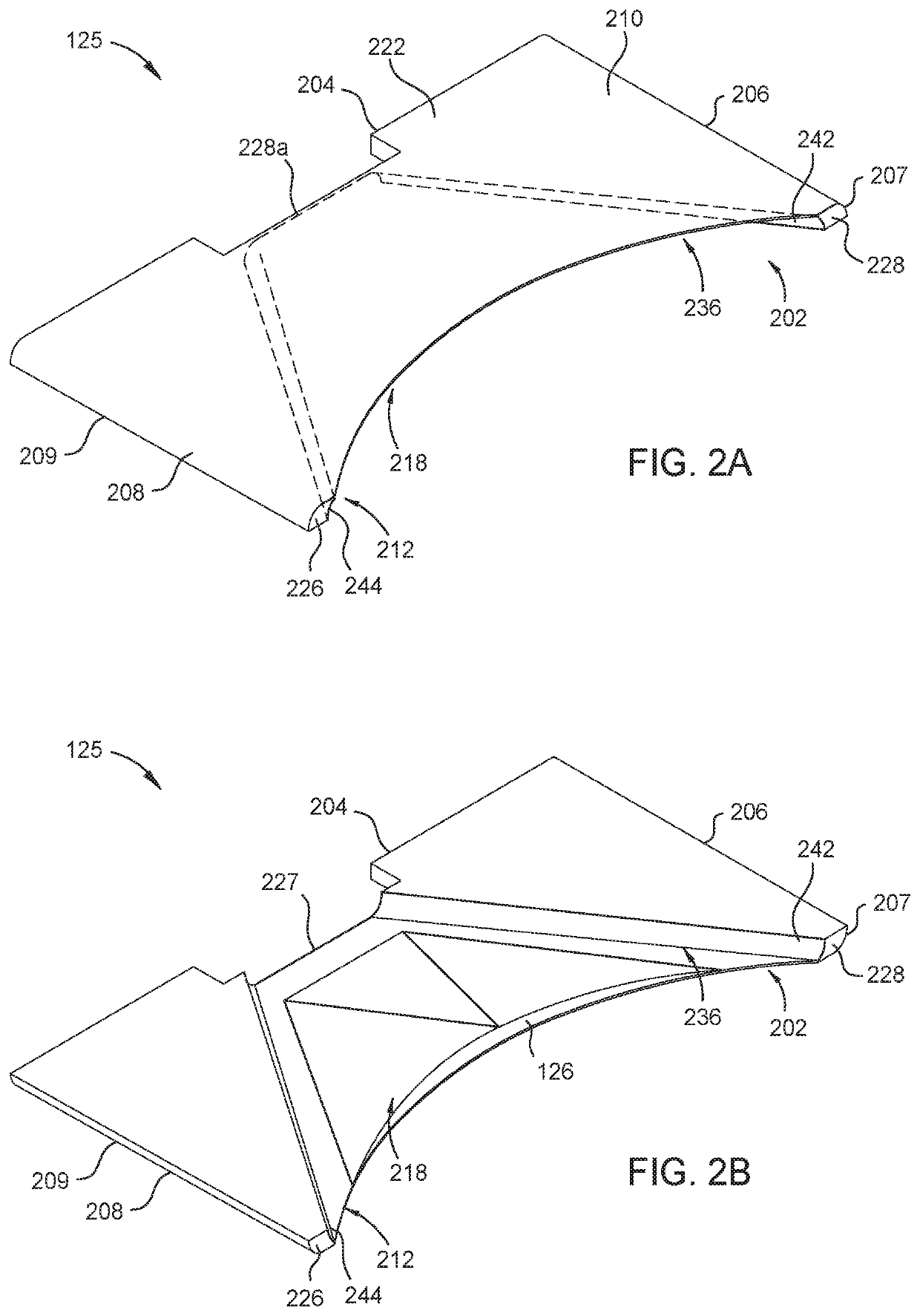

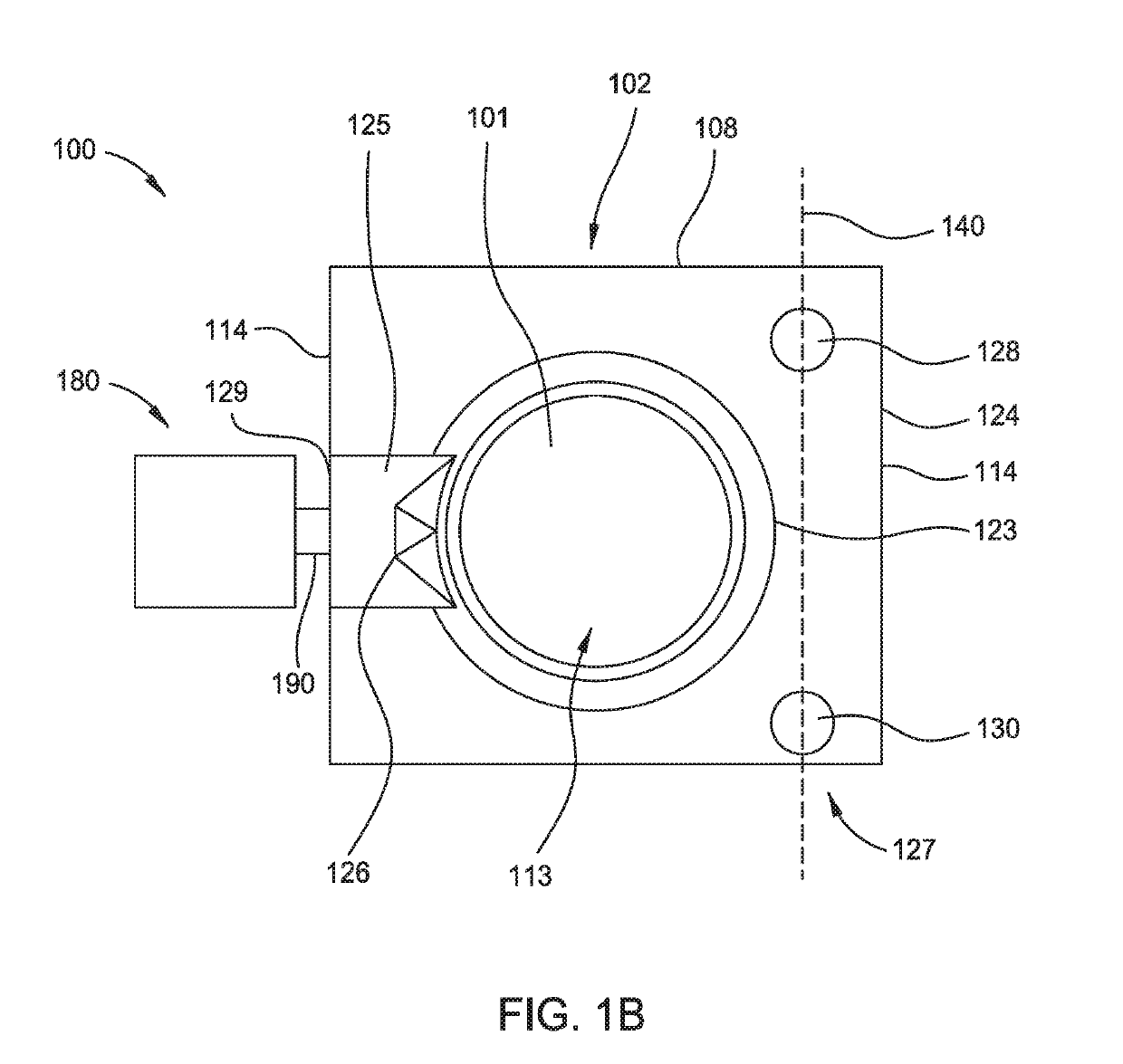

Dogbone inlet cone profile for remote plasma oxidation chamber

ActiveUS10636626B2Electric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaEngineering

Embodiments of the present disclosure generally relate to a processing chamber for conformal oxidation of high aspect ratio structures. The processing chamber includes a chamber body with a first side and a second side opposite the first side, and a flow assembly disposed in the first side. The flow assembly includes a flow divider to direct fluid flow away from a center of a substrate disposed in a processing region of the processing chamber. The flow divider includes a crescent shaped first side, a top, and a bottom. The processing chamber also includes a distributed pumping structure located adjacent to the second side. The flow assembly is designed to reduce flow constriction of the radicals, leading to increased radical concentration and flux.

Owner:APPLIED MATERIALS INC

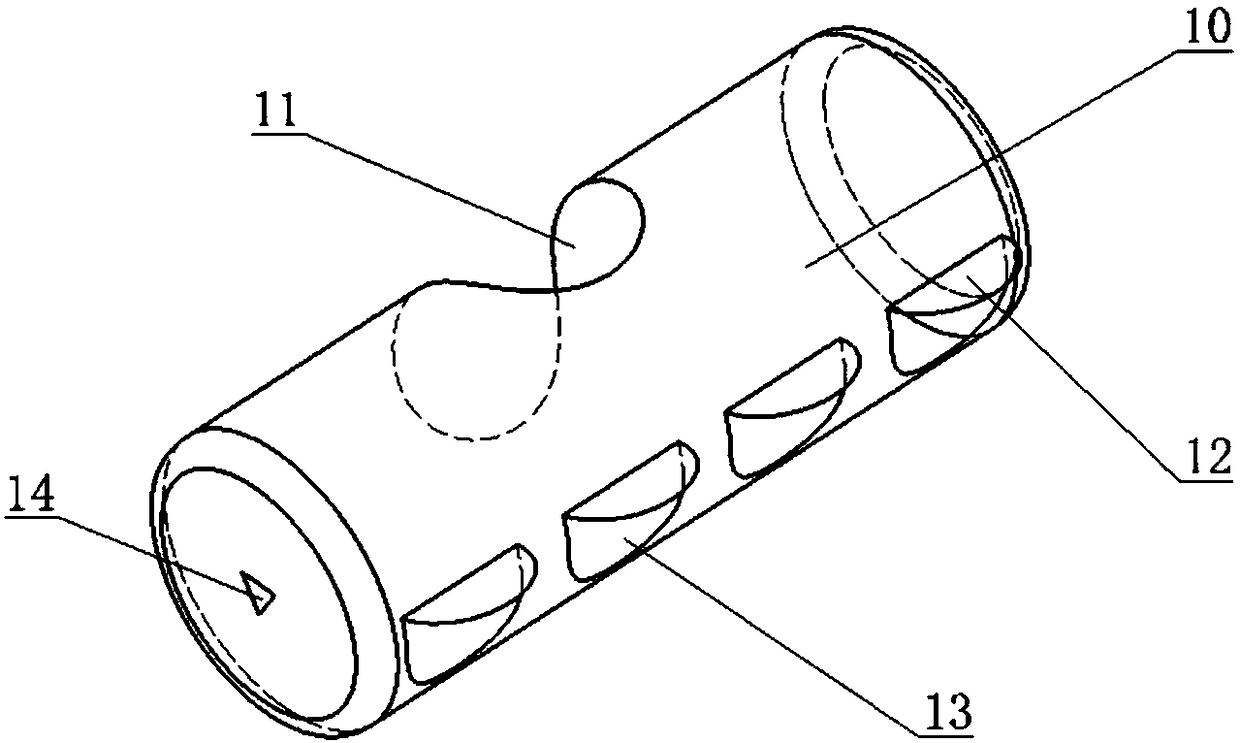

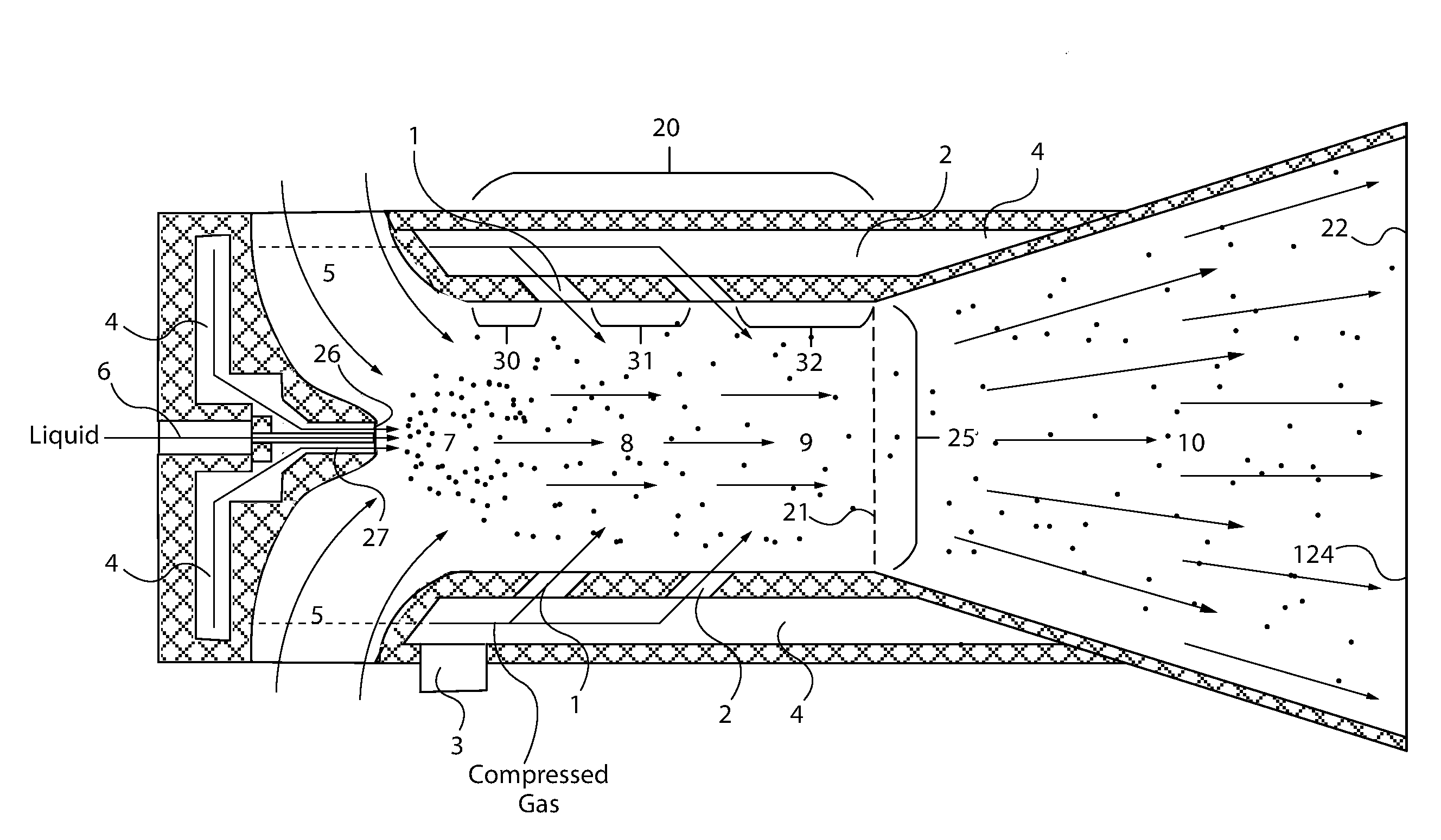

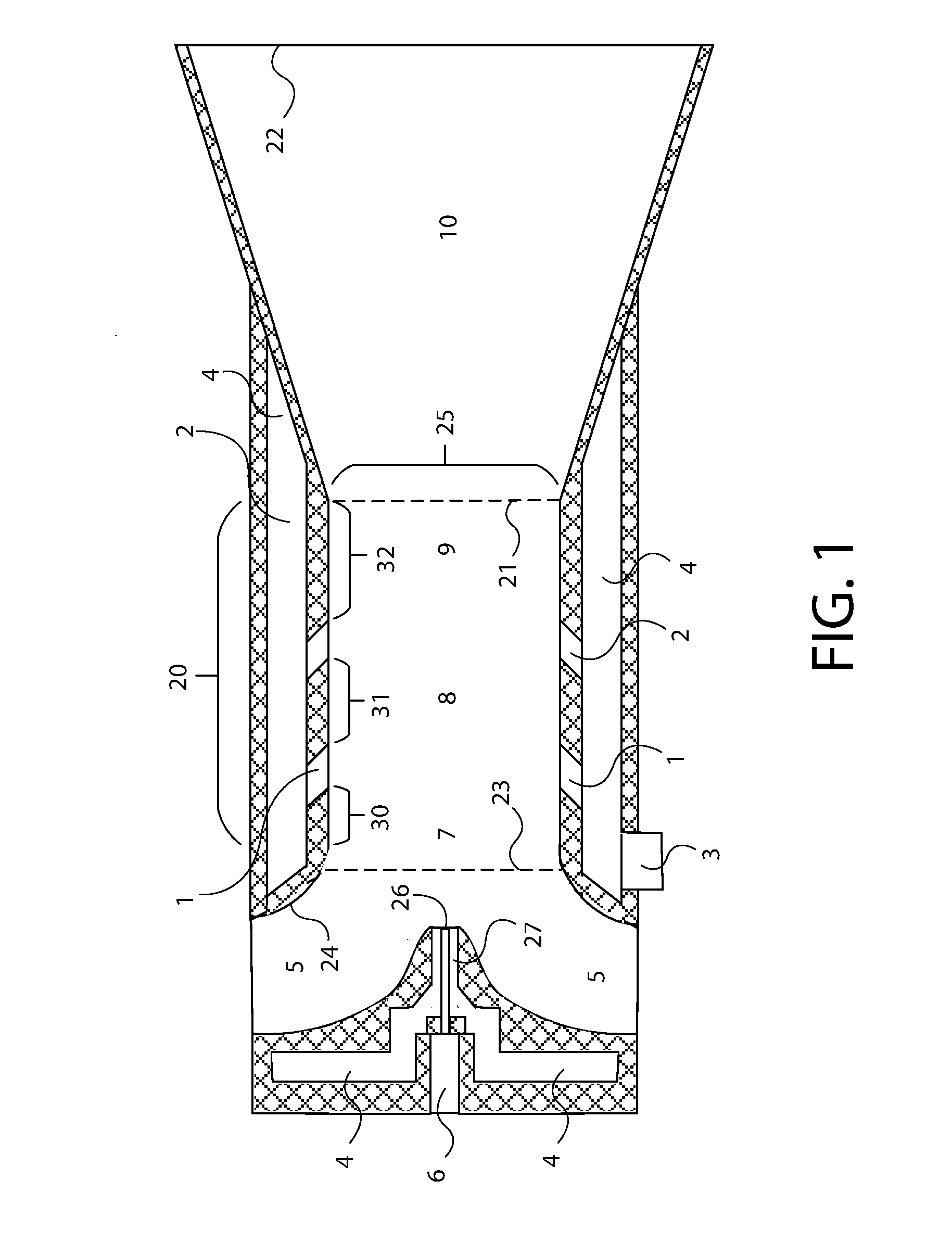

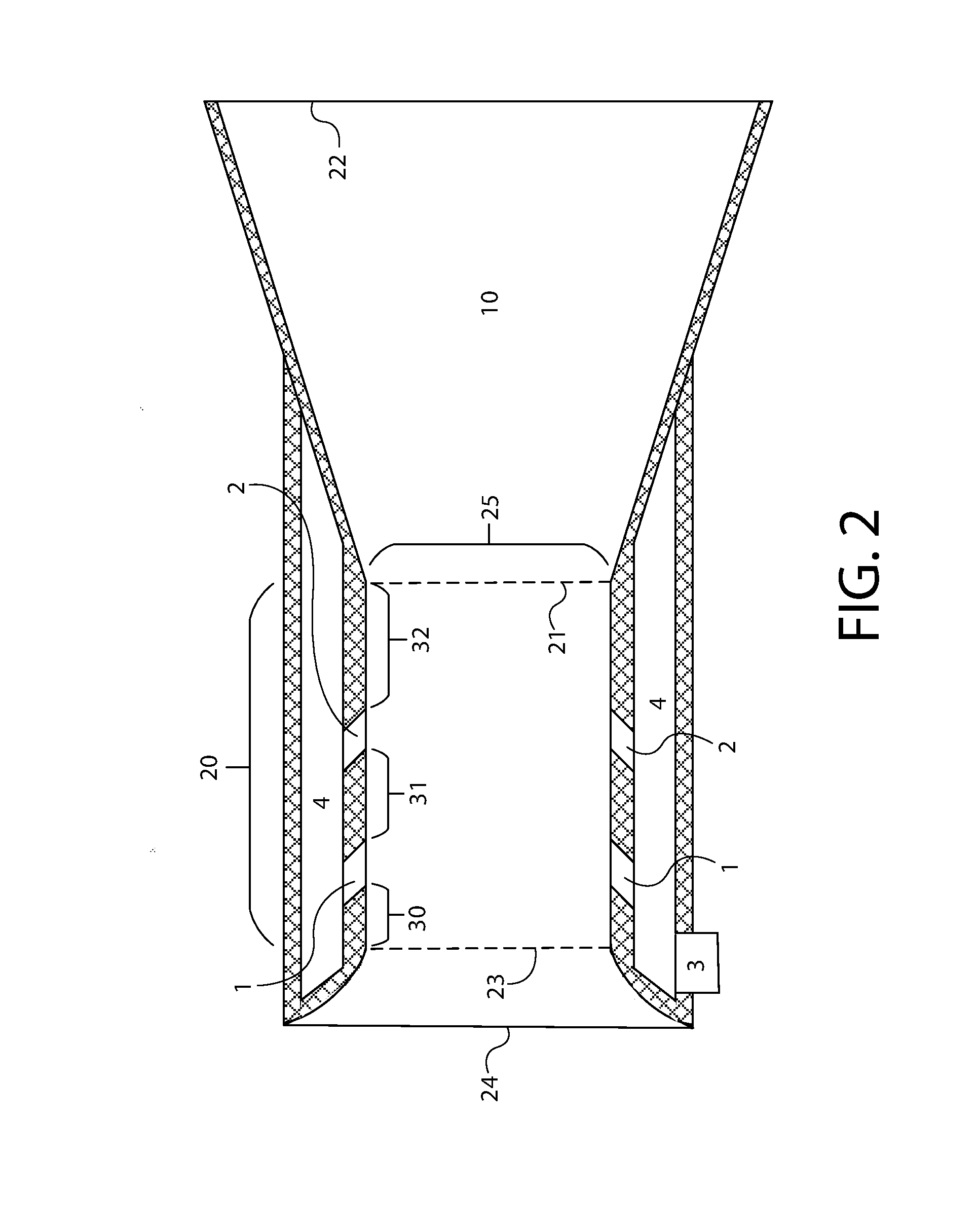

Apparatus for nanoparticle generation

InactiveUS20160303592A1Improve liquidityIncrease back pressureIndividual molecule manipulationLiquid spraying apparatusNanoparticleEngineering

An apparatus for creating solid or liquid nanoparticles having a nozzle to create a first particle size from a bulk liquid flow that is in fluid communication with a gas flow amplifier comprising an inlet cone connected to and in fluid communication with the inlet of a cylindrical housing; a diffuser connected to and in fluid communication with the outlet of said housing; and said housing comprising at least two rings of ports disposed of along a circumference of the cylindrical housing; and a means to inject compressed gas into the housing through said ports.

Owner:NANOVAPOR

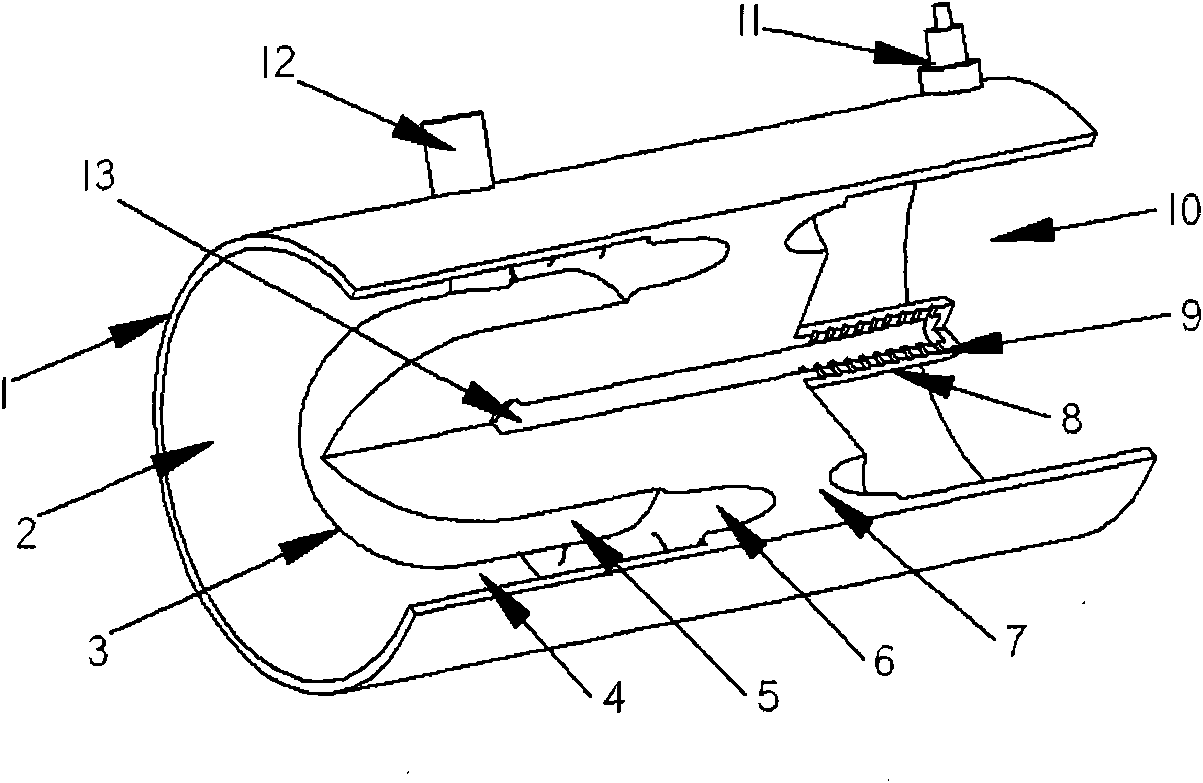

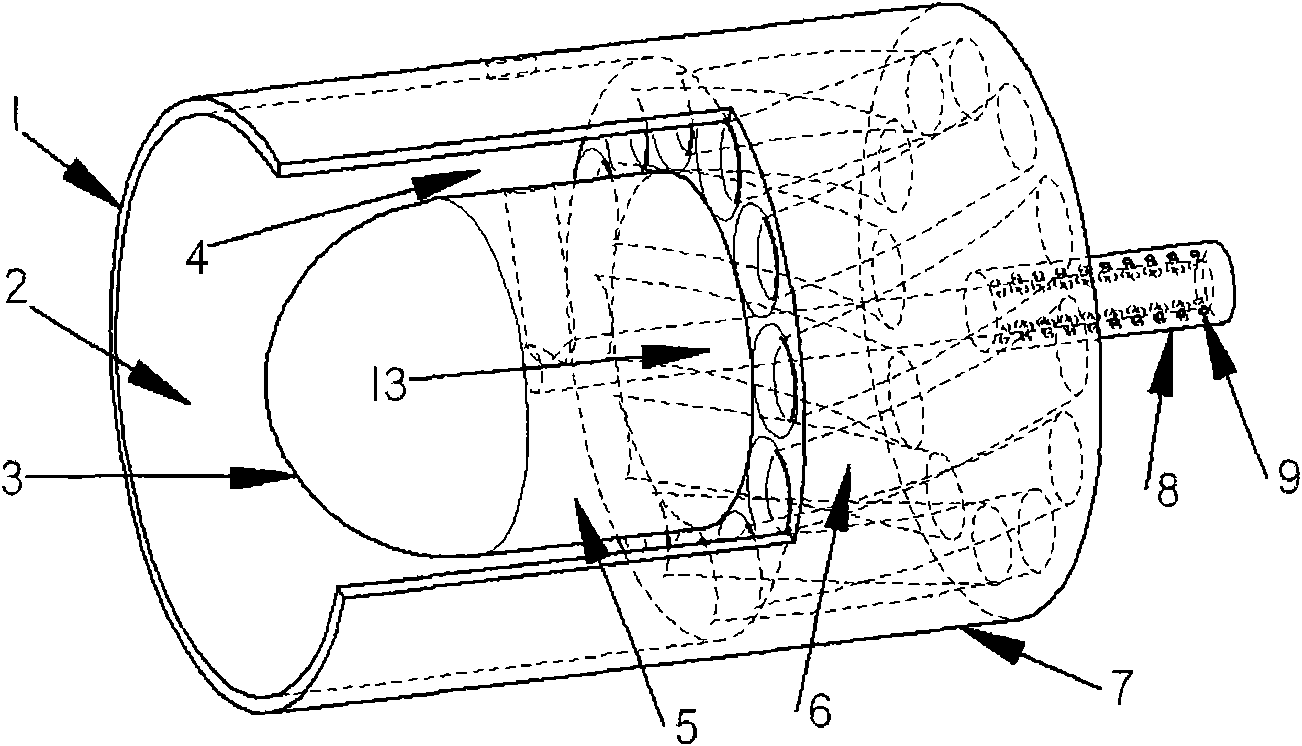

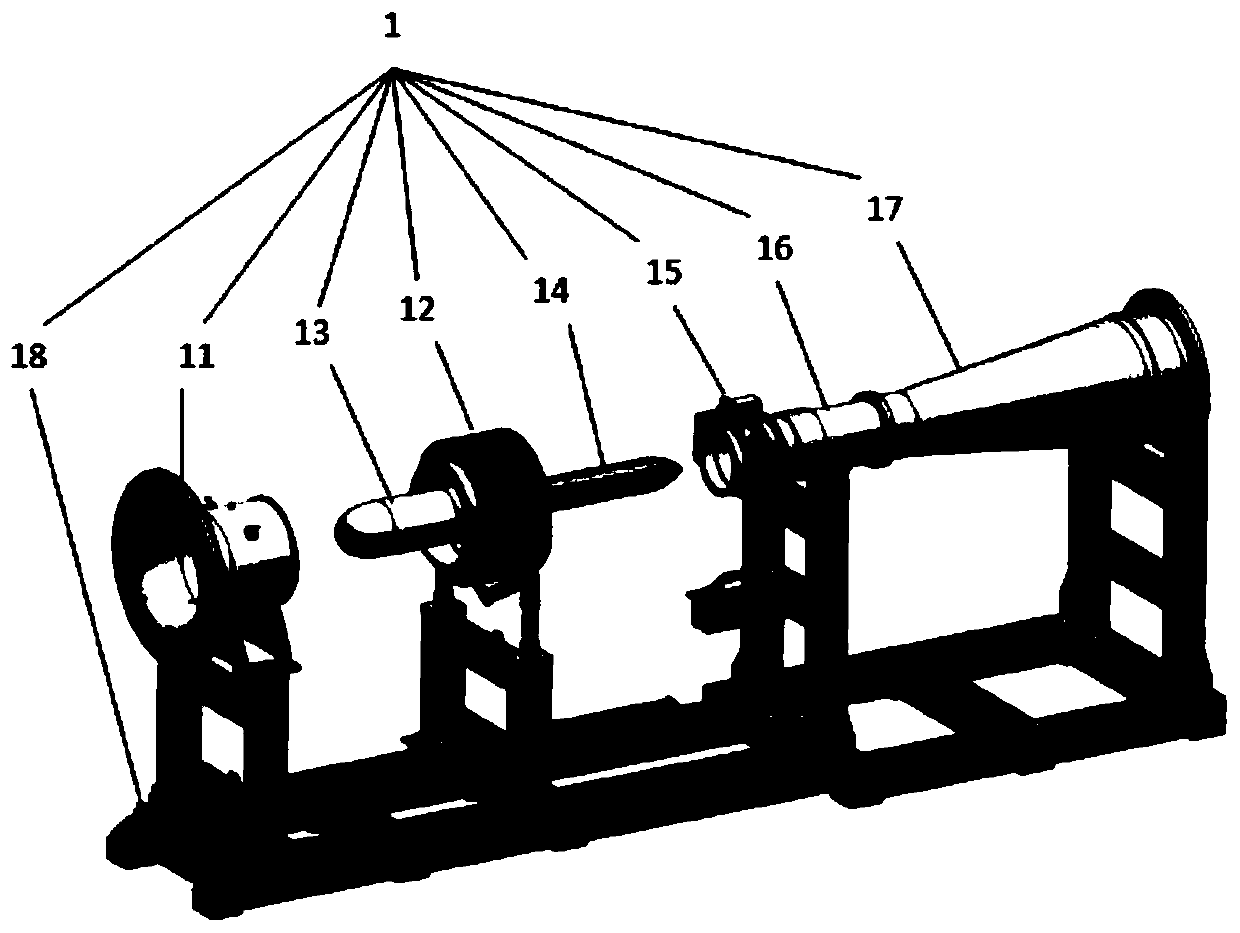

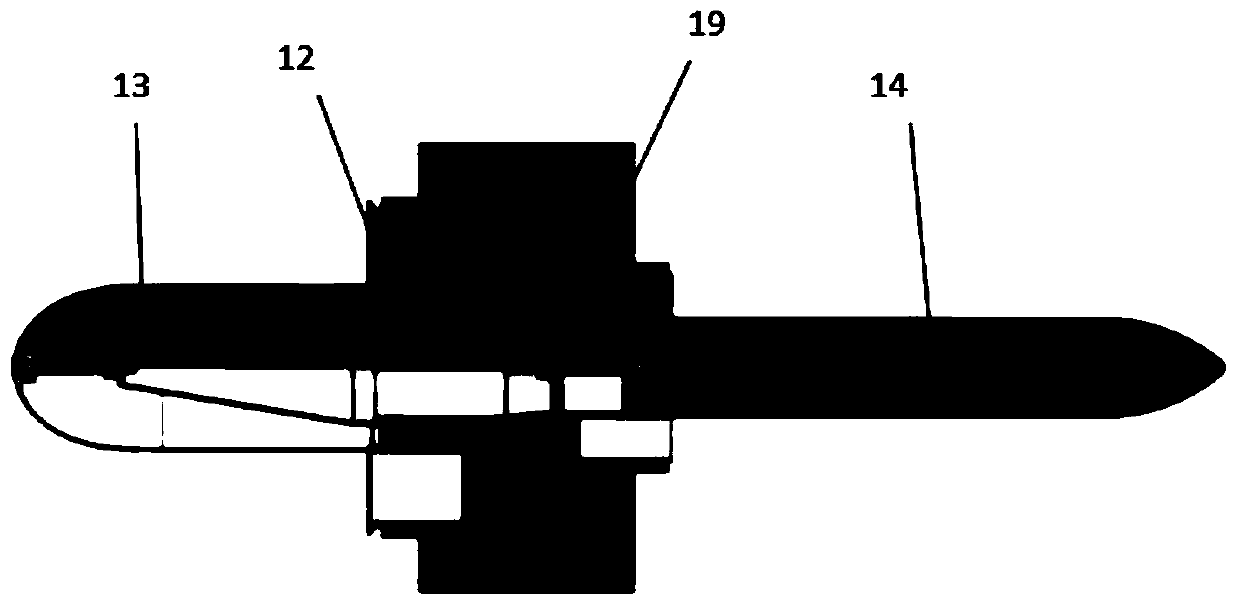

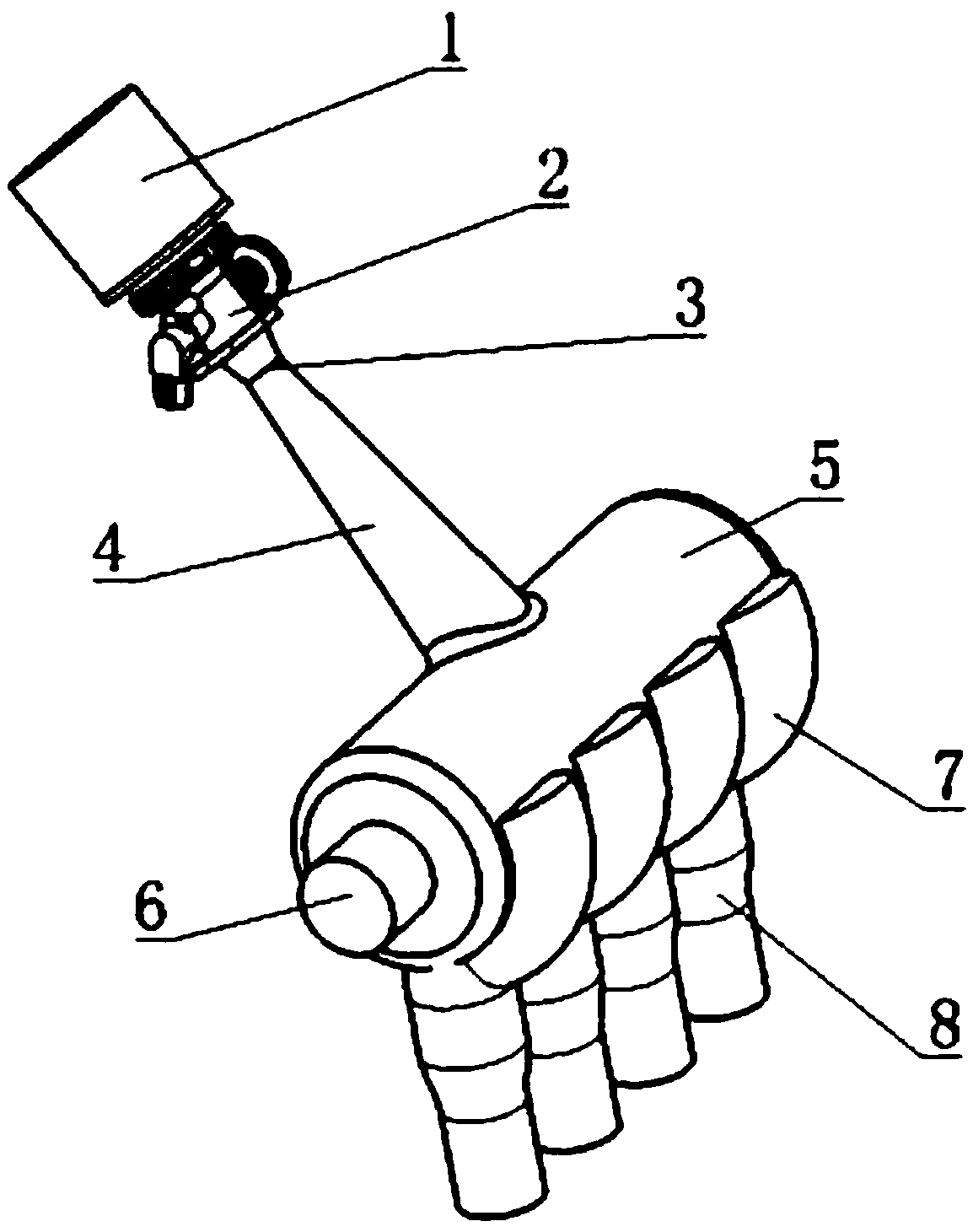

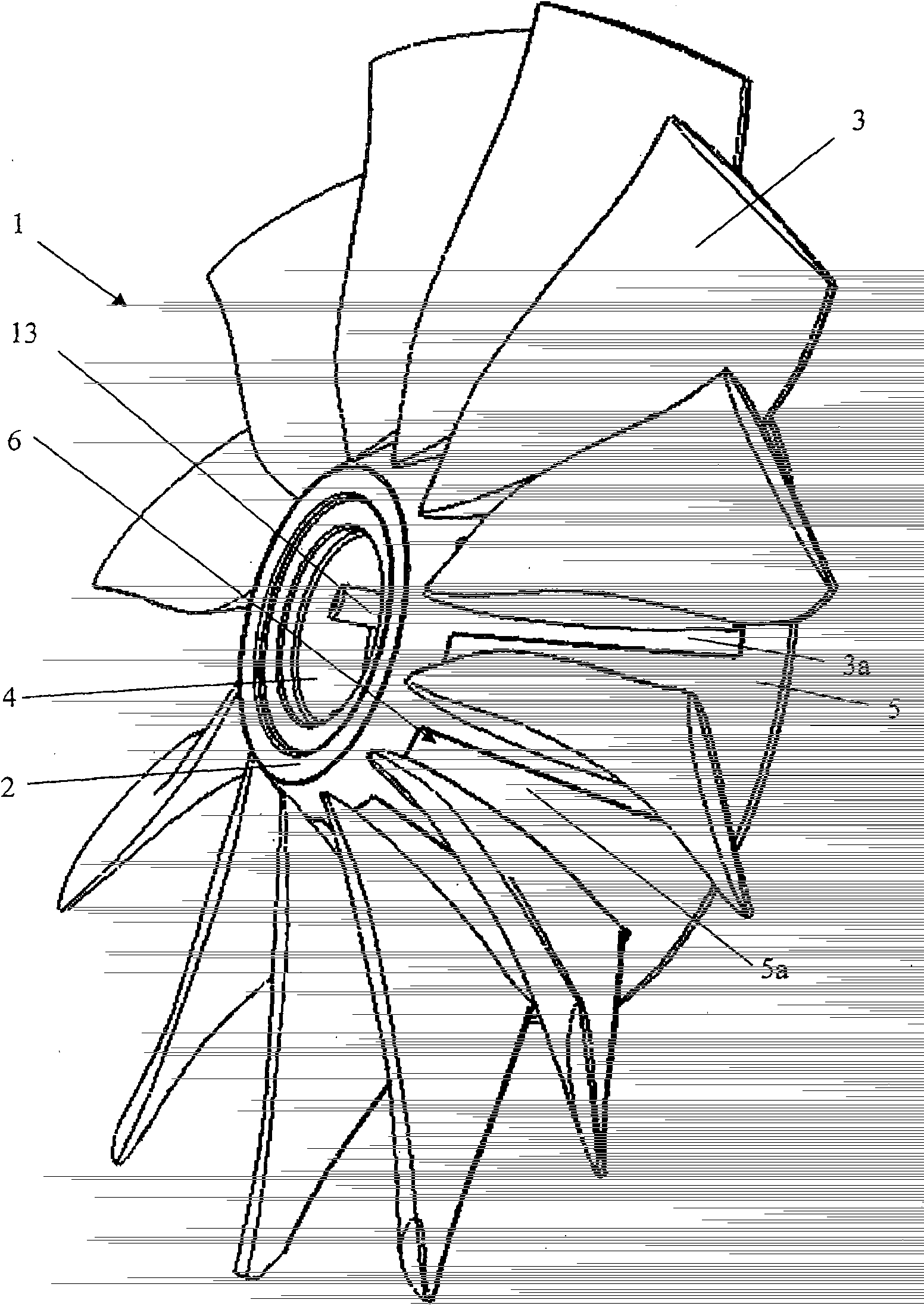

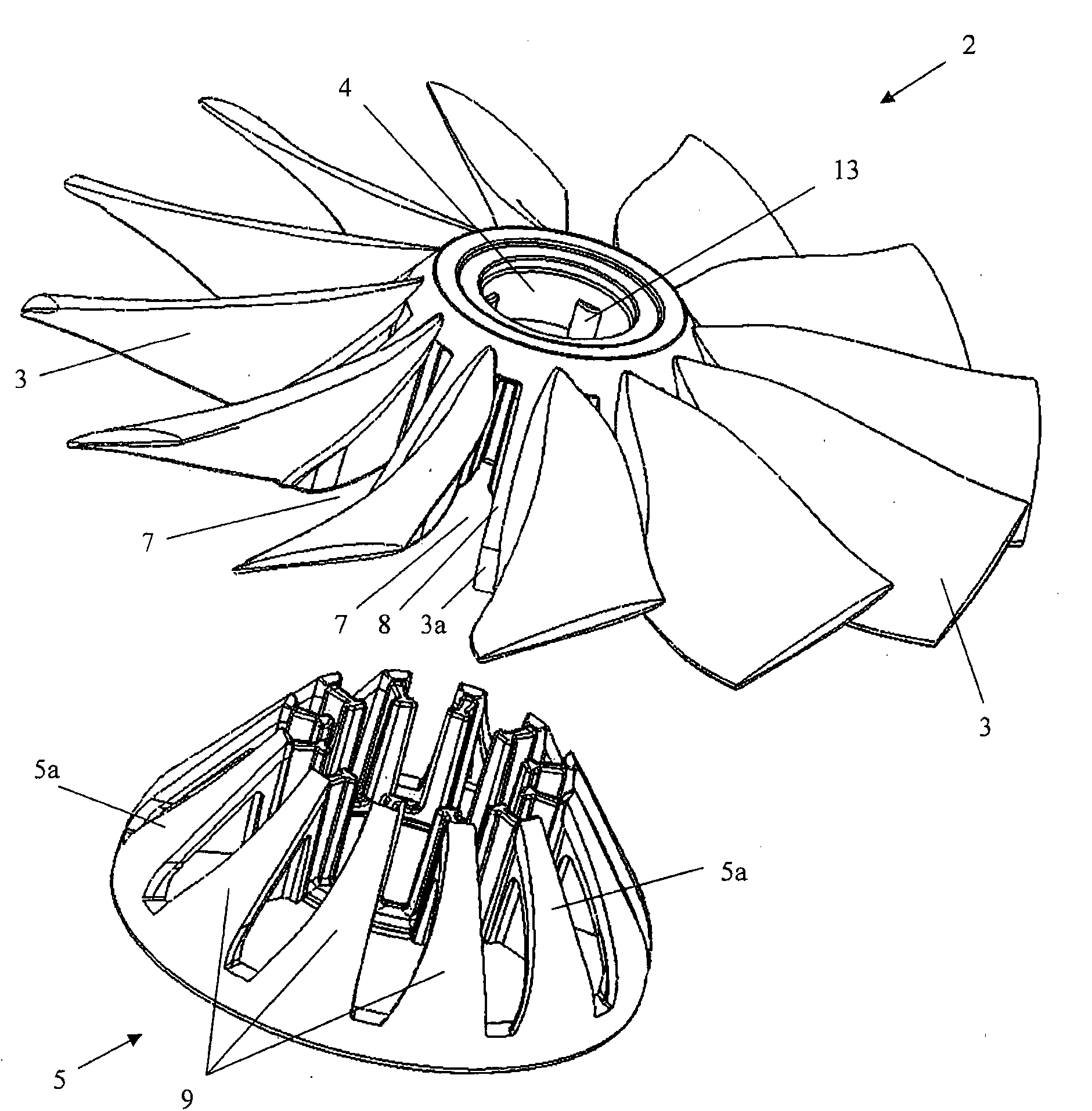

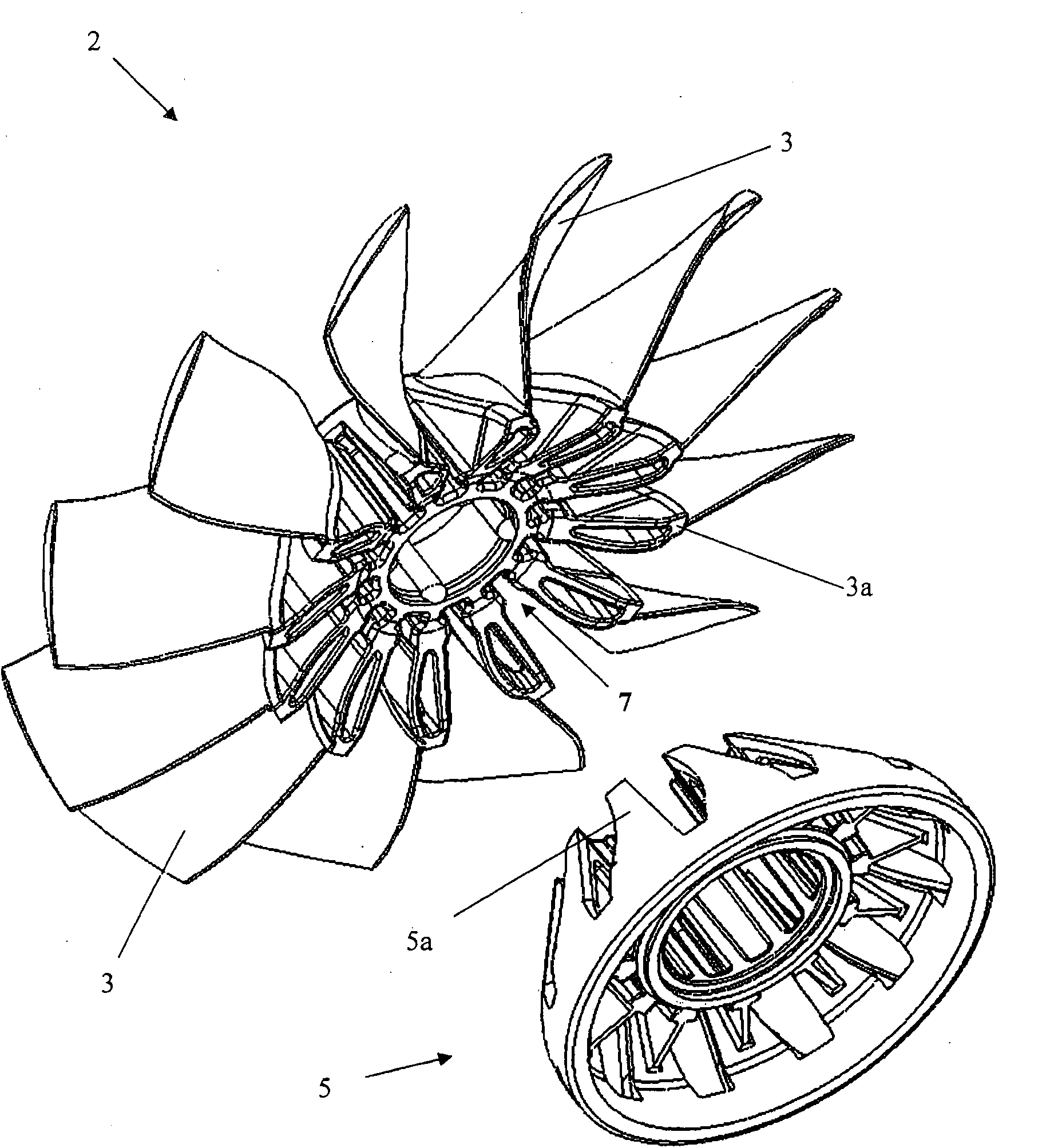

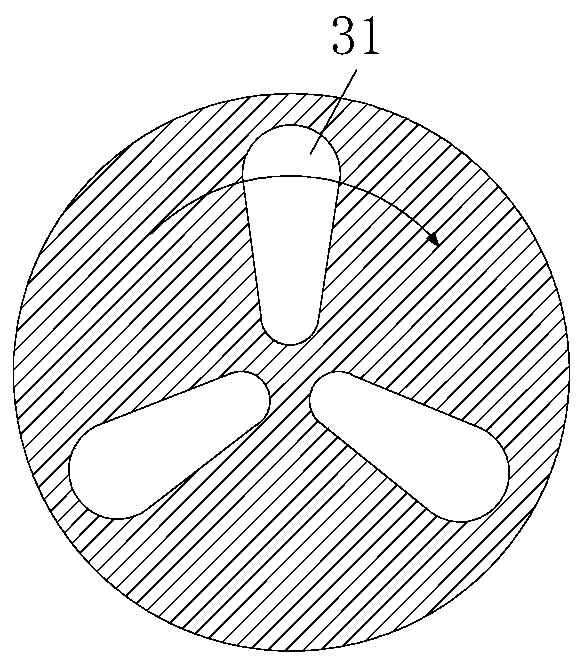

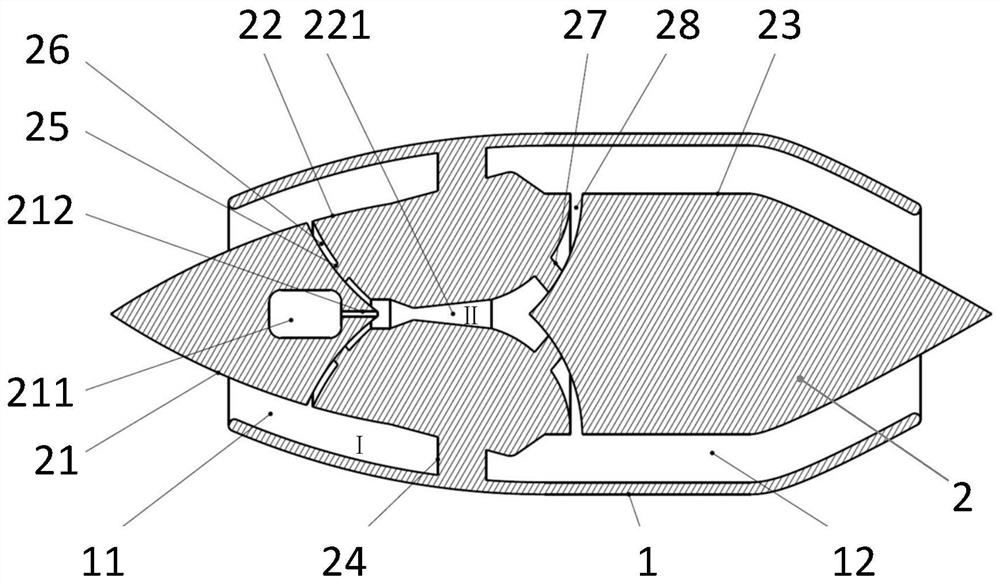

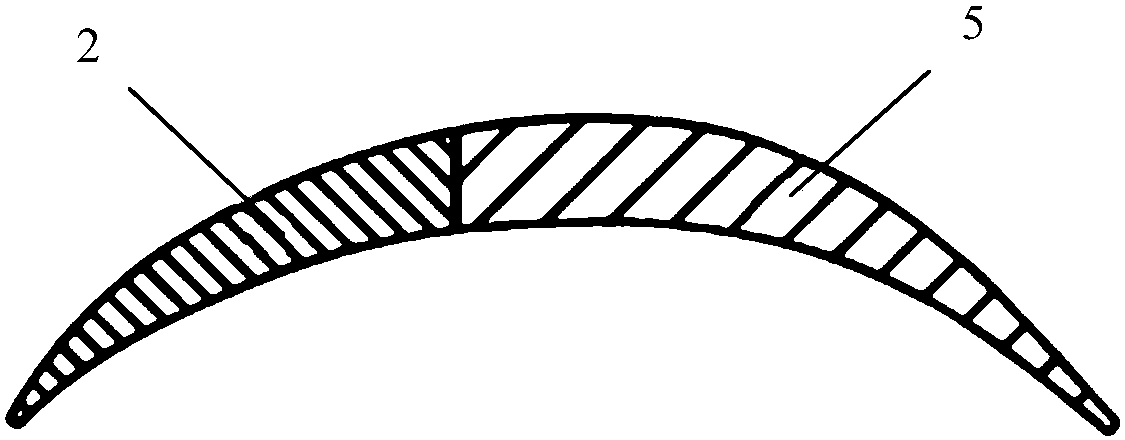

Propeller of a pulsed airflow generator, in particular for a portable blower

The invention relates to a propeller (1) of a pulsed airflow generator, in particular for a standalone portable blower, of the type made up of the assembly of two parts coaxially adjoining one another, i.e.: a first front part (2) made as a single piece and comprising a plurality of twisted blades (3) connected to a central ring (4), and a second rear part (5) with a generally conical shape also made as a single piece, the central portion (6) of said assembly having a conical shape and making up the rear portion of an air-inlet cone, said propeller being characterised in that said first front part and second rear part are secured by means of a clamping device (10) made up of a hub including two parts (11, 12) assembled coaxially and between which said two parts (2, 5) that make up the propeller (1) are clamped, said hub being rotatably secured to the latter and maintaining said front and rear parts in the assembled position thereof.

Owner:PELLENC SA

Dogbone inlet cone profile for remote plasma oxidation chamber

ActiveUS20190228951A1Simple structureElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaEngineering

Embodiments of the present disclosure generally relate to a processing chamber for conformal oxidation of high aspect ratio structures. The processing chamber includes a chamber body with a first side and a second side opposite the first side, and a flow assembly disposed in the first side. The flow assembly includes a flow divider to direct fluid flow away from a center of a substrate disposed in a processing region of the processing chamber. The flow divider includes a crescent shaped first side, a top, and a bottom. The processing chamber also includes a distributed pumping structure located adjacent to the second side. The flow assembly is designed to reduce flow constriction of the radicals, leading to increased radical concentration and flux.

Owner:APPLIED MATERIALS INC

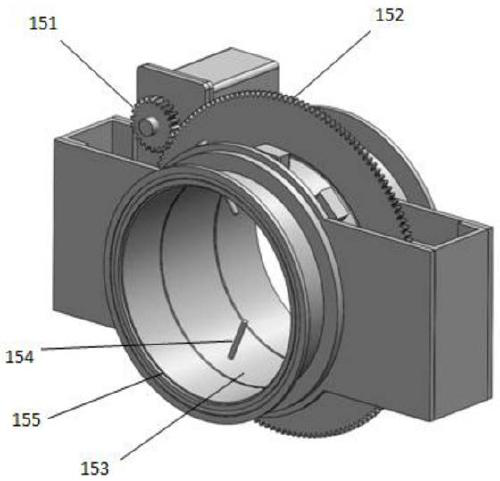

Intermittent swirl separator

ActiveCN110882560AAvoid carryingImprove Cyclone Separation EfficiencyLiquid separationImpellerEngineering

An intermittent swirl separator is provided. The swirl separator comprises a water phase outlet pipe, an impeller shaft, a small bevel gear, a big bevel gear, a big-bevel-gear shaft, an intermittent rotation mechanism shell, a big-bevel-gear shaft sealing structure, a fixing structure, a tangential inlet, an oil phase outlet pipe, a swirl chamber, an oil phase baffle, a small bevel gear shaft, animpeller shell, a bypass pipe, a tangential outlet, an outlet cone, an inlet cone, a rotation speed adjusting pipe, an impeller, a rotation disc, a guide slot, a pushing block, a guide column, a cross-shaped block, and the like. The tangential outlet has an arc-shaped structure. One end of the tangential outlet, close to the swirl chamber, is tangential to the top end of the swirl chamber, and theend of the tangential outlet, far from the swirl chamber, is forked into the bypass pipe and the rotation speed adjusting pipe which are two liquid flow passages. The impeller shell is on the rotation speed adjusting pipe. The impeller is in a chamber formed by the impeller shell and the rotation speed adjusting pipe. The big bevel gear is outside the intermittent rotation mechanism shell. The swirl separator has the advantages of high separation efficiency, strong system integration, a compact structure and a low cost.

Owner:NORTHEAST GASOLINEEUM UNIV

Air-sucking pulse detonation combustion driven pre-mixed carbon dioxide pneumatic laser

ActiveCN110739600ARealize burning and producing lightCombustion produces light withLaser constructional detailsCombustion chamberEngineering

The invention discloses an air-sucking pulse detonation combustion driven pre-mixed carbon dioxide pneumatic laser which comprises an air-sucking pulse detonation combustion device, a transition section, a CO2 pneumatic laser generating device and an exhaust section. The air-sucking pulse detonation combustion device is used for generating a high temperature and high pressure gas heat source as atotal energy source for downstream laser output and comprises a shell, a center body, a rotating valve and a turbulent spiral. An air inlet channel is formed between the air inlet cone part of the center body and the conical shell. A propellant mixing zone is formed between the back of the air inlet channel and the rotating valve. The pulse detonation combustion chamber is located downstream of the rotating valve. The turbulent spiral is coaxially arranged in the pulse detonation combustion chamber. When the air-sucking aircraft flies at supersonic speed, the propellant pulse supply is realized by controlling the rotating valve to generate pulse detonation combustion, and the burned gas generates pulse laser after passing through the CO2 pneumatic laser generating device. The laser outputefficiency is high and the energy is saved. The device can generate both thrust and laser without increasing its load.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

Balance assembly, rotor system, gas turbine and balance method

ActiveCN112012966AAvoid cumbersome proceduresReduce processing costsPump componentsEfficient propulsion technologiesControl theoryMechanics

The invention relates to a gas turbine, a rotor system and a balancing assembly and a balancing method for balancing the rotor system. The balance assembly comprises a balance screw used for being connected with an air inlet cone rear supporting ring of the rotor system in the circumferential direction, the balance screw is provided with a groove extending from the head end of the balance screw tothe tail end of the balance screw, the groove comprises a groove head and a groove body extending from the groove head, and a first mass balance piece is contained in the groove body.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

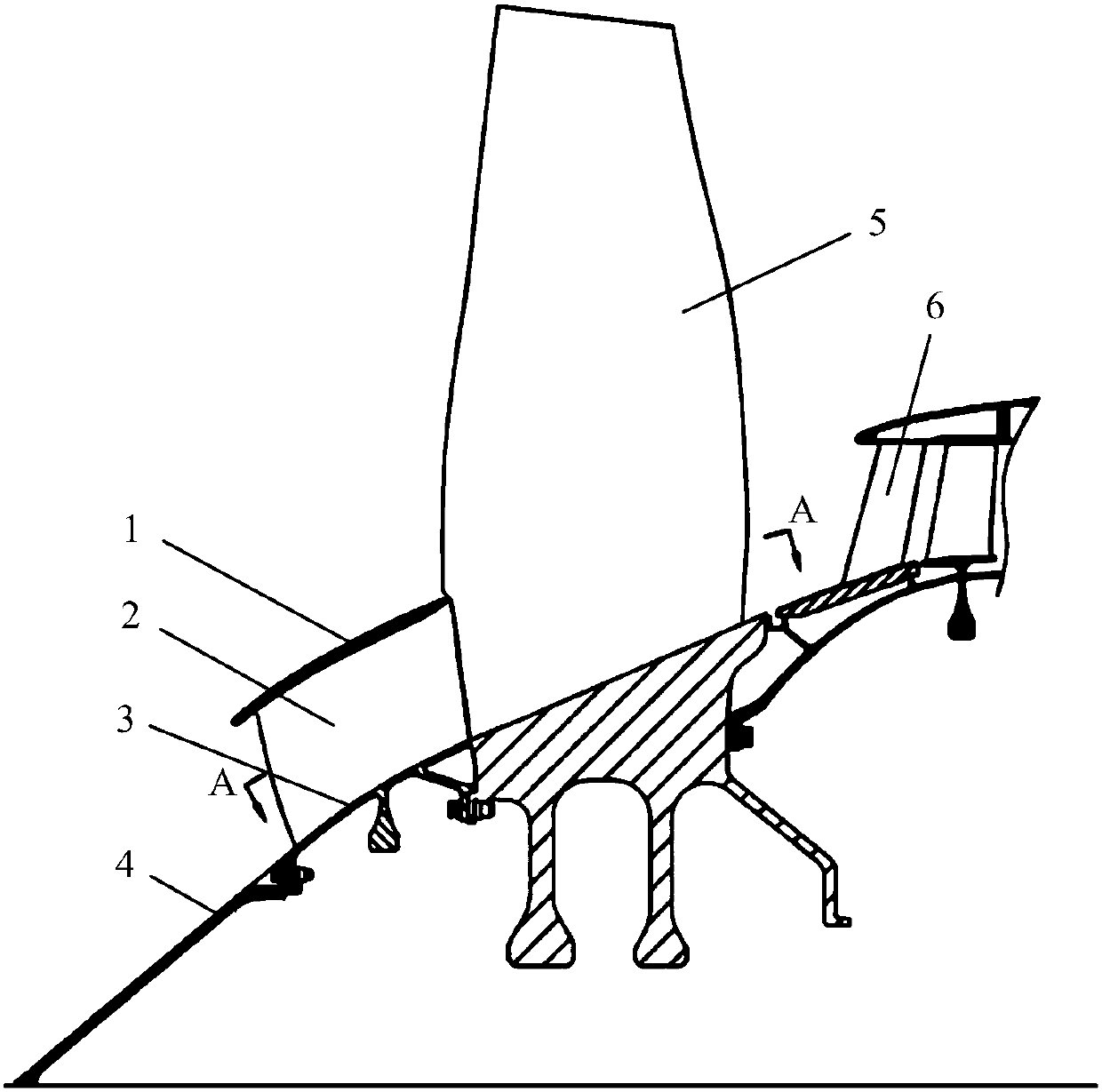

Shell structure of air-breathing stamping rotary knocking engine adopting liquid state fuel

ActiveCN111663969APromote atomizationSpeed up the evaporation processTurbine/propulsion fuel supply systemsTurbine/propulsion air intakesCombustion chamberLiquid state

The invention relates to an air-breathing engine adopting a liquid state fuel, in particular to a shell structure of an air-breathing stamping rotary knocking engine adopting a liquid state fuel. Theinvention aims to solve the technical problem of quick atomization and relatively large evaporation difficulty in the prior art and provides the shell structure of the air-breathing stamping rotary knocking engine adopting the liquid state fuel. The structure comprises an engine outer shell and a premixed gas shell assembly which comprises an air inlet cone, an isolation section center body and acombustion chamber center body. The isolation section center body is connected to the engine outer shell through a main supporting rod; the air inlet cone is connected to the isolation section centerbody through a front supporting rod, and a circular seam-shaped air inlet channel is formed between the air inlet cone and the isolation section center body; the combustion chamber center body is connected to the isolation section center body through a back supporting rod, and a circular seam-shaped injection channel is formed between the combustion chamber center body and the isolation section center body; a fuel box and a nozzle are arranged in the air inlet cone; and a mixing chamber is arranged in the isolation section center body and the mixing chamber communicates to the nozzle.

Owner:XIAN AEROSPACE PROPULSION INST

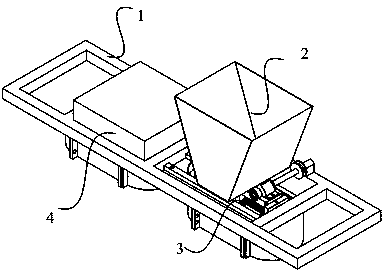

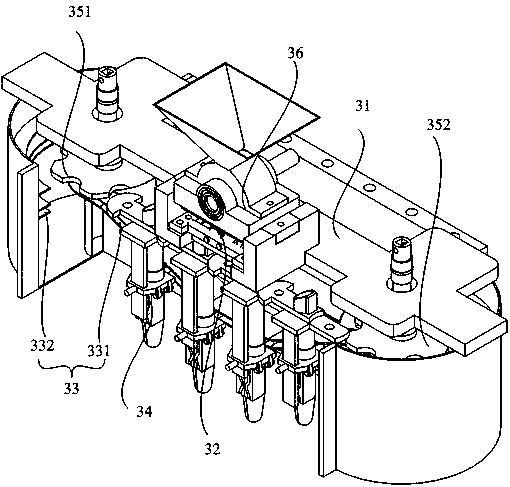

Agricultural automatic planter with adjustable spacing

InactiveCN108243672ARealize opening and closingMeet line spacing requirementsPlantingDibble seedersBraced frameAgricultural engineering

The invention discloses an agricultural automatic planter with adjustable spacing. The planter comprises a trailer rack and a plurality of automatic seeding modules, wherein each automatic seeding module comprises a sliding rack and a hoeing assembly, a material storage box and a seeding assembly which are arranged on the sliding rack, each hoeing assembly includes a base, a hinge four-bar mechanism and a hoe, and each seeding assembly comprises a support frame, a material feeder, a guiding mechanism and a plurality of seeding mechanisms; each material feeder comprises two rotary blocks and asynchronization mechanism which is used for controlling the two rotary blocks to rotate synchronously and reversely, each guiding mechanism comprises an annular guide groove, each annular guide groovecomprises a horizontal guide groove part and a concave guide groove part which sinks downwards, and each seeding mechanism comprises a conveying cylinder, a slide base, a soil inlet cone and a guideplate. The manufacturing cost of the agricultural automatic planter with the adjustable spacing can be reduced, and the operational reliability of the agricultural automatic planter planter can be improved.

Owner:周爽

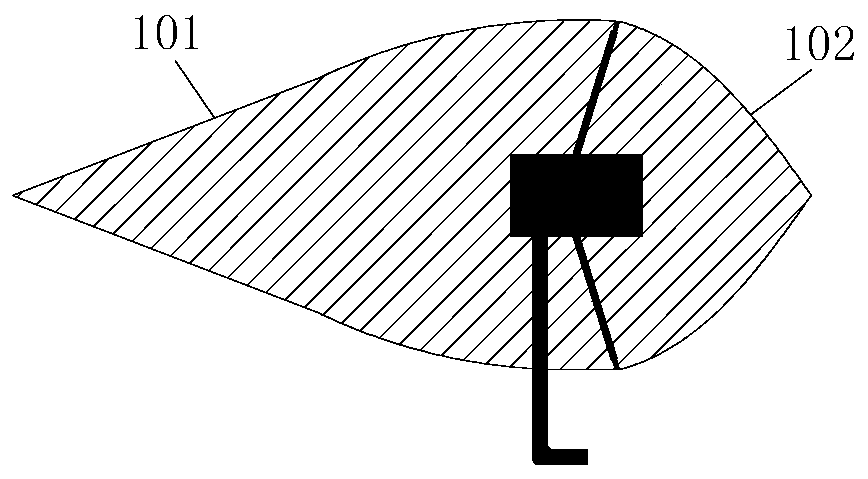

Fan assembly of built-in generator

InactiveCN110761849AImprove power supply capacityEasy to installLeakage preventionMachines/enginesElectric machineCoupling

The invention belongs to the structural design scheme of aero-engines and relates to a fan assembly of a built-in generator. The fan assembly is composed of a fan rotor, a coupling shaft, an air inletsupport plate, an air inlet cone, a motor and a bearing, wherein the fan rotor is a self component of the generator and rotates at a high speed; the front end of the fan rotor is connected with the coupling shaft; a motor rotor is mounted on the coupling shaft; the fan rotor drives the motor rotor to rotate through the coupling shaft; the air inlet support plate is mounted on a fan casing; the fan casing is connected with a bearing casing; the fan casing and the bearing casing are self force transmitting components of the generator; the air inlet cone is mounted on the air inlet support plateand is static; a sealing structure is arranged at the connecting position of the air inlet cone and the rotor; and a motor stator a bearing for supporting the motor rotor are fixedly mounted on the air inlet cone. The fan assembly can improve the power supply capacity of the generator and reduces the weight of the generator; and the built-in motor is convenient to mount and easy to maintain.

Owner:中国航发贵阳发动机设计研究所

High bypass ratio turbofan engine and aero engine compression system

InactiveCN109538525ASupercharge effect is goodIncrease pressure ratioPump componentsPumpsPre compressionBypass ratio

The invention provides a high bypass ratio turbofan engine and an aero engine compression system. The high bypass ratio turbofan engine and the aero engine compression system can improve the overall supercharging effect of a fan inner duct and an increasing level under the premise of increasing the engine mass as little as possible. The aero engine compression system includes a pre-compression configuration, and the pre-compression configuration is located at the front end of a fan rotor and at the rear end of an air inlet cone; the pre-compression configuration includes a rectifying outer ring, a plurality of blades and an internal flow passage ring, the rectifying outer ring is located at an outer ring, the internal flow passage ring is located at an inner ring, and the multiple blades are located between the outer ring and the inner ring; and the rectifying outer ring, the blades and the internal flow passage ring constitute a contraction passage.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com