Fan assembly of built-in generator

A technology for fan components and generators, applied in the directions of electric components, engine components, electrical components, etc., can solve the problems of increasing the power supply capacity of the engine, low output power efficiency, and large additional weight, etc., to improve the power supply capacity, convenient installation, and easy The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

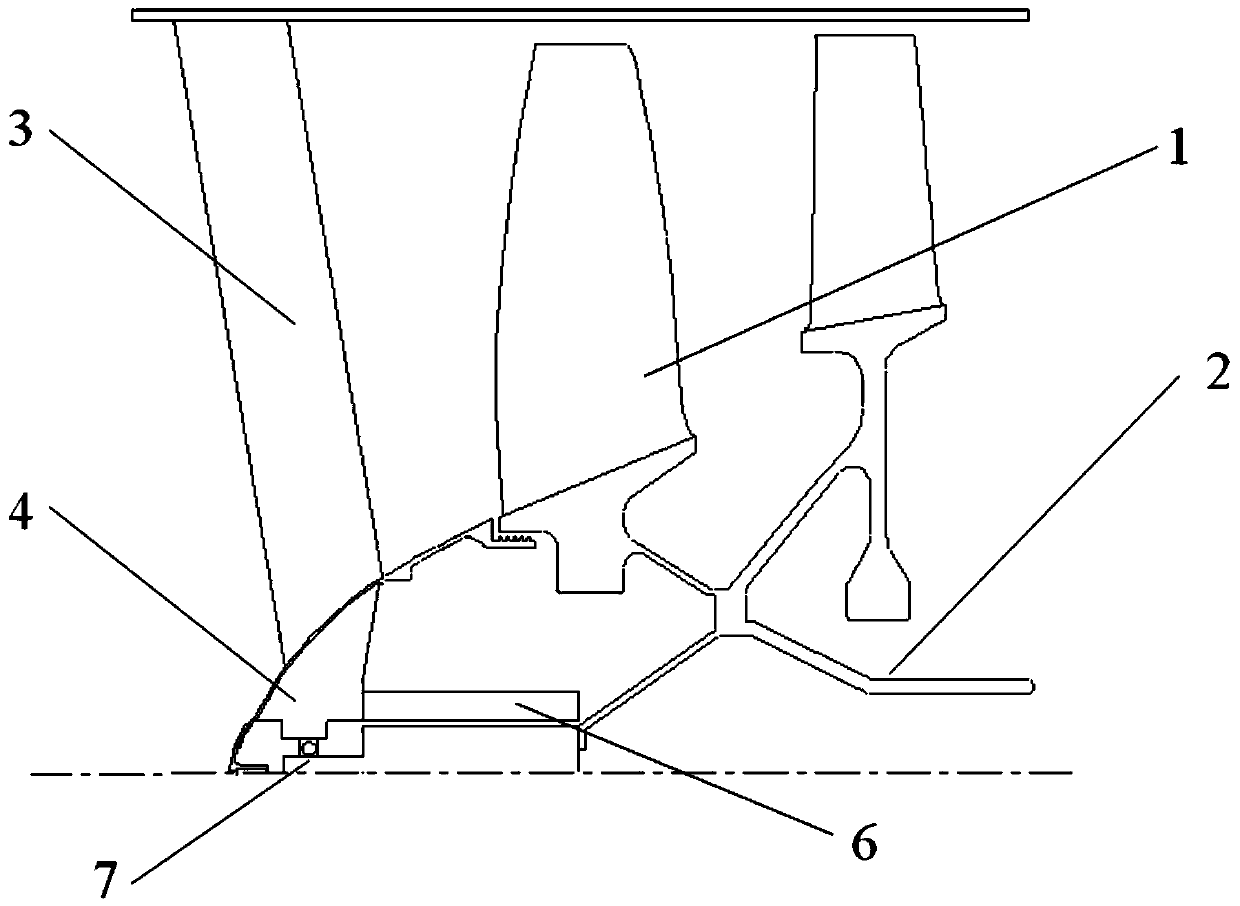

[0010] Taking the built-in electric excitation doubly salient generator as an example, the present invention proposes a fan assembly with a built-in generator in detail, as follows: figure 1 As shown, the dual-rotor turbofan engine fan built-in electrically-excited double-salient pole generator solution is used to install electrically-excited double-salient pole motors 4 and 5 in the cavity of the fan 1 and the intake cone 4 to extract low-voltage rotor power, wherein the motor The rotor 5 is installed on the fan shaft 2, and the motor stator is installed on the intake cone 4, and is fixed by the intake support plate. When the low-pressure rotor of the dual-rotor turbofan engine rotates, the motor rotor 4 is rotated, and the motor rotor 4 and the motor stator 5 cut the magnetic induction lines to generate electric energy. In order to realize the scheme of building electric excitation doubly salient generators 4 and 5 in the fan 1, it is necessary to carry out some adaptive imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com