Automobile part punching mechanism with powerful scrap iron suction and discharge functions

A technology for auto parts and iron filings, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. Conducive to suction and discharge, improving processing efficiency and quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

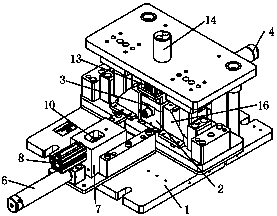

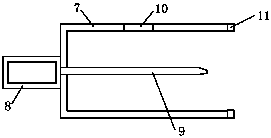

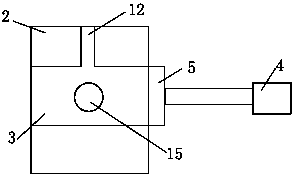

[0012] Combine below Figure 1 to Figure 3 Specific description embodiment:

[0013] The auto parts punching mechanism includes a base 1, the base 1 is provided with a hole die 2, and the hole die 2 is provided with a through hole 3 for placing a workpiece, and the through hole 3 One end is provided with a feed cylinder 4, and the output end of the feed cylinder 4 is provided with a seal 5 that seals one end of the through hole; the base 1 is provided with a stamping cylinder 6, and the output end of the stamping cylinder 6 The side punching sleeve 7 and the side punching motor 8 are arranged on the top, the side punching motor 8 is connected with the side punching head 9, the side punching head 9 is arranged in the side punching sleeve 7, the top of the side punching sleeve 7 is provided with a suction port 10, and the side punching An annular elastic pressing piece 11 matching the through hole is arranged on the sleeve at one end close to the through hole, and the side punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com