Formula car engine air intake system

A formula racing and air intake system technology, applied in the field of formula racing engine intake system, can solve the problems of engine output power and torque drop, unfavorable intake system intake efficiency, large intake resistance of intake system, etc. The effect of improving gas efficiency, light weight, and reducing gas flow loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

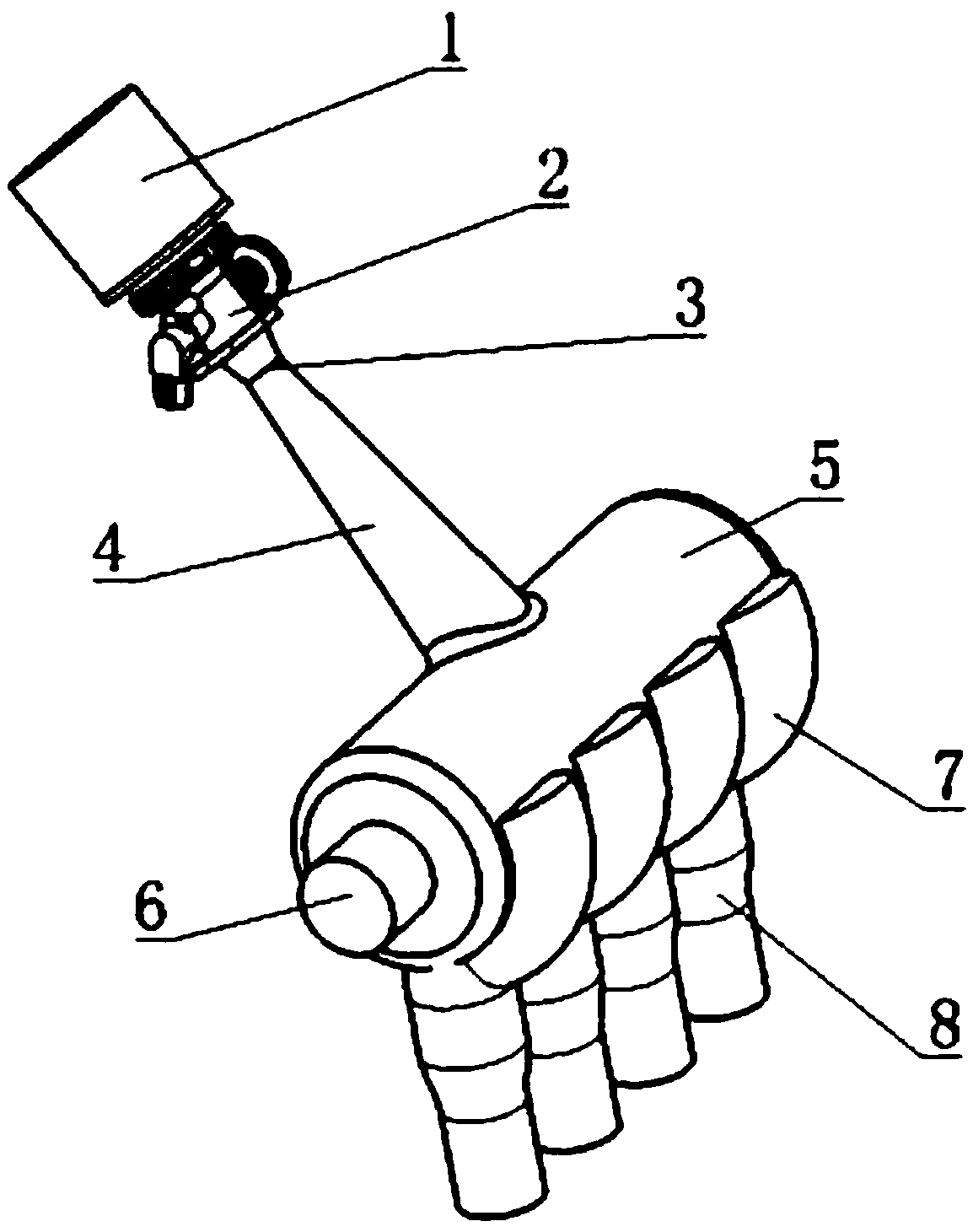

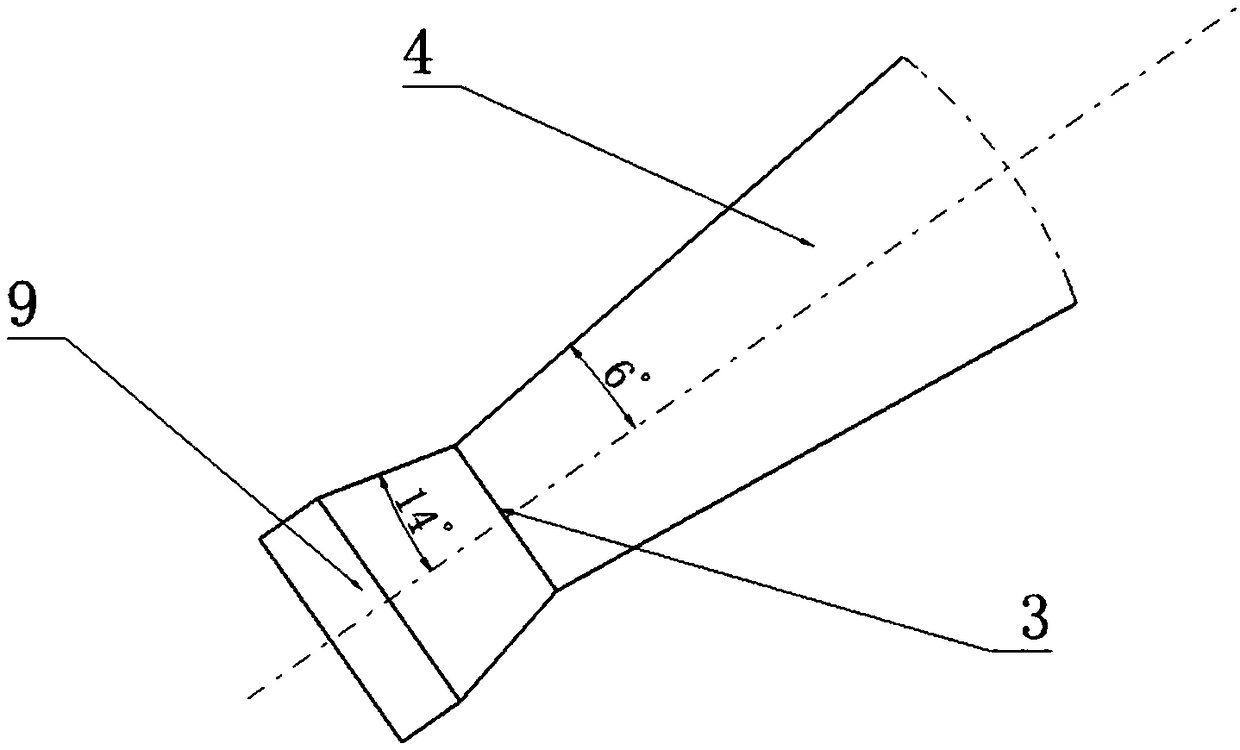

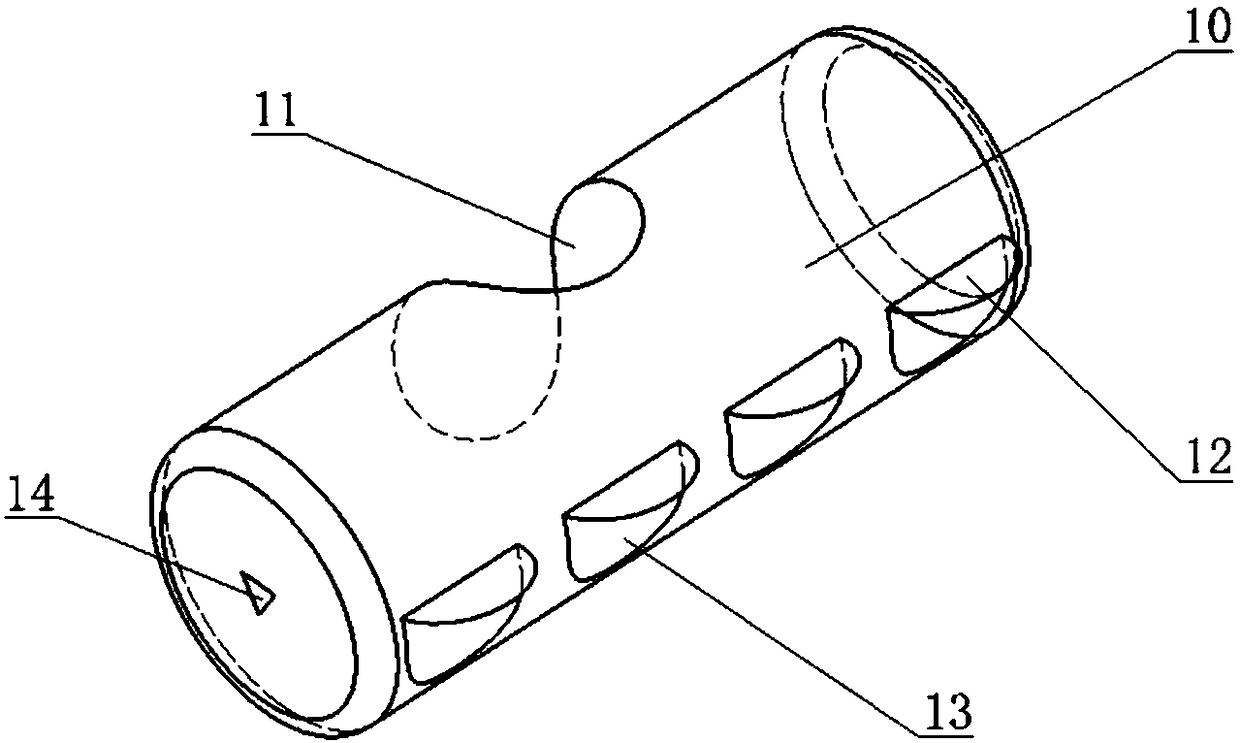

[0023] see figure 1 , a formula car engine intake system, including an air filter 1, a throttle valve 2, a restrictor 3, a diffuser 4, a resonance cavity 5, a variable intake manifold 7, a fixed intake manifold 8 and a manifold Tube length regulator 10; the throttle valve 2 is a pull-wire mechanical throttle valve with an inner diameter of 28 mm, the inlet of the throttle valve 2 is connected to the air filter 1, and a mechanical clamp is used between the air filter 1 and the throttle valve 2 Connection, the rear end of the throttle valve 2 outlet is connected to the restricted flow port 3, the inner diameter of the restricted flow port 3 is 20mm, and it is formed by CNC milling of stainless steel material, and the inlet cone angle and outlet cone angle of the restrictor port 3 are 14° and 6° respectively. °, the cross-sectional area of the inta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com