Patents

Literature

219results about How to "Stable ignition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

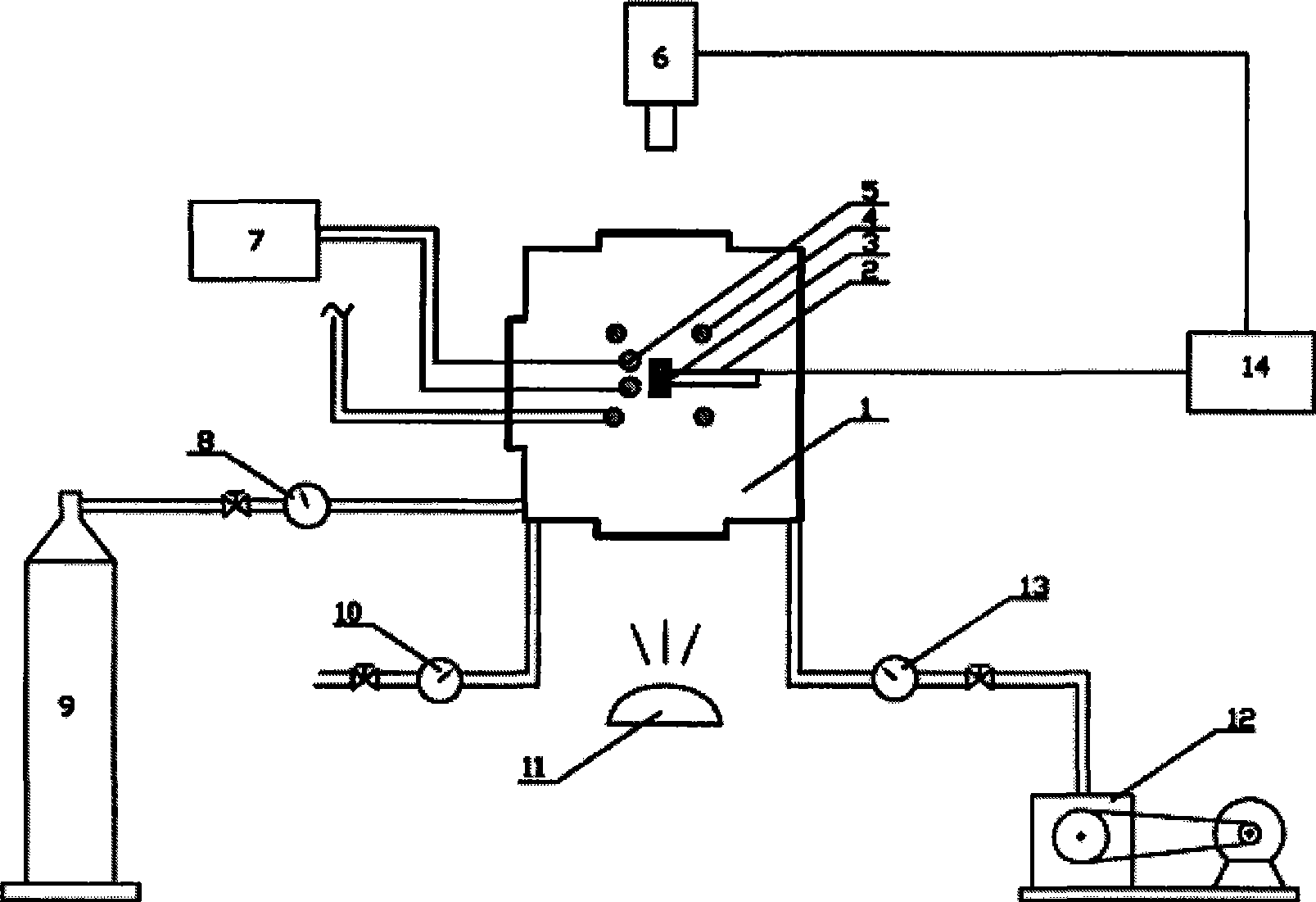

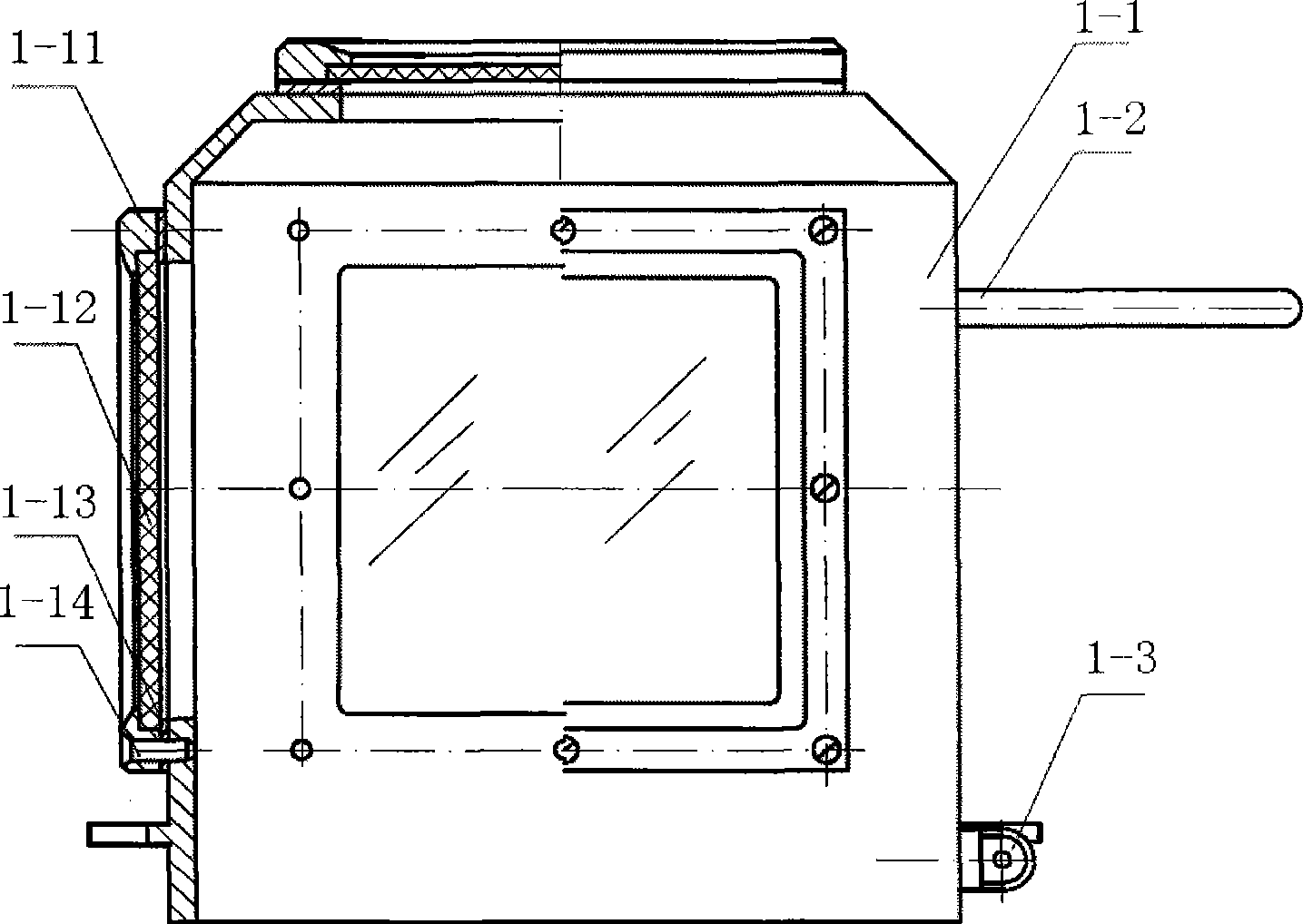

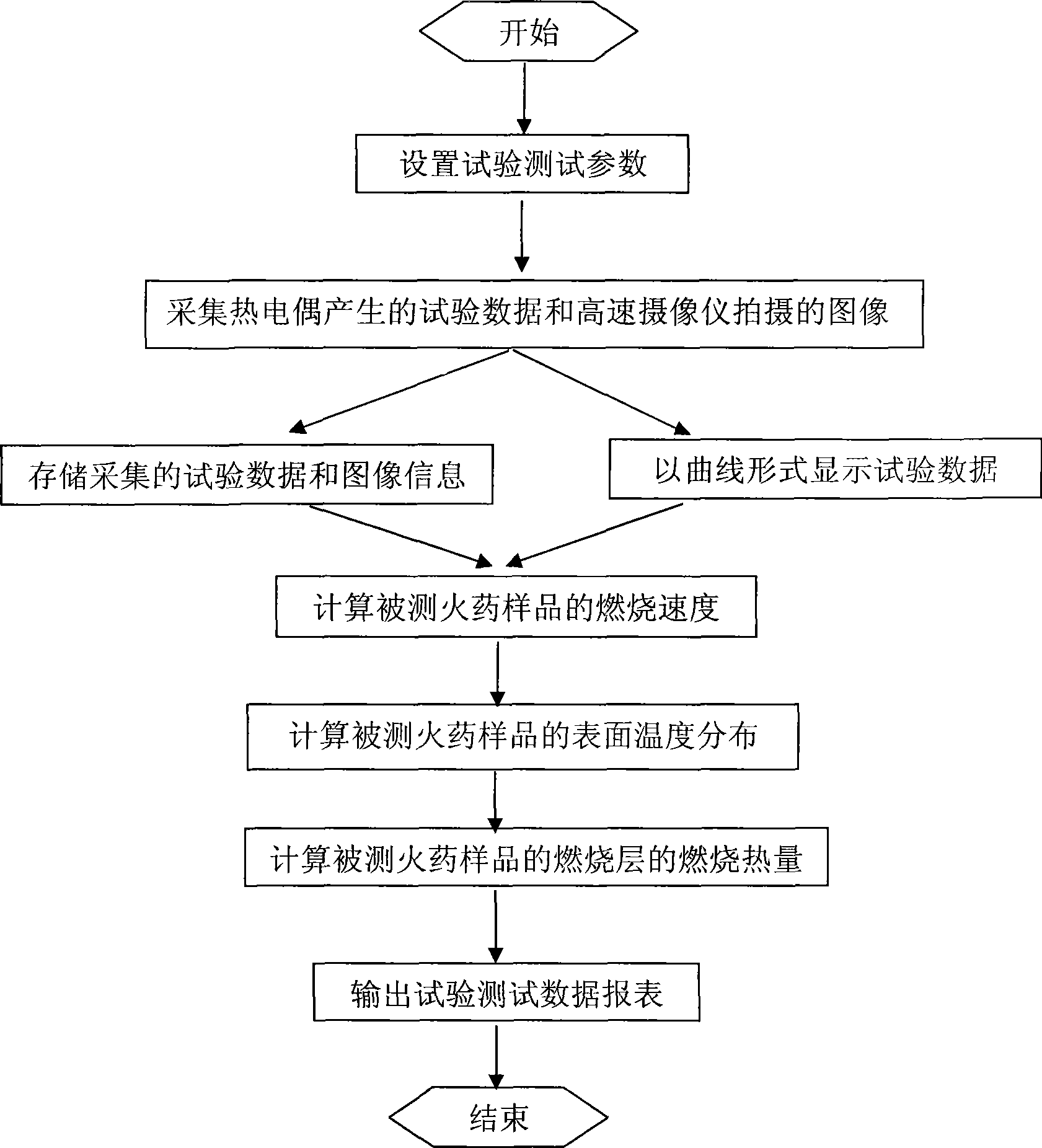

Device for testing powder combustion characteristics in vacuum condition

InactiveCN101382533ARealize measurementEfficient use ofChemical analysis using combustionFuel testingCombustion chamberHeating time

The invention discloses a testing device of gunpowder combustion characteristics in vacuum, which mainly comprises a combustion chamber, a vacuum pump, an electric heater, a thermoelectric couple, a high speed camera and a data acquisition and processing system; wherein, the vacuum pump provides vacuum environment for the combustion chamber; by controlling the heating current and the heating time of the electric heater, different ignition isoperibols can be provided for tested gunpowder samples in the combustion chamber; and the data acquisition and processing system collects the test data generated by the thermoelectric couple and the gunpowder combustion images shot by the high speed camera when the tested gunpowder samples combust, and finally obtains the combustion characteristics of the tested gunpowder samples through corresponding processing and calculation. The invention not only can be used for testing the parameters such as combustion speed, combustion surface temperature and combustion heat and the like of the gunpowder in vacuum, but also can be used for the generation and collection of the combustion products of the gunpowder under different vacuum conditions. The invention has the overriding advantages of high integration level, obtaining various parameters by one testing and low testing expenses.

Owner:XIAN MODERN CHEM RES INST

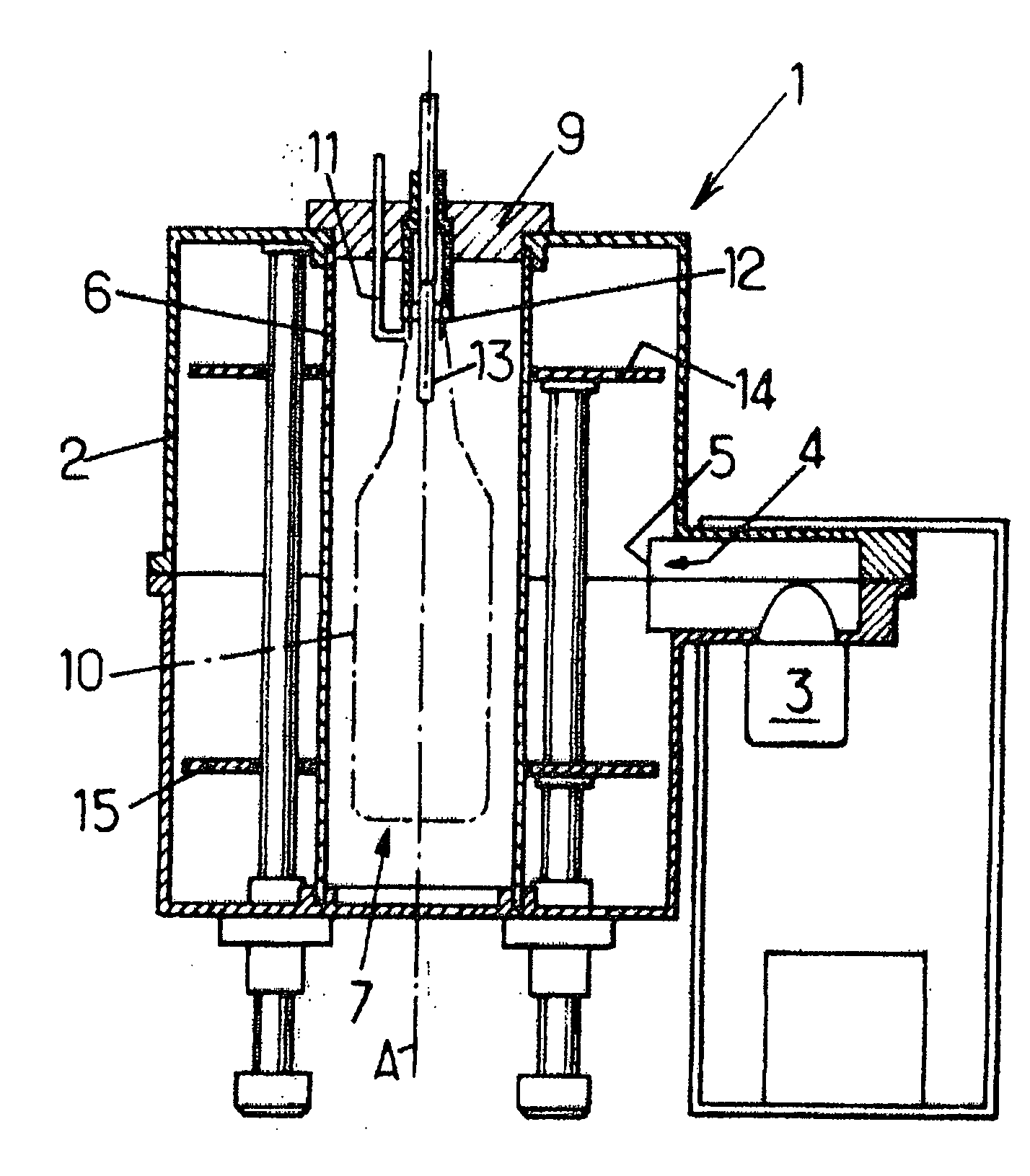

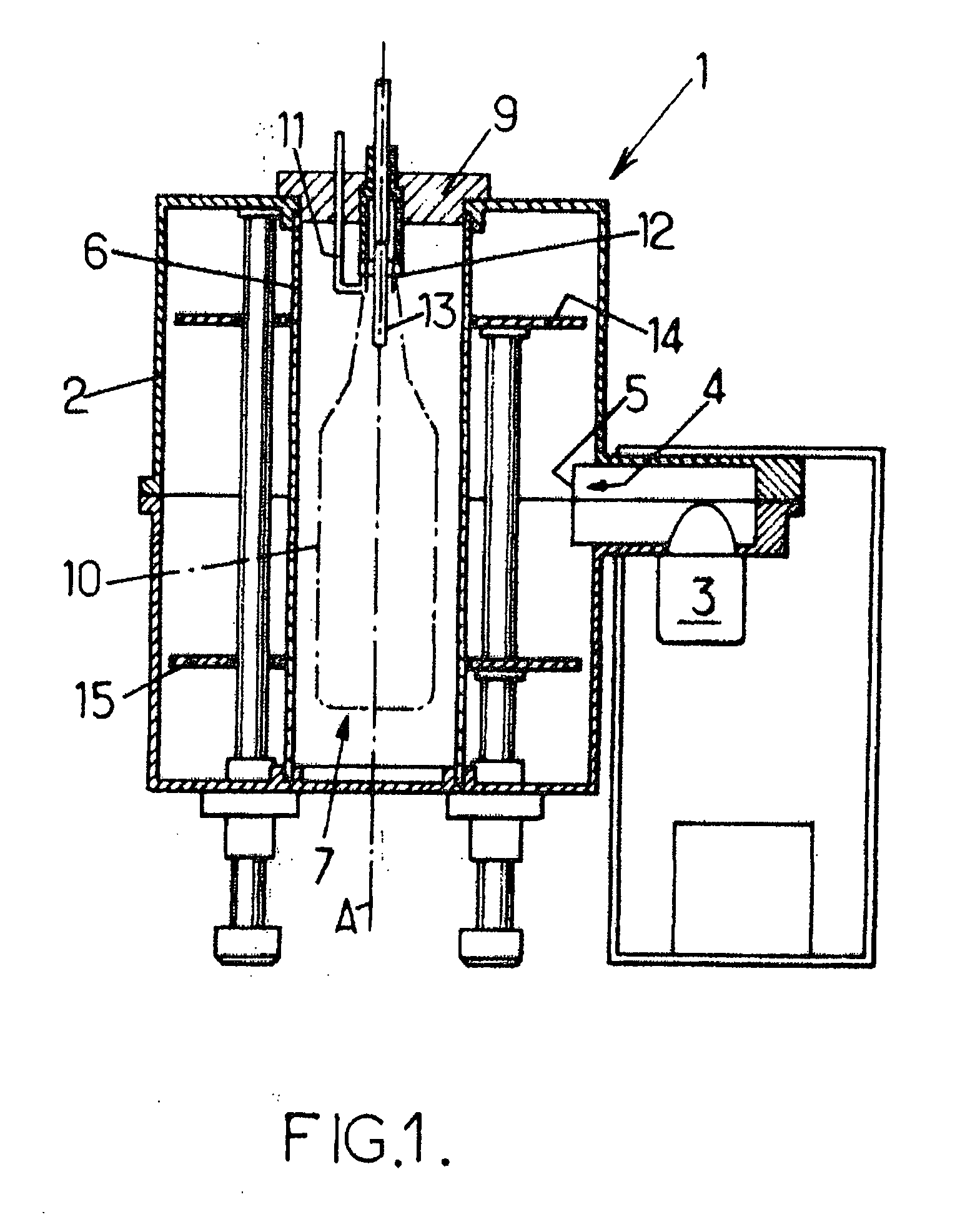

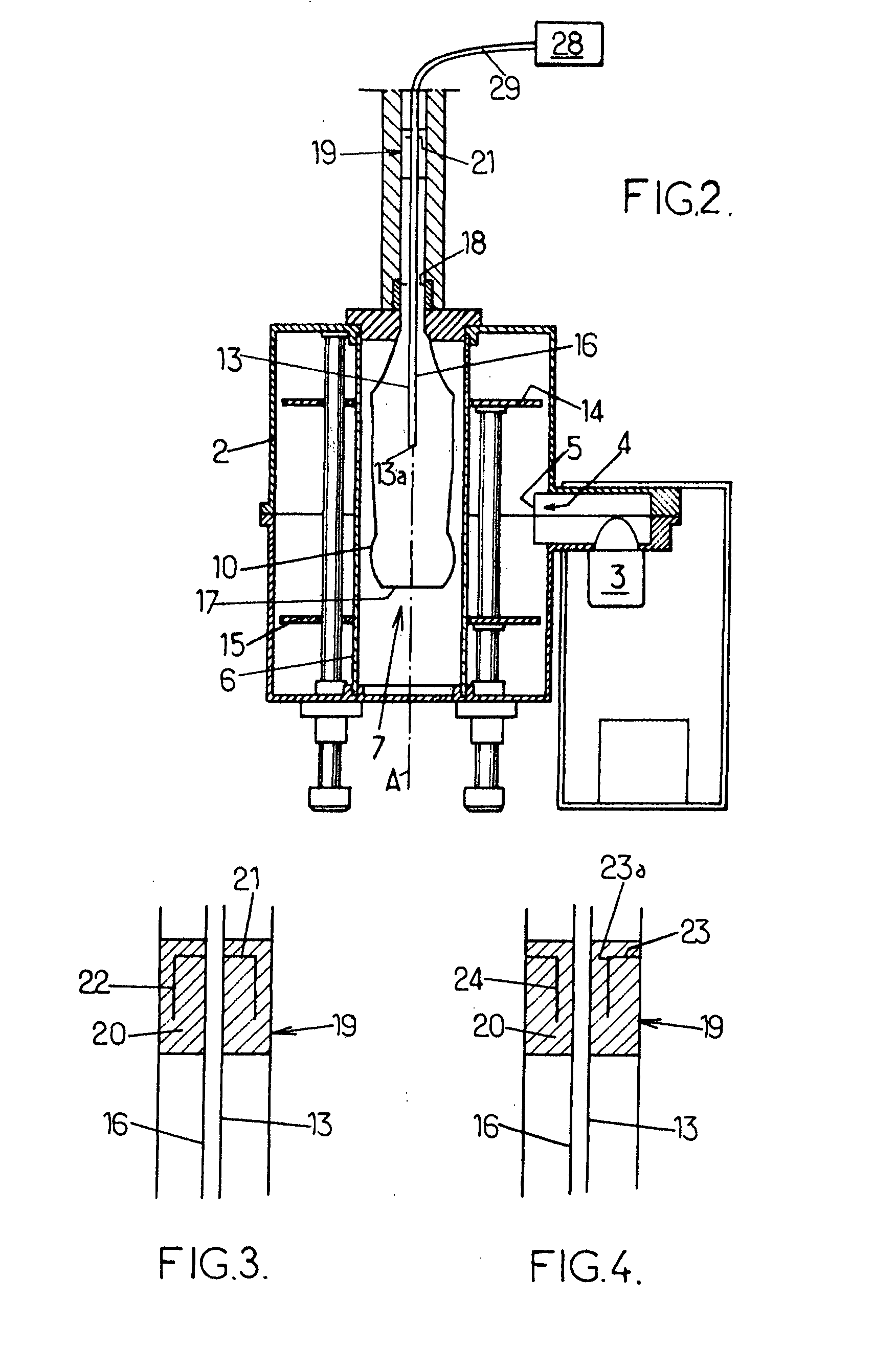

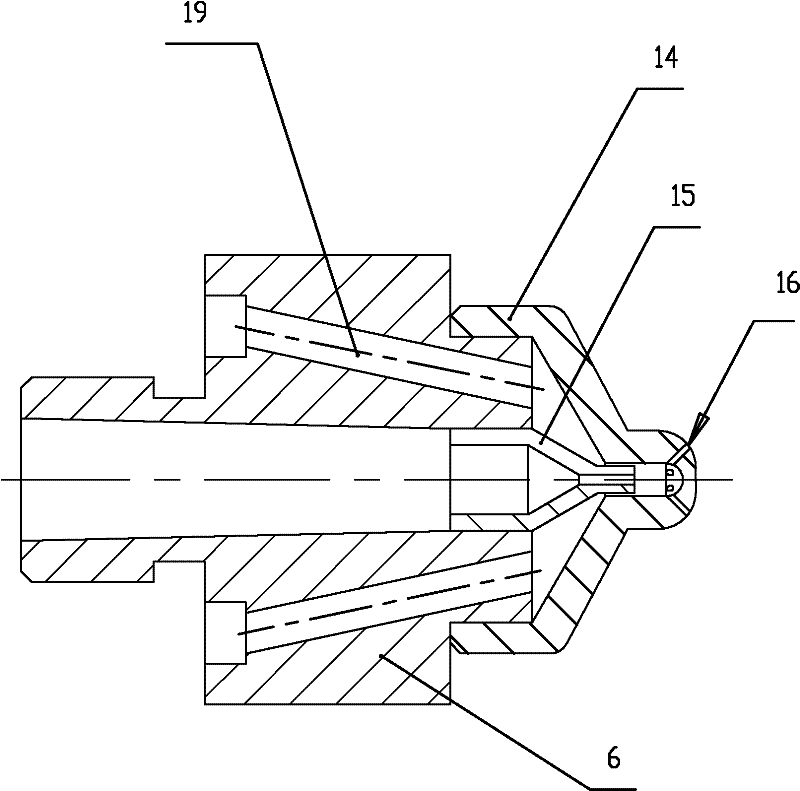

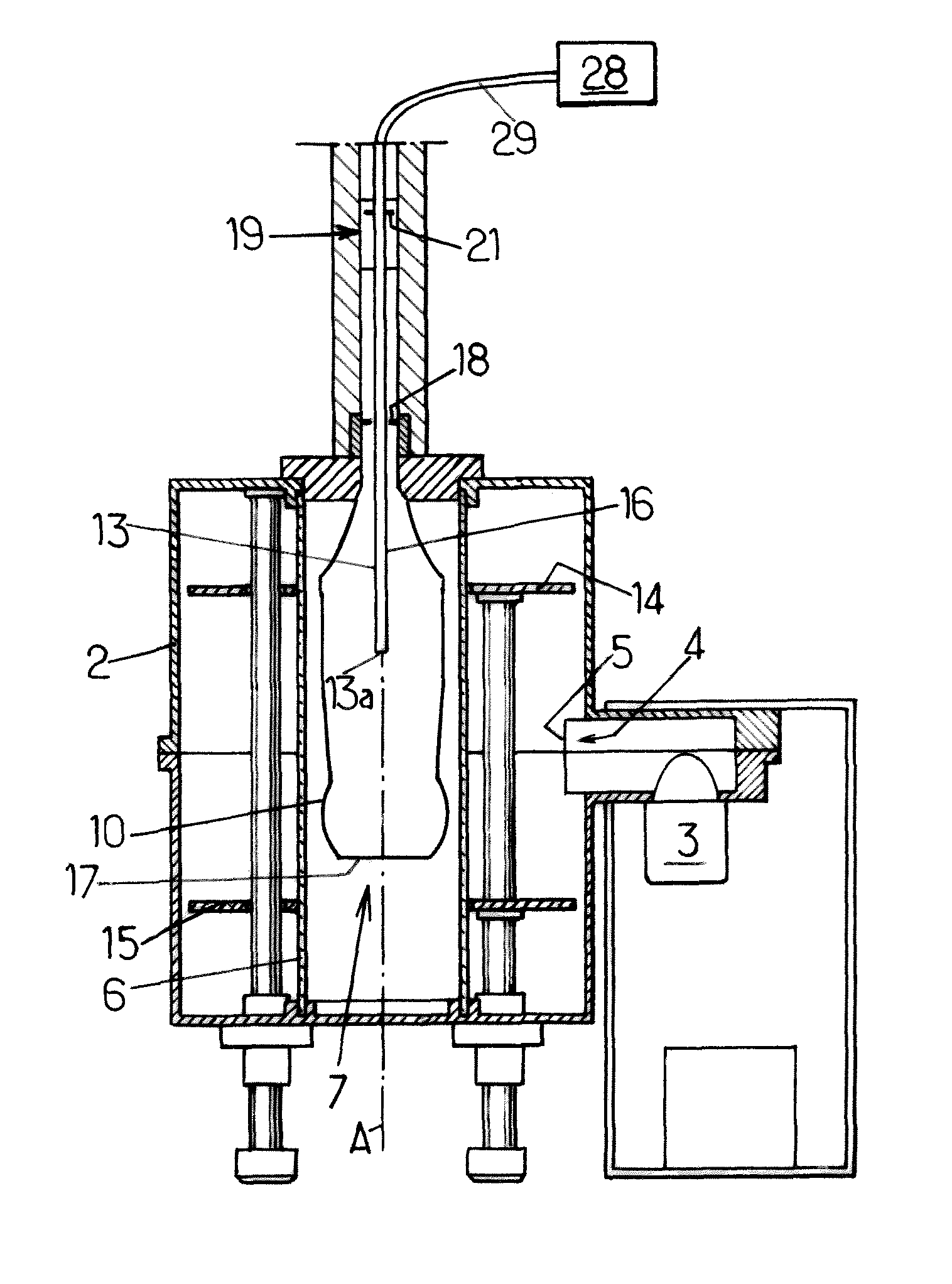

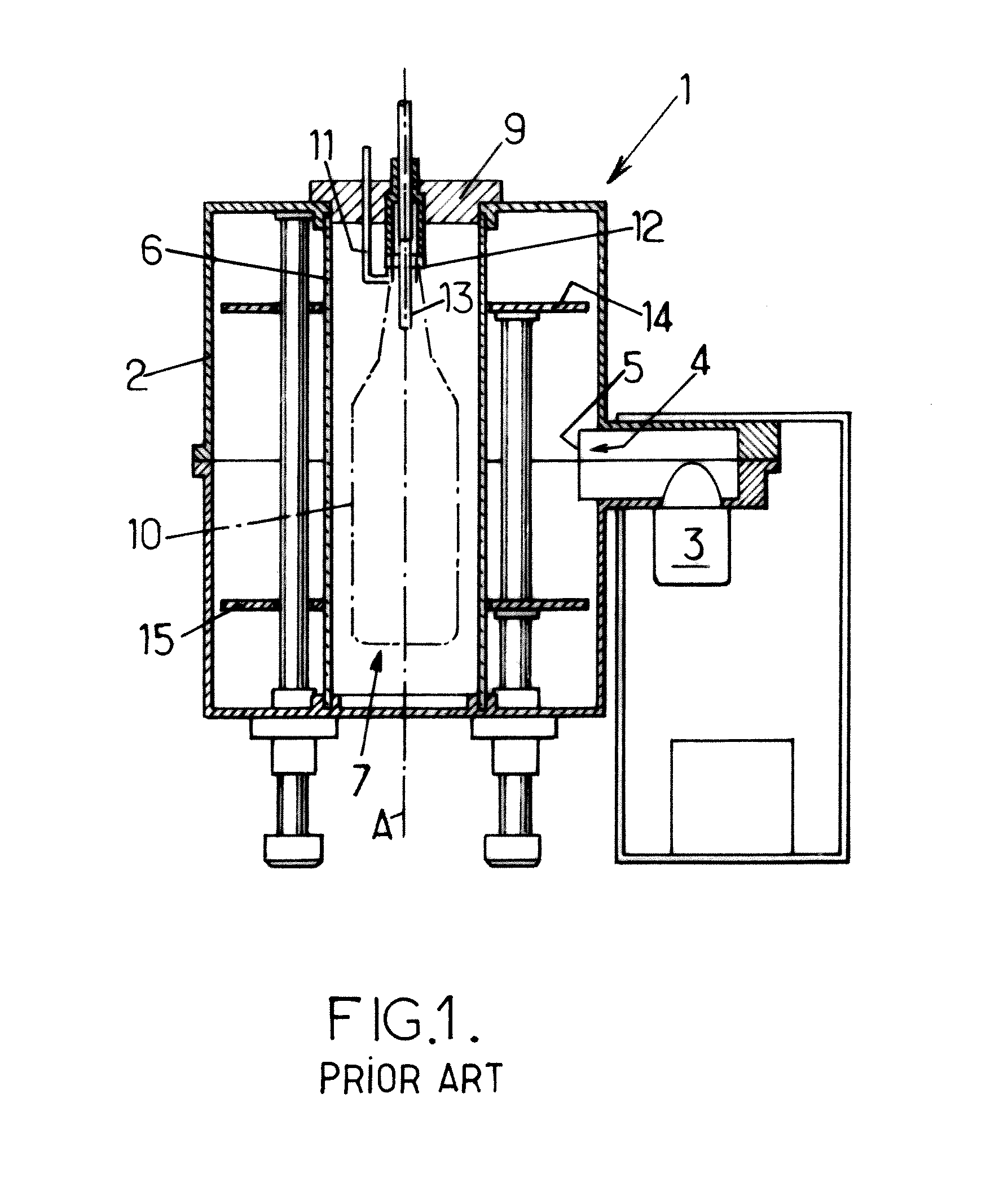

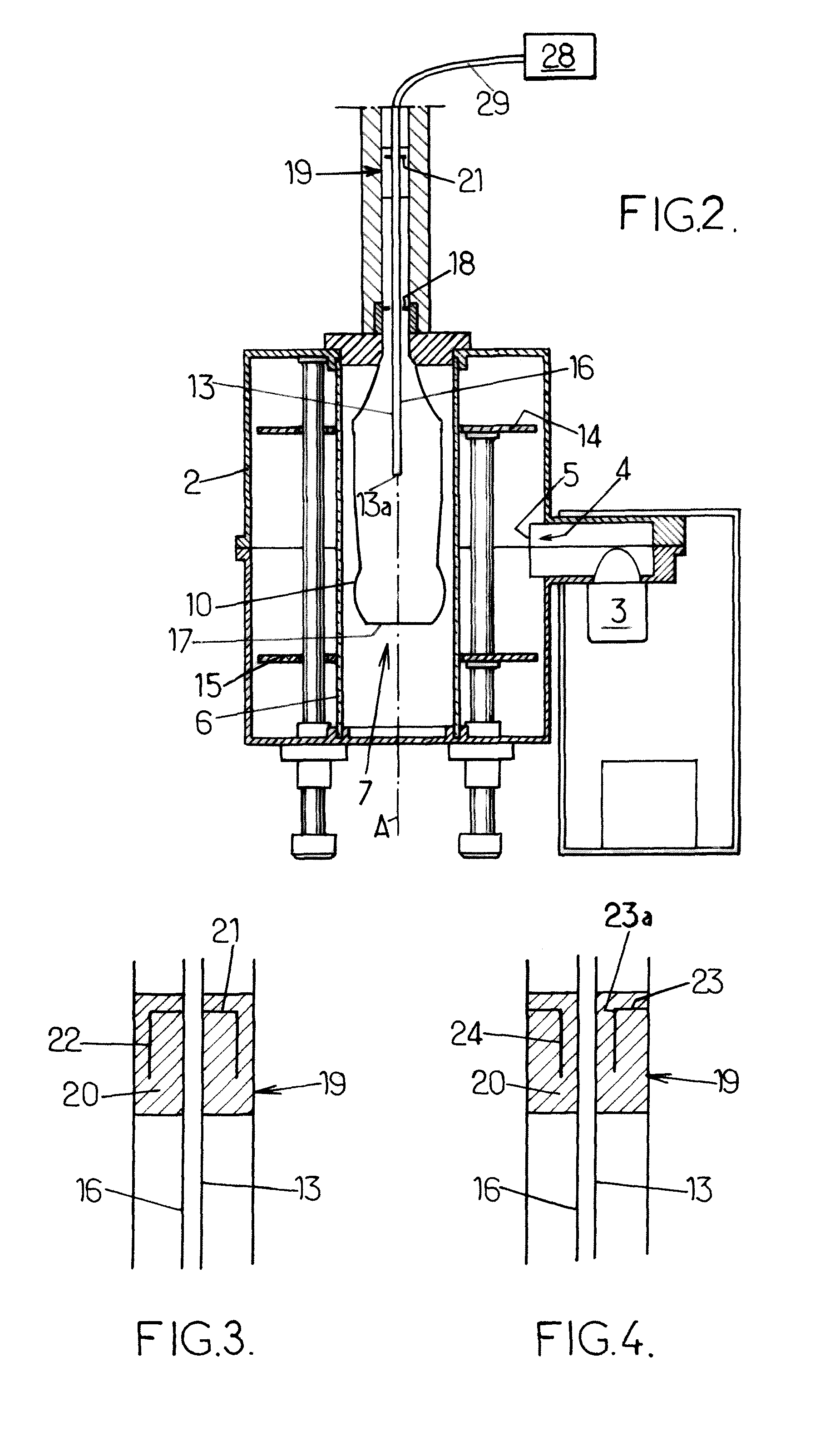

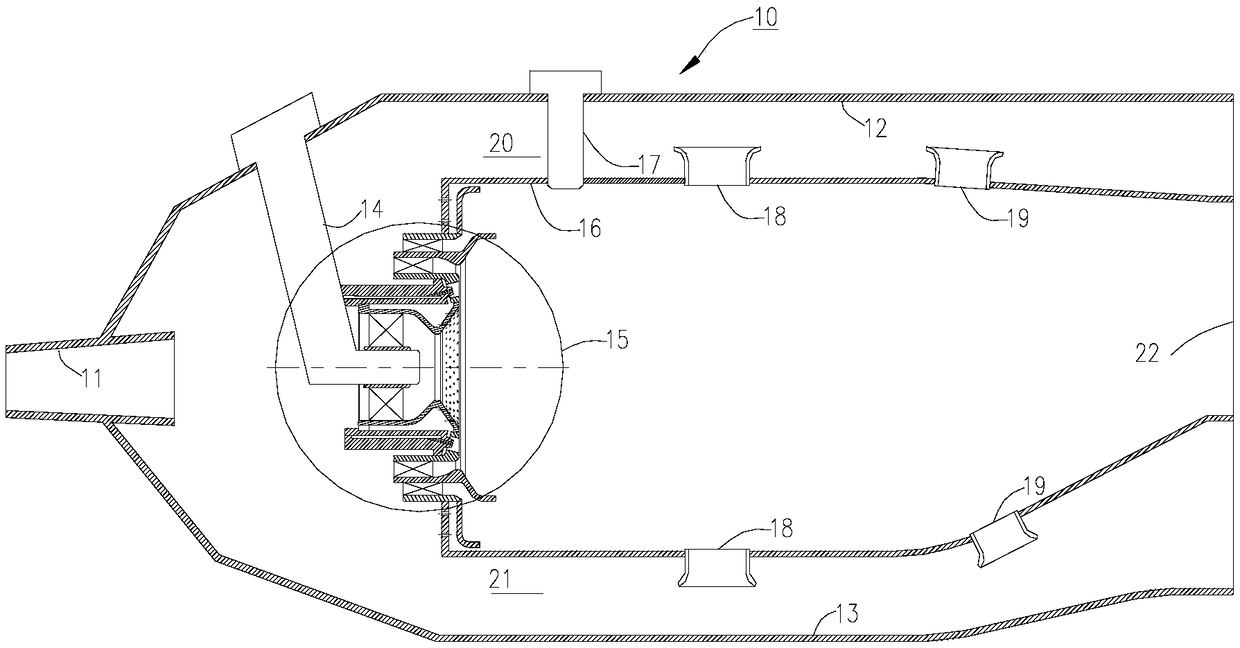

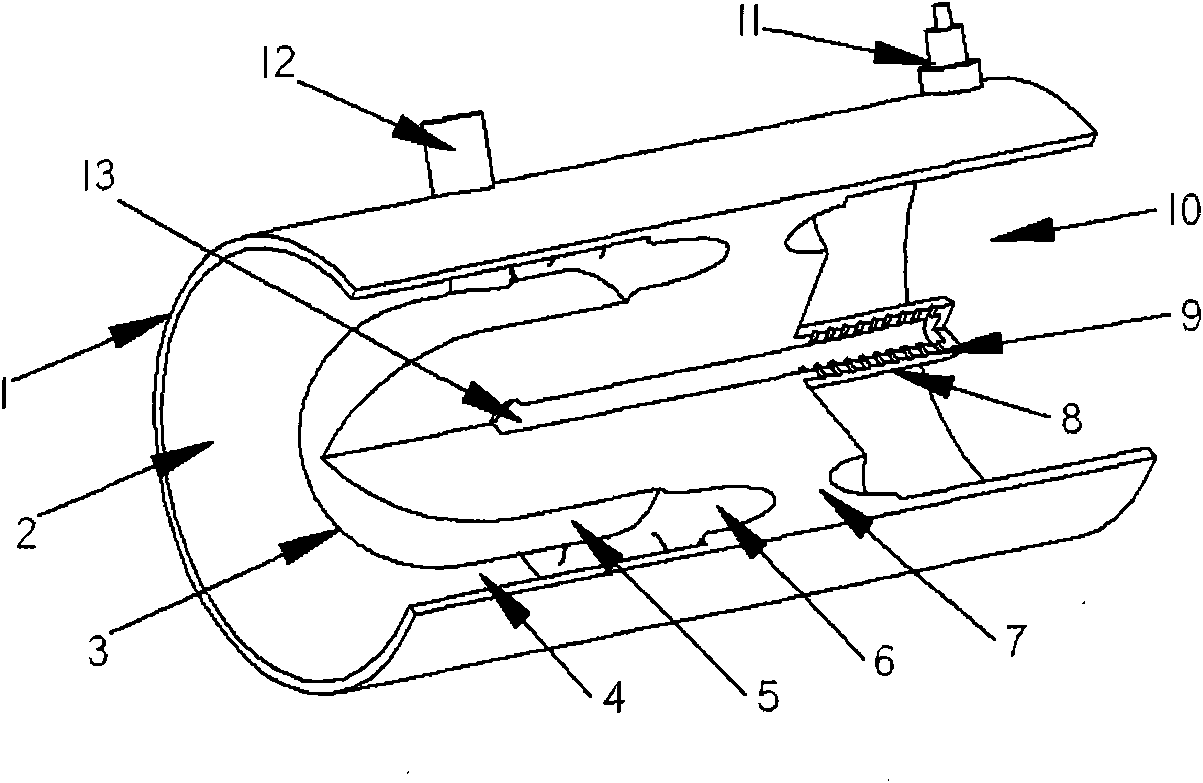

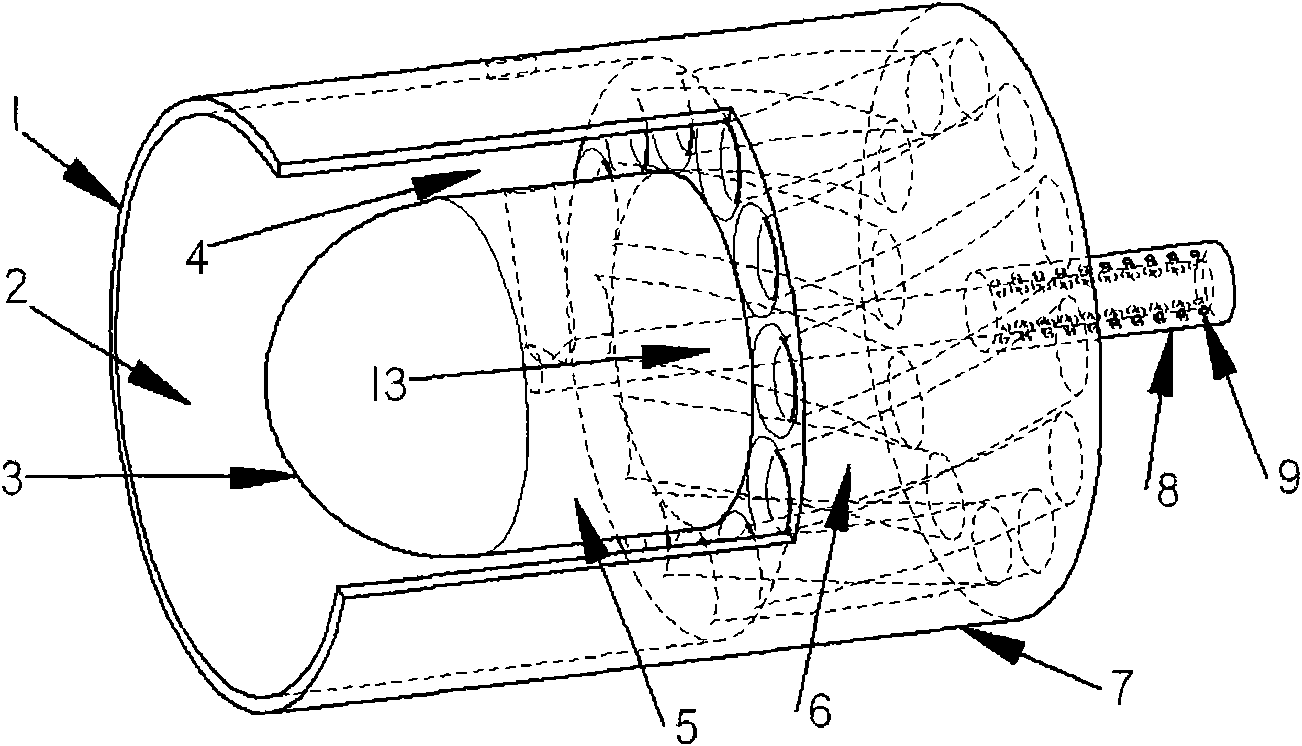

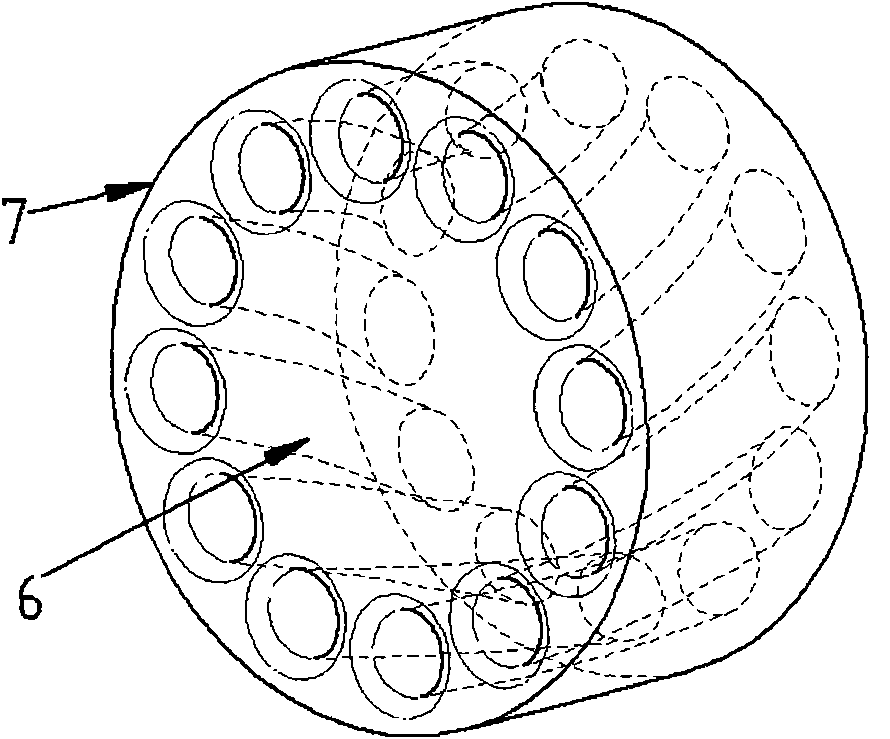

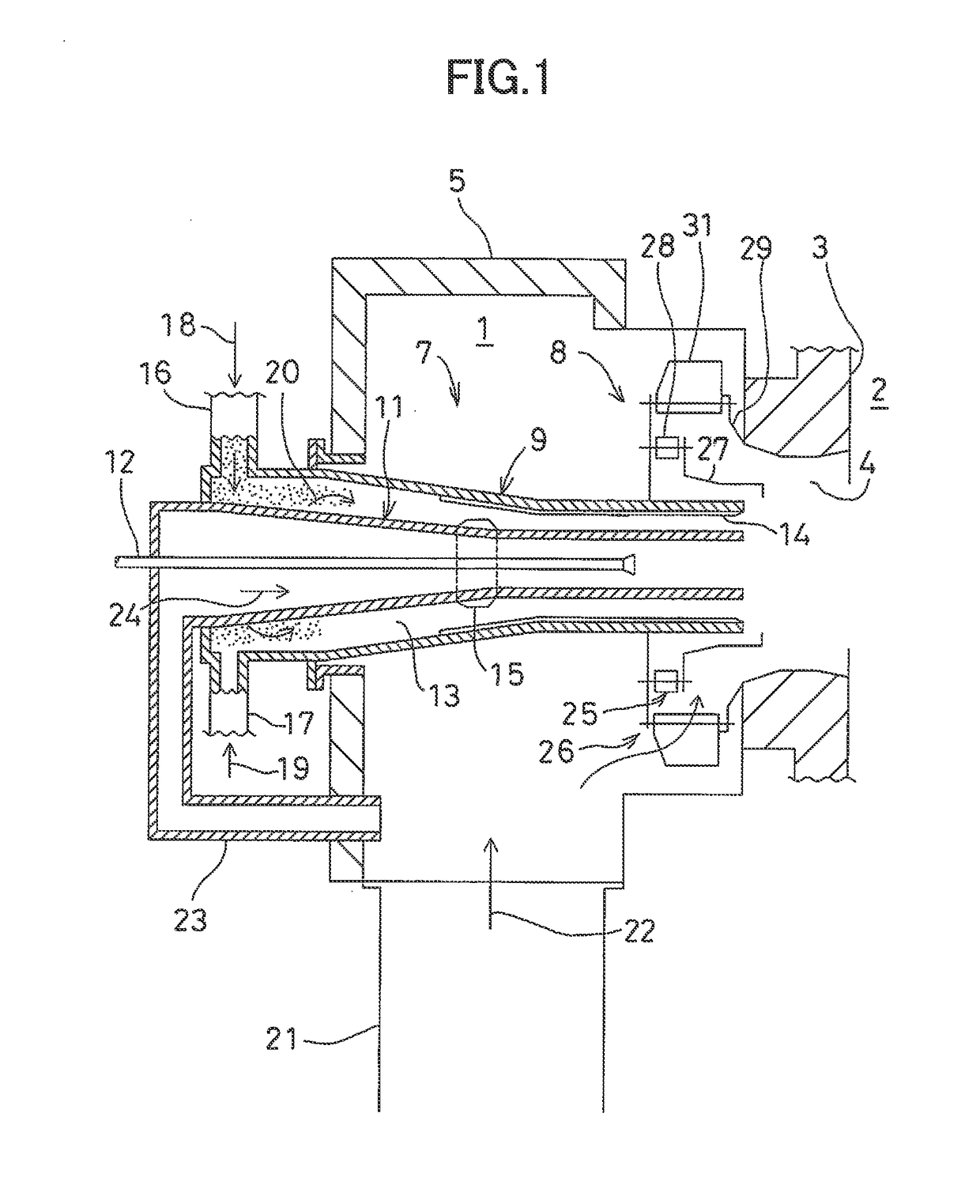

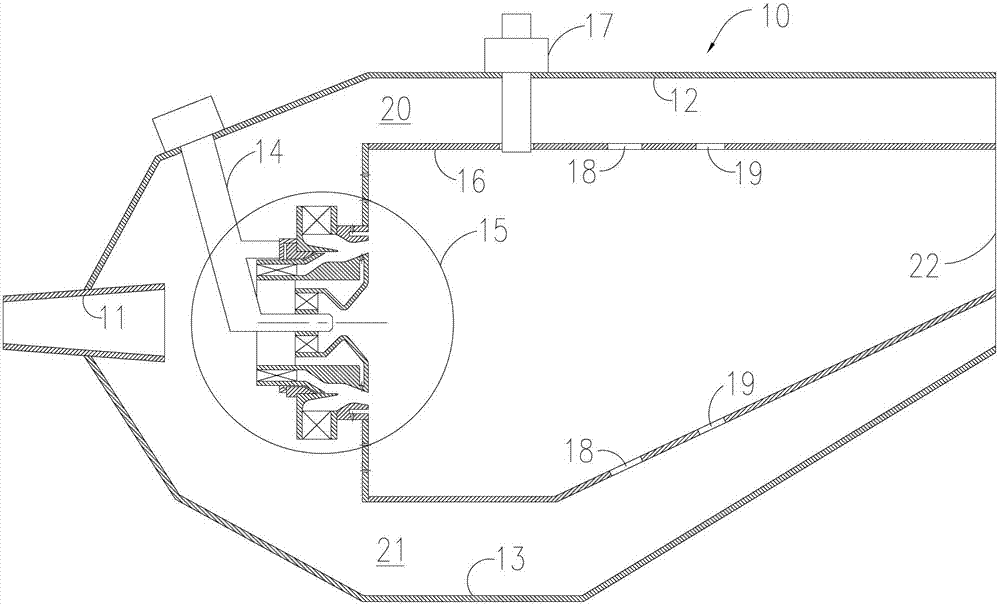

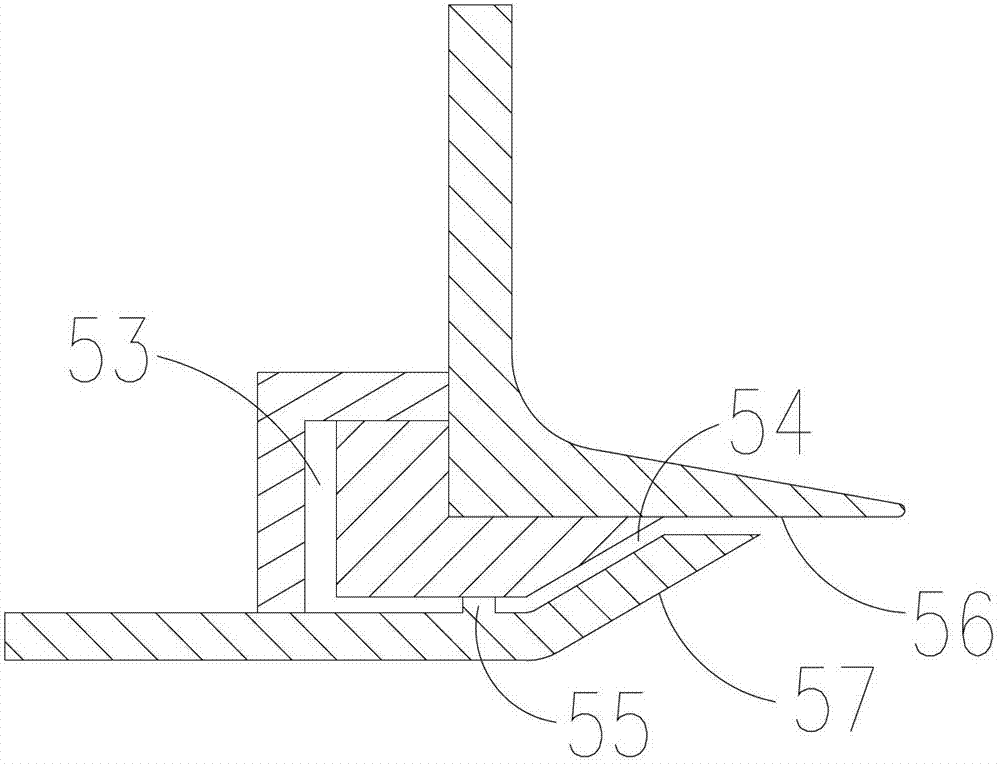

Device for depositing a coating on an internal surface of a container

InactiveUS20080011232A1Improve blockageReduce the amount requiredLiquid surface applicatorsElectric discharge tubesMicrowaveEngineering

Device for depositing a coating on an internal surface of a container (10), of the type in which the deposition is carried out by means of a low-pressure plasma created inside the container (10) by excitation of a precursor gas by microwave-type electromagnetic waves. An injection tube (13) is provided that dips into the container (10) to a length of between one quarter and one half of the total height of the container (10) in question, between the top (18) and the bottom (17) of the container (10), said length of the injection tube (13) constituting a longitudinal antenna (16) capable of picking up a UHF electromagnetic wave generated by said generator (3) and of propagating the HT ignition signal, a UHF short-circuit (19) in the form of a plate (21, 23, 25) being provided on the injection tube (13) in such a way that the face of said plate (21, 23, 25) on the cavity side defines a point of zero amplitude of the electromagnetic wave propagating along said injection tube (13), the length between said short-circuit (19) and the free end (13a) of said injection tube (13) corresponding to an odd number of quarter-wavelengths so as to obtain a maximum amplitude, that is to say an antinode, at the free end (13a) of the injection tube (13).

Owner:SIDEL PARTICIPATIONS SAS

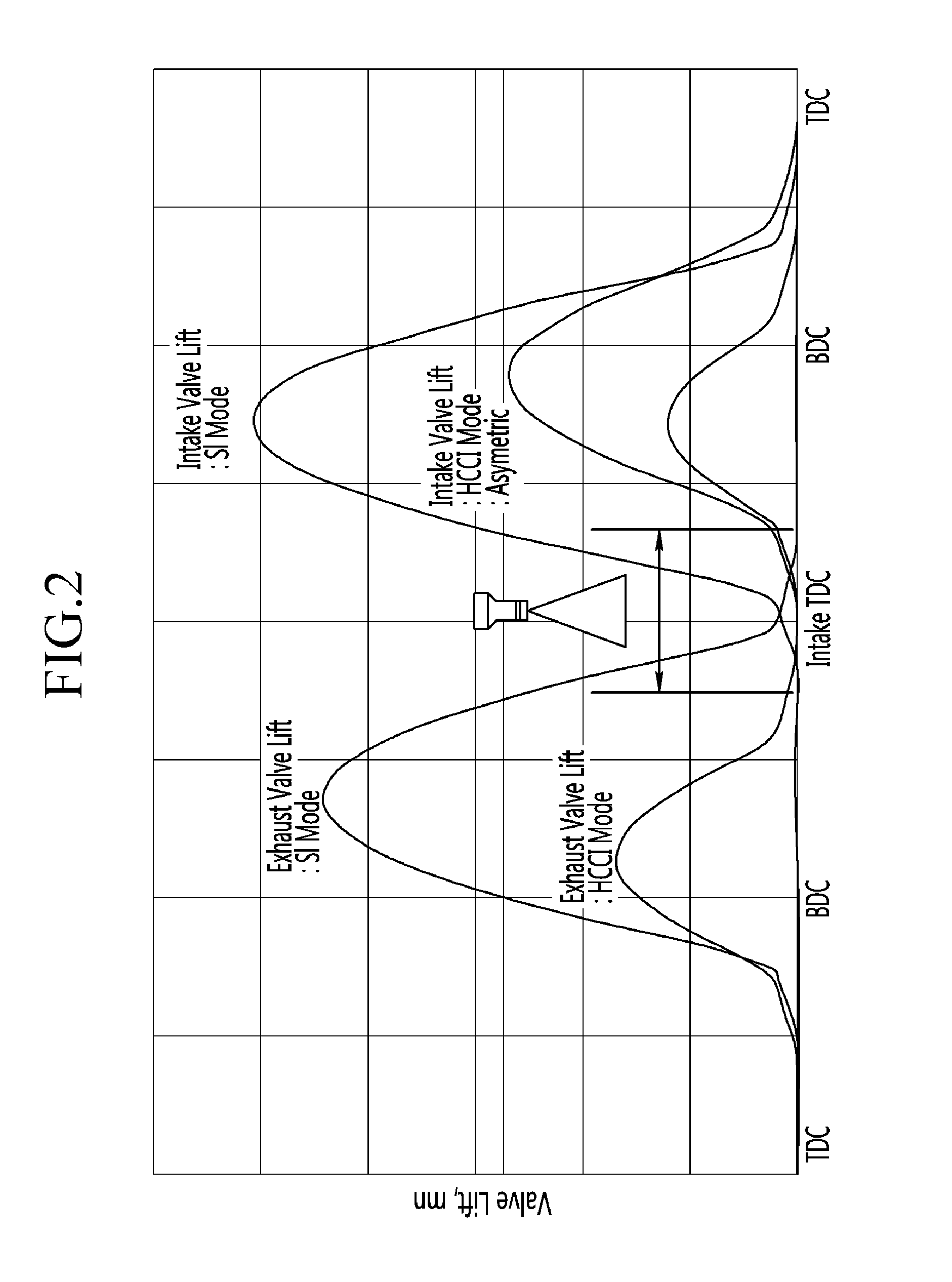

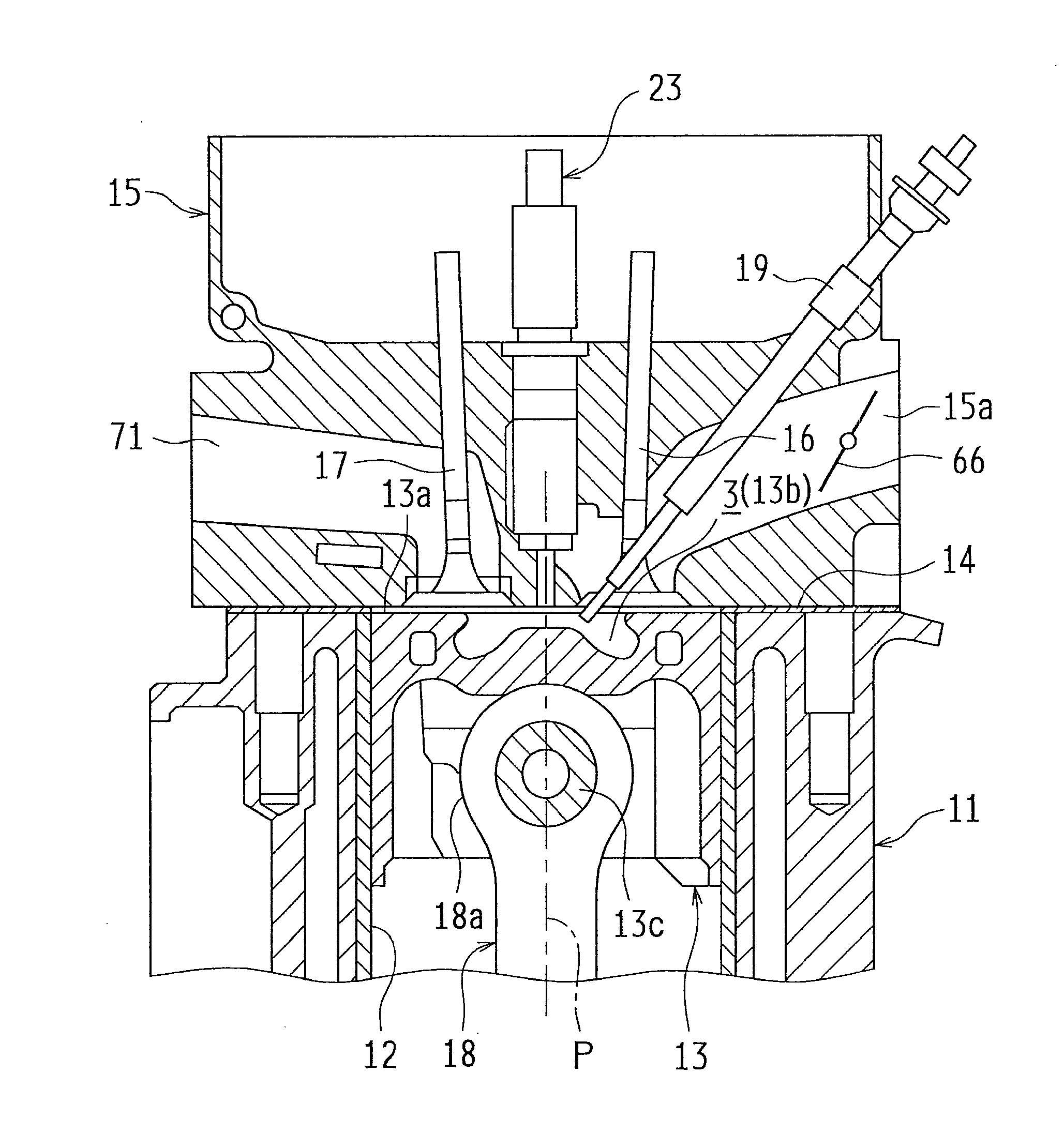

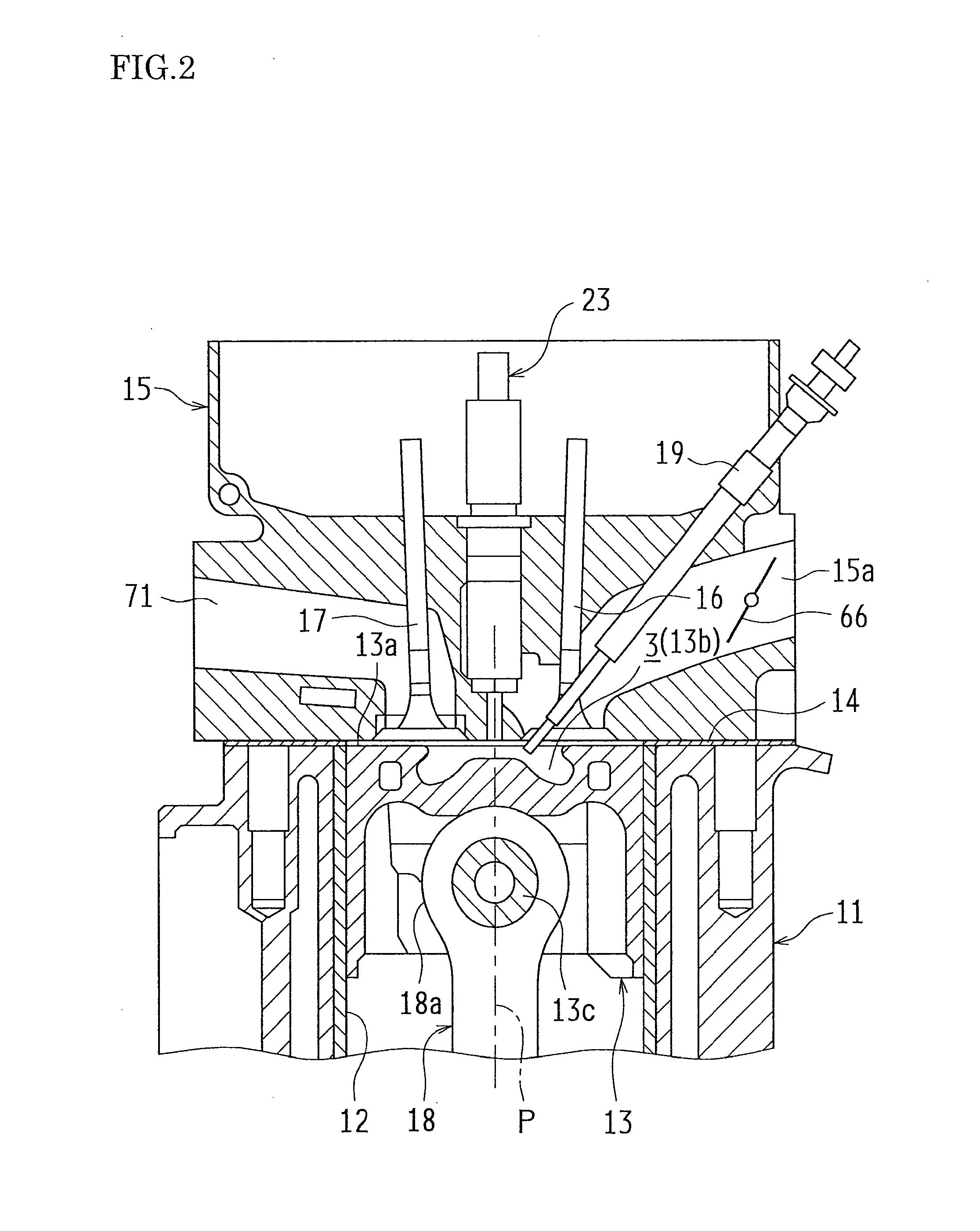

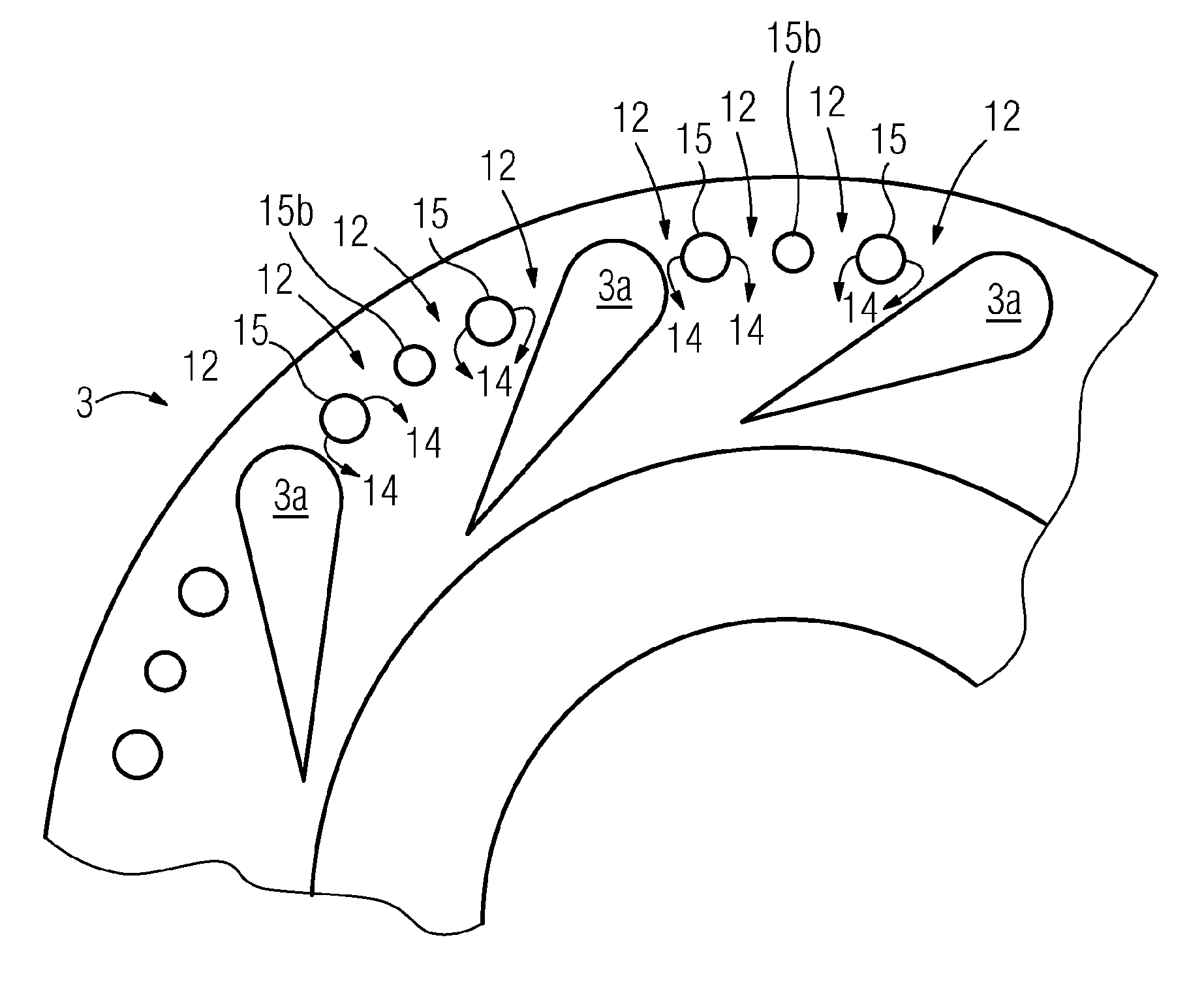

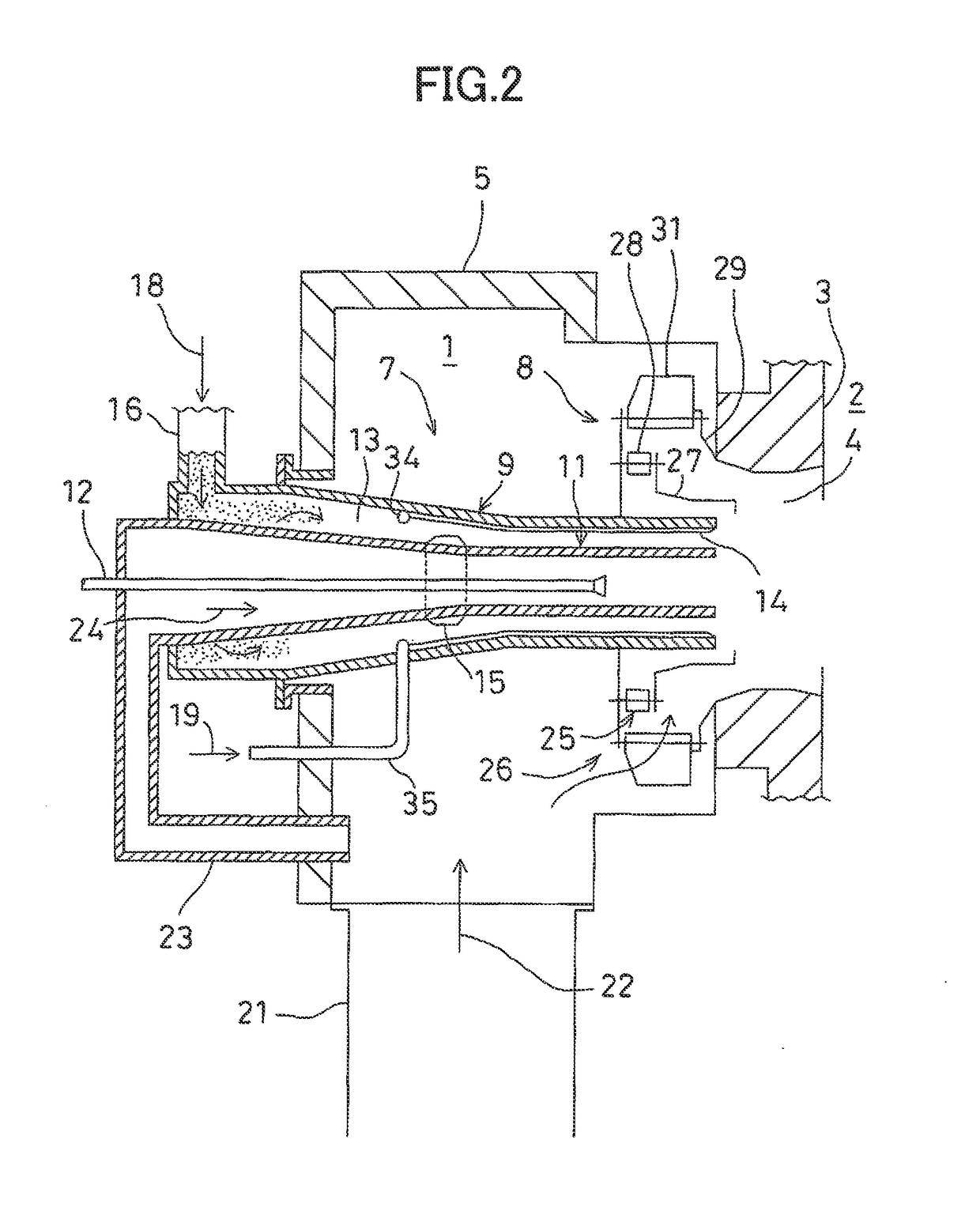

Compression ignition gasoline engine

ActiveUS20110108001A1Suppress excessive self-ignitionRapid increase of combustion noiseValve arrangementsElectrical controlCombustion chamberExhaust valve

A compression ignition gasoline engine uses low-cetane number fuel, such as gasoline. The engine includes a combustion control device having an injector directly injecting fuel into a combustion chamber, intake and exhaust valves, and a variable valve device changing a valve timing, in which the compression ignition gasoline engine includes: at least two intake valves and two exhaust valves; a spark plug positioned at the center portion of the combustion chamber; and an injector positioned adjacent to the spark plug toward the center portion of the combustion chamber, in which the exhaust valve is a symmetric valve lift in which the lift and the opening section of the tow exhaust valves are the same in low lift, and the intake valve is an asymmetric valve lift in which the lift and the opening of the two intake valves are different in the low lift.

Owner:HYUNDAI MOTOR CO LTD

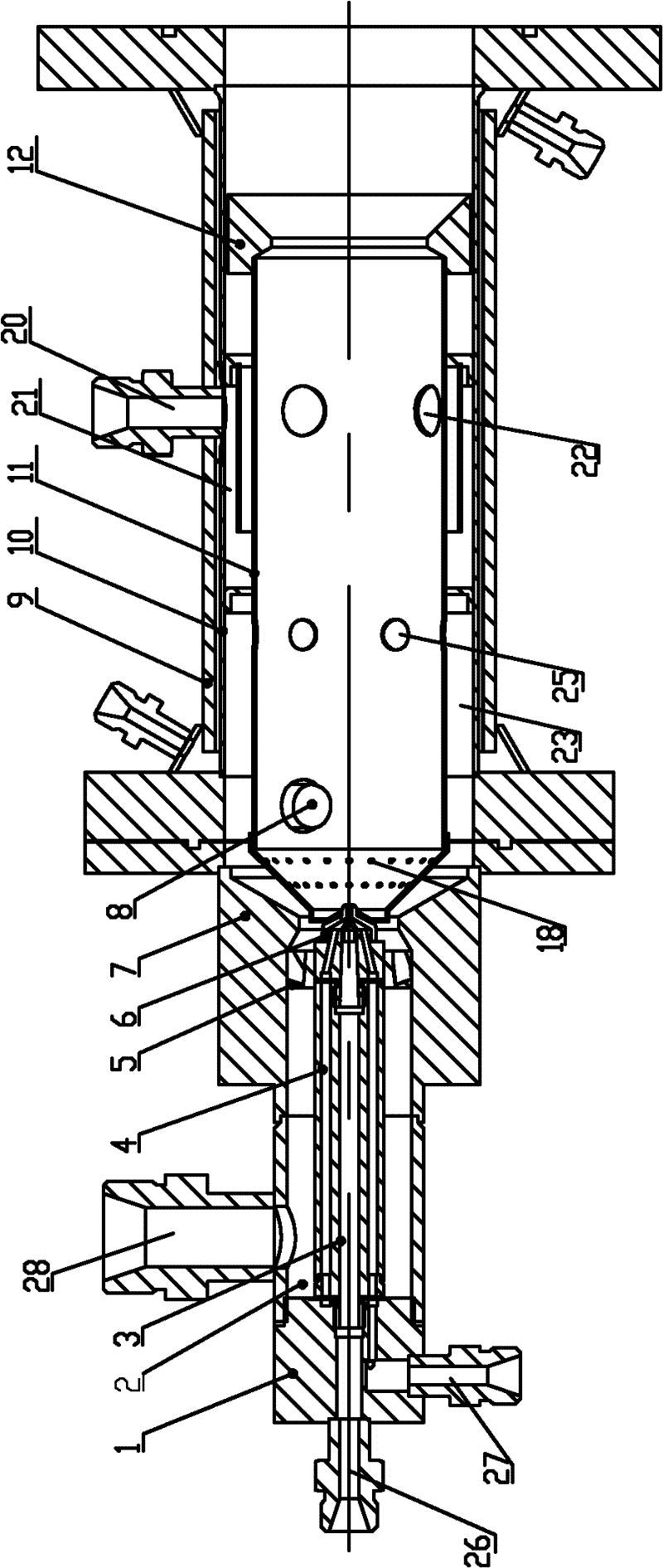

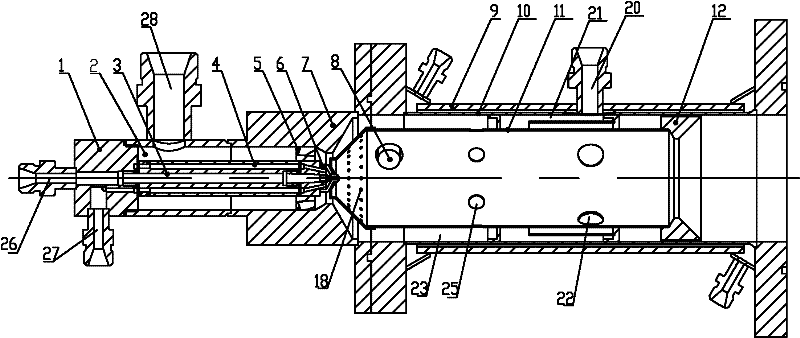

Low-flow, high-mixing ratio and stepless regulation gas-liquid mixing gas generator

InactiveCN102174338AIncrease the mixing ratioLarge adjustment rangeBurnersFuel supply regulationGas generatorEngineering

The invention relates to a low-flow, high-mixing ratio and stepless regulation gas-liquid mixing gas generator, which comprises a round mixing channel, a spray head, an igniter and a body part. The spray head is arranged between the round mixing channel and the body part, and the opening of the spray head faces the body part; the igniter is arranged in the body part; and the round mixing channel comprises a fuel channel communicated with a fuel joint, a main air channel communicated with a main air joint, and an auxiliary air channel communicated with an auxiliary air joint. The technical problem that defects exist in the prior art is solved. The gas-liquid mixing gas generator can be reliably operated and realizes large-scale stable and high-efficiency combustion and stepless regulation.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

Device for depositing a coating on an internal surface of a container

InactiveUS7975646B2Stable ignitionEasy to igniteLiquid surface applicatorsElectric discharge tubesMicrowaveEngineering

Device for depositing a coating on an internal surface of a container, of the type in which the deposition is carried out by means of a low-pressure plasma created inside the container by excitation of a precursor gas by microwave-type electromagnetic waves. An injection tube is provided that dips into the container to a length of between one quarter and one half of the total height of the container in question, between the top and the bottom of the container said length of the injection tube constituting a longitudinal antenna capable of picking up a UHF electromagnetic wave generated by said generator and of propagating the HT ignition signal, a UHF short-circuit in the form of a plate being provided on the injection tube in such a way that the face of said plate on the cavity side defines a point of zero amplitude of the electromagnetic wave propagating along said injection tube, the length between said short-circuit and the free end of said injection tube corresponding to an odd number of quarter-wavelengths so as to obtain a maximum amplitude, that is to say an antinode, at the free end of the injection tube.

Owner:SIDEL PARTICIPATIONS SAS

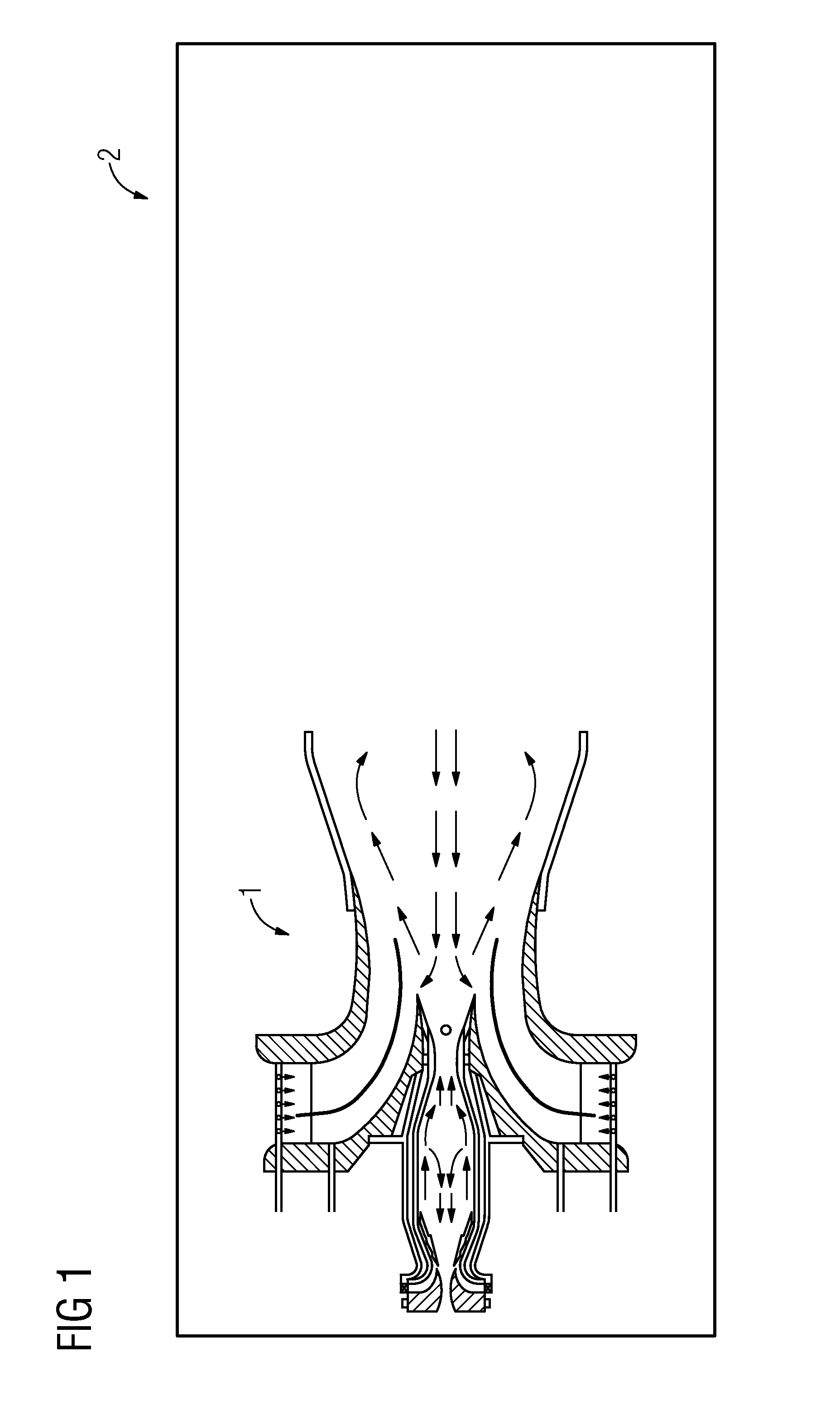

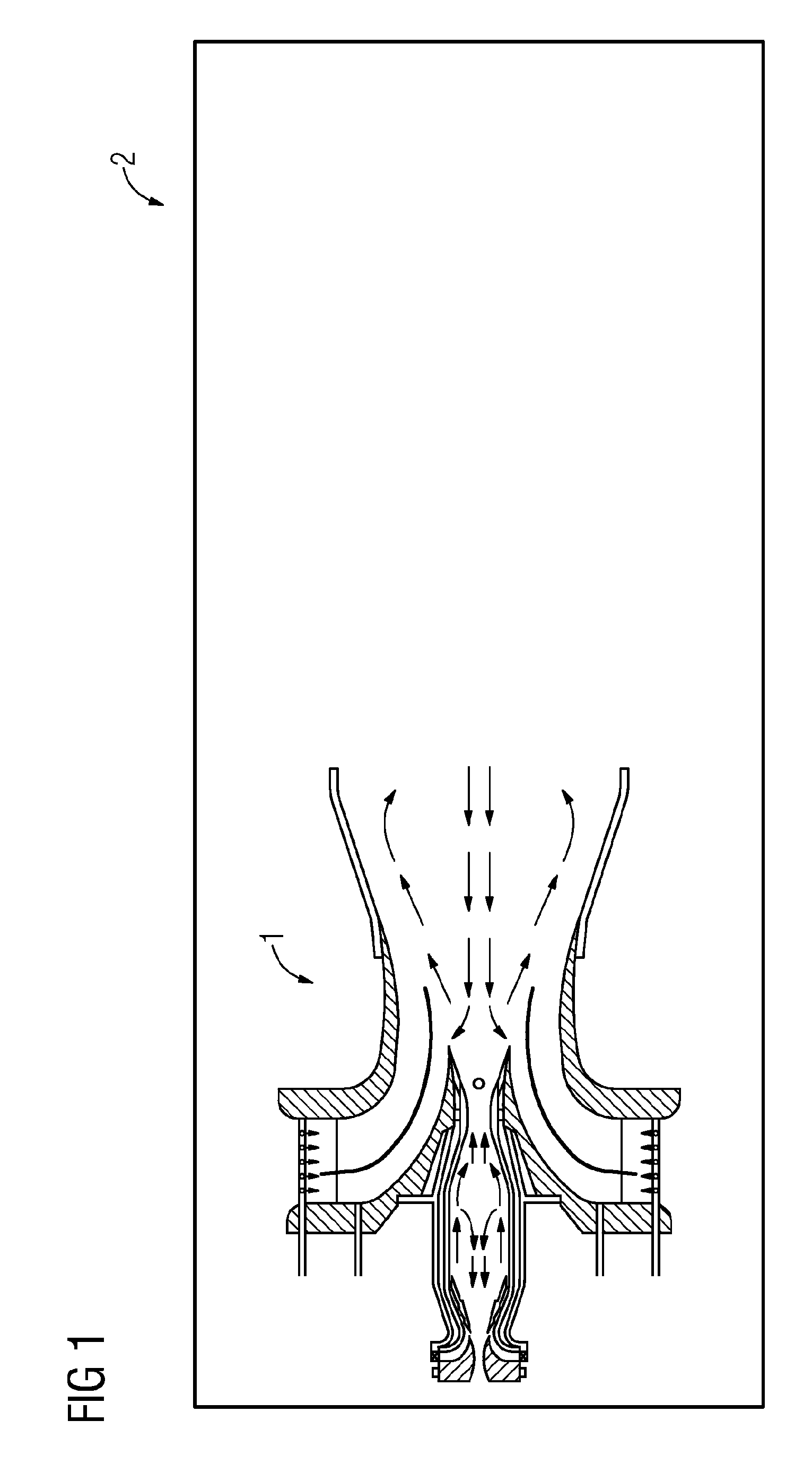

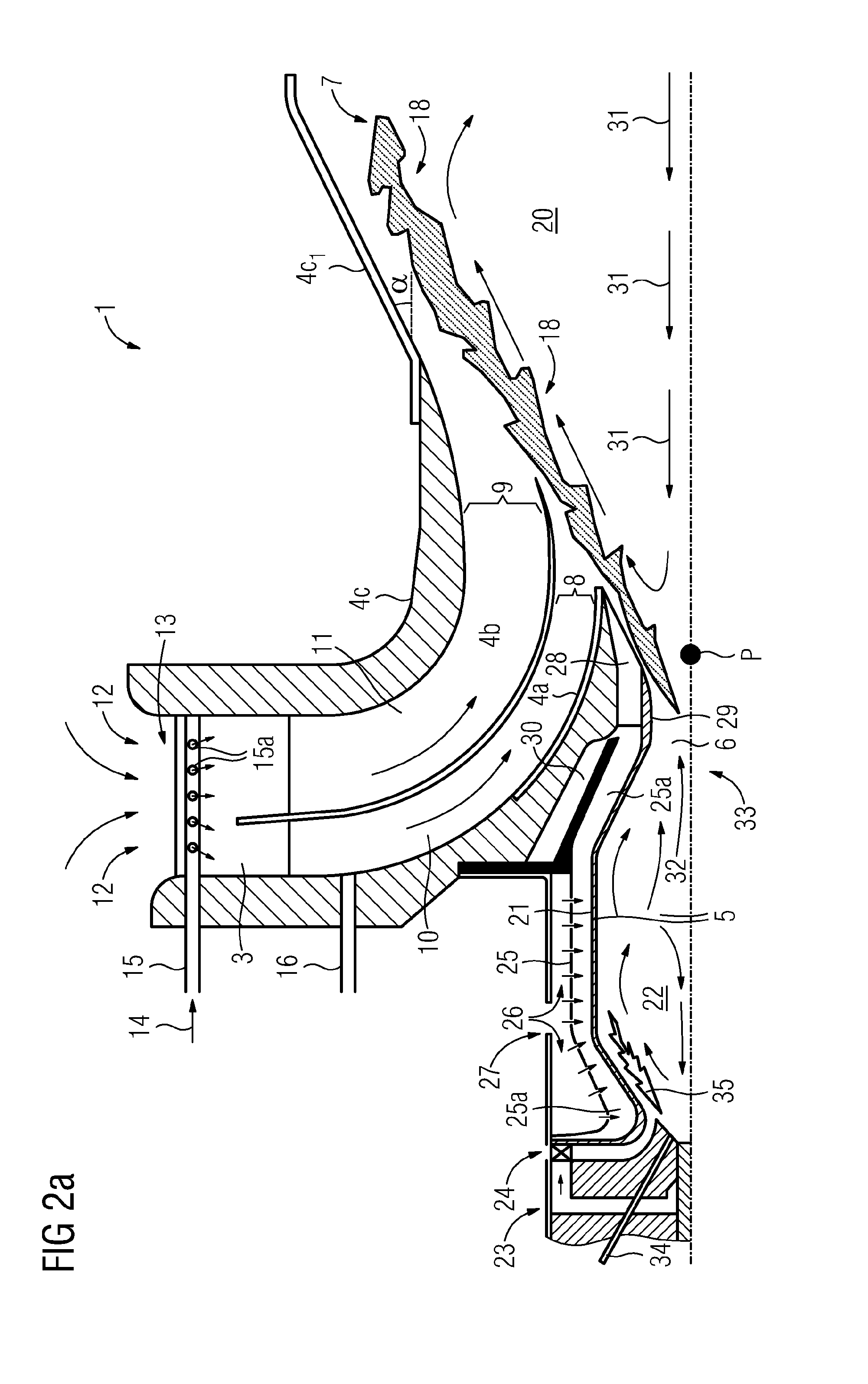

Pilot combustor in a burner

InactiveUS20110113787A1Rapid and stable combustionReduce the temperatureBurnersContinuous combustion chamberCombustorCombustion chamber

A pilot combustor particularly for use in a burner of a gas turbine engine is provided. A method for burning a fuel in a pilot combustor zone of a pilot combustor is also provided. The pilot combustor includes rotationally symmetric walls defining a combustion room with an exit having a rich concentration of fuel in air for burning the fuel for the creation of a flow of an non equilibrium unquenched concentration of radicals elevated to a temperature above 2000 K in the combustion room and directed along a centre line of the pilot combustor through a throat at the exit of the pilot combustor, wherein a quarl is located downstream of the throat of the pilot combustor. According to the method the pilot combustor is arranged upstream of a burner for providing a main lean partially premixed combustion process.

Owner:SIEMENS AG

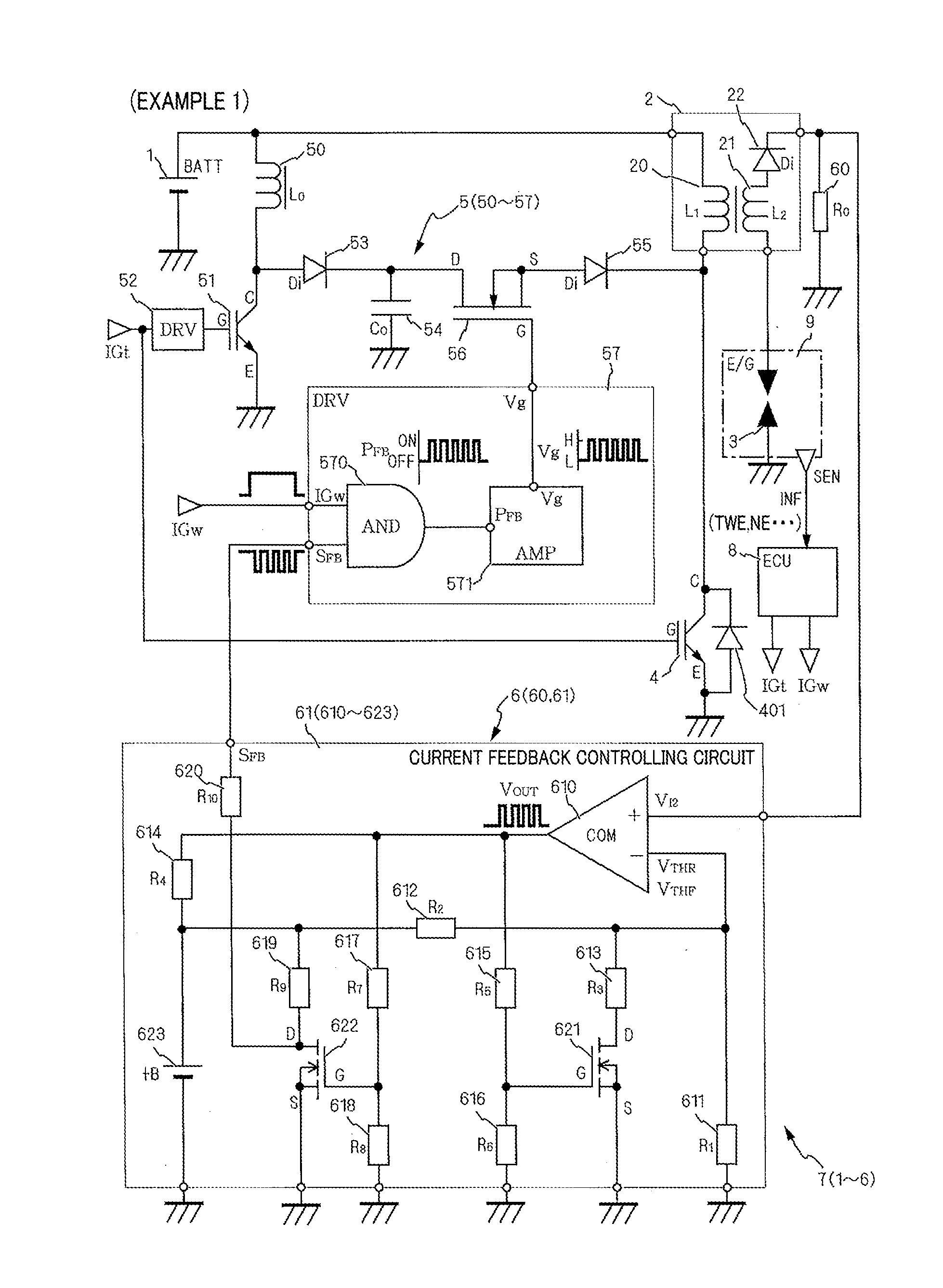

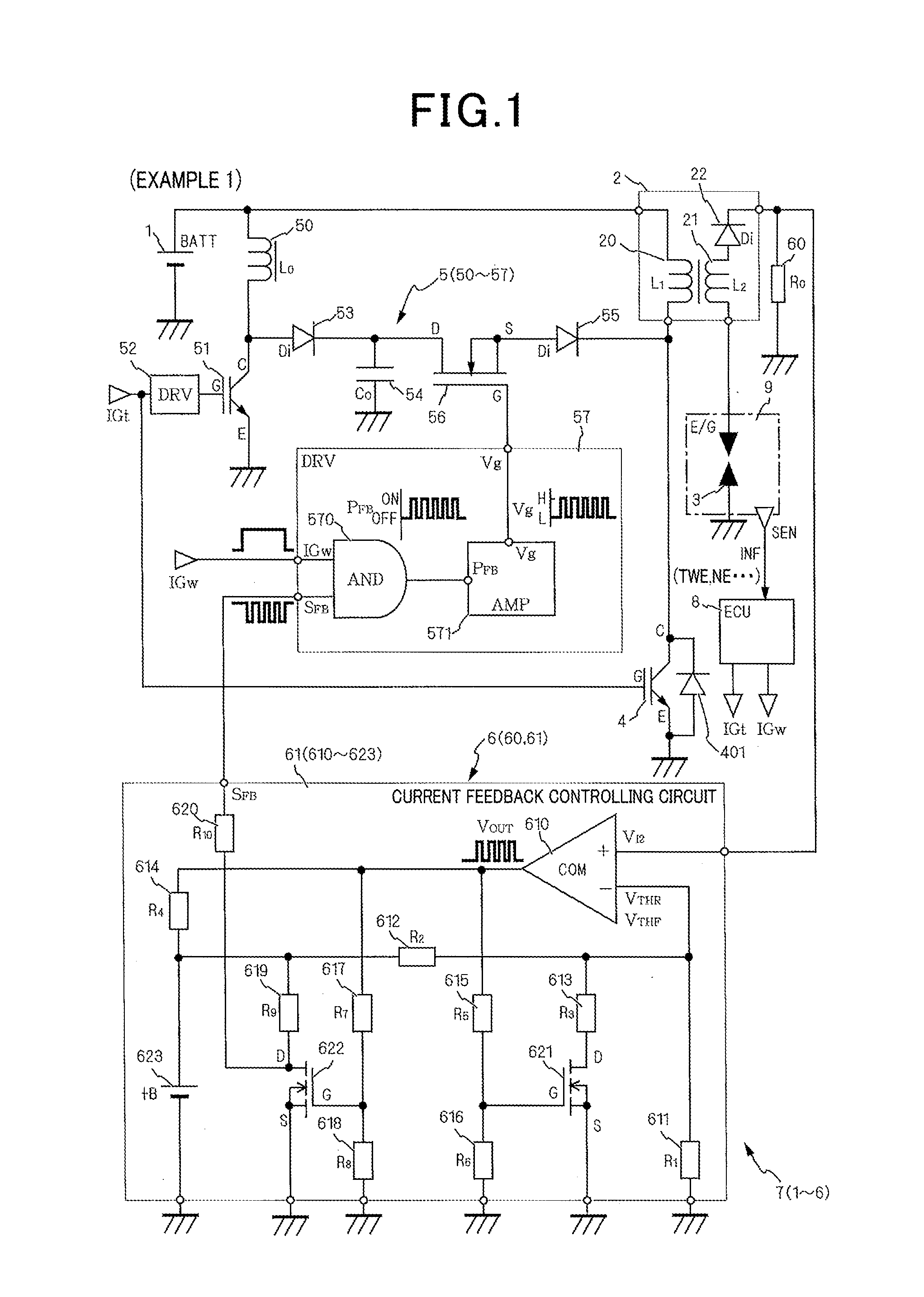

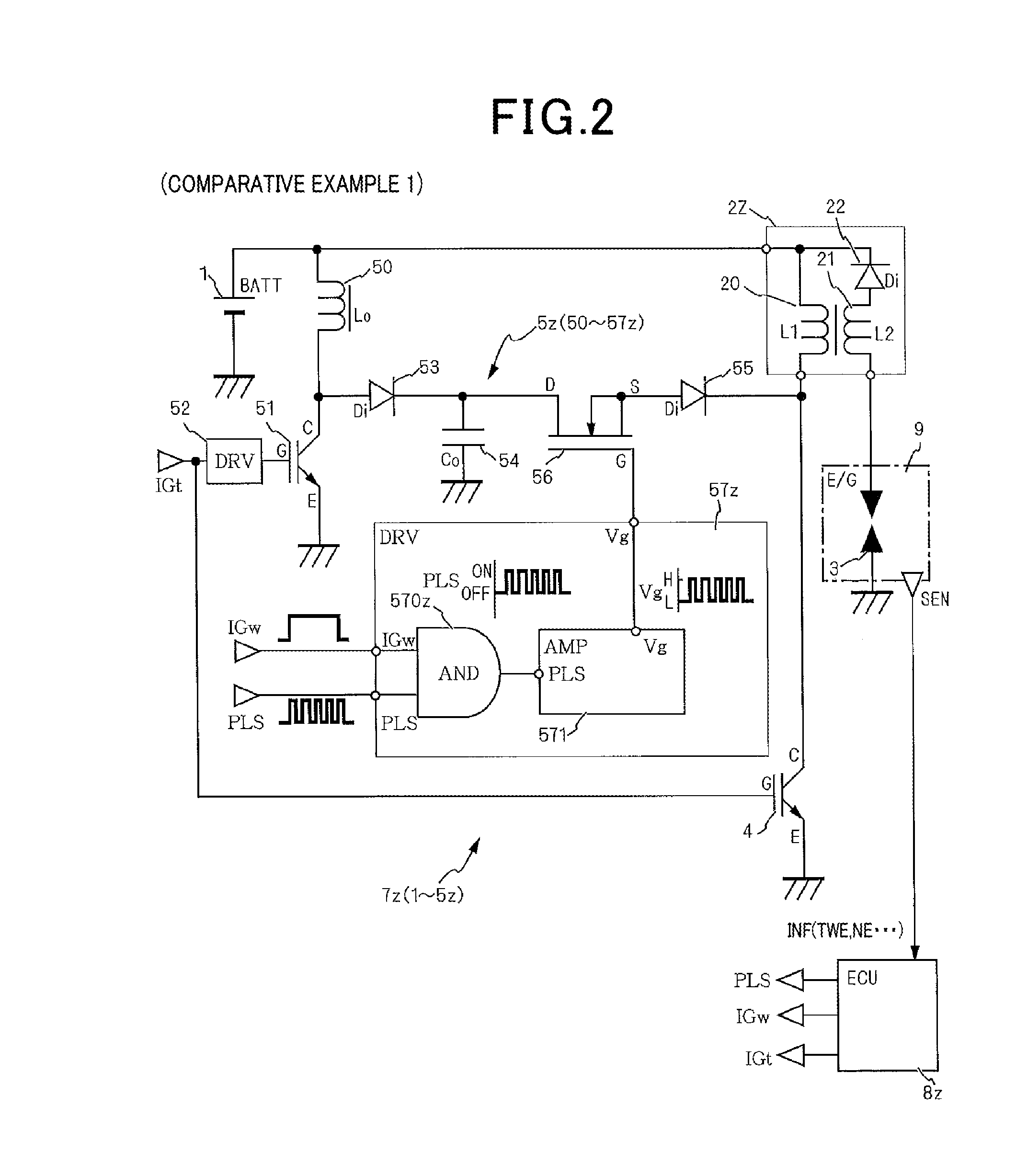

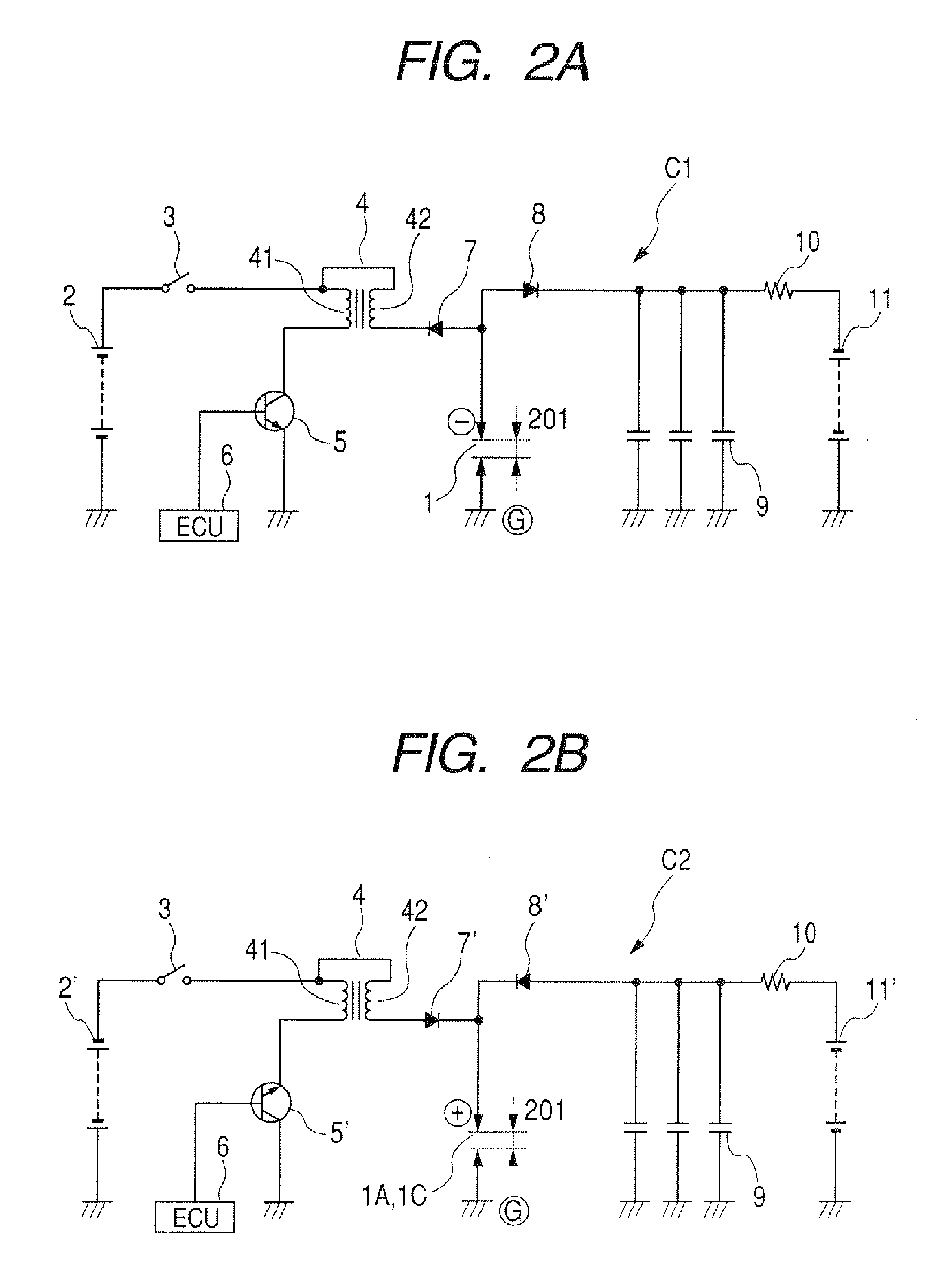

Ignition device

ActiveUS20170045025A1Easily configuredStabilized ignitionInternal combustion piston enginesIgnition automatic controlIgnition coilEngineering

An ignition device at least equipped with a DC power source, an ignition coil unit, a spark plug, an ignition switch, and an auxiliary power source, wherein the auxiliary power source is at least equipped with a discharge energy accumulating means, a discharge switch, and a discharge driver. The ignition device is further equipped with a secondary-current feedback controlling means comprising a secondary current detecting means for detecting a secondary current flowing during the ignition coil unit discharge period, and a secondary current feedback control circuit-for determining an upper limit and a lower limit for the secondary current from binary threshold values, and driving so as to open and close the discharge switch on the basis of the determination results. Furthermore, energy is introduced from the auxiliary power source without switching the polarity of the secondary current.

Owner:DENSO CORP

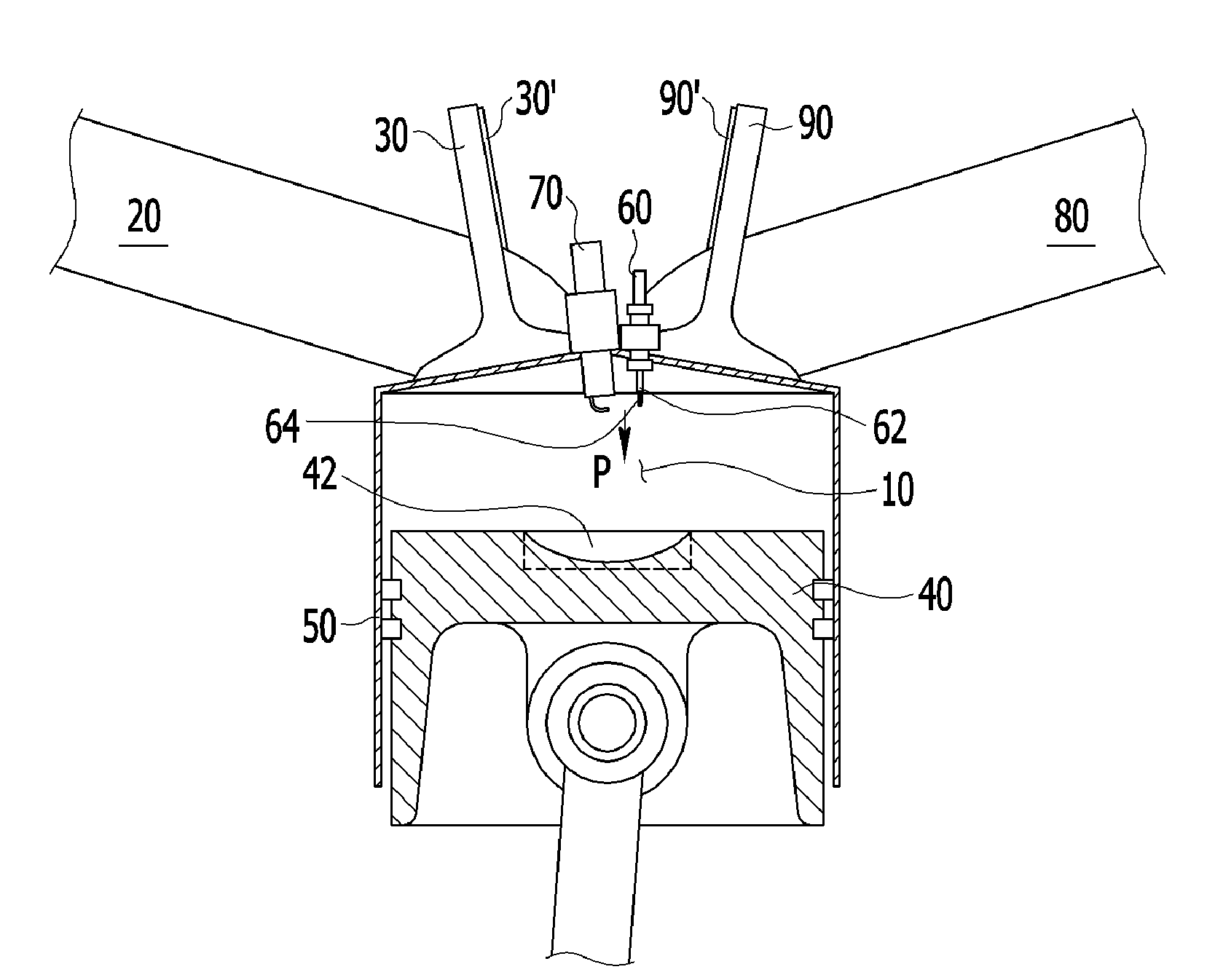

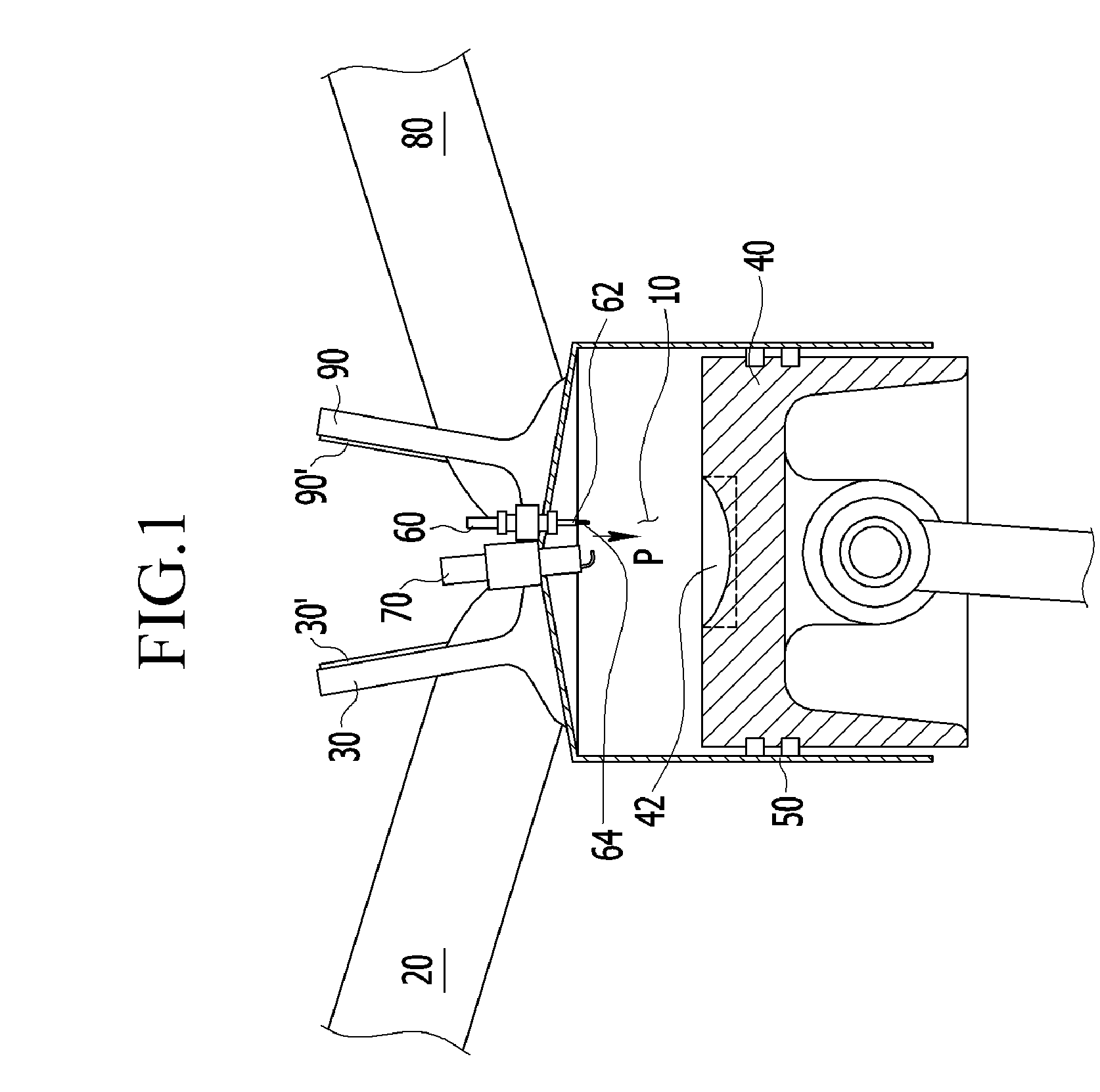

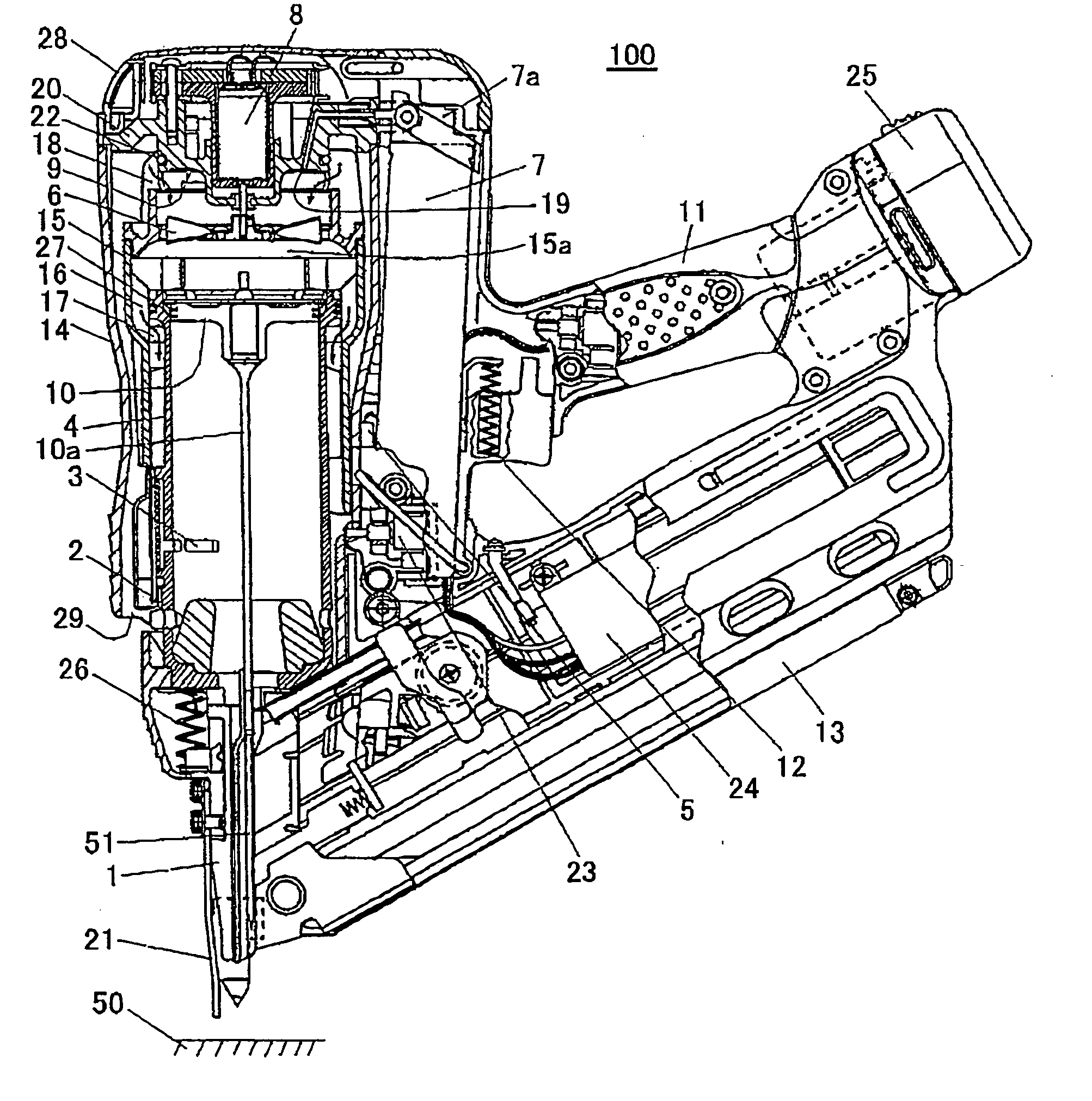

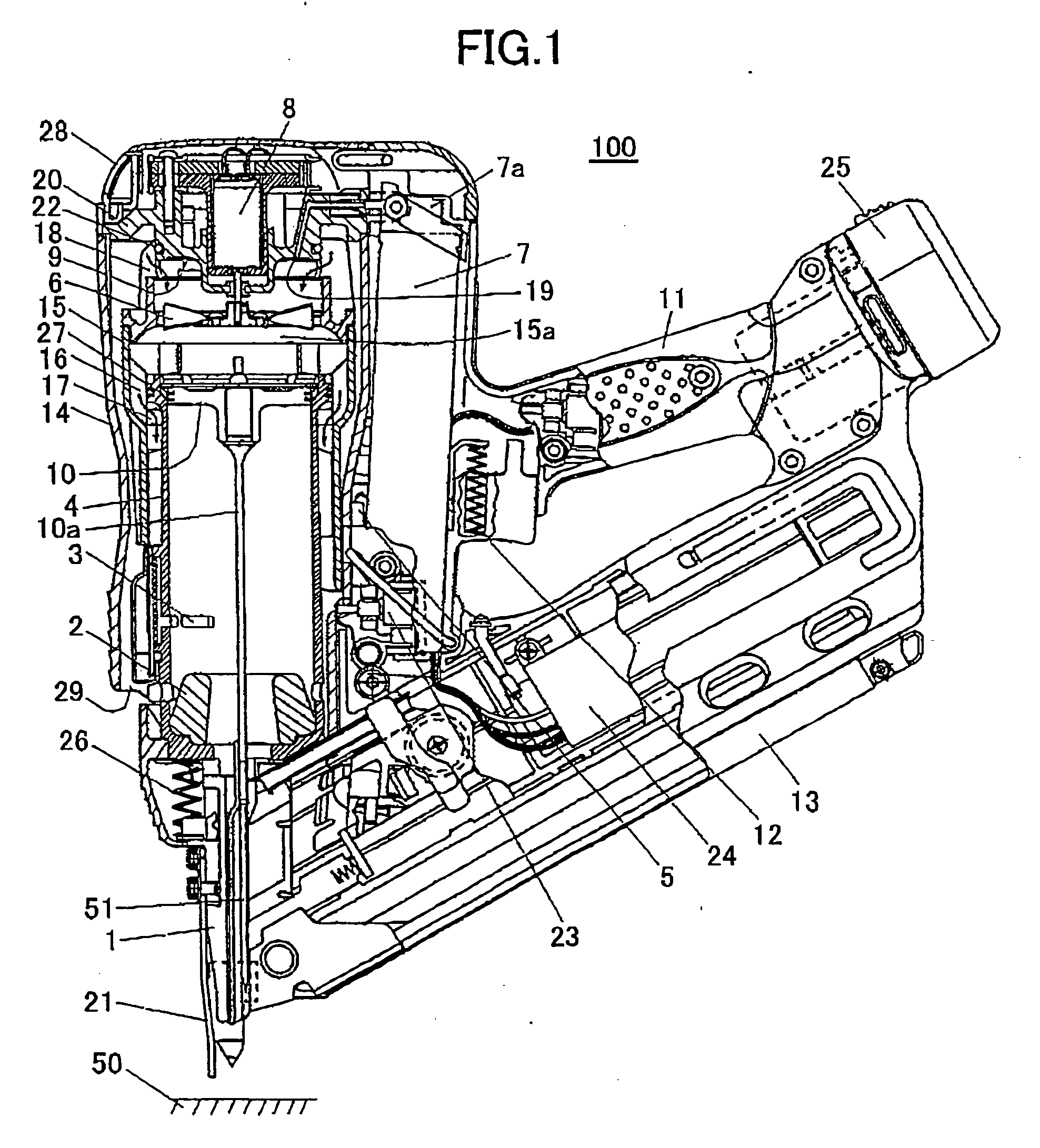

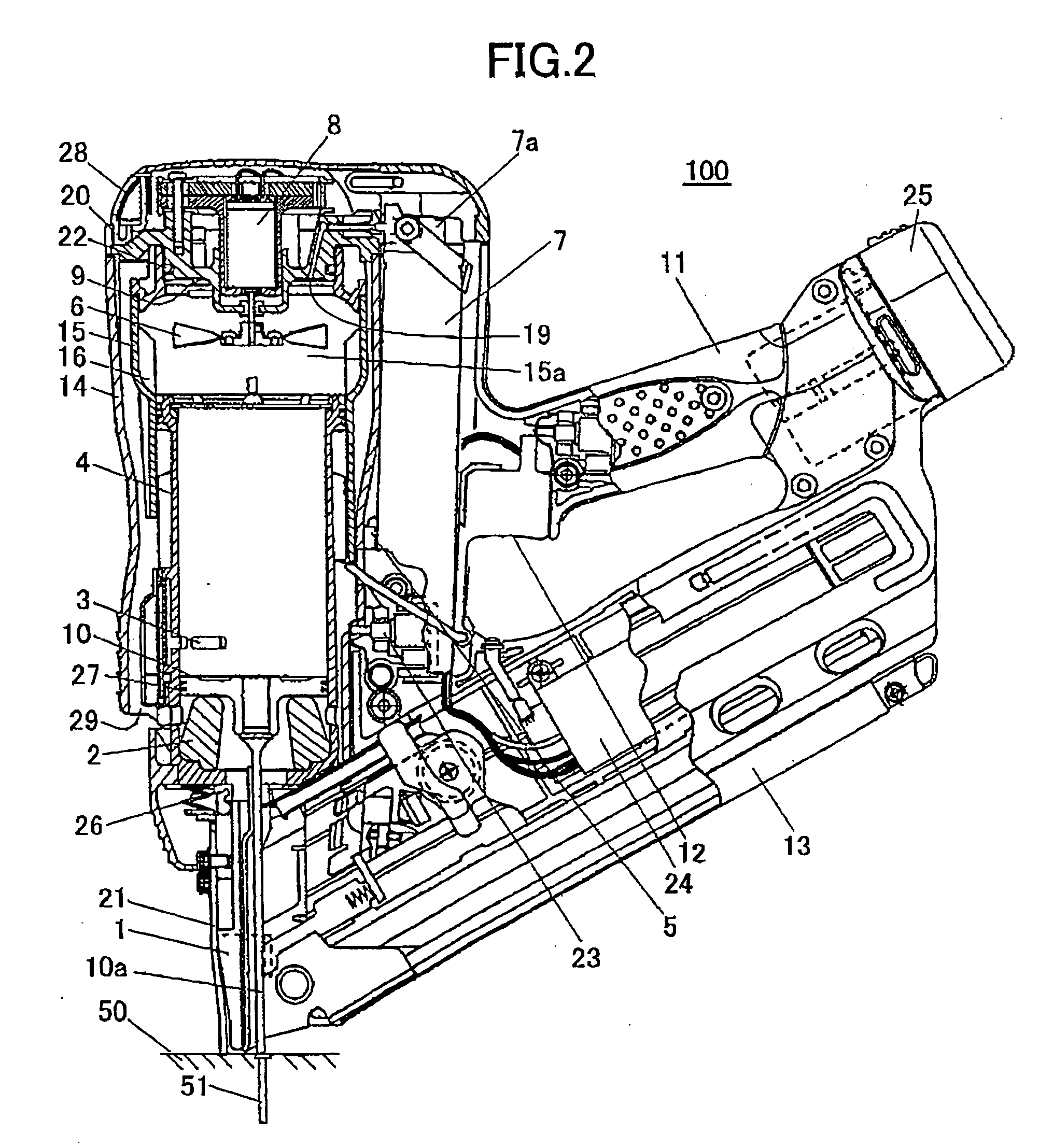

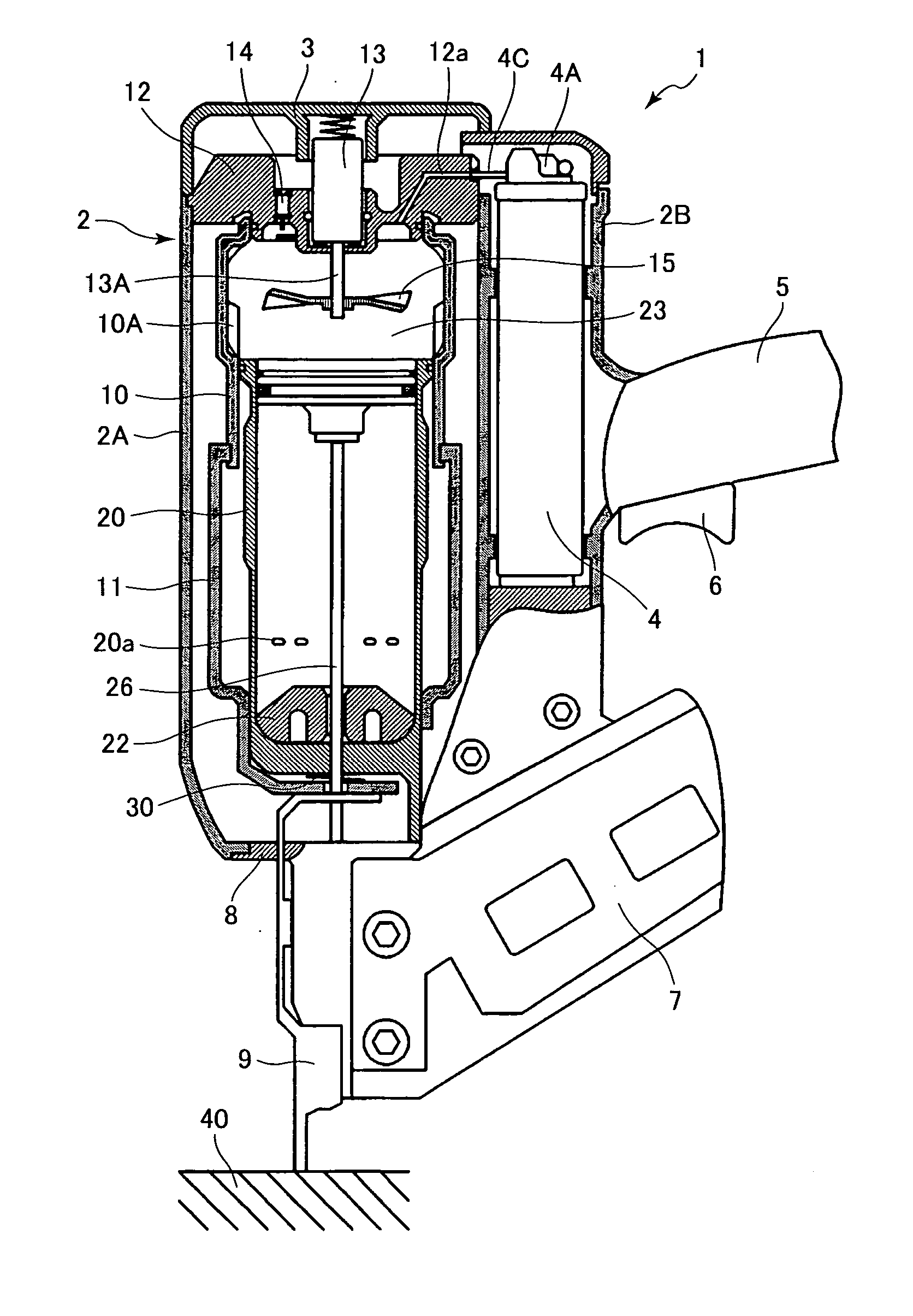

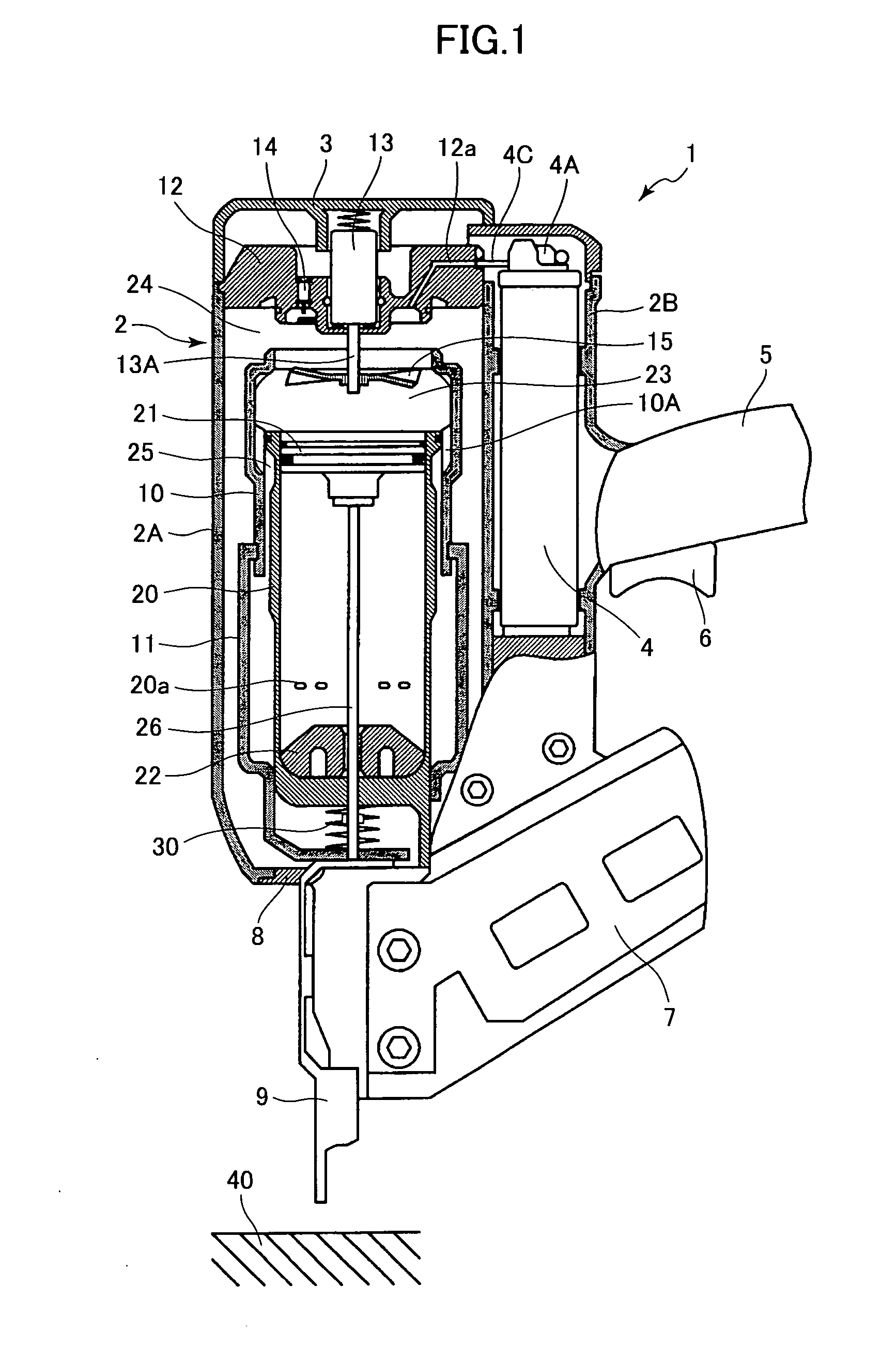

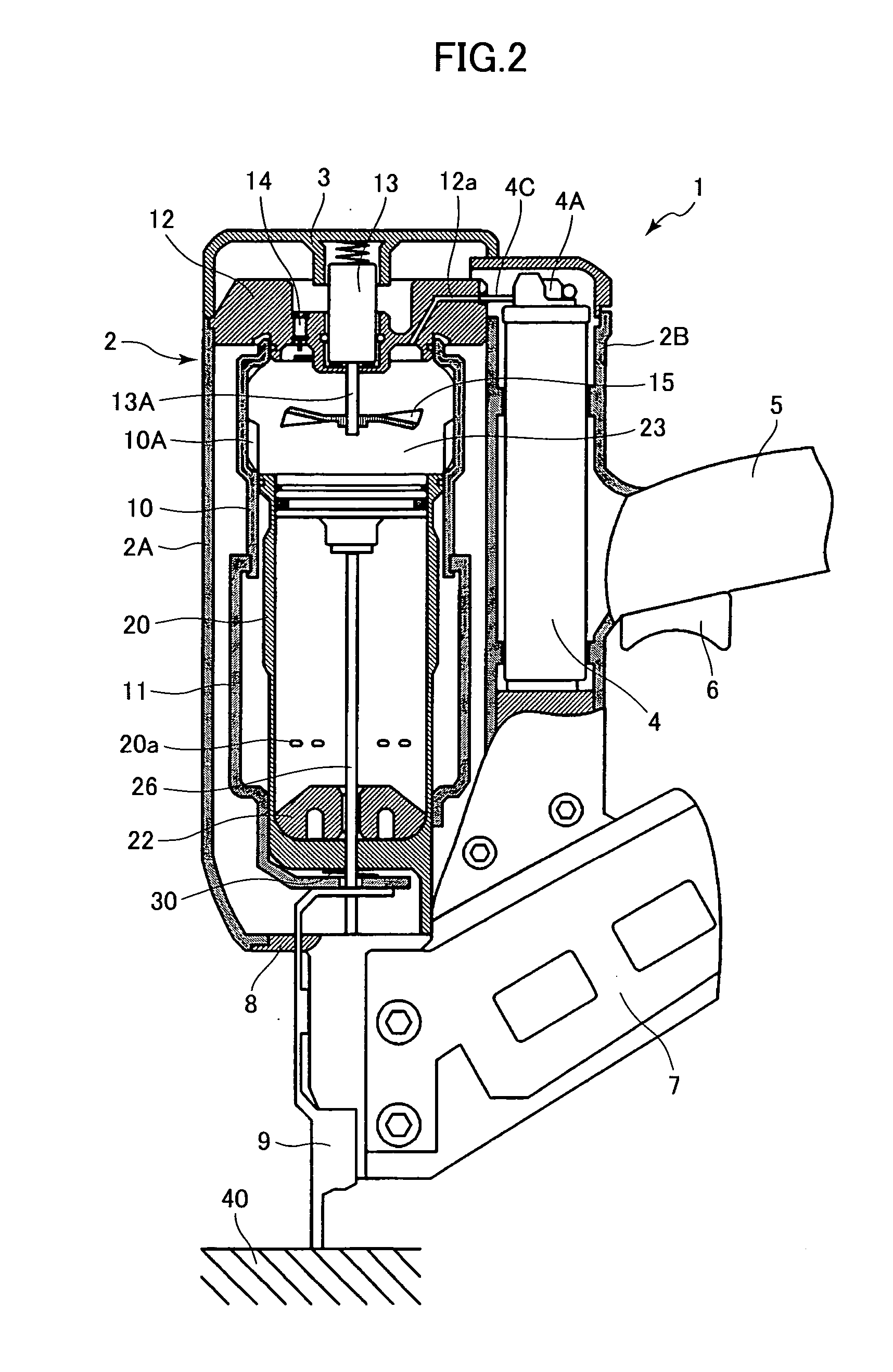

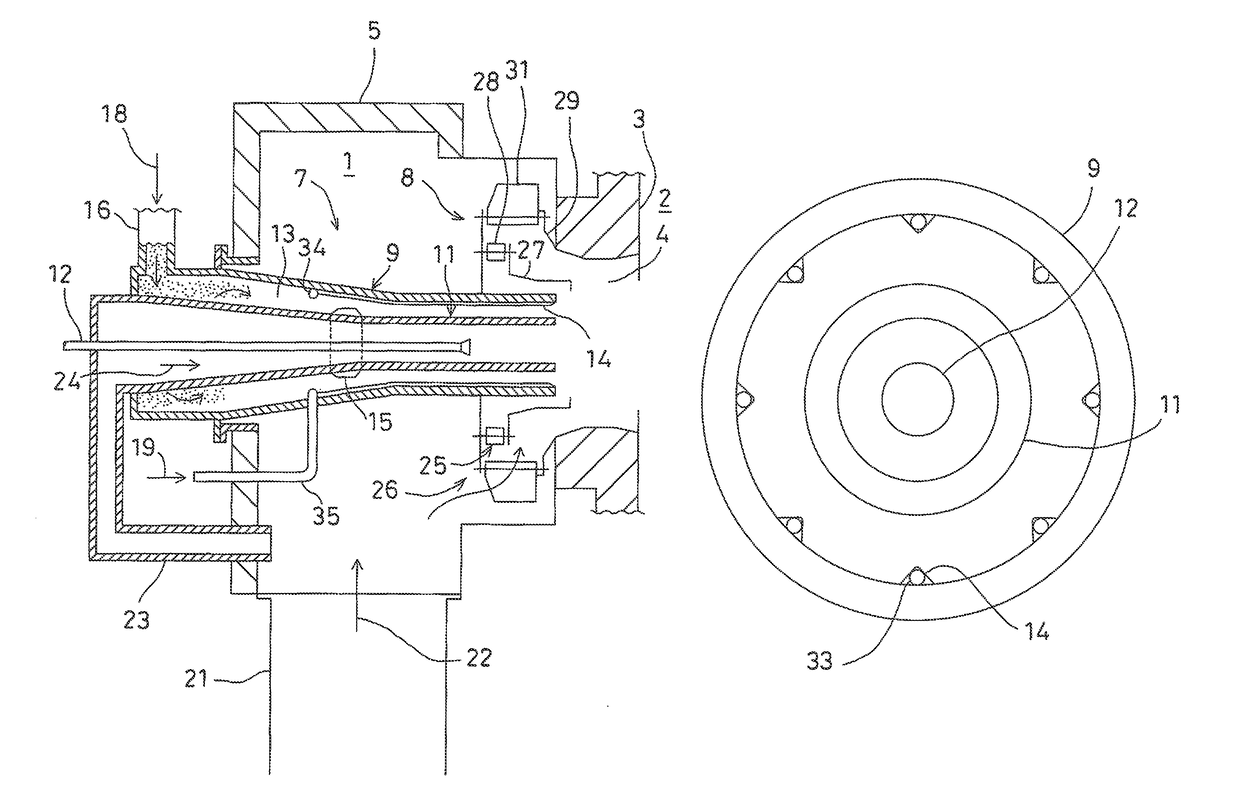

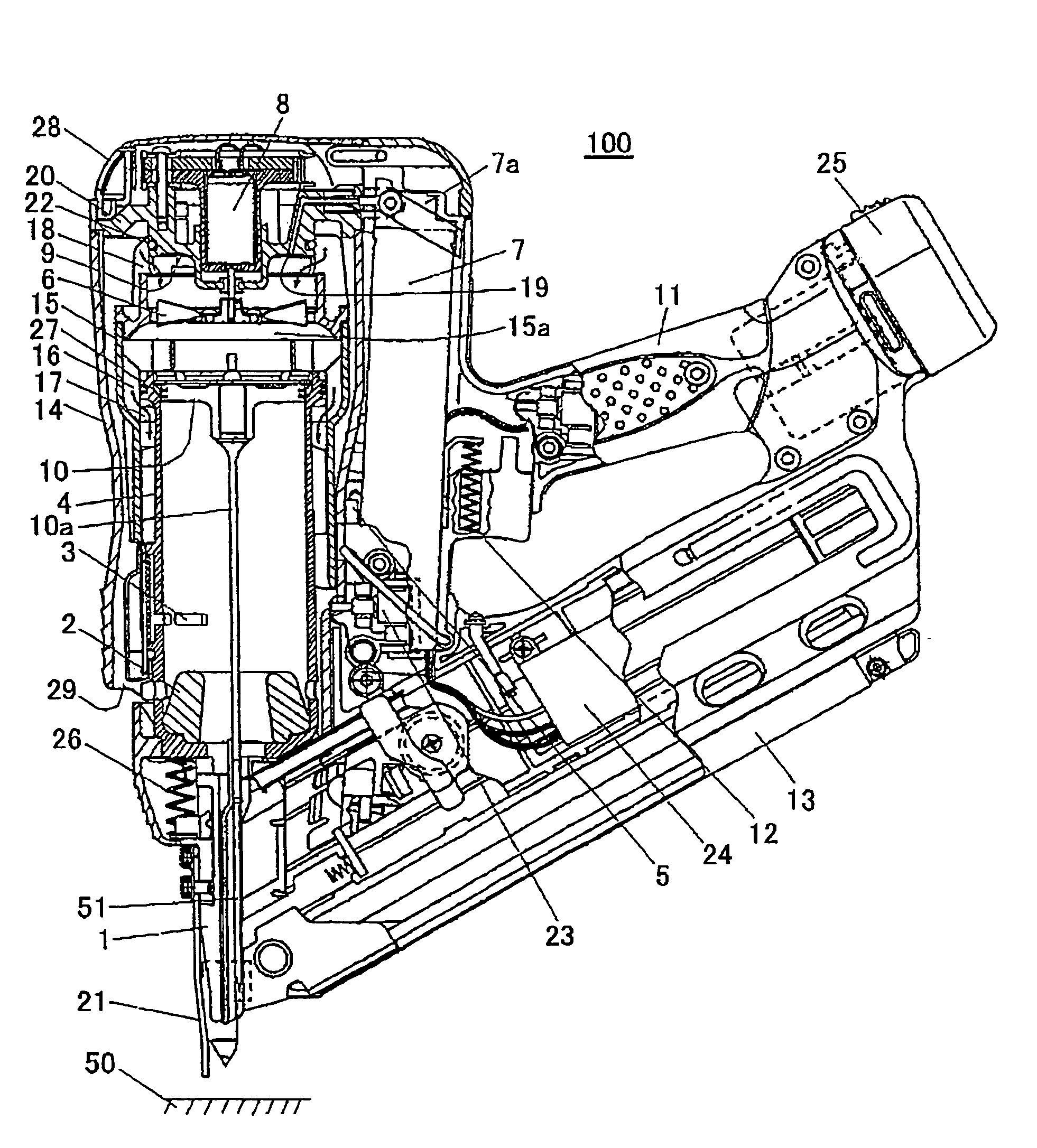

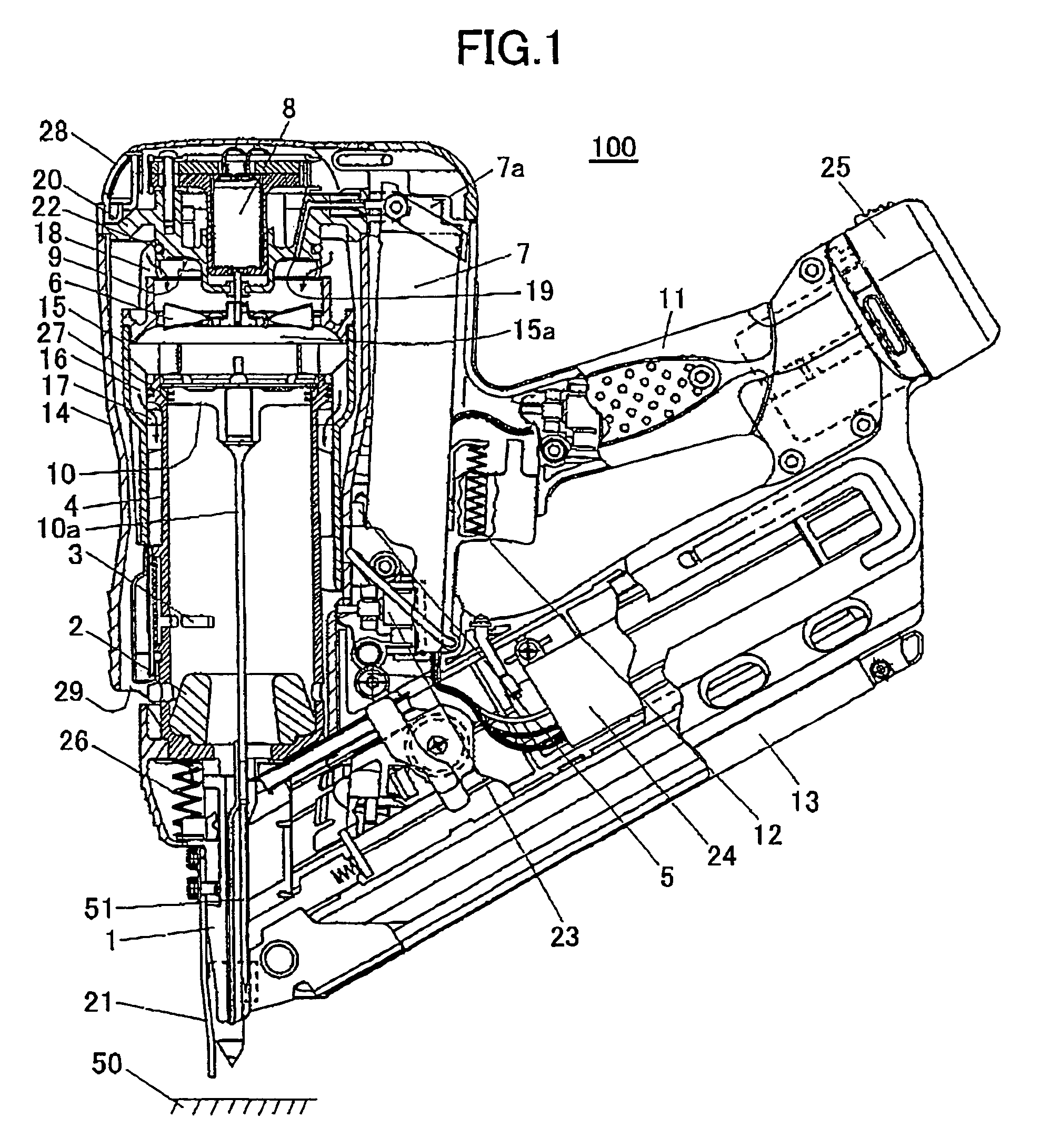

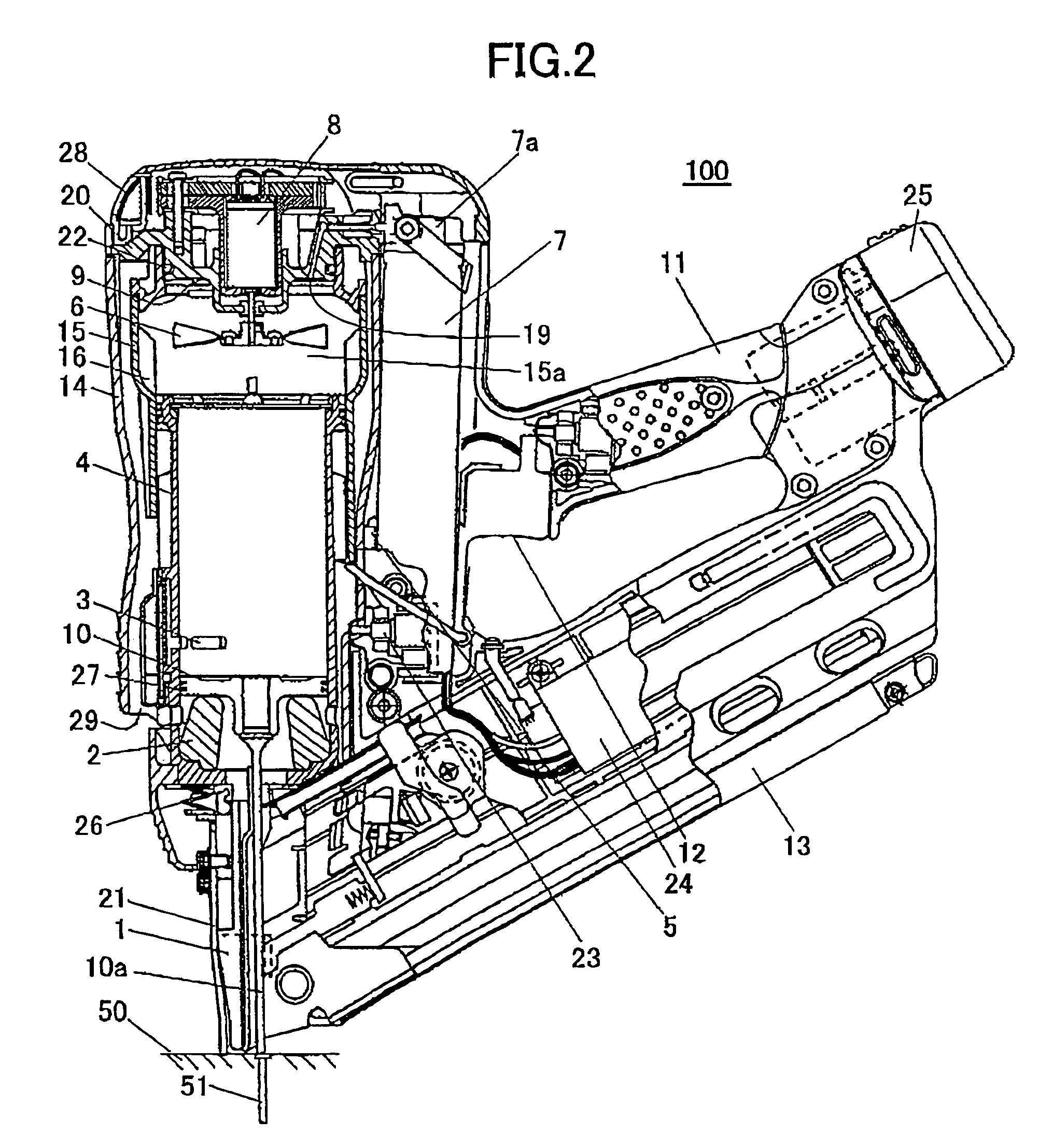

Combustion-powered, fastener-driving tool generating sparks in succession when triggered

InactiveUS20060065690A1Reliably producedIncrease opportunitiesStapling toolsNailing toolsCombustion chamberPiston

A combustion-powered, fastener-driving tool includes a cylinder and a combustion chamber disposed on top of the cylinder that accommodates a gaseous mixture of existing air in the combustion chamber and fuel injected therein. A spark plug generates a spark to combust the gaseous mixture in the combustion chamber. A trigger produces the spark in the spark plug when operated. A piston is movably supported in the cylinder and driven by combustion in the combustion chamber. A driving blade is coupled to the piston for driving a fastener. A spark controller is provided for generating a plurality of sparks in succession with the spark plug.

Owner:HITACHI KOKI CO LTD

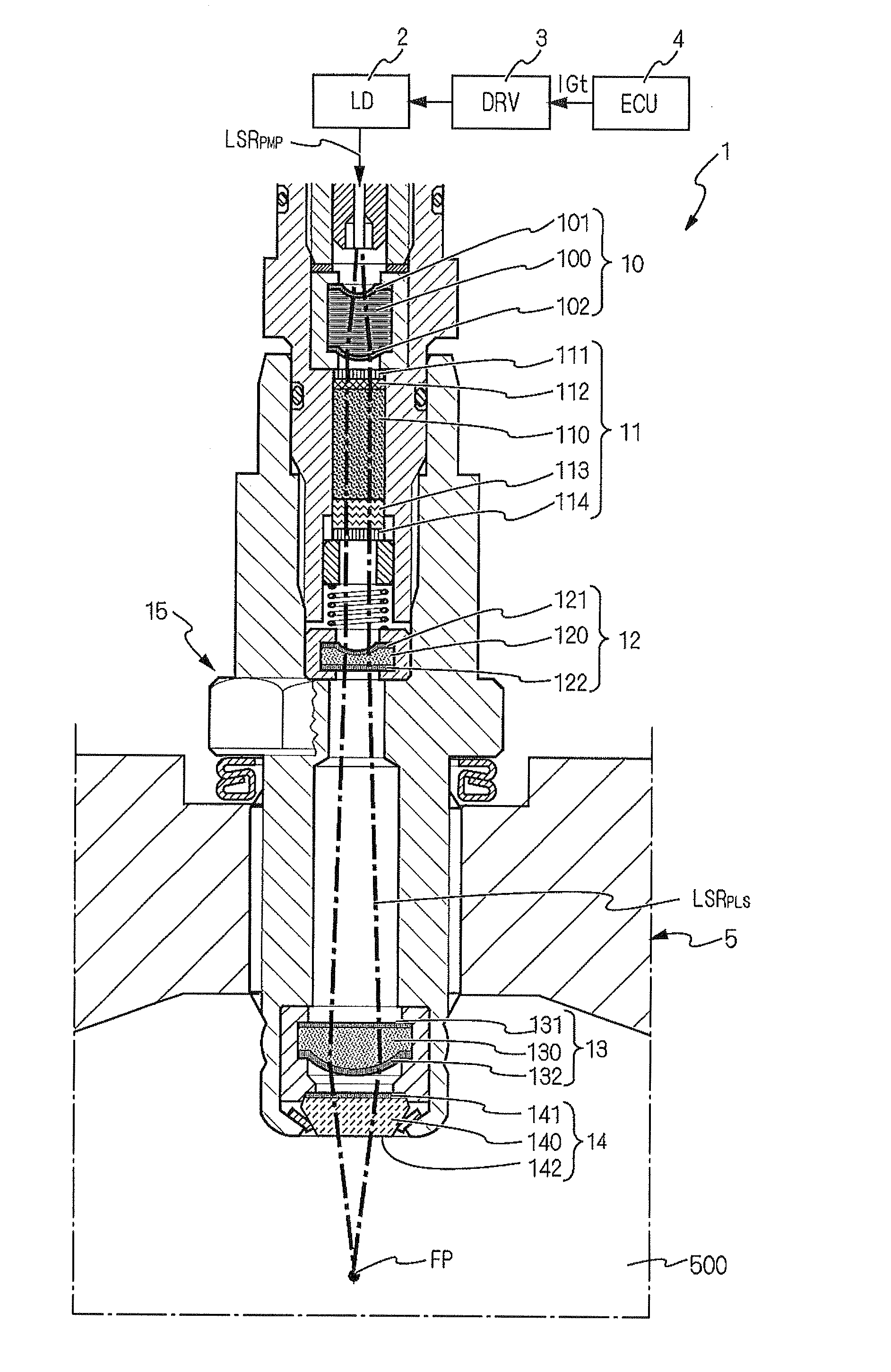

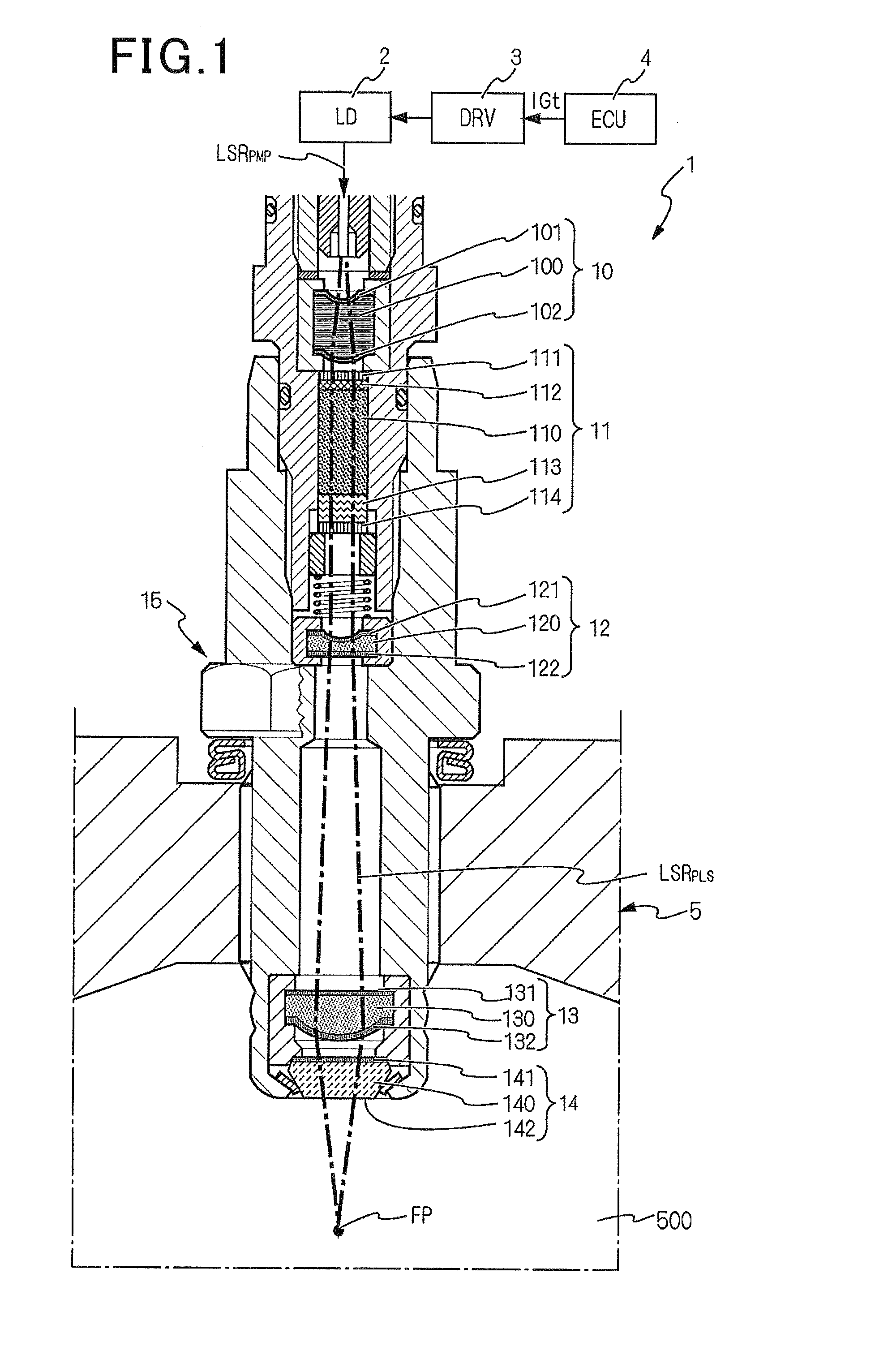

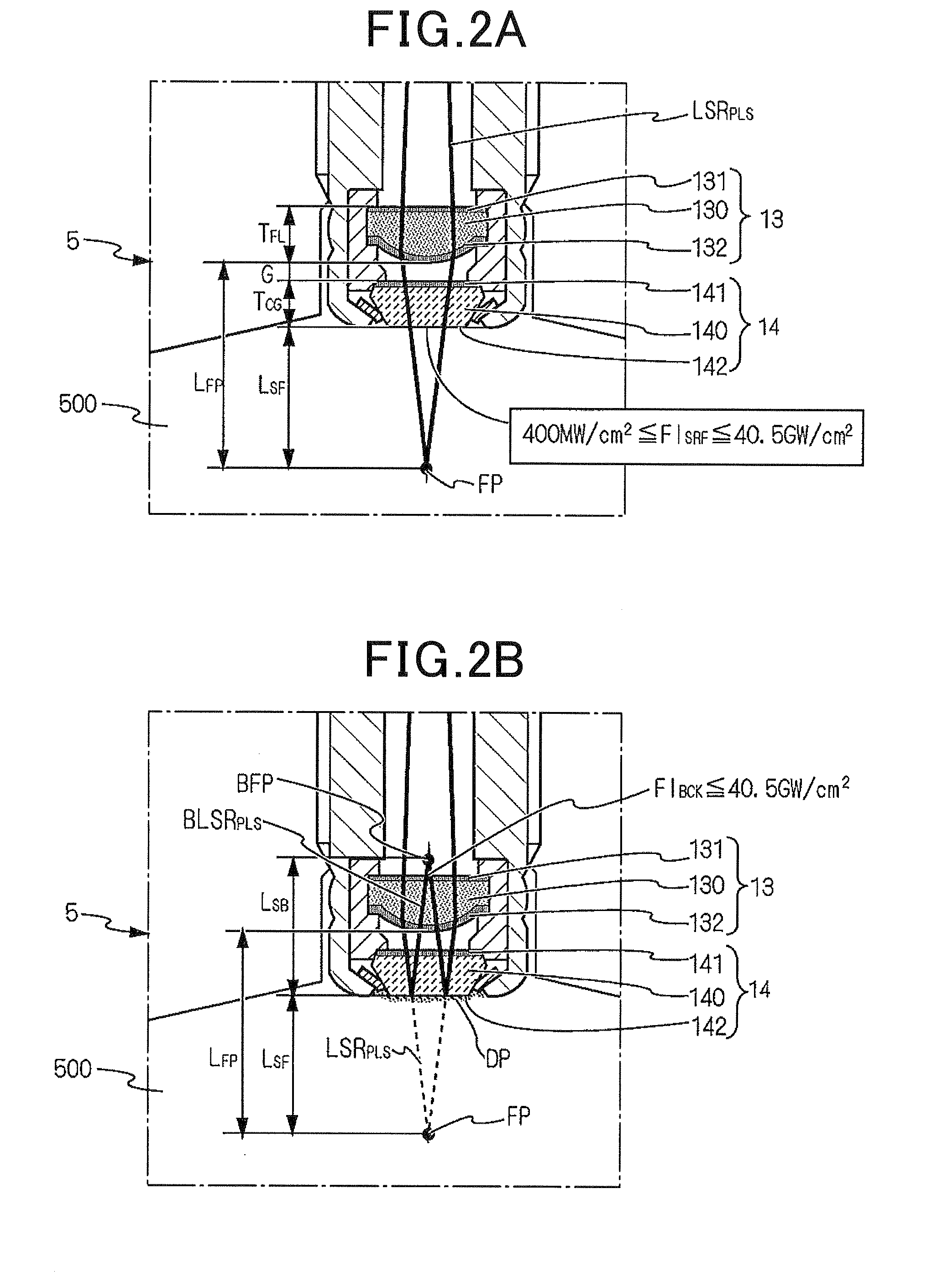

Laser ignition apparatus

ActiveUS20130206091A1Stable ignitionImprove power densitySparking plugsCombustion enginesCombustion chamberOptoelectronics

In a laser ignition apparatus, a focusing optical element is configured to focus a pulsed laser light to a predetermined focal point in a combustion chamber of an engine. An optical window member is arranged on the combustion chamber side of the focusing optical element so as to separate the focusing optical element from the combustion chamber. A catoptric-light focal point, at which a catoptric light is to be focused, is positioned on the anti-combustion chamber side of a combustion chamber-side end surface of the optical window member. The catoptric light results from the reflection of the pulsed laser light by a pseudo mirror that is formed by the optical window member when the combustion chamber-side end surface thereof is fouled with contaminants. Further, the catoptric-light focal point falls in a region where no solid material forming either the focusing optical element or the optical window member exists.

Owner:NIPPON SOKEN +1

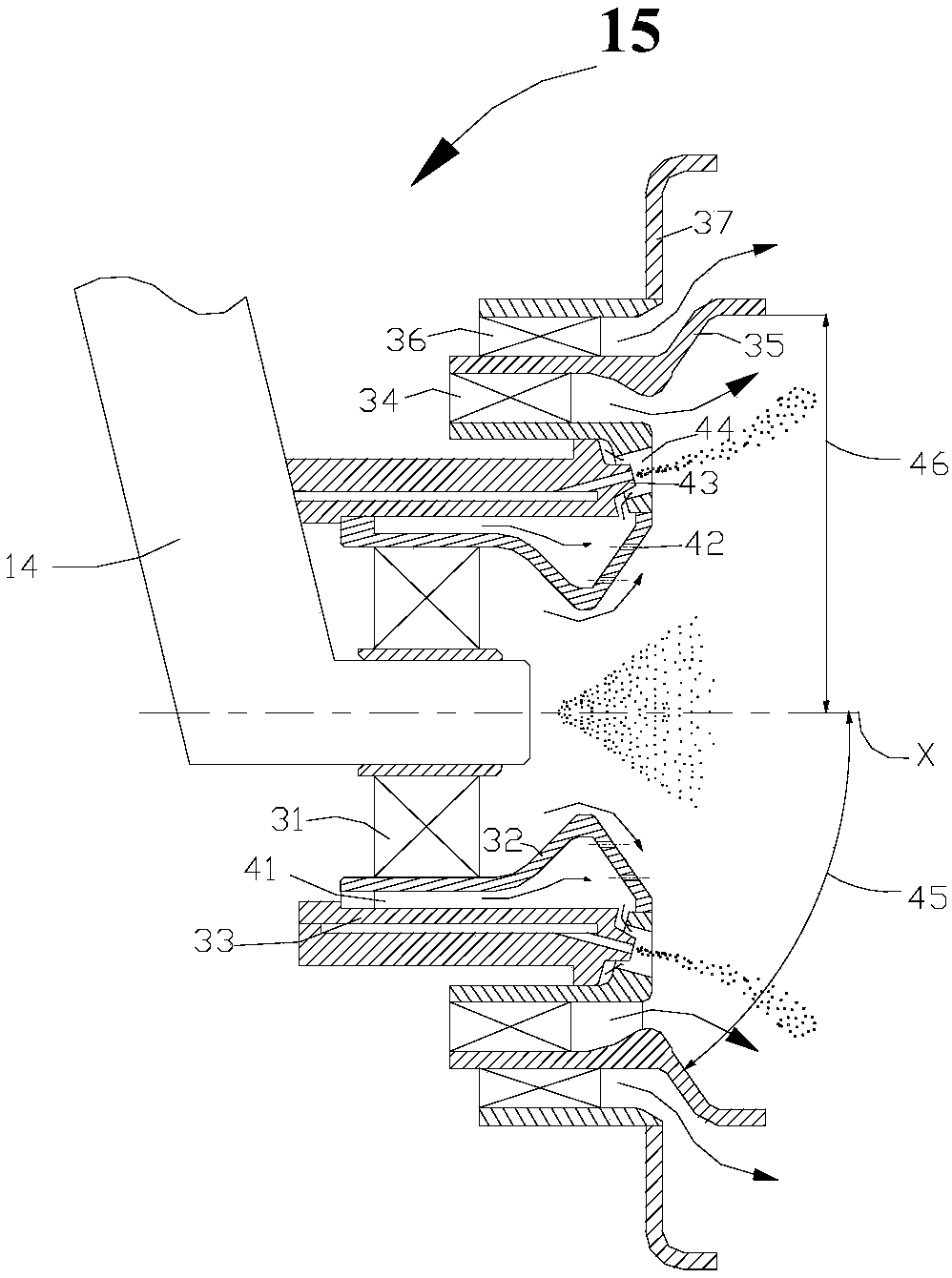

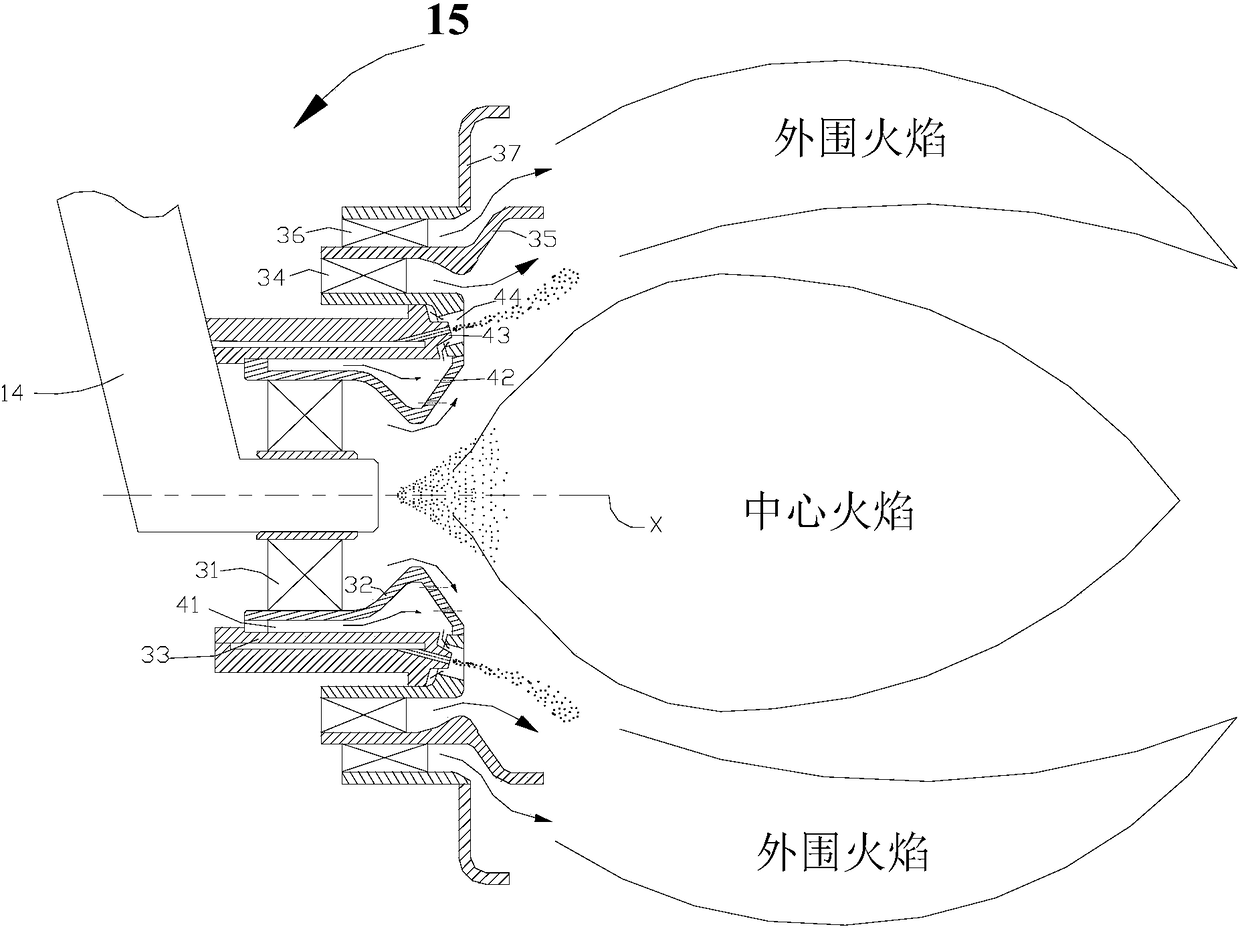

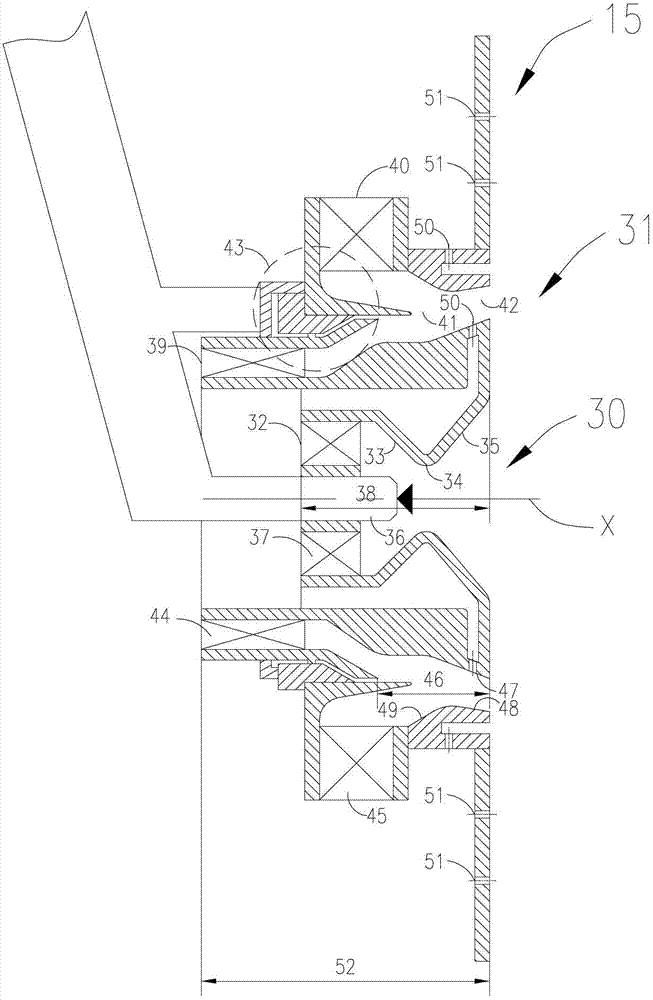

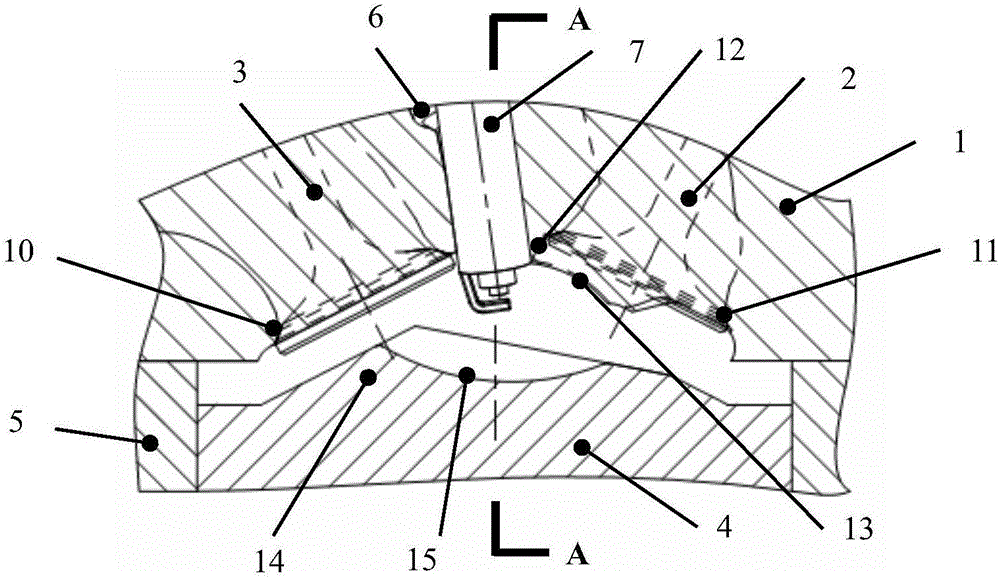

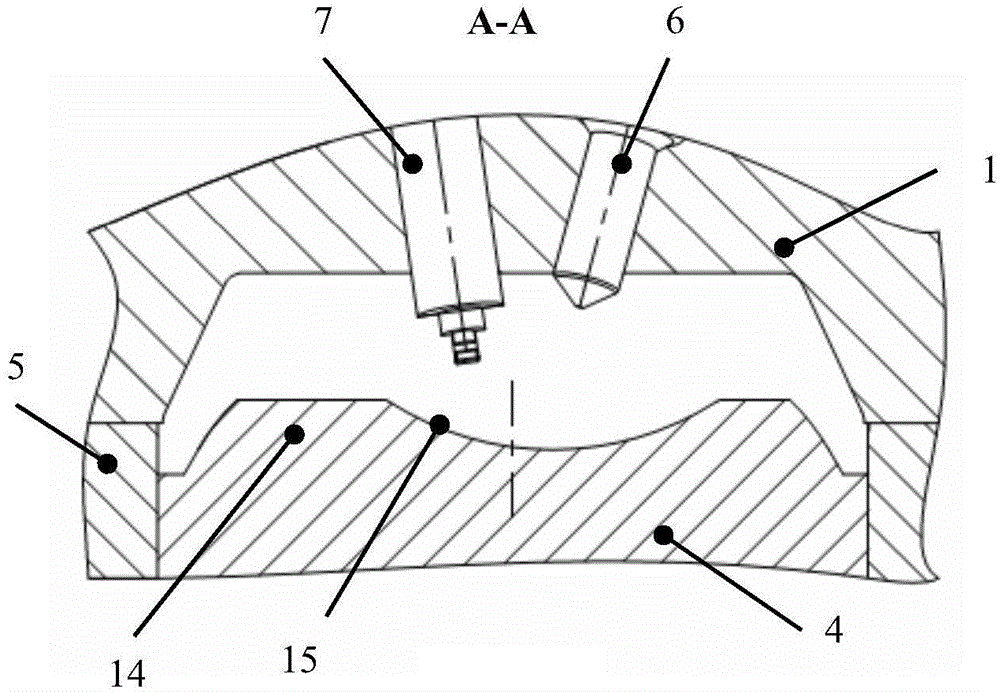

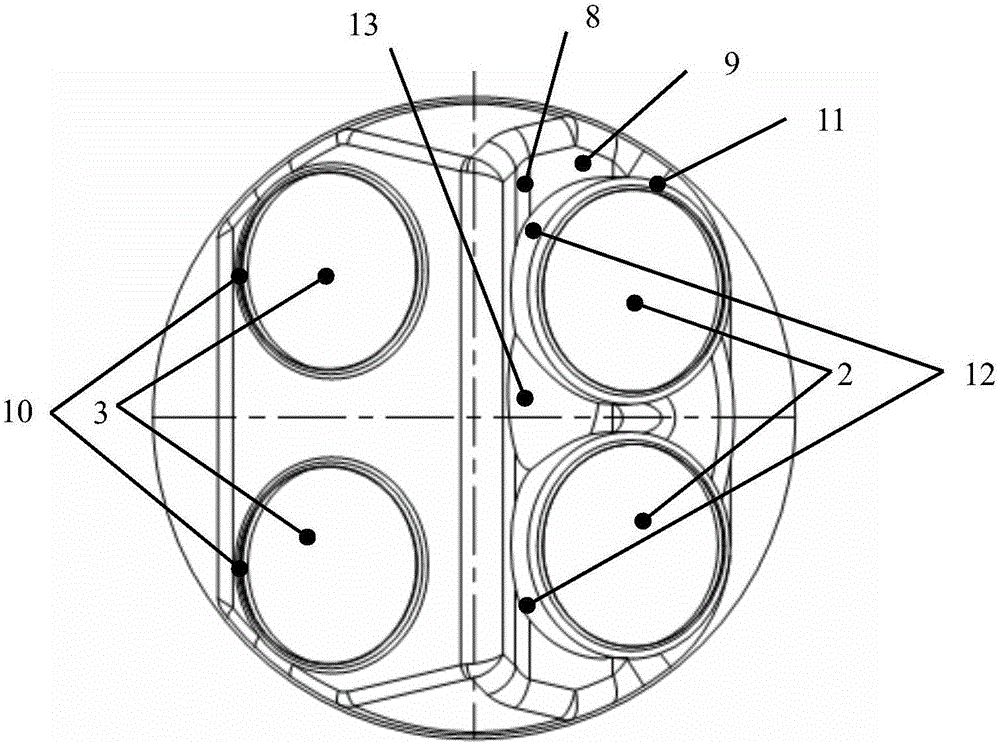

Coaxial partition high-temperature-rise combustor head

ActiveCN108561898AReliable ignitionStable jobContinuous combustion chamberCombustorCombustion chamber

The invention relates to a coaxial partition high-temperature-rise combustor head which comprises a first-stage axial hydrocyclone (31), a venturi (32), a main-stage fuel oil way (33), a second-stageaxial hydrocyclone (34), a baffling device (35), a three-stage axial hydrocyclone (36) and a splash pan (37). A middle cooling runner (41) is formed between the venturi (32) and the main-stage fuel oil way (33), an expansion section of the venturi (32) is provided with a plurality of rows of cooling small holes (42), part of air flowing into the middle cooling runner (41) flows out from the cooling small holes (42) in the expansion section of the venturi (32), the other part of air flows through the periphery of a main spraying opening (43) in the tail end of the main-stage fuel oil way (33) to flow out from a main-stage fuel oil atomization channel (44).

Owner:AECC SICHUAN GAS TURBINE RES INST

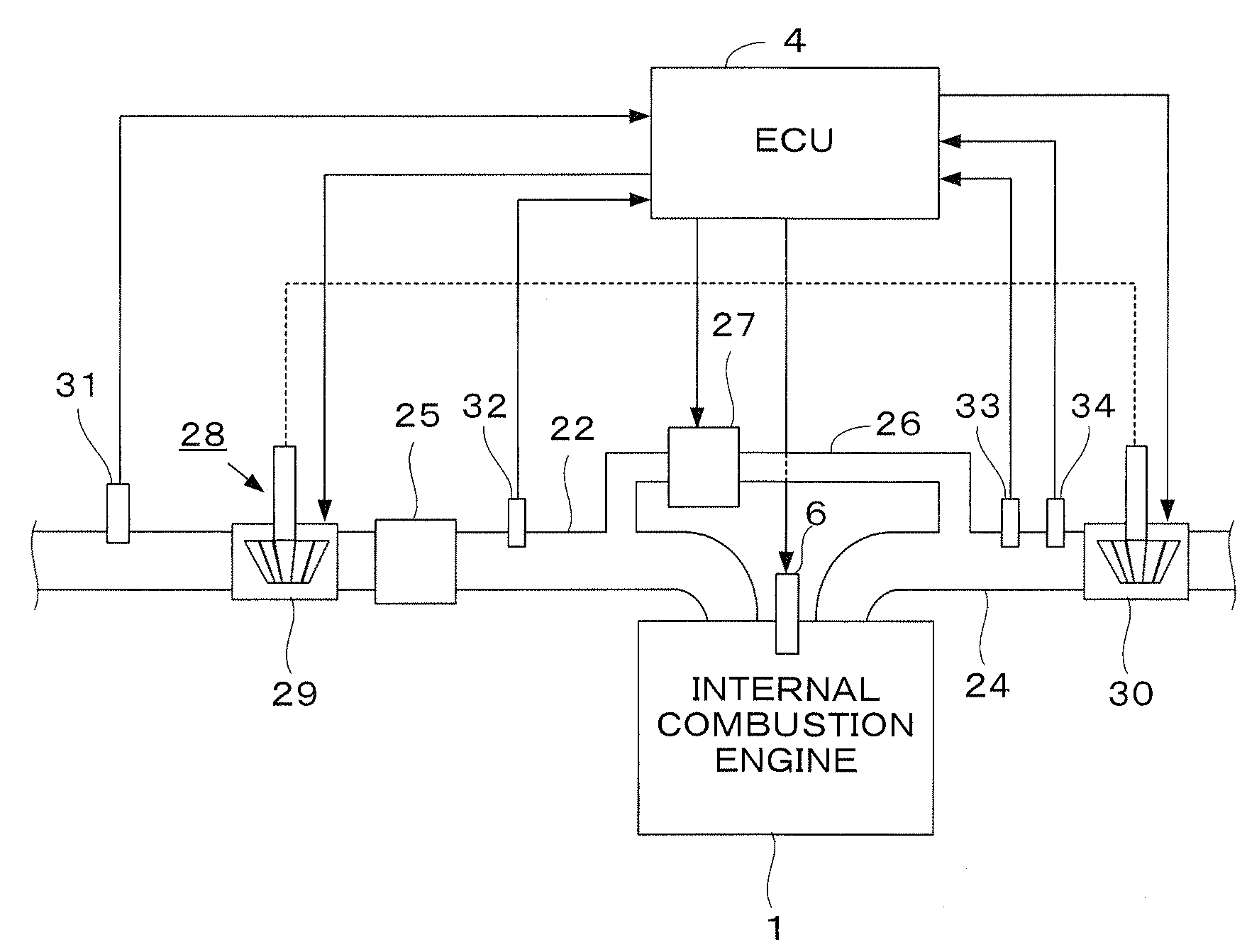

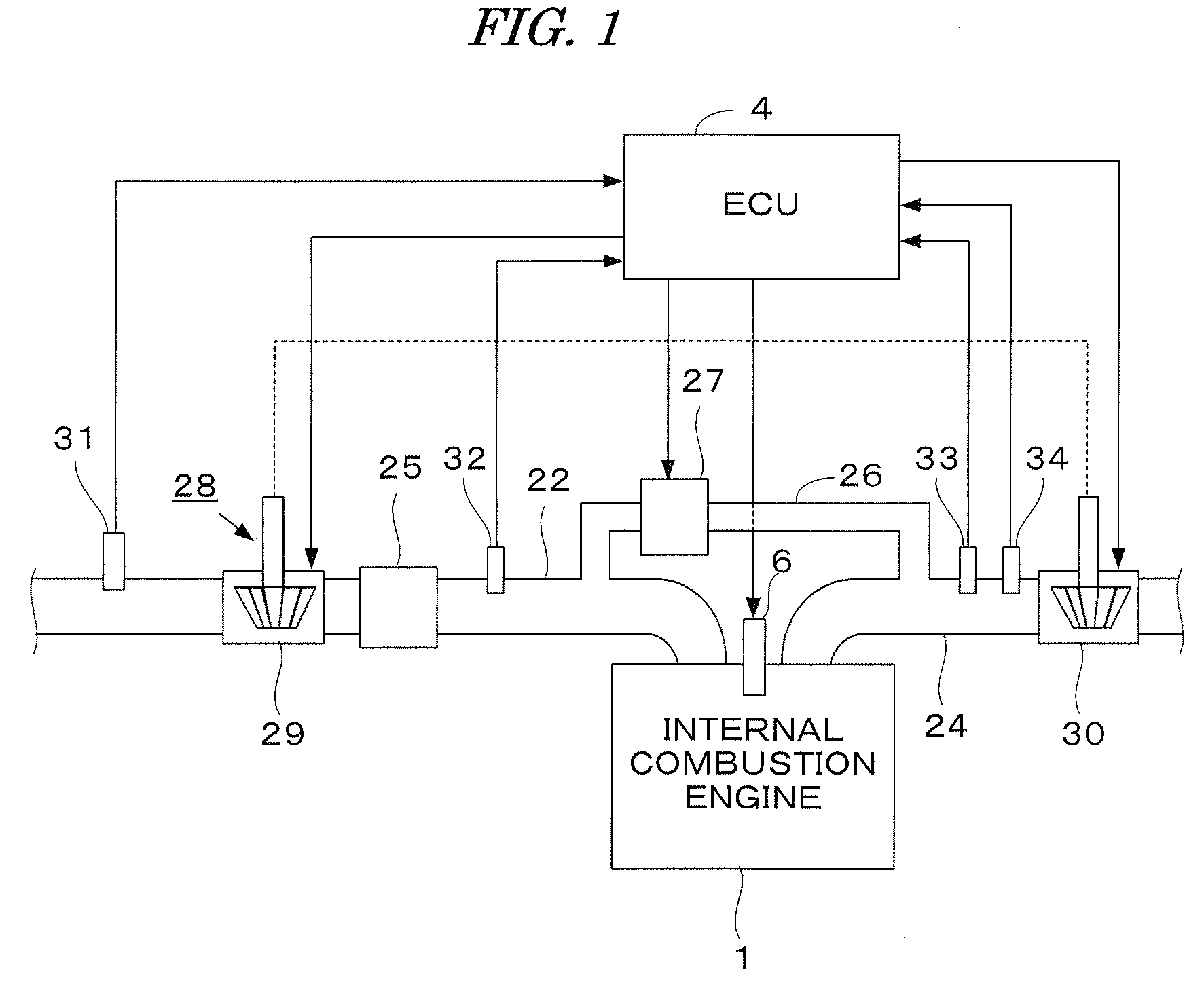

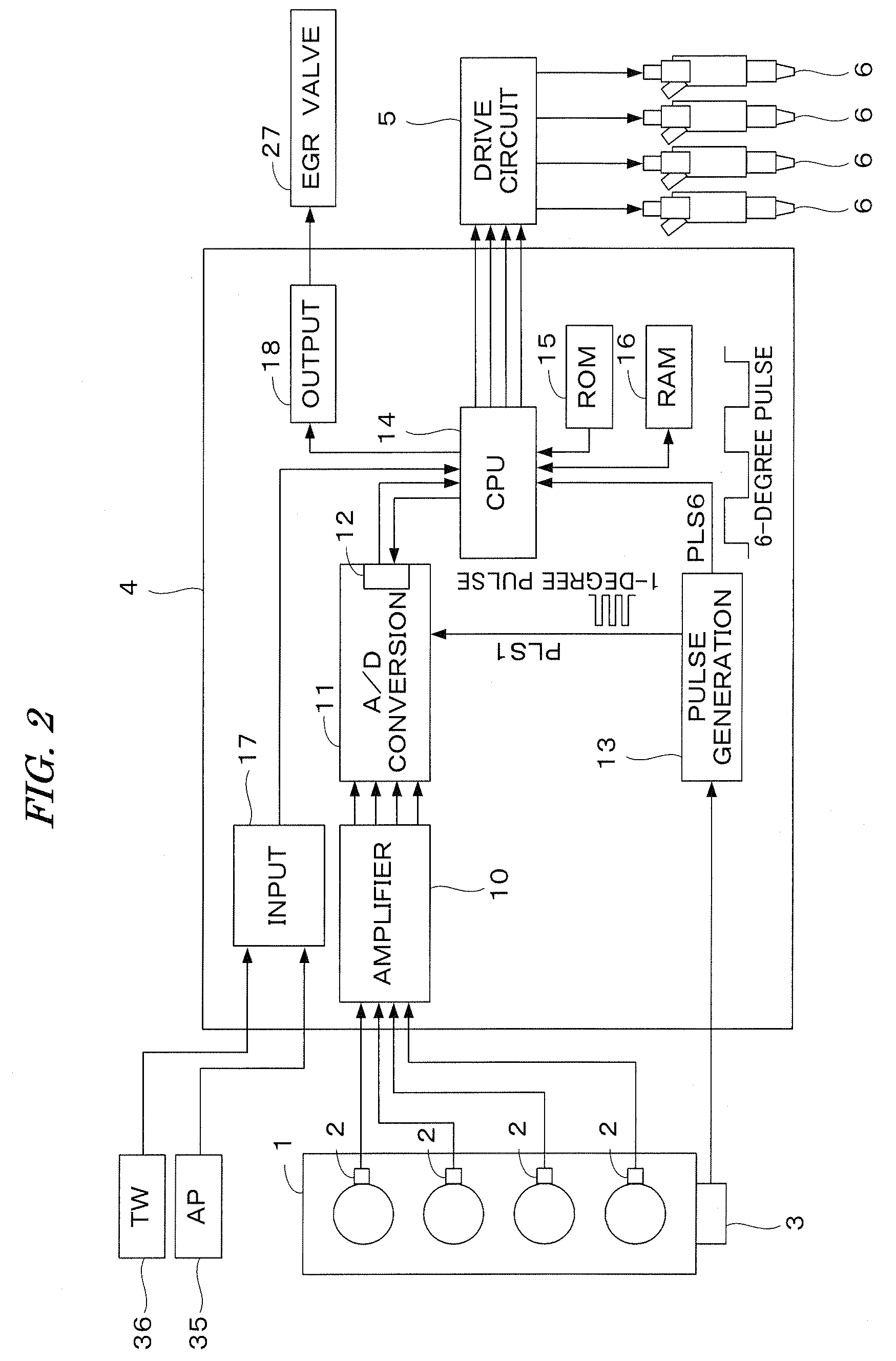

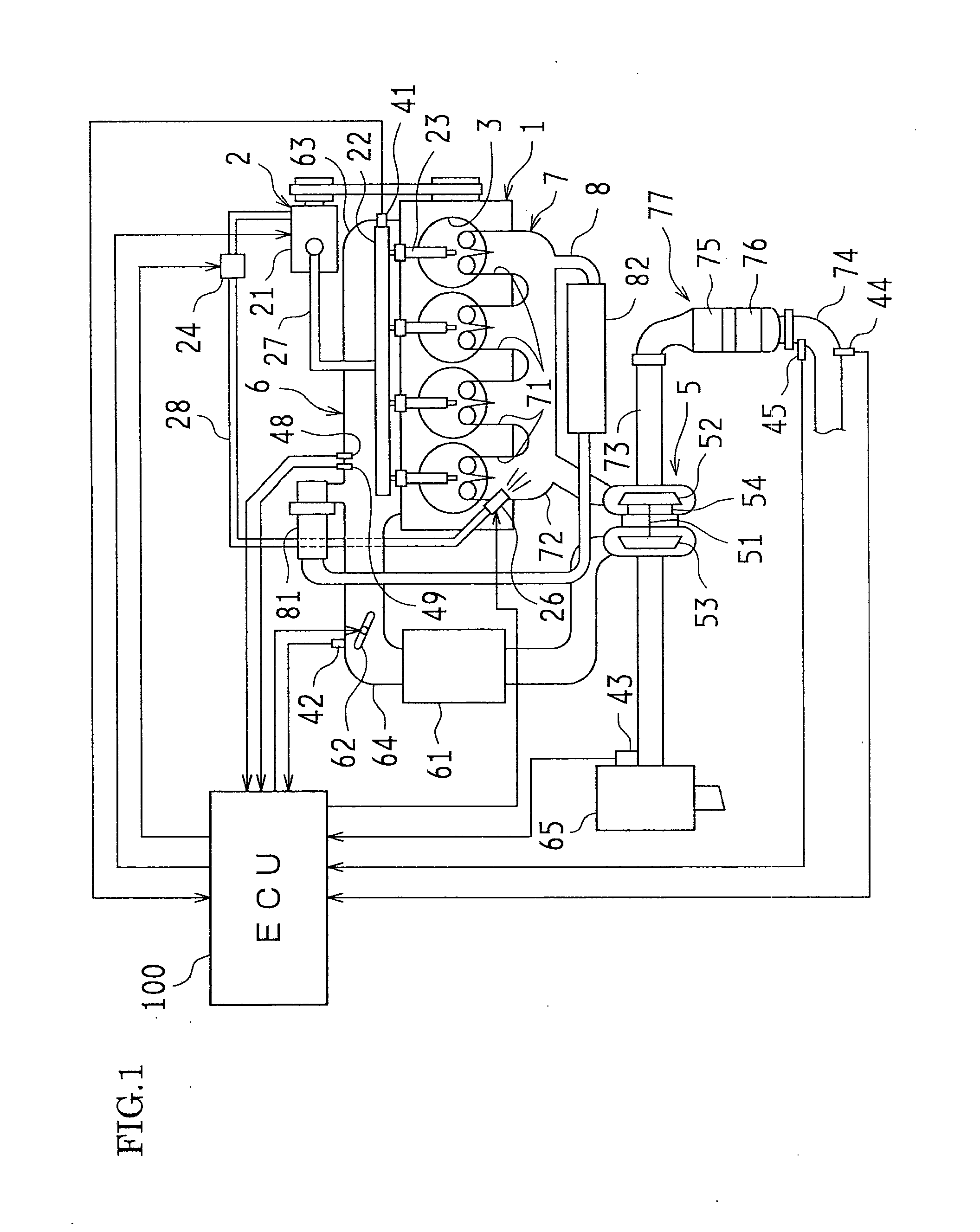

Control System for Internal Combustion Engine

ActiveUS20090151697A1Stable ignitionabilityIgnitionability is improvedElectrical controlInternal combustion piston enginesExternal combustion engineInternal combustion engine

A control system for an internal combustion engine having at least one fuel injection valve for injecting fuel into a combustion chamber of the engine. A compression end temperature in the combustion chamber is estimated. A target compression end temperature is calculated according to an operating condition of the engine. A main injection and a plurality of pilot injections before the main injection are performed by at least one fuel injection valve. A fuel injection amount in a first-performed pilot injection of the plurality of pilot injections is controlled so that the estimated compression end temperature coincides with the target compression end temperature.

Owner:HONDA MOTOR CO LTD

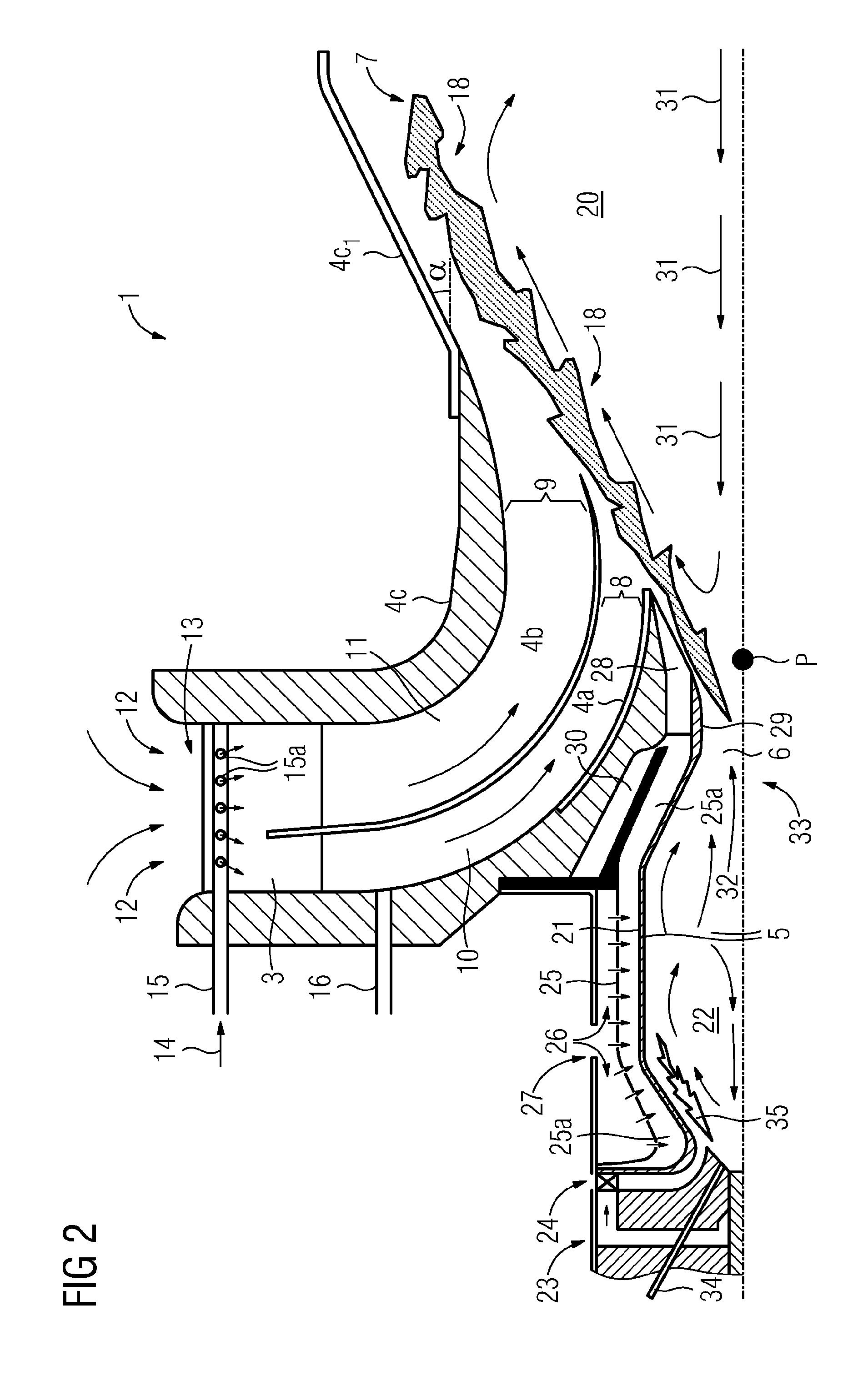

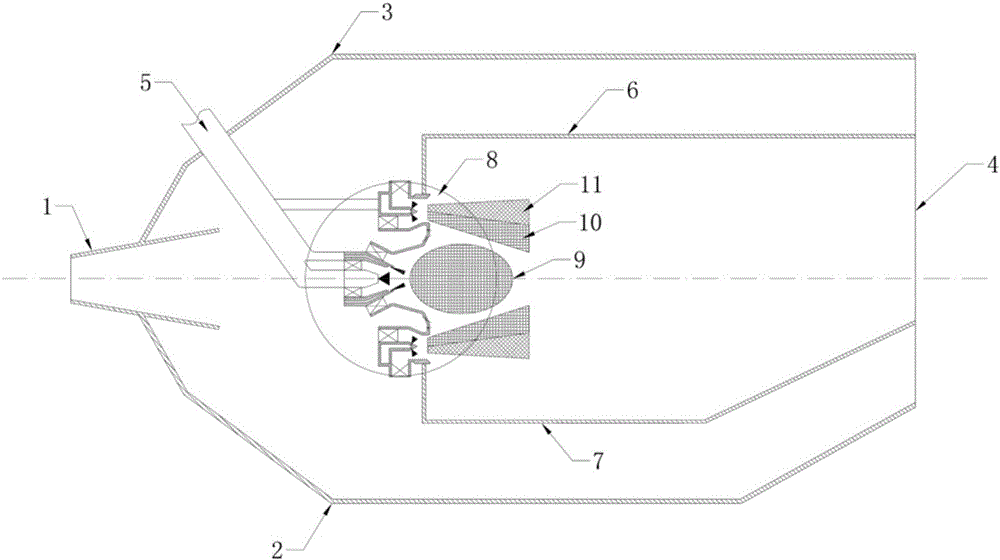

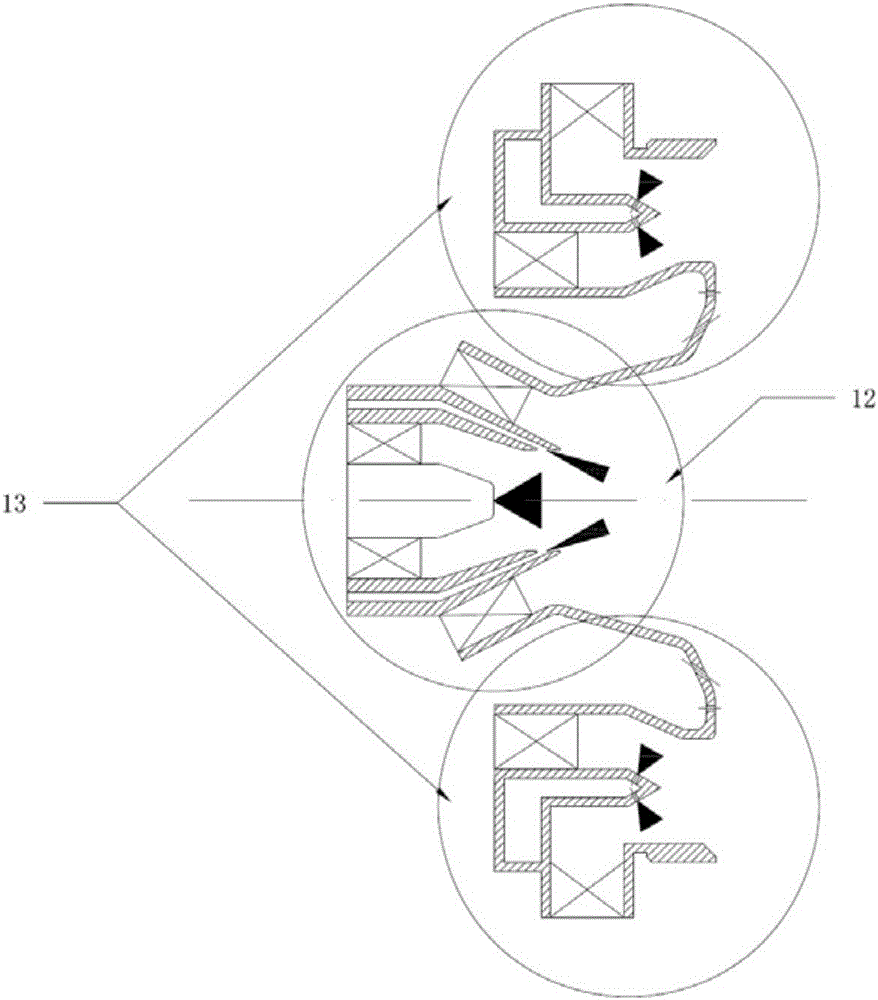

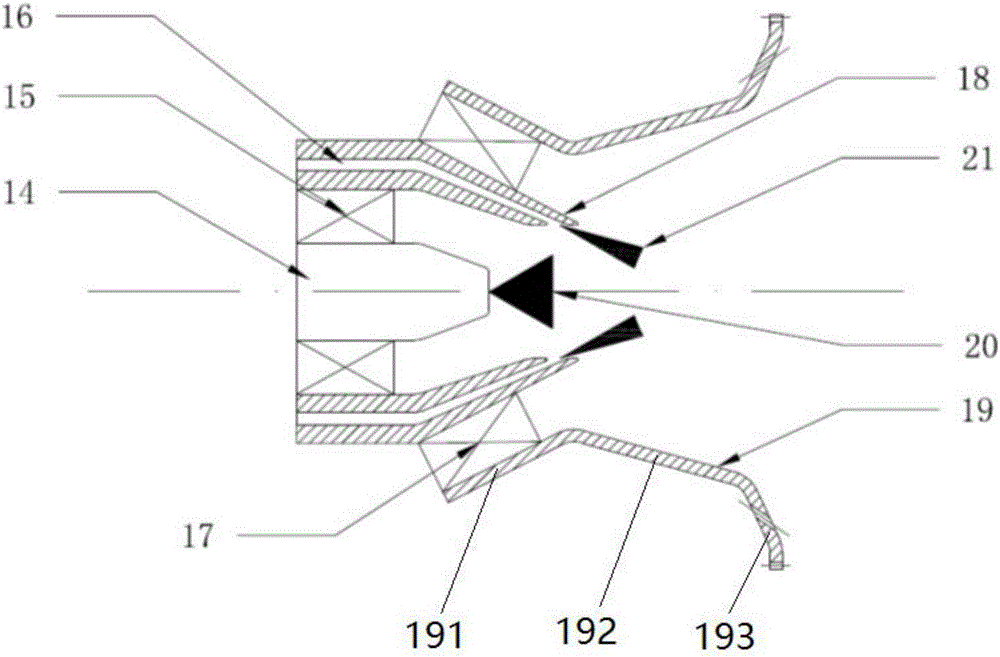

Air inlet of air-breathing pulse detonation engine

The invention discloses an air inlet of an air-breathing pulse detonation engine. The housing of the engine constitutes the circular air inlet, wherein an inlet cone is arranged on the medial axis at the rear end of the air inlet; a cylindrical structure at the rear part of the inlet cone and the housing of the engine constitute a ring-shaped channel; the air flow is fed into a special-shaped channel having a special-shaped structure via the ring-shaped channel; the special-shaped channel is evenly distributed on the circumference of the air inlet with the distance between the central symmetrical curve of the special-shaped channel and the medial axis of the engine remaining unchanged but deviating along the circumference; a fuel channel is arranged on the medial axis of the inlet cone, and the two ends of the fuel channel are connected with the fuel inlet and a fuel injection lever located on the medial axis outside the rear end of the cylindrical structure; the fuel injection lever is particularly a hollow oil tube with one end thereof being closed; a plurality of fuel injection holes are formed on the lateral surface of the fuel injection lever; the housing of the engine and the rear end surface of the cylindrical structure constitute a mixing chamber; and an igniter is located on the lateral wall of the mixing chamber. The invention can improve the atomization and evaporation of the fuel and reduce the impact of reversed fuel on the air inlet.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

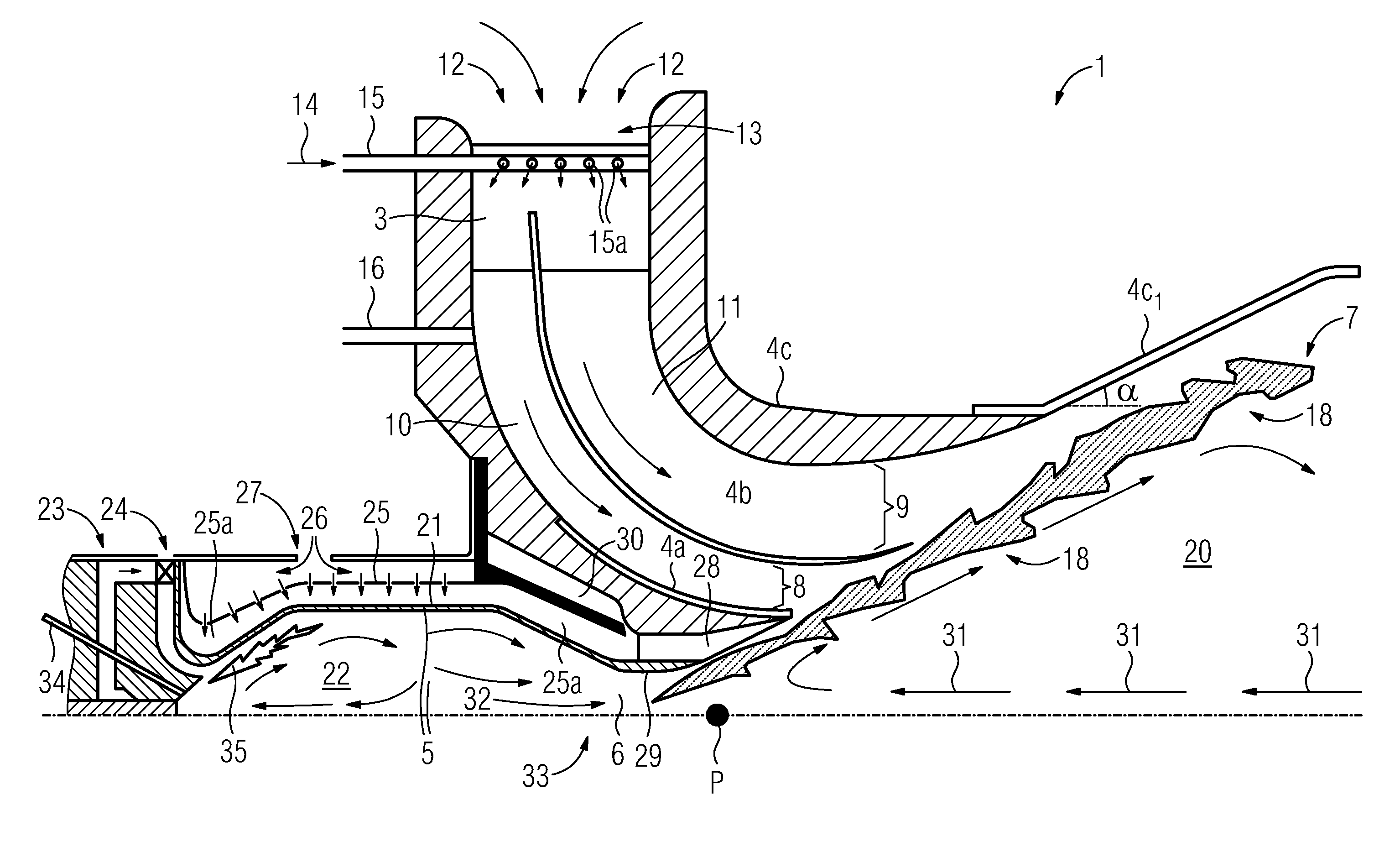

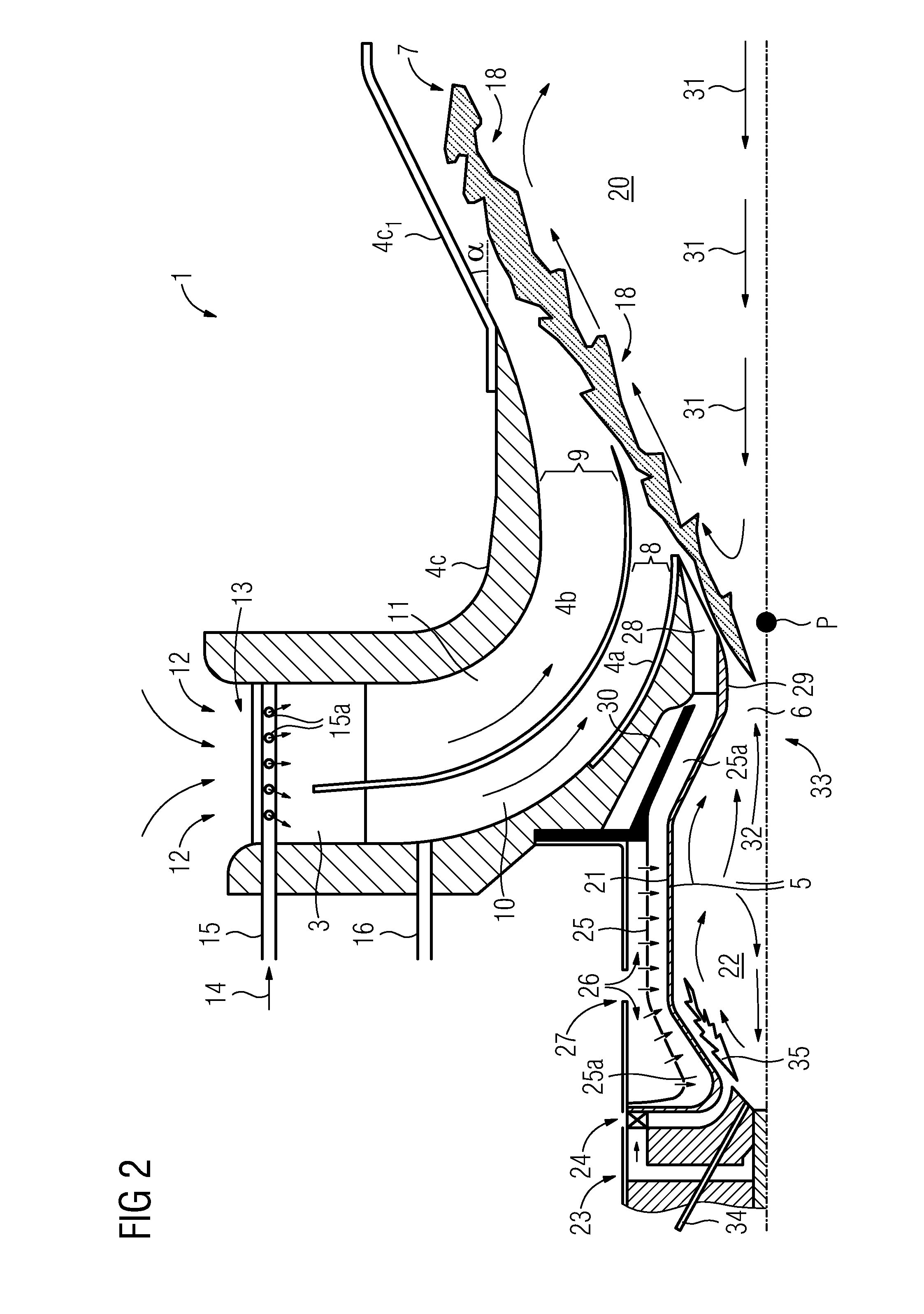

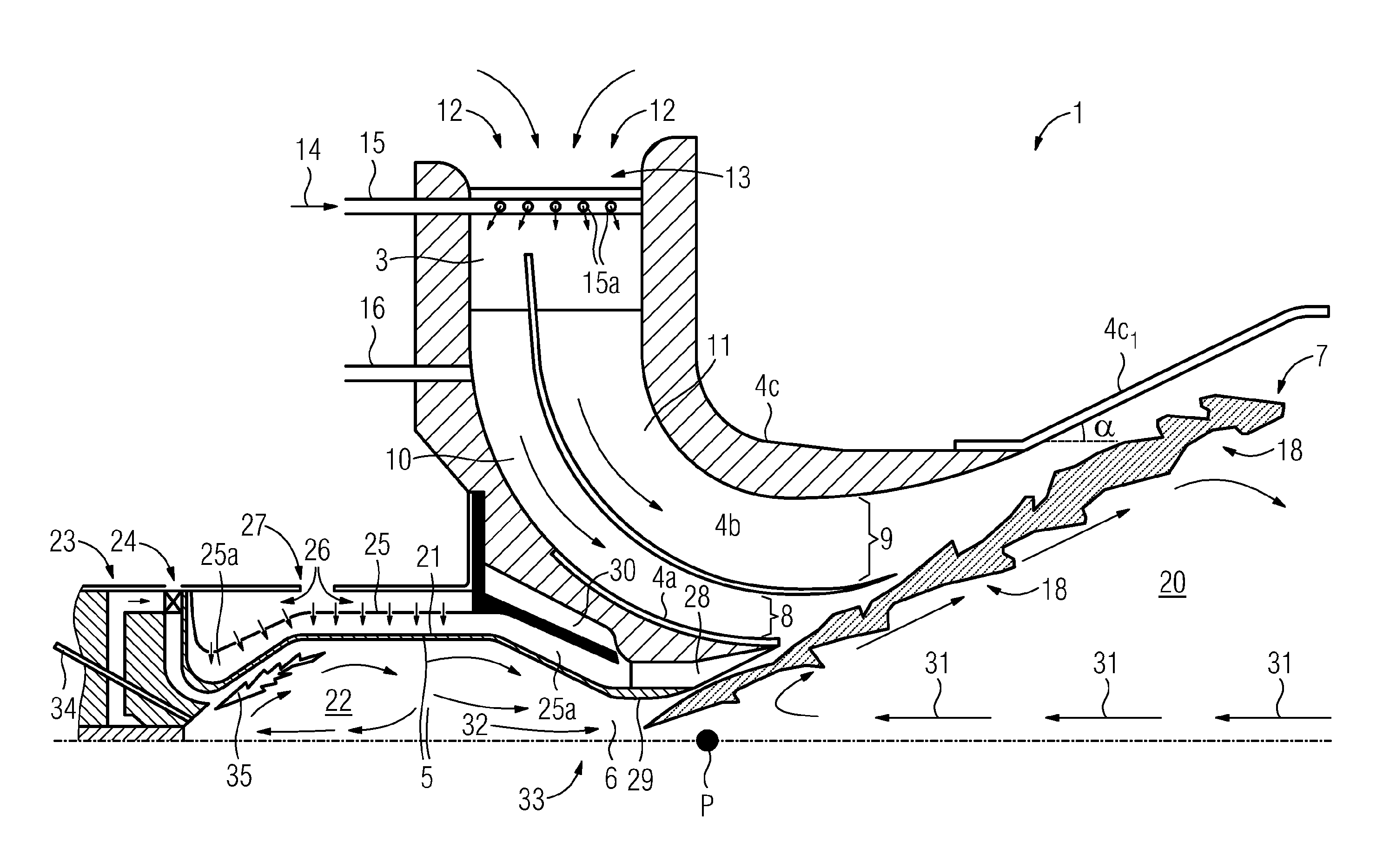

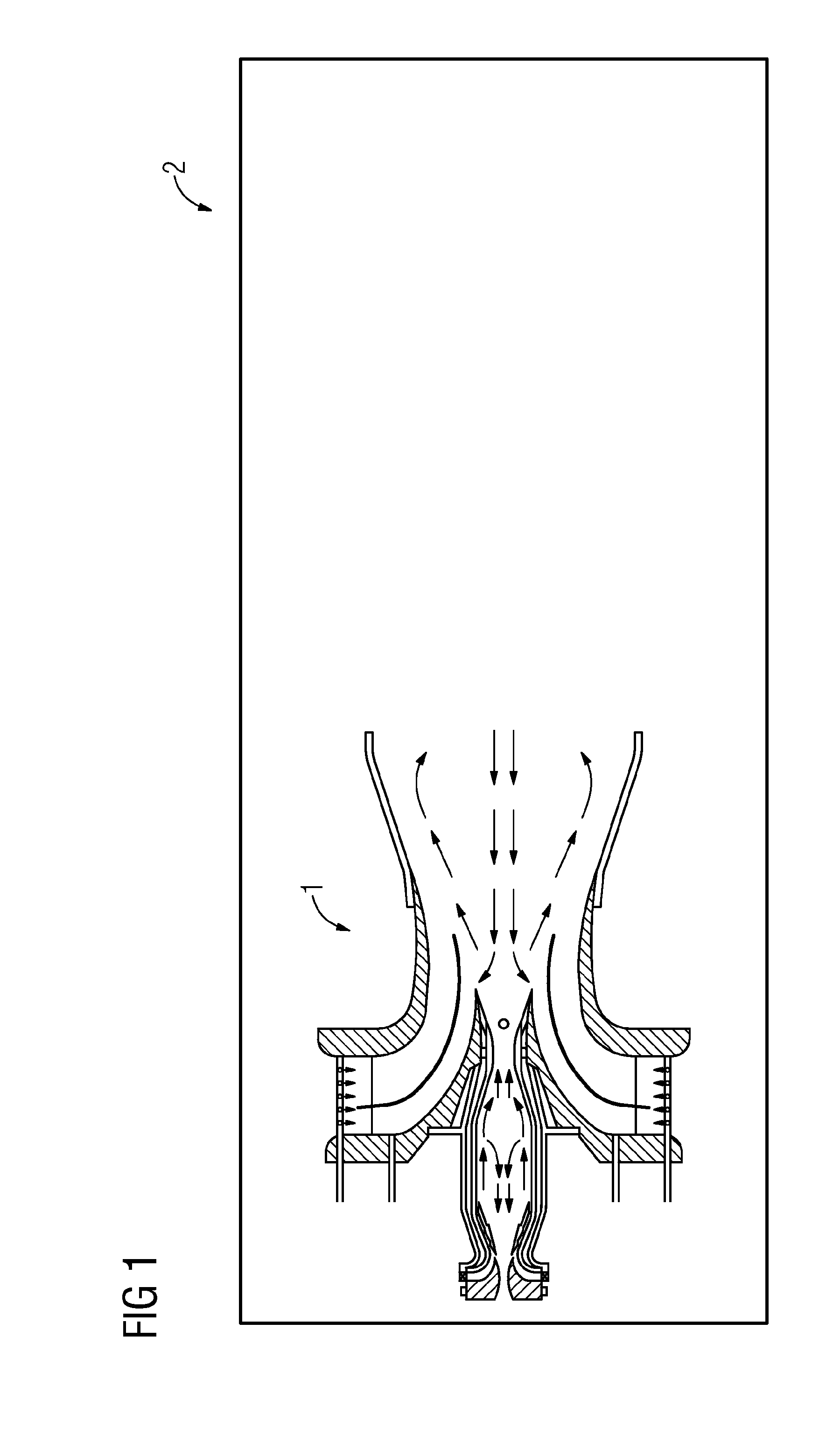

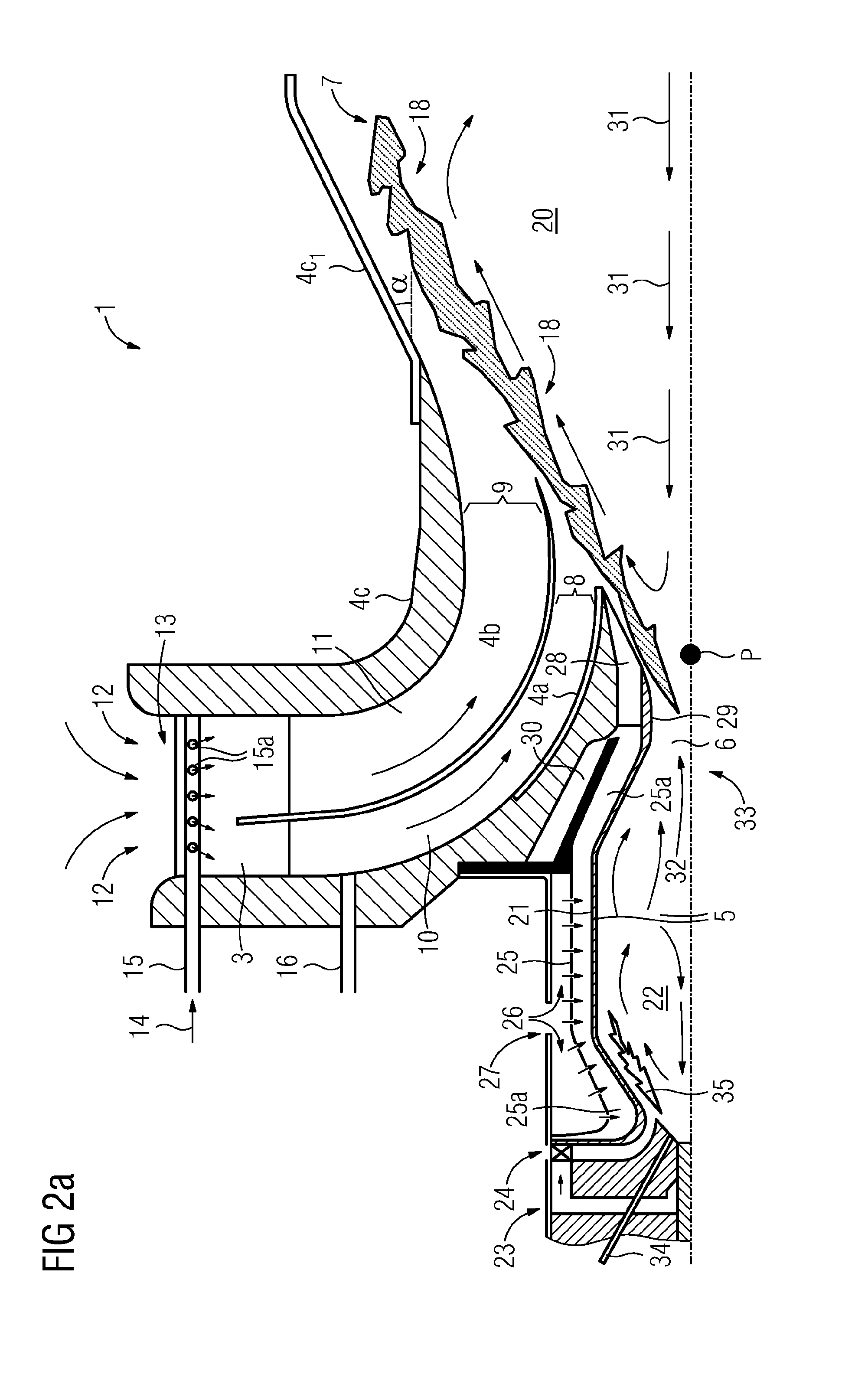

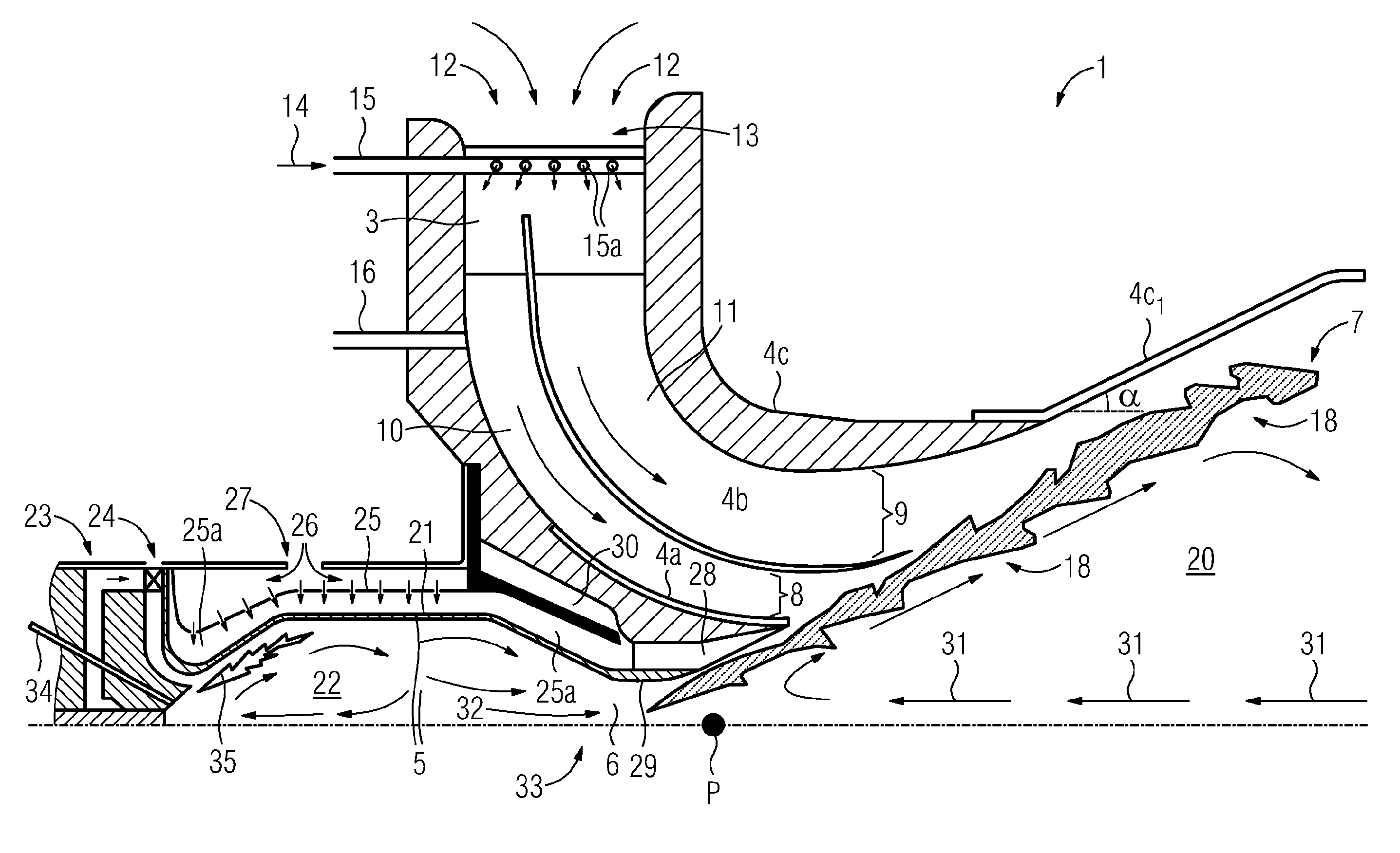

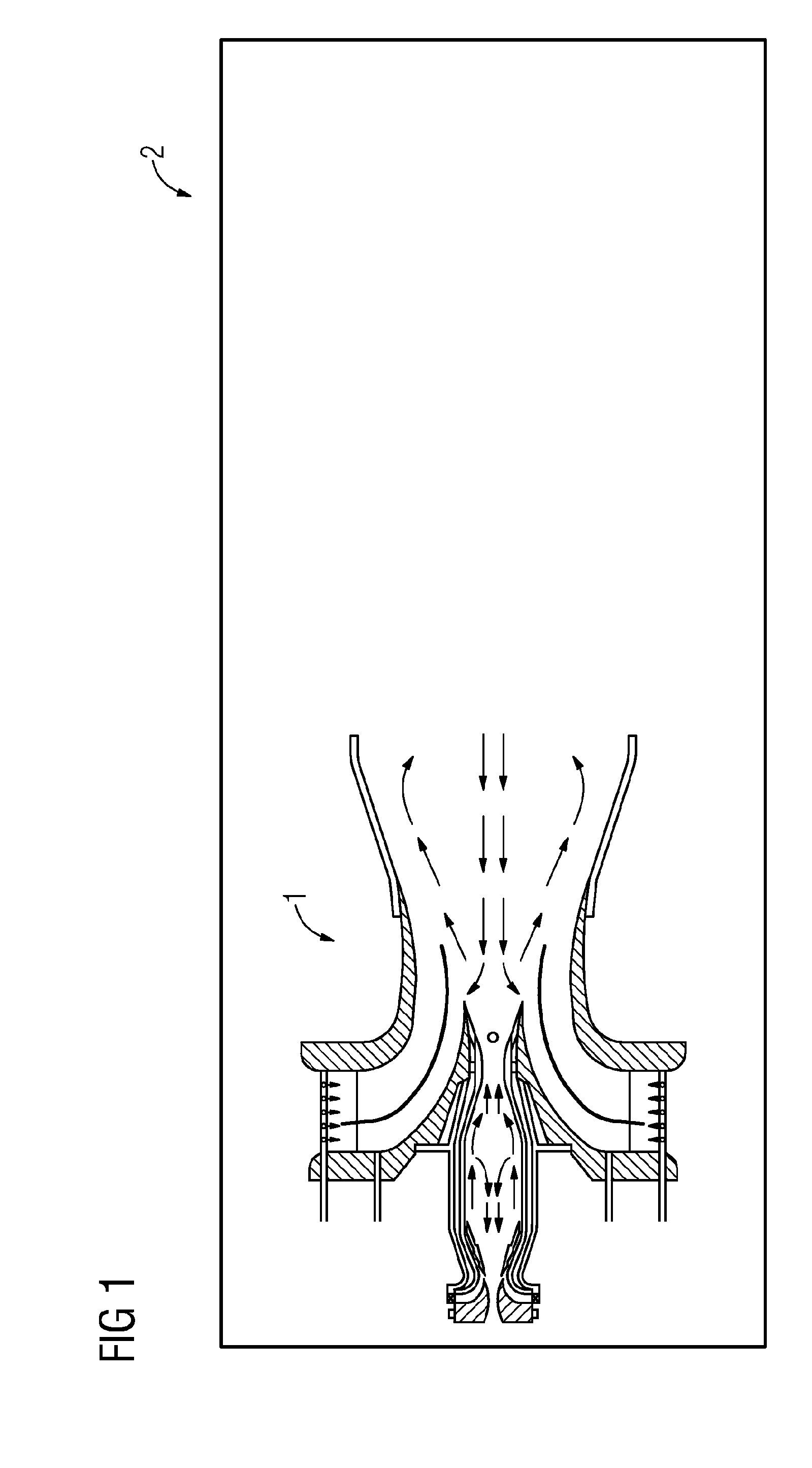

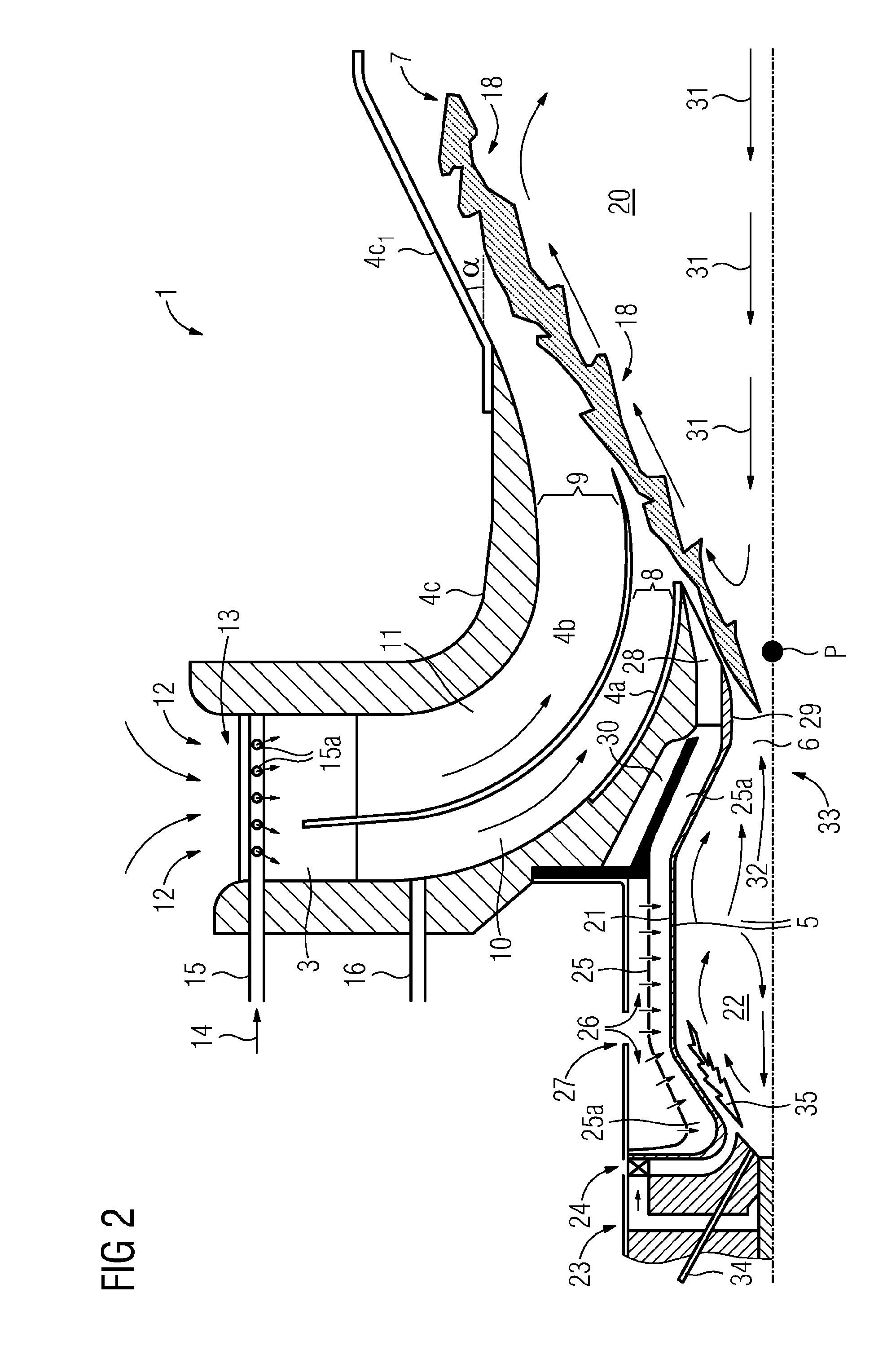

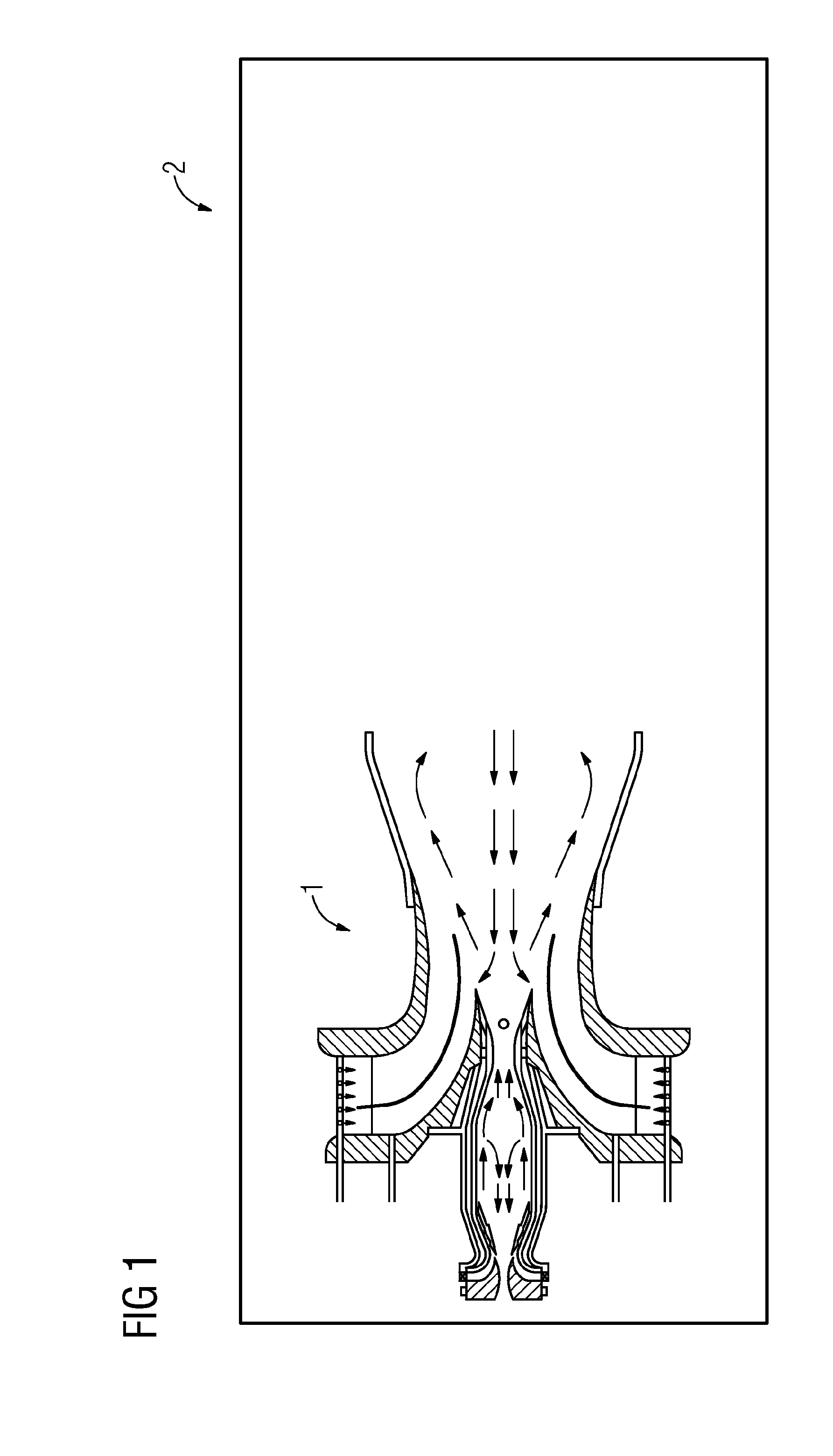

Burner

ActiveUS8863524B2Rapid and stable combustionStable combustionBurnersContinuous combustion chamberCombustion chamberCombustor

A burner for a gas turbine including a burner housing is provided. Provided is a lean-rich partially premixed low emission burner for a gas turbine combustor providing stable ignition and combustion process at all engine load conditions. At the upstream end of that burner a pilot combustor creates a flow of an unquenched concentration of radicals and heat. Respectively provided is a plurality of quarl sections surrounding the exit of the pilot combustor, a main combustion room defined downstream the pilot combustor and at least a first channel defined as an annular space between an upstream quarl section and the closest downstream quarl section providing air and fuel to a main flame in the combustion room.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

Fuel injection control apparatus of internal combustion engine

ActiveUS20120253640A1Reduce the temperatureReduce pressureElectrical controlInternal combustion piston enginesTemperature controlTop dead center

An auxiliary injection is carried out at an in-cylinder temperature at which a premixed combustion by the auxiliary injection is separatable into a low-temperature oxidation reaction and a high-temperature oxidation reaction, in a compression self-igniting internal combustion engine in which fuel injected into a cylinder from a fuel injection valve combusts in the cylinder, and that is configured to carry out an operation of fuel injection from the fuel injection valve. The operation of fuel injection includes at least a main injection and the auxiliary injection. The main injection causes a combustion mainly including a diffusion combustion in the cylinder. The auxiliary injection is carried out prior to the main injection and causes a combustion mainly including the premixed combustion in the cylinder. Specifically, an in-cylinder gas temperature (750K) is used as a reference, and the auxiliary injection is carried out before the in-cylinder gas temperature reaches 750K, so as to separate the low-temperature oxidation reaction and the high-temperature oxidation reaction from one another. This control makes the premixed combustion slow before a compression top dead center is reached, and ensures control of the premixed combustion in a temperature controlled manner in accordance with the transition of the in-cylinder gas temperature. This ensures unambiguous determination of the injection time of the auxiliary injection based on the in-cylinder temperature, and facilitates the attempt to simplify the fuel injection control.

Owner:TOYOTA JIDOSHA KK

Swirler with gas injectors

InactiveUS8033112B2Rapid and stable combustionStable combustionContinuous combustion chamberGas turbine plantsCombustorGas turbines

Owner:SIEMENS AG

Combustion-type power tool providing specific spark energy

InactiveUS20060042574A1Stabilize ignition performanceAvoid excessive power consumptionEngine controllersAdvancing/retarding ignitionPower toolPiston

A combustion type power tool having a combustion chamber in which a fan is rotatably provided and an ignition plug is exposed. A combustible gas and air are mixed together by the fan, and the mixture is ignited by a spark generated at the ignition plug. As a result of combustion, gas expansion occurs to permit a piston and a driver blade to move for driving a fastener into a workpiece. A spark energy is set in a range of from 0.04 J to 0.08 J.

Owner:HITACHI KOKI CO LTD

Burner

ActiveUS9822968B2Stable ignitionEasy to ignitePulverulent fuel combustion burnersIndirect carbon-dioxide mitigationCombustorEngineering

A burner comprises a nozzle main body (7) which is installed along a central axis of a throat (4) provided on a furnace wall (3) and comprises an inner nozzle (11) in which an auxiliary combustion air (24) flows and an outer nozzle (9) which is provided on an outer side and concentrically with the inner nozzle and in which a pulverized coal mixed flow (18) obtained by mixing a carrying medium with a pulverized coal flow, a wind box (5) for accommodating the nozzle main body, a secondary air regulator (8) accommodated in the wind box and provided at a tip portion of the nozzle main body, an auxiliary combustion air intake pipe (23) for introducing a combustion air as an auxiliary combustion air (22) into the inner nozzle from the wind box, a pulverized coal flow supply pipe (16) for introducing a pulverized coal mixed flow into the outer nozzle, and an oxygen-containing gas supply pipe (17) for supplying an oxygen-containing gas (19) to the pulverized coal mixed flow and raising the oxygen concentration in the pulverized coal mixed flow.

Owner:IHI CORP

Partial pre-mixing and pre-evaporation burning chamber with prefilm type nozzle

InactiveCN103047682AStable jobStable emissionsContinuous combustion chamberCombustion chamberEvaporation

The invention belongs to the field of aeroengines and mainly relates to a partial pre-mixing and pre-evaporation burning chamber with a prefilm type nozzle. The head of the burning chamber consists of an auxiliary burning level and a main burning level, wherein the auxiliary burning level comprises a primary axial swirler, a contraction section, a throat, an expansion section and an auxiliary oilway nozzle; and the main burning level comprises a primary axial swirler, a primary radial swirler, a pre-mixing section, a contraction throat and the prefilm type nozzle. The burning chamber at the head in the above structure adopts a DIPME (direct injection pre-mixing and pre-evaporation) mixed burning mode with central classification, when in small fire state, the auxiliary burning level adopts a rich oil direct injection burning mode, and when in large fire state, the auxiliary burning level adopts a lean oil direct injection burning mode, and the main burning level adopts a lean oil partial pre-mixing and pre-evaporation burning mode. In order to guaranteeing fuel oil atomization, the main burning level adopts the prefilm type nozzle. The head of the burning chamber can guarantee performance of the burning chamber, and pollutant discharge is greatly reduced.

Owner:CHINA GAS TURBINE ESTAB

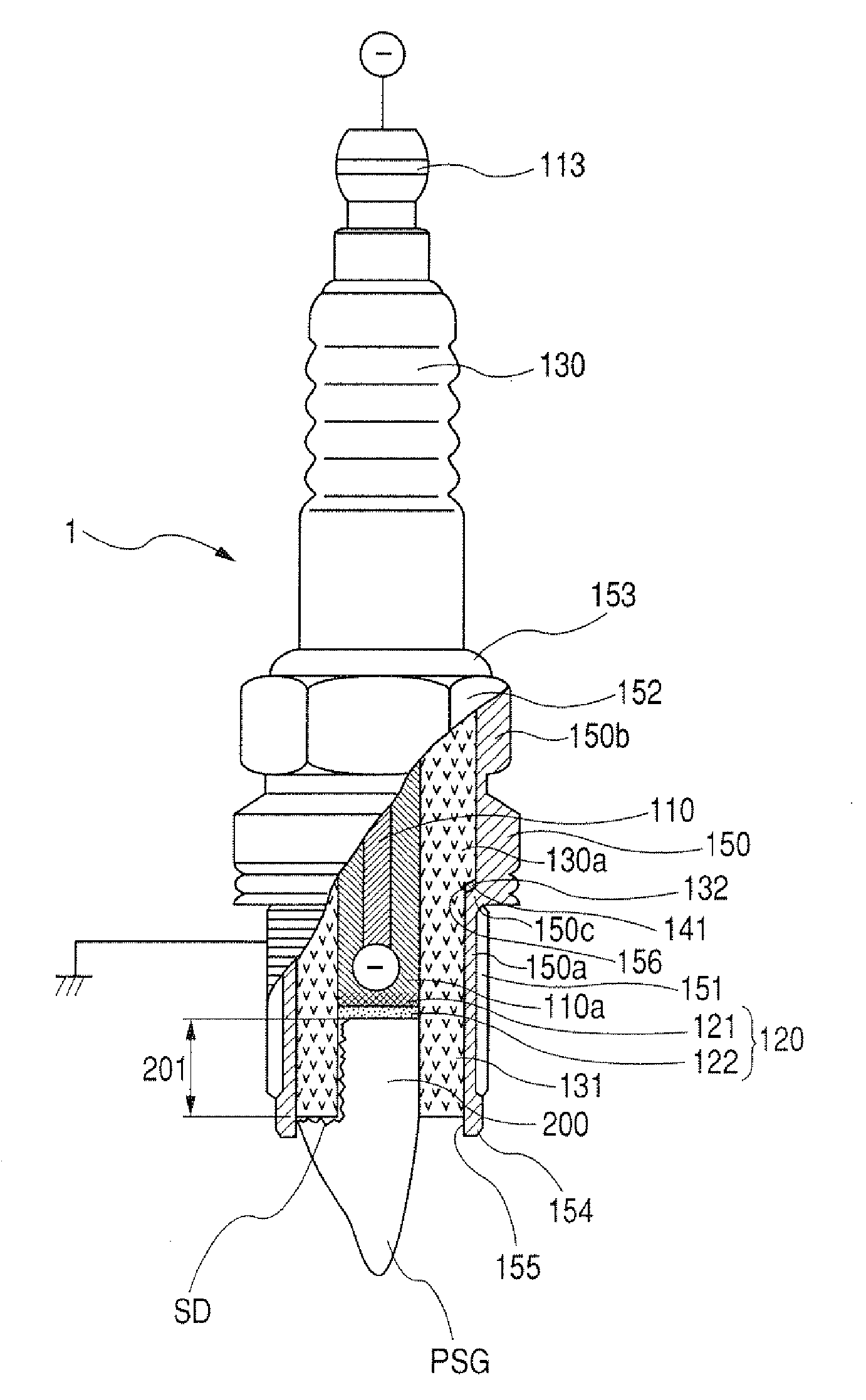

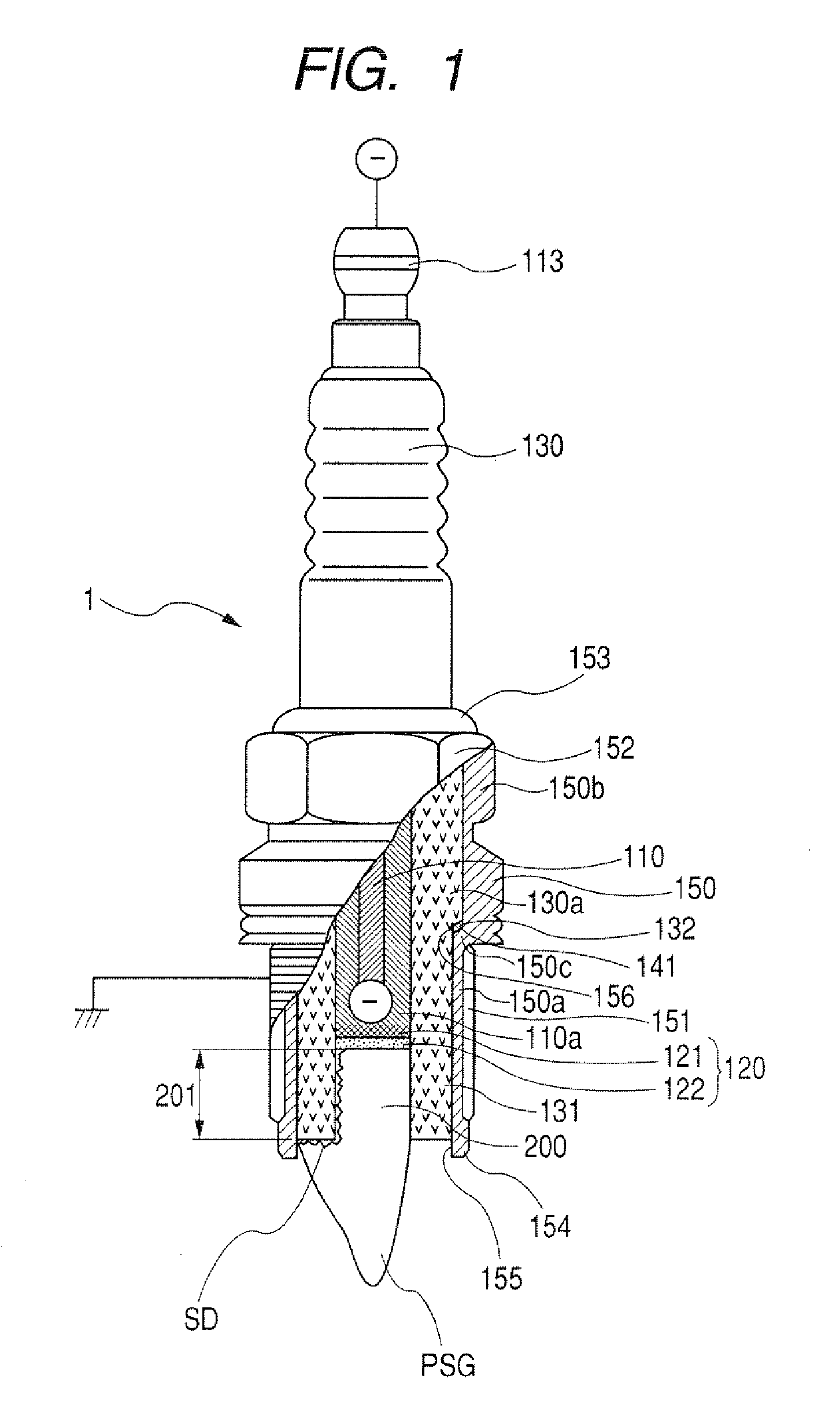

Plasma type ignition plug

InactiveUS20080121200A1Avoid excessive wearLess occurrenceSparking plugsCombustion enginesEngineeringInternal combustion engine

A plasma type ignition plug for igniting an internal combustion engine is disclosed having a negative electrode, a positive electrode, and a discharging distance fixing member, which includes an electrically conductive material replenishing section, made of an electrically conductive material available to melt when subjected to a heat of gas in plasma state, and an electrically conductive material replenished section to which the electrically conductive material is replenished. The discharging distance fixing member is covered on a surface of the negative electrode for initiating the spark discharge between a surface of the discharging distance fixing member and the positive electrode so as to avoid a fluctuation in a spark discharge distance caused by a wear of the negative electrode due to a collision of gas in the plasma state.

Owner:DENSO CORP

Swirler with gas injectors

InactiveUS20110101131A1Reduce transportationRapid and stable combustionContinuous combustion chamberGas turbine plantsCombustorGas turbines

A swirler for premixing a flow of fuel and a flow of air provided to a burner for a gas turbine engine is provided. The burner is provided with a swirler for mixing the air and the fuel and wherein the swirler is provided with swirler wings, wherein a channel formed between two adjacent swirler wings defines a passage. The swirler includes one fuel tube for gaseous fuel positioned in parallel on each side of a mixing rod in the passage, wherein the fuel tubes are provided with a plurality of diffuser holes distributed along the tube acting as gas injectors for efficiently distributing fuel in a flow of air passing through the swirler passage.

Owner:SIEMENS AG

Three-stage stratified combustion high temperature rise combustion chamber structure

ActiveCN106091013AImprove stabilityImproved flame stabilityContinuous combustion chamberAutomotive engineeringFuel oil

The invention relates to a three-stage stratified combustion high temperature rise combustion chamber structure which is applied to an aircraft engine high in thrust-weight ratio. An oil-gas mixing device at the head of a combustion chamber is divided into a precombustion stage and a main combustion stage. Precombustion stage fuel oil enters a precombustion area through a center direct jet nozzle and a precombustion stage pre-film nozzle to form a solid atomizer cone, and the stability of precombustion stage flame is improved. The main combustion stage injects fuel oil through two rows of fuel oil injection holes, the inner-layer fuel oil injection hole injects the fuel oil into a swirler air channel inside the main combustion stage, the outer-layer fuel oil injection hole injects the fuel oil into a swirler air channel outside the main combustion stage, and thus two combustion areas, that is, the inner-layer main combustion area and the outer-layer main combustion area are formed in the main combustion stage. The oil-gas ratio of the inner-layer main combustion area is larger than that of the outer-layer main combustion area, so that the inner-layer main combustion area is ignited by the precombustion stage flame more easily, and a stabilizing effect is further achieved on the outer-layer main combustion area by the inner-layer main combustion area. Step-by-step stable combustion is achieved among the three combustion areas, and hence the combustion stability of the head of the high temperature rise combustion chamber is jointly improved.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

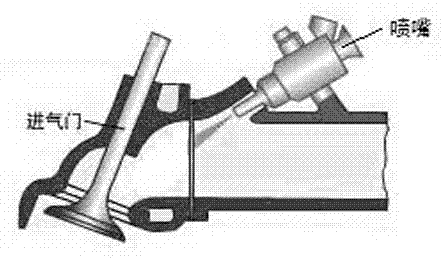

Multiple-injection control method for fuel supply device of natural gas engine

InactiveCN104500248ASpread fastStable ignitionElectrical controlInternal combustion piston enginesCrankTop dead center

The invention relates to a fuel gas injection method for natural gas engines, in particular to a multiple-injection control method for a fuel supply device of a natural gas engine. The method includes that the natural gas engine is a four-stroke engine, and each working cycle of the natural gas engine includes four stages; the fuel supply device of the natural gas engine is arranged on the lateral side of a gas inlet, and natural gas and air are mixed for combustion in a cylinder; multiple-injection control of the fuel supply device is realized by adjusting injection times and quantity of natural gas supplied by the fuel supply device in a crank angle range from 2400 before top dead center of compression stroke of an engine piston to 2400 after top dead center of compression stroke of the engine piston. Aiming at different engine load conditions, stability in ignition of engines is guaranteed by means of partial stratification, flame propagation velocity is increased, and firing stability is improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

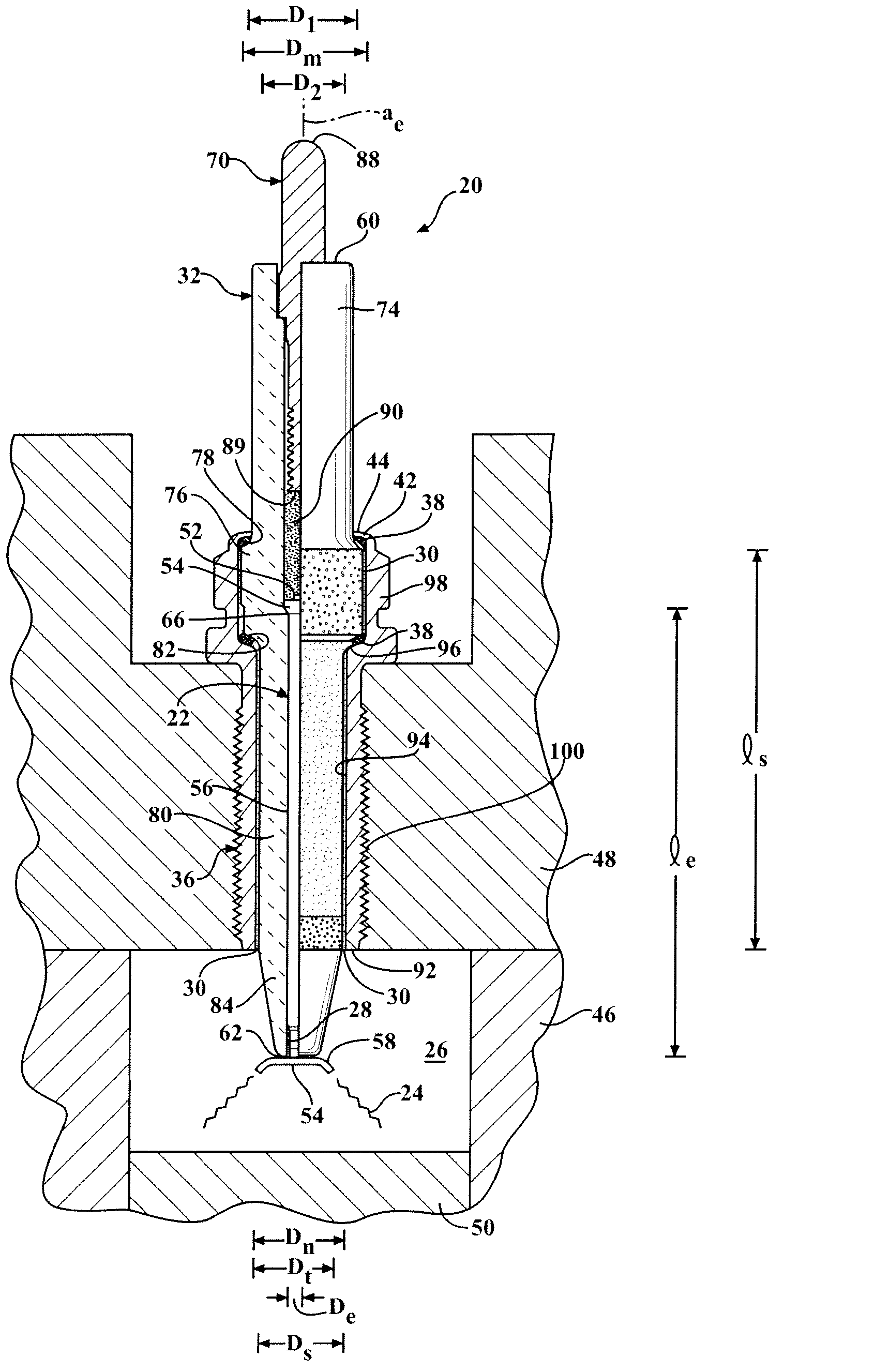

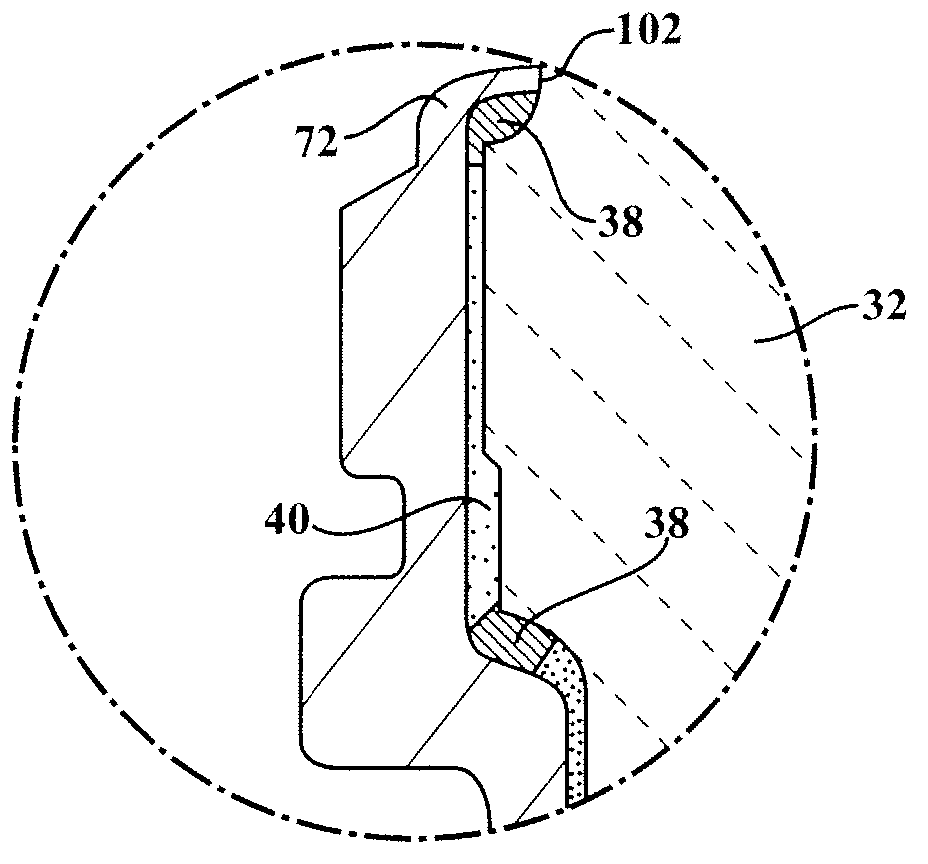

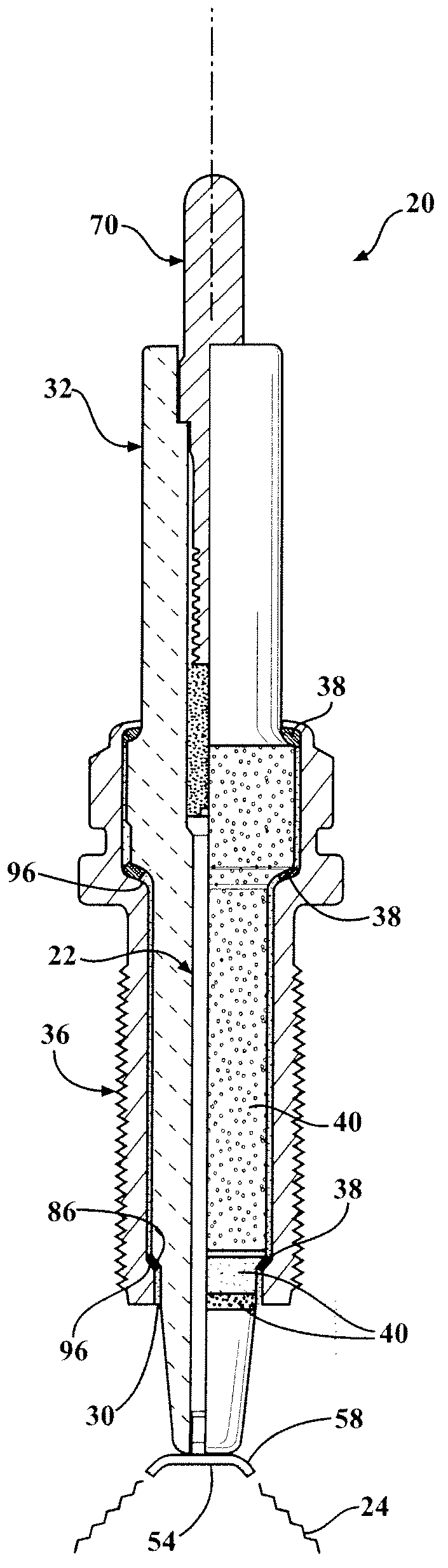

Corona igniter with improved corona control

ActiveCN103210556APrevent ionizationStable ignitionSparking plugs manufactureCorona dischargeFilling materialsVoltage drop

A corona igniter 20 includes an electrode gap 28 between the central electrode 22 and the insulator 32 and a shell gap 30 between the insulator 32 and the shell 36. The gaps 28, 30 are filled with a filler material 40 to prevent corona discharge 24 in the gaps 28, 30 and to concentrate the energy at a firing tip 58 of the central electrode 22. The filler material 40 may be electrically insulating or conductive. The shell gap width ws may be greatest at a shell lower end 92. The shell gap 30 may also be in a turnover region between a shell upper end 44 and the insulator 32, in which case the filler material 40 is injection molded around the turnover region. During operation of the igniter 20, the filler material 40 provides a reduced voltage drop across the gap 28, 30.

Owner:FEDERAL MOGUL IGNITION

Pitch slurry and its preparation method

InactiveCN1955266ARetain combustion propertiesImprove liquidityLiquid carbonaceous fuelsGranularityMetallurgy

This invention relates to coal tar pitch slurry and its preparation, and it belongs to waste residue disposal technology field and energy and environmental protection field. It mainly solves the problem of hard to burn directly of coal tar pitch. Its feature is that this coal tar pitch slurry is a fluid liquid fuel, and its components and their weight percentage is that coal tar pitch powder 50%-60%, water 38%-49.5%, dispersant 0.5%-2%. The preparation is that middle temperature coal tar pitch whose softening point is 85-95deg.C or high temperature coal tar pitch whose softening point is 100-110deg.C is freezed 20-28h with brittle temperature -30-15 deg.C, then shattered after adding surfactant, and then screening to get coal tar pitch powder with particle size 200-320 meshes, and then adding this coal tar pitch powder into water solution of dispersant, at last, coal tar pitch slurry fuel with good fluidity, good atomization performance, high combustion efficiency and low pollutants emission is produced by stirred homogeneously.

Owner:TAIYUAN UNIV OF TECH +1

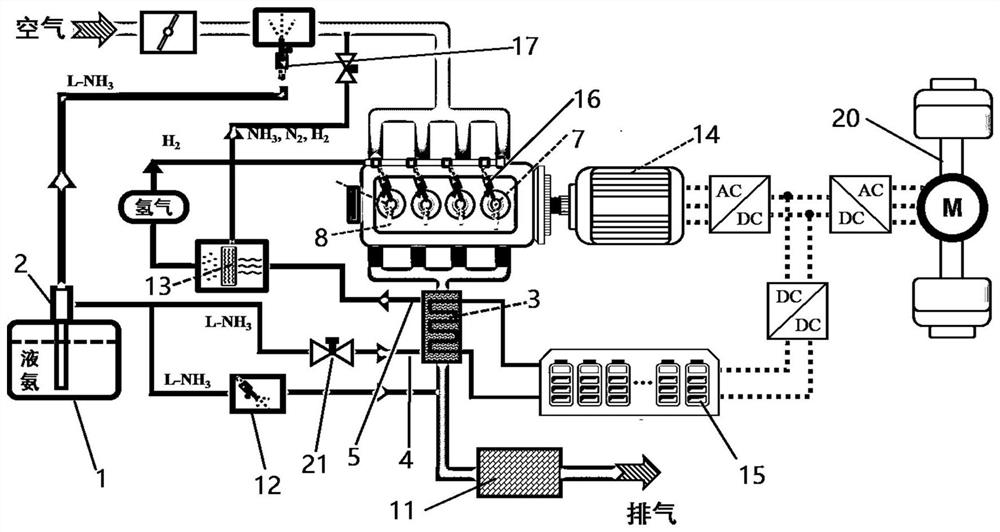

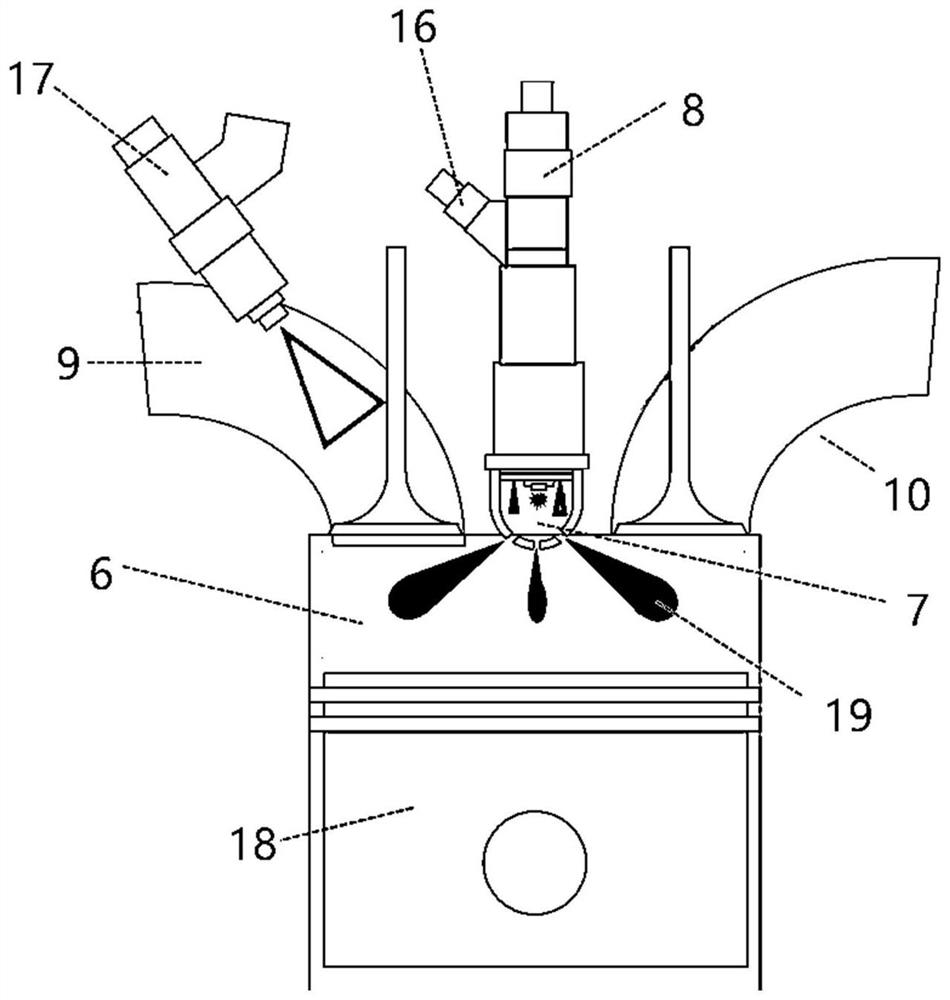

Ammonia-hydrogen fusion type hybrid power system and engine

ActiveCN114412668AStable combustionBurn quicklyInternal combustion piston enginesFuel supply apparatusCombustion chamberThermodynamics

The invention relates to the technical field of ammonia fuel engines, and provides an ammonia-hydrogen fusion type hybrid power system and an engine. The ammonia-hydrogen fusion type hybrid engine includes: a fuel tank for storing liquid ammonia, the fuel tank including a discharge port; the ammonia catalysis hydrogen production device is used for catalyzing ammonia gas to form hydrogen and comprises an ammonia inlet and a hydrogen outlet, and the ammonia inlet is connected with the discharge port; the ammonia fuel engine comprises a main combustion chamber, a jet ignition cavity and an ignition device, the main combustion chamber is connected with the discharge port, the hydrogen discharge port is connected with the jet ignition cavity, the ignition device is arranged in the jet ignition cavity, and the jet ignition cavity is communicated with the main combustion chamber. Combustion hydrogen can form jet flames and enter the main combustion chamber, and ammonia mixed gas is stably ignited. The hydrogen flame jet flow has multiple ignition sites and can form free radicals such as OH <-> with high concentration in the main combustion chamber, the combustion speed of ammonia mixed gas can be increased, and therefore stable ignition and rapid combustion of ammonia gas are achieved.

Owner:TSINGHUA UNIV

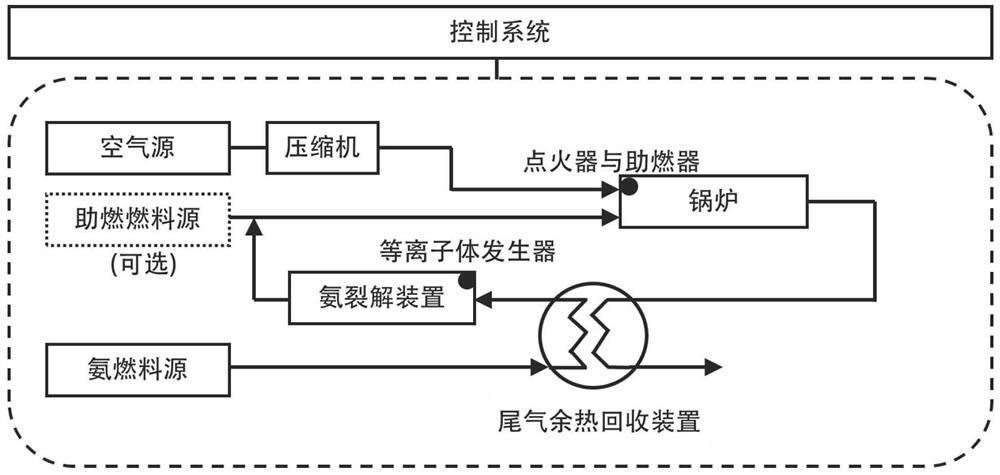

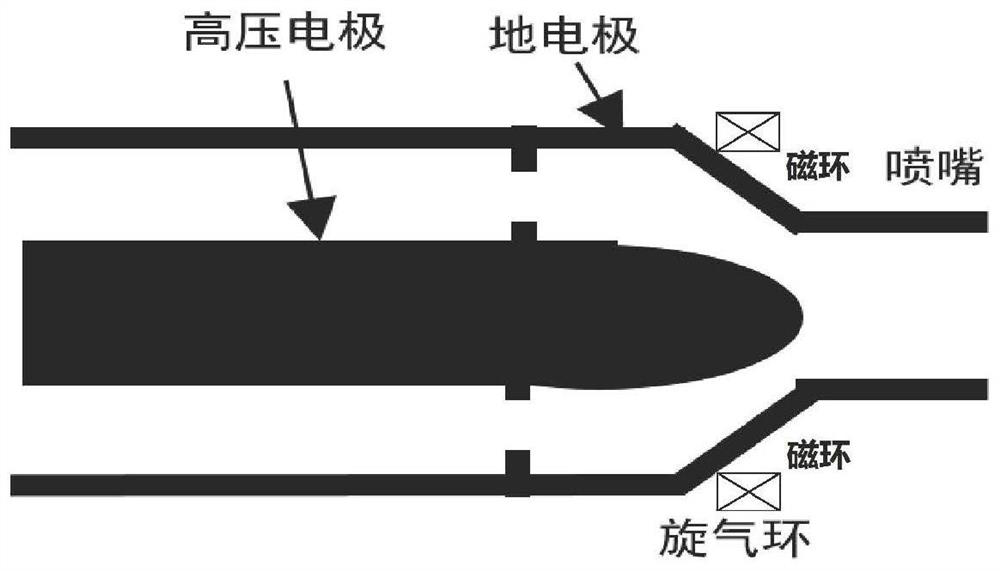

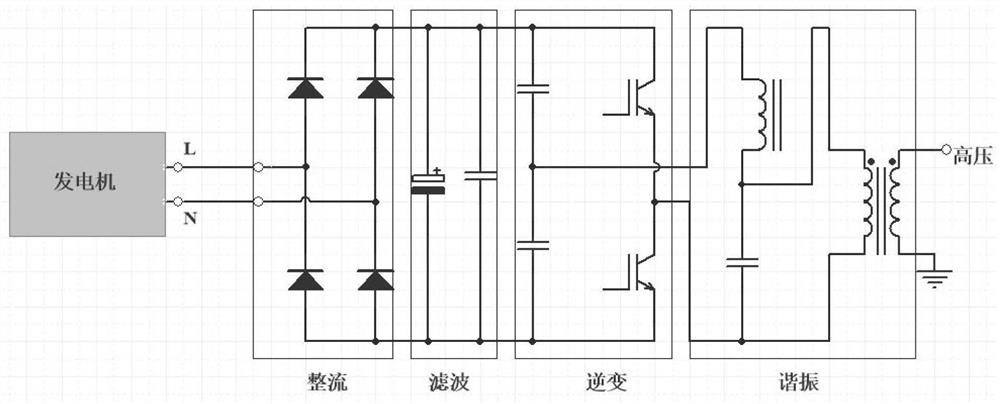

Molten salt energy storage-based ammonia boiler for real-time cracking of ammonia fuel through plasma

PendingCN113048469AQuick resetPrecisely adjust the ratioBurnersElectric spark ignitersCombustion chamberEmission standard

The invention discloses a molten salt energy storage-based ammonia boiler for real-time cracking of ammonia fuel through magnetic ring enhanced rotating arc plasma, and relates to the technical field of new energy boilers. The molten salt energy storage-based ammonia boiler comprises an ammonia decomposition box, and the ammonia decomposition box comprises a plasma ammonia cracker, a temperature sensor, a gas pressure sensor and a hydrogen component sensor. Before mixed combustion with an air source, an ammonia fuel source firstly passes through the ammonia decomposition box, the ammonia fuel source is cracked in real time through a magnetic ring enhanced rotating arc plasma ammonia cracker, and ammonia / hydrogen mixed gas is prepared; and a plasma igniter and a plasma combustion-supporting device are arranged in a combustion chamber of the ammonia boiler. According to the molten salt energy storage-based ammonia boiler,the discharge power of the magnetic ring enhanced rotating arc plasma ammonia cracker is adjusted, so that the ratio of ammonia gas to hydrogen can be accurately adjusted, ammonia / hydrogen mixed fuel can be stably combusted in the boiler combustion chamber, an on-line ammonia boiler tail gas treatment system performs purification treatment on the tail gas by utilizing the existing ammonia fuel of a combustion system, and therefore, the emission standard is reached.

Owner:INST OF ENERGY HEFEI COMPREHENSIVE NAT SCI CENT (ANHUI ENERGY LAB)

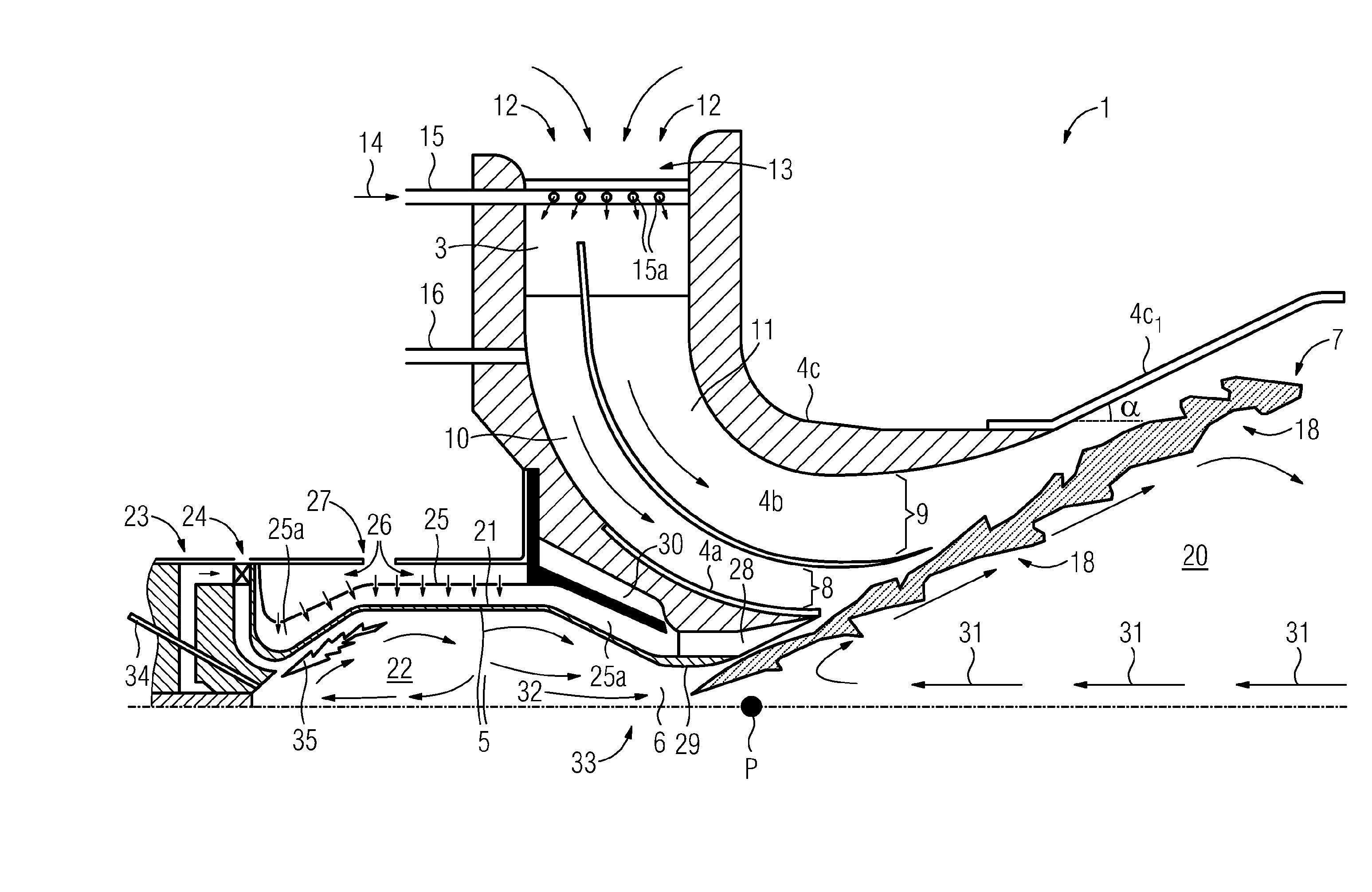

Burner

ActiveUS20110041508A1Rapid and stable combustionStable combustionBurnersContinuous combustion chamberCombustorCombustion chamber

A burner for a gas turbine including a burner housing is provided. Provided is a lean-rich partially premixed low emission burner for a gas turbine combustor providing stable ignition and combustion process at all engine load conditions. At the upstream end of that burner a pilot combustor creates a flow of an unquenched concentration of radicals and heat. Respectively provided is a plurality of quarl sections surrounding the exit of the pilot combustor, a main combustion room defined downstream the pilot combustor and at least a first channel defined as an annular space between an upstream quarl section and the closest downstream quarl section providing air and fuel to a main flame in the combustion room.

Owner:SIEMENS ENERGY GLOBAL GMBH & CO KG

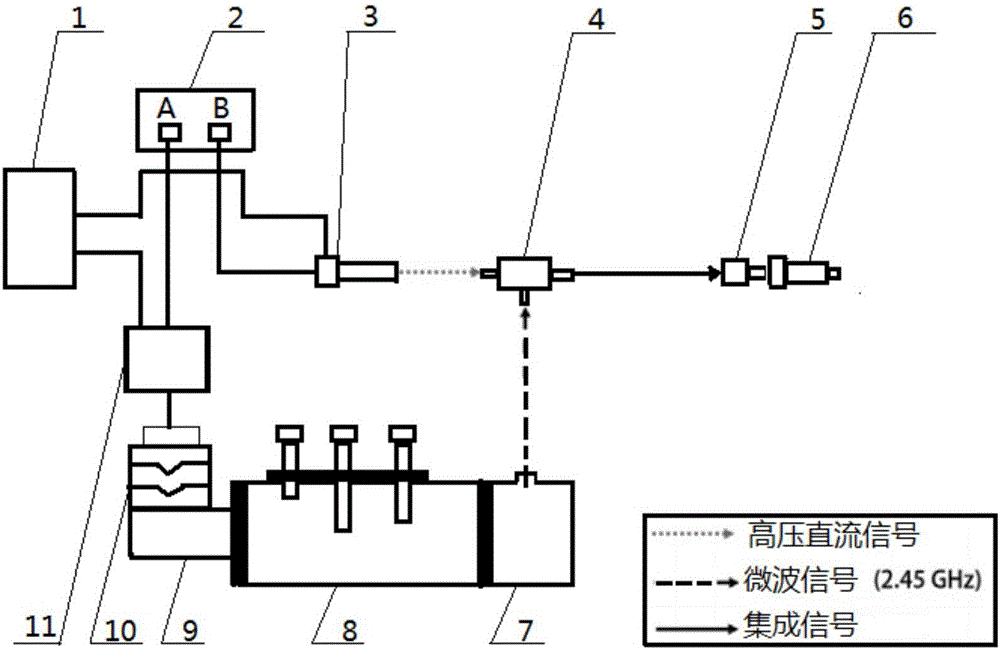

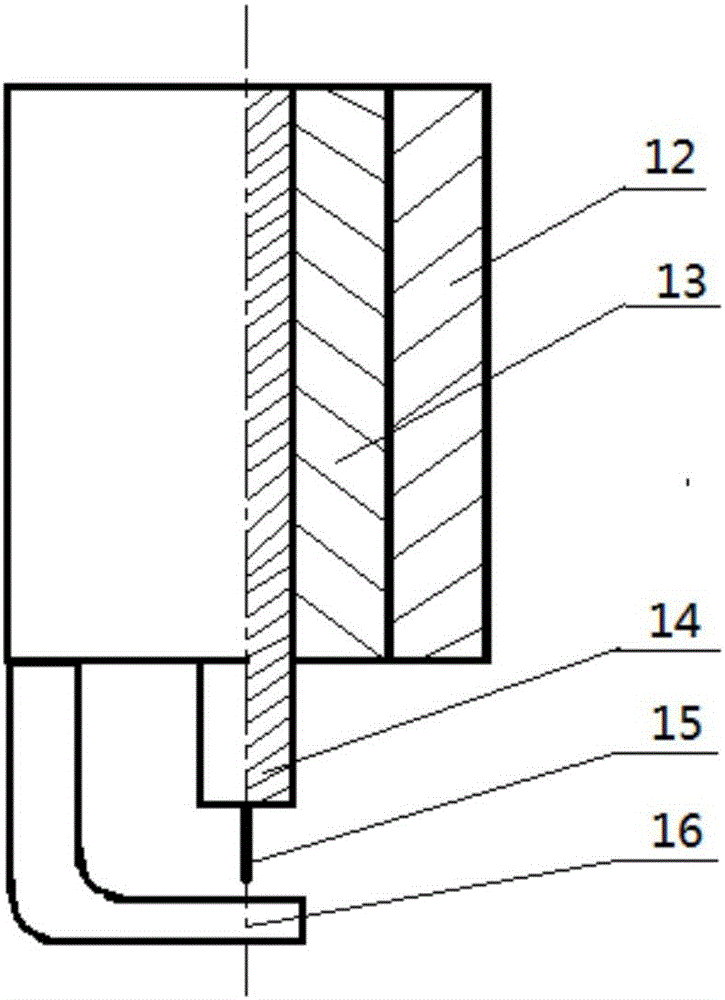

Microwave-assisted spark plug ignition method and microwave-assisted spark plug ignition integrated set

ActiveCN106762331AStable ignitionBroaden the lean burn limitSparking plugsEngine ignitionCombustion chamberEngineering

The invention discloses a microwave-assisted spark plug ignition method, comprising the steps of issuing a pulse signal to a spark plug system to trigger the same to generate a pulse high voltage; issuing a pulse signal to a microwave system to trigger the same to generate a microwave pulse of specific frequency and power; loading the pulse high voltage to a spark plug, breaking down thin gas via arc discharging to generate a plasma cluster; the plasma cluster can be expanded via microwave pulse irradiation to achieve ignition via thin combustion in an internal combustion engine. The invention also discloses a microwave-assisted spark plug ignition integrated set. The method of the invention combines the advantages of spark plug high-voltage discharge breakdown and those of microwave-to-plasma-cluster coupling energy; the integrated set of the invention includes a spark plug system and a microwave system, and achieves stable ignition via thin combustion in high-pressure environment of a combustor of the internal combustion engine.

Owner:HUAZHONG UNIV OF SCI & TECH

Overhead-valve combustion chamber of two-stroke gasoline direction injection engine

InactiveCN106640338AReduce bumpsMiniaturizationInternal combustion piston enginesCylinder headsCombustion chamberExhaust valve

The invention discloses an overhead-valve combustion chamber of a two-stroke gasoline direction injection engine. The overhead-valve combustion chamber is a cavity encircled by a cylinder cover, an intake valve, an exhaust valve, a piston, a cylinder sleeve, a gasoline injector and a spark plug. The inclined surface of a ceiling at the intake side of the cylinder cover is composed of two connected inclined surfaces having different included angles with the axis of the piston, and a spherical gasoline avoiding pit is sunken in the inclined surface; the position of an intake door seat is higher than the ceiling at the intake side in a vertical direction, and the intake door seat and the ceiling form a step; the gasoline injector is a piezoelectric crystal outwards-opening gasoline injector and arranged at the centre of the cylinder with the spark plug; and the centre of the piston is bulged, the top surface of the bulge is inclined, and a spherical pit is sunken in the top surface. According to the overhead-valve combustion chamber disclosed by the invention, reverse tumble scavenging is realized through the step on the ceiling, and intake short-circuit is reduced; wall wetting due to fuel oil is reduced through the gasoline avoiding pit, the top surface of the bulge of the piston and the pit of the piston; and a layered mixed gas is organized through the outwards-opening gasoline injector arranged at the centre. The overhead-valve combustion chamber disclosed by the invention is capable of realizing efficient scavenging for the two-stroke gasoline engine, optimizing the layering of the fuel oil and reducing the wall wetting due to the fuel oil, and beneficial to realizing the miniaturization of the gasoline engine.

Owner:TIANJIN UNIV

Combustion-powered, fastener-driving tool generating sparks in succession when triggered

InactiveUS7467739B2Reliably producedIncrease opportunitiesStapling toolsCombustion enginesCombustion chamberControl theory

A combustion-powered, fastener-driving tool includes a cylinder and a combustion chamber disposed on top of the cylinder that accommodates a gaseous mixture of existing air in the combustion chamber and fuel injected therein. A spark plug generates a spark to combust the gaseous mixture in the combustion chamber. A trigger produces the spark in the spark plug when operated. A piston is movably supported in the cylinder and driven by combustion in the combustion chamber. A driving blade is coupled to the piston for driving a fastener. A spark controller is provided for generating a plurality of sparks in succession with the spark plug.

Owner:KOKI HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com