Supercharging type centrifugal blower fan

A centrifugal fan and fan technology, applied in the field of air purification, can solve the problems of unfavorable environmental protection, low suction, high noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

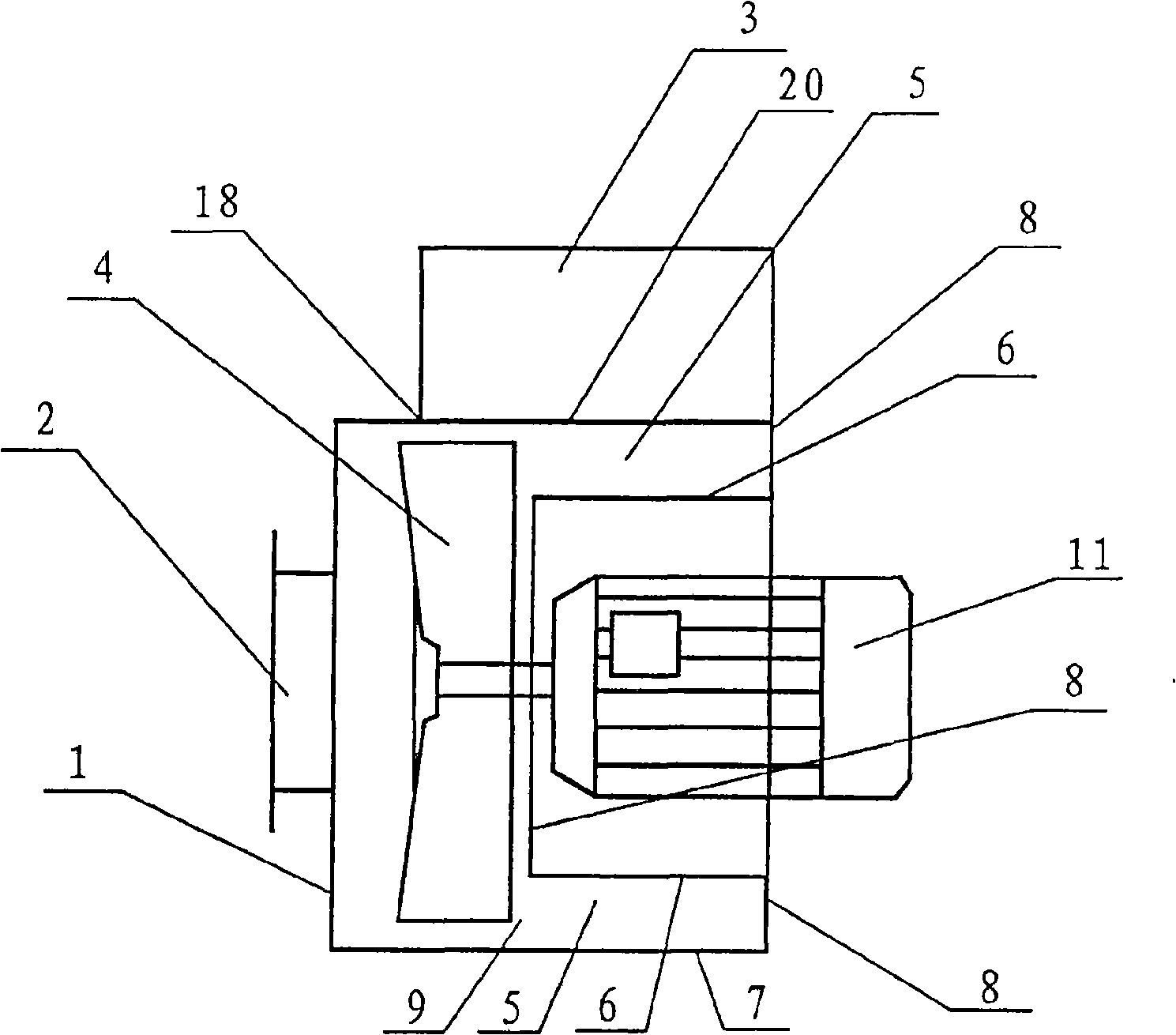

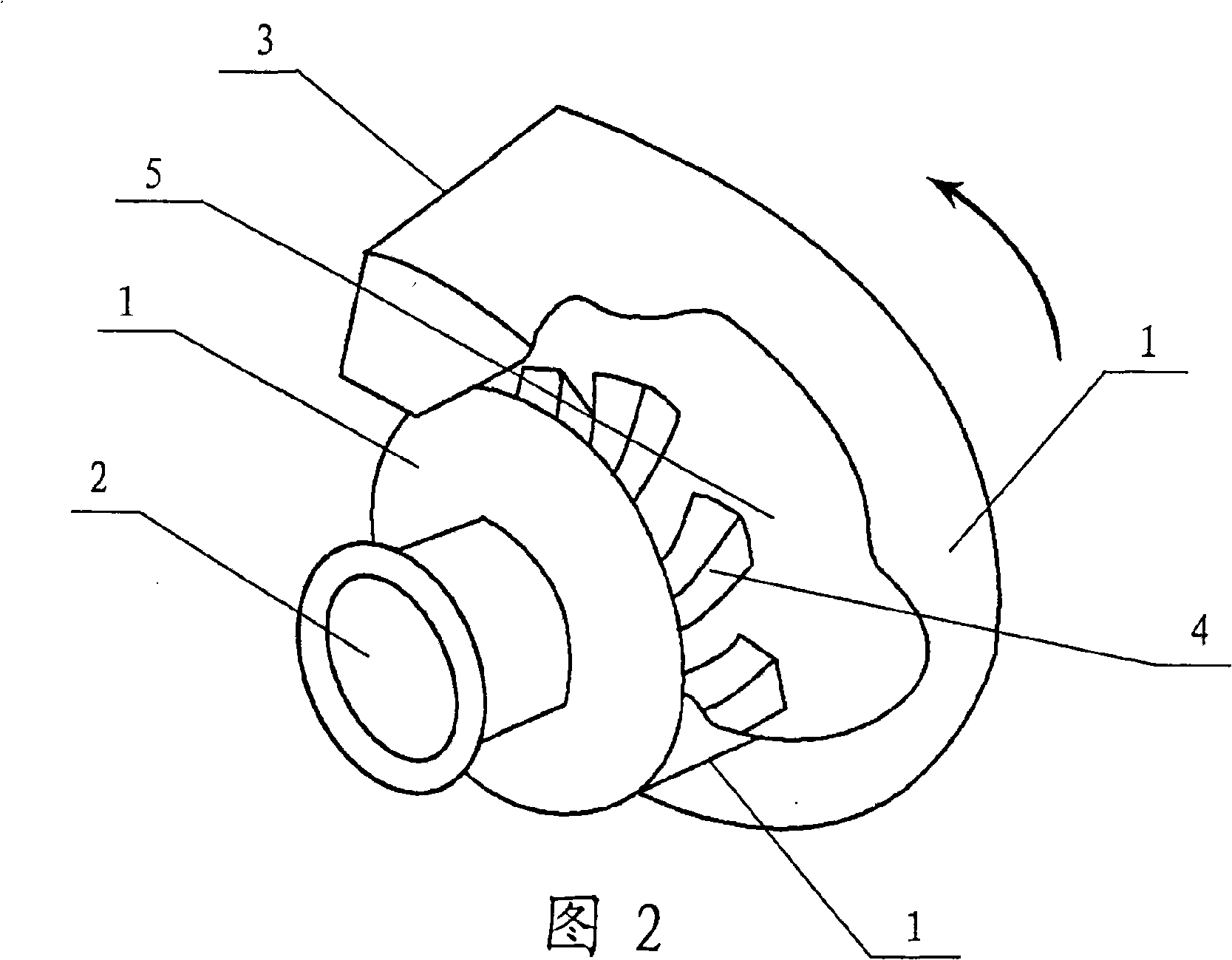

[0029] Embodiment 1, supercharged centrifugal fan (reference figure 1 ,figure 2, Figure 10 ), with a casing 1, a fan air inlet 2, a fan outlet 3, a centrifugal backflow fan impeller 4, an airflow diffusion channel 5 inside the casing, and a motor 11, and the airflow diffusion channel 5 inside the casing is located on the centrifugal backflow fan The rear shaft of the impeller at the radially rear of the impeller 4 is outside the rear shaft, and the air diffusion channel 5 inside the casing is directly connected with the fan outlet 3. The position is facing the air inlet 2 of the fan. The air flow diffuser channel 5 inside the casing is composed of three side walls, the radial inner side wall 6 of the cylindrical casing, the outer side wall 7 of the cylindrical casing, and the axial (rear) side wall 8 of the casing, forming an annular cavity structure. The front axial side of the airflow diffusion channel 5 inside the casing is provided with an inlet 9 of the airflow diffusi...

Embodiment 2

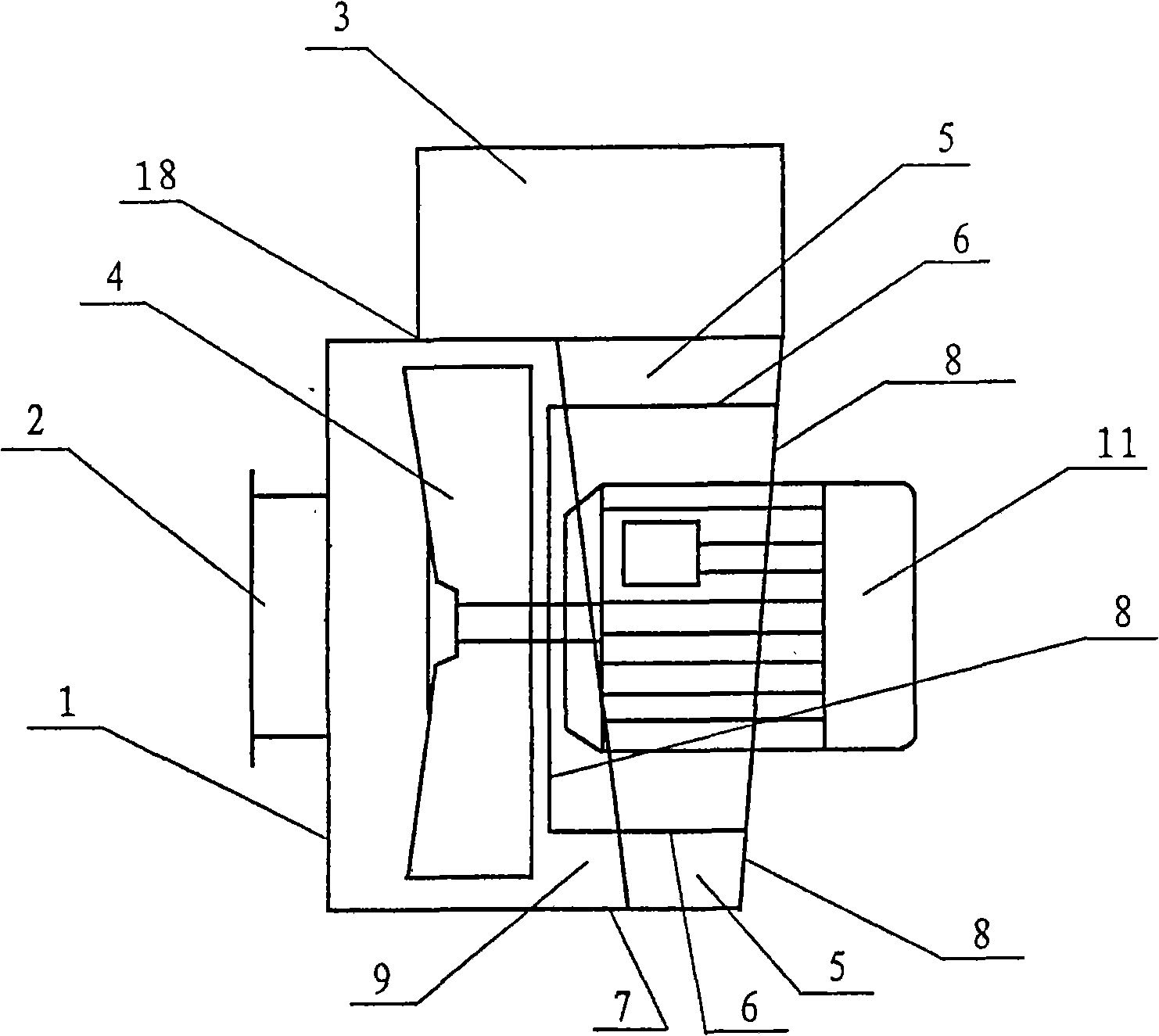

[0033] Embodiment 2, refer to image 3 , 4, 5, this example is basically the same as example 1, the difference is that the air flow diffuser channel 5 inside the casing of this example starts from the volute tongue 18 of the fan outlet 3, and gradually expands in the axial direction along the direction of the impeller, that is The axial dimension of the radial outer wall 7 of the casing is getting larger and larger.

[0034] When working, because the airflow discharged from the impeller collides with the airflow in the airflow diffuser channel inside the casing from the outer surface, the degree of disturbance is small and the eddy current is relatively weak. Therefore, it can be ensured that the airflow in the airflow diffusion channel inside the casing is decelerated and diffused steadily and fully in the airway gradually expanding in the axial direction, and finally reaches the required wind pressure. In this example, since the frictional loss and eddy current loss of the...

Embodiment 3

[0036] Embodiment 3, refer to Figure 6 , 7 , this example is basically the same as Example 1, the difference is that the air flow diffuser channel 5 inside the casing of this example starts from the volute tongue 18 of the fan outlet 3, and gradually expands radially along the impeller direction, that is, the casing axis The radial size of the (rear) sidewall 8 is getting bigger and bigger, and the radial size of the airflow diffusion channel 5 inside the casing is getting bigger and bigger. This structural formula is suitable for making the airflow diffusion channel inside the large-capacity casing.

[0037] When this example works, the high-speed airflow discharged from the impeller contacts and collides with an outer surface of the airflow in the airflow diffuser channel inside the casing, the degree of disturbance is small, and the eddy current is weak, so its friction loss and eddy current loss are relatively small. The biggest feature of the fan is that it can ensure t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com