Traction power supply network tail end voltage boosting device with power fusing function and method of device

A traction power supply and power integration technology, applied in circuit devices, harmonic reduction devices, AC network voltage adjustment, etc., can solve the problems of low power factor, small series compensation capacity, and single function on the measurement and assessment side of the substation, and achieve Improve the overall capacity utilization, suppress the vehicle network resonance function, and suppress the effects of ripple current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

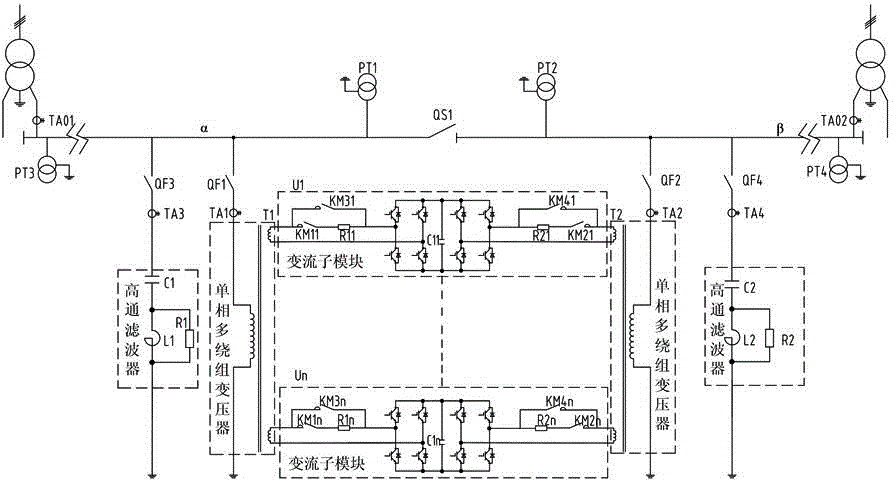

[0040] Such as figure 1 As shown, this embodiment has a traction power supply terminal network voltage lifting device with power integration function, including:

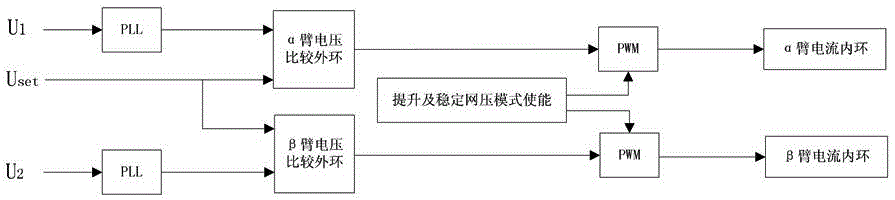

[0041] The multiple step-down module is used to connect to the power supply of the two power supply arms at the end of the traction network and step down the voltage. It includes two single-phase multi-winding transformers with the same structure. The two single-phase multi-winding transformers are respectively connected to two Power supply arm power supply, corresponding to multiple sets of α-arm voltage and β-arm voltage after output voltage reduction;

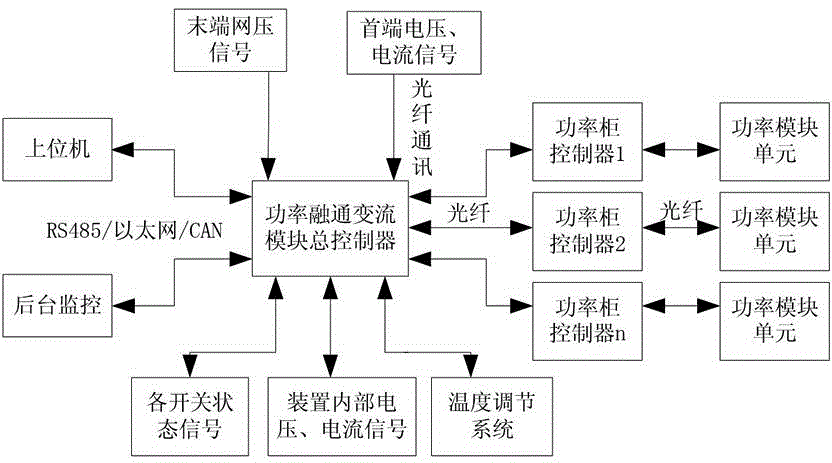

[0042] The power integration and conversion module is used to convert the energy of the connected two power supply arm power sources respectively,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com