Oil smoke removing device of cold header

A technology of oil fume device and cold heading machine, which is applied in the direction of operation device, dust removal, forging/pressing/hammer device, etc., which can solve the problems of accumulated oil fume, machine damage, large oil fume, etc., and achieve the effect of increasing resistance and promoting shaking off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

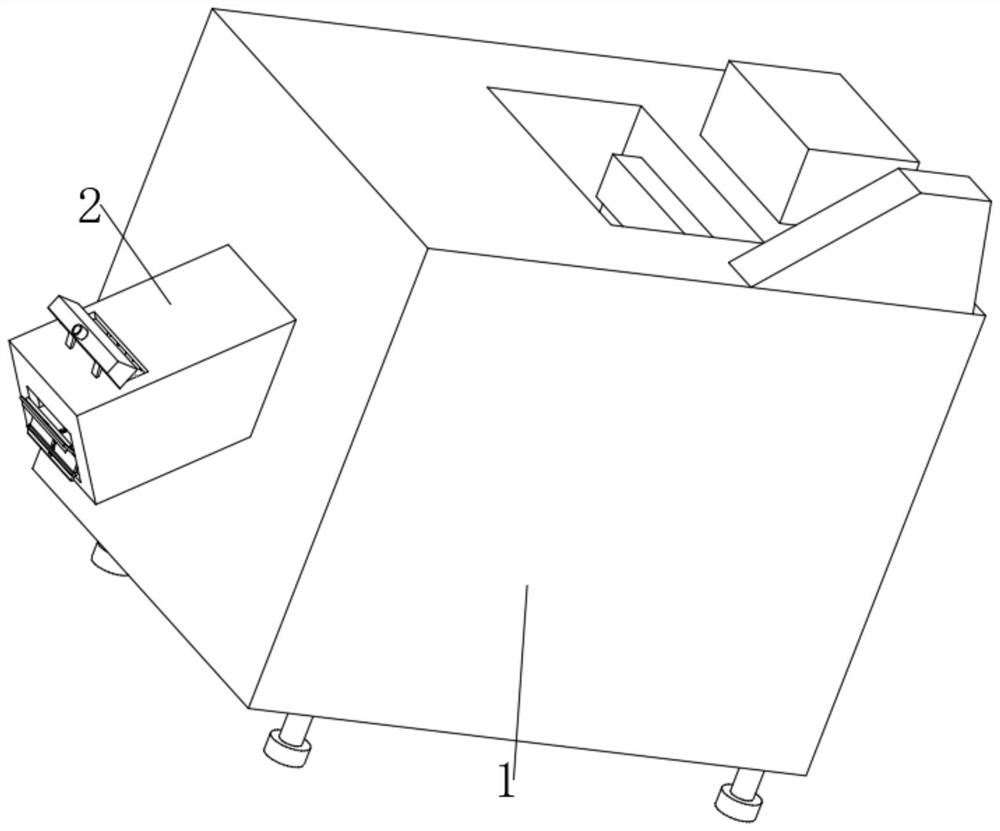

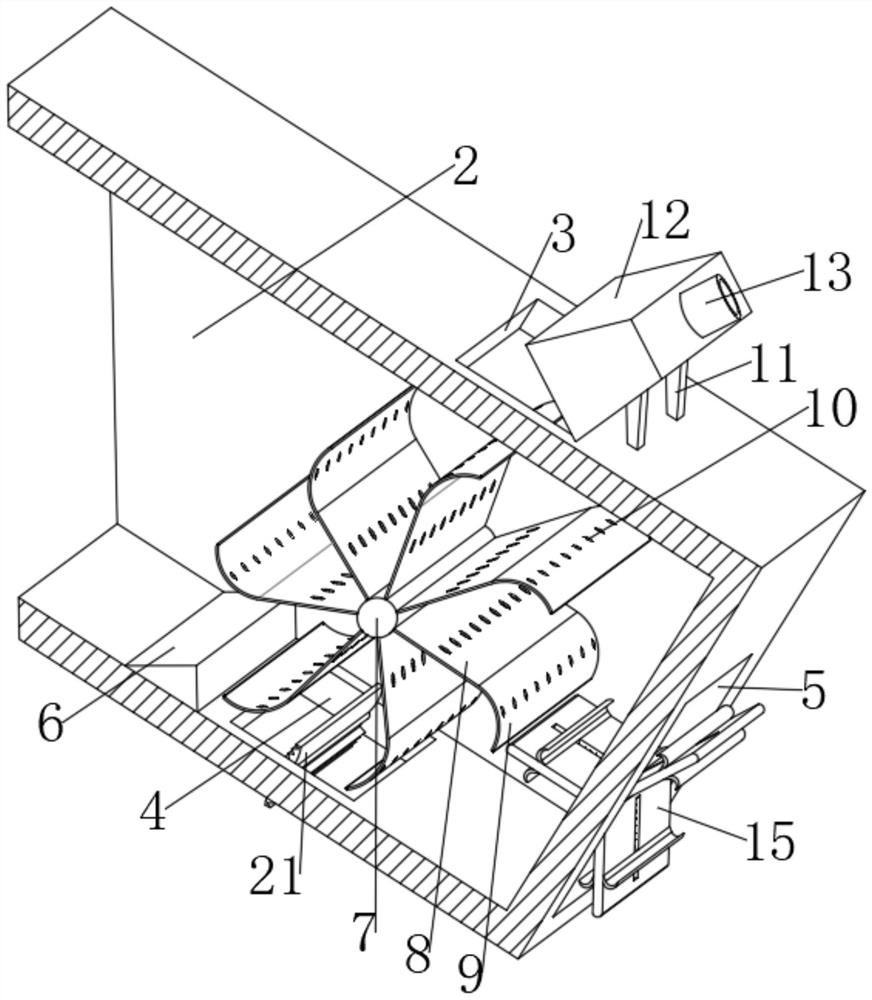

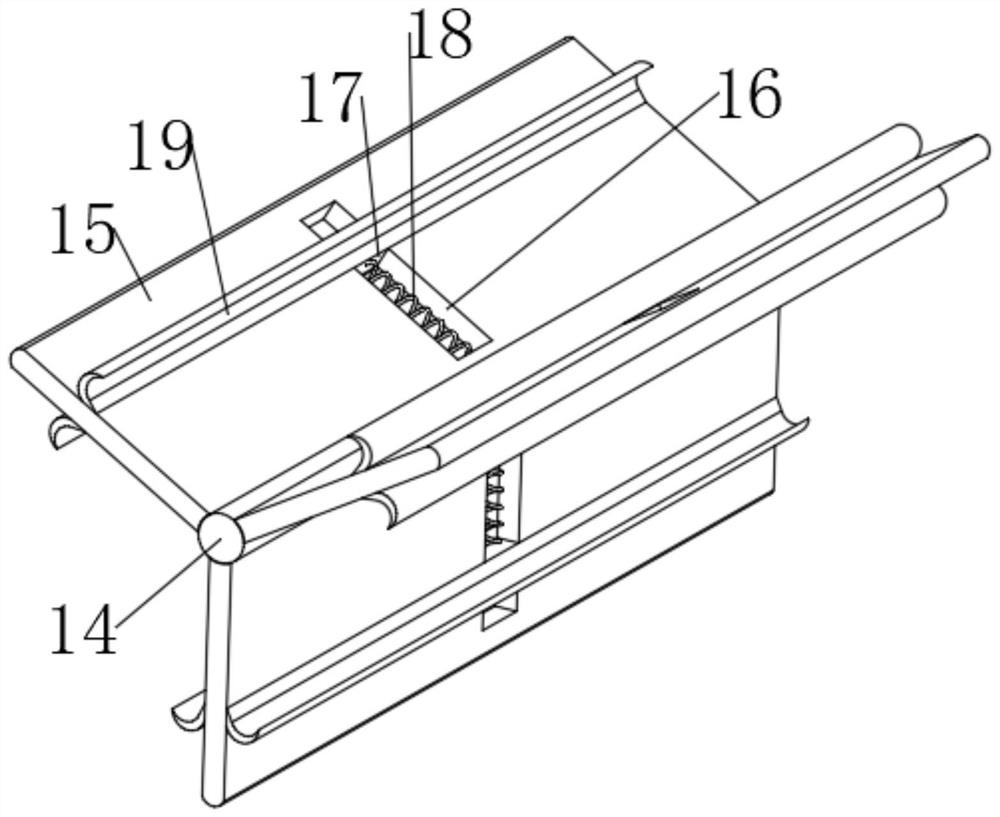

[0032] refer to Figure 1-2 and Figure 4-6 , a cold heading machine oil fume removal device, including a cold heading machine body 1, a discharge channel 2 is fixed by bolts at the outlet of the cold heading machine body 1, and the discharge channel 2 is inclined to the side away from the cold heading machine body 1 Next, the top of the discharge channel 2 is provided with an air outlet 3, the bottom of the discharge channel 2 is provided with an air inlet 4, and the side of the discharge channel 2 away from the cold heading machine body 1 is provided with a discharge port 5. The discharge channel 2 The inner wall of the bottom is fixed with a jump-helping block 6 by bolts. To the mechanism, the discharge port 5 is provided with a discharge aid mechanism, and the discharge channel 2 is provided with an oil filter mechanism.

[0033] Further, the smoking mechanism includes a fume suction head 12, two symmetrically distributed ribs 11 are fixed on the top of the discharge cha...

Embodiment 2

[0042] refer to Figure 1-2 , Figure 4-5 and Figure 7-8 , a cold heading machine oil fume removal device, including a cold heading machine body 1, a discharge channel 2 is fixed by bolts at the outlet of the cold heading machine body 1, and the discharge channel 2 is inclined to the side away from the cold heading machine body 1 Next, the top of the discharge channel 2 is provided with an air outlet 3, the bottom of the discharge channel 2 is provided with an air inlet 4, and the side of the discharge channel 2 away from the cold heading machine body 1 is provided with a discharge port 5. The discharge channel 2 The inner wall of the bottom is fixed with a jump-helping block 6 by bolts. To the mechanism, the discharge port 5 is provided with a discharge aid mechanism, and the discharge channel 2 is provided with an oil filter mechanism.

[0043] Further, the smoking mechanism includes a fume suction head 12, two symmetrically distributed ribs 11 are fixed on the top of th...

Embodiment 3

[0052] refer to Figure 1-5 and Figure 7-8 , a cold heading machine oil fume removal device, including a cold heading machine body 1, a discharge channel 2 is fixed by bolts at the outlet of the cold heading machine body 1, and the discharge channel 2 is inclined to the side away from the cold heading machine body 1 Next, the top of the discharge channel 2 is provided with an air outlet 3, the bottom of the discharge channel 2 is provided with an air inlet 4, and the side of the discharge channel 2 away from the cold heading machine body 1 is provided with a discharge port 5. The discharge channel 2 The inner wall of the bottom is fixed with a jump-helping block 6 by bolts. To the mechanism, the discharge port 5 is provided with a discharge aid mechanism, and the discharge channel 2 is provided with an oil filter mechanism.

[0053] Further, the smoking mechanism includes a fume suction head 12, two symmetrically distributed ribs 11 are fixed on the top of the discharge cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com