Coaxial partition high-temperature-rise combustor head

A combustion chamber and head technology, which is applied in the field of coaxial partition high-temperature rise combustion chamber head, can solve the problems of inability to guarantee high-efficiency and low-smoke combustion in the main combustion area, smoke in the main combustion area, and carbon deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below in conjunction with the accompanying drawings and specific implementation examples.

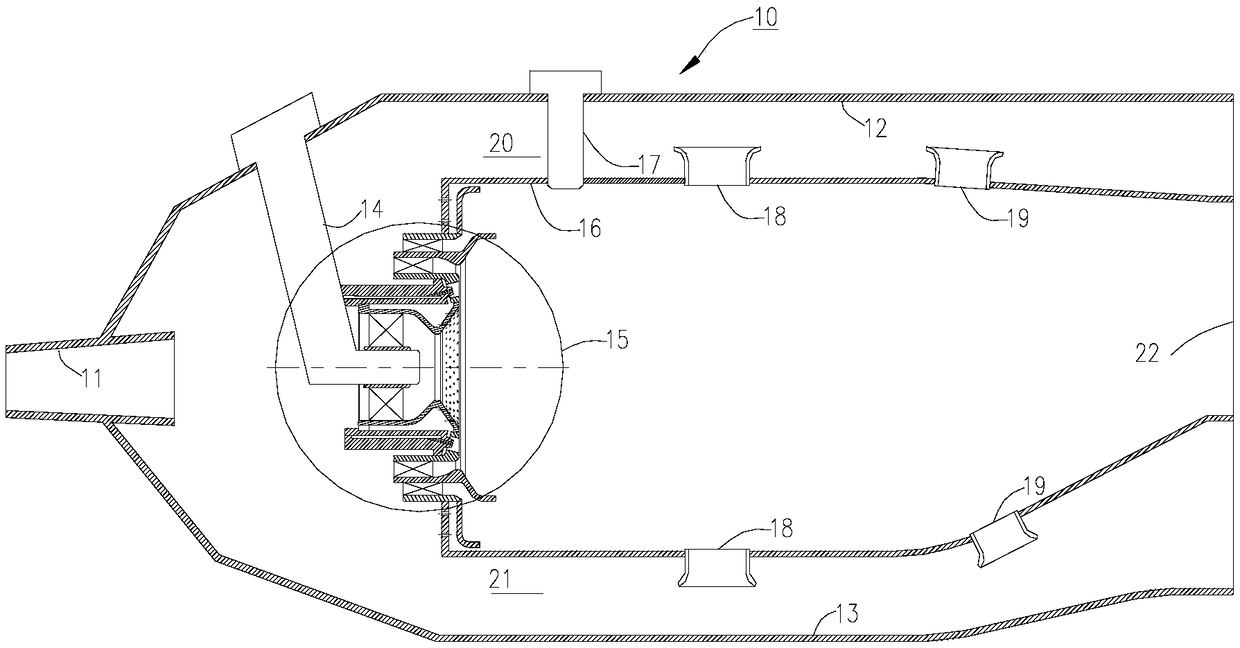

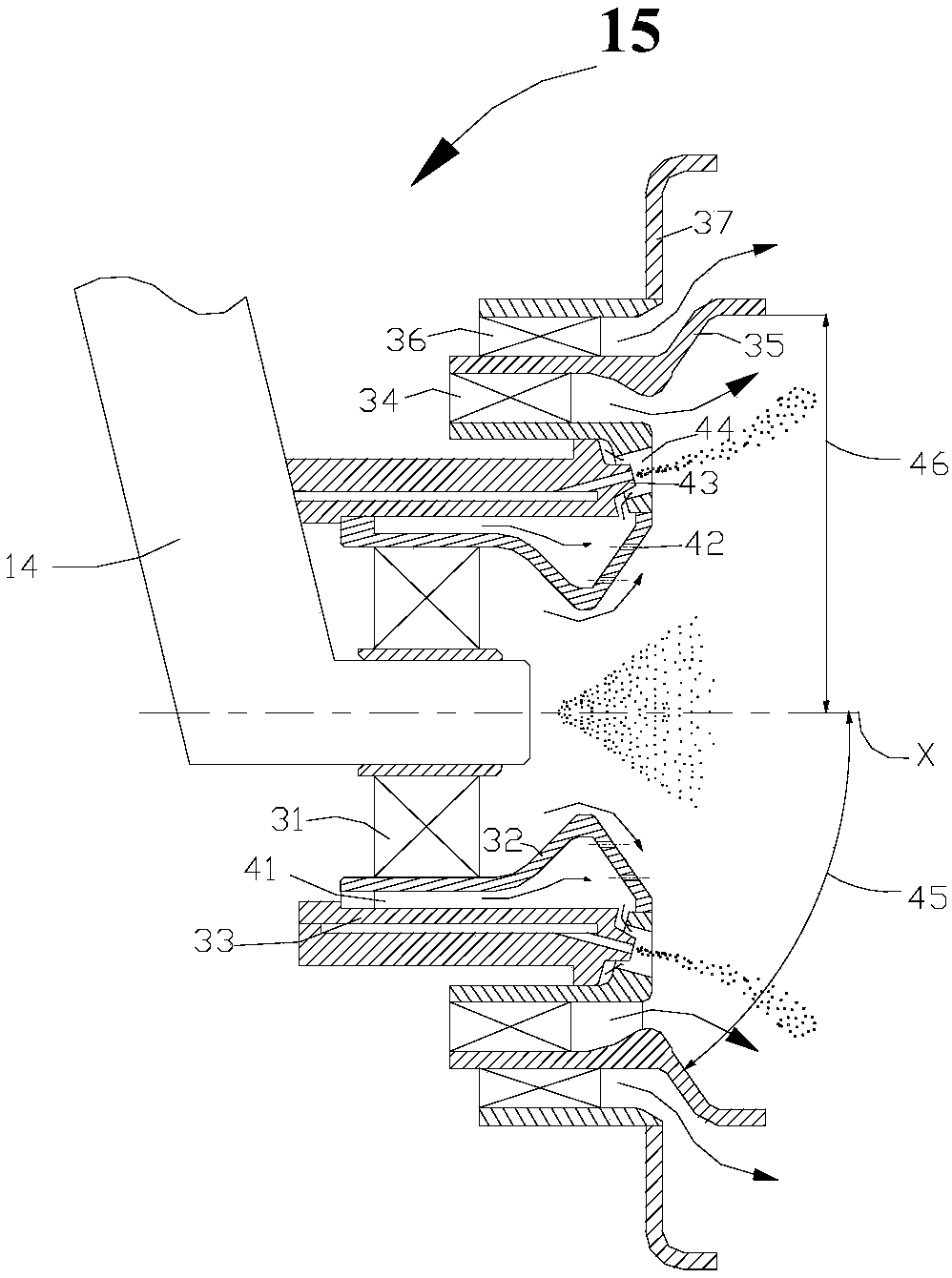

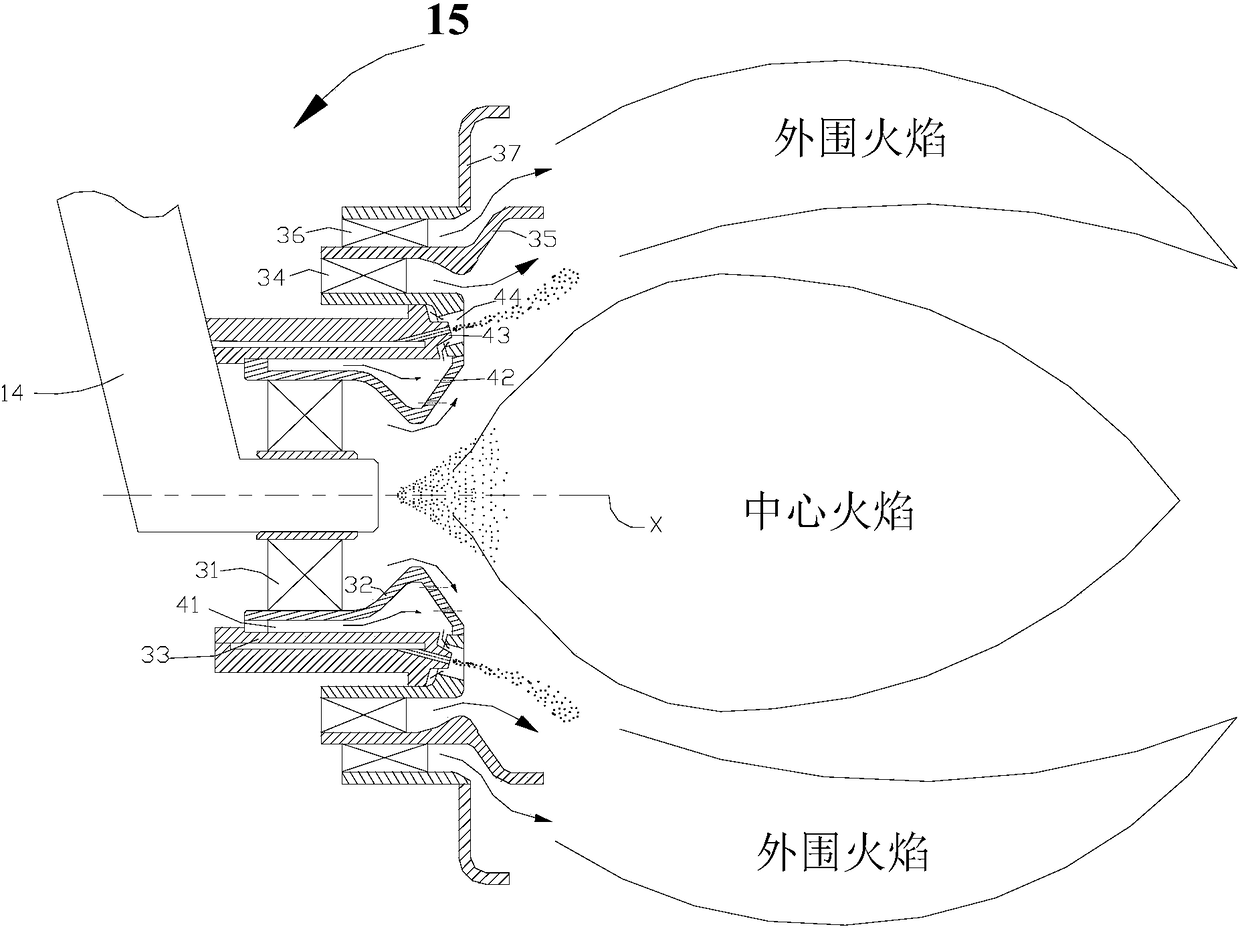

[0028] refer to figure 1 , is a schematic structural diagram of a coaxial partitioned high-temperature rise combustion chamber 10, including a diffuser 11, an outer casing 12, an inner casing 13, a nozzle 14, a head 15, a flame cylinder 16, an electric nozzle 17, and a flame cylinder as required Main combustion hole 18 and mixing hole 19 are arranged, or can cancel main combustion hole 18 and keep mixing hole 19. The working conditions of the combustion chamber are: air enters the combustion chamber from the diffuser 11, more than 40% of the air enters the flame cylinder 16 from the head 15, and the remaining air enters the flame cylinder 16 through the combustion outer ring 20 and the combustion inner ring 21, and the fuel oil It enters the flame tube 16 through the nozzle 14. In the flame tube 16, after the electric nozzle 17 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com