Patents

Literature

123results about How to "Supercharge effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

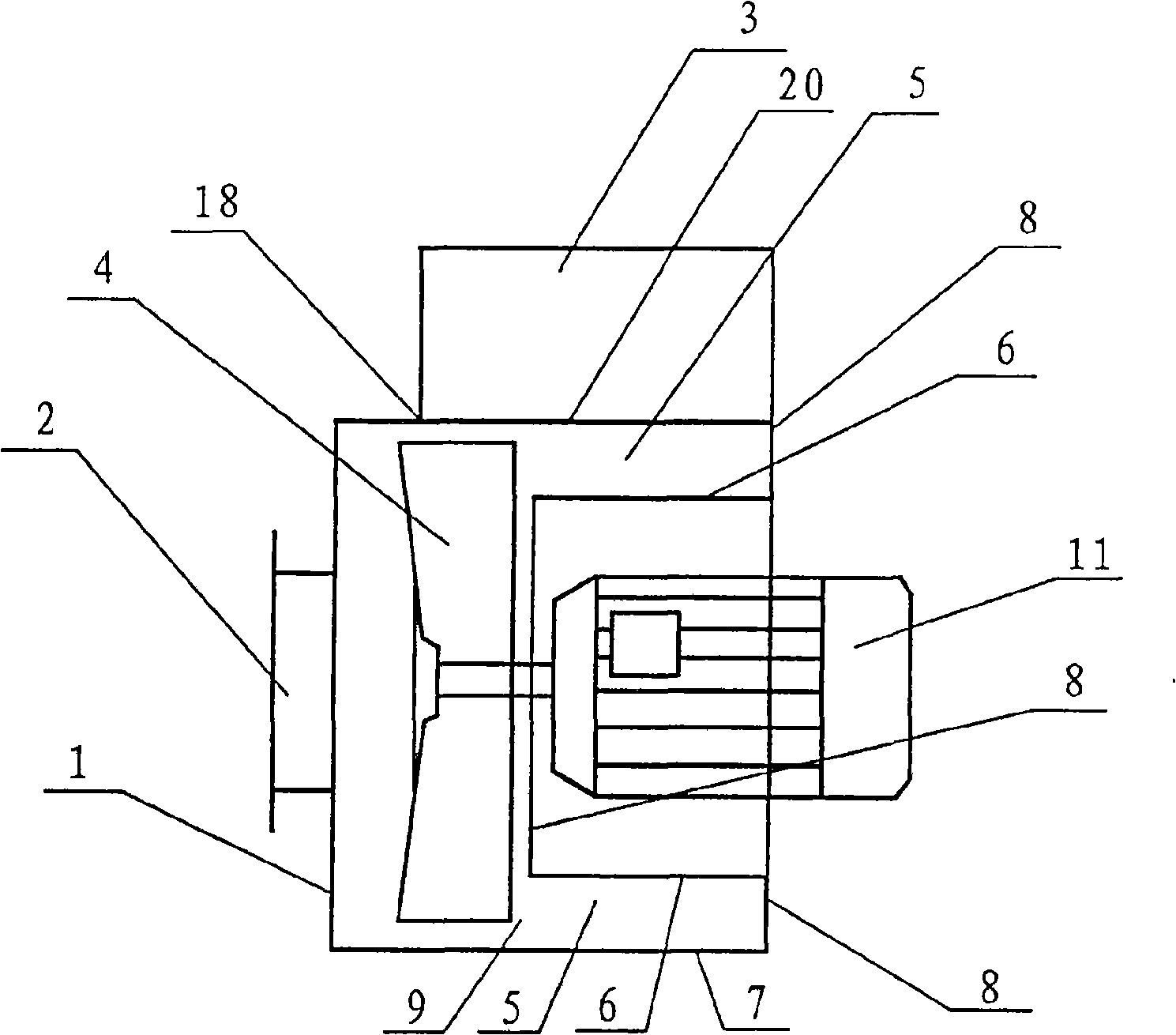

Double-shaft air-injection rotary jet type stirring pile machine and method for forming pile by using pile machine

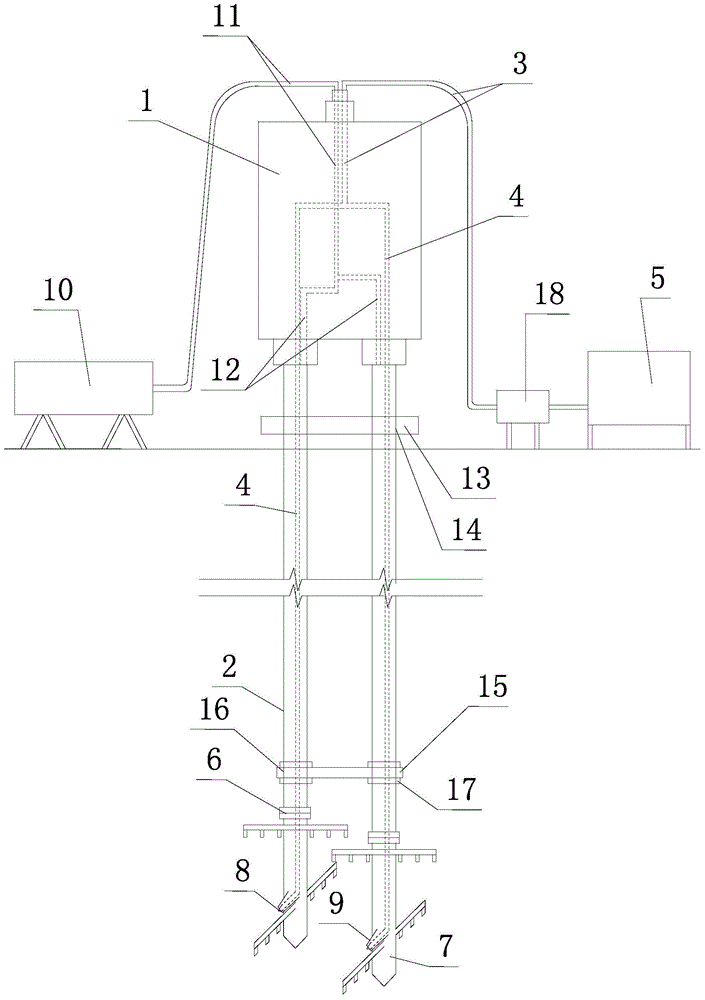

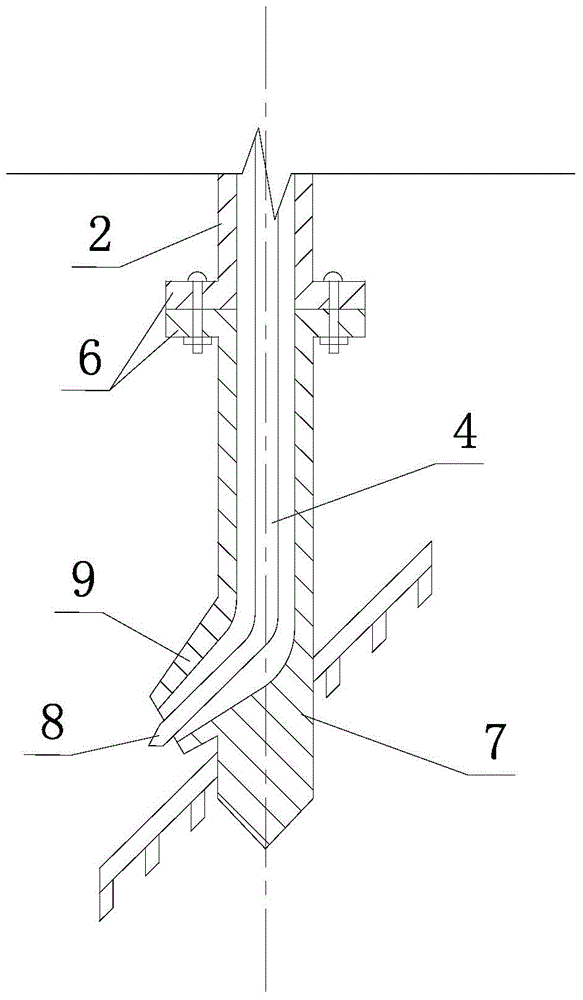

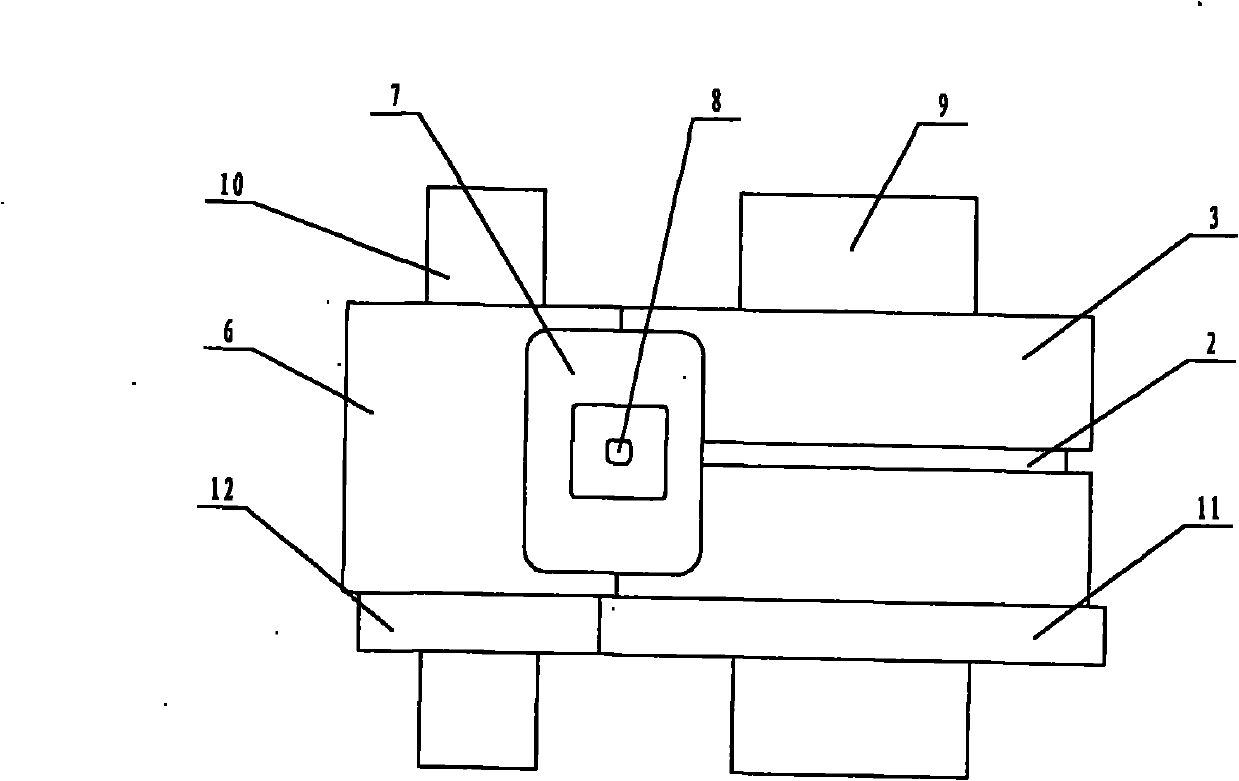

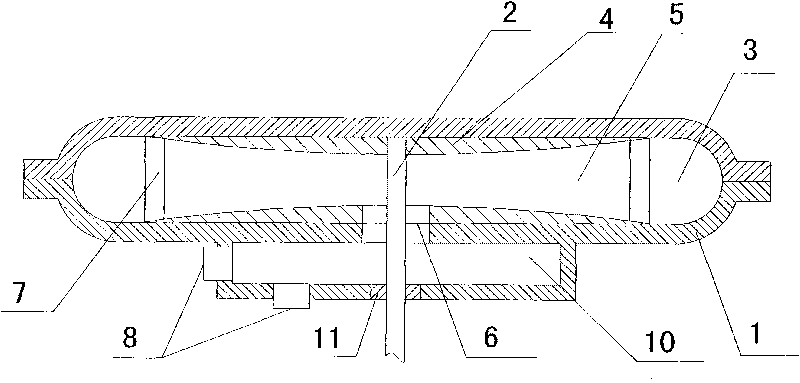

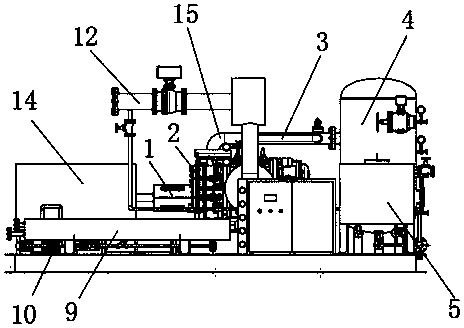

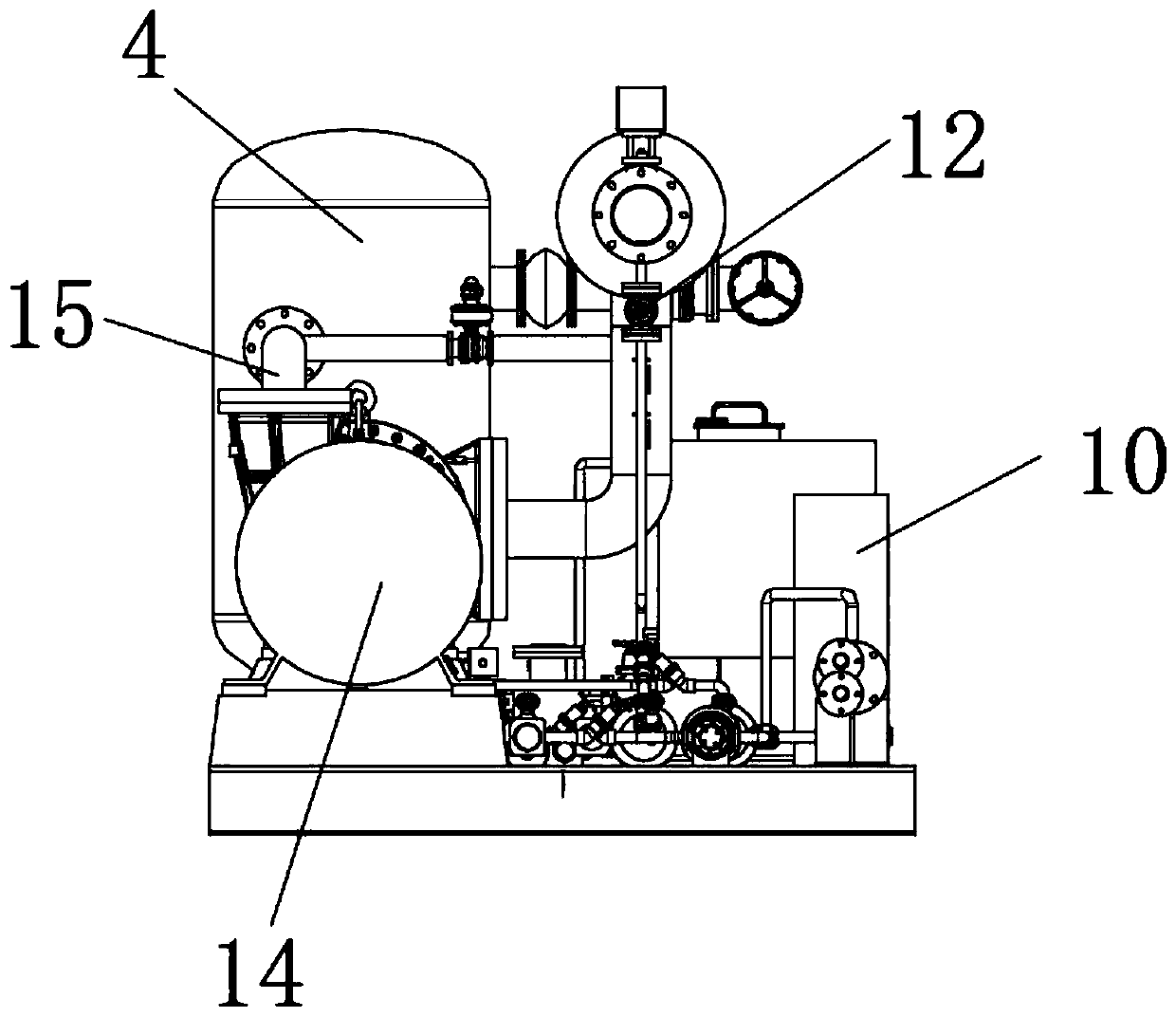

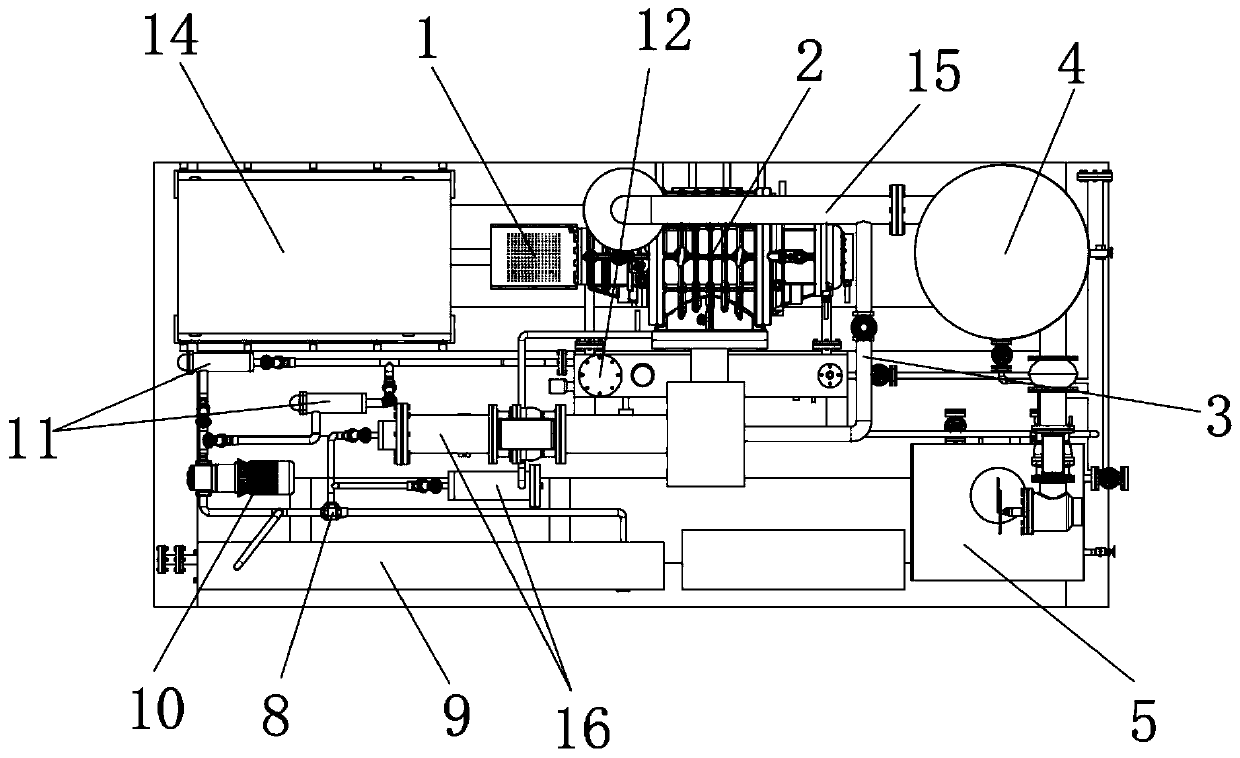

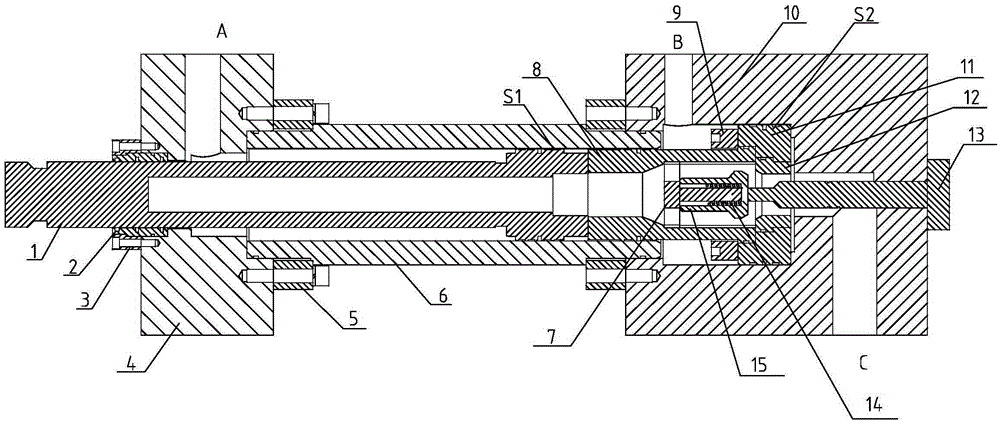

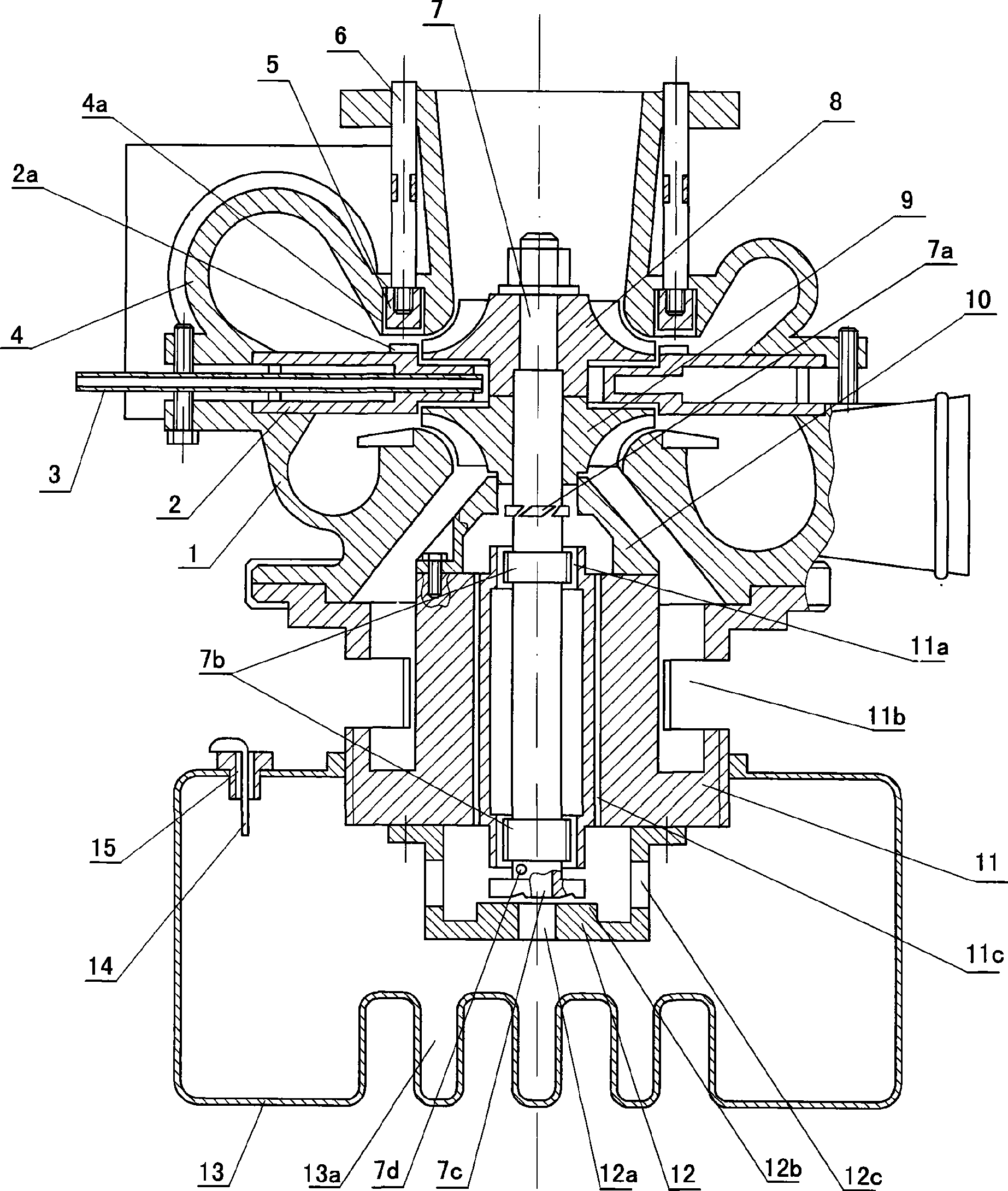

The invention discloses a double-shaft air-injection rotary jet type stirring pile machine and a method for forming a pile by using the pile machine. The pile machine disclosed by the invention comprises a pile frame, a power head (1), a stirring shaft (2), an air nozzle (9), an air compressor (10), an air transmission header pipe (11) and an air transmission branched pipe (12); a slurry nozzle (8) and the air nozzle (9) are fixed on a stirring head (7); the air nozzle (9) is arranged outside the slurry nozzle (8) in a sleeving manner; the air nozzle (9) is communicated with the air transmission branched pipe (12); the air transmission branched pipe (12) is communicated with the air transmission header pipe (11) and the air compressor (10). The construction method provided by the invention comprise the key step of spraying slurry under coercing of high-pressure air while drilling through a stirring shaft (2) or lifting upwardly and stirring a soil body. Due to the pile machine and the method for forming the pile by utilizing the pile machine, which are disclosed by the invention, piled cemented soil is uniform in density and good in pile-forming quality; the pile-forming depth can be increased; furthermore, a pile can be formed in a soil body with relatively high hardness; in addition, the construction efficiency is improved; the time limit for a project is shortened; the machine-shift cost and the labour cost are saved.

Owner:NINGBO HONGCHEN CONSTR +1

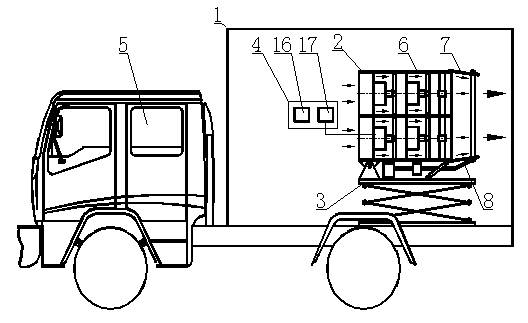

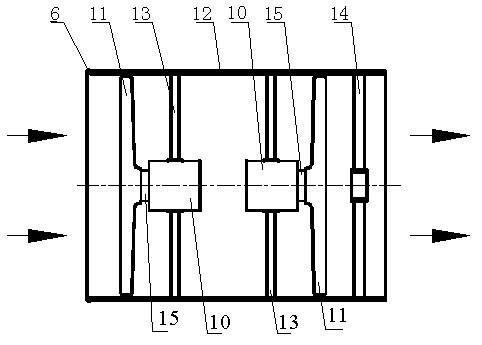

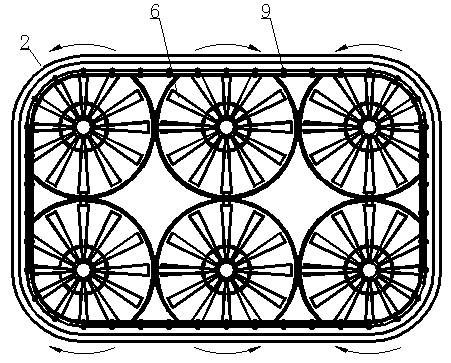

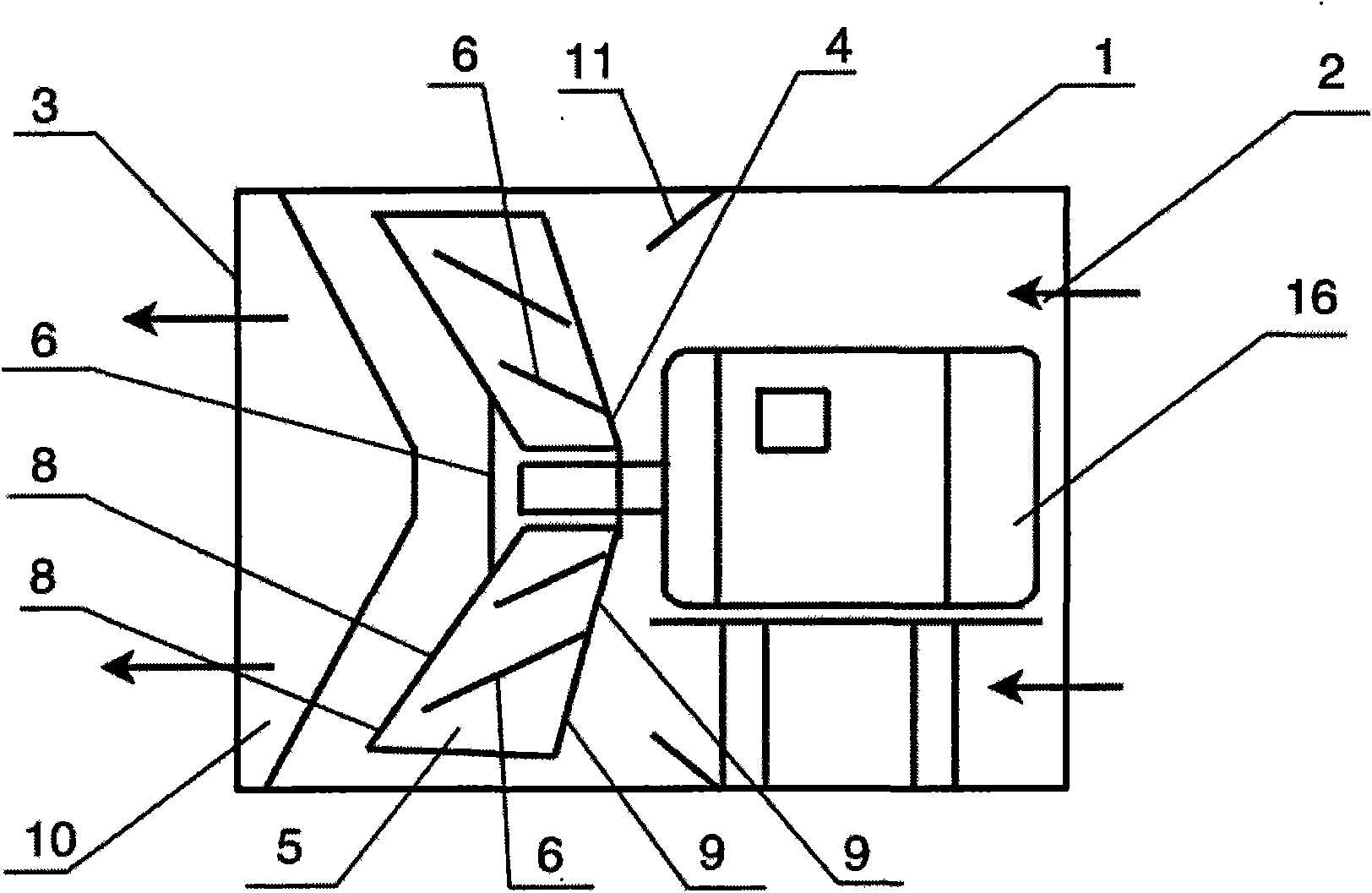

Multi-core-driven multi-stage booster combined fire-extinguishing and smoke-controlling device

ActiveCN101943174AIncrease the outlet wind speedLarge exhaust air volumeFire rescuePump installationsControl systemEngineering

The invention discloses a multi-core-driven multi-stage booster combined fire-extinguishing and smoke-controlling device which comprises a carrier. The carrier is provided with a rotating lifting mechanism which is fixedly provided with a combined exhaust blower group, the carrier is also provided with a control system which is connected with the combined exhaust blower group formed by assembling and fixedly mounting six exhaust blowers together, and the six exhaust blowers are arranged up and down and integrally combined in two rows with three exhaust blowers in a row and share an outer air duct, a water supply pipeline and a water mist nozzle. The multi-core-driven multi-stage booster combined fire-extinguishing and smoke-controlling device of the invention has great exhaust air rate in case of a certain volume.

Owner:陕西银河消防科技装备股份有限公司 +1

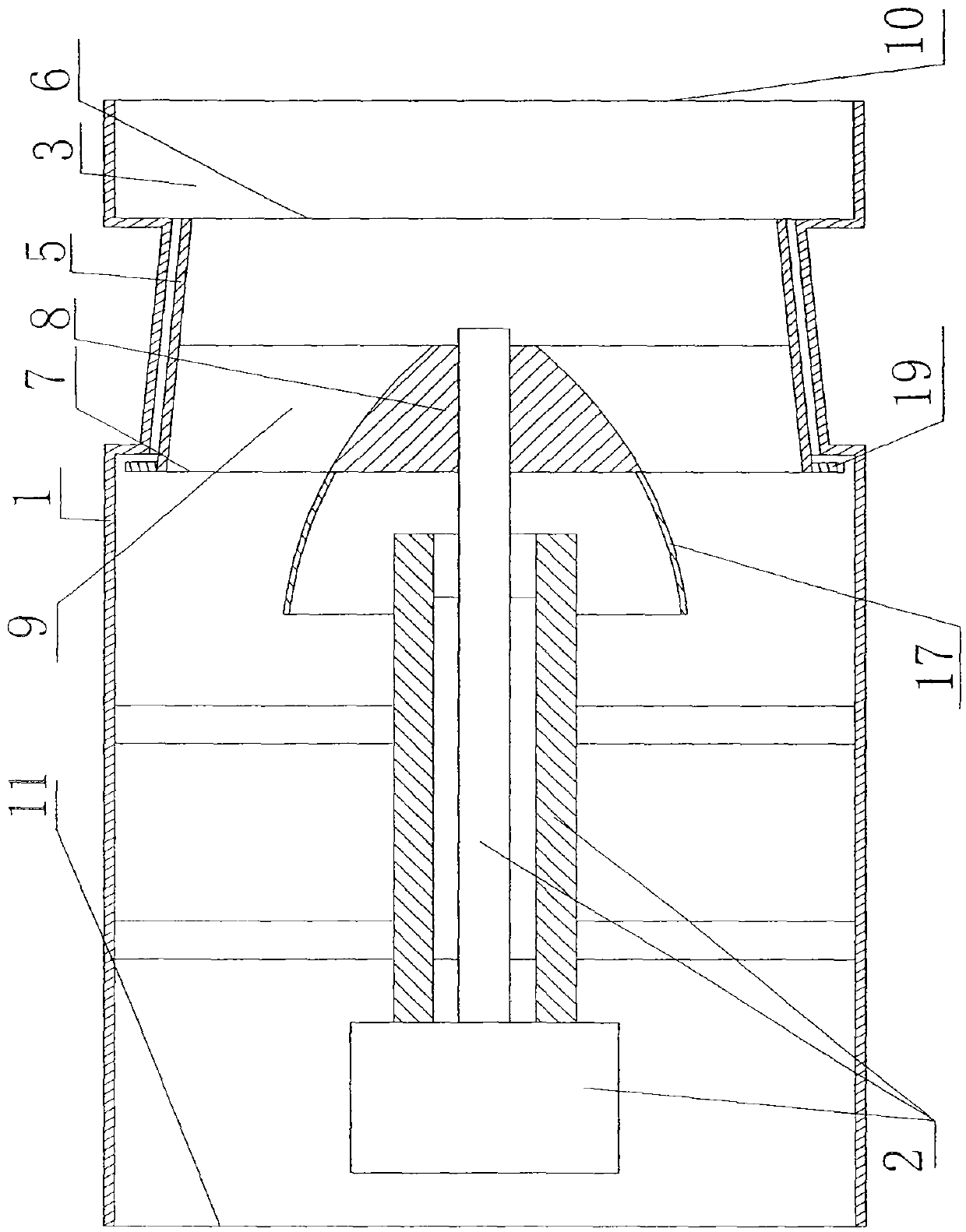

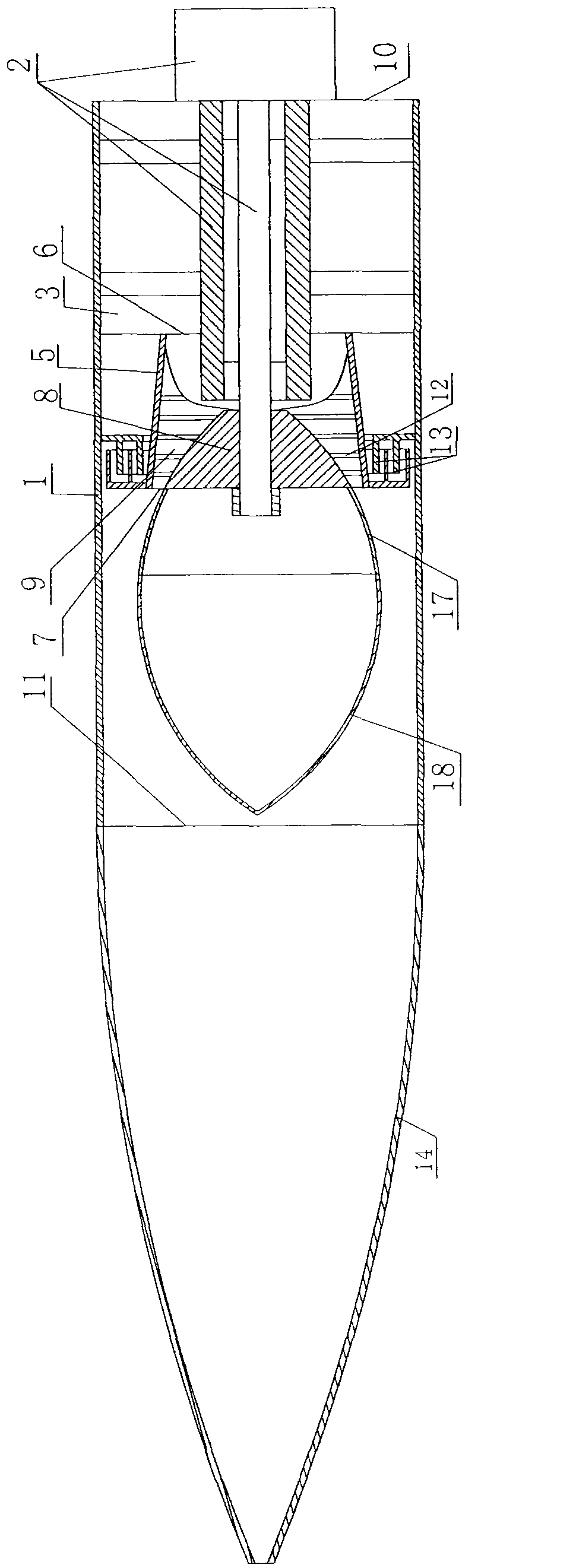

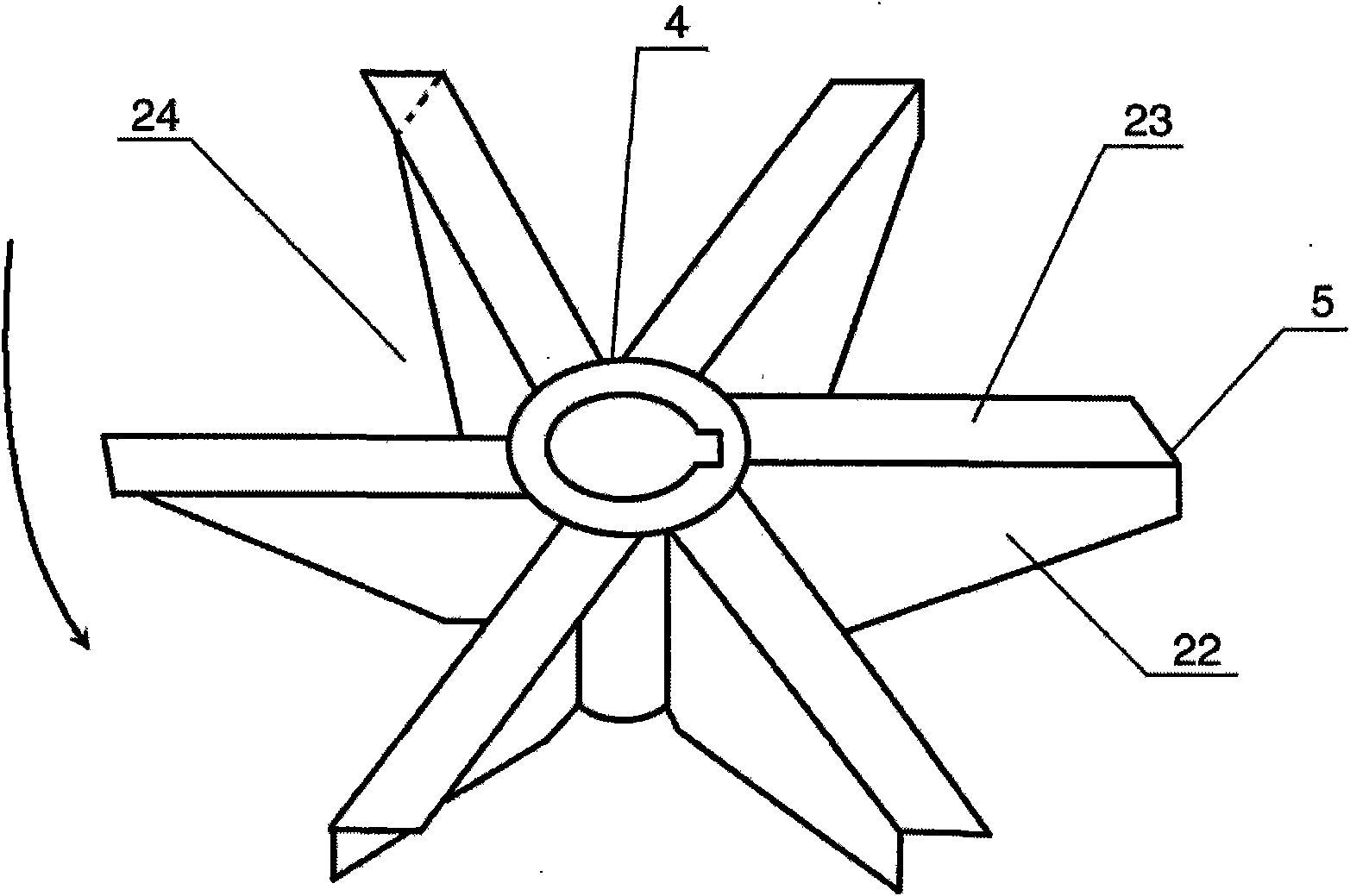

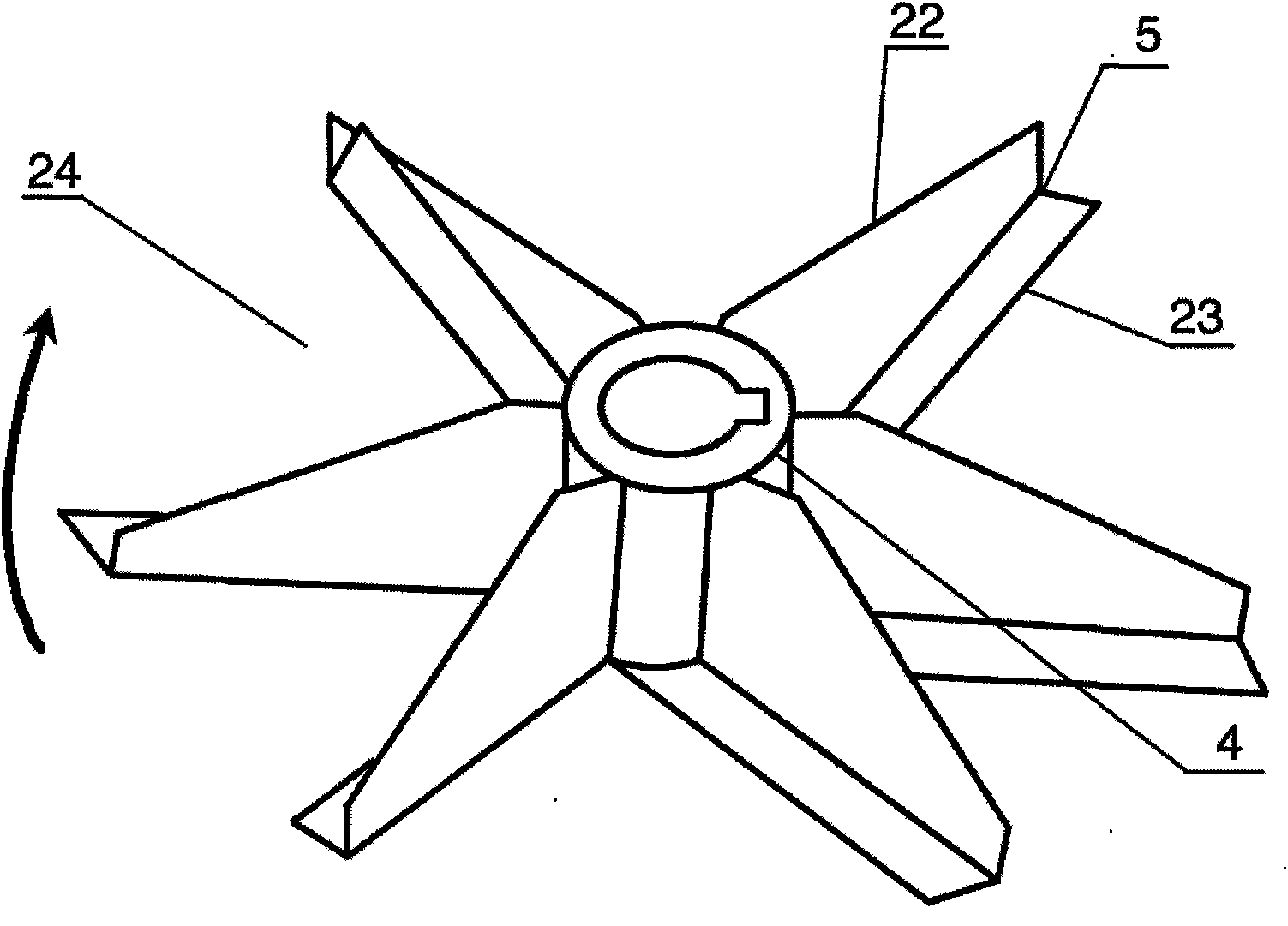

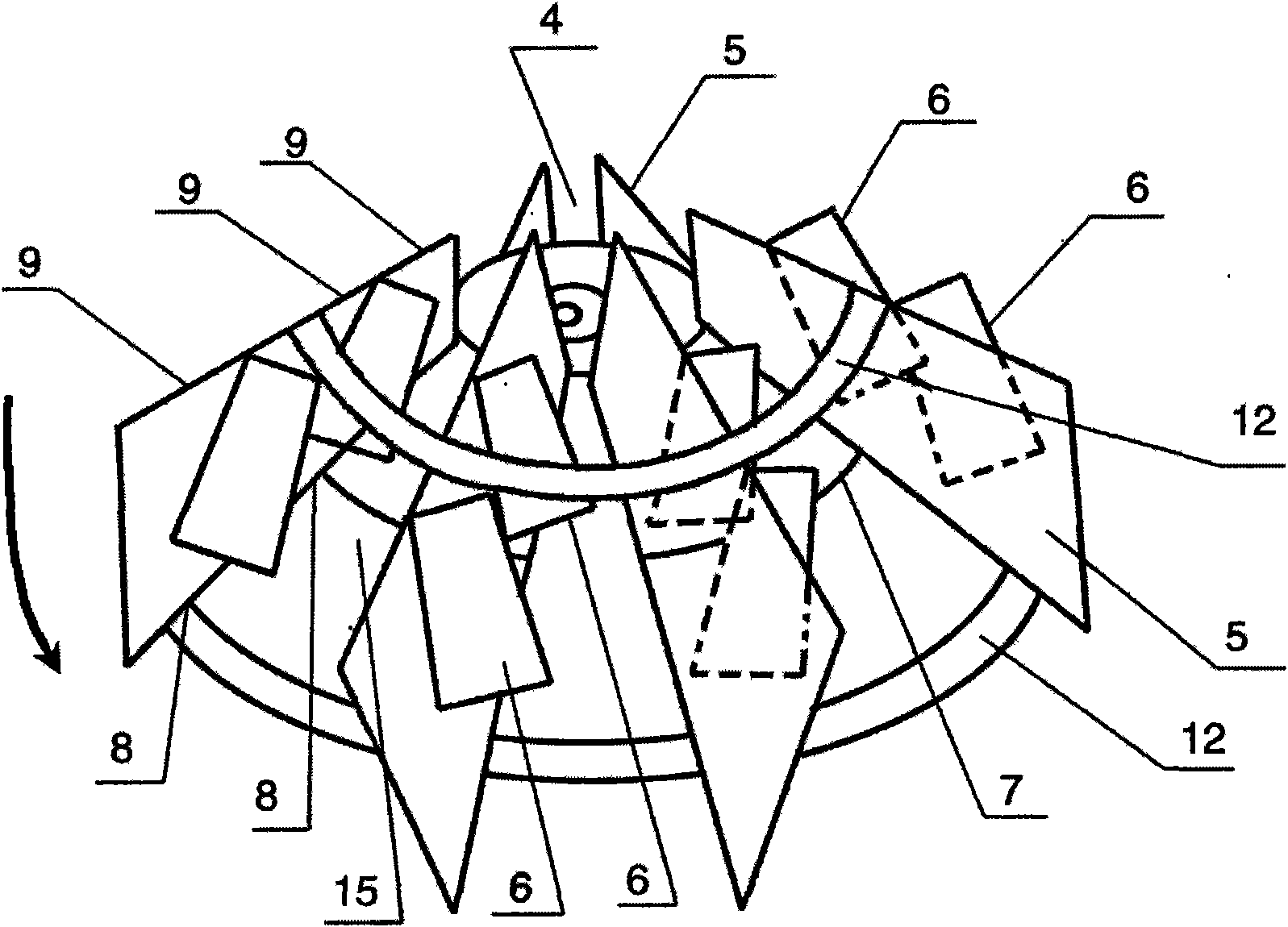

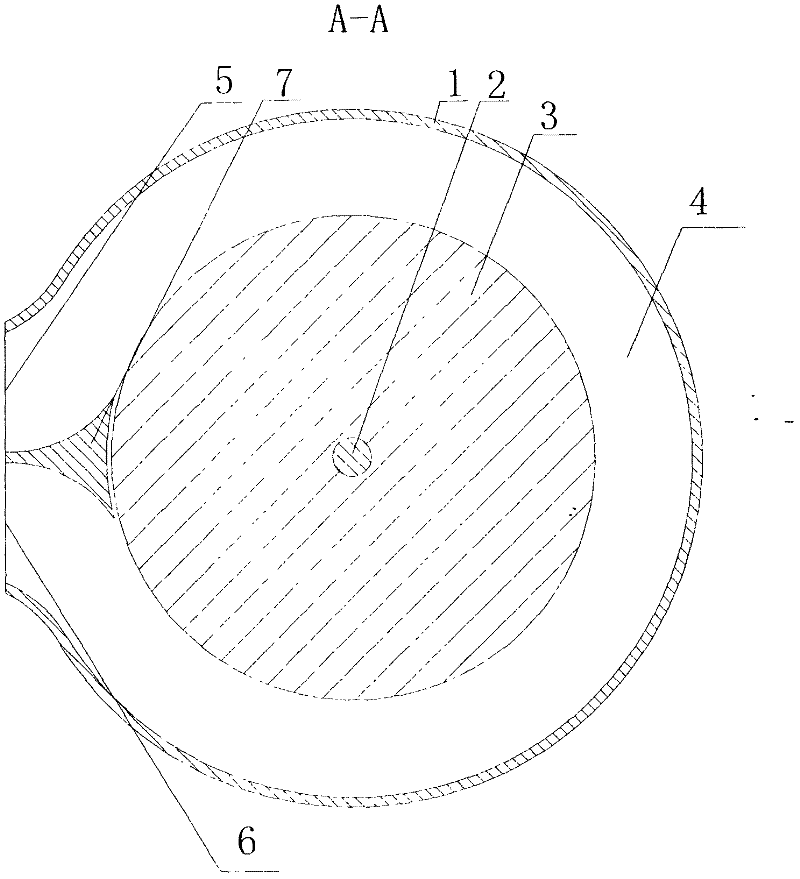

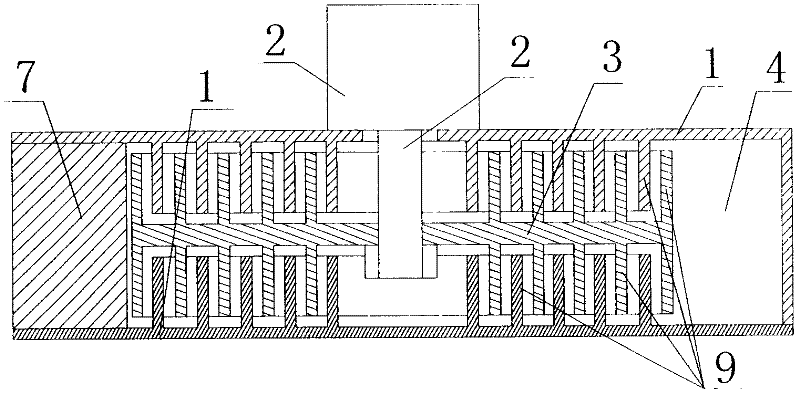

Axial flow device

InactiveCN102734175AUniform irrigationRealize micro-sprayPump componentsAxial flow pumpsImpellerSuction equipment

The invention provides an axial flow device comprising a shell and a transmission device. The shell is provided with the transmission device and is internally provided with a shell cavity; a vortex tube impeller is arranged in the shell cavity; the transmission device is connected with a vortex tube impeller; the vortex tube impeller is provided with a vortex tube which is provided with an impeller opening A and an impeller opening B and is internally provided with a wheel body, and the wheel body is provided with a guide blade; an inclined angle is formed between the guide blade and a rotating shaft of the vortex tube impeller; the guide blade is connected to the inner wall of the vortex tube; a shell cavity opening A is arranged at one end, which corresponds to the impeller opening A, of the shell cavity; and a shell cavity opening B is arranged at the other end of the shell cavity. The axial flow device is more energy-saving and can be used for pressurizing and conveying fluid. The axial flow device can serve as a water pump, vacuum equipment, air suction equipment, an air blower, a compressor, atomizing equipment, sprinkling equipment, a reactor, air blowing equipment, propelling equipment, a sewage processor, a dust remover, a dust collector, dressing equipment, a steam turbine, a water turbine, a wind turbine, a vortex pressurizing device utilizing residual heat of an engine, foam material manufacturing equipment, nano material manufacturing equipment and the like; and the axial flow device can be used for manufacturing a brand new foam material.

Owner:陈久斌

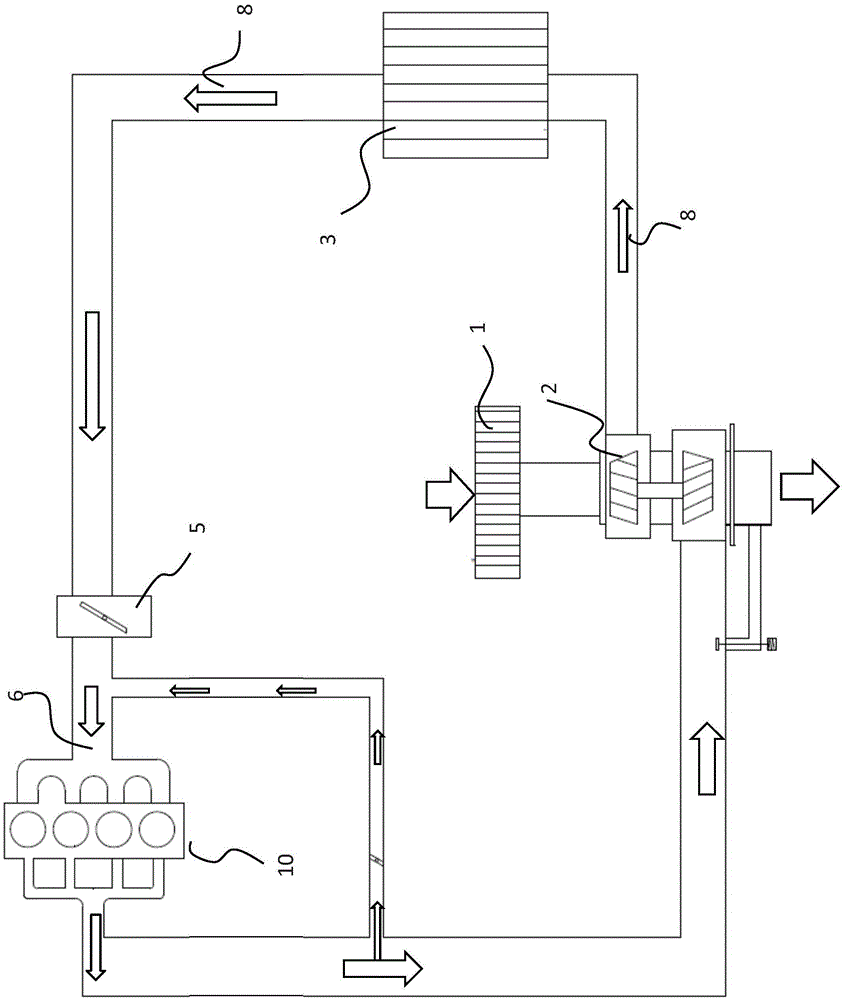

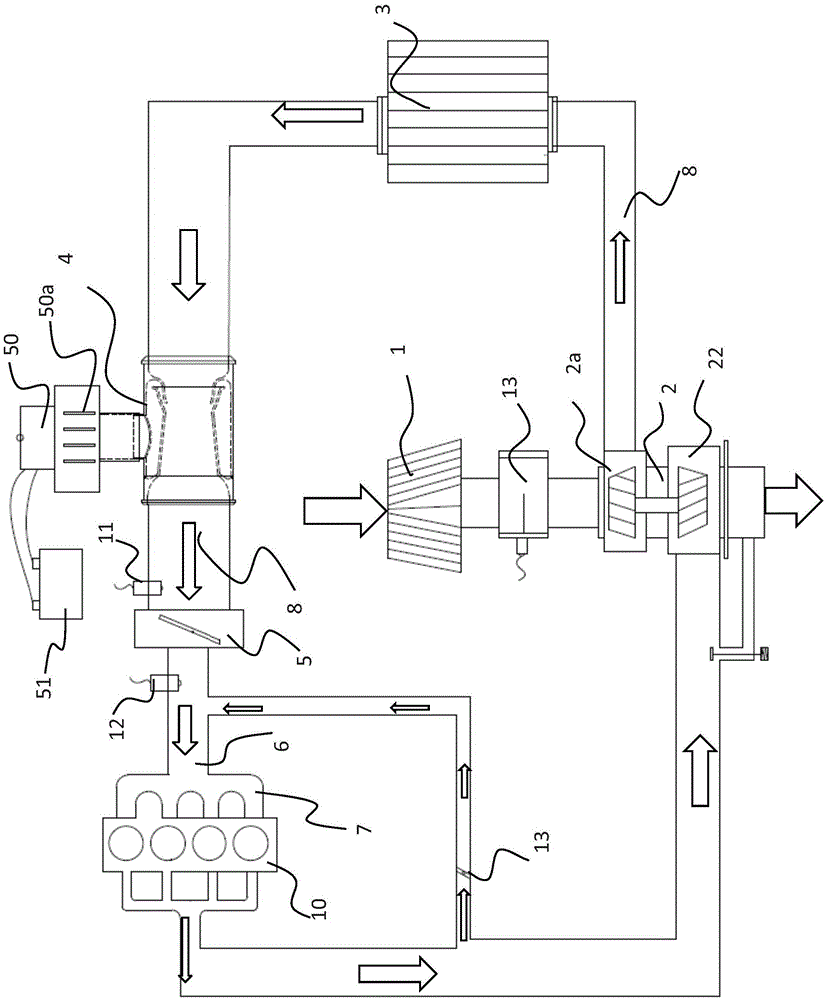

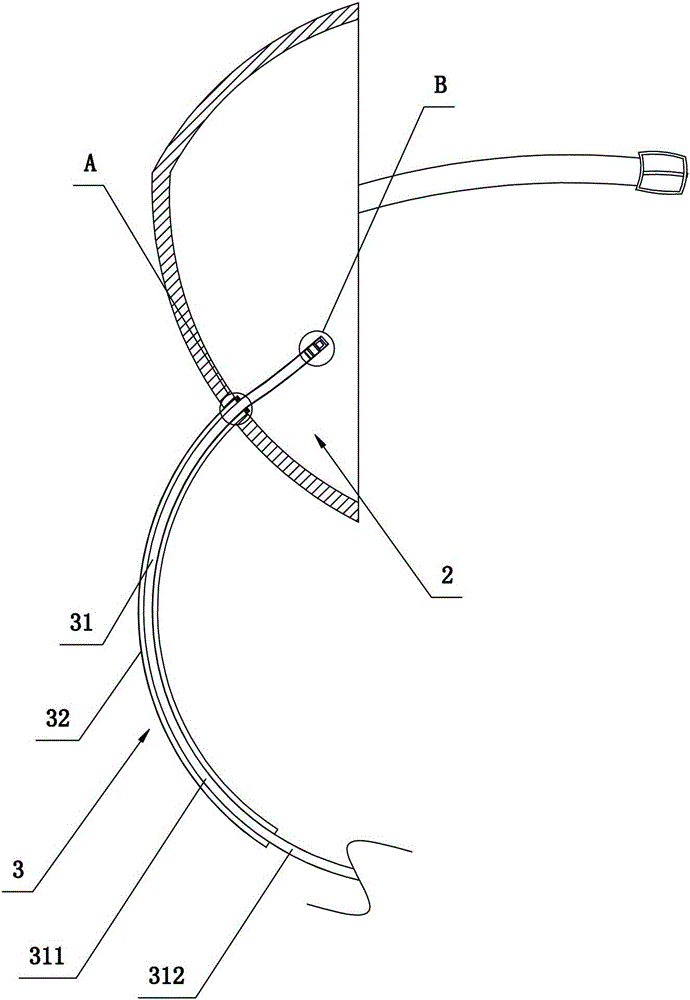

Engine and air inlet system thereof

ActiveCN105804896AIncrease boost effectSupercharge effect is goodMachines/enginesThermal treatment of fuelLow speedEngine efficiency

The invention discloses an engine and an air inlet system thereof. The air inlet system of the engine comprises an air inlet pipe, an air inlet manifold, an air inlet manifold header and an electric supercharger arranged on the air inlet pipe and located in front of the air inlet manifold header of the engine. The electric supercharger comprises a base, a motor arranged in the base, fan blades arranged in the base and a supercharging pipe communicated with the base through fluid. The base is provided with an air inlet, and the supercharging pipe is provided with an air outlet. The supercharging pipe is connected to the air inlet pipe in series and communicated with the air inlet pipe through fluid, and the motor can drive the fan blades to rotate, so that air flow flows in through the air inlet and flows out from the air outlet, and the air flow is mixed with air flowing in from the air inlet pipe to be sucked into an air cylinder of the engine together. By means of the engine and the air inlet system of the engine, emission can be effectively reduced, the efficiency of the engine is improved, the low-speed torque characteristics of the engine are improved, and engine surge is not caused.

Owner:SHANGHAI QINGCHE AUTOMOTIVE ENG CO LTD

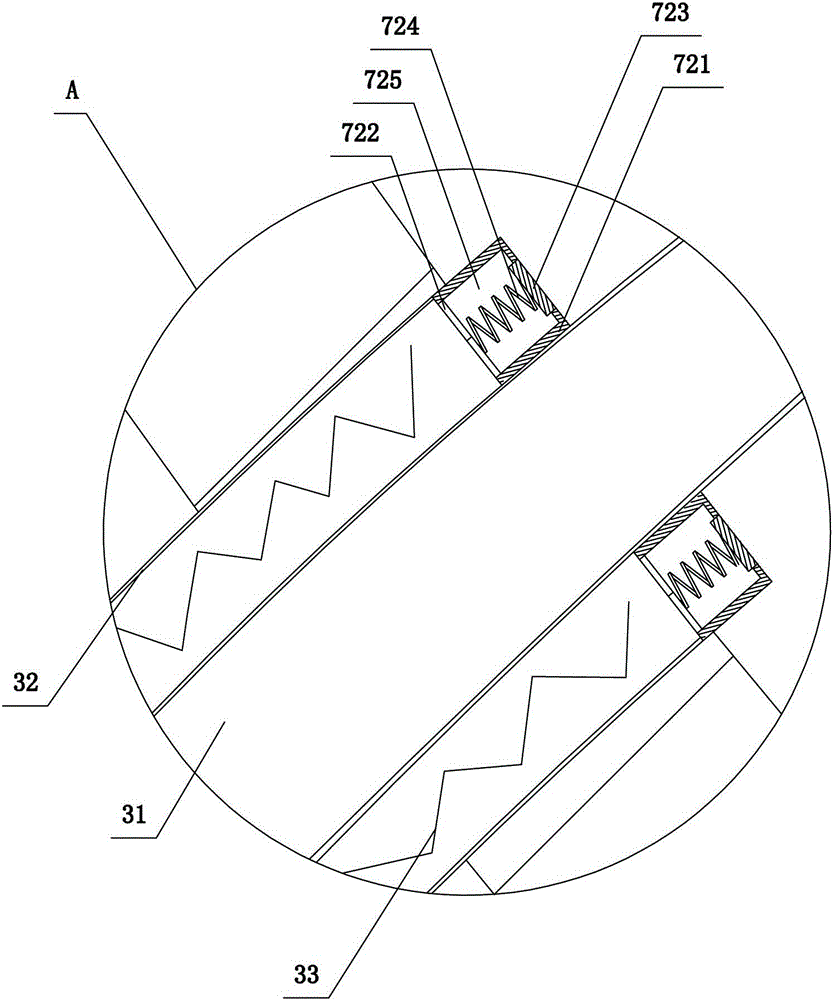

Engine and air inlet system thereof

ActiveCN106246336ASupercharge effect is goodEasy to installInternal combustion piston enginesJet pumpsComing outOil consumption

The invention discloses an engine and an air inlet system thereof. The air inlet system of the engine comprises an air inlet pipe, an air inlet manifold, and an auxiliary air inlet component that is arranged on the air inlet pipe and located at the front of the air inlet manifold of the engine; the auxiliary air inlet component comprises an auxiliary air inlet passage, an auxiliary air outlet passage and a center passage; air enters via the auxiliary air inlet passage, comes out from the auxiliary air outlet passage, enters the center passage, and is mixed with air coming from the air inlet pipe; the auxiliary air inlet component may comprise at least one nozzle for humidifying the air; the nozzle is detachably mounted on the auxiliary air inlet component; and liquid is sucked into a main pipeline of the air inlet system by differential pressure in the main pipeline, is mixed with the air, and then enters an air cylinder of the engine. With the adoption of the engine and the air inlet system of the engine, emission and oil consumption can be reduced effectively, the efficiency of the engine, the low-speed torque characteristic of the engine and the low-temperature cold start effect of the engine can be improved, surging of the engine can be inhibited, and the shifting smoothness can be improved.

Owner:SHANGHAI QINGCHE AUTOMOTIVE ENG CO LTD

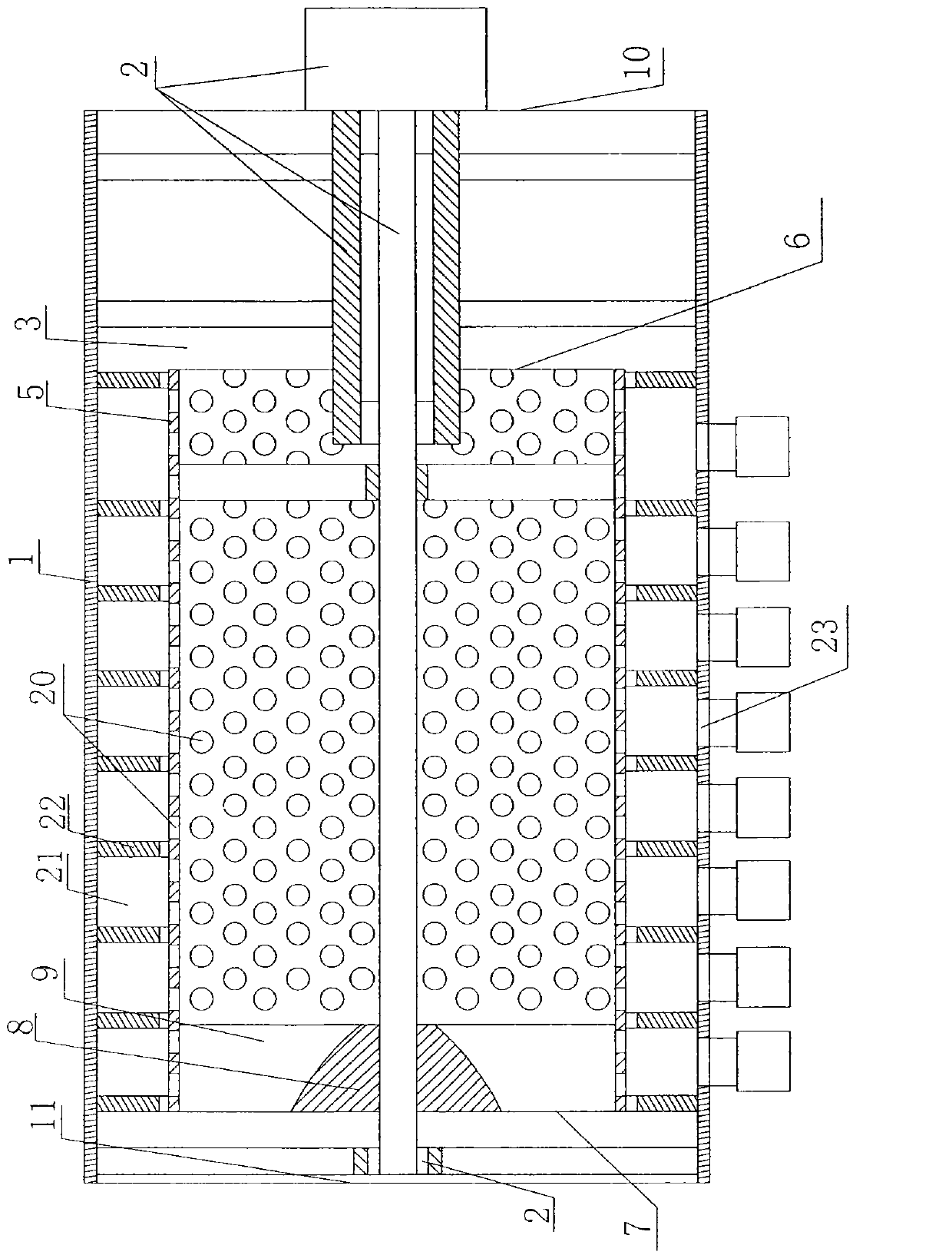

Synchronous after flow ventilating compressor

InactiveCN101566165AReduce the number of seriesLess twists and turnsPump componentsAxial flow pumpsLow noiseImpeller

The invention discloses a synchronous after flow ventilating compressor, which comprises a shell, an air inlet of the shell, an outlet of the shell, an impeller, impeller blades, an airflow channel inside the impeller, a blisk of the impeller. The compressor is characterized in that the axial back sides of the impeller blades gradually axially tilt along the radial direction of the impeller from front to back towards the axial direction of the impeller; the axial back side of the impeller gradually axially tilts along the radial direction of the impeller from front to back towards the axial direction of the impeller; and gradually and axially tilting part of the axial direction back side of the impeller is provided with an axial air outlet of the impeller. Compared with the prior art, the compressor has the advantages of simple structure, small volume, few materials, light weight, convenient transportation and mounting, resources, saving good pressurized effect, high efficiency, energy saving, low noise, favorability for environment protection and the like.

Owner:林钧浩

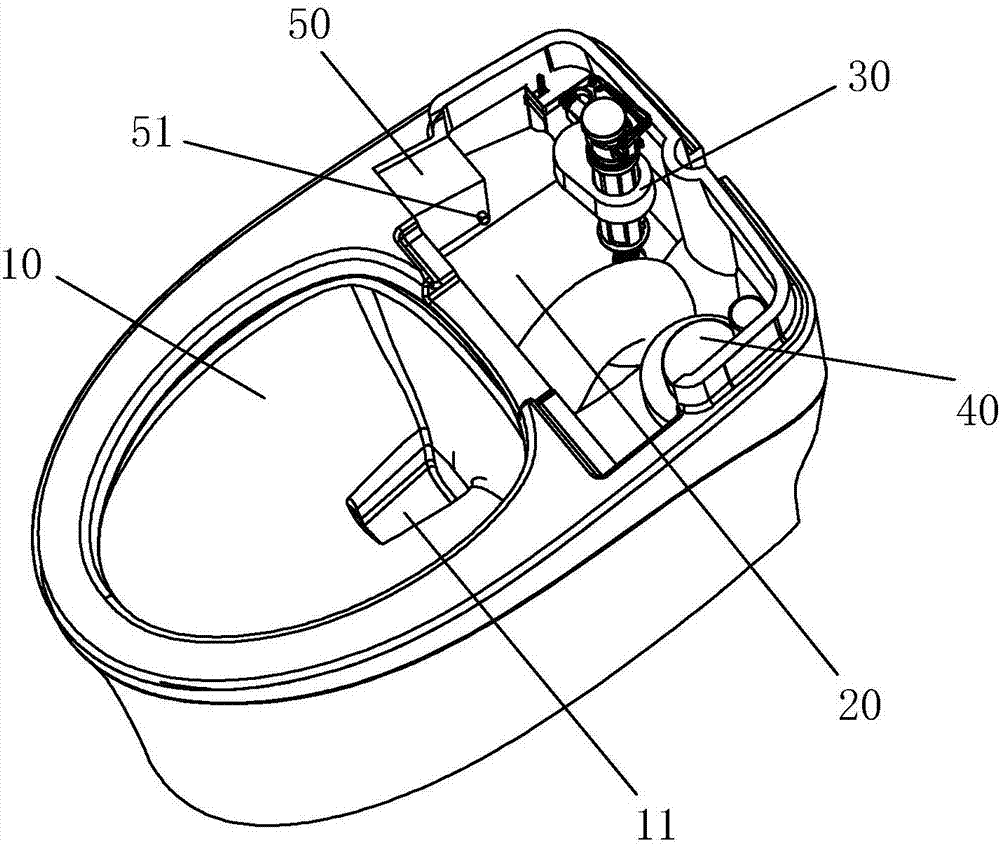

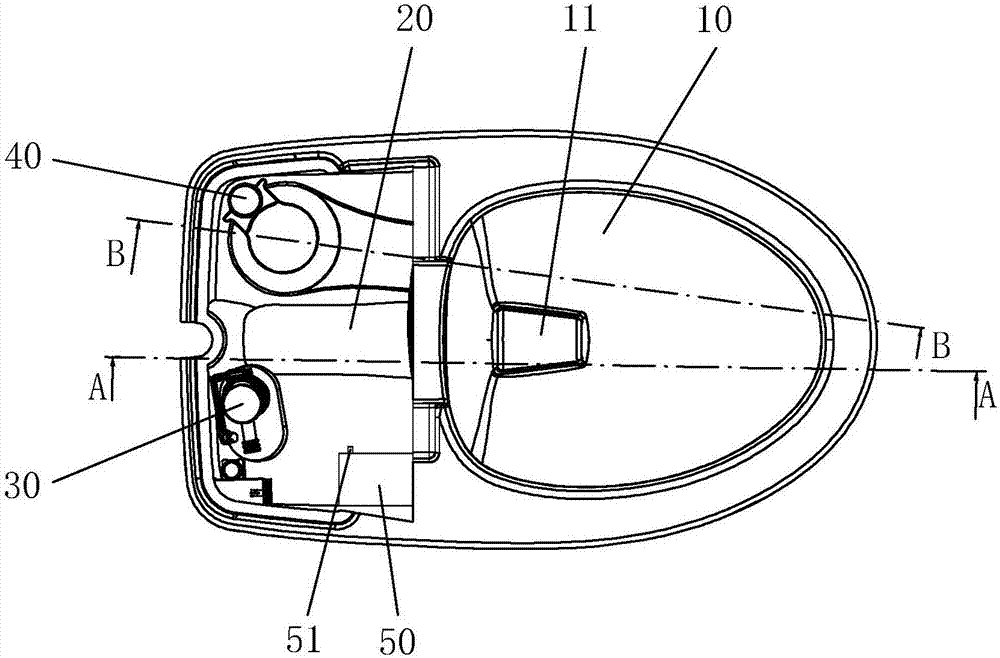

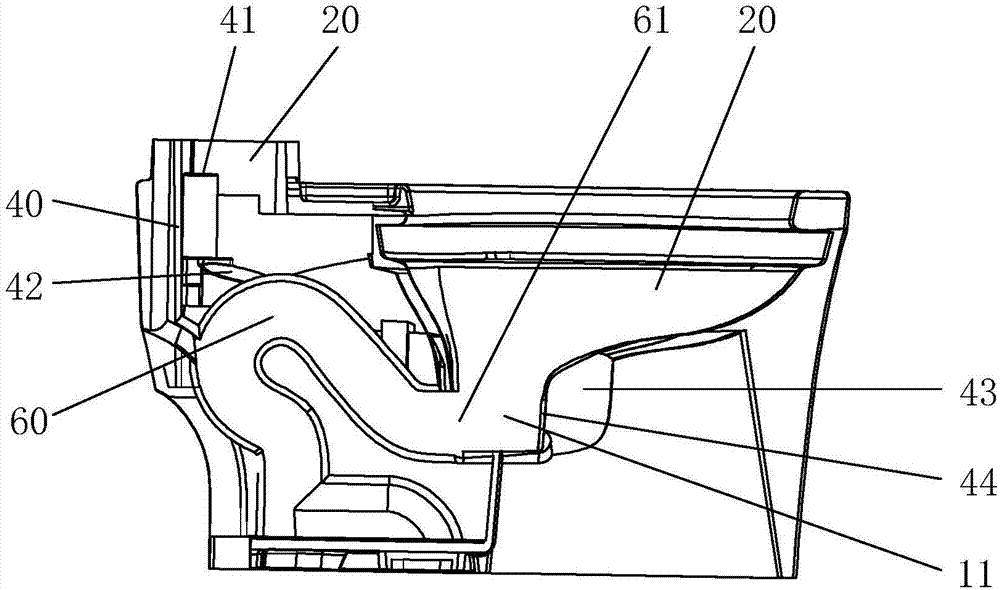

Low-pressure flushing system for intelligent toilet bowl

InactiveCN107130669AOutstanding and Beneficial Technical EffectsRinse thoroughlyFlushing devicesLavatory sanitoryWater sourceSprayer

The invention belongs to the technical field of toilet bowls, and relates to a low-pressure flushing system for an intelligent toilet bowl. The low-pressure flushing system comprises a close-stool with a water tank, a water inlet component and a water outlet component are mounted in the water tank, a flushing tank is arranged at the upper edge of the close-stool, an outlet of the flushing tank is positioned on the inner surface of the upper edge of the close-stool, a water inlet of the flushing tank is positioned in the water tank or on the rear outer surface of the close-stool, a water pump is mounted in the water tank, a water outlet of the water pump is connected with a flushing sprayer, the flushing sprayer is positioned in the outlet of the flushing tank at the upper edge of the close-stool, a water inlet of the water pump is communicated with an inner cavity of the water tank through a guide pipe or connected with a guide pipe which can be externally connected with a water source, or the water outlet of the water pump is connected with the water inlet of the flushing tank, and a flushing port is formed in the outlet of the flushing tank. The low-pressure flushing system has the advantages that tap water or low-pressure water in the water tank is pressurized by the water pump and then performs thorough high-pressure flushing on the inner wall of the close-stool, and the low-pressure flushing system is applicable to high-grade, medium-grade and low-grade toilet bowls.

Owner:浙江星星便洁宝有限公司

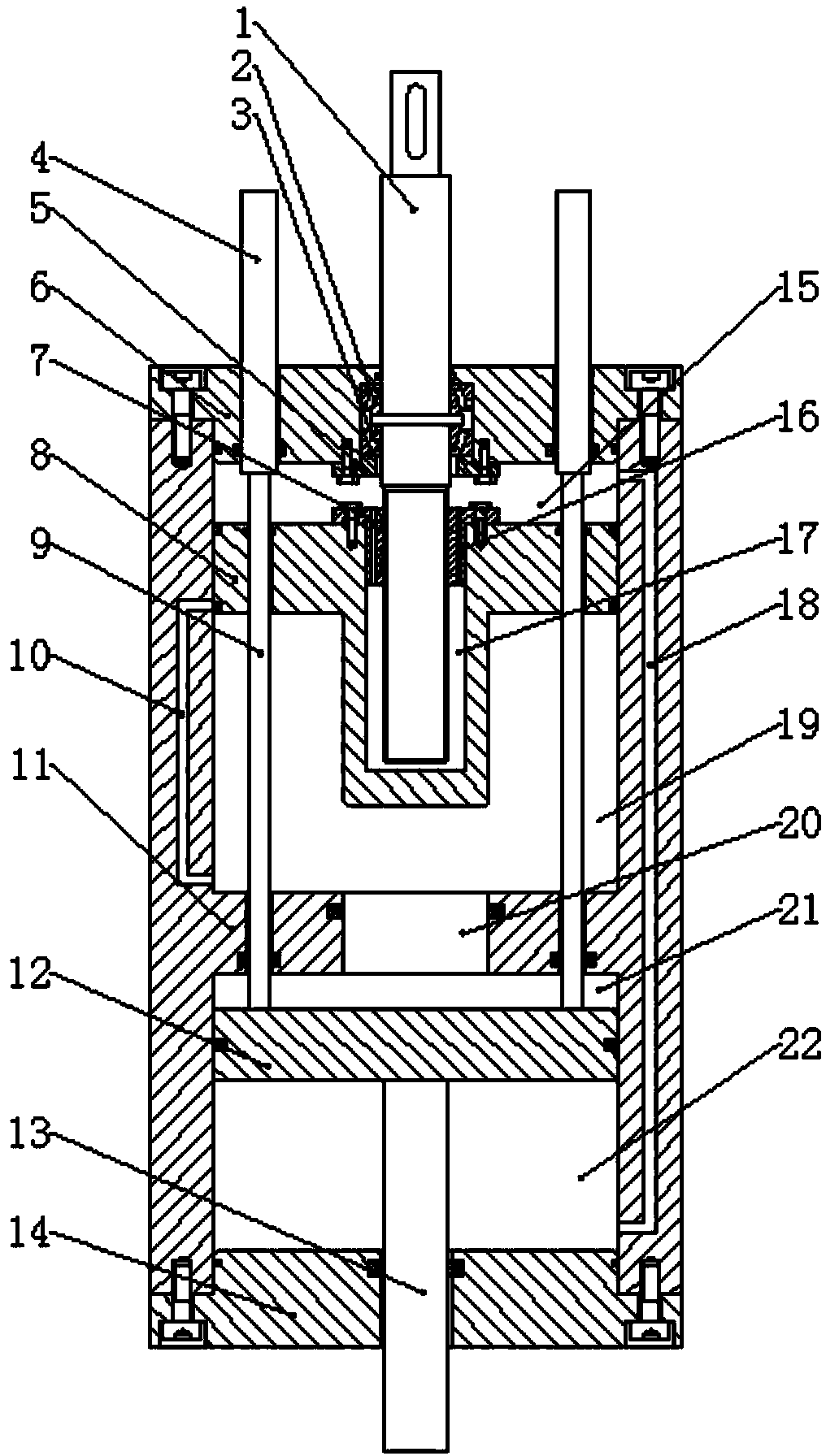

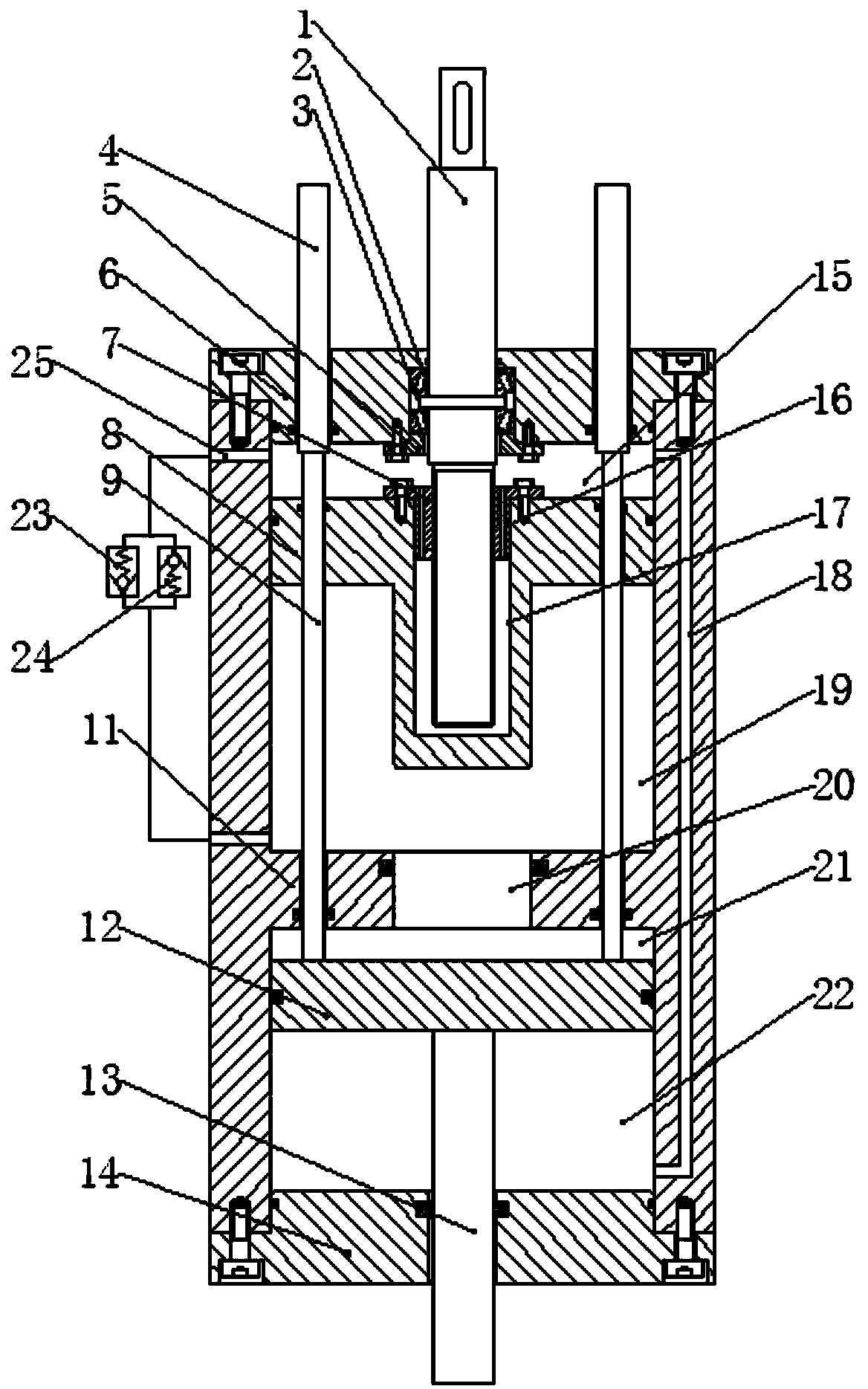

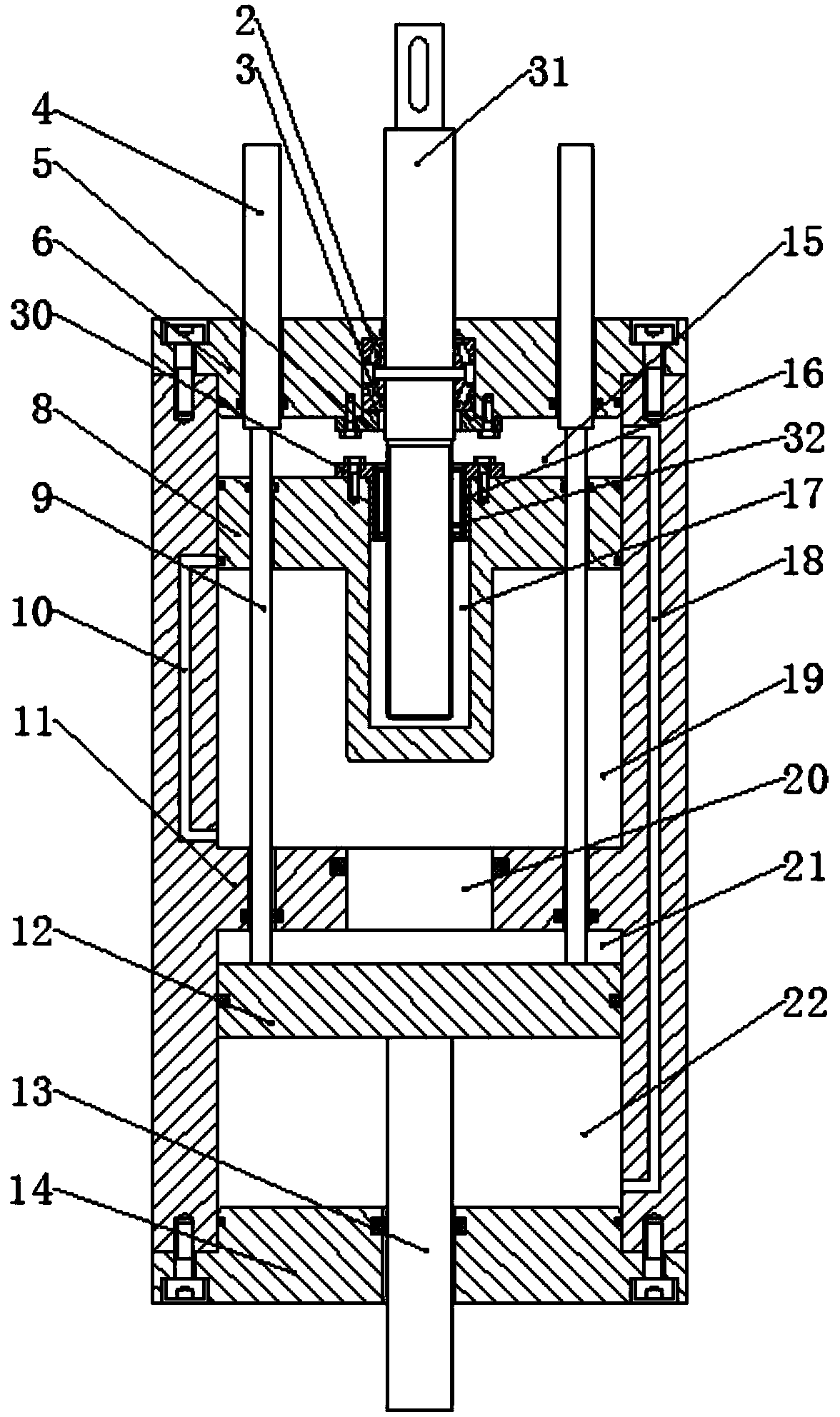

Electric boosting hydraulic cylinder and boosting method thereof

InactiveCN103850994ASimple structureSmall footprintFluid-pressure convertersHydraulic cylinderMultiple forms

The invention discloses an electric boosting hydraulic cylinder and a boosting method thereof. A first thickened piston is arranged in the upper chamber of a cylinder body; a second piston is arranged in lower chamber of the cylinder body; a ball screw nut on the lower part of a ball screw is connected integrally with the first thickened piston; a servo motor is connected outside the upper part of the ball screw; a piston rod is connected below the second piston; the piston rod extends out of the cylinder by passing through the bottom of the cylinder; the piston rod is used for applying force outwards during working of the hydraulic cylinder; the second piston is connected more than two pull rods; each pull rod passes through the cylinder body and the first thickened piston, and is connected with the lower ends of filling rods; the upper ends of the filling rods pass through a cylinder cover; the total sectional area of more than two filling rods is equal to the sectional area of the piston rod; the sectional area of the second piston is larger than the sectional area of the piston rod of the first thickened piston. Hydraulic boosting is realized, the structure is simple, complex pumps, valves and the like are not needed, convenience is brought to maintenance, and a better working effect can be achieved by improving in a plurality of forms.

Owner:XI AN JIAOTONG UNIV

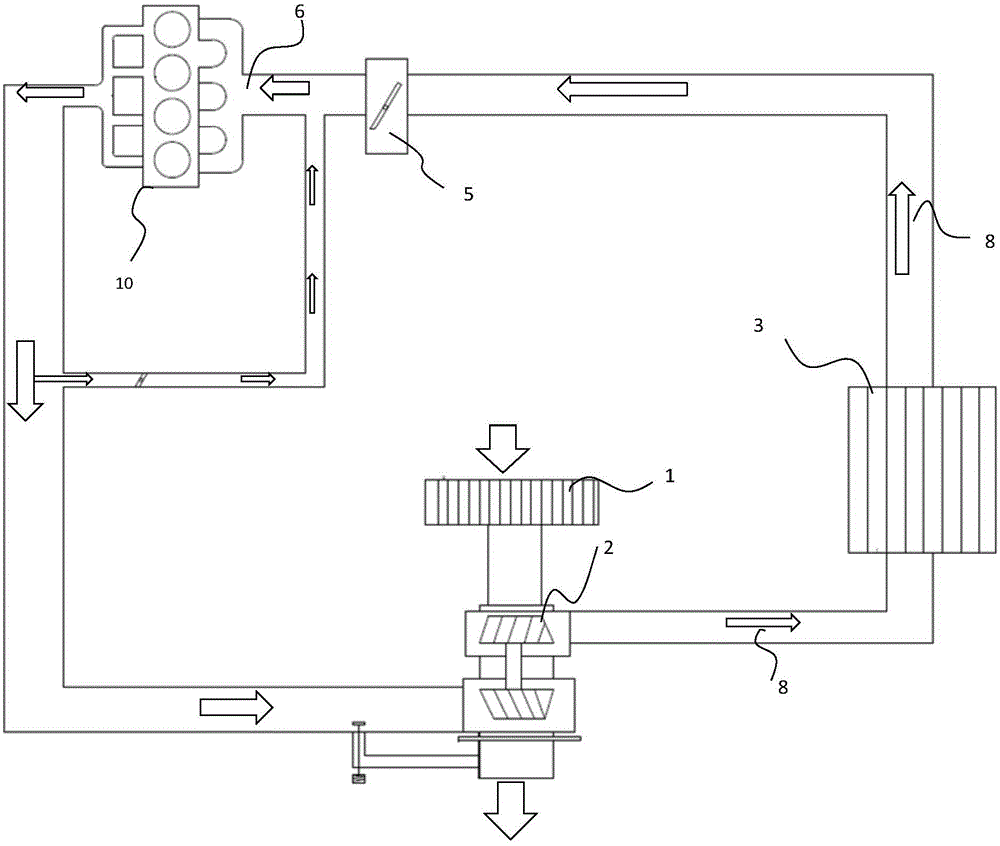

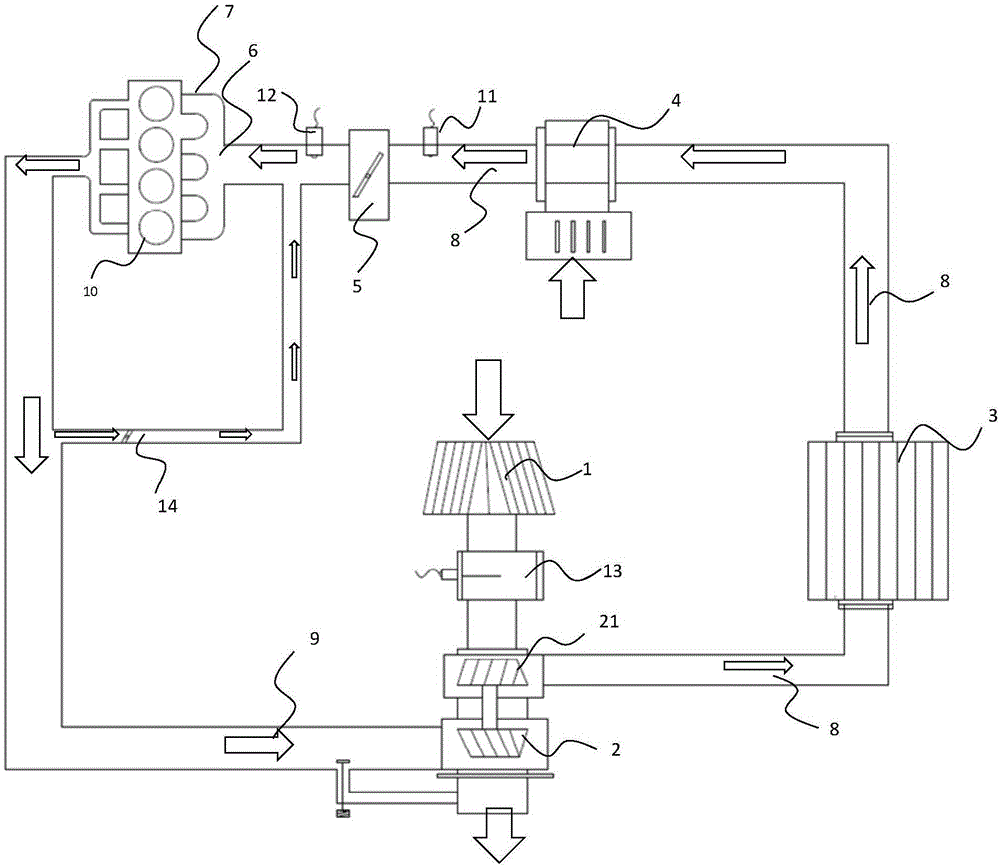

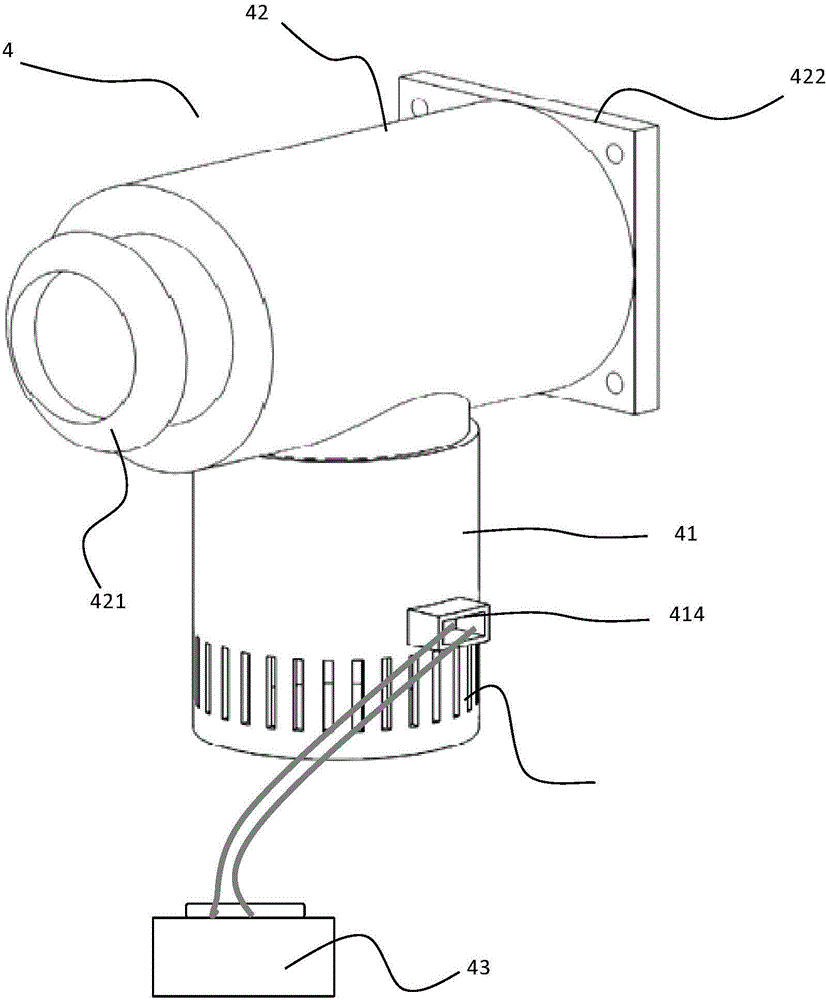

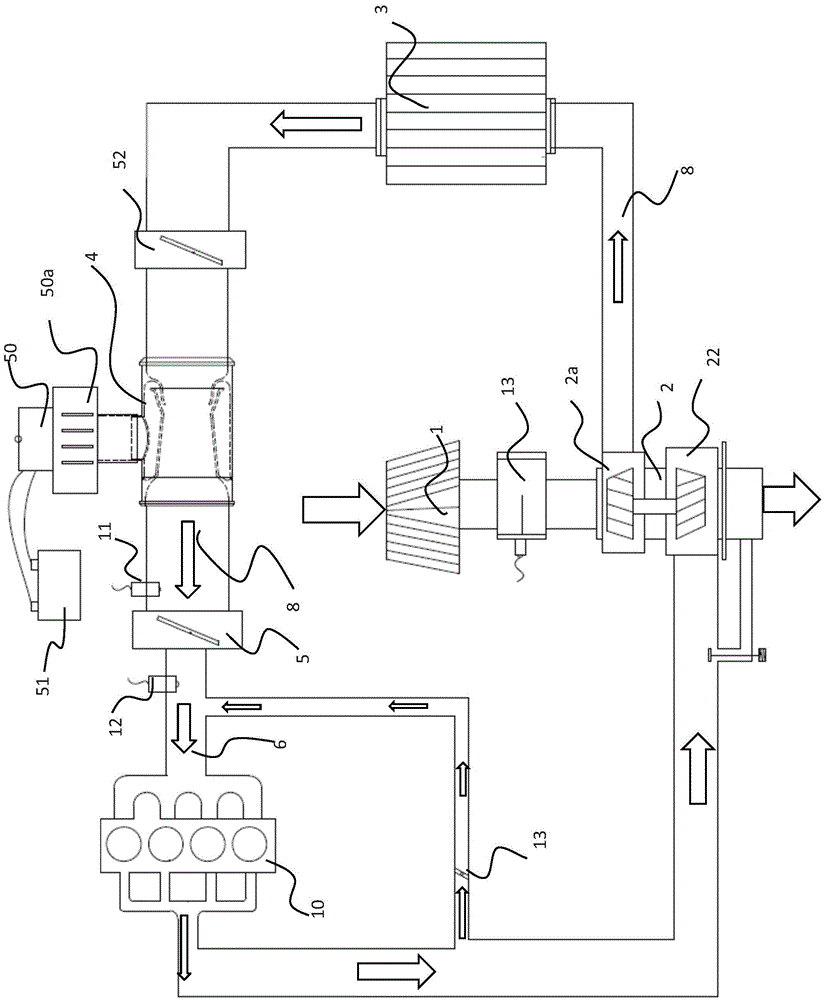

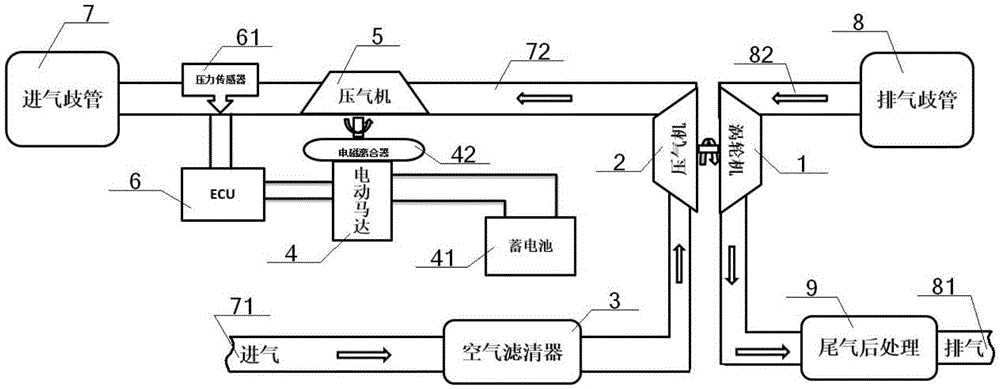

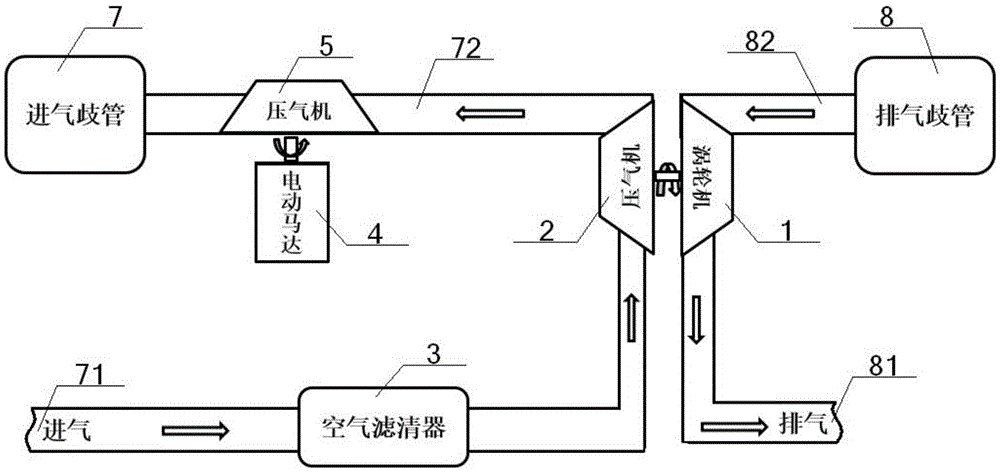

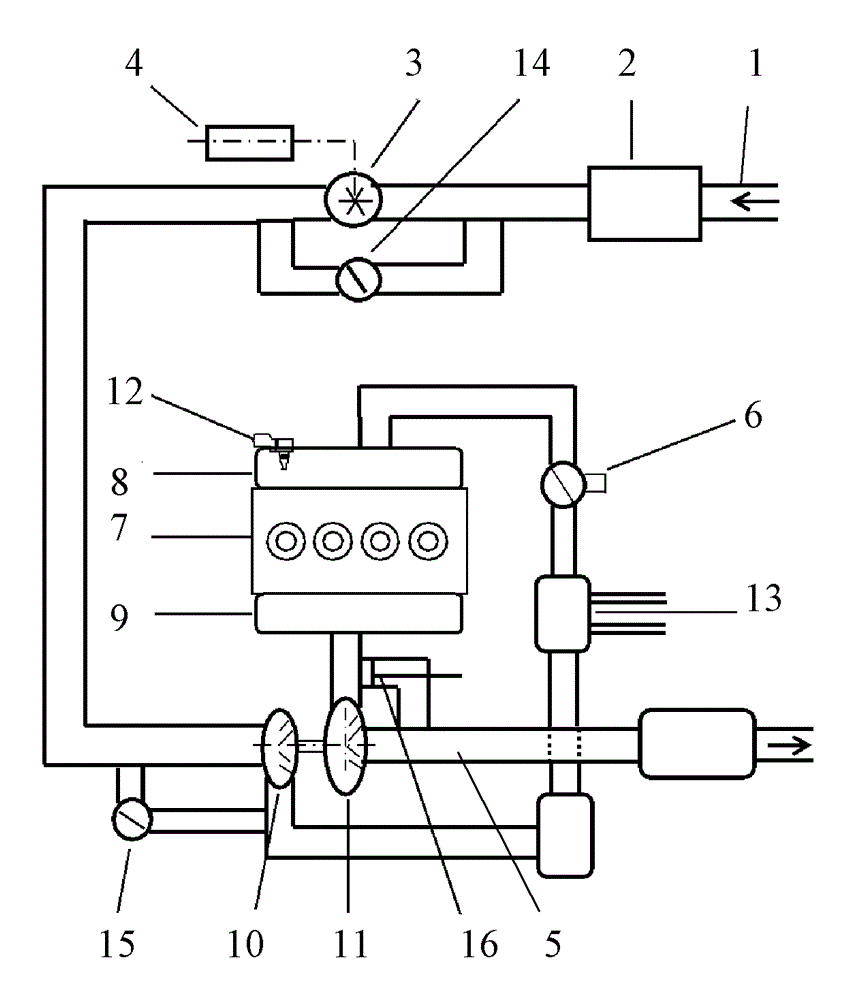

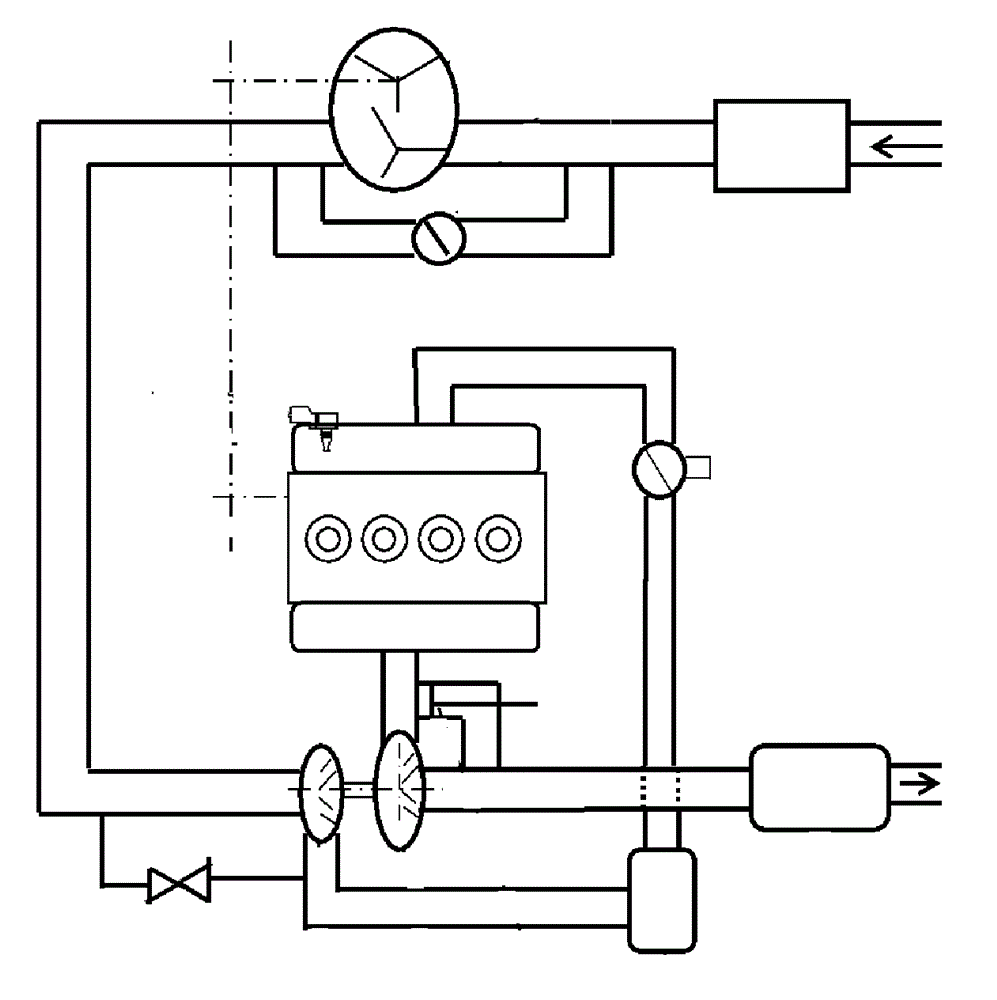

Electric auxiliary pressurization system and application method thereof

InactiveCN105626237AReduce distractionsSolve the hysteresis problemInternal combustion piston enginesAir intakes for fuelHysteresisImpeller

An electric auxiliary pressurization system comprises a waste gas turbine motor, a waste gas compressor, an air filter, an electric motor and an auxiliary gas compressor. The output end of the electric motor is connected with a drive shaft of an impeller in the auxiliary gas compressor. One end of the air filter communicates with an air inlet, and the other end of the air filter sequentially passes through the waste gas compressor and an impeller gas flue in the auxiliary gas compressor to communicate with an intake manifold. An impeller in the waste gas compressor is coaxially connected with a turbine in the waste gas turbine motor. The two ends of the waste gas turbine motor communicate with an exhaust manifold and a waste gas outlet. During using, the electric motor drives the auxiliary gas compressor firstly to provide compressed air for an engine, the waste gas turbine motor and the waste gas compressor can work accordingly, and when the output of the engine is larger and larger, electric pressurization gradually retreats till waste gas turbine pressurization completely replaces electric pressurization. According to the electric auxiliary pressurization system, the problem of hysteresis of an exhaust gas turbocharger can be solved, the pressurization effect is good, precision is relatively high, and the installing difficulty is relatively low.

Owner:DONGFENG COMML VEHICLE CO LTD

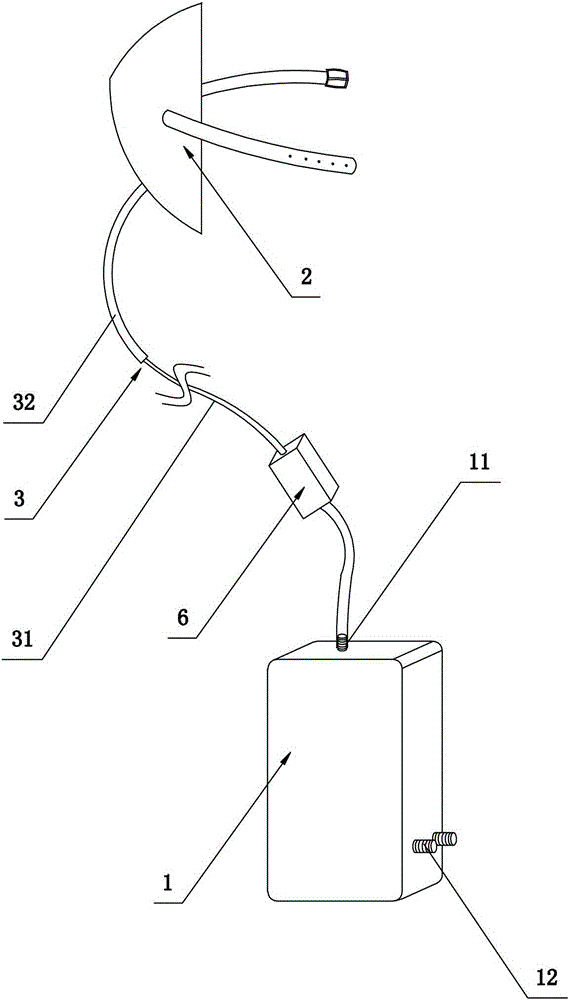

Breathing device capable of being used in plateau

ActiveCN105288889AReduce altitude sickness symptomsReduces chances of altitude sickness symptomsFire rescueRespiratory apparatusEngineeringPlateau

The invention discloses a breathing device capable of being used in plateau. The breathing device comprises an air conveying mechanism capable of generating compressed air through body actions, and a closed breathing mask, wherein the air conveying mechanism and the closed breathing mask are communicated through an air guide component; a one-way air guide component with an exhaust direction from the air conveying mechanism to the closed breathing mask is mounted in the air guide component; and the closed breathing mask is provided with an expiration back pressure adjusting mechanism for adjusting the pressure of air in the closed breathing mask. After users absorb air exhausted by the one-way air guide component, the air only can be exhaled through the expiration back pressure adjusting mechanism; when the pressure of the expiration back pressure adjusting mechanism is increased, the expiration pressure of the users is also increased, so that the probability of the users generating the altitude stress symptoms can be reduced; and as the air entering the closed breathing mask is generated through own sports of the users, the users can hike outdoors in plateau areas for a long time.

Owner:聊城约取知识产权运营有限公司

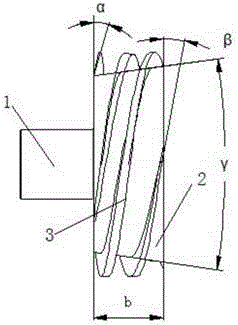

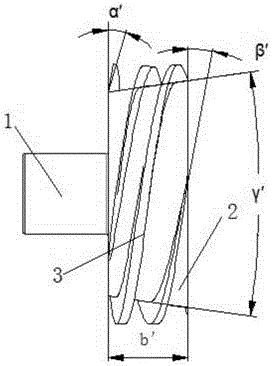

High-lift helical-blade impeller

InactiveCN104832454AIncreased capacity for media with high air contentSolve the problem of low capacity of high gas content mediaPump componentsPumpsHelical scanImpeller

The invention relates to a high-lift helical-blade impeller which comprises a pump shaft sleeve, an impeller ring and a blade. The impeller ring is arranged at the end portion of the pump shaft sleeve, and the impeller ring is provided with the blade; the blade is in a helical shape; the spiral wrap angle of the blade is 200-220 degrees; the entrance installation angel of the blade is 10-12 degrees; the exit installation angel of the blade is 14-18 degrees; the impeller ring is of a cone shape; the cone angle of the impeller ring is 6-10 degrees; the width of the impeller ring is 40-52 mm; and the impeller ring is uniformly provided with a plurality of keyholes. The high-lift helical-blade impeller improves delivery capacity of a pump in transmitting a high gas content medium.

Owner:江苏永一泵业科技集团有限公司

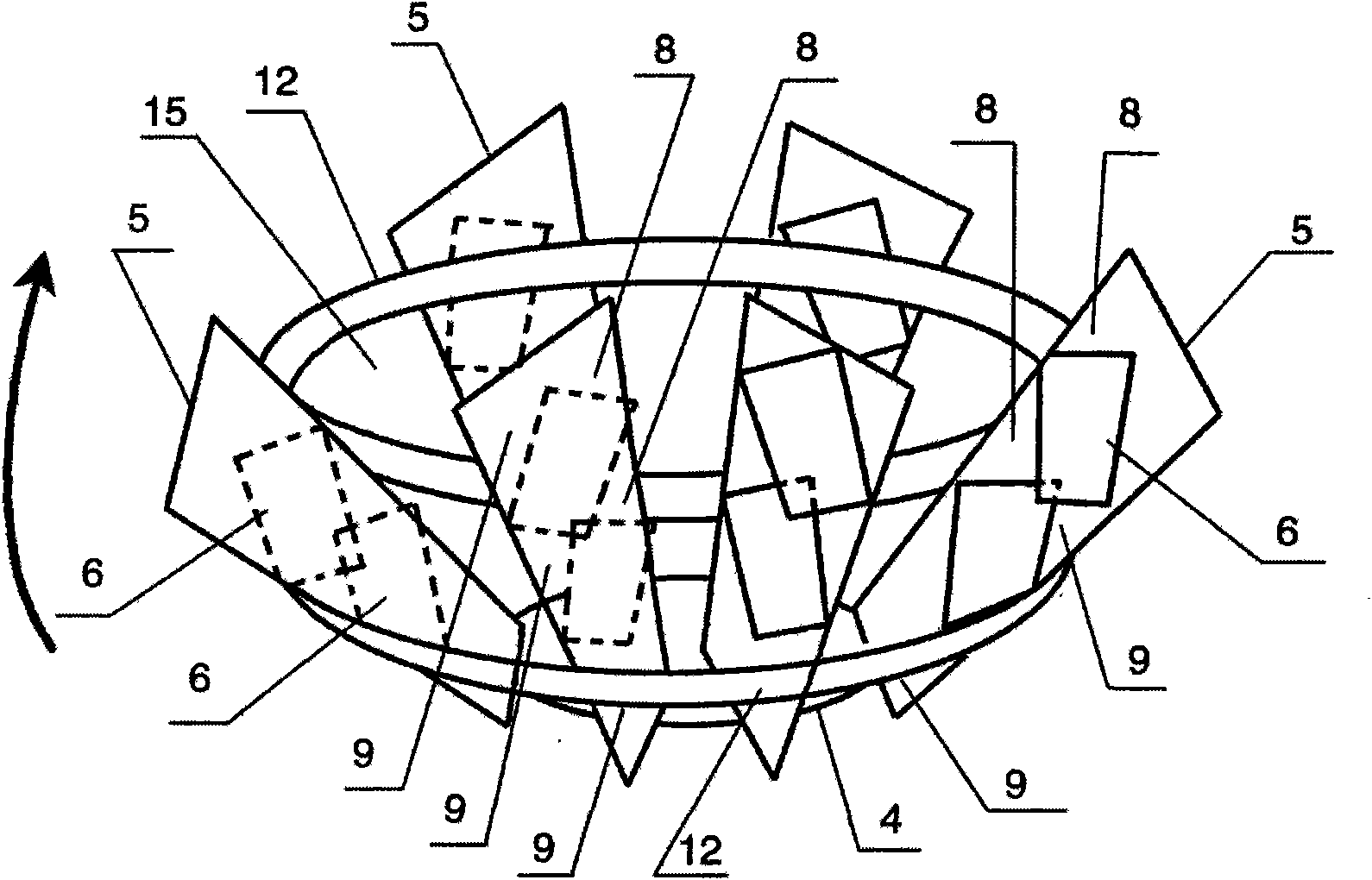

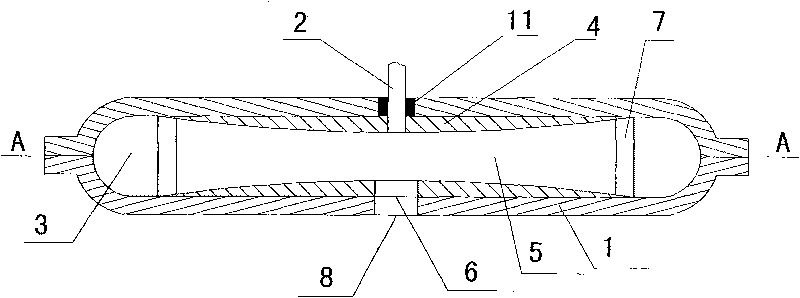

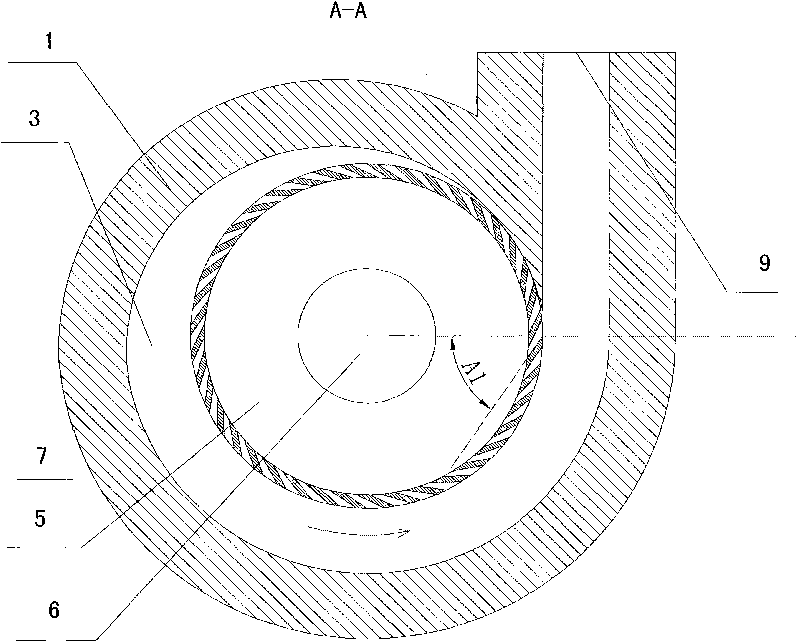

Multifunctional synchronous after flow ventilating compressor

InactiveCN101566164AImprove suction and dischargeReduce the number of seriesPump componentsAxial flow pumpsImpellerResource saving

The invention discloses a multifunctional synchronous after flow ventilating compressor, which comprises a shell, an air inlet of the shell, an air outlet of the shell, an impeller, impeller blades, an airflow channel inside the impeller and a blisk of the impeller. The compressor is characterized in that the axial front sides of the impeller blades gradually axially tilt along the radial direction of the impeller from front to back towards the radial direction of an impeller; the axial back sides of the impeller blades gradually axially tilt along the radial direction of the impeller from front to back towards the axial direction of the impeller; the axial front side of the impeller gradually axially tilts along the radial direction of the impeller from front to back towards the axial direction of the impeller; the axial direction back side of the impeller gradually axially tilts along the radial direction of the impeller from front to back towards the axial direction of the impeller; and the airflow channel inside the impeller gradually axially tilts from front to back along the radial direction of the impeller. Compared with the prior art, the compressor has the advantages of simple structure, small volume, few materials, light weight, convenient transportation and mounting, resources saving, good pressurized effect, high efficiency, energy saving, low noise, favorability for environment protection and the like.

Owner:林钧浩

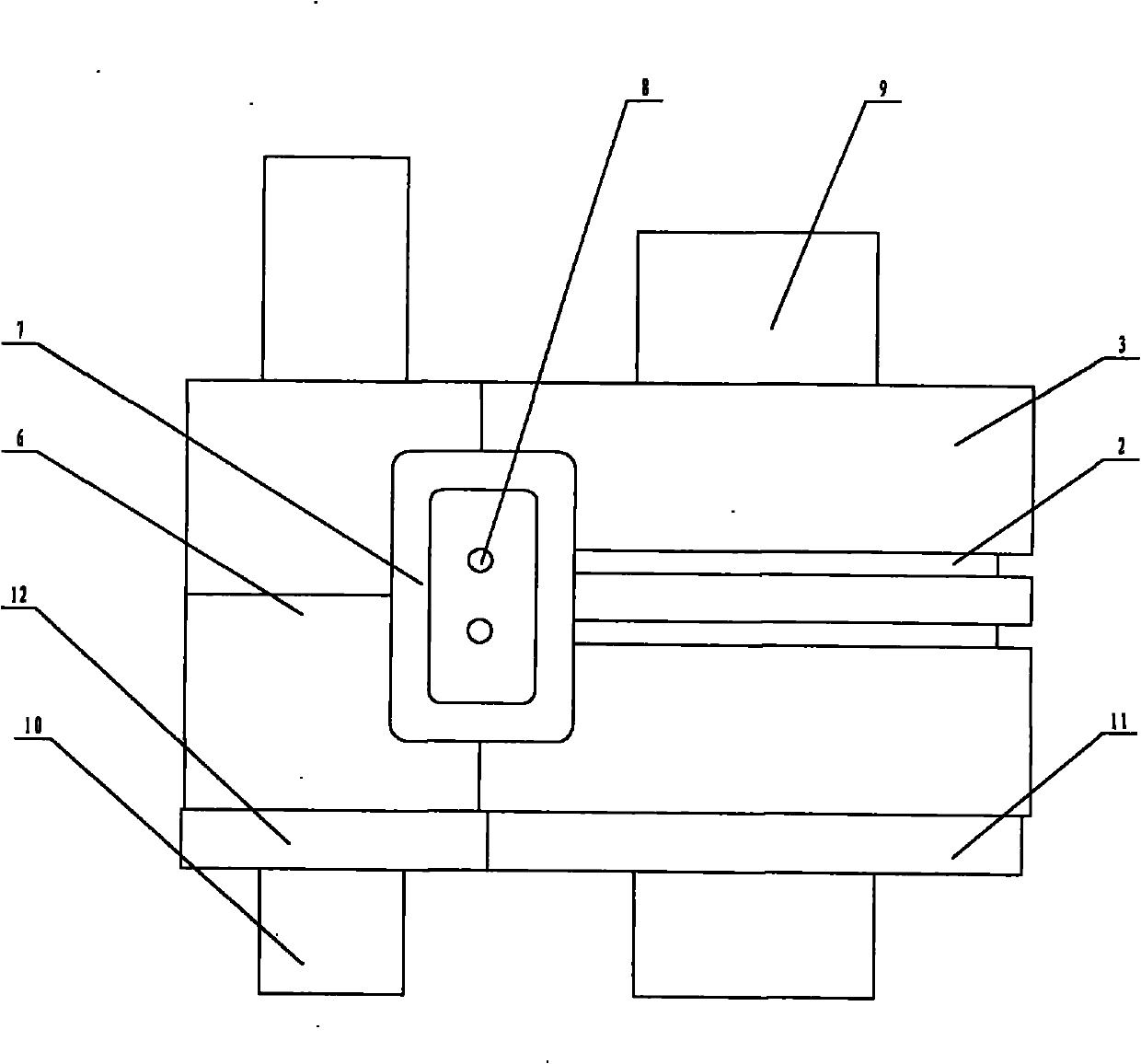

Continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials

InactiveCN101905241AEasy to formGuarantee the balance of extrusion forceExtrusion profiling toolsMetal rolling arrangementsDrive shaftAlloy

The invention relates to a continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials, solving the problem that the traditional machining and molding device of Al-Mg alloy and the composite materials has lower performance of section bars due to the structural imperfection. A driven shaft is arranged on a stand, a casting roller is arranged on the driven shaft, the roller surface at the lower part of the casting roller is in transitional fit with the upper surfaces of a squeezing seat and a groove sealing block, a crystallizer is arranged above the casting roller and an extruding roller, a crystallizing hole is arranged on the crystallizer, the lower end of the crystallizing hole is positioned above the contact part between the casting roller and the extruding roller, the lower surface of the crystallizer is in transitional fit with the roller surfaces of the casting roller and the extruding roller, and a rotatable driving mechanism is respectively arranged on a driving shaft and the driven shaft. The invention greatly improves the performance of the section bars by additionally arranging the casting roller and the crystallizer, ensures that the section bars are possible to be made to meet the requirements for high-precision thin walls with ultra thinness and ultra length and simultaneously has the advantages of simple structure, convenient operation and low cost.

Owner:山西奥铭科技有限公司

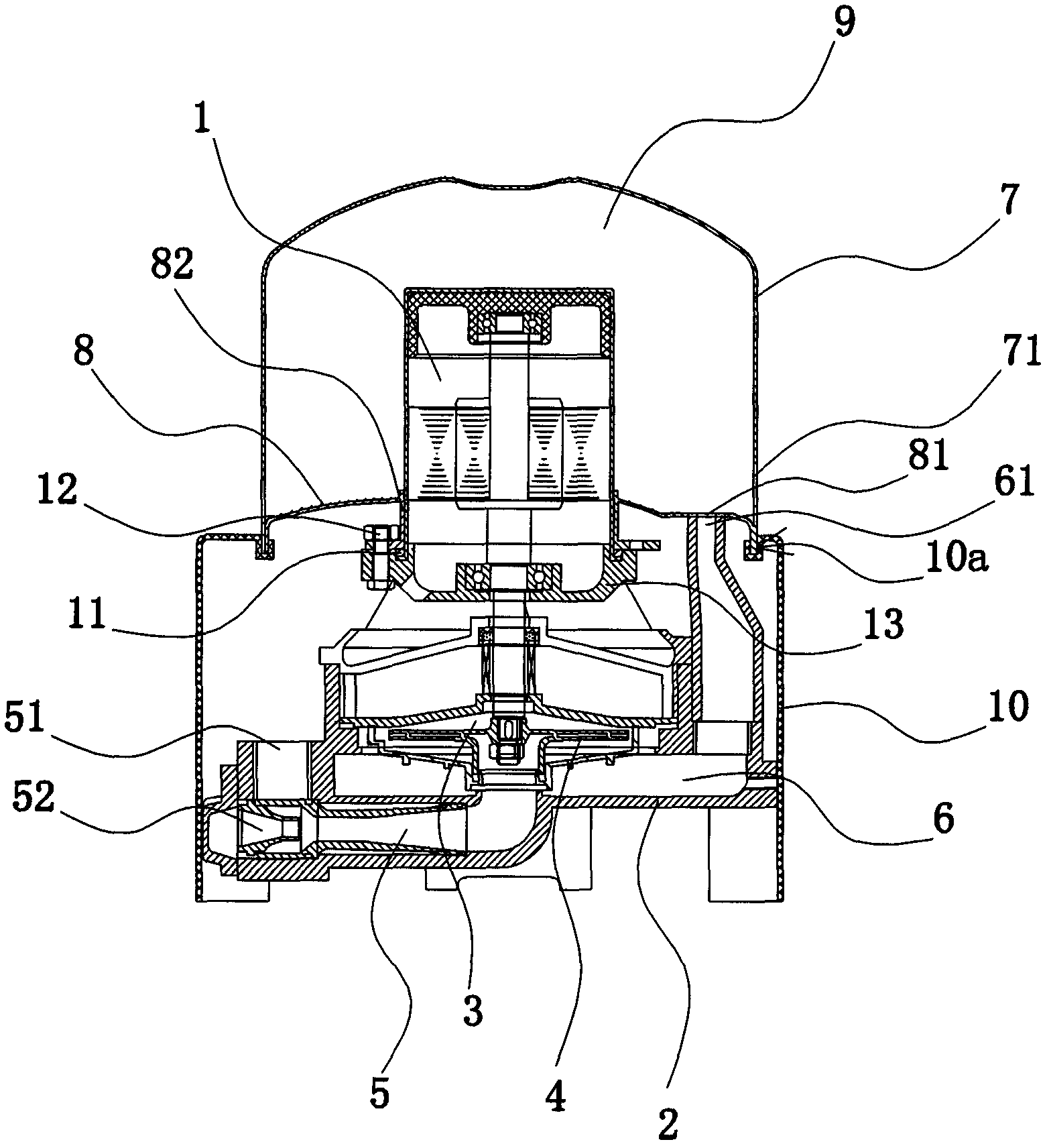

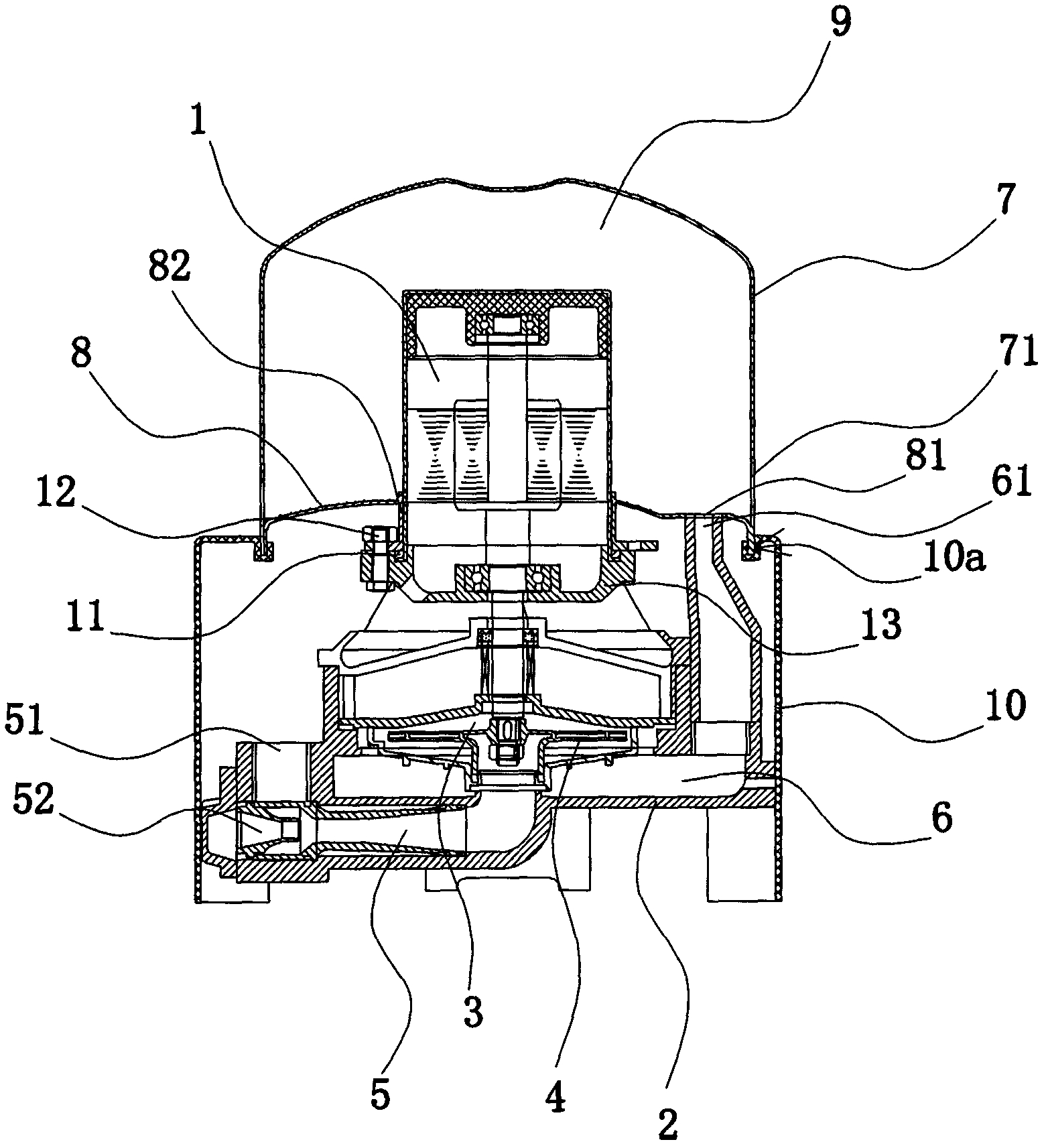

Novel water pump

InactiveCN102635557AImprove cooling effectSave waterPump componentsPump installationsImpellerInlet channel

The invention provides a novel water pump and belongs to the technical field of machinery. According to the invention, the problem of an unsatisfactory motor cooling effect in the existing water pump is solved. The novel water pump comprises a motor and a pump body with a pump cavity; the pump body is provided with a water inlet channel and a water outlet channel which are communicated with the pump cavity; an impeller is arranged in the pump cavity; the output shaft of the motor extends into the pump cavity, and the impeller is fixedly connected to the output shaft of the motor; the water pump also comprises a cylindrical pressure tank with an opening at one end; the opening is in sealed connection with a sealing cover; the sealing cover is in sealed connection with the end, close to the output shaft, of the motor shell; the entire motor penetrates through the sealing cover, and the rear end of the entire motor is located in a cavity formed by the inner side wall of the pressure tank, the sealing cover and the motor shell wall; a through hole is arranged on the sealing cover; the water outlet channel is communicated with the cavity via the through hole; and a water outlet hole communicated with the cavity is arranged on the side wall of the pressure tank. The novel water pump provided by the invention has the advantages of good cooling effect, convenience in carrying and beautiful appearance.

Owner:TAIZHOU YANGCHUN ELECTRIC MOTOR

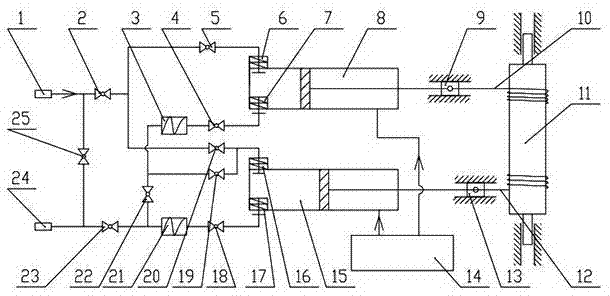

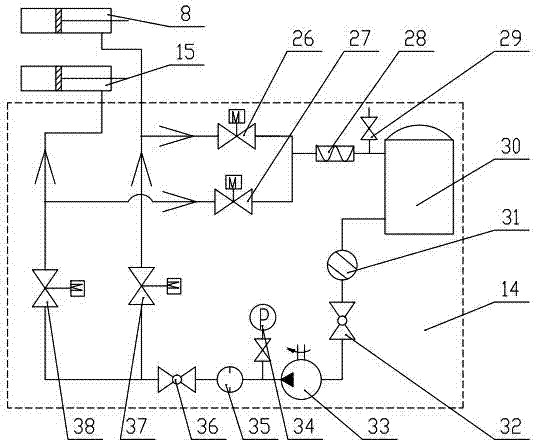

Pressurization and mixed transportation process and device of gas field well station

InactiveCN104500362ASupercharge effect is goodHigh mixing efficiencyFluid-pressure convertersPipeline systemsHydraulic cylinderReciprocating motion

The invention relates to a process and a device for performing the pressurization and the mixed transportation for natural gas in a gas field well station, and solves the problems of weak adaptability to variable working conditions, limited adjusting capacity and low mixed transportation efficiency in a traditional gas field natural gas compressor. A hydraulic cylinder A and a hydraulic cylinder B alternately pump in hydraulic oil under the control of a hydraulic working station to push a piston to move; with a steel wire rope A and a steel wire rope B, when any one of the hydraulic cylinders advances, the other one of the hydraulic cylinders can return, so that alternate reciprocating motion is realized; the hydraulic cylinder A and the hydraulic cylinder B not only can realize series connection operation, but also can realize parallel connecting operation; and the pressurization and the outward transportation of gas and liquid two-phase flows can be realized by continuous reciprocating motion of the hydraulic cylinder A and the hydraulic cylinder B under combined actions of a one-way valve A, a one-way valve B, a one-way valve C and a one-way valve D. The process and the device have strong adaptability to single wells, good pressurization effect on the gas and liquid two-phase flows and high mixed transportation efficiency, can be flexibly regulated according to the production conditions of single wells administered by a gas gathering station, and save the production cost.

Owner:CHENGDU TINGYUAN TECH

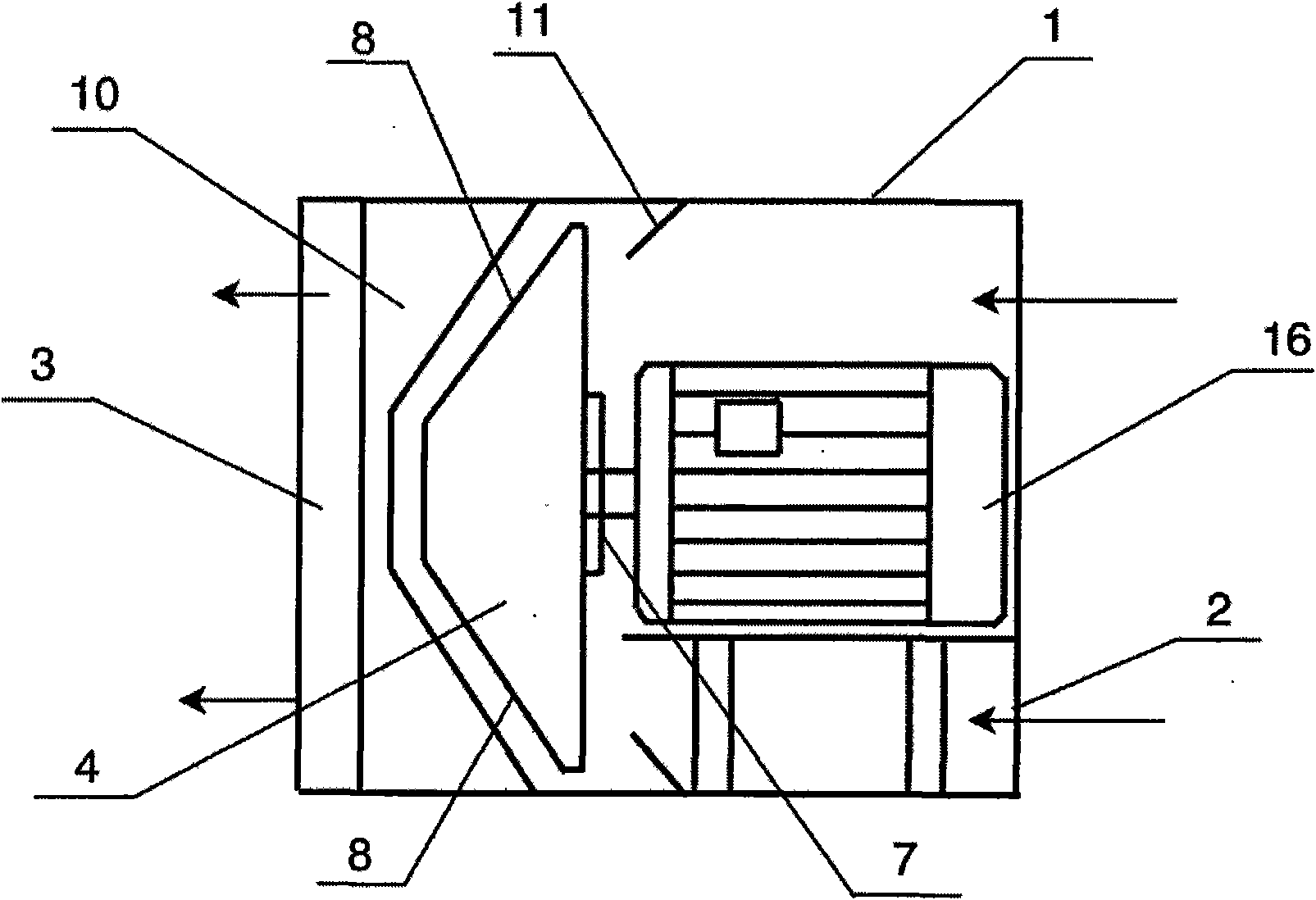

Engine air intake system and vehicle

InactiveCN104595011AIncreased torque outputIncrease air densityInternal combustion piston enginesAir intakes for fuelElectricityTurbocharger

The invention relates to an engine air intake system. The engine air intake system comprises an air intake pipe and an air exhaust pipe, the two of which keep in air communication with a cylinder of an engine, and further comprises a filter, a first turbocharger, a loading device, a throttle valve and an engine controller. The filter is arranged in an inlet of the air intake pipe; the first turbocharger is arranged on the air intake pipe; the loading device is electrically connected with the first turbocharger; the throttle valve is arranged on the air intake pipe, and is used for adjusting the flow of air entering the cylinder of the engine; the engine controller keeps communicating with the loading device and the throttle valve; and when the rotating speed of the engine exceeds a first rotating speed value, the engine controller commands the loading device to drive the first turbocharger to operate. The invention further relates to a vehicle provided with the engine air intake system. The engine air intake system has such advantages as compact arrangement and good supercharging effect.

Owner:SAIC GENERAL MOTORS +1

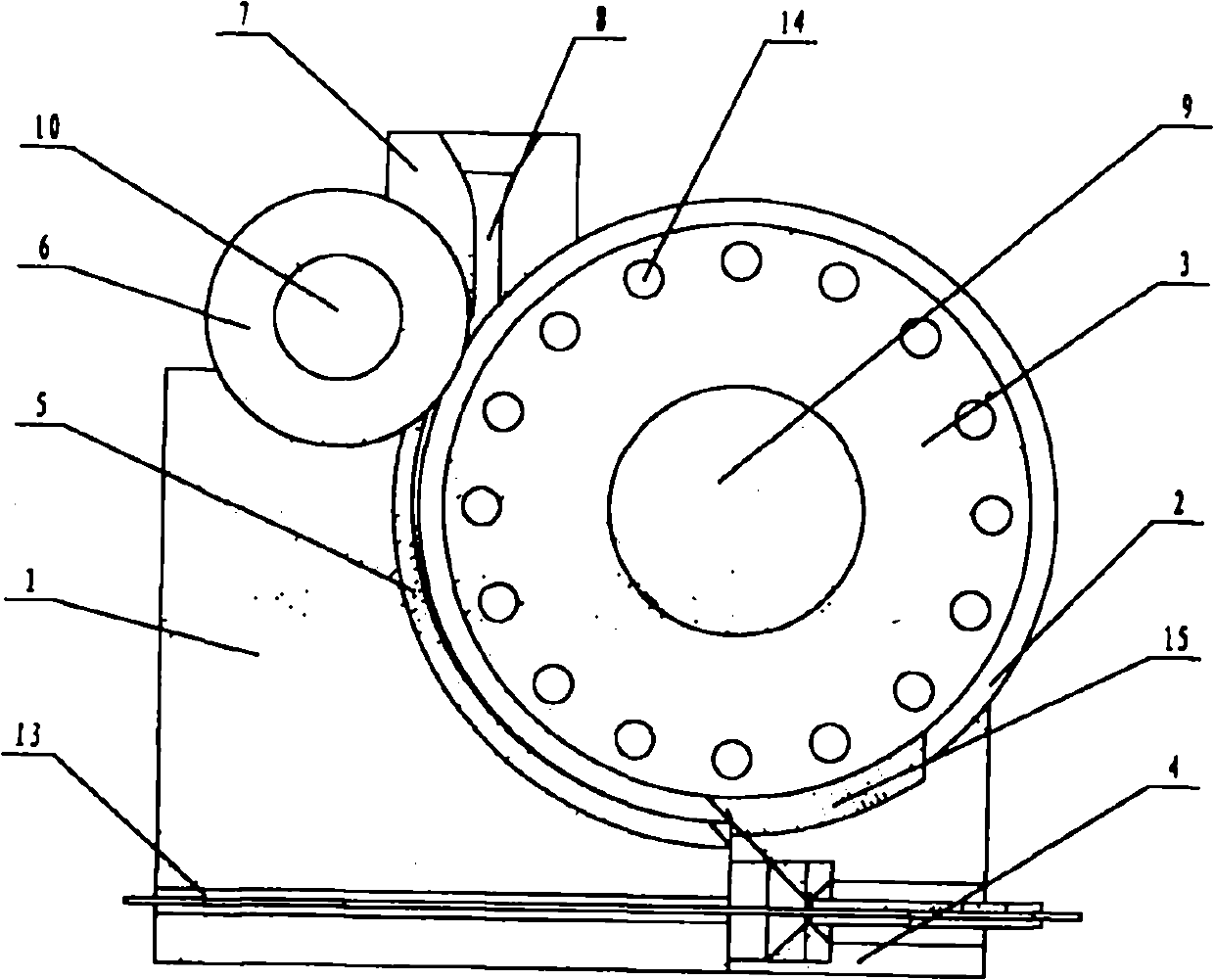

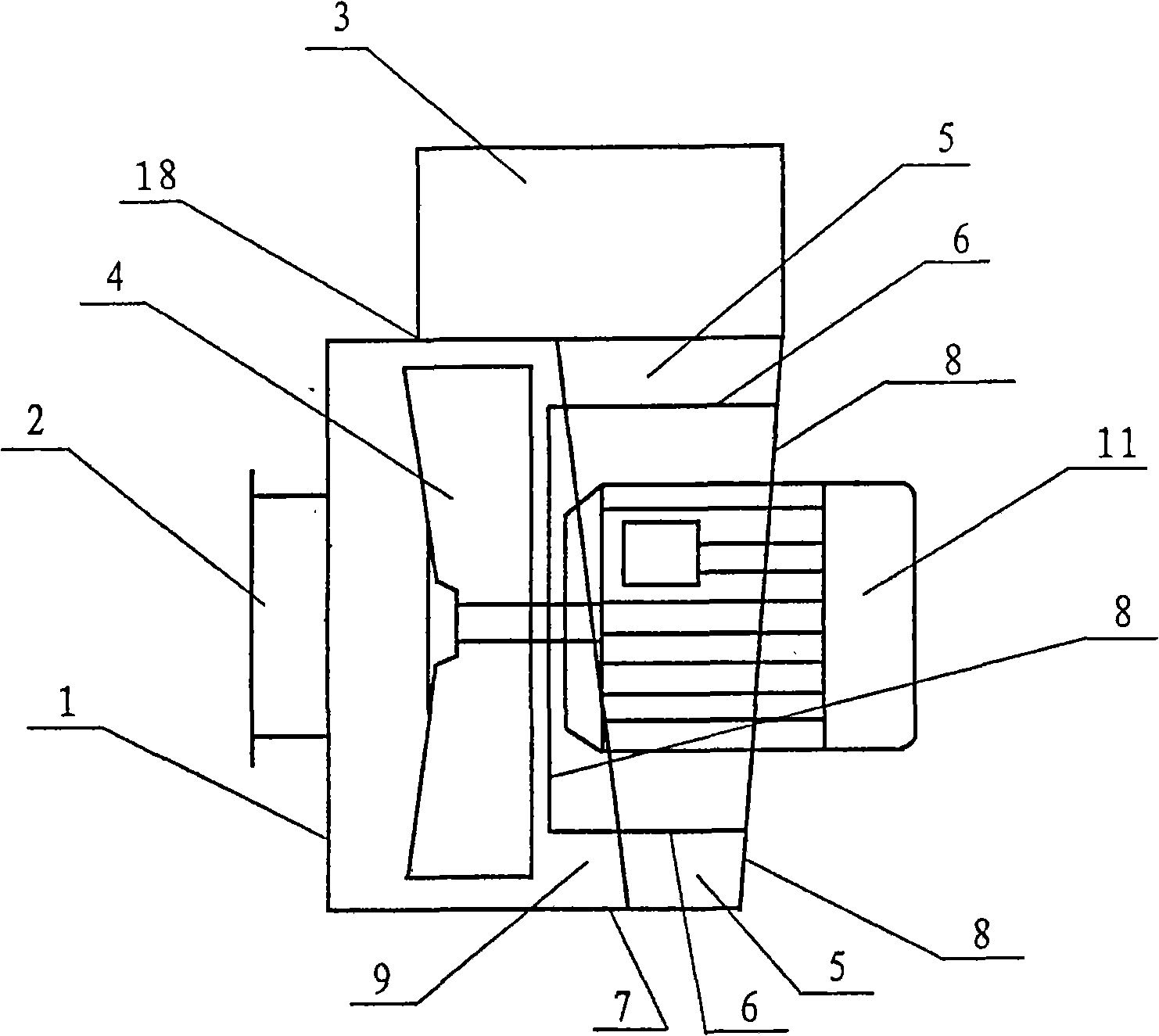

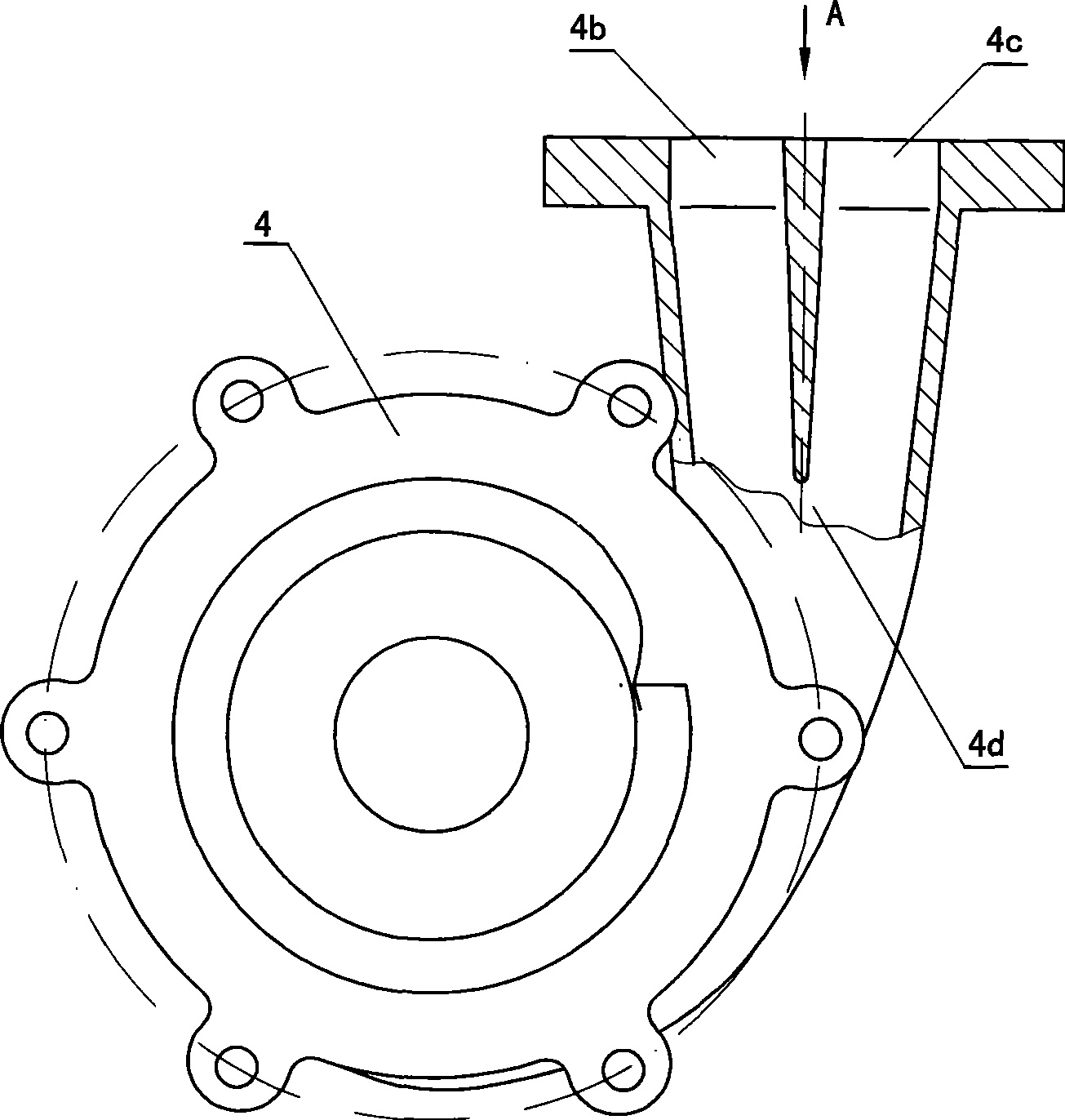

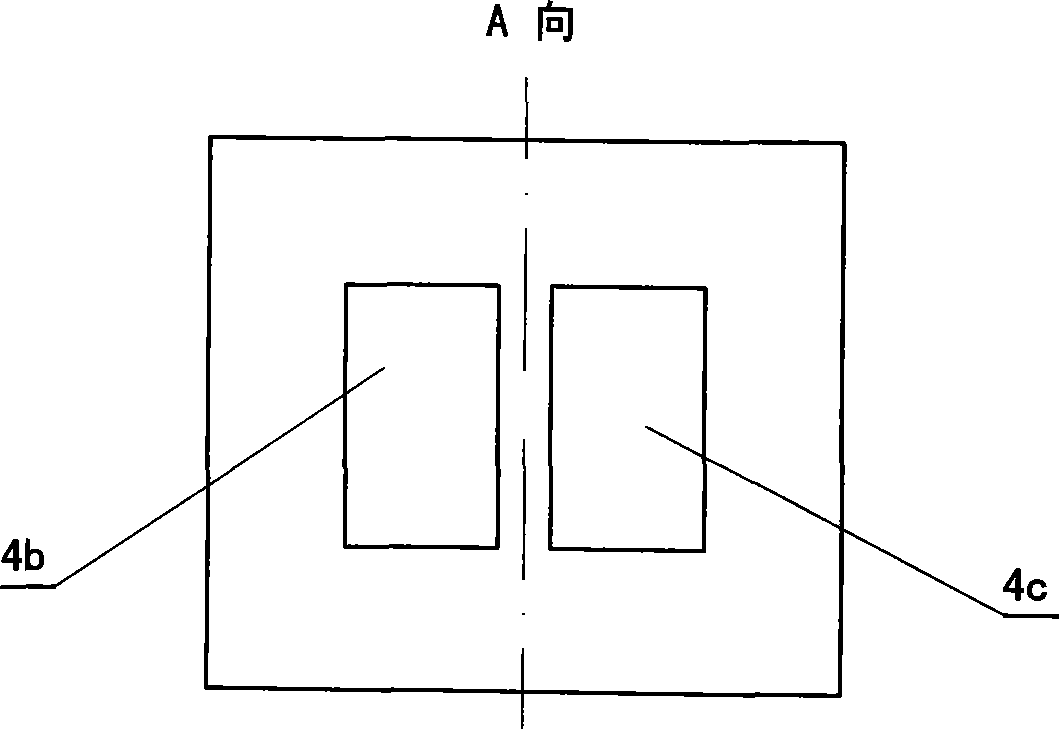

Supercharging type centrifugal blower fan

InactiveCN101280790AReduce wear and tearSupercharge effect is goodPump componentsPumpsImpellerEngineering

The invention discloses a pressurized centrifugal fan which comprises a fan casing, a fan air inlet, a fan air outlet, an impeller and an airflow diffusion channel arranged inside the casing. The pressurized centrifugal fan is characterized in that: the airflow diffusion channel inside the casing is arranged at the axial lateral of the impeller at the radial rear part of the impeller and directly communicated with the air outlet of the fan; the airflow diffusion channel and the air inlet of the fan are respectively arranged at the two axial sides of the impeller; the airflow diffusion channel inside the casing is an annular channel structure shape consisting of three side walls of a radial internal side wall of the casing, a radial external side wall of the casing and an axial side wall of the casing; one axial side wall of the airflow diffusion channel inside the casing, which is faced with the impeller, is provided with an inlet of the airflow diffusion channel inside the casing; the inlet of the airflow diffusion channel inside the casing is an axial type and the outlet of the airflow diffusion channel inside the casing is a radial type; and the air outlet of the fan is a radial type. The pressurized centrifugal fan of the invention has the advantages of great suction, good pressurized effect, high mechanical efficiency, energy saving, being quiet, etc.

Owner:林钧浩

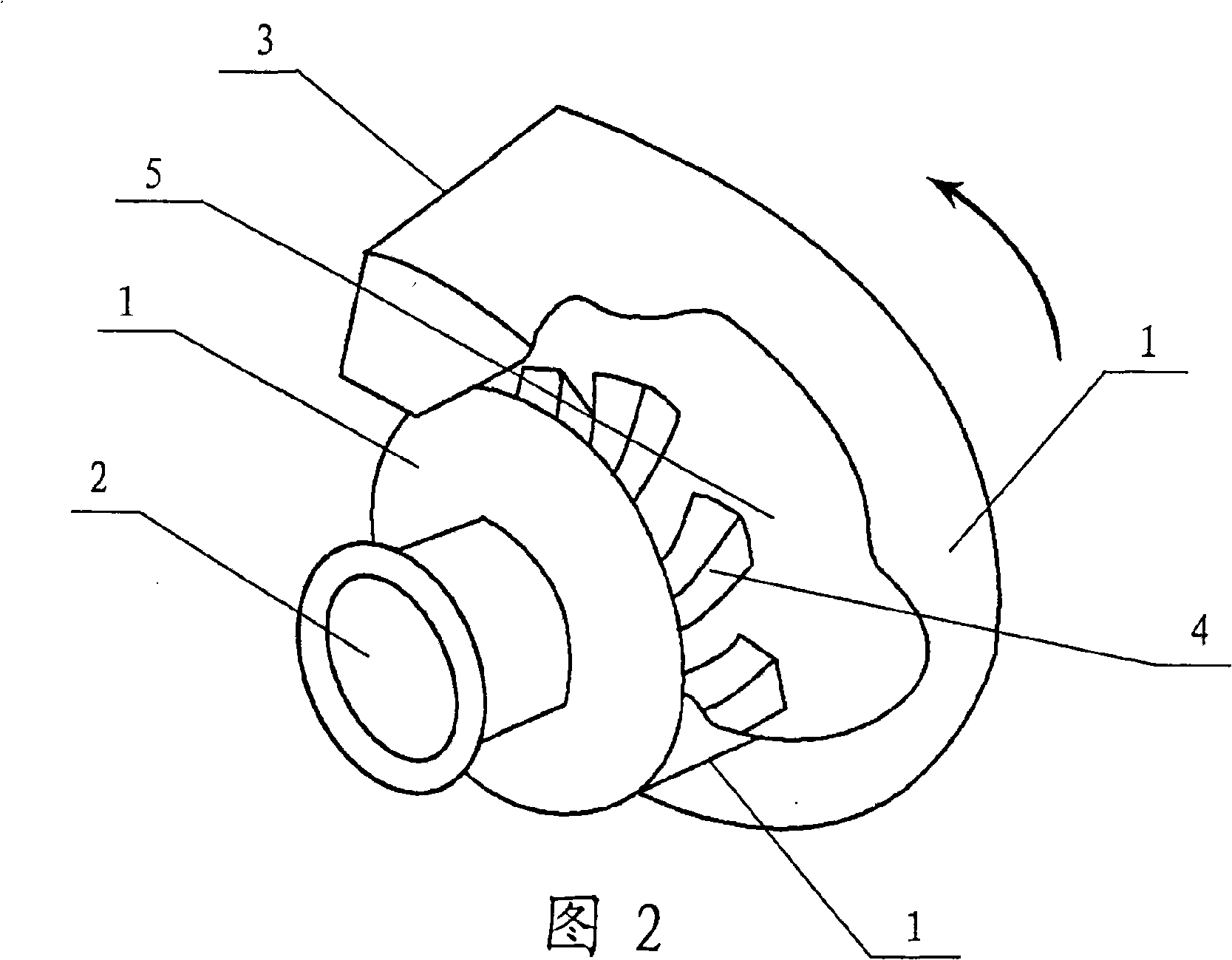

Swirler

InactiveCN101737334AReduce frictionSlow downRadial flow pumpsNon-positive displacement fluid enginesDrive shaftEngineering

The invention provides a swirler. The swirler comprises a shell and a transmission shaft, wherein the transmission shaft is arranged in the shell; at least one swirling wheel is arranged in the shell; the transmission shaft is connected with the swirling wheel; a swirling chamber is arranged in the swirling wheel; the middle part of the swirling chamber is provided with a swirling chamber inlet; the periphery of the swirling chamber is provided with a plurality of guide vanes; and the shell is provided with an inlet. The swirler makes full use of circumferential motion and fluid motion, causes fluid to be automatically sucked into eddy current from an eddy current central region by using the eddy current of which a rotational speed is steadily increased from a center to the periphery, produces a suction force by the center of the eddy current, produces high pressure at the periphery of the eddy current by the eddy current of which the rotational speed is gradually decreased from the center to the periphery, can be widely applied in the fields of fluid pressurizing, delivering and the like, can be used as a water pump, a vacuum pump, air suction equipment, a fan, a compressor and the like, and also can be used as spraying equipment, an atomizer, a reactor and the like.

Owner:陈久斌

Production process of EPP (Expanded Polypropylene) foam plastics

The invention discloses a production process of EPP (Expanded Polypropylene) foam plastics. The production process comprises the following steps: 1) initial expansion: heating raw materials of EPP foam plastics with water vapor to achieve the effect of initial expansion, wherein the heating temperature is 65 DEG C, and heating time is 25 minutes; 2) pressing: a) pre-pressing: applying a pressure of 0.7kg to the initially-expanded EPP foam plastics, wherein pressing time is 25 minutes; b) first pressurization: after the pre-pressing is finished, applying a pressure of 3kg to the EPP foam plastics, wherein the pressing time is 500 minutes. Compared with other production processes, the production process disclosed by the invention has the advantages of low technology price and mature process.The EPP foam plastics are pressurized and deflated twice in the pressing process, thereby making the foam plastics firmer, harder and better in quality. Moreover, no flipping occurs after two times of pressure relief, so that the pressure-applied foam plastics is reversed, and each side is pressed evenly, thereby improving the pressurization effect, reducing internal bubbles and uneven hardness,and meeting the needs of customers.

Owner:苏州勤联塑胶制品有限公司

Screw type water vapor compressor unit and working method

InactiveCN110671326ASupercharge effect is goodEffective coolingRotary/oscillating piston combinations for elastic fluidsRotary/oscillating piston pump componentsSoftened waterWater vapor

The invention relates to a screw type water vapor compressor unit. The screw type water vapor compressor unit comprises a main motor, a screw type compressor, a gas-liquid separator, an oil tank, an oil cooler and a softened water tank; the output end of the main motor is connected with the screw type compressor through a coupling; the gas inlet end of the screw type compressor is connected with avapor inlet pipe; the gas outlet end of the screw type compressor is connected with one end of a vapor outlet pipe; the other end of the vapor outlet pipe communicates with the gas-liquid separator;the lower end of the gas-liquid separator communicates with a main drain and an auxiliary water spraying pipeline. Compared with the original pump body pressurization manner, the screw type compressorhas the higher pressurization capability; the oil way circulation manner is adopted, so that lubricating oil in the compressor is cooled effectively, and meanwhile, the problem of reduction of lubrication efficiency due to the excessively high temperature of the lubricating oil is avoided; metal scraps carried by the lubricating oil after use are reduced by the aid of a coarse oil filter, damageto an oil pump is reduced, meanwhile, filtration is performed again by the aid of a fine oil filter, and damage to the screw type compressor is reduced.

Owner:山东钜容重工科技有限公司

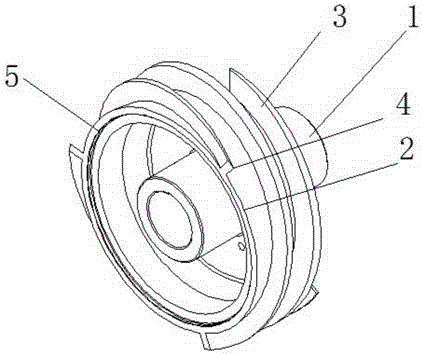

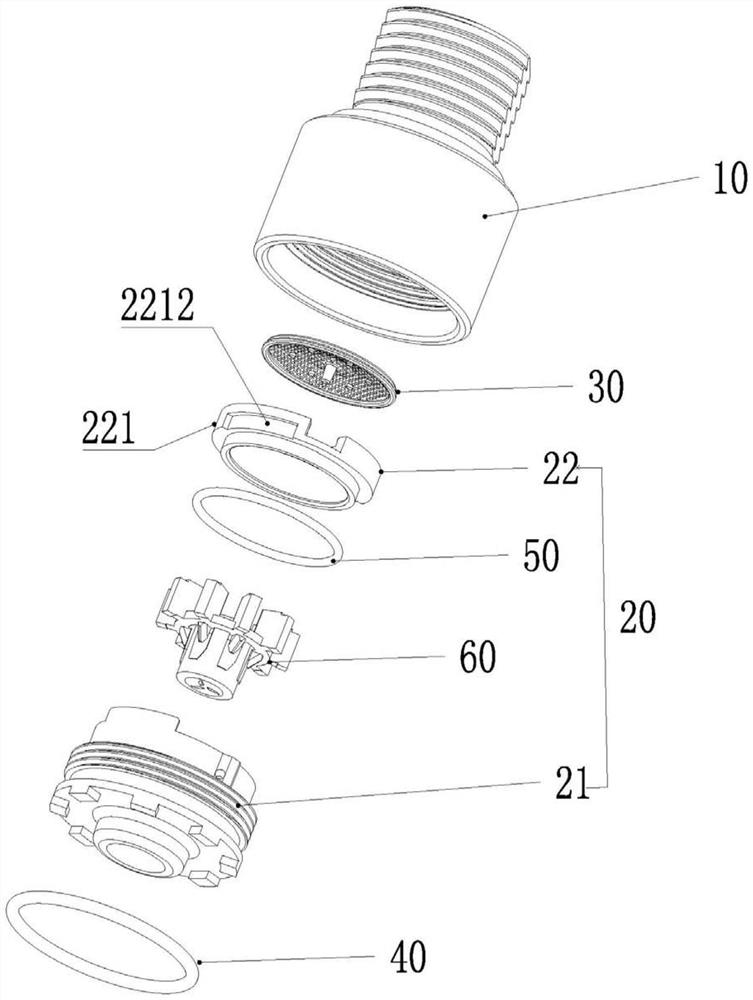

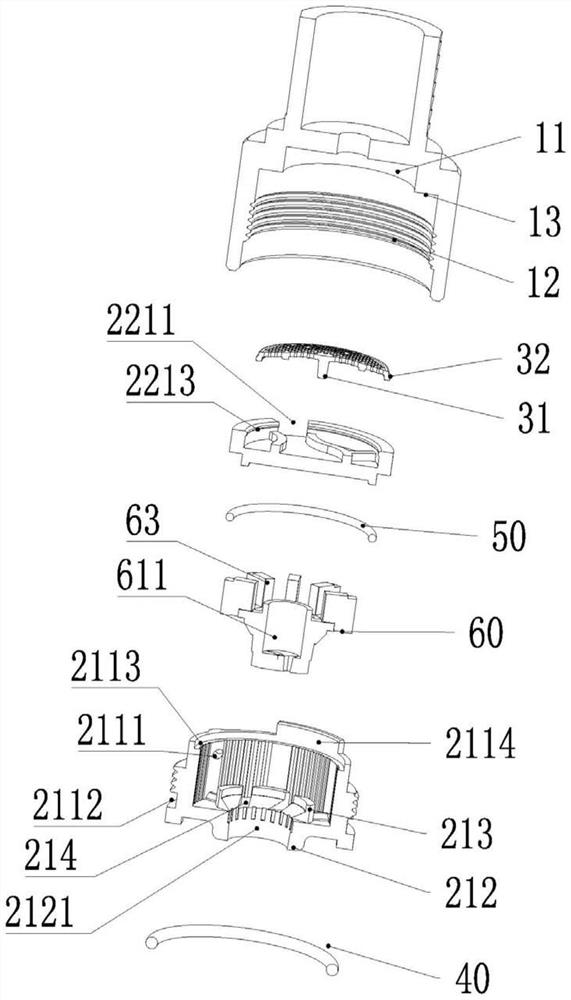

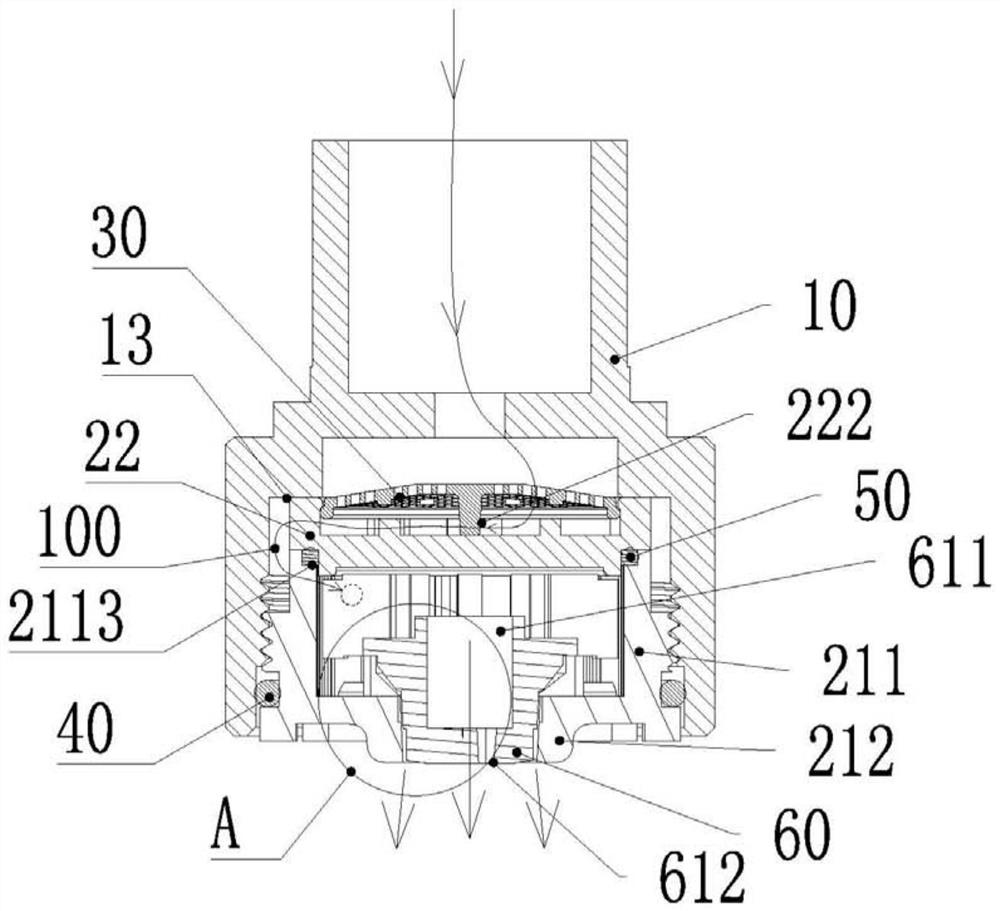

Water outlet device

PendingCN113369031AReduce water flow areaIncrease flow ratePhysical therapySpray nozzlesImpellerWater flow

The invention discloses a water outlet device which comprises a water outlet body and a rotating part. The water outlet body is provided with a water passing cavity, the bottom wall and the side wall of the water passing cavity are provided with a water outlet hole and inclined water channels respectively, a plurality of protruding blocks are further arranged in the water passing cavity around the water outlet hole, an inclined water groove is formed between every two adjacent protruding blocks, and the tangential water flow rotation directions formed by the inclined water grooves and the inclined water channels are consistent; each protruding block is provided with a supporting surface; the rotating part extends into the water outlet hole, and a water outlet gap is formed between the rotating part and the water outlet hole; the rotating part is provided with impellers corresponding to the inclined water channels, abutting surfaces opposite to the supporting surfaces and a plurality of water pressing blocks corresponding to the inclined water channels; and pushing faces are arranged on the water pressing blocks in the water outlet directions of the inclined water channels and incline relative to the supporting surfaces, so that outlet water of the inclined water channels can push the abutting surfaces to be away from the supporting surfaces. The water outlet device provided by the invention can rapidly rotate under the action of high-pressure water flow and low-pressure water flow, and the water outlet effect is ideal.

Owner:FUJIAN XIHE SANITARY WARE TECH

Circulator

InactiveCN102384091AImprove atomization effectSmall dropletPump componentsCircumferential flow pumpsChemical reactionWater turbine

The invention relates to a circulator, comprising a housing and a transmission gear, wherein a circulation cavity is arranged in the housing; a transmission gear is mounted on the housing; a rotating wheel is arranged in the housing; the transmission gear and the rotating wheel are connected with each other, the circulating cavity is internally provided with a circulating cavity inlet and a circulating cavity outlet; the circulating cavity expands gradually from one end to the other end, and an isolator is arranged in the housing between the circulating cavity inlet and the circulating cavity outlet. The circulator makes full use of circular motion and fluid motion, can better convert torsion force into pressure or thrust force through fluid, and better convert pressure or thrust force into torsion force through fluid. Moreover, particle mixing is realized through eddy flow, and chemical reaction becomes more sufficient by utilizing eddy flow. The circulator can be used as water pumps, slurry pumps, sewage pumps, blower fans, compressors, spraying equipment, atomizers, reactors, water turbines, steam turbines, wind turbines, vacuum equipment, foam material production equipment, nanometer material equipment and the like. The circulator provided by the invention has the advantages of high efficiency, low abrasion, etc., can be used for manufacturing fire-new foam material, and can usher in material revolution.

Owner:陈久斌

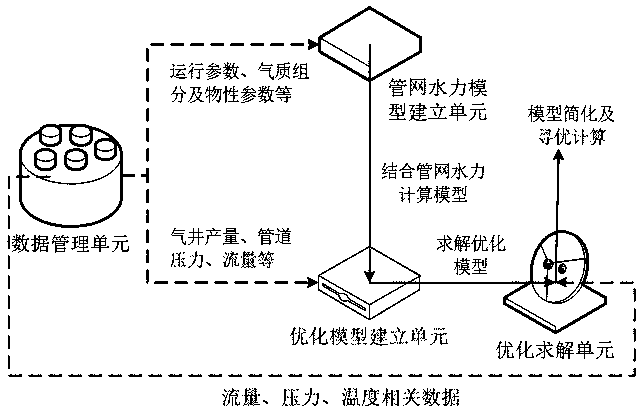

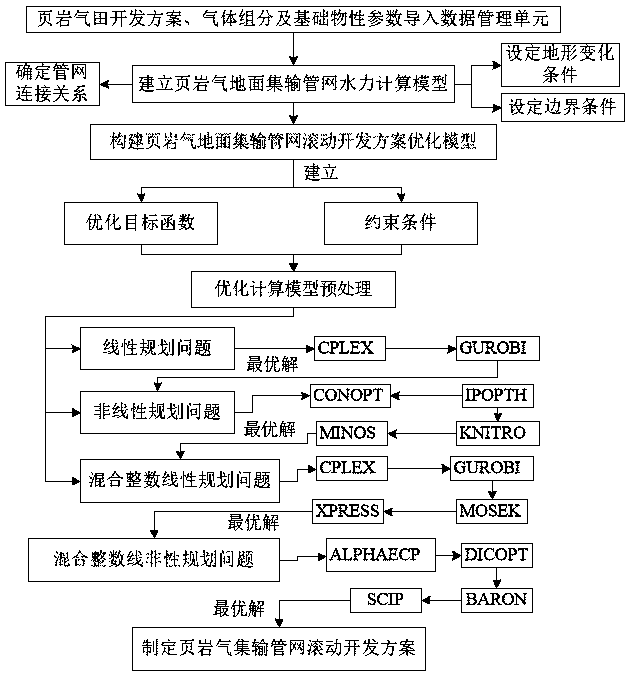

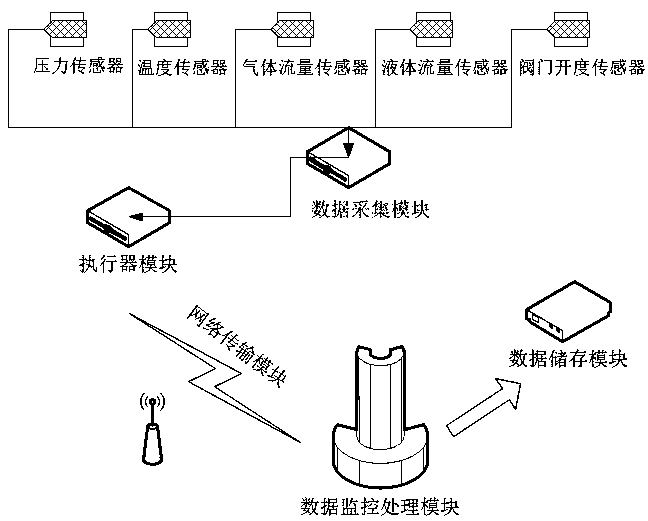

Shale gas ground gathering and transportation pipe network rolling development scheme optimization solver and method

ActiveCN110348176ASupercharge effect is goodConvenient timeData processing applicationsDesign optimisation/simulationManagement unitNetwork connection

The invention relates to a shale gas ground gathering and transportation pipe network rolling development scheme optimization solver and method. The solver comprises four units of a data management unit, a pipe network hydraulic model establishment unit, an optimization model establishment unit and an optimization solution unit, and integrates multiple functions of pipe network simulation calculation, new well access pipe network time optimization, extension pipe network connection relation optimization, pressurization station distribution, pressurization capacity optimization and the like. According to the shale gas ground gathering and transportation pipe network rolling development scheme optimization solution method, an objective function and a constraint condition construction moduleare combined, and a pipe network optimization objective function is established with the maximum gas field income; model simplification is carried out through a linear interpolation and optimization model boundary condition processing method, and conversion from a MINLP problem to LP, NLP and MILP optimization problems can be realized; a plurality of optimization solvers such as CPLEX, GUROBI, SCIP and the like are adopted to carry out optimization calculation on LP, NLP, MILP and MINLP problems in sequence, and an optimal scheme for rolling development of the shale gas gathering and transportation pipe network is formulated.

Owner:CHINA PETROLEUM & CHEM CORP +1

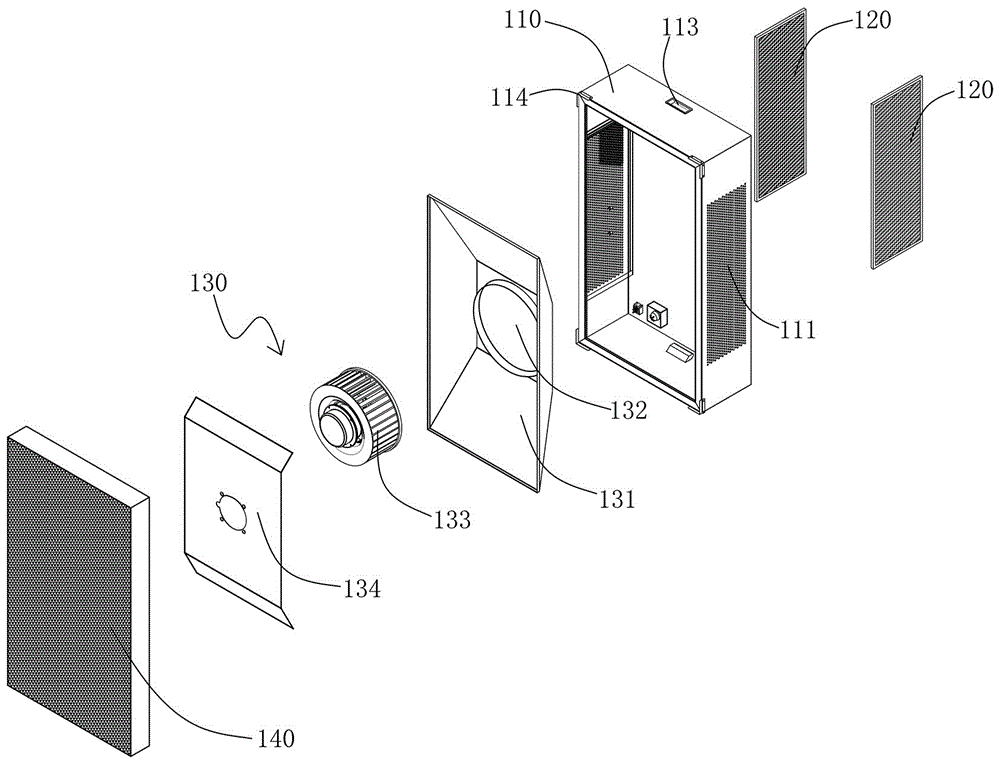

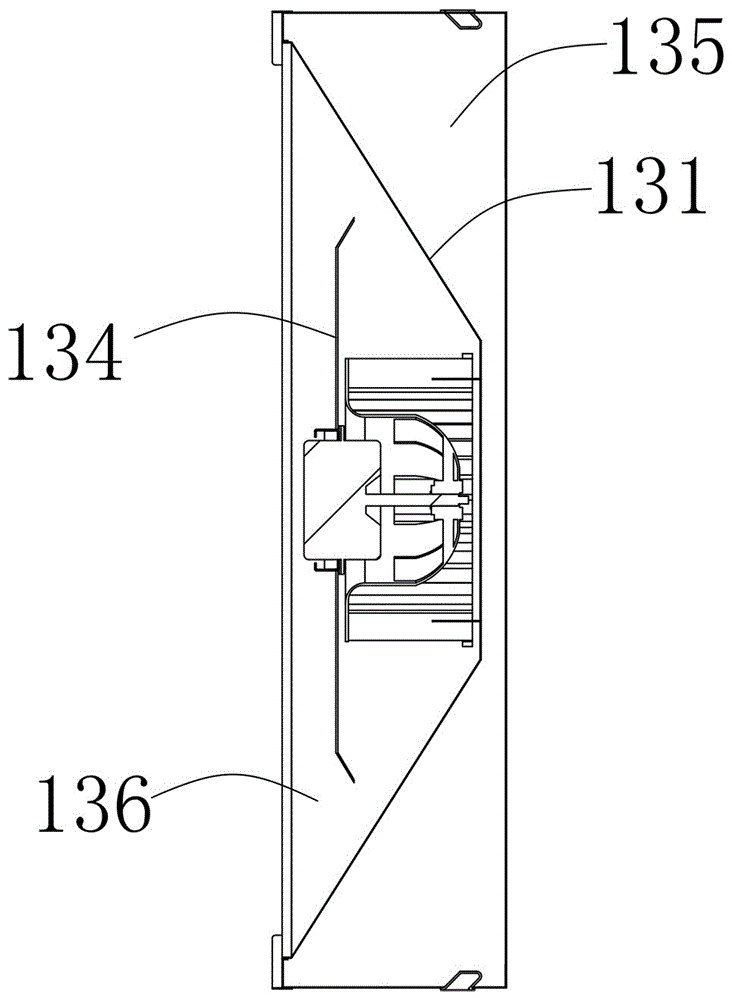

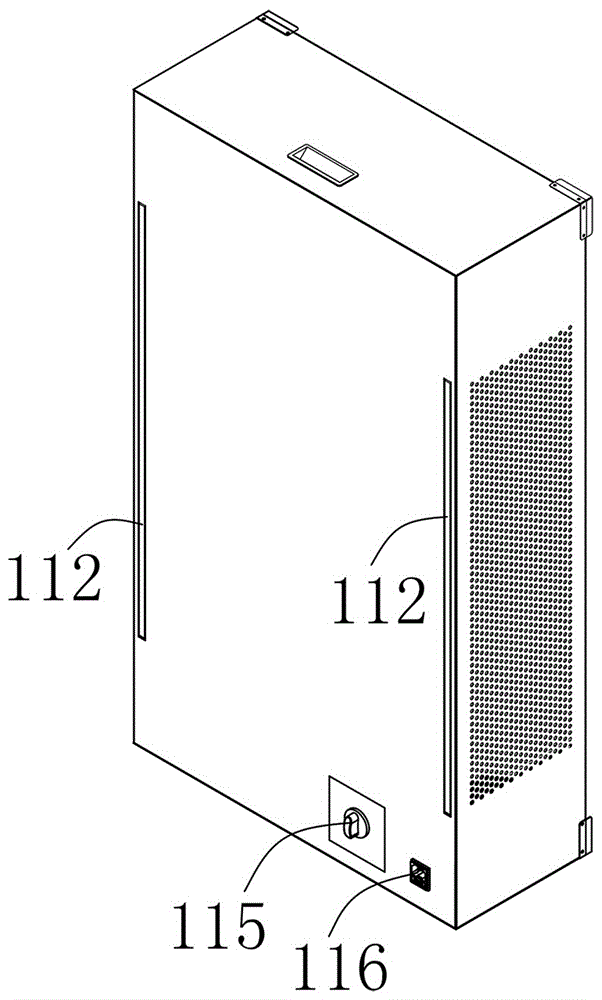

Air purifying unit

PendingCN106705263AHigh primary filtration efficiencySmooth air intakeMechanical apparatusLighting and heating apparatusSurface platePositive pressure

The invention discloses an air purifying unit and relates to the field of air purifying equipment. The air purifying unit comprises a housing. Air inlet holes are formed in two side faces of the housing; filter screen slots are separately arranged on the back, close to the air inlet holes, of the housing; an initial effect filter screen is inserted into each of the filter screen slots; air filtered by the initial effect filter screens are successively purified through a fan device and an efficient filter; the fan device comprises an air partition plate, a fan and a fan bottom plate; a cavity is formed in the air inlet of the air partition plate, the fan is mounted in the cavity, and the fan bottom plate is mounted at an air outlet of the fan; the air purifying unit has the advantages of being high in initial effect filter efficiency, smooth to intake air and fast to blow; a plurality of air outlet nozzles are mounted in an air outlet panel and the angles of the nozzles can be adjusted, so that air can be blown to different angles, and the fan bottom plate plays roles of guiding air in a positive pressure chamber and accelerating air to pressurize.

Owner:周波

Pressing-injecting oil cylinder with pressurization system

InactiveCN105402199AUnique designNovel structureFluid-pressure convertersFluid-pressure actuatorsEngineeringPiston rod

The invention relates to a pressing-injecting oil cylinder with a pressurization system. The pressing-injecting oil cylinder is characterized in that a pressing-injecting piston rod passes through a front cover of the oil cylinder and then is positioned into a barrel of the oil cylinder; a pressurizing position is positioned in an inner cavity of a rear cover of the oil cylinder; one end of a pressurizing piston rod is connected to the pressurizing piston while the other end of the pressurizing piston rod is positioned into the barrel of the oil cylinder; a one-way valve sleeve is mounted into an axial through hole of the pressurizing piston; a through hole is formed in the axis position of the pressurizing piston rod; a blind hole is formed in the axis position of the pressing-injecting piston rod; a one-way valve element is mounted on a spring pressing cover in the through hole through an one-way valve spring; a first oil port in the front cover of the oil cylinder communicates with a rod port of the pressing-injecting piston rod; a second oil port in the rear cover of the oil cylinder and an oil channel communicate with the rod port of the pressurizing piston rod; a third port in the rear cover of the oil cylinder and the oil channel correspondingly communicate with the through hole in the pressurizing piston rod and the blind hole in the pressing-injecting piston rod through inner holes of the one-way valve sleeve; a valve element ejector rod is inserted from the rear cover of the oil cylinder into the inner holes of the one-way valve sleeve and is opposite to the one-way valve element. According to the pressing-injecting oil cylinder, the one-way valve element can be automatically opened and closed to achieve piston area difference, and thus the pressurization effect can be achieved.

Owner:SUZHOU SANJI FOUNDRY EQUIP

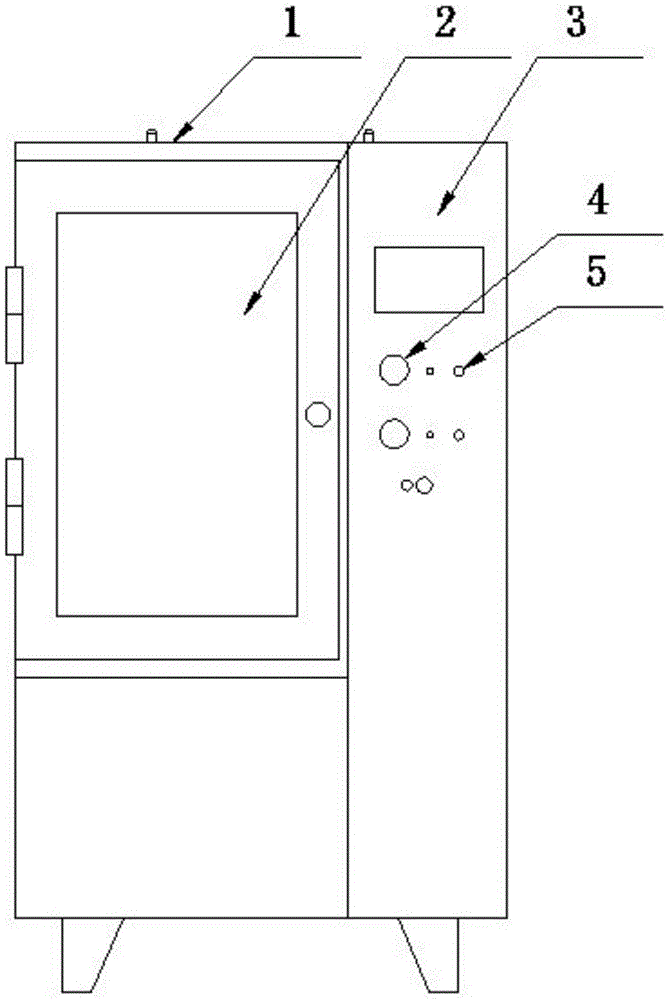

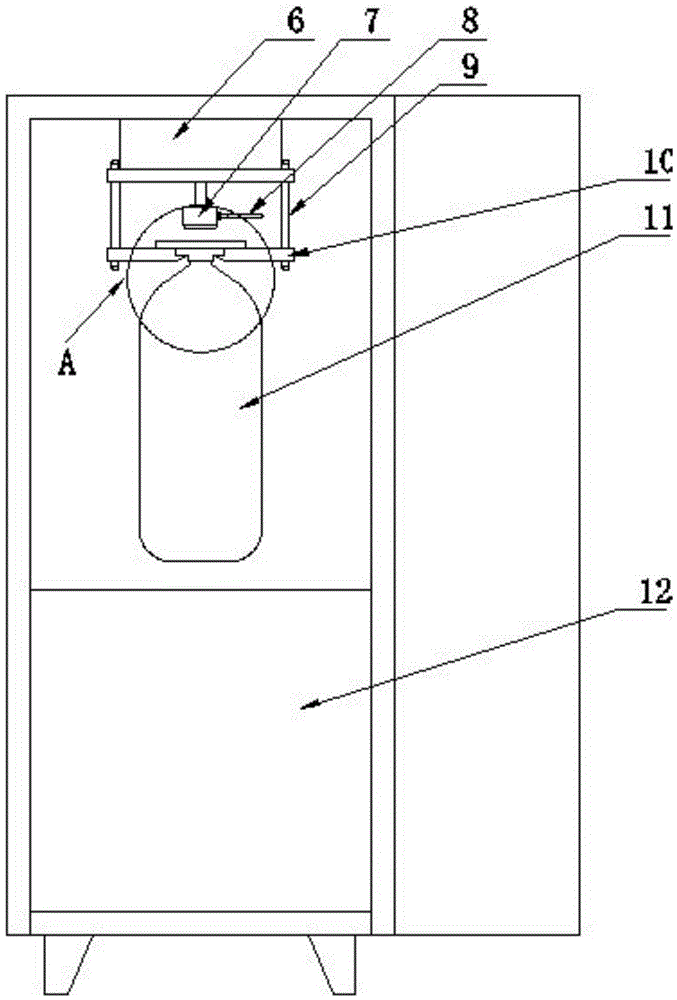

Aerosol can interval pressure withstand testing device

PendingCN105527061AResistance to internal pressure test achievedSupercharge effect is goodMeasurement of fluid loss/gain rateMaterial strength using tensile/compressive forcesInternal pressureEngineering

The present invention relates to an aerosol can interval pressure withstand testing device which is characterized in that the device is formed by a testing box body, a pressing cylinder, a can opening pressing head, a can opening bracket, and a controller, the inner top surface of the testing box body is fixedly equipped with the pressing cylinder. The cylinder rod bottom end of the pressing cylinder is fixedly equipped with the can opening pressing head. The can opening bracket at the lower part of the can opening pressing head is horizontally and fixedly installed in the testing box body. An L-shaped liquid inlet opening is made in the can opening pressing head. The inner end of the liquid inlet is at the lower surface of the can opening pressing head, and the outer end of the liquid inlet is at the side wall of the can opening pressing head and is connected to external compressed air through a pipeline. The structural design of the aerosol can interval pressure withstand testing device is scientific and rational, the pressure increase and can opening pressing are realized by using the compressed air and a pressed air source, by using the specially designed aerosol can opening bracket and can opening pressing head, the stabilization and sealing of the can body in a pressurization process is realized, thus the aerosol can interval pressure withstand test with a high internal pressure is satisfied, the testing time is short, the efficiency is high, the operation is easy, and the device is safe and reliable.

Owner:CHINA PACKAGING RES & TEST CENT

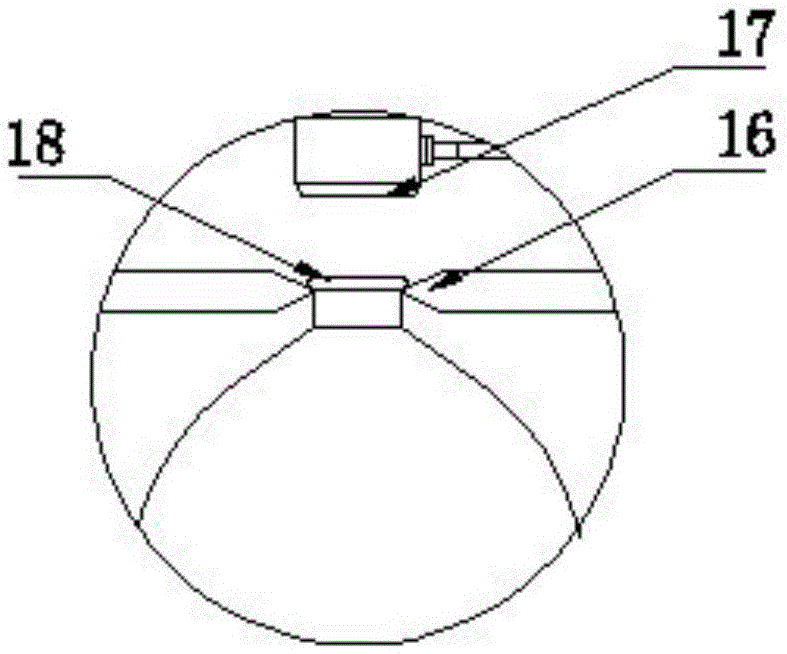

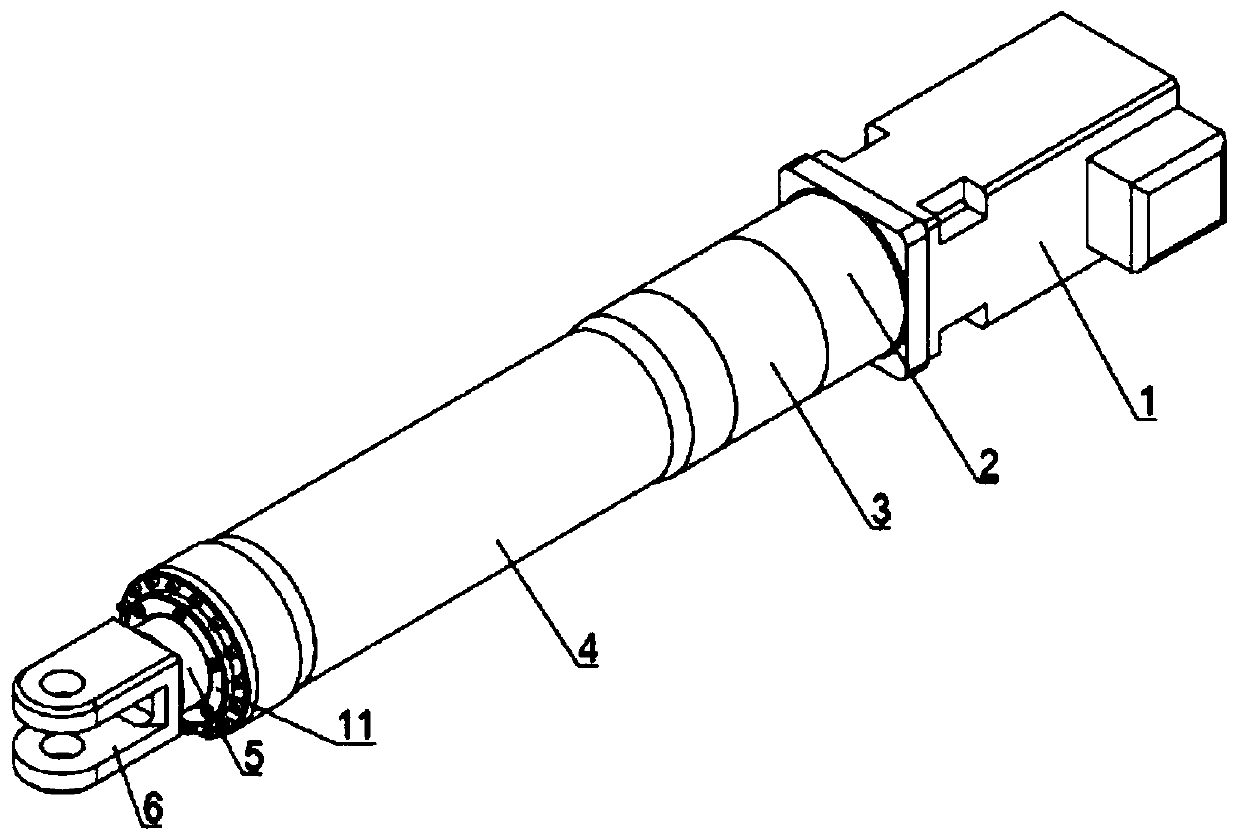

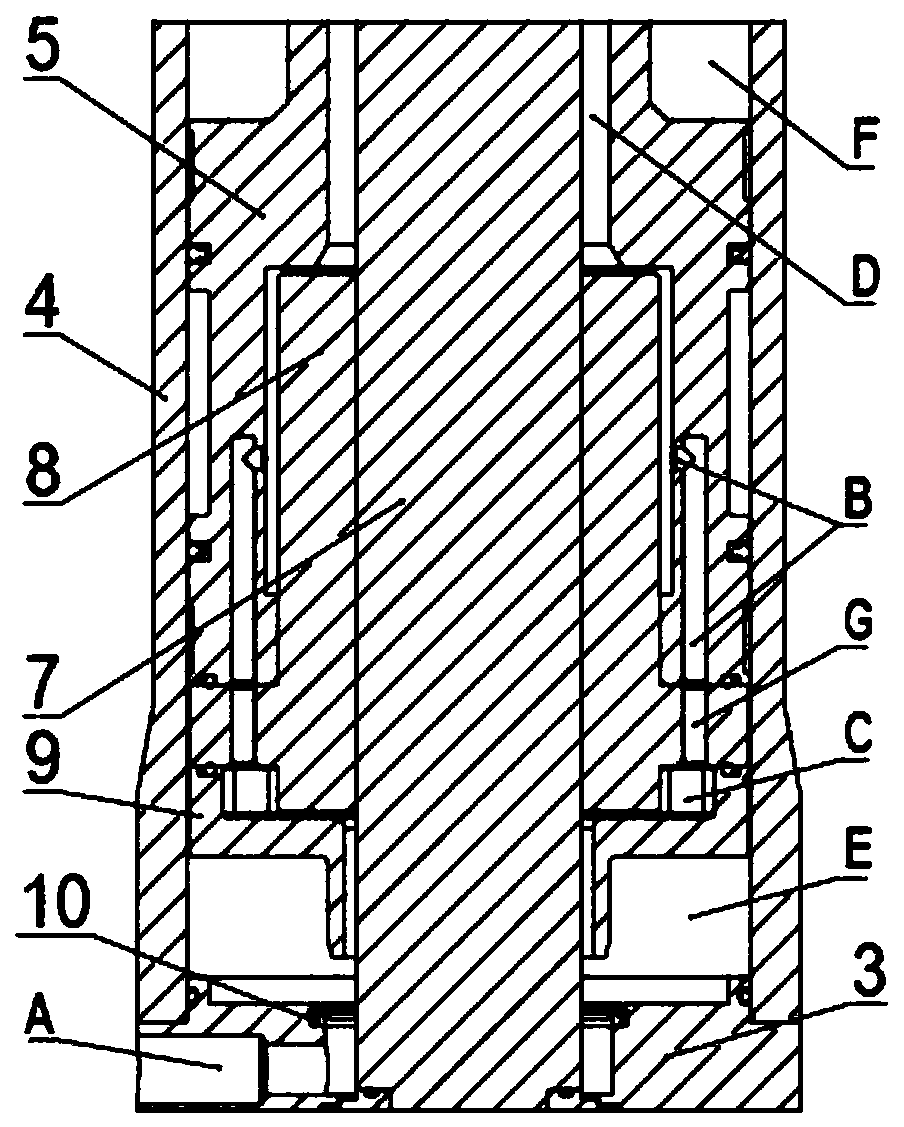

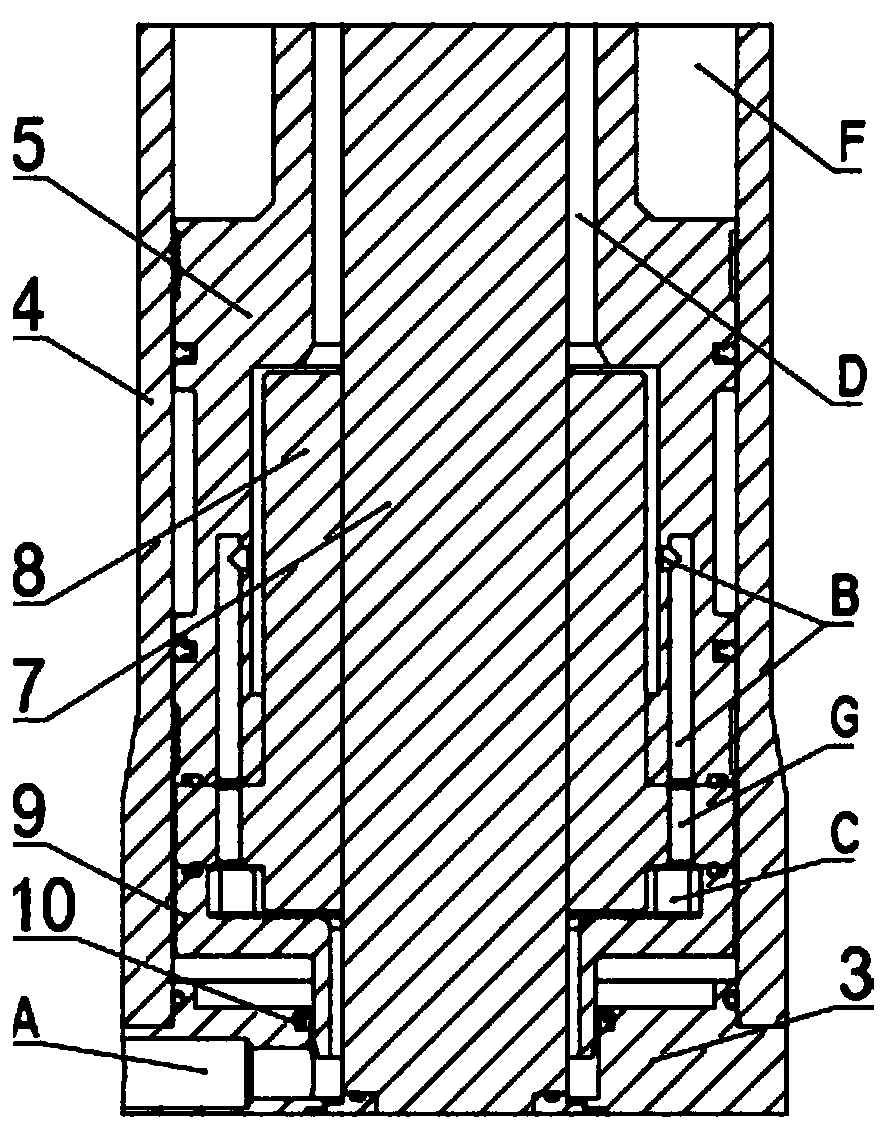

Gas-assisted electric cylinder device

PendingCN111431333AReduce energy consumptionHigh positioning accuracyFluid-pressure actuatorsMechanical energy handlingElectric machineEngineering

The invention relates to an electric cylinder, in particular to a gas-assisted electric cylinder device. The provided gas-assisted electric cylinder device comprises a motor, a flange, a bearing base,a cylinder barrel, a lead screw and a piston rod. The motor drives the lead screw to rotate, and a lead screw nut converts rotary motion into reciprocating linear motion, so that the piston rod connected with the lead screw nut is driven to do telescopic motion in the cylinder barrel; a vent hole is formed to ventilate the cylinder barrel, and a ventilation loop, an air compressor, an air storagetank and the like are used to form an air-assisted system, so that the functions of pressure maintaining, buffering and force increasing are achieved. According to the gas-assisted electric cylinderdevice, a gas-assisted device is additionally arranged in the electric cylinder, and the advantages of the electric cylinder and the air cylinder are integrated, so that the positioning precision is high; the pressurizing effect can be achieved through movement under the action of the gas-assisted device and the lead screw; and when the electric cylinder is kept at a specific position for a long time, the motor does not need to continue to increase power consumption under the action of air pressure, so that energy consumption is reduced.

Owner:MOTUS TECHNOLOGIES INC

Novel vertical vehicle turbocharger

InactiveCN101519996ASupercharging Efficiency GuaranteeFully exhaustedInternal combustion piston enginesGas turbine plantsImpellerTurbocharger

The invention discloses a novel vertical vehicle turbocharger. A thermal baffle is arranged between a turbine shroud and a compressor casing, wherein the turbine shroud and the compressor casing are connected together. The compressor casing is supported by a bearing shell having an air inlet. The upper part of a rotating shaft arranged inside the bearing shell is positioned in the compressor casing and the turbine shroud. A turbine and a compressor impeller which are arranged on the upper part of the rotating shaft are positioned in the turbine shroud and the compressor casing respectively. The lower end of the bearing shell is connected with an oil tank, and the lower end of the rotating shaft is positioned in the oil tank. Two induction trunks are arranged on the turbine shroud for the initial charging stage and arranged at a place where the entrances of the air channels meet in the turbine shroud and are in smooth connection with the entrances of the air channels. A conduit runs through the thermal baffle to reach a place between the turbine and compressor impellor. The turbocharger is simple in structure, reliable in use, good in self-pressurization and capable of improving the charging efficiency of a cylinder of an engine.

Owner:费传华

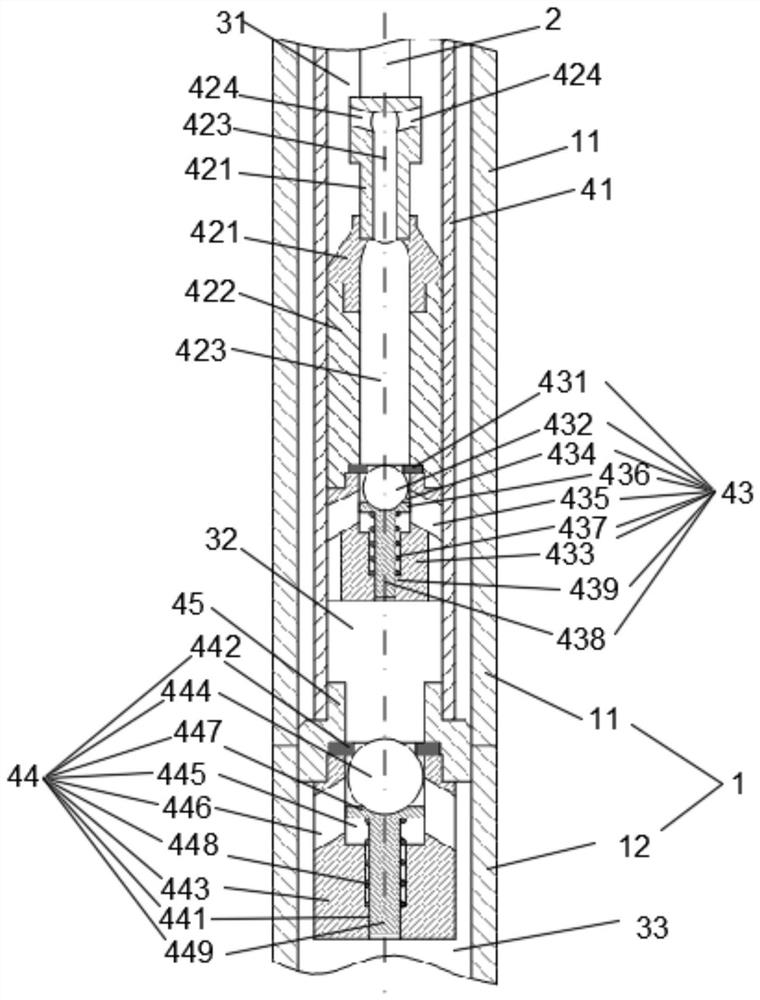

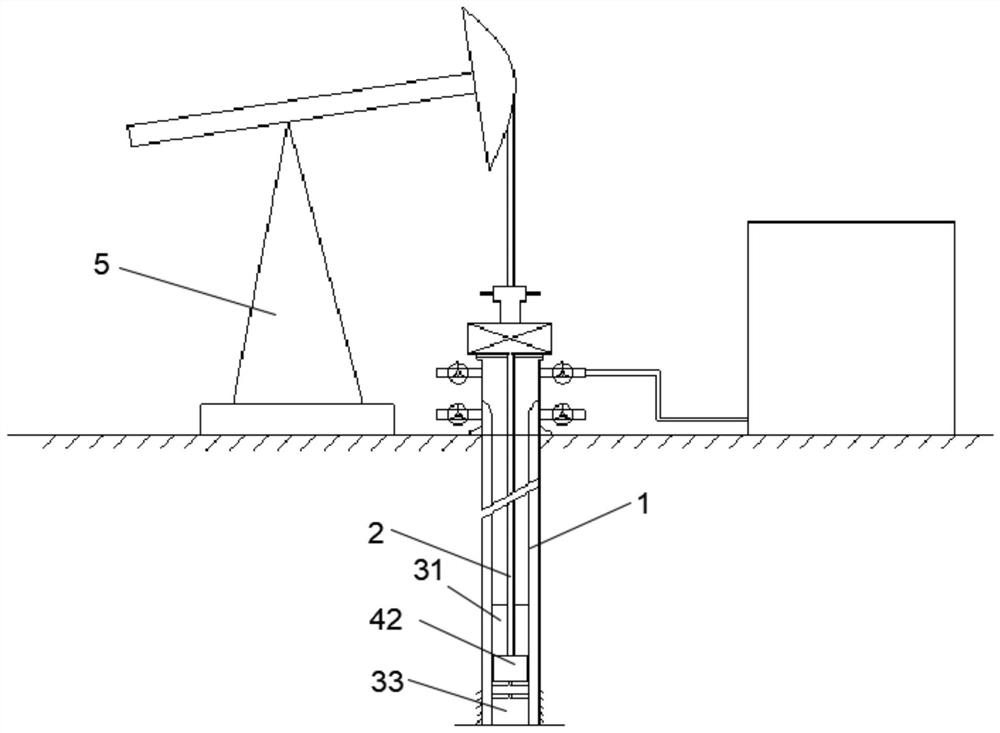

Underground reciprocating type water injection device

ActiveCN112282712AReduce lossesTransportation safetyPositive displacement pump componentsFluid removalWater flowMechanical engineering

The invention discloses an underground reciprocating type water injection device. The underground reciprocating type water injection device comprises a piston sleeve, a piston, a first one-way valve assembly and a second one-way valve assembly; the piston sleeve is fixed in a well communicating with an oil layer, a water supply port communicating with water supply equipment is formed in the upperend of the piston sleeve, and a water injection port communicating with the oil layer is formed in the lower end of the piston sleeve; the piston is in sliding fit with the piston sleeve in the pistonsleeve, the outer wall of the piston is dynamically sealed with the inner wall of the piston sleeve, and a first water flow channel communicating with the upper space of the piston sleeve located above the piston in the piston sleeve and the lower space of the piston sleeve located below the piston in the piston sleeve is formed in the piston; the first one-way valve assembly is arranged at the first water flow channel; and the second one-way valve assembly is arranged at the water injection port. According to the underground reciprocating type water injection device, underground pressurization water injection is achieved, energy loss is small when pressurized water reaches the oil layer, the pressurization effect is better, water is conveyed under normal pressure on the ground, safety ishigher, and cost is lower.

Owner:PETROCHINA CO LTD

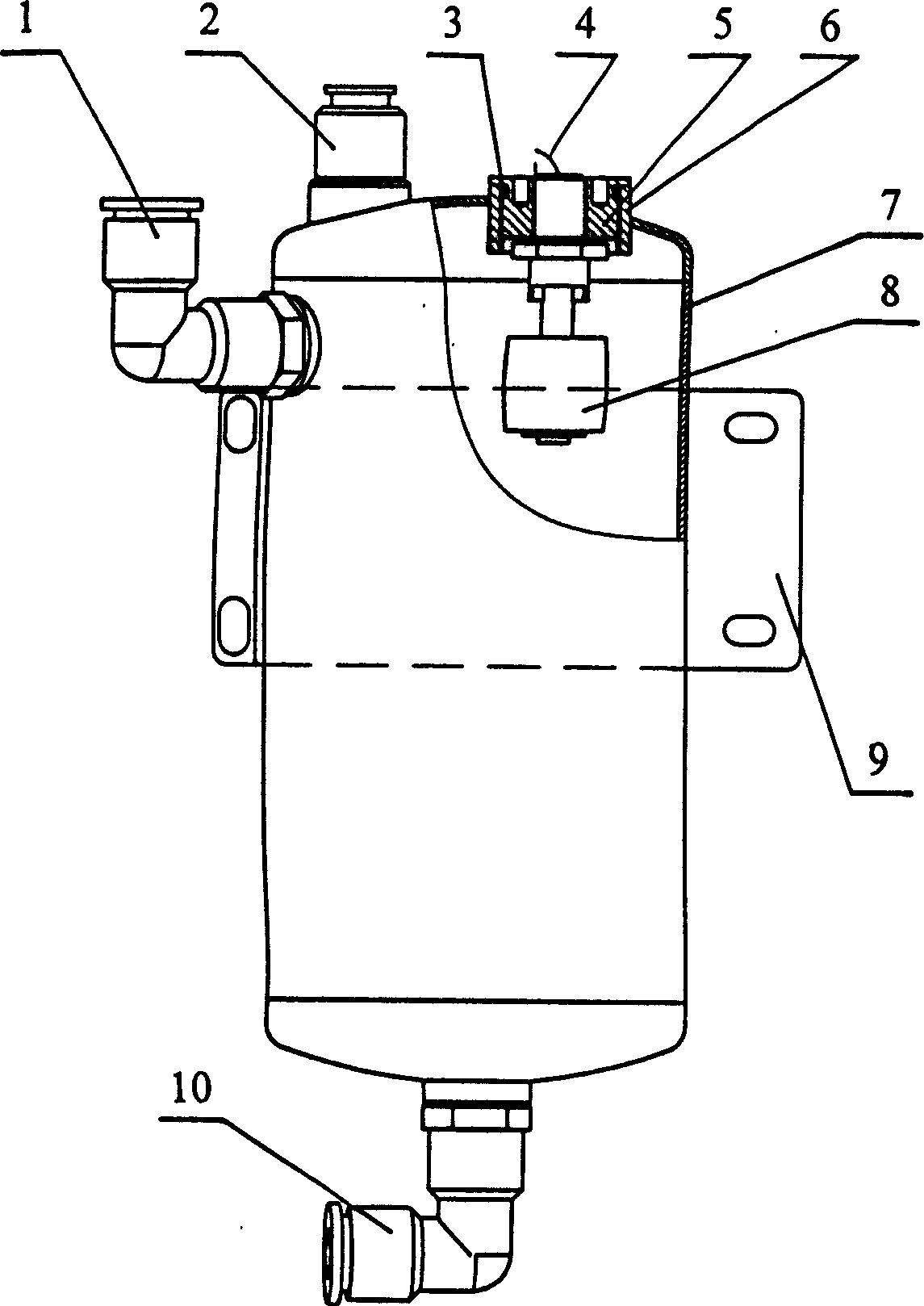

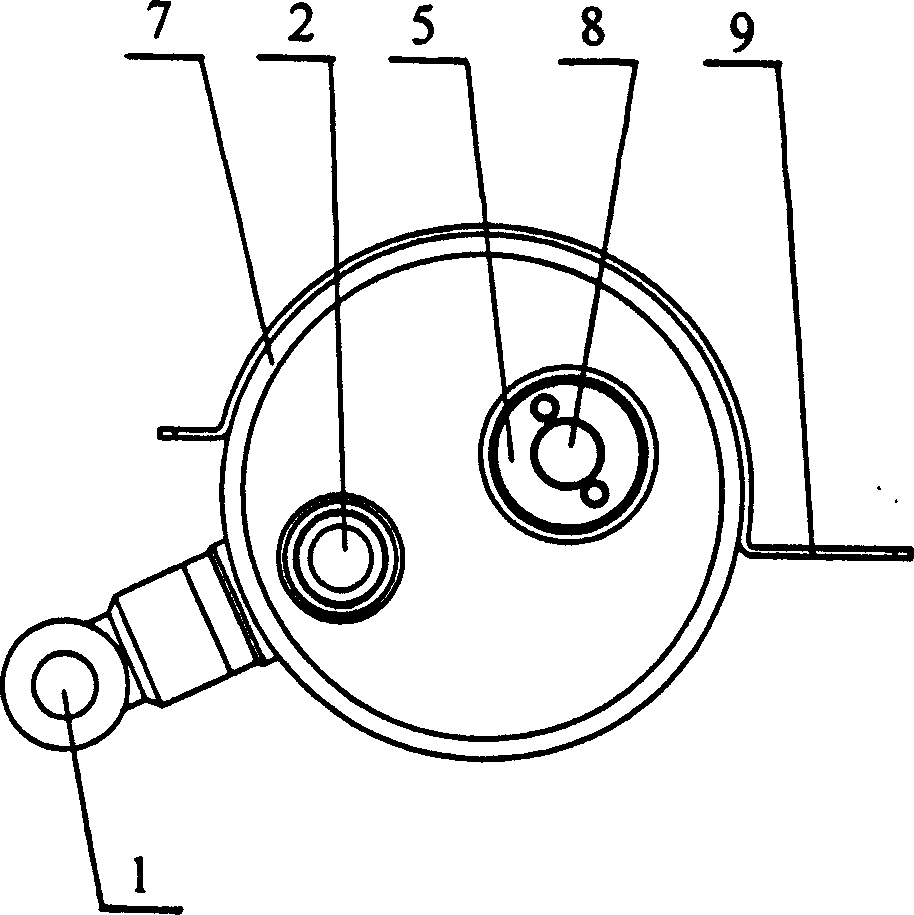

Water pressurizer for vacuum excrement collector

InactiveCN1851164AImprove the use environmentHigh degree of automationFlushing devicesEngineeringWater level

The invention is a water pressurizer for vacuum excrement and urine collector, comprising cylinder body, water inlet, air inlet and water outlet, and water level switch able to automatically feed back water full signal, where the water level switch is connected through signal line with a controller of the collector, the cylinder body is installed in the collector casing through installation plate, the water inlet, air inlet and water outlet all adopt fast joints, and the compressed air is directly applied onto the water surface. And the invention has characters of simple structure, small bulk, good pressurizing effect, saving the troubles in maintenance and change, etc.

Owner:NINGBO CRRC TIMES TRANSDUCER TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com