Continuous casting-rolling and extrusion molding device of Al-Mg-Cu alloy and composite materials

A composite material and extrusion forming technology, which is applied in metal extrusion forming tools, metal extrusion, metal rolling, etc., can solve the problems of low performance of profiles, achieve the effect of improving performance and preventing deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

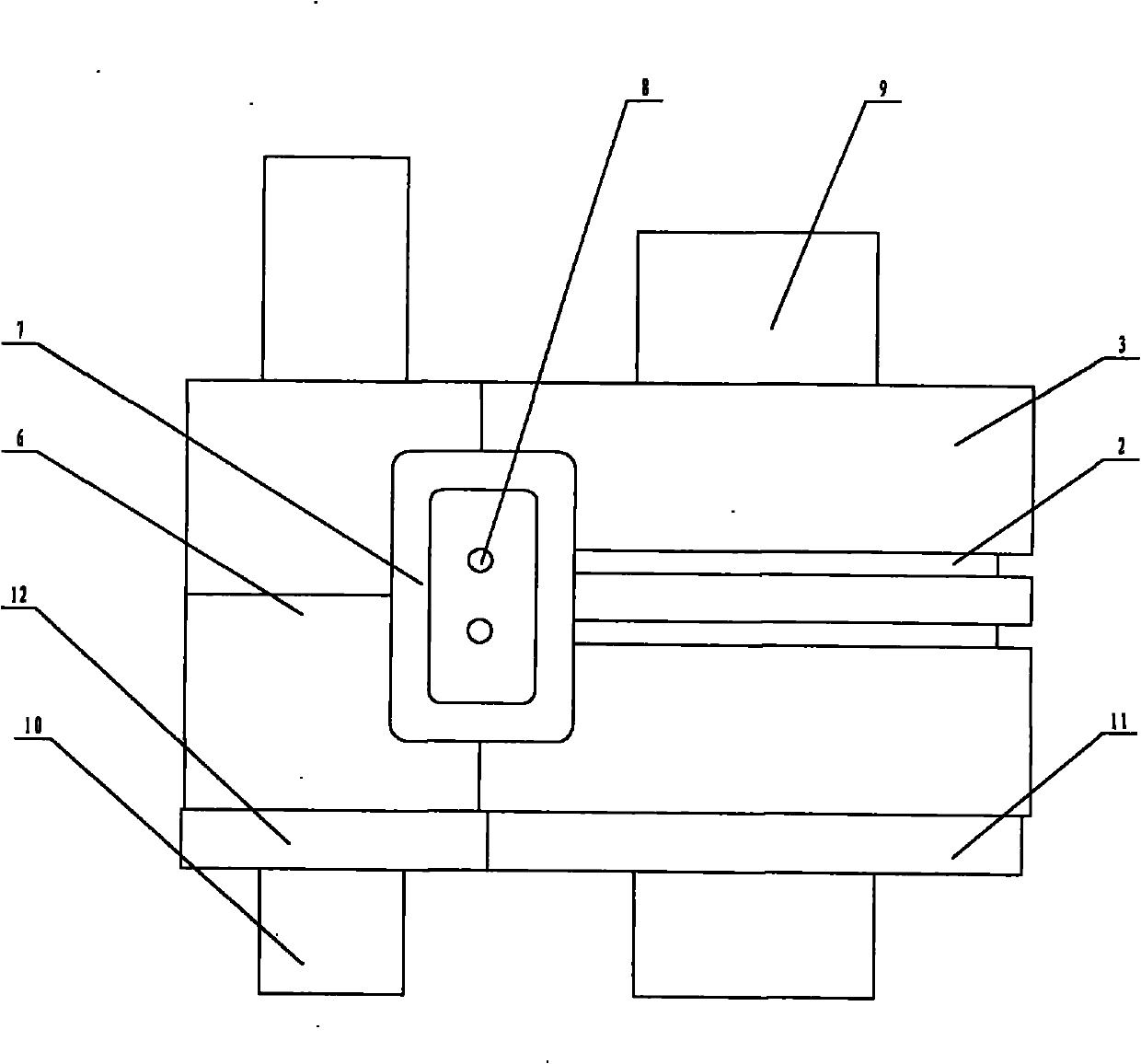

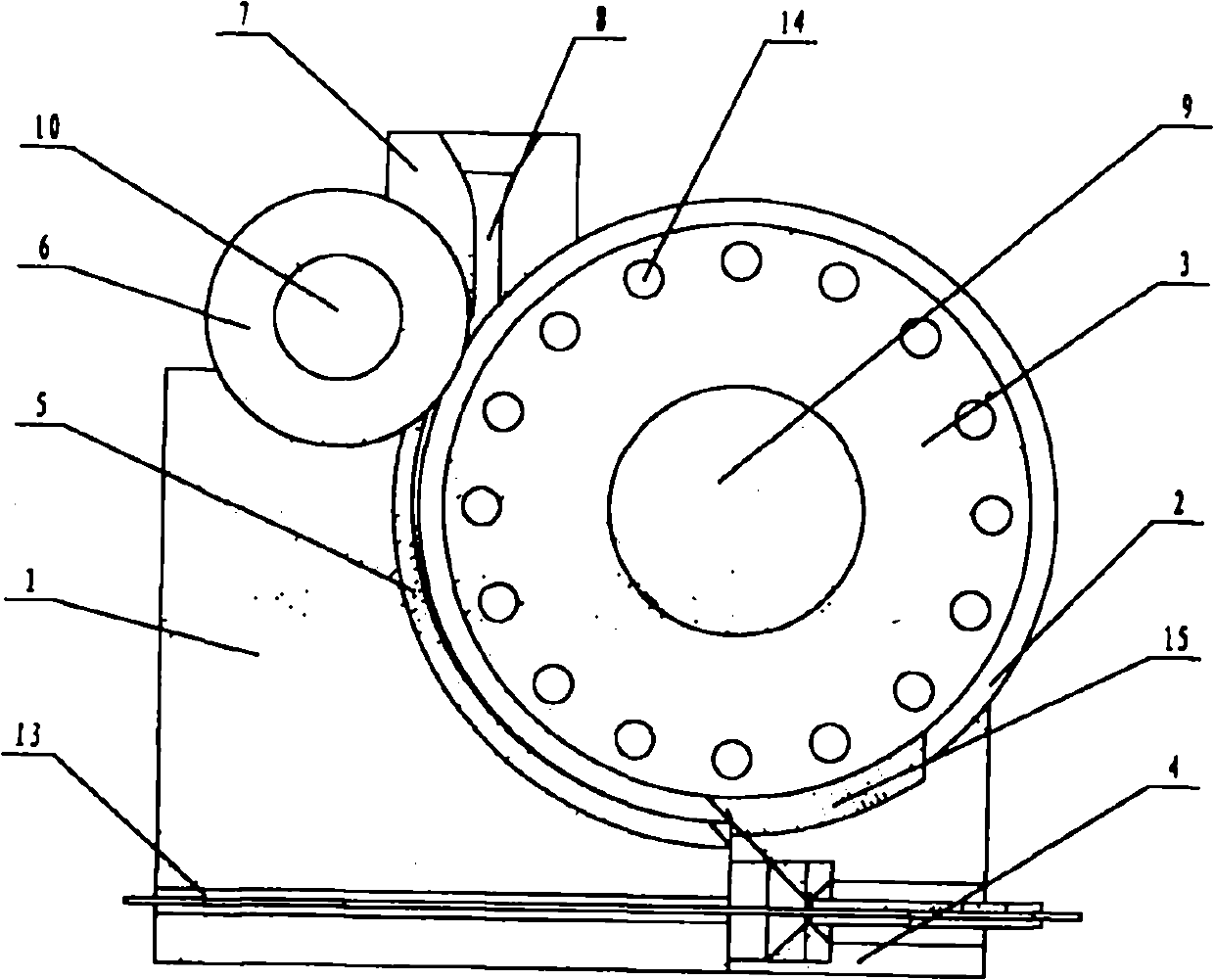

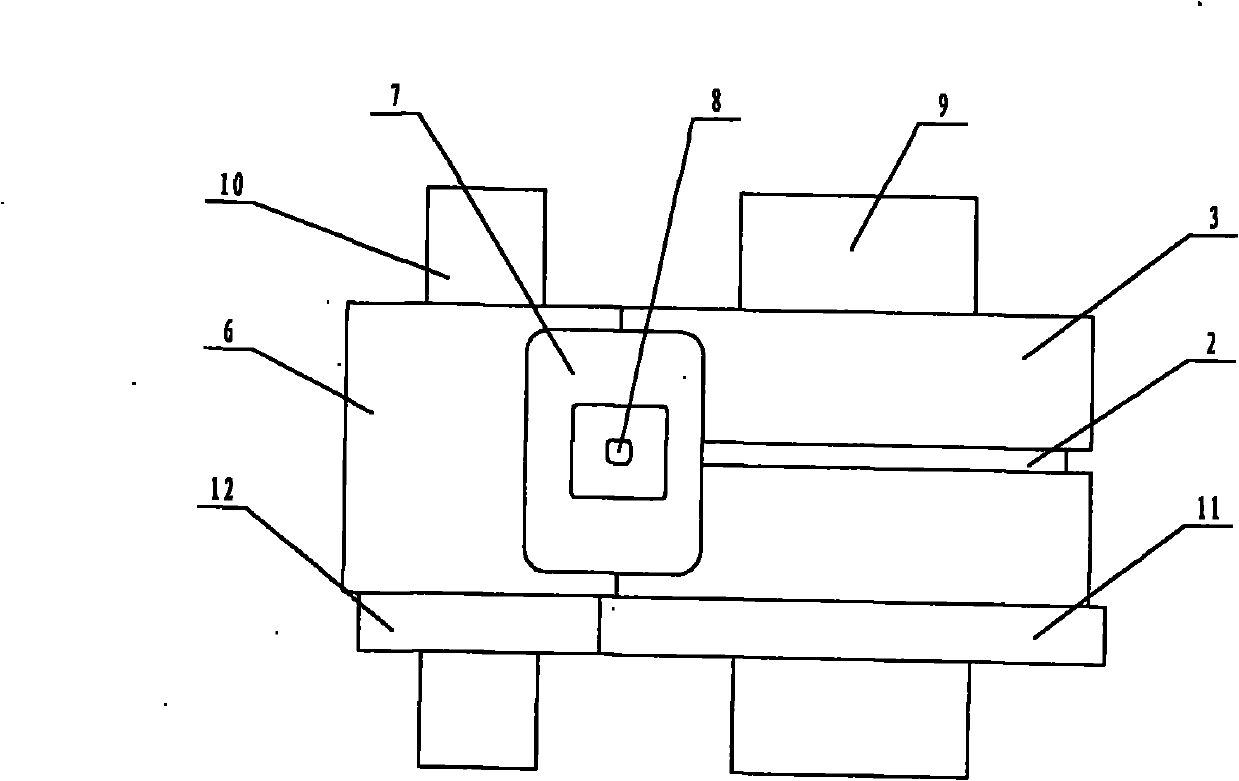

[0018] A continuous casting-rolling extrusion forming device for aluminum, magnesium, copper alloys and composite materials, a machine frame, an extrusion seat 1, a material stopper 15, a drive shaft 9, and an extrusion groove 2 fixed on the roller surface Squeeze roller 3, mold 4 and groove sealing block 5 between extrusion seat 1 and extrusion roller 3, driven shaft 10 is arranged on the frame, and the roller surface is fixed on the driven shaft 10 to be close to the extrusion roller Casting roll 6 with 3 roll surfaces and located above the extrusion seat 1, the lower roll surface of the casting roll 6 is transitionally matched with the extrusion seat 1 and the upper surface of the groove sealing block 5, and the casting roll 6 is surrounded by a crystallizer fixed on the frame 7. There are crystallization holes 8 on the crystallizer 7 and the lower end of the crystallization holes 8 is located above the contact part of the casting roll 6 and the extrusion groove 2, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com