Method for extracting sa-son seed gum from artemisia sphaerocephala krasch seed

A technique for extracting Artemisia polysaccharides and Artemisia seeds, which is applied in the field of mechanized extraction of Artemisia polysaccharides, can solve the problems of low yield, low purity, and high cost of finished gum, and achieve high gum extraction rate, high purity of finished products, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

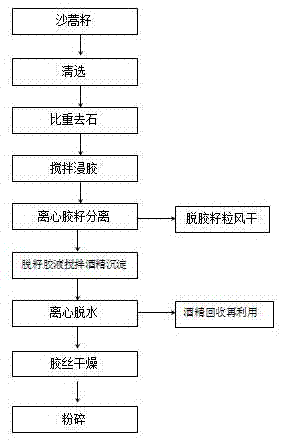

[0025] The method uses Artemisia baicalensis seeds as raw materials and utilizes a mechanized separation method. The specific steps are as follows: the Artemisia annua seeds are cleaned by a cleaning machine, and then selected and stone-removed by a specific gravity de-stoning machine to obtain clean Artemisia annua seeds. Weigh 10 kg of clean material, put it into a liquid mixing tank, add 80L of tap water (8 times the weight of the net material), and stir in the mixing tank at a speed of 65 rpm for 40 minutes to make a gel-like viscous mixture . The stirred gelatinous material is continuously added to the two-phase separation horizontal screw sedimentation centrifuge for separation, the non-glue grains are discharged through the slag outlet at the small end of the drum, and the glue liquid flows out from the overflow weir at the large end of the drum. This separation process can be operated continuously. . Naturally dry the glue-free seeds to obtain 7.92 kg of glue-free se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com