Air energy firewood stove

A technology of air energy and wood stove, which is applied in the direction of exhaust gas exhaust device, household stove/stove, climate sustainability, etc. It can solve the blockage. It must be completely disengaged and cleaned, and the connection head cannot be installed, and the installation work is troublesome To achieve good smoke collection effect, improve heat energy utilization rate, and good diversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

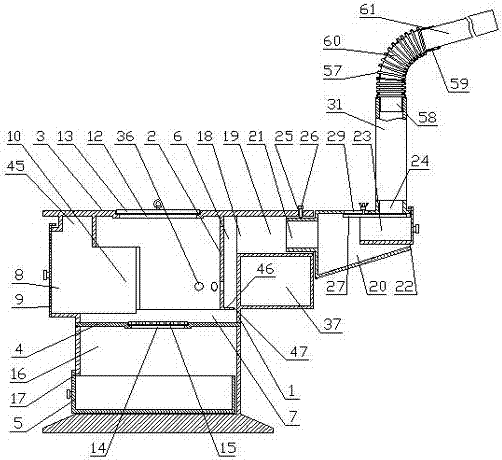

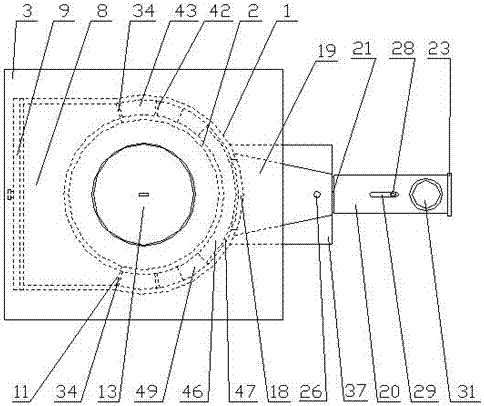

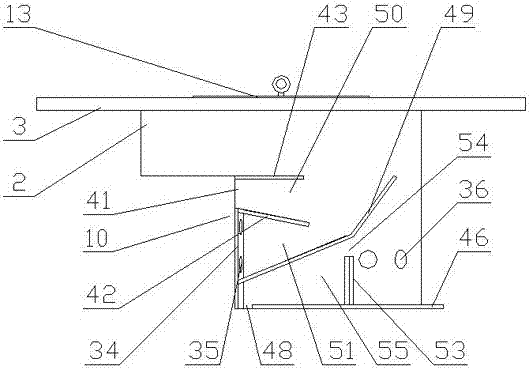

[0025] Depend on figure 1 and figure 2 Shown, a kind of air energy wood stove, it mainly comprises outer jacket 1, inner jacket 2, furnace surface 3, furnace bottom 4, ash hopper 5, inserting plate 27, smoke exhaust device and smoke exhaust pipe, the outer jacket 1 The upper end is connected to the furnace surface 3, the lower end of the outer jacket 1 is connected to the furnace bottom 4, the inner jacket 2 is located in the outer jacket 1, and its upper end is connected to the furnace surface 3, and a gap 6 is formed between the inner jacket 2 and the outer jacket 1 and they are set together A sunken flue 7 is formed between the lower end of the inner sleeve 2 and the furnace bottom 4. In this way, a certain height is maintained between the inner sleeve 2 and the furnace bottom 4 to realize the functions of heat transfer and dust removal and smoking. A firewood inlet 8 is provided on the outer cover 1, and a smoke collection area 45 is formed in the outer jacket 1 above th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com