Mulberry soft can preparation method

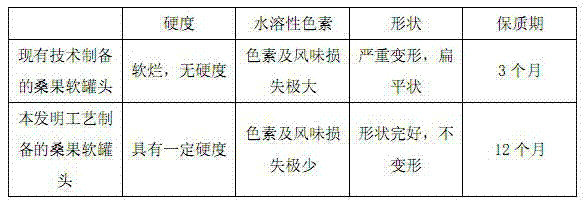

A technology for soft canning and mulberry fruit, which is applied in the fields of fruit and vegetable preservation, fruit/vegetable preservation with sugar, food preservation, etc. It can solve the problem of water-soluble pigments, loss of nutrients, affecting the sales prospect of canned mulberry fruit market, loss of shape and application Some problems such as hardness, to achieve the effect of maintaining natural properties and nutritional value, reducing product heating time, and maintaining the original texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of preparation method of mulberry soft can of the present invention specifically comprises the following steps:

[0026] (1) Selection of fresh mulberries: select eight or nine mature "Hongguo No. 2" as raw materials, and remove rot and sundries;

[0027] (2) Destemming and grading: remove the green roots at the bottom of the mulberries and grade them according to their size;

[0028] (3) Cleaning and draining: Wash the graded mulberry fruits with flowing water according to the specifications, and drain them in time;

[0029] (4) Weighing and canning: Weigh the mulberries and put them into soft cans;

[0030] (5) Prepare soup and add soup: add white sugar and citric acid to drinking water according to the following mass percentages to obtain soup liquid, wherein the concentration of white sugar is 21wt%, and the concentration of citric acid is 0.5wt% (wt% refers to the concentration of mass percentage Meaning), the soup liquid is heated to and maintained at 92°...

Embodiment 2

[0038] A kind of preparation method of mulberry soft can of the present invention, with embodiment 1, its difference is:

[0039] In step (5), white sugar and citric acid are added to drinking water in the following mass percentages to obtain a soup, wherein the white sugar concentration is 18wt%, and the citric acid concentration is 0.4wt%, and the soup is heated to and maintained at 88 °C and pour it into the soft cans filled with mulberries in time, wherein the solid content of mulberries is 45%;

[0040] In step (6), under the vacuum condition of 95KPa, the soft can is subjected to impulse sealing;

[0041] In step (7), put the sealed soft can in a water bath at 83°C for 10 minutes; in step (8), cool the sterilized soft can to 38°C in time with normal temperature water;

[0042] In step (10), put the drained soft cans into a heat preservation warehouse at 37°C for 7 days.

Embodiment 3

[0044] A kind of preparation method of mulberry soft can of the present invention, with embodiment 1, its difference is:

[0045] In step (5), white sugar and citric acid are added to drinking water in the following mass percentages to obtain a soup, wherein the white sugar concentration is 24wt%, the citric acid concentration is 0.6wt%, and the soup is heated to and maintained at 95 °C and pour it into the soft cans filled with mulberries in time, wherein the solid content of mulberries is 55%;

[0046] In step (6), under the vacuum condition of 110KPa, the soft can is subjected to impulse sealing;

[0047] In step (7), put the sealed soft can in a water bath with a temperature of 85°C and keep it for 8 minutes; in step (8), cool the sterilized soft can to 40°C in time with room temperature water;

[0048] In step (10), put the drained soft cans into a heat preservation storehouse at 37°C for 10 days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com