Multifunctional synchronous after flow ventilating compressor

A wind compressor, multi-functional technology, applied in axial flow pumps, mechanical equipment, machines/engines, etc., can solve problems such as poor boosting effect, unfavorable environmental protection, and inability to save energy, and achieve good suction and discharge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

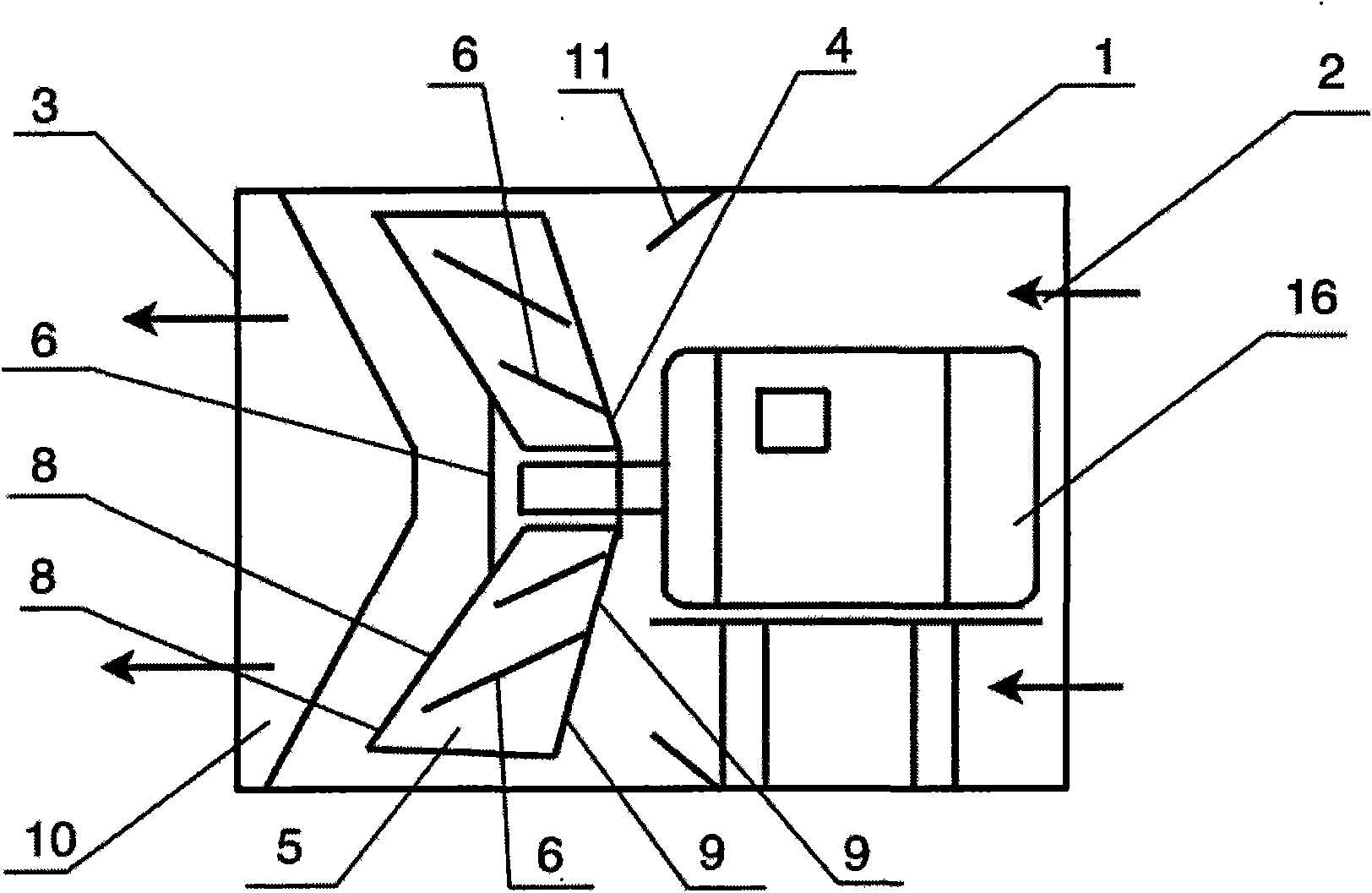

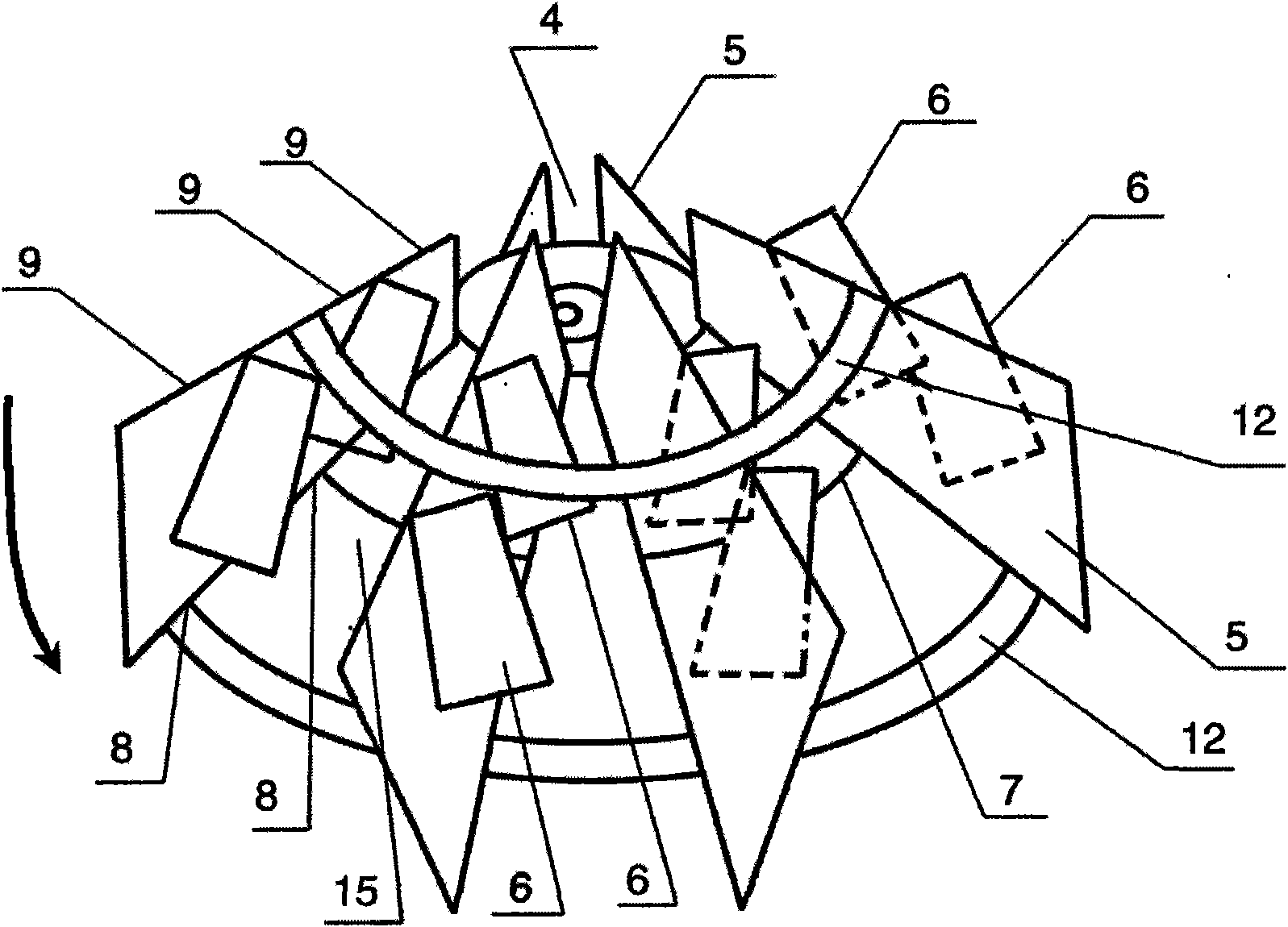

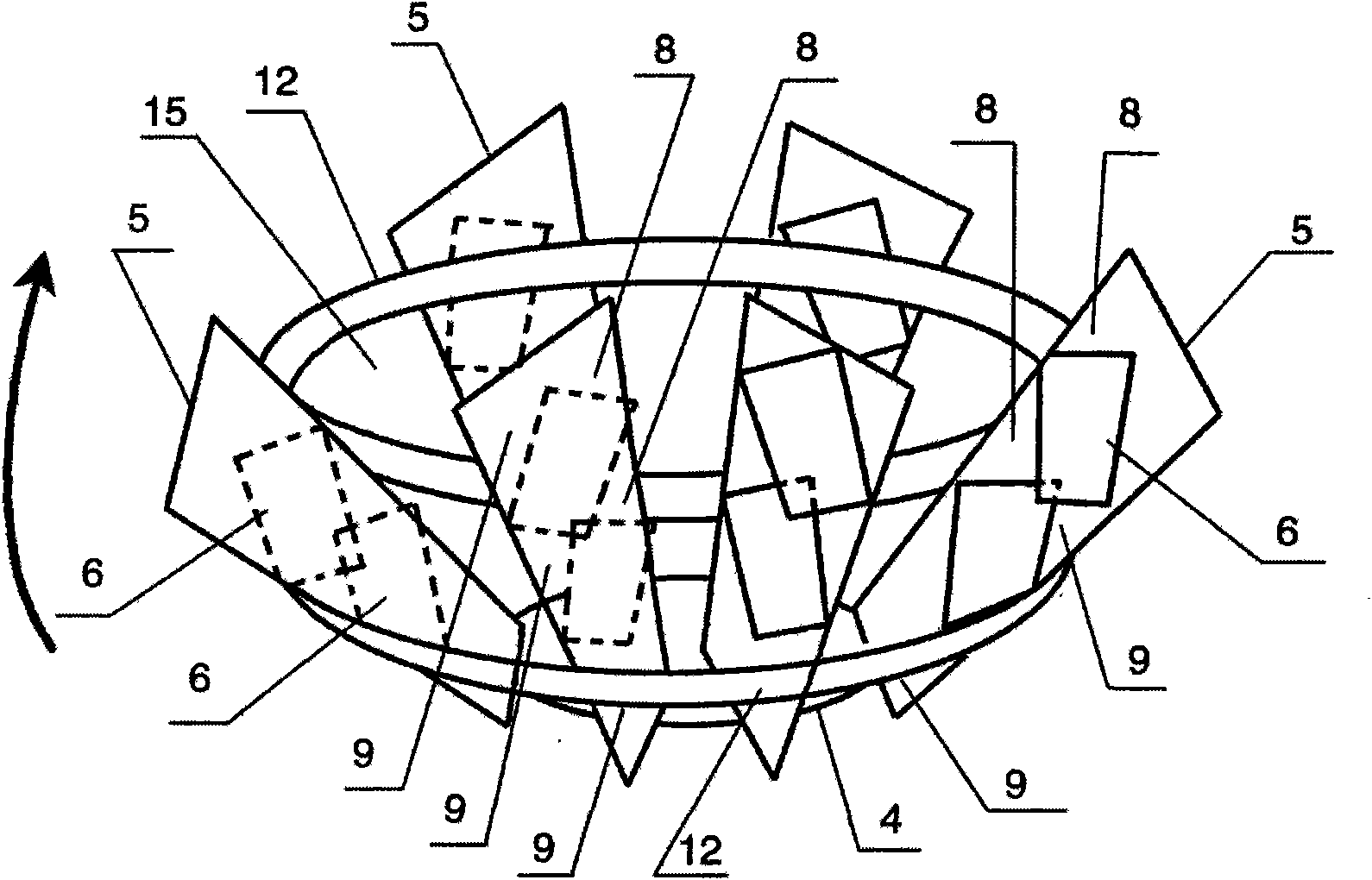

[0064] Embodiment 1 (with reference to figure 1 , figure 2 , image 3 ), a multi-functional synchronous backflow ventilation compressor, including a casing 1 in a cylindrical structure, a casing air inlet 2, a casing air outlet 3, an impeller 4 composed of a synchronous diversion supercharger impeller blade, and an impeller blade 5 ( With a half-span type synchronous diversion supercharger 6), an impeller blade disc 7, the axial rear side and the axial front side of the impeller blade 5 are gradually inclined axially from front to rear in the impeller radial direction toward the impeller axial rear, The axial rear side of the entire impeller is axially front side along the radial direction of the impeller from the front to the rear and gradually axially inclines towards the axial rear thereof, and the air flow channel 15 inside the impeller is in the form of an axially radially inclined structure. The rear side of the impeller axially inclines from front to rear in the radi...

Embodiment 2

[0068] Embodiment 2 (with reference to Figure 4 , Figure 5 ), the multifunctional synchronous backflow ventilation compressor, this example is basically the same as example 1, the difference is that the casing of this example is a variant volute type centrifugal fan casing, and the casing air outlet 3 is located at the diameter of the casing On the side wall, the outlet direction is radial axial. The impeller adopts the single-blade (thrust wall only) structure of the old-style centrifugal fan. The axial front side and the axial rear side of the impeller are gradually inclined at the same angle from front to back along the impeller radial direction to the rear of the impeller axial direction. Then the width is the same. The front and rear sides of the impeller shaft are provided with impeller vanes 7, and the middle part of the front side of the impeller shaft is provided with a special air inlet 13 in the middle of the impeller, and the whole impeller is closed. The radi...

Embodiment 3

[0072] Embodiment 3 (with reference to Figure 6 , figure 2 , image 3 ), a multifunctional synchronous backflow ventilation compressor, this example is basically the same as example 1, the difference is that the rotor of this example is combined with the same drive shaft in series with 4 synchronous backflow fan impellers. The axial front side and the rear side of each impeller axially incline gradually toward the rear of the impeller axially from front to rear along the radial direction of the impeller, and the axial inclination angles are equal, and the impeller blades have the same width from front to rear along the radial direction of the impeller. The front side of the first-stage impeller shaft is not provided with an impeller blade disc, and the side of the entire front shaft is provided with a synchronous downstream air inlet 9, and the side of the whole front shaft is used to suck objects. The impeller axial air outlet 8 is provided on the entire axially inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com