Air inlet of air-breathing pulse detonation engine

A technology of pulse detonation and air inlet, which is applied in the direction of machine/engine, rocket engine device, jet propulsion device, etc., and can solve the problem of shortening the length of the engine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

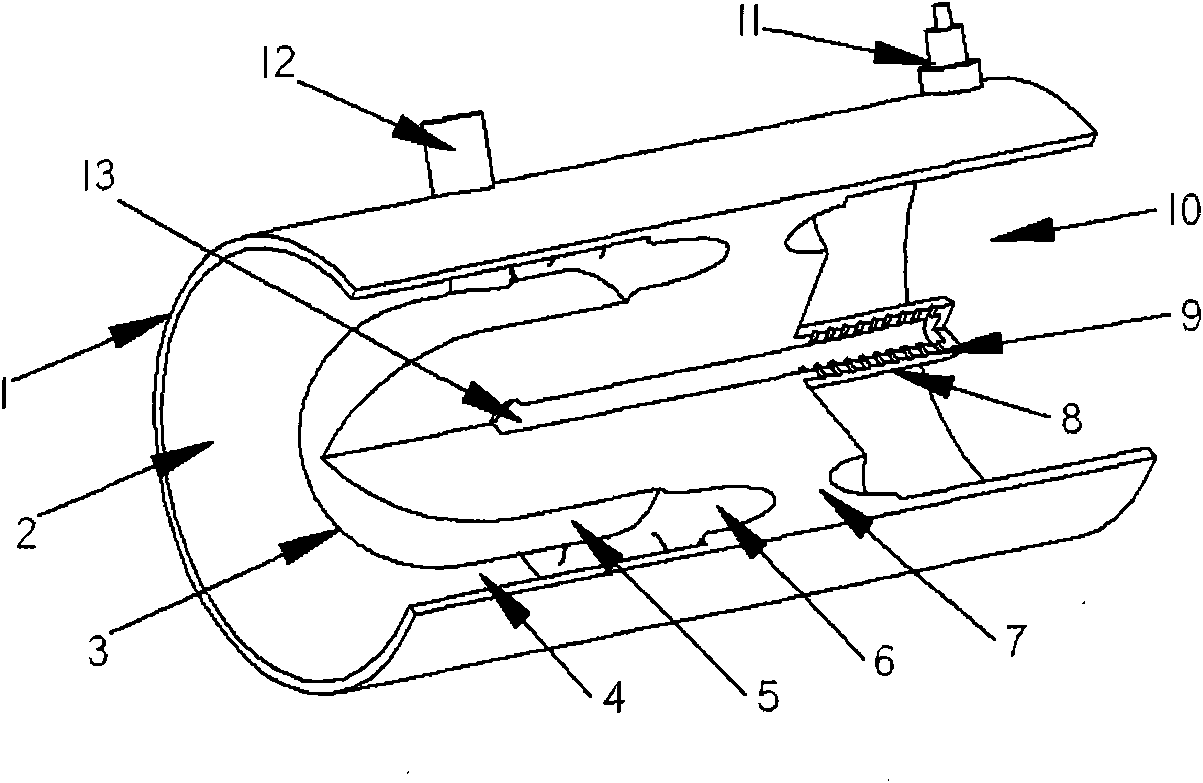

[0017] The field of application of the present invention is as figure 1 Air-breathing pulse detonation engine inlet and head shown. But the present invention is also applicable to certain burners that require faster oil-gas mixing and higher atomization quality.

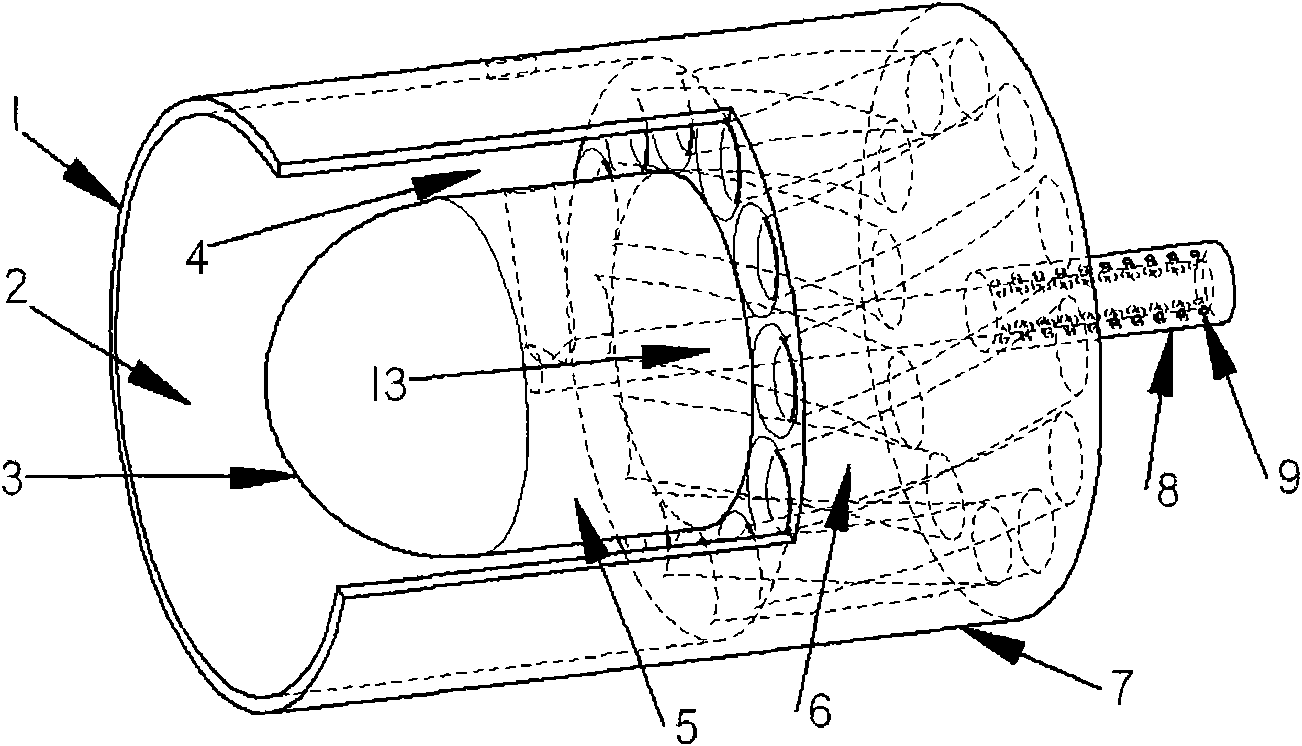

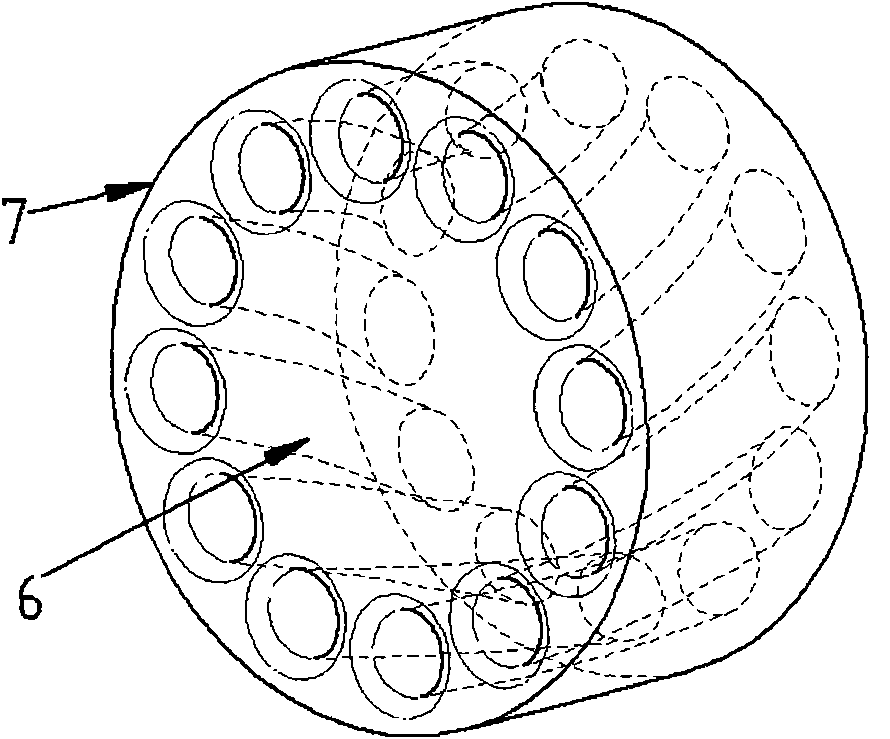

[0018] Such as figure 1 , figure 2 Shown, the present invention comprises engine housing 1, air intake duct 2, intake cone 3, cylindrical structure 5 at the rear of intake cone, special-shaped structure 7, fuel injection rod 8, mixing chamber 10, spark plug 11, fuel oil Inlet 12 and fuel passage 13. The engine casing 1 forms a circular air inlet 2, and the air flows into the engine head through the air inlet 2. There is an air inlet cone 3 at the central axis of the rear end of the air inlet, and the cylindrical structure 5 at the rear of the air inlet cone An annular channel 4 is formed with the engine housing 1 . The air flows into the special-shaped structure 7 after passing through the annular channel. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com