Novel vertical vehicle turbocharger

A turbocharger, vertical vehicle technology, applied in gas turbine devices, machines/engines, internal combustion piston engines, etc., can solve the problems of reducing the charging efficiency of the engine cylinder, reducing the supercharging efficiency of the supercharger, and not solving the problems. The effect of improving the charging efficiency, ensuring the supercharging efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is further described below in conjunction with embodiment and accompanying drawing.

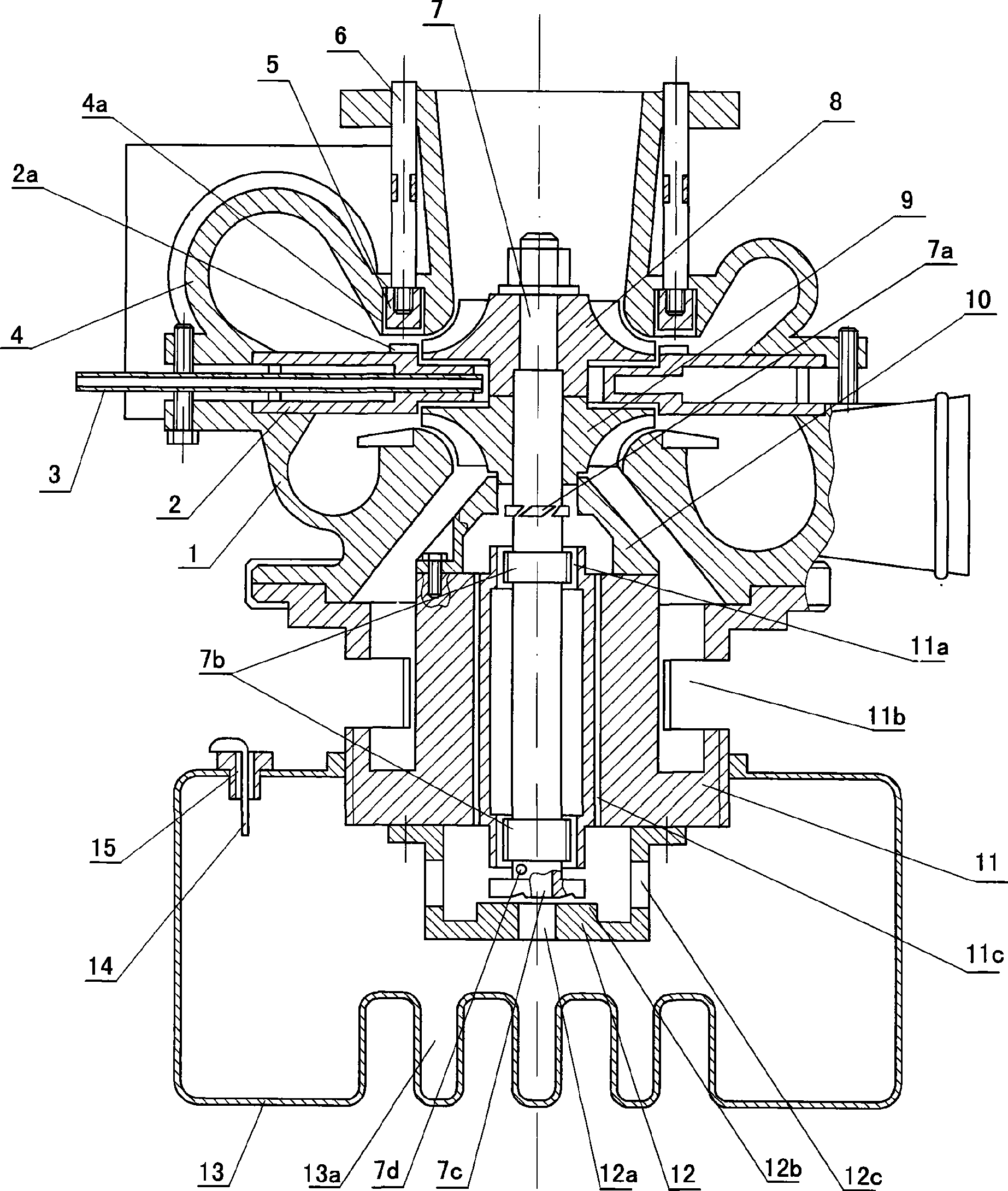

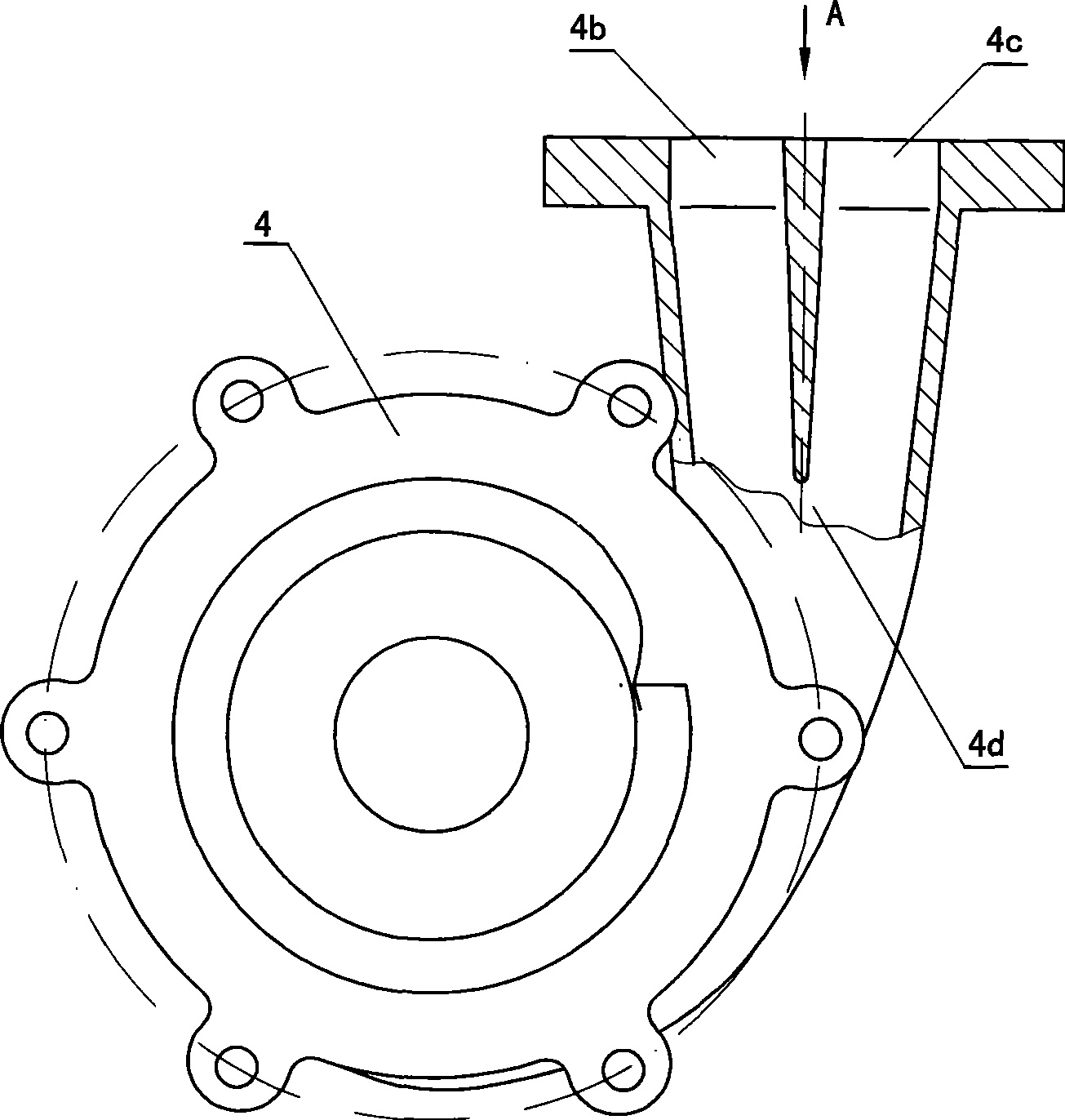

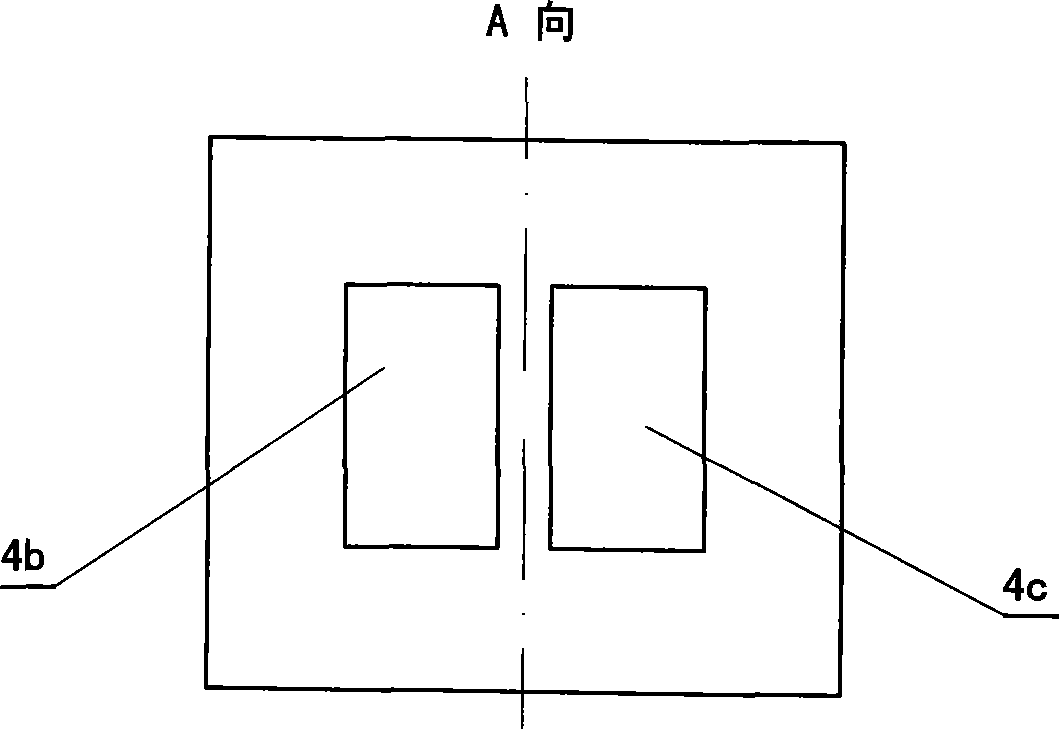

[0011] The connected turbine casing 4 and the compressor casing 1 are separated by a heat shield 2 between their inner cavities, the turbine casing 4 and the compressor casing 1 are connected by bolts, and the heat shield 2 is located in the turbine casing 4 On one side of the nozzle vanes 2a uniformly distributed along the throat of the turbine shell 4 are fixed. The compressor housing 1 is supported by a bearing housing 11 , and the bearing housing 11 is provided with an air inlet 11 b communicating with the inner cavity of the compressor housing 1 . The top of the rotating shaft 7 installed in the bearing housing 11 is located in the compressor casing 1 and the turbine casing 4, and the turbine 8 and the compressor impeller 9 installed on the top of the rotating shaft 7 are respectively in the turbine casing 4 and the compressor casing 1. Turbine 8 is a radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com